Air compression system of water spraying screw compressor and lubrication and sealing method

A screw compressor and air compression technology, which is applied in the field of compressors, can solve problems such as poor lubrication and sealing effects, cumbersome and inconvenient maintenance, etc., and achieve the effects of reducing vibration and noise, simplifying sealing devices, and eliminating the need for booster pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

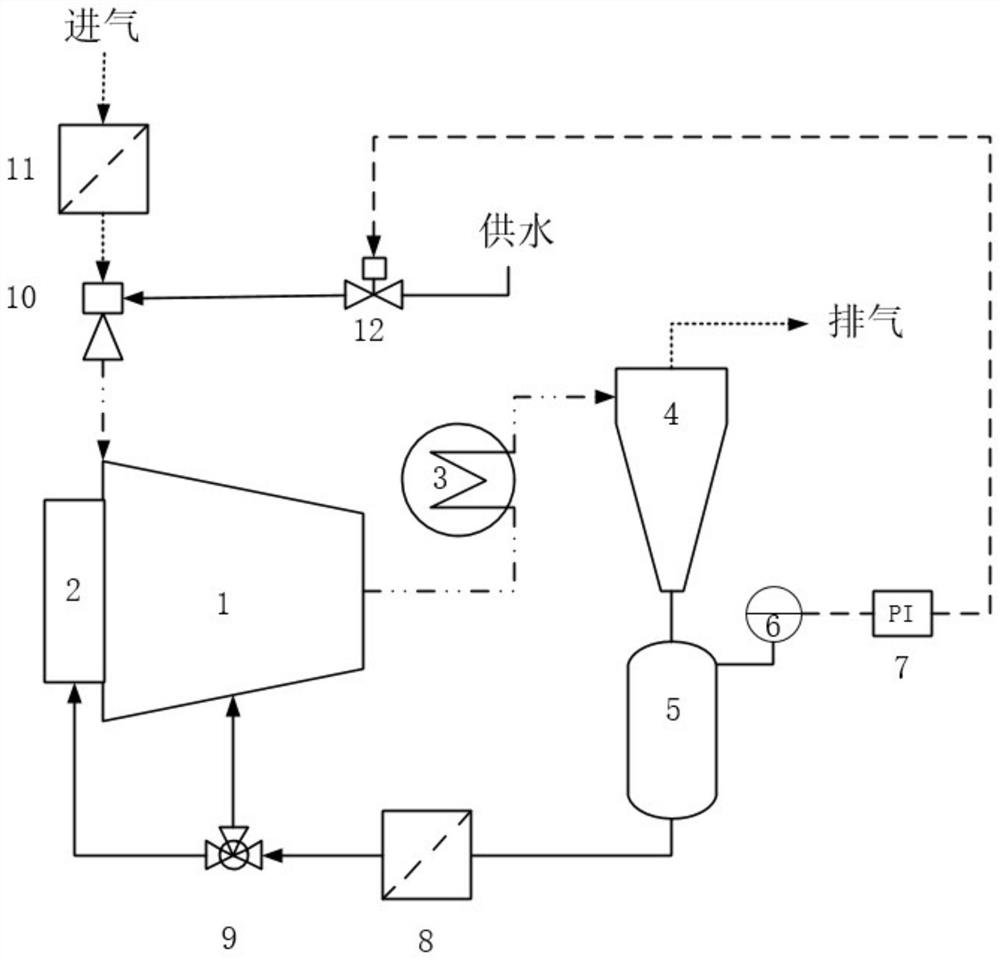

[0028] see figure 1 , the water-sprayed screw compressor air compression system of the embodiment of the present invention comprises a screw compressor 1, the screw compressor 1 is a twin-screw compressor 1 with a bearing 2, and a heat exchanger is arranged on the exhaust pipeline of the screw compressor 1 3. The heat exchanger 3 adopts an air-cooled finned heat exchanger. The gas and condensed water in the exhaust pipeline are cooled by the heat exchanger 3 and sent to the steam-water separator 4, and the cooling water separated by the steam-water separator 4 is sent to the water storage tank 5, and the cooling water is supplied to the water storage tank 5 Add a polymer thickener, set a feed water filter 8 and a three-way valve 9 on the output pipeline of the water storage tank 5 in sequence, and pass the filtered cooling water into the twin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com