Plug valve capable of assisting in replenishing flow

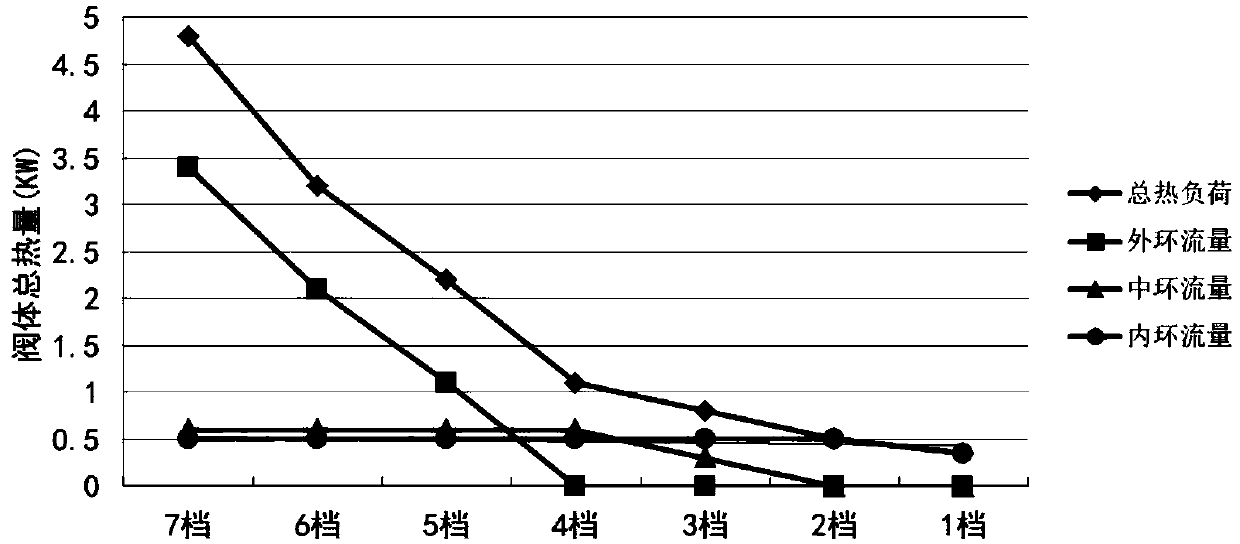

A plug valve and flow technology, applied in the field of plug valves, can solve the problems of thin mixed gas, small outer ring flow, burner tempering, etc., to achieve the effect of increasing heat load, sufficient cooking power, and meeting the needs of instant high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples illustrate the invention, but the invention is not limited by these examples. Modifications to the specific implementation of the present invention or equivalent replacement of some technical features without departing from the spirit of the present invention should be included in the scope of the technical solution claimed in the present invention.

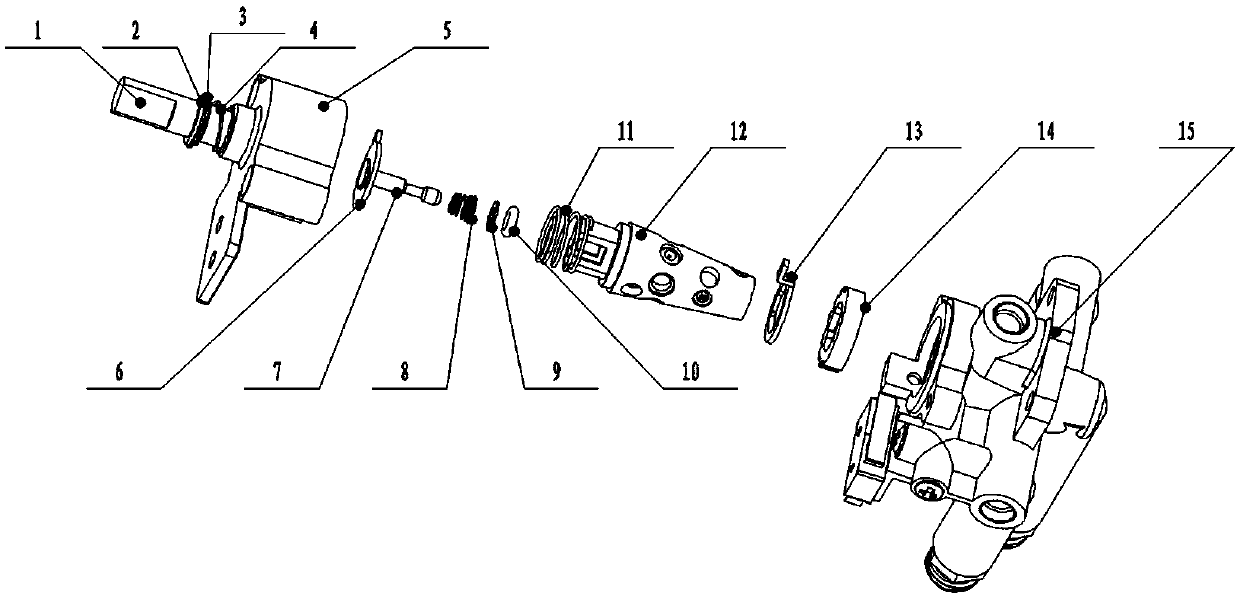

[0029] Figure 2-11 Schematically showing a plug valve that can assist supplementary flow according to an embodiment of the present invention.

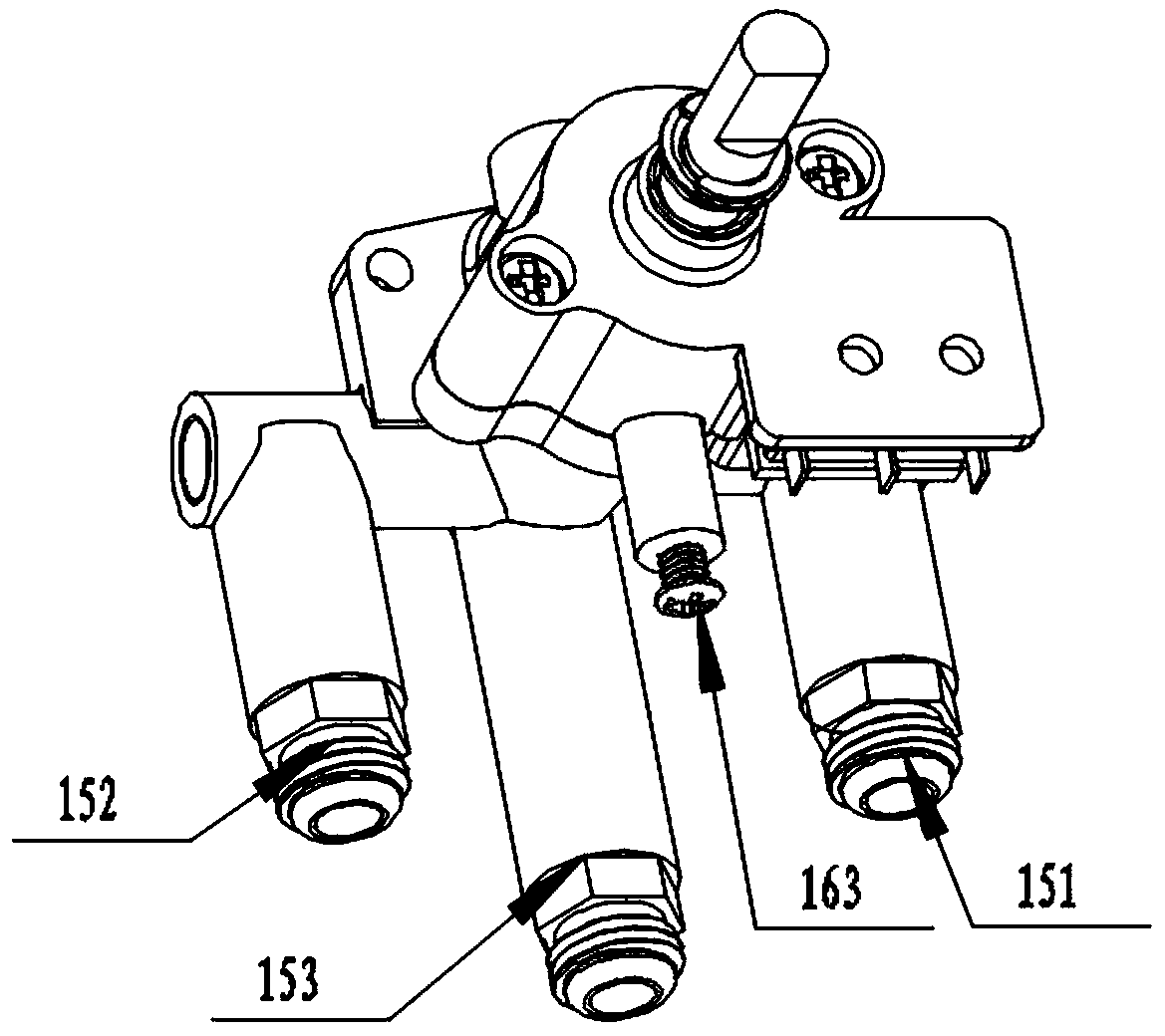

[0030] Such as figure 2 As shown, a plug valve that can assist supplementary flow includes a valve seat 15 with a cavity 157, a valve core 12 rotatably arranged in the cavity 157, and a plunger inserted into the valve core 12 from top to bottom. 7. The paddle 6 arranged on the upper end of the valve core 12, the valve cover 5 installed above the valve body seat 15, and the rotating shaft 1. Such as Figure 2-5 As shown, the valve seat 15 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com