Ironmaking method based on top gas cyclic utilization

A gas and gas pipeline technology, applied in the field of ironmaking based on the recycling of top gas, can solve the problems of underutilization, high carbon emissions, and high content of reducing gases, so as to improve reduction efficiency, reduce carbon emissions, and reduce energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

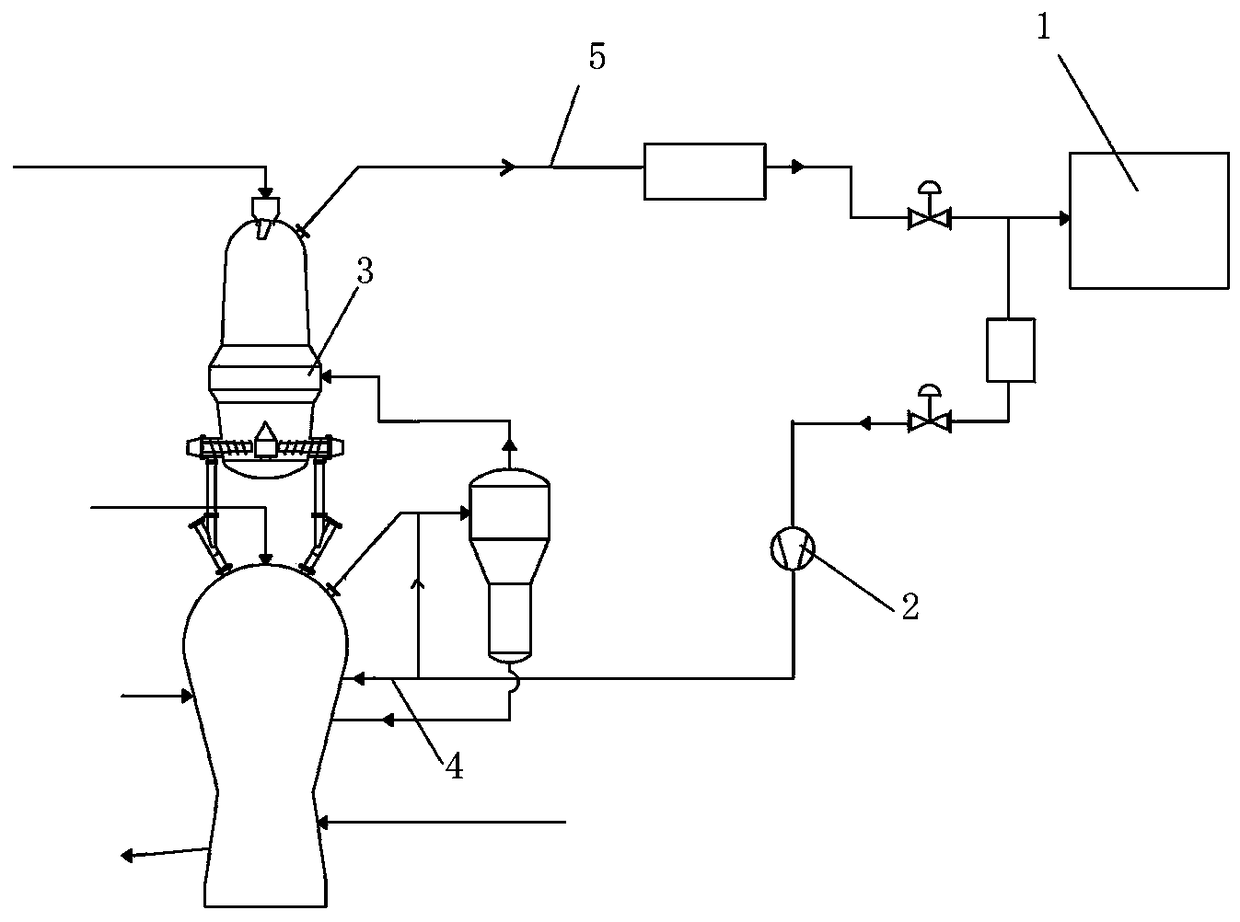

[0021] An ironmaking method based on top gas recycling, such as figure 1 As shown, the process steps are: after the top coal gas is dedusted by the fine dust collector, only 10% of the top coal gas enters the output gas system 1, and 90% of the top coal gas enters the gas pressurizer system 2 after cooling down, and a part of the top coal gas after pressurization is sprayed. Into the vault area 3 of the gasifier, in the space of 1050°C in the vault area of the gasifier, due to the presence of a large amount of carbon powder, the carbon dioxide in the shaft furnace top gas reacts with the carbon powder to form carbon monoxide, which enters the gas pipeline as produced gas 5. Another part of the top gas after pressurization enters the generating gas pipeline 4 directly as cold gas to realize the adjustment of the temperature of the generating gas, and realizes the reutilization of the top gas in such a cycle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com