Patents

Literature

108results about How to "Improved air distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

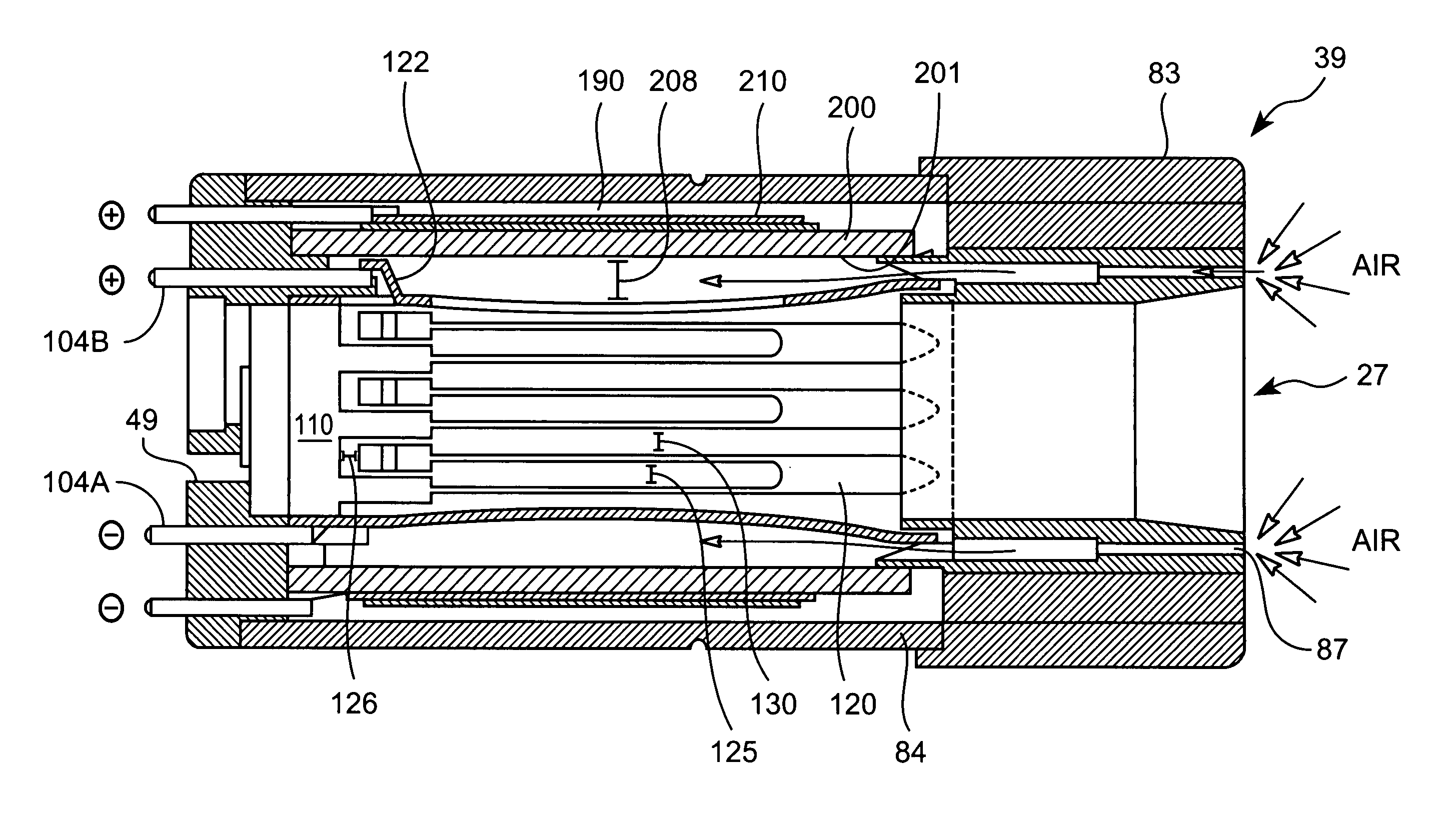

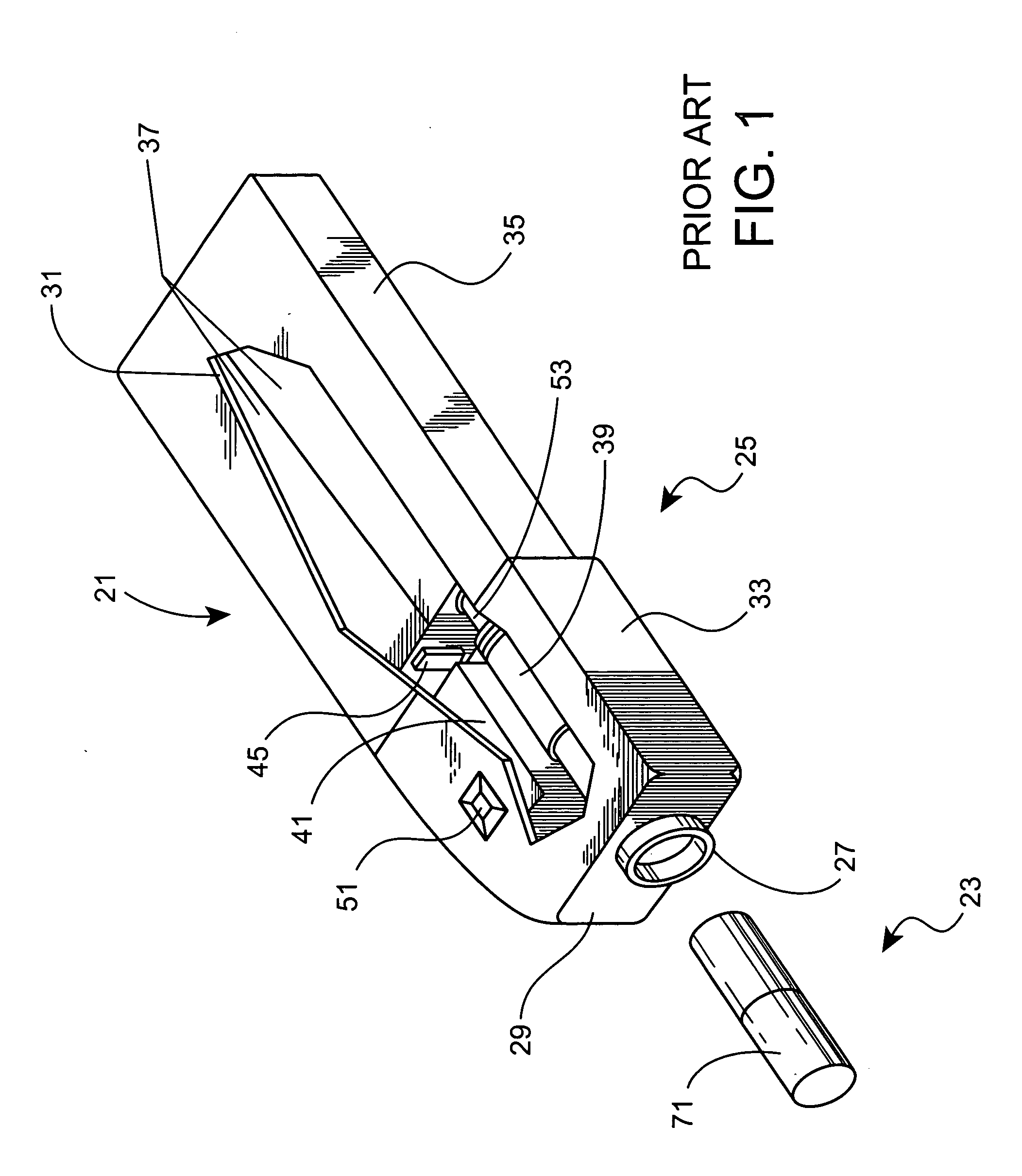

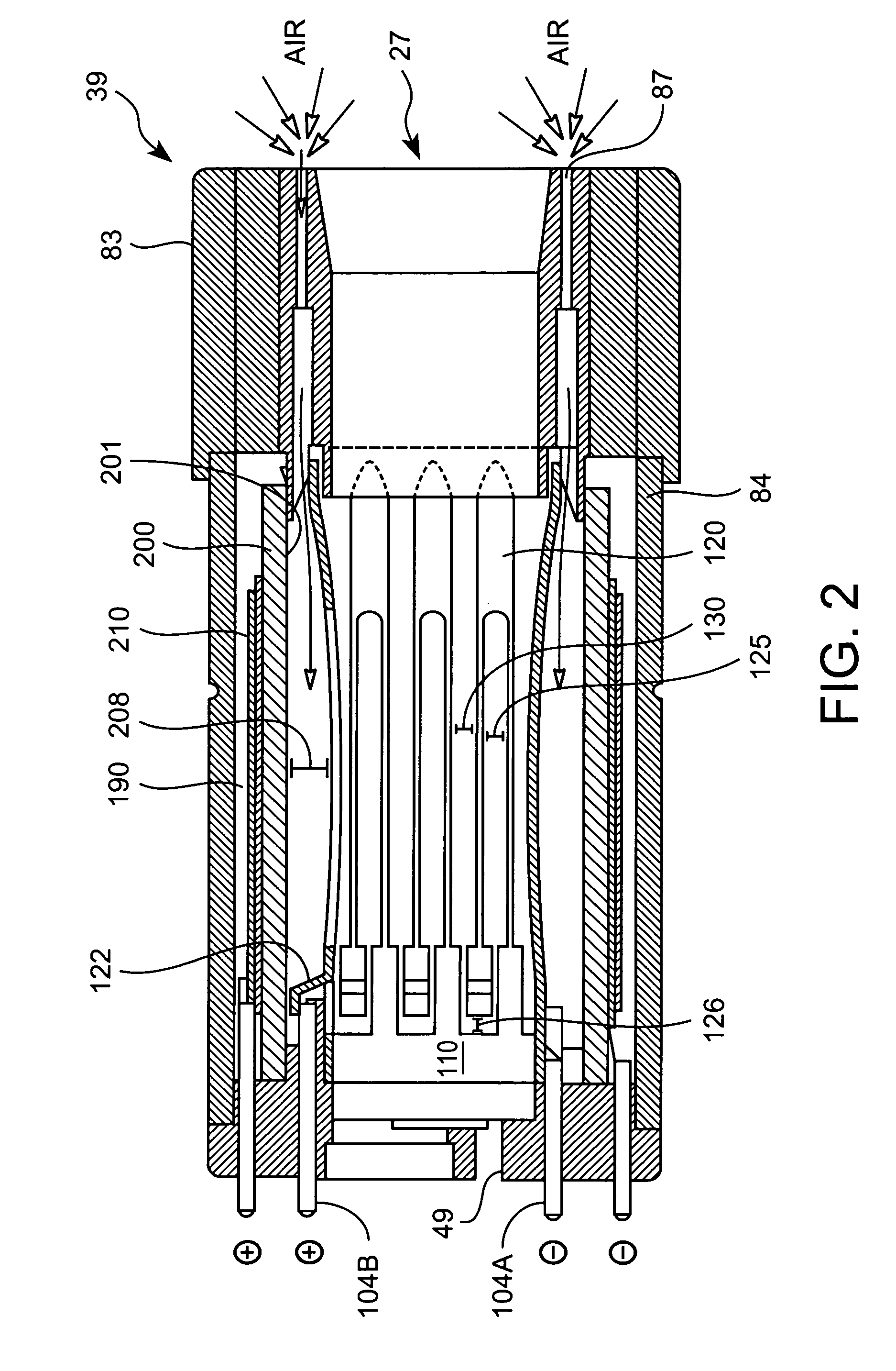

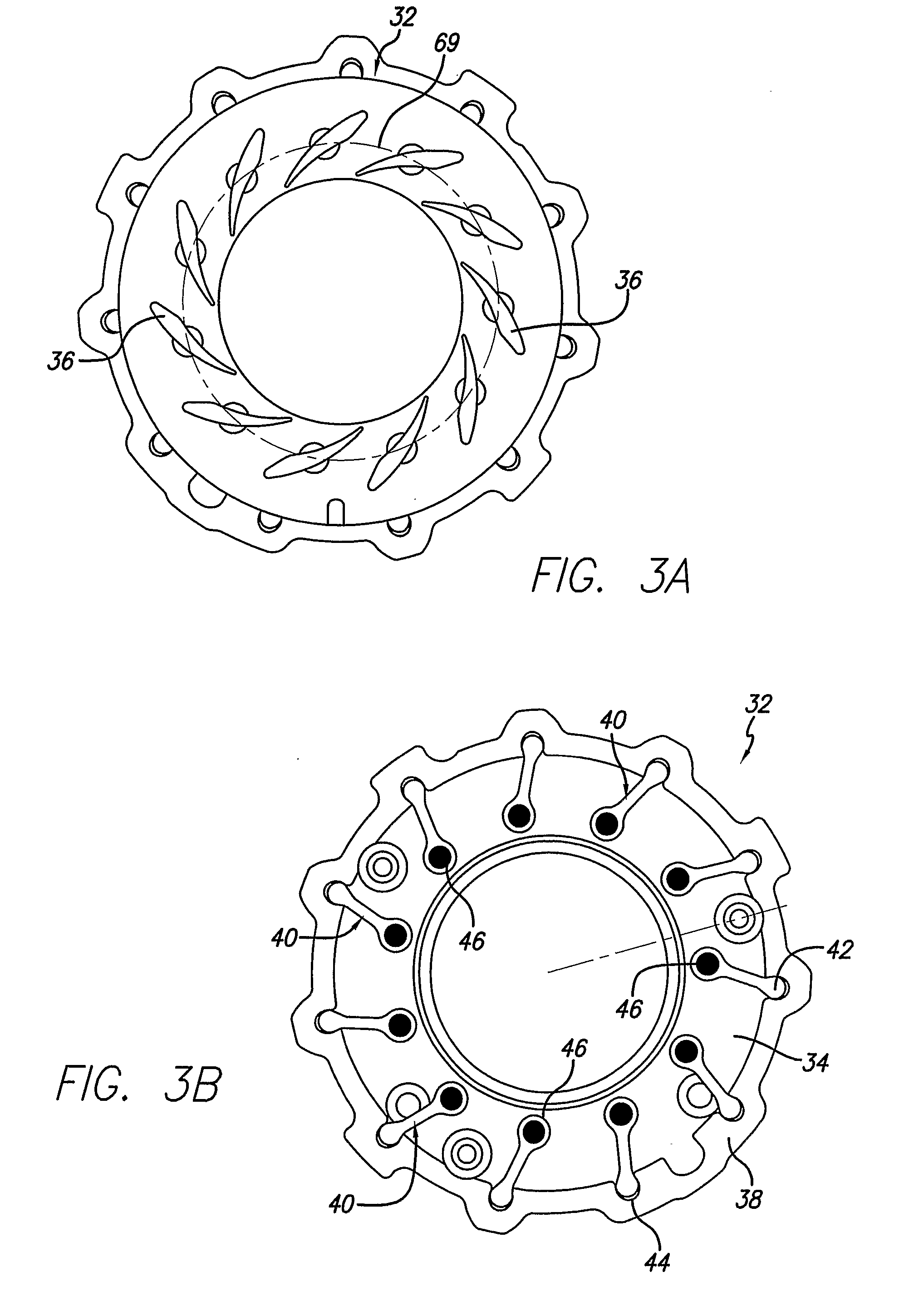

Flow distributor of an electrically heated cigarette smoking system

InactiveUS20060070633A1Increase of total aerosol deliveryImproved air distributionTobacco pipesTobacco devicesEngineeringDistributor

Owner:PHILIP MORRIS USA INC

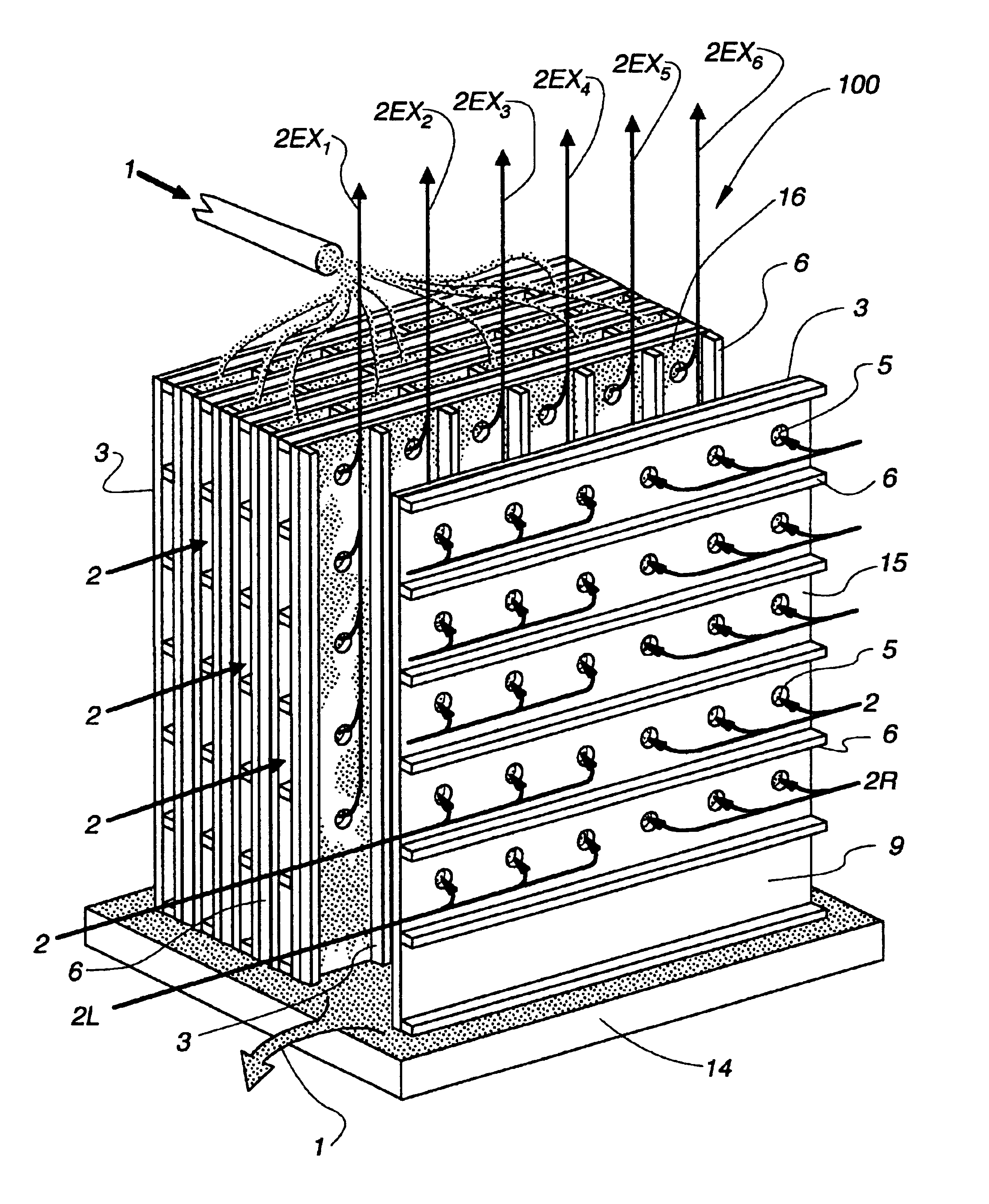

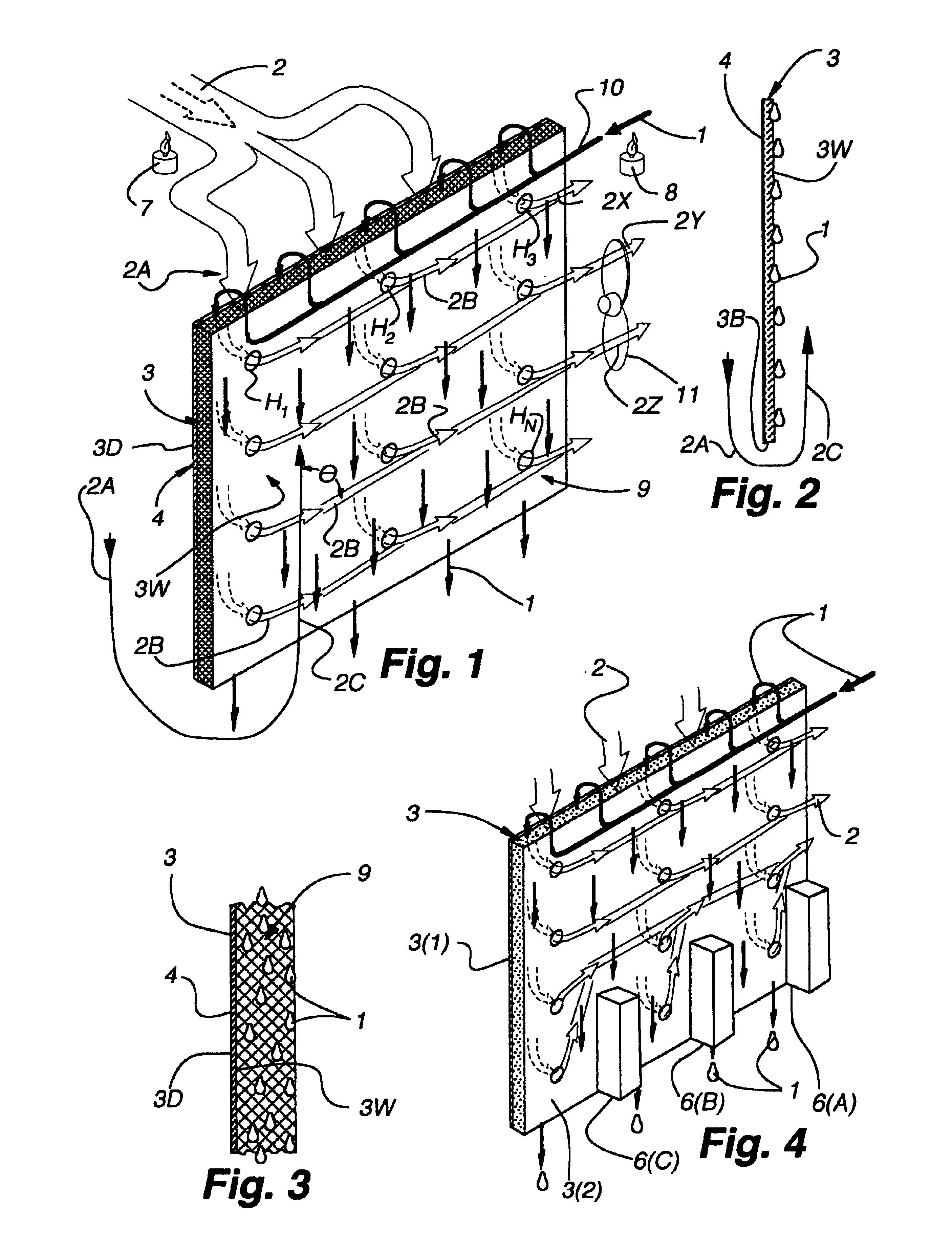

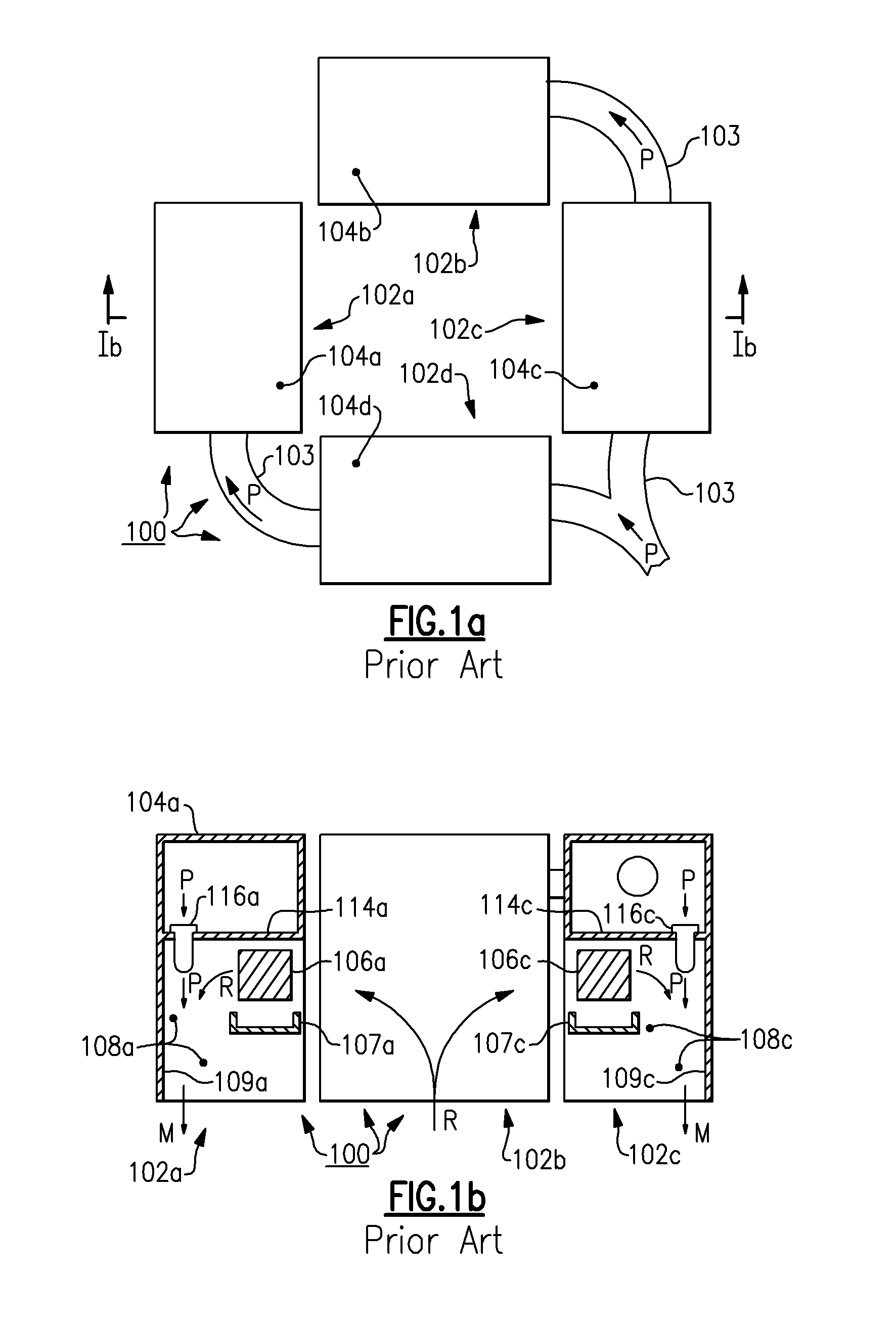

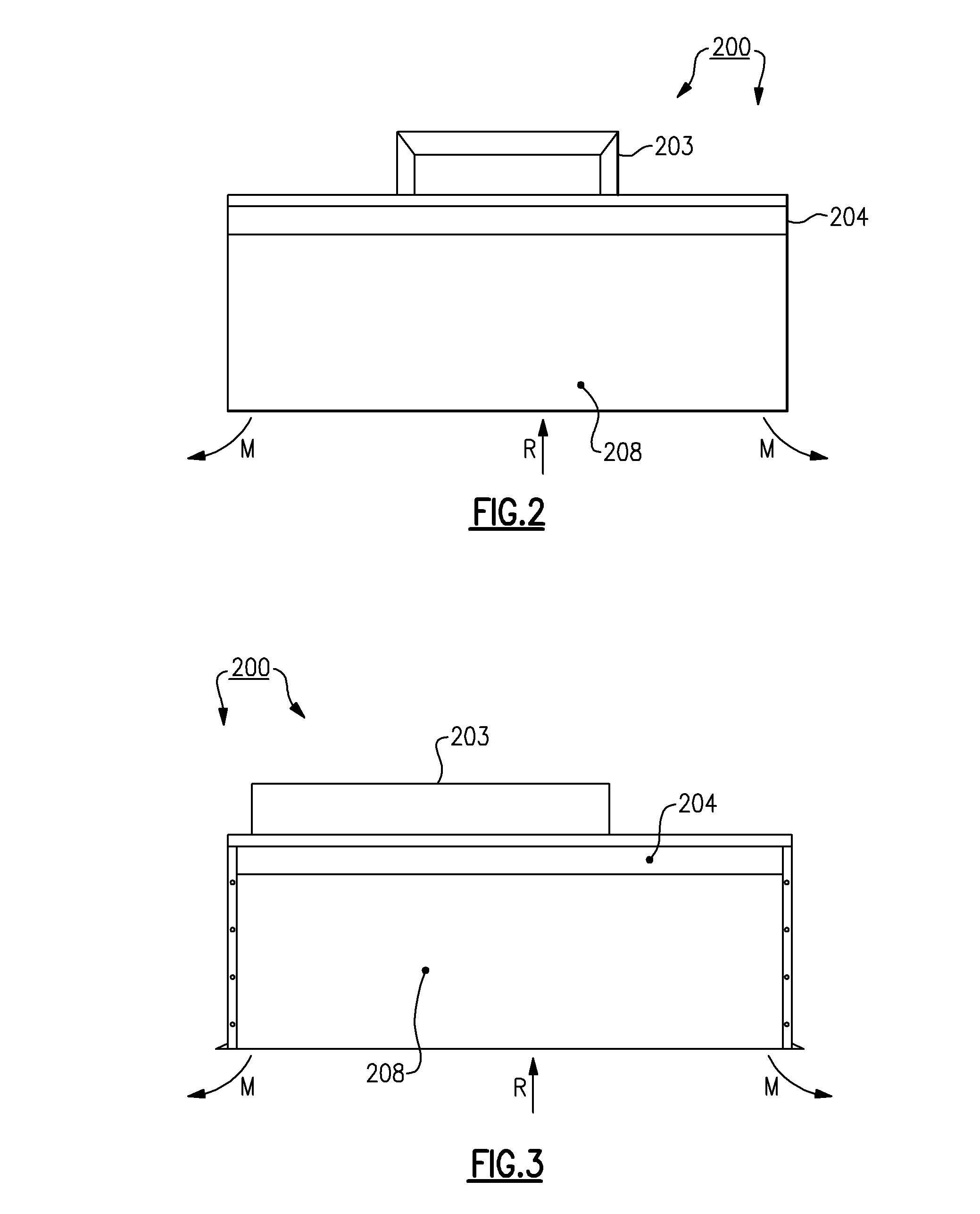

Method of evaporative cooling of a fluid and apparatus therefor

InactiveUS6854278B2Reduce the temperatureLess pressure dropMechanical apparatusSpace heating and ventilation safety systemsDesiccantMechanical engineering

The operating efficiency of indirect evaporative cooling processes and indirect evaporative cooling apparatus employing a dry side channel and a wet side channel separated by a heat exchange plate are improved by placement of holes in the heat exchange plate. Further improvements are obtained when the flow direction in the wet side channel is cross-current to the flow direction in the dry side channel. Placement of desiccant materials in the dry side channel also serve to improve the operating efficiencies of these processes and apparatus.

Owner:IDALEX TECH INC

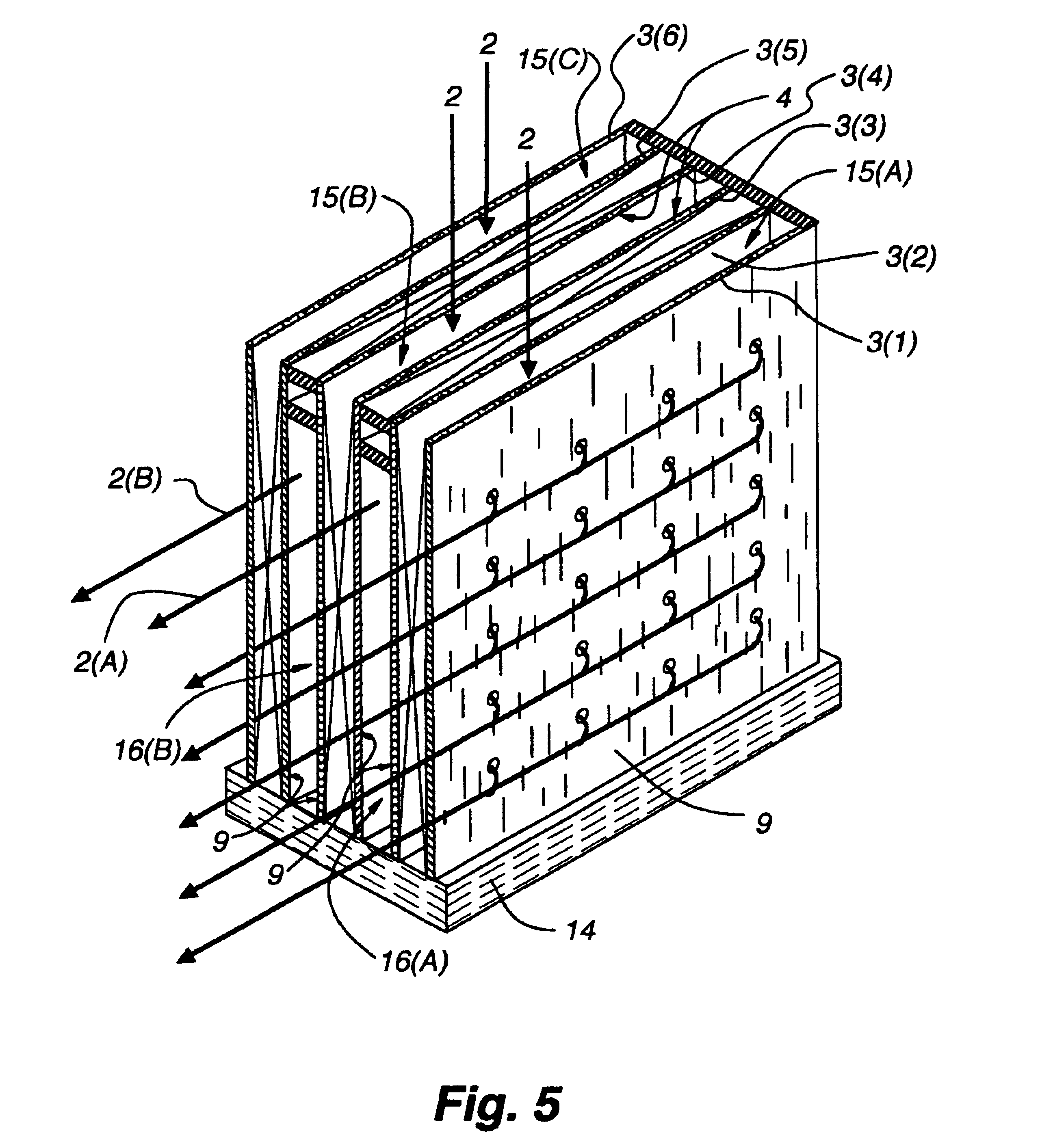

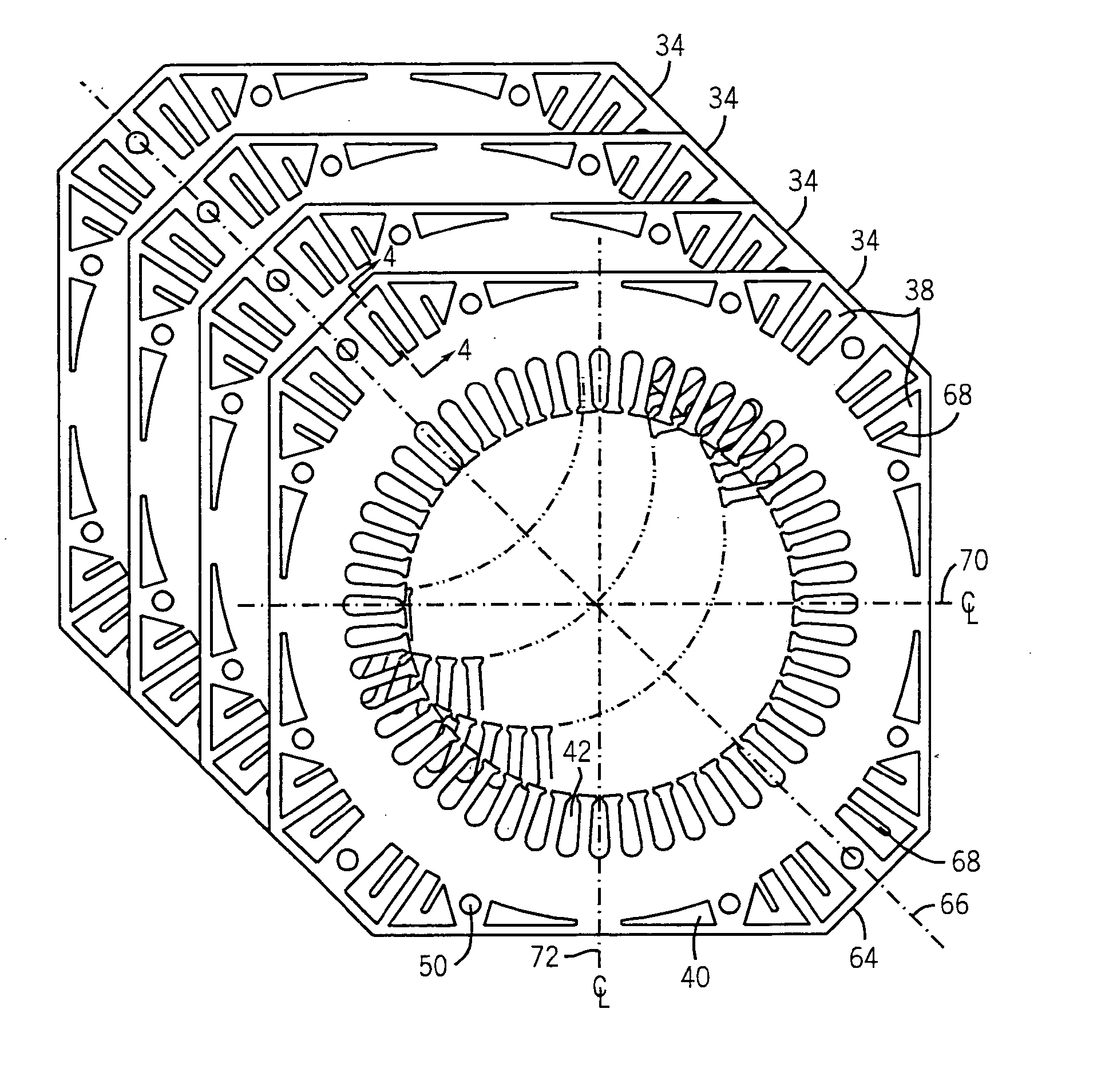

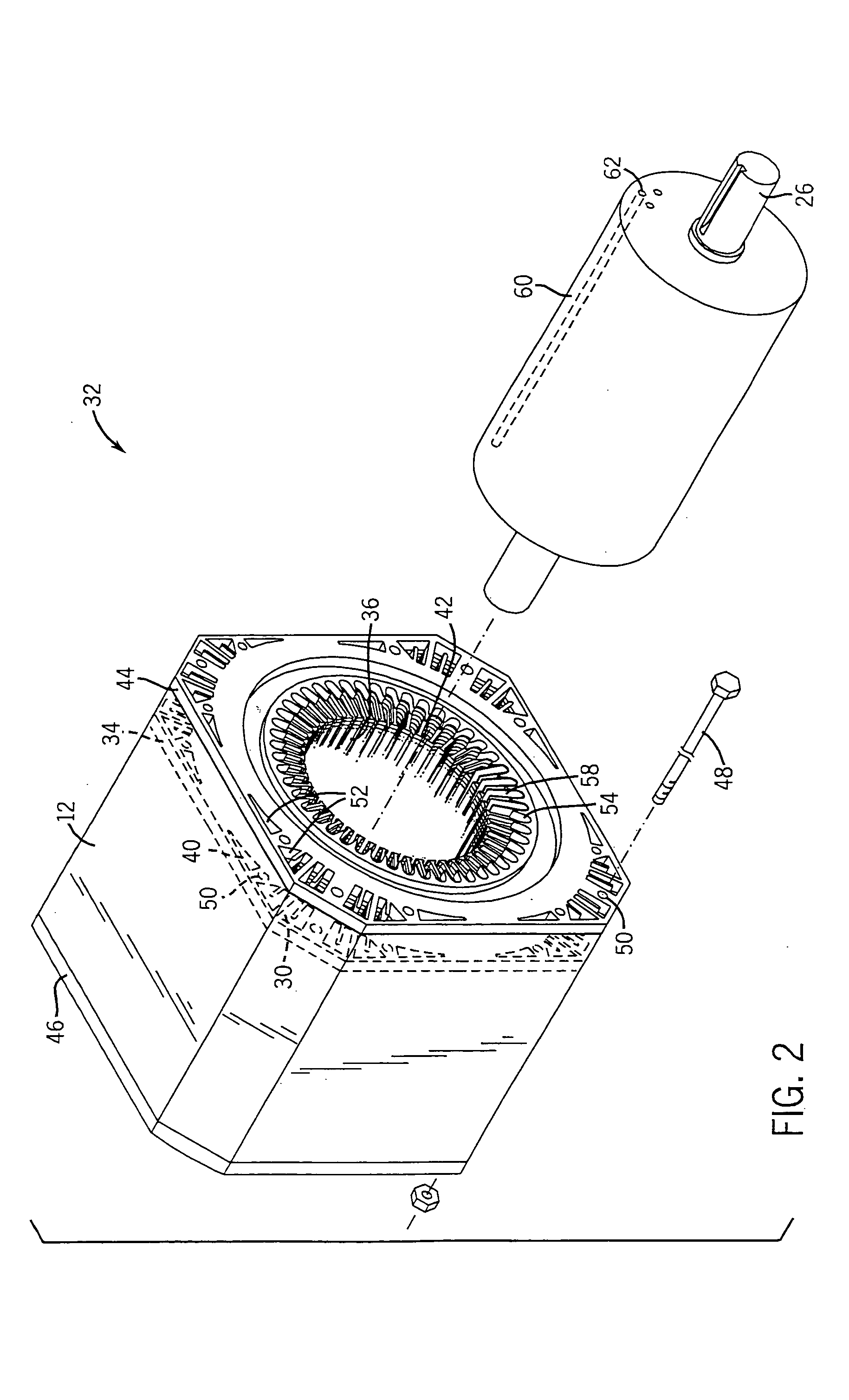

Stator cooling method and apparatus

InactiveUS20050067905A1Improve cooling effectImproved convection coolingMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringForced-air

According to one embodiment of the present technique, forced air (i.e., air flow) is routed through a motor stator having corners and center ducts. Advantageously, by routing the air flow through ducts in accordance with the present technique, air flow is more evenly distributed throughout the motor, thereby reducing hotspots. By way of example, the motor stator my include fins that affect air flow and provide heat dissipation surfaces to the motor.

Owner:RELIANCE ELECTRIC TECH

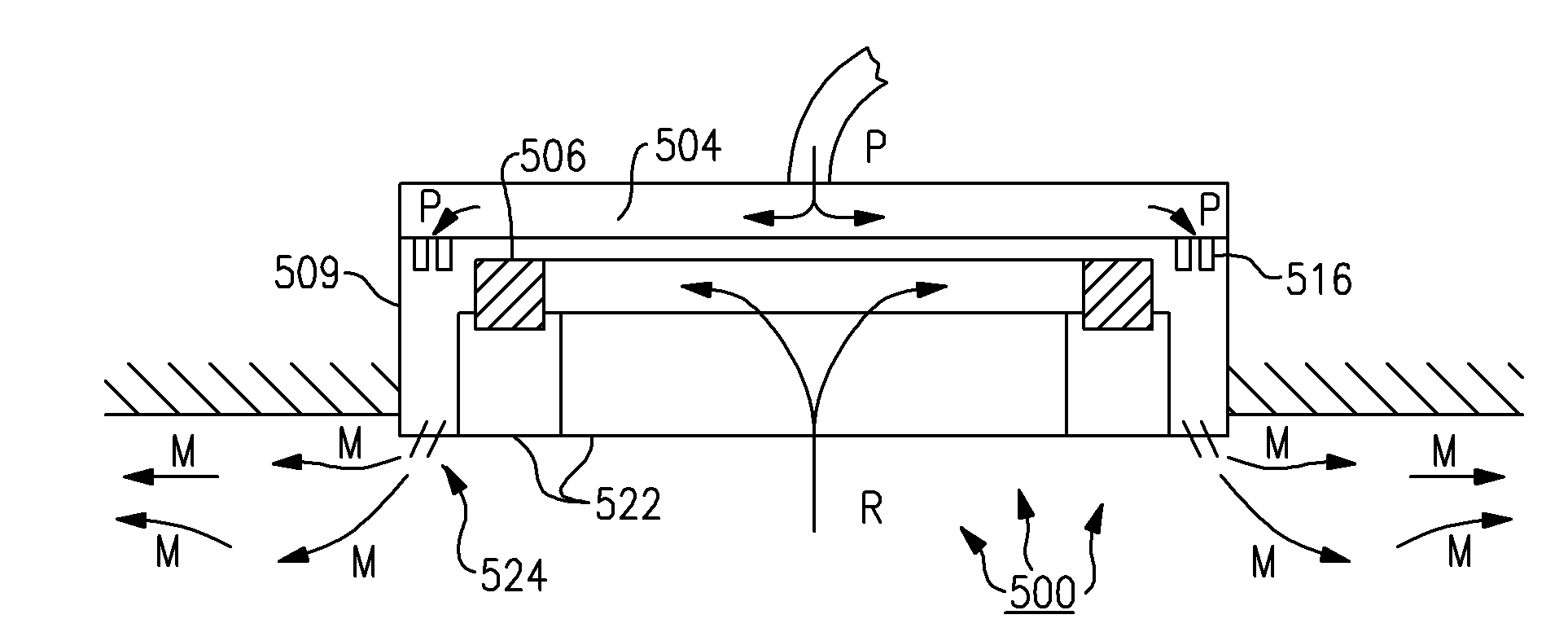

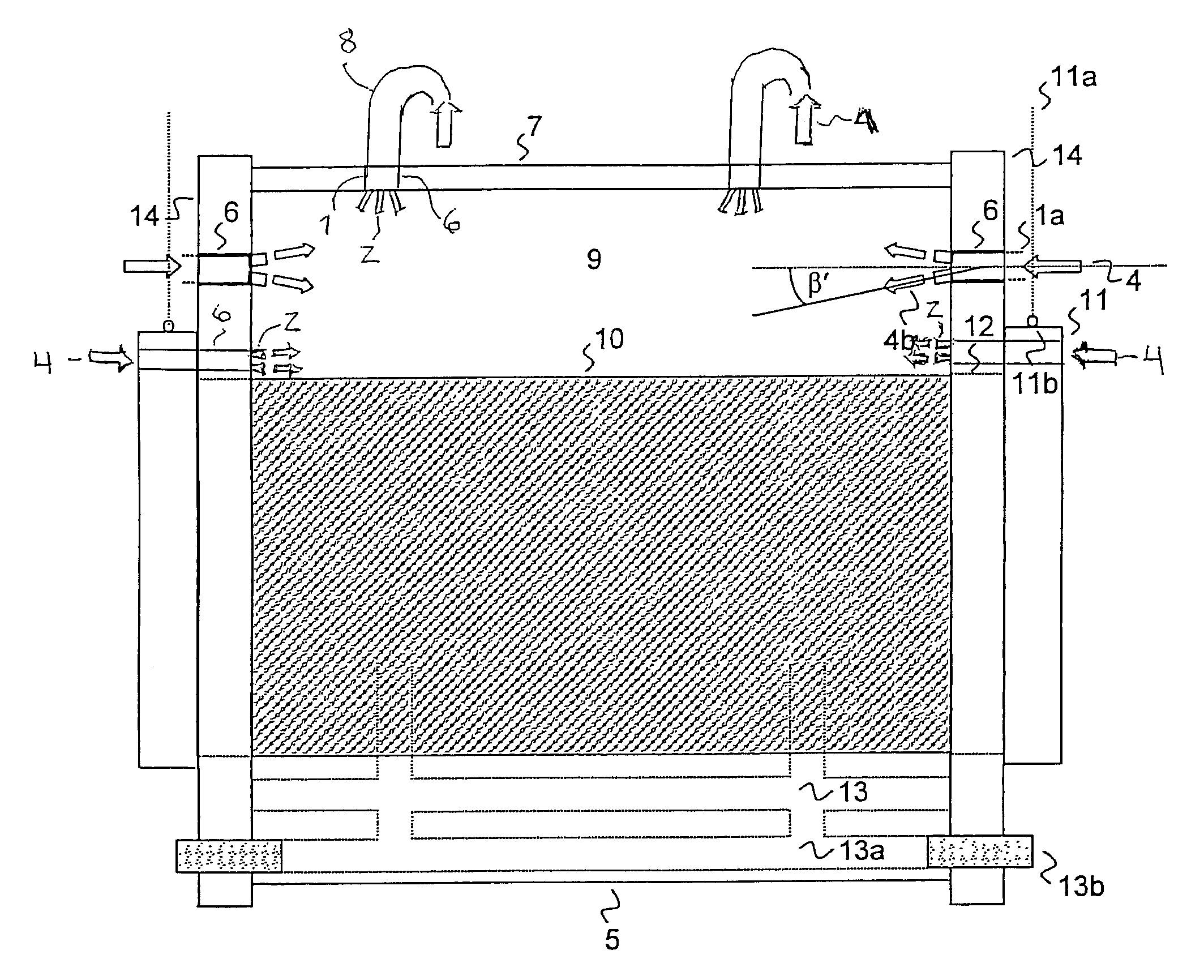

Ventilation system

InactiveUS20090264062A1Increase flexibilityOptimize volumeLighting and heating apparatusSpace heating and ventilation detailsEngineeringMixing chamber

The present invention is directed to a 360 degree ventilation system with a single unitary plenum. The present invention is also directed to a 360 degree ventilation system with a single mixing chamber extending at least substantially entirely around the perimeter of the blow ventilation system. The present invention is also directed to a 360 degree ventilation system with a heating / cooling units that extend substantially all the way around the perimeter of the ventilation system. The present invention is also directed to a 360 degree ventilation system with a single return air chamber.

Owner:NUCLIMATE AIR QUALITY SYST

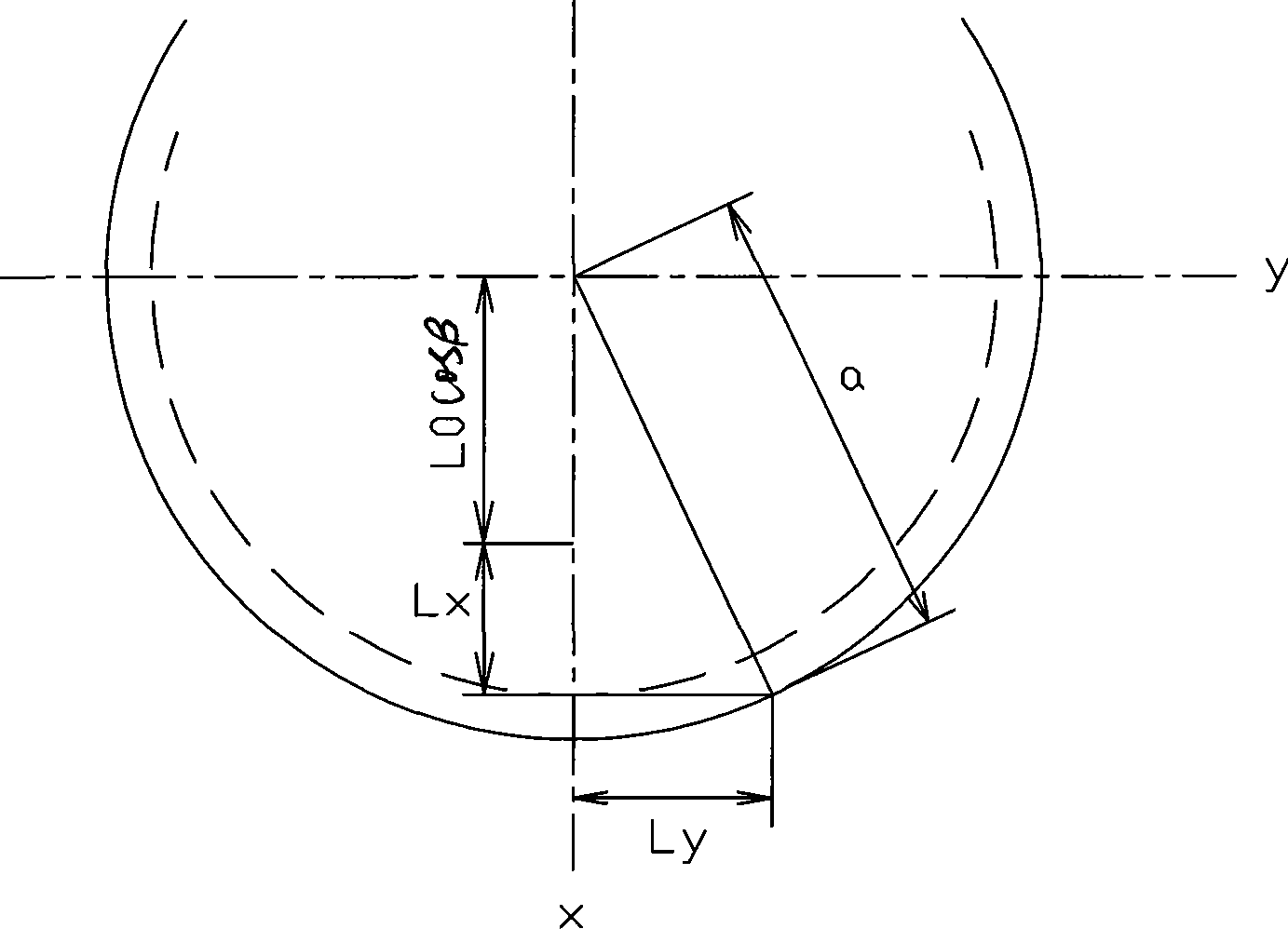

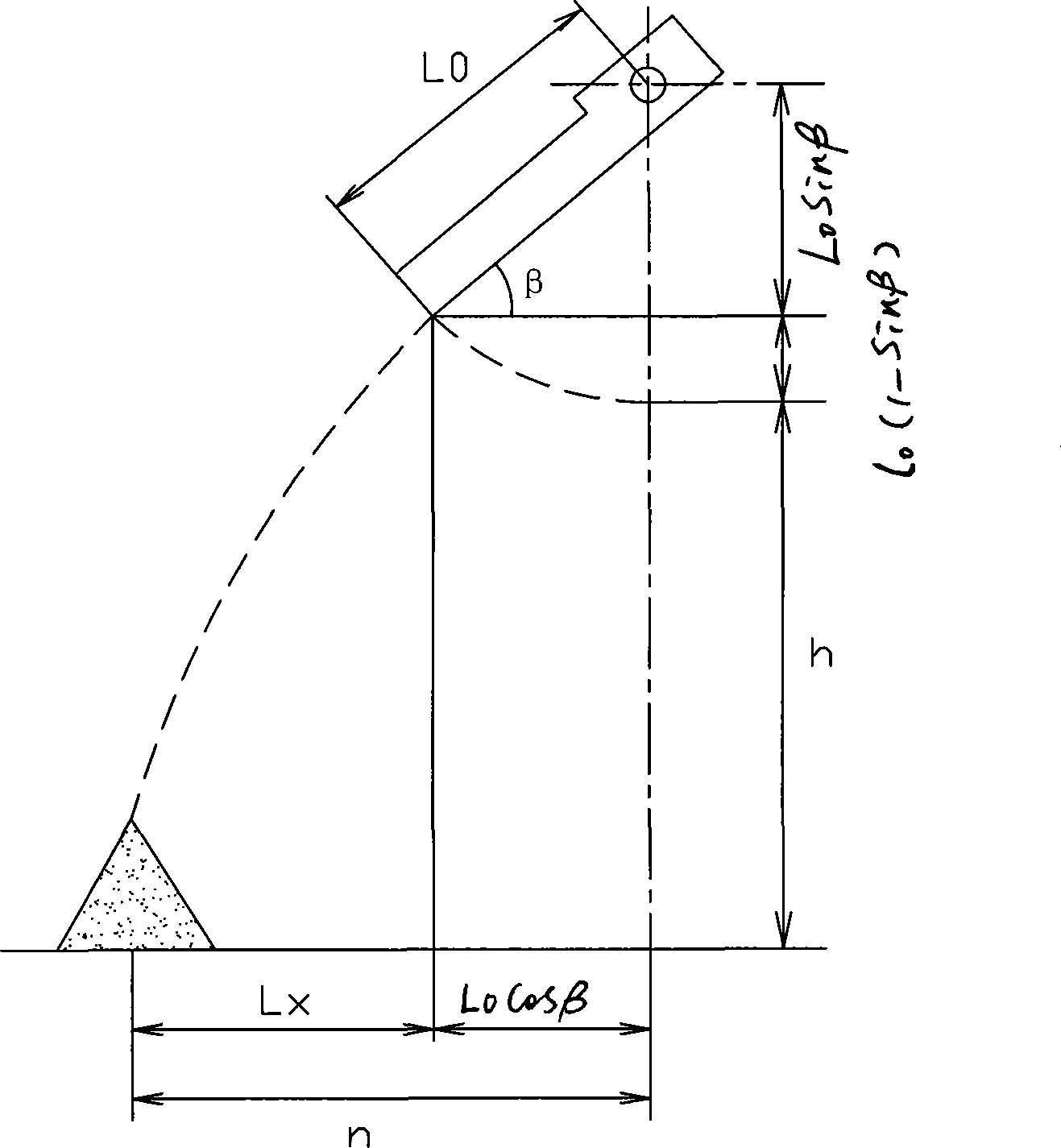

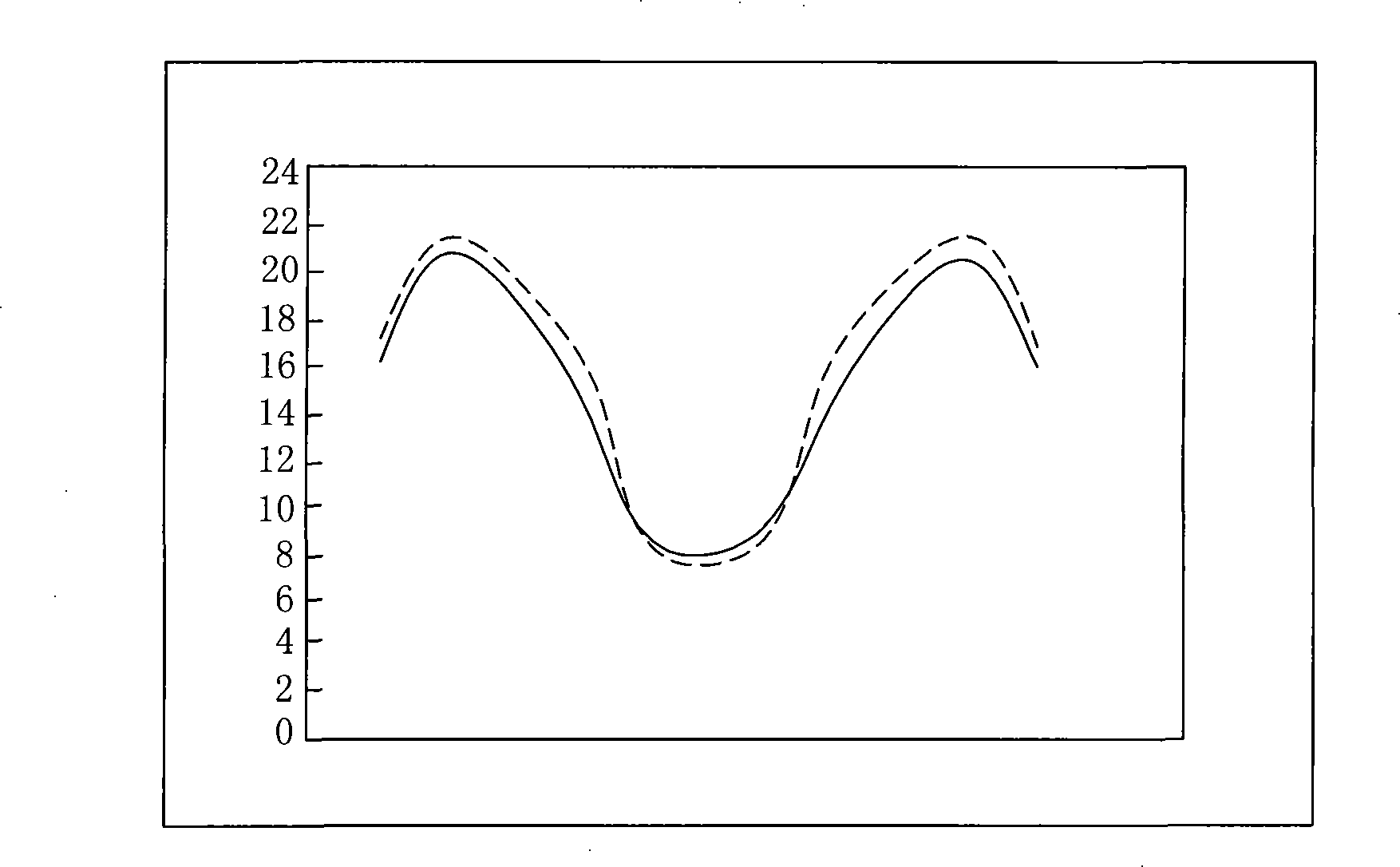

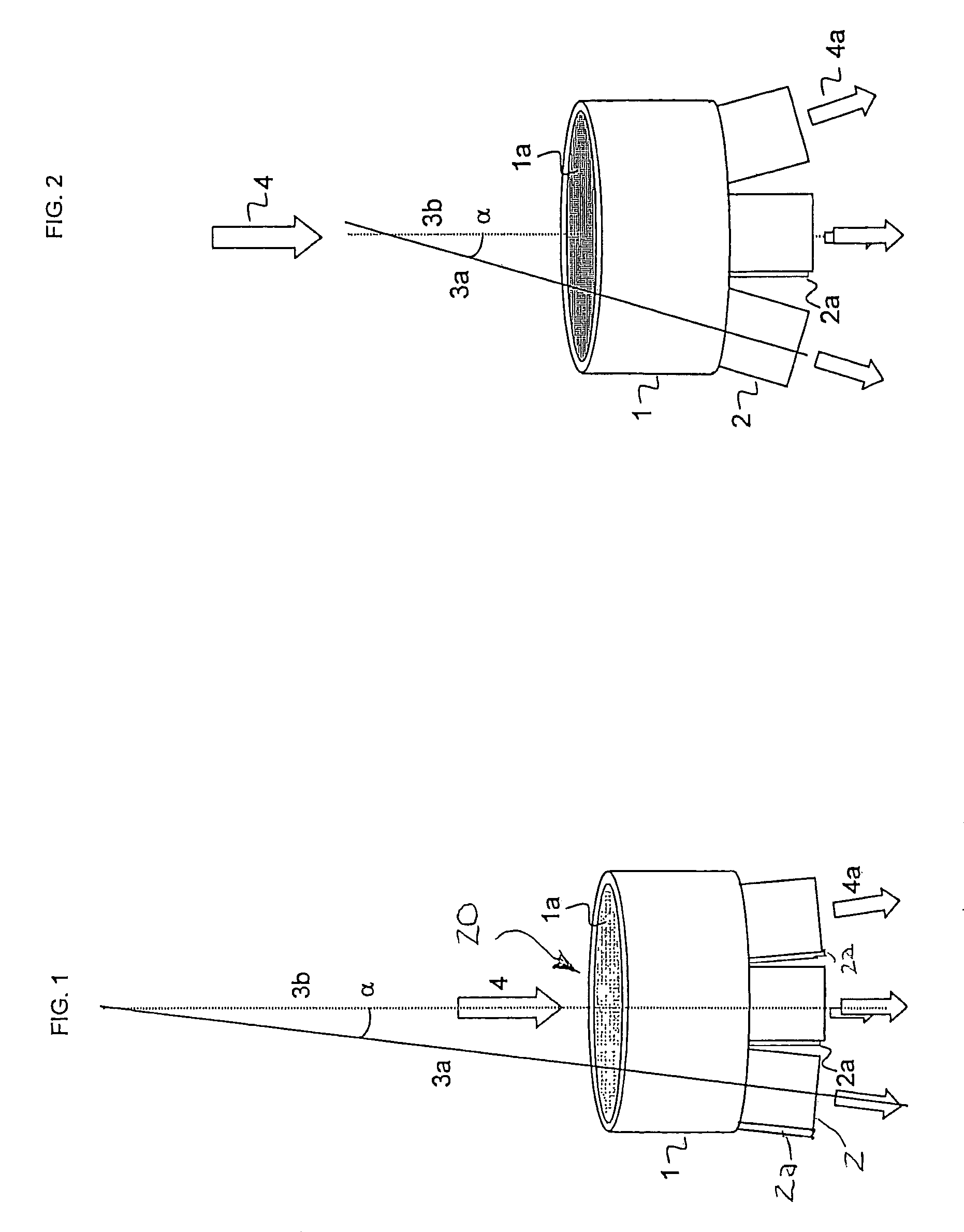

Blast furnace chute polycyclic distributing method

InactiveCN101250602AIncrease production capacityUniform material layerBell-and-hopper arrangementBlast furnace detailsRing numberGravitation

The invention discloses a blast furnace chute multi-ring burden distribution, which comprises firstly calculating the distance from the center of furnace burden from the center of a blast furnace after furnace burden fell into an xy plane, secondly deciding largest and smallest burden distribution angles in theory, thirdly deciding the actual burden distribution angles of outer ring and inner ring of ores and coke, fourthly deciding the burden distribution ring number of ores and coke, determining the burden distribution angle of middle ring of ores and coke and the angel difference of adjacent rings, and sixthly determining the burden distribution rings of each ring in ores and coke. The process largely enriches the regulating method on the upper portion of the blast furnace, changes coal gas distribution, effectively increases the coal gas usage of the blast furnace, reduces coke ratio, realizes the stable and long term operation of the blast furnace, has strong loading material capacity, can eliminate furnace burden gravity segregation and the existing of pile top, much reasonably distributes furnace burden, is beneficial for strengthening smelting, and improves the press amount relationship and further increases the air quantity of the blast furnace.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

Air distributing device for primary air in coke ovens

ActiveUS9404043B2Improved air distributionReduce formationCombustible gas coke oven heatingHorizontal chamber coke ovensCombustionCoke oven

A device for introduction of primary combustion air into the primary heating space of a coke oven chamber admits primary air through ports in the top of a oven chamber or in the oven chamber walls above the door or in the chamber door or in several or all of the mentioned positions These ports have inserts that are equipped with spouts, with the spouts having an opening through which primary air is conducted at a chamfered angle onto the coke cake. The primary air from the opening ports in the coke oven chamber top streams to the coke oven at an angle of less than 90° and primary air from the opening ports in the chamber wall above the door or in the door streams to the coke oven at an angle of greater than 0°. Also shown is a method for use with the described device.

Owner:THYSSENKRUPP IND SOLUTIONS AG

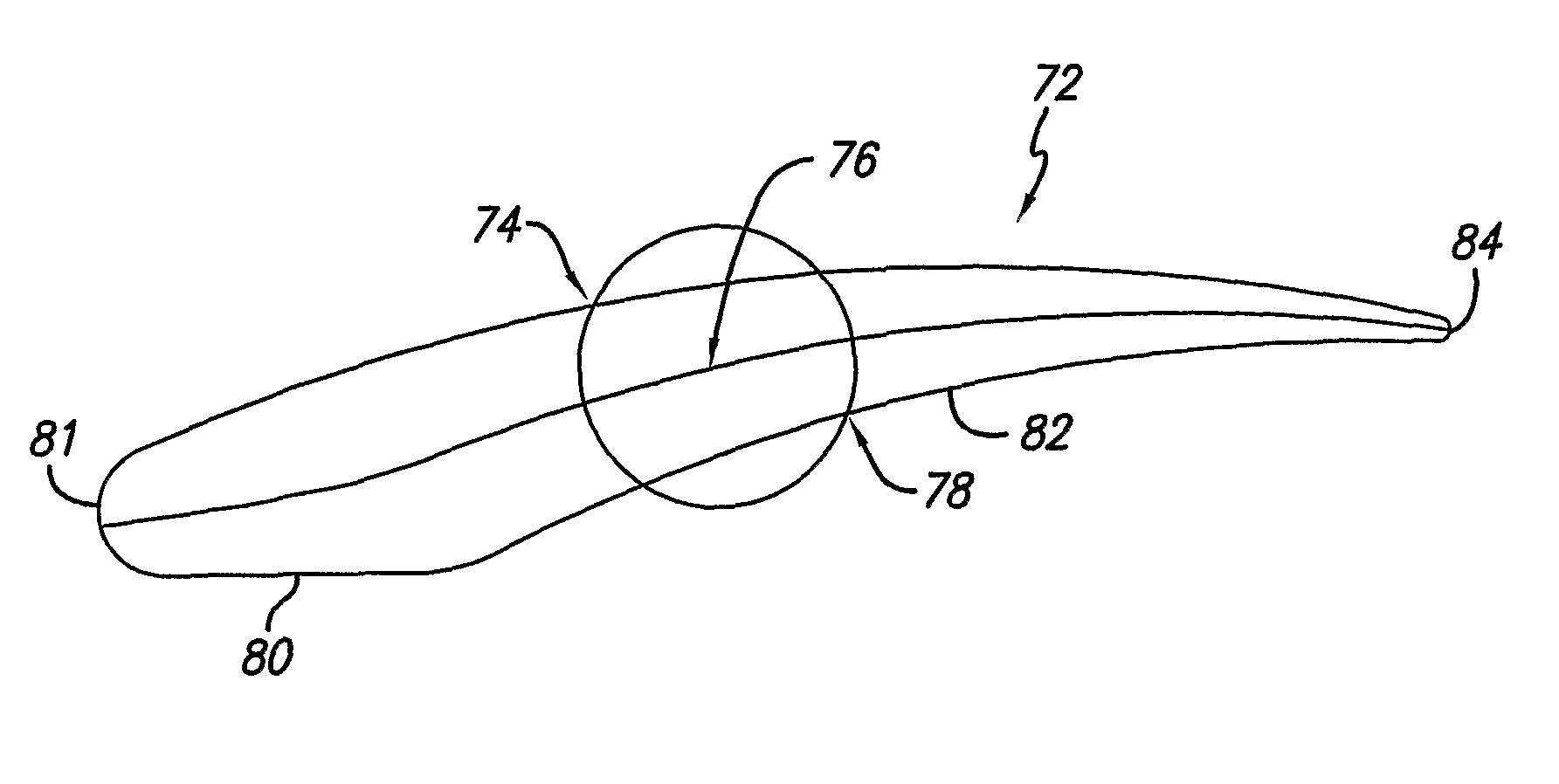

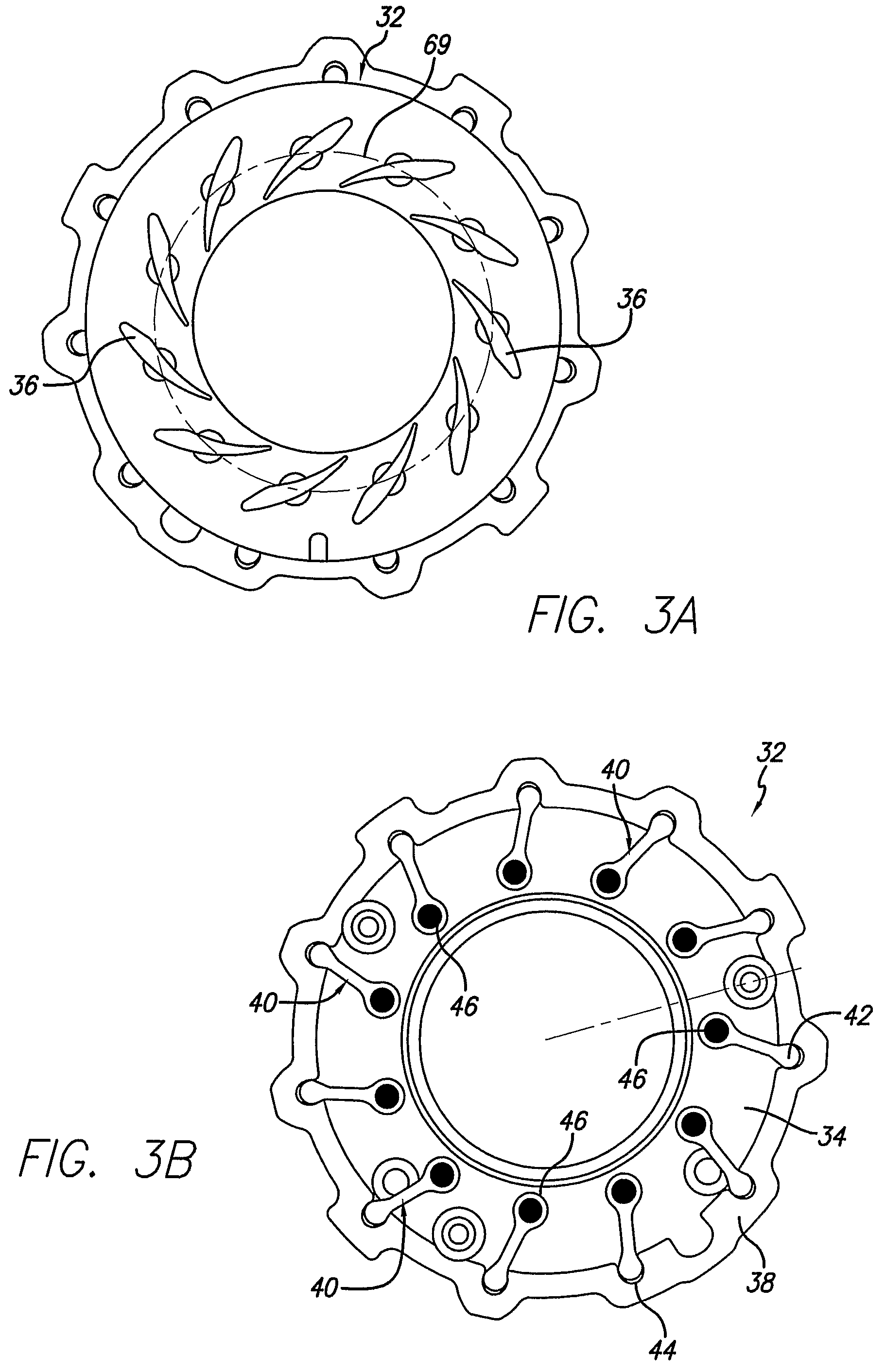

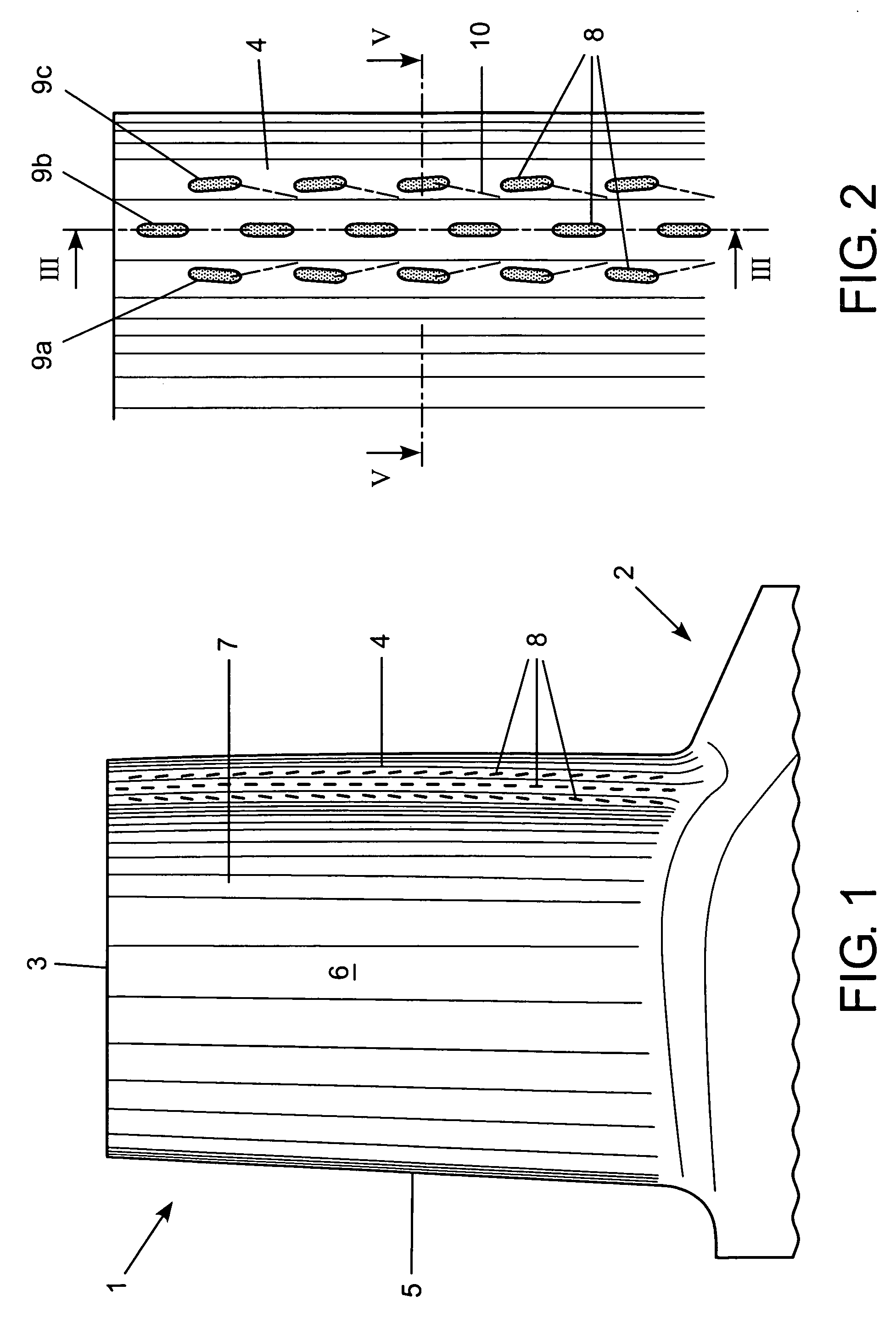

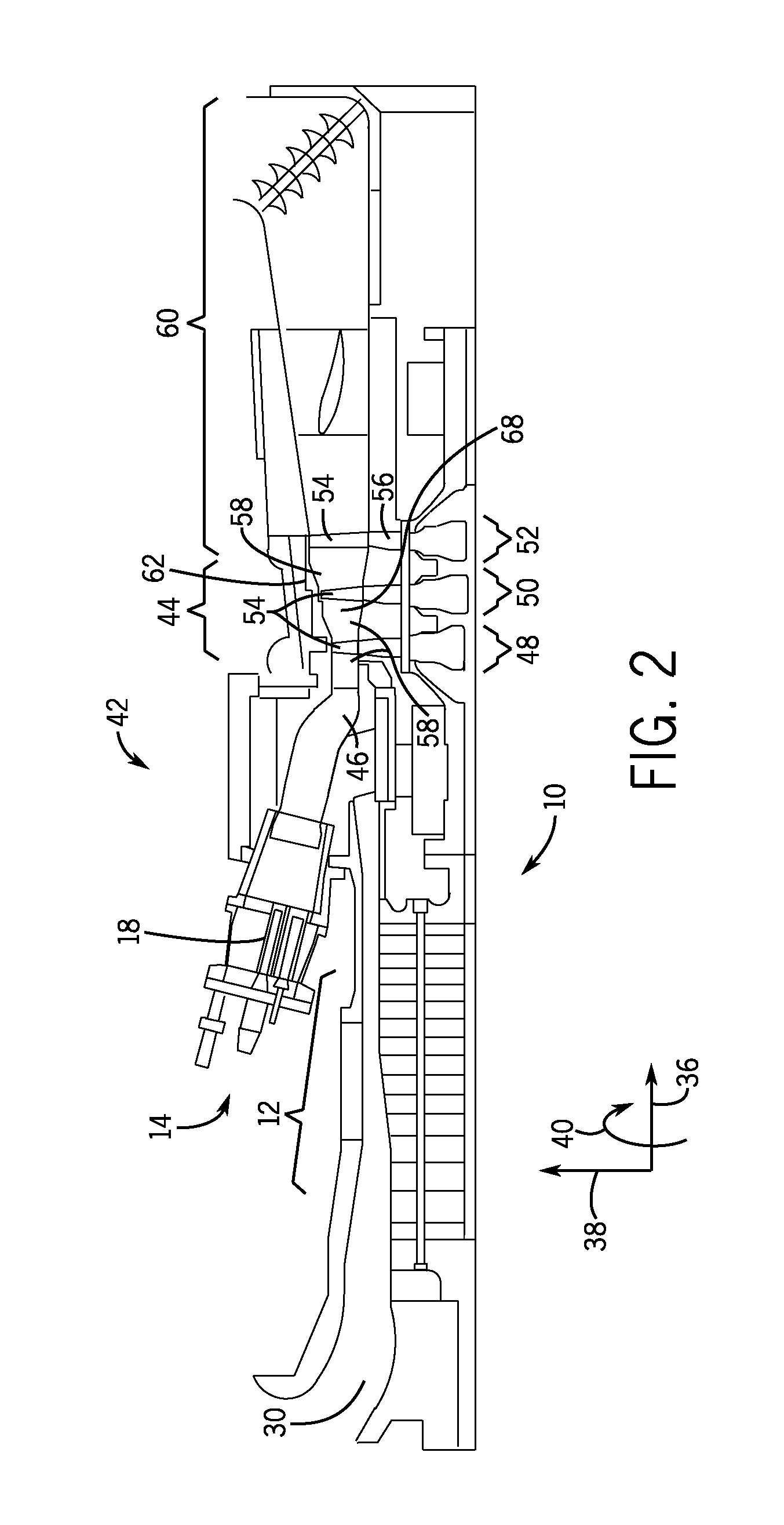

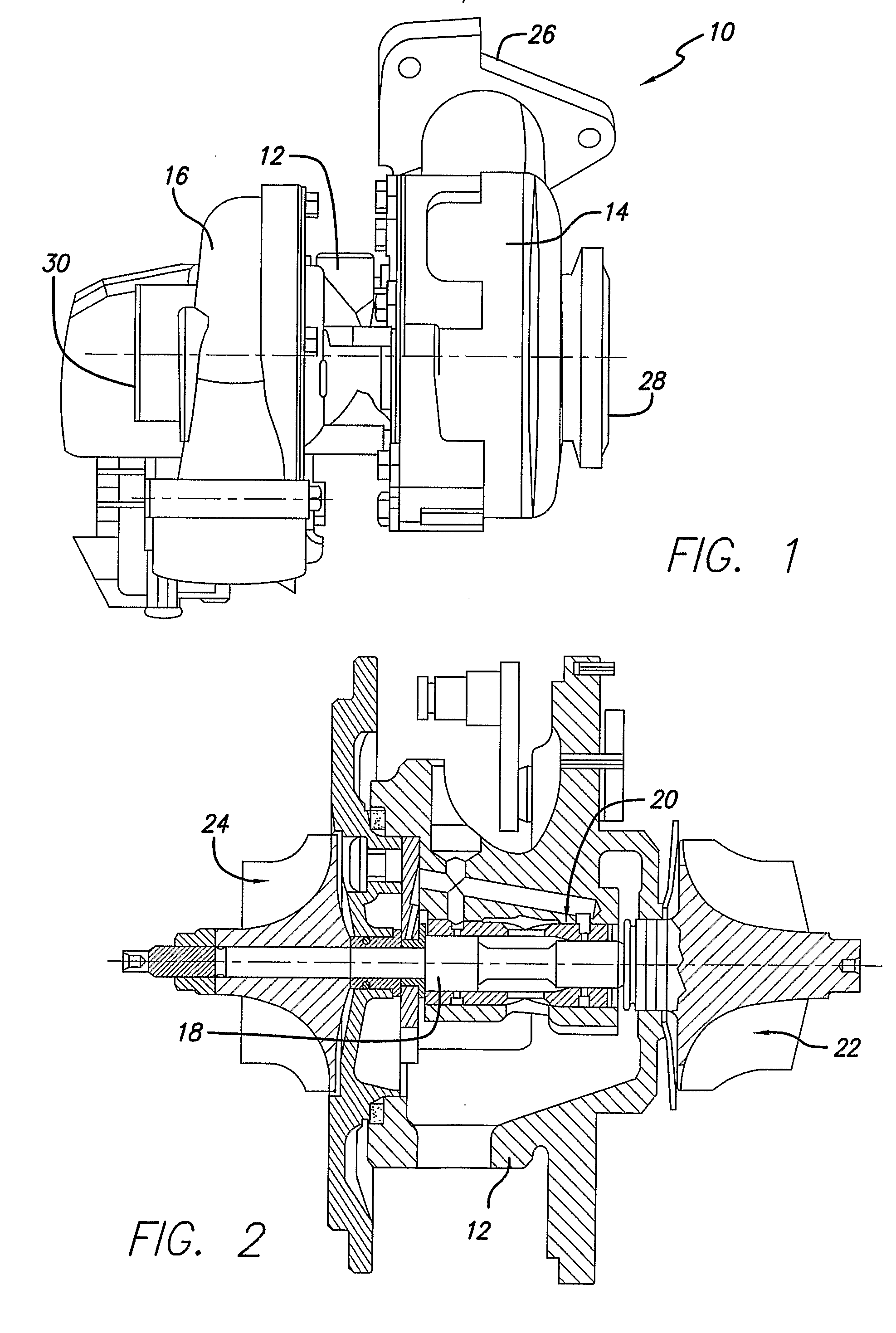

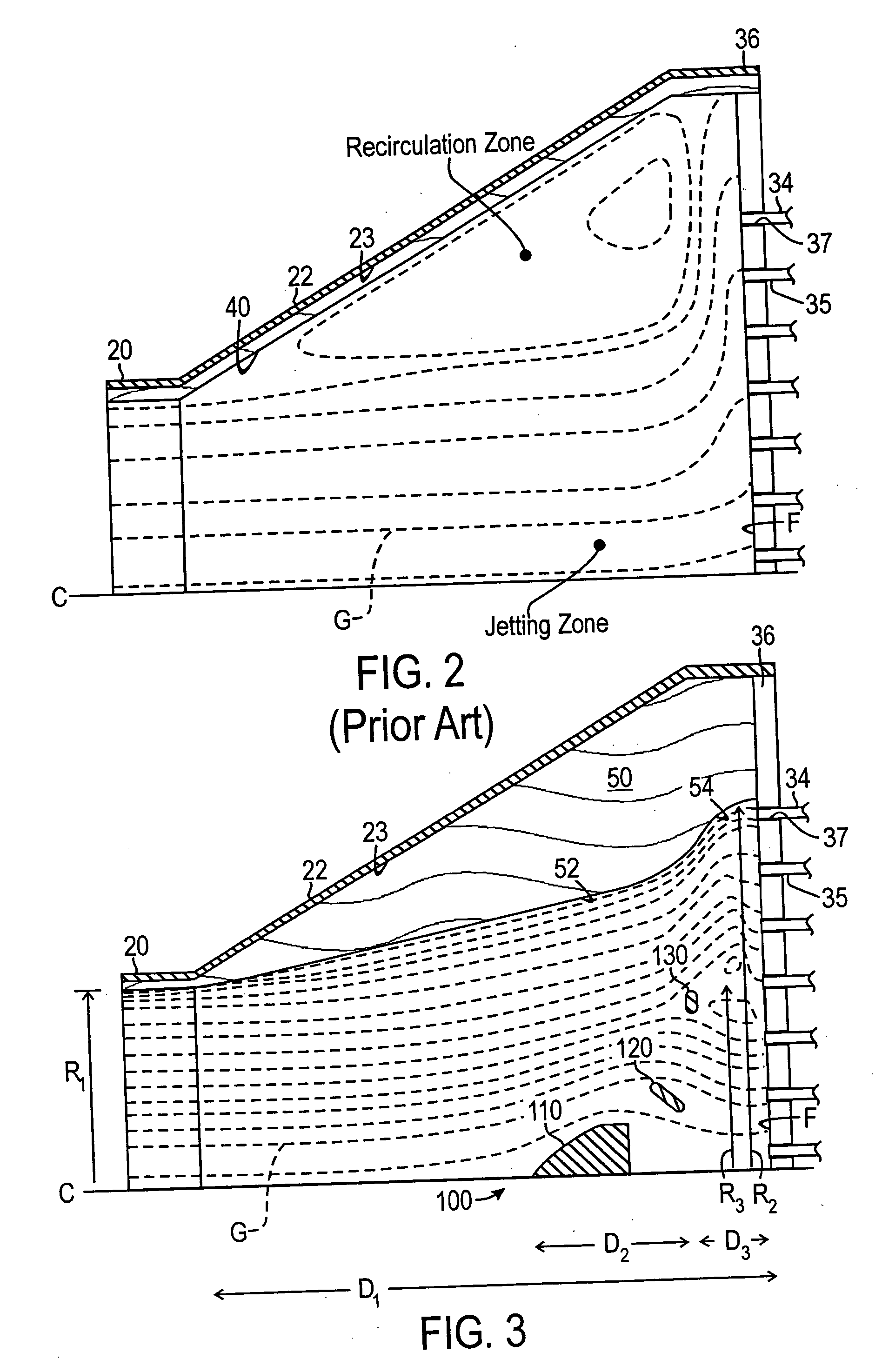

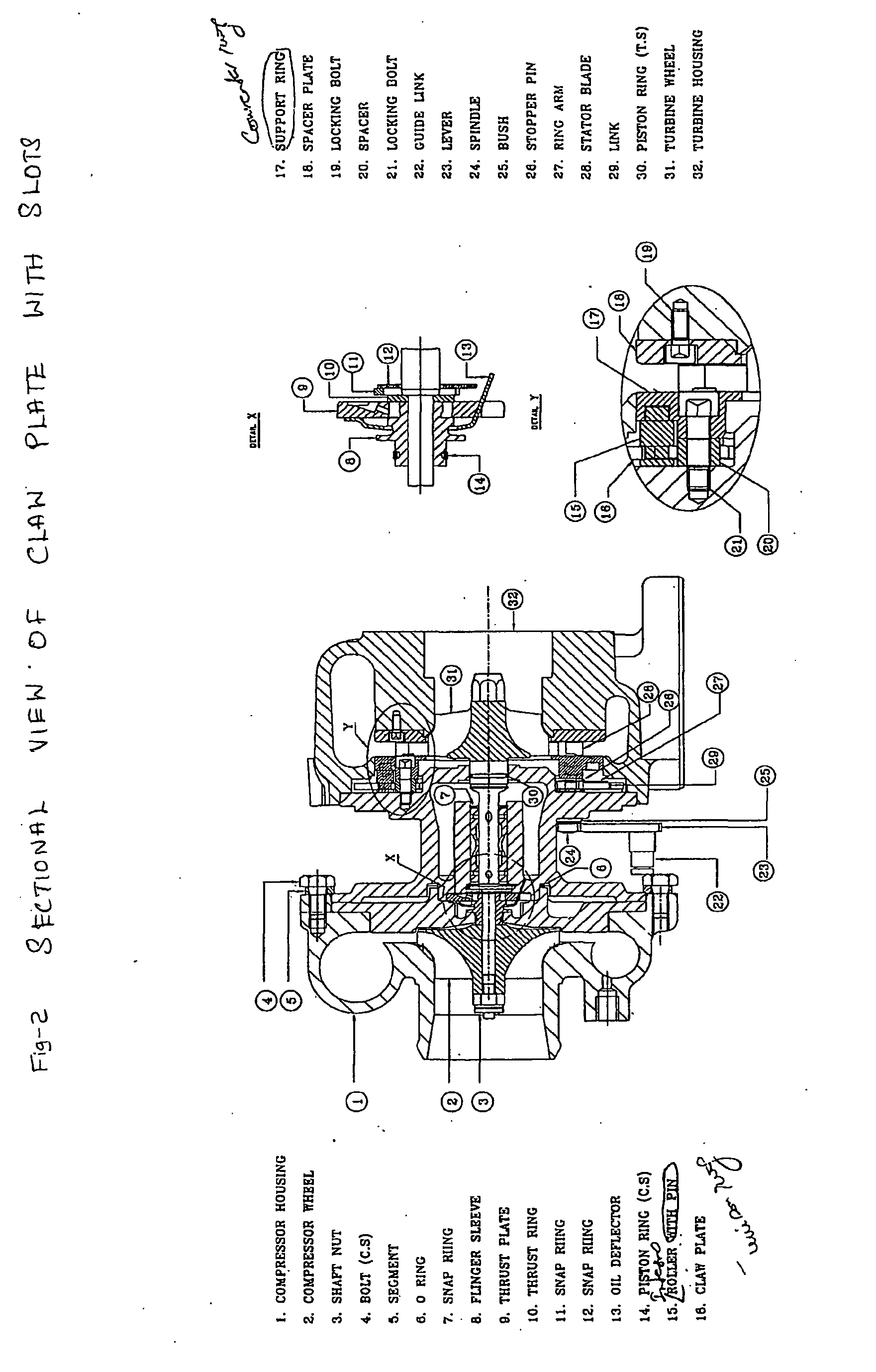

Cambered vane for use in turbochargers

InactiveUS7771162B2Increase the effective working rangeImproved air distributionWind motor controlPump componentsLeading edgeImpeller

Various cambered vanes are constructed for use within a vaned turbocharger and include an inner airfoil surface oriented adjacent a turbine wheel, and an outer airfoil surface oriented opposite the inner airfoil surface. The inner and outer airfoil surfaces define a vane airfoil thickness. A cambered vane leading edge or nose is positioned along a first inner and outer airfoil surface junction, and a vane trailing edge positioned along a second inner and outer surface junction. The vane inner and outer airfoil surfaces are specially configured to provide a vane camberline having a curved section, which can. provide for improved gas flow distribution, thereby increasing the effective operating range of the turbocharger.

Owner:HONEYWELL INT INC

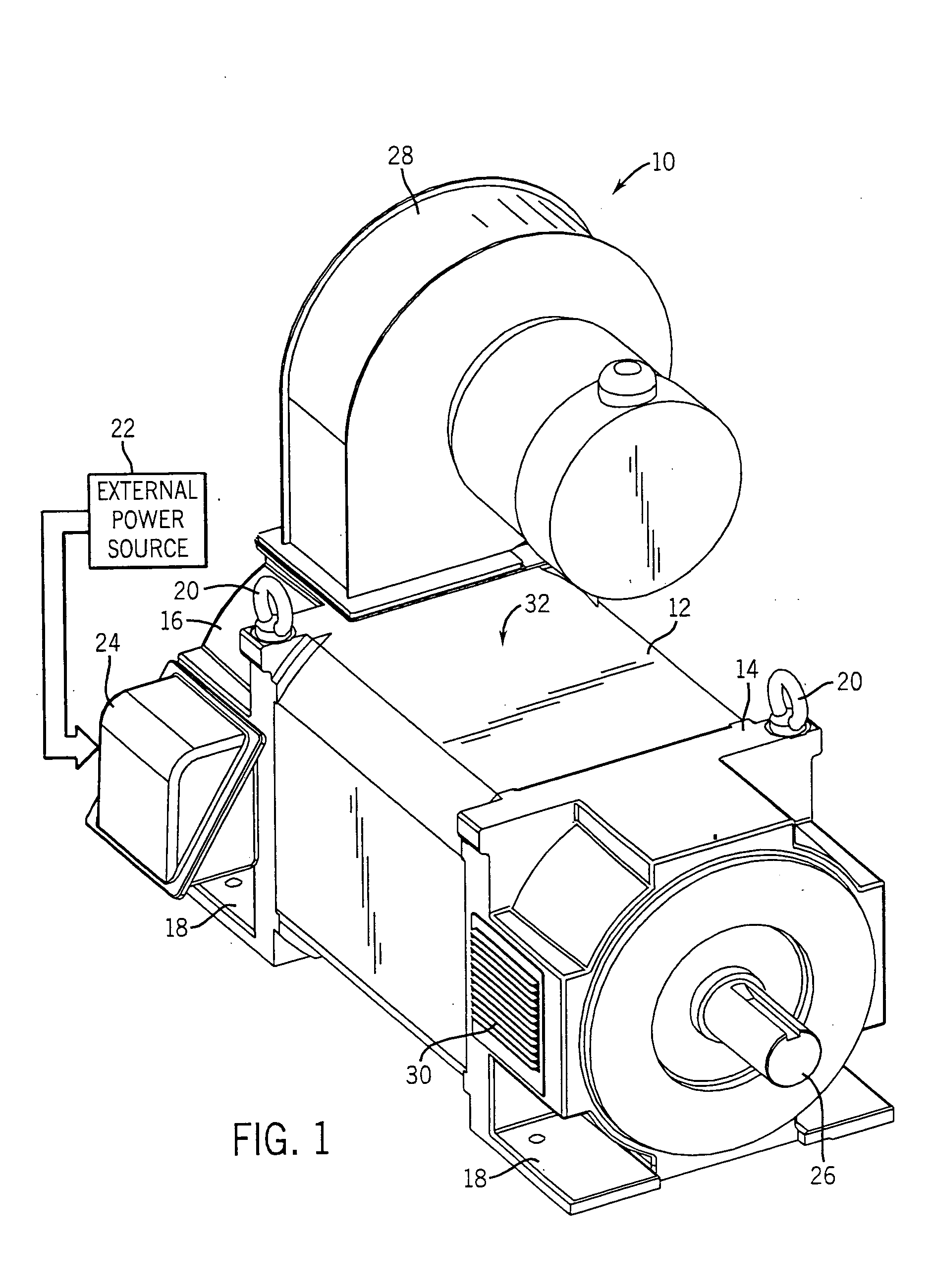

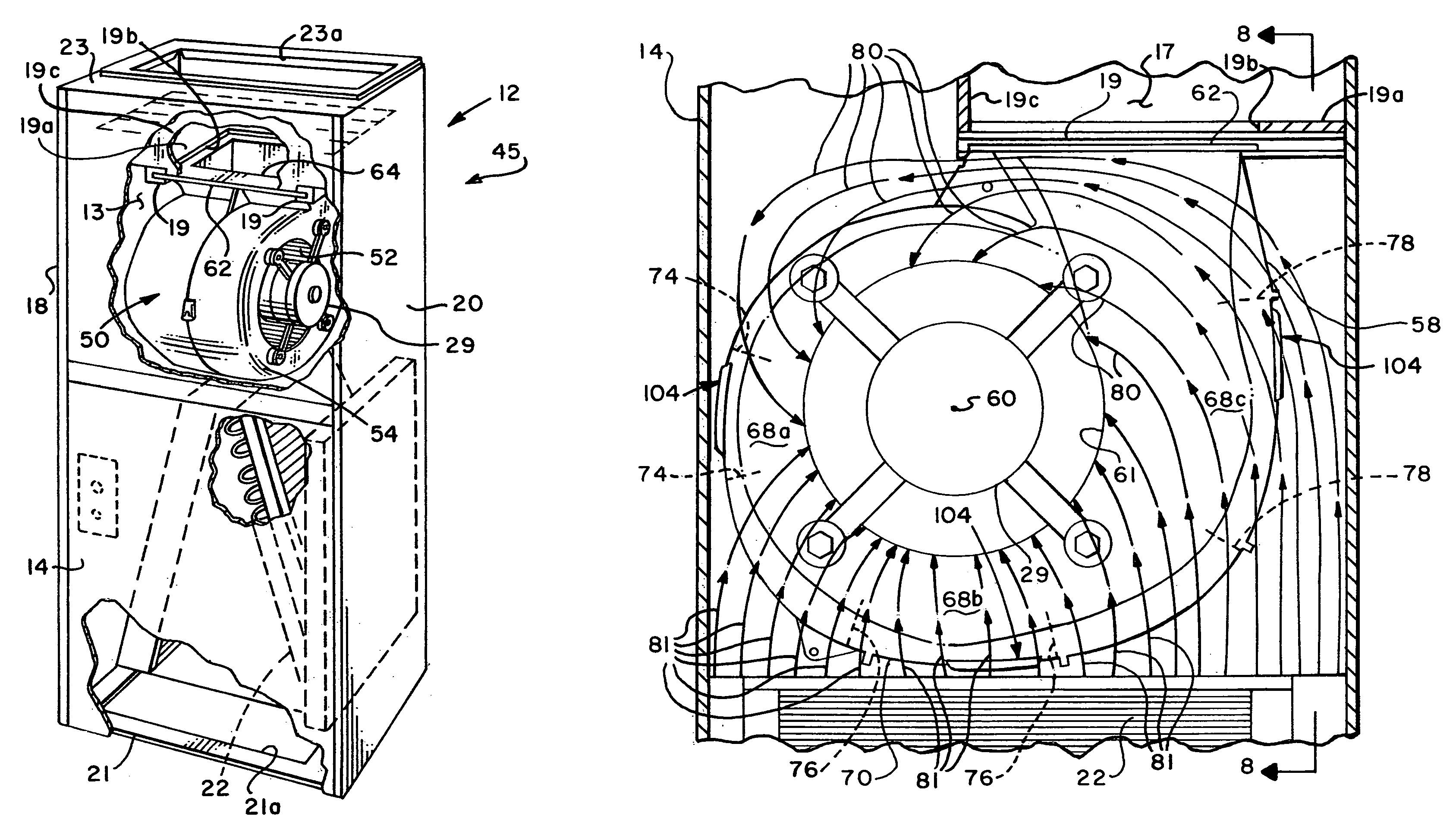

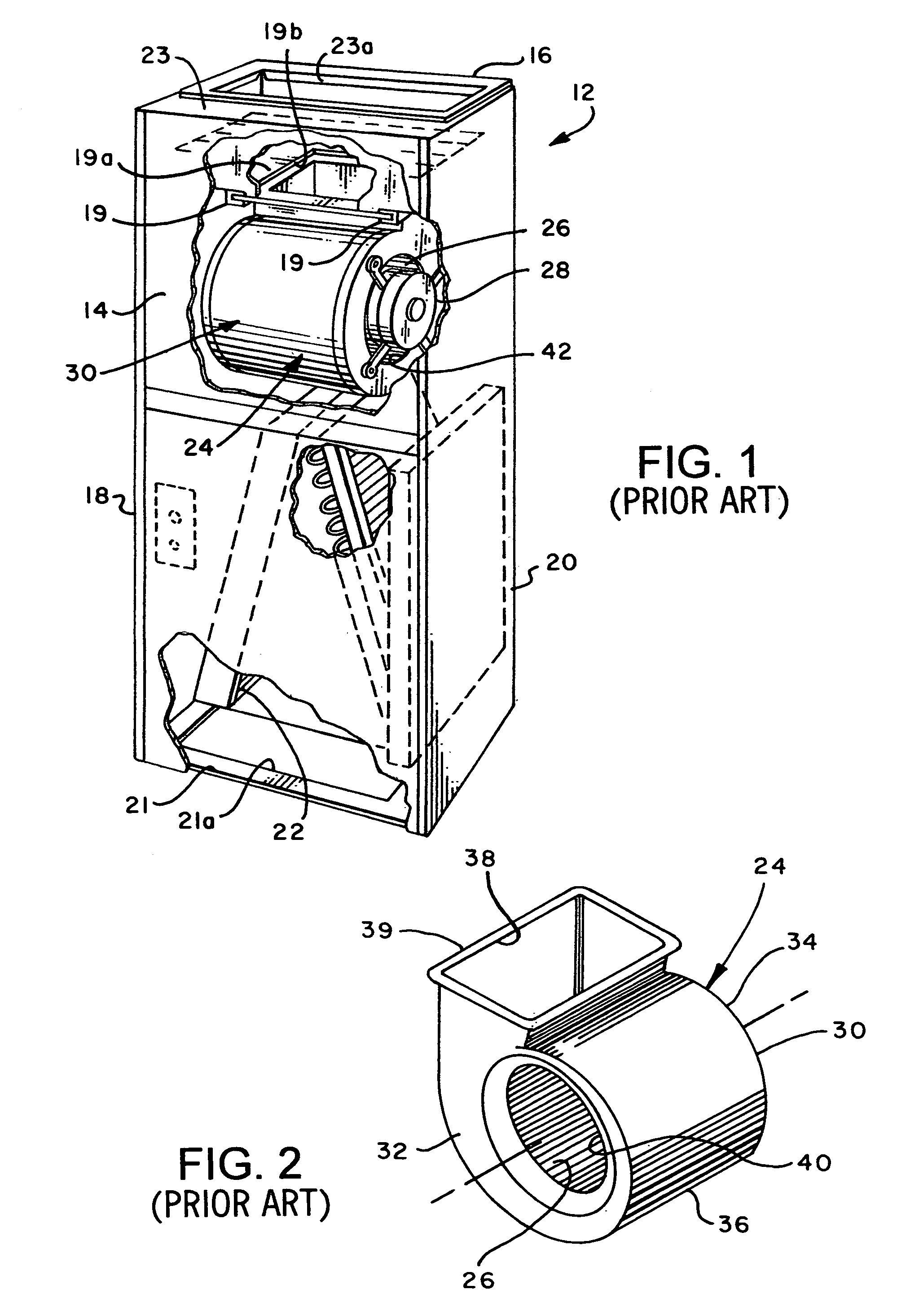

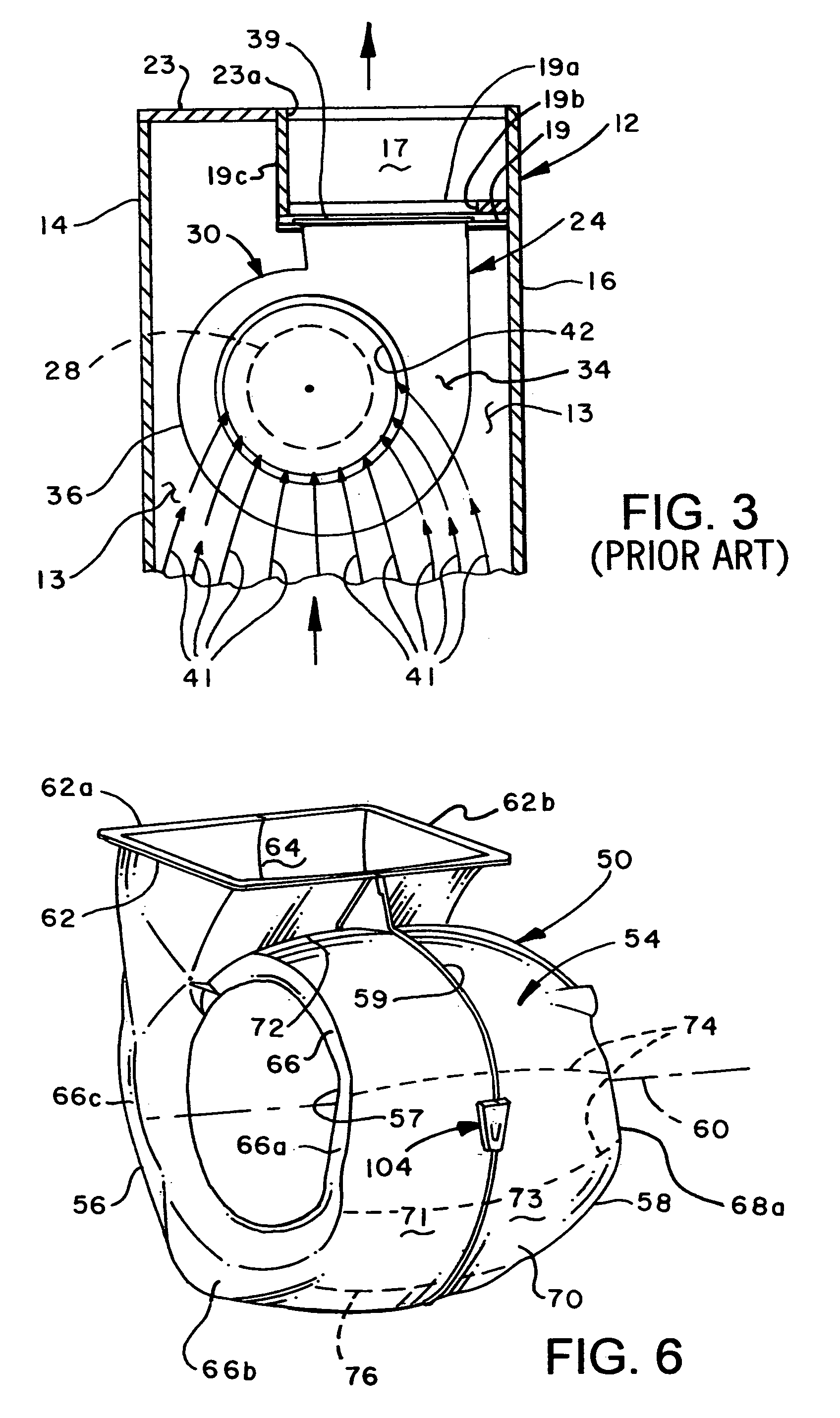

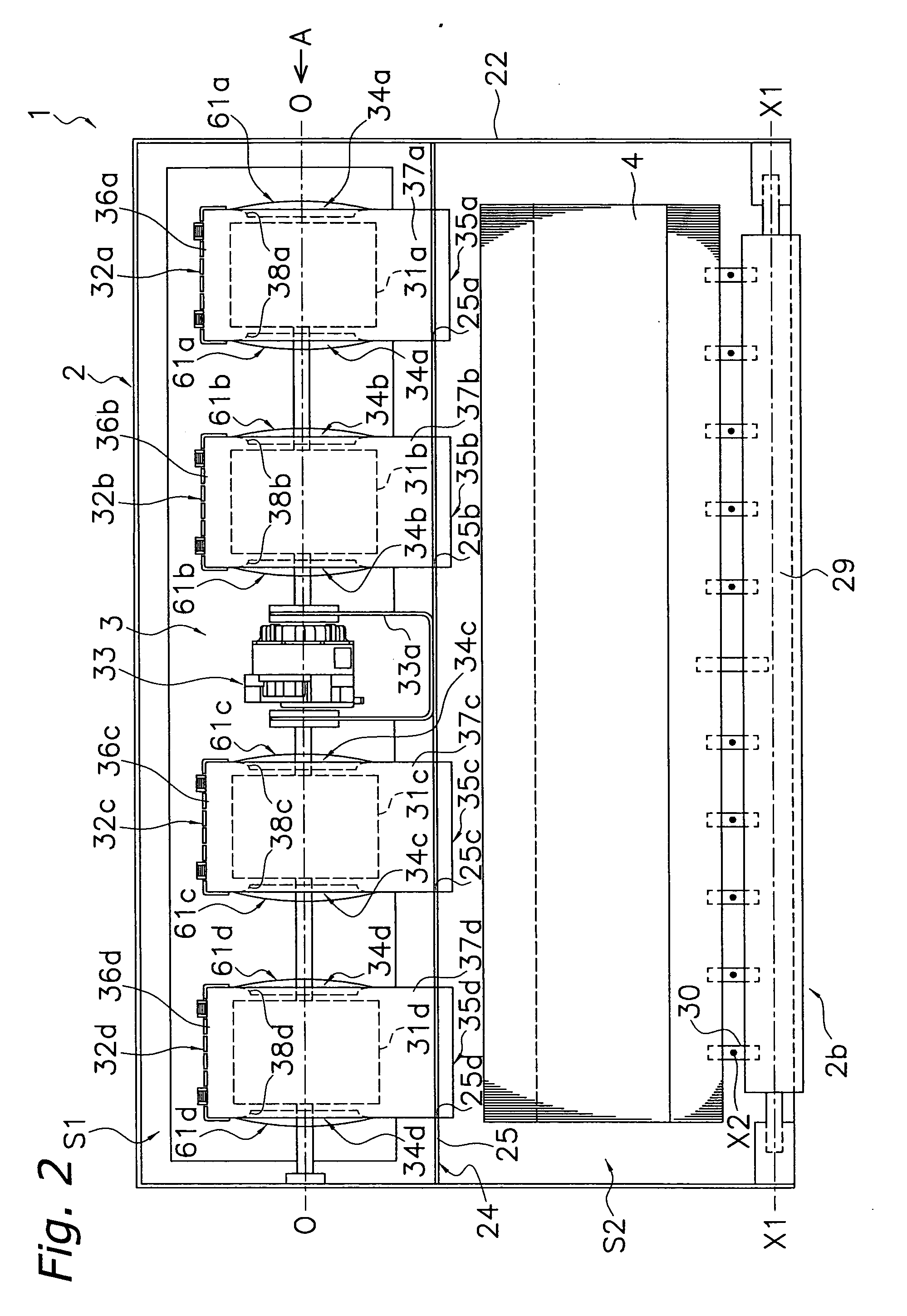

Blower housing and cabinet with improved blower inlet airflow distribution

InactiveUS7108478B2Improved inlet airflowIncrease capacityPump componentsLighting and heating apparatusImpellerAirflow

An airhandling unit for an HVAC system includes a cabinet having an electric motor driven centrifugal blower disposed therein. The blower includes a scroll or volute type blower housing which may be formed of opposed releasably connectable housing parts. The blower housing parts include opposed sidewalls with axially extending compound curved portions which cooperate with an end wall which is configured to have portions which are not of substantially constant increasing radial distance from the blower impeller axis of rotation. However, a constantly increasing airflow cross-sectional flow area is provided within the blower housing for blower discharge air. The disposition of the blower housing sidewalls with respect to the cabinet walls provides improved airflow distribution for air flowing into the blower air inlet openings.

Owner:TRANE INT INC

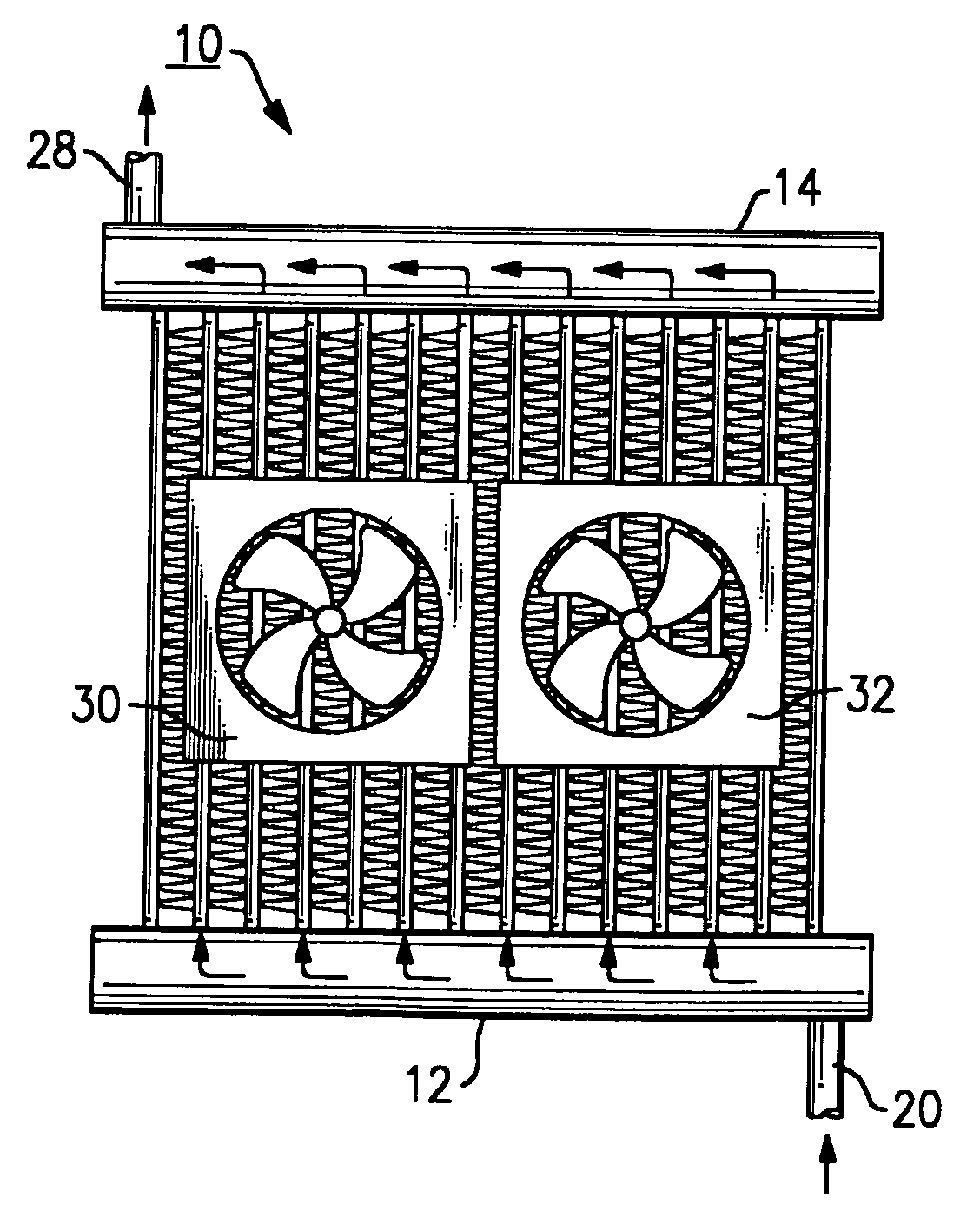

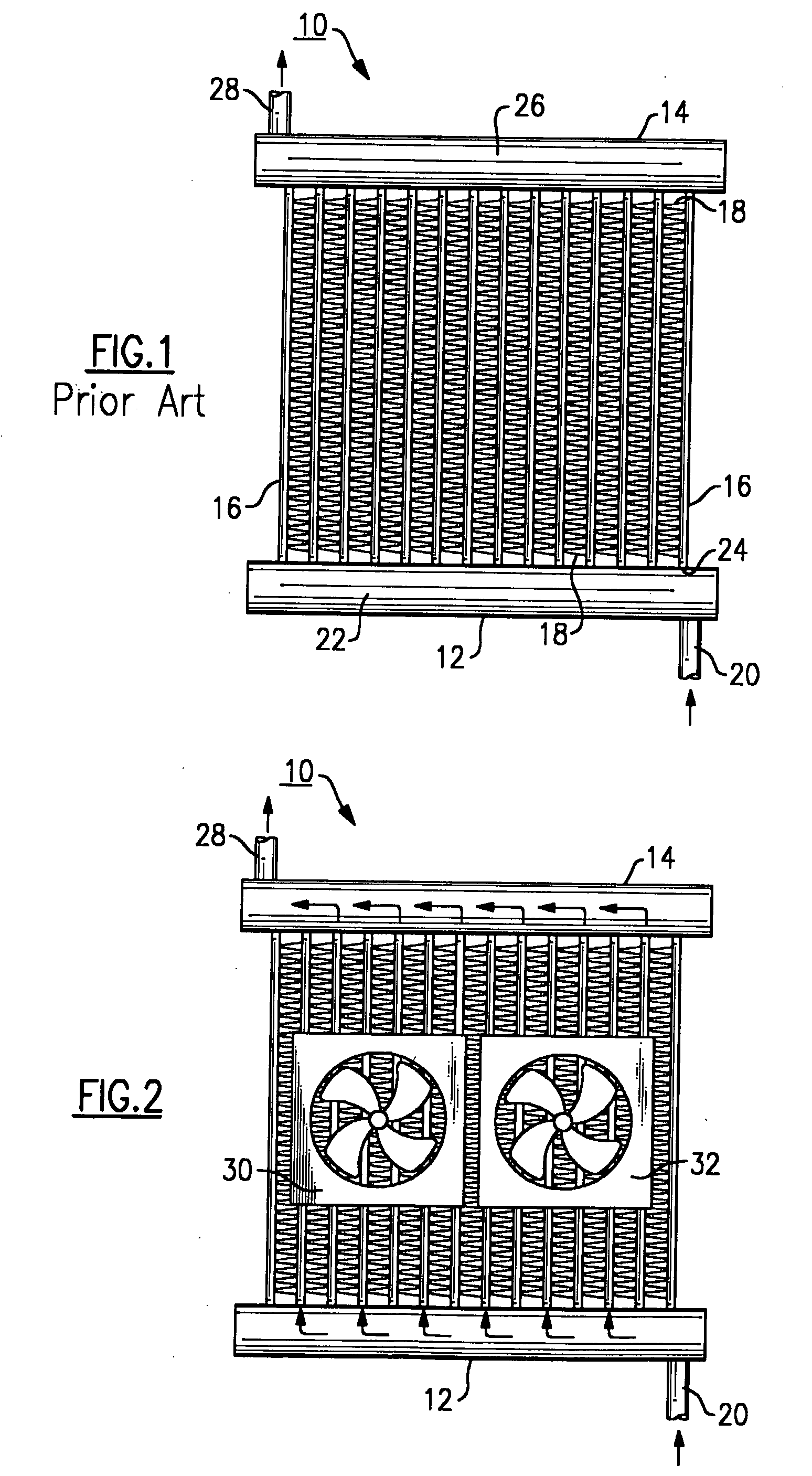

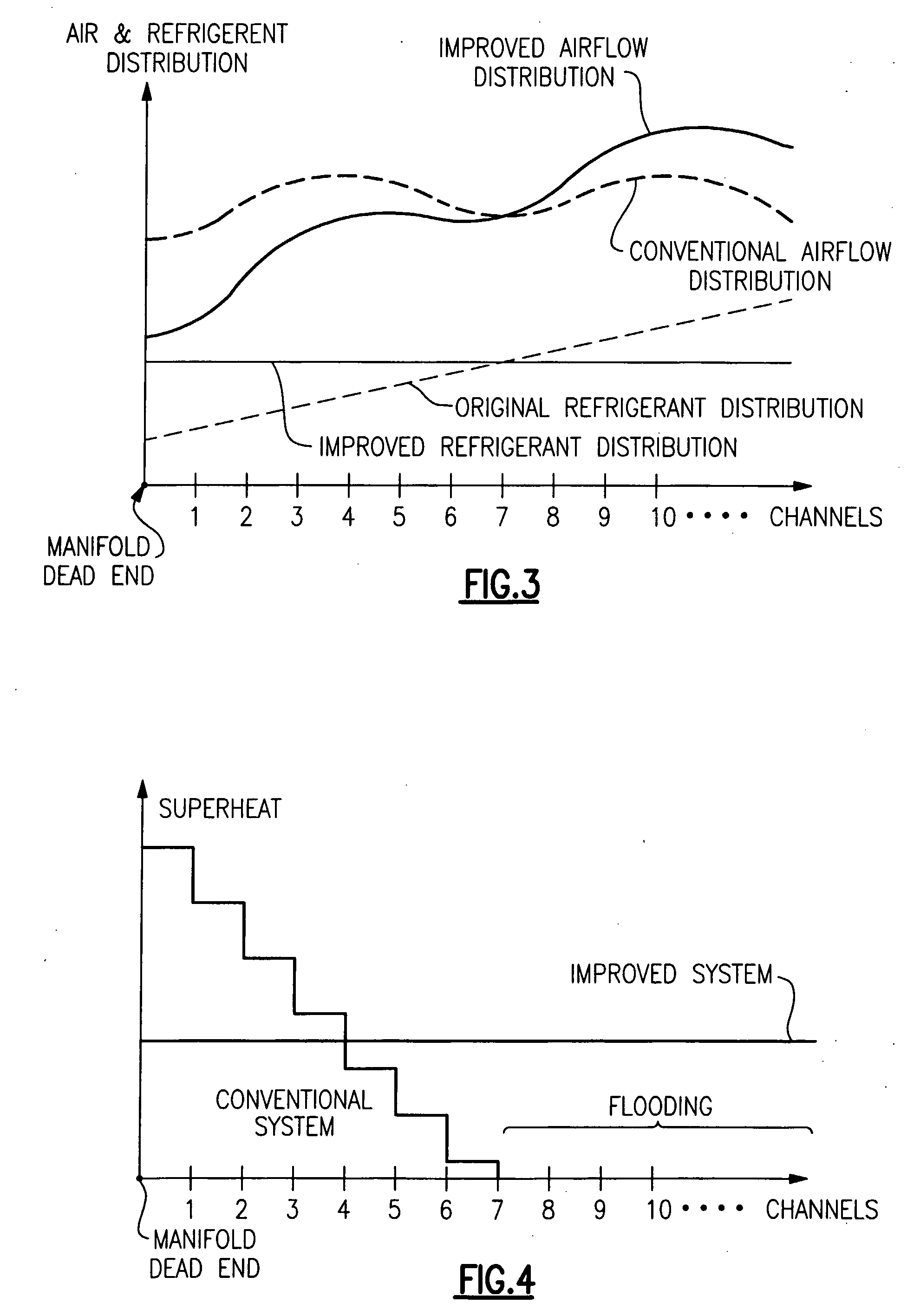

Pulse Width Modulation Or Variable Speed Control Of Fans In Refrigerant Systems

InactiveUS20080110610A1Reduce in quantityEasy to controlTemperatue controlEfficient regulation technologiesControl theoryRefrigerant

A refrigerant system heat exchanger is characterized by improved airflow distribution through the use of at least one of the fans operating in the pulse width modulation or variable speed mode. Improved airflow distribution can be used to alleviate the effects of refrigerant maldistribution, enhance heat exchanger performance, prevent compressor flooding and improve comfort in the conditioned space.

Owner:CARRIER CORP

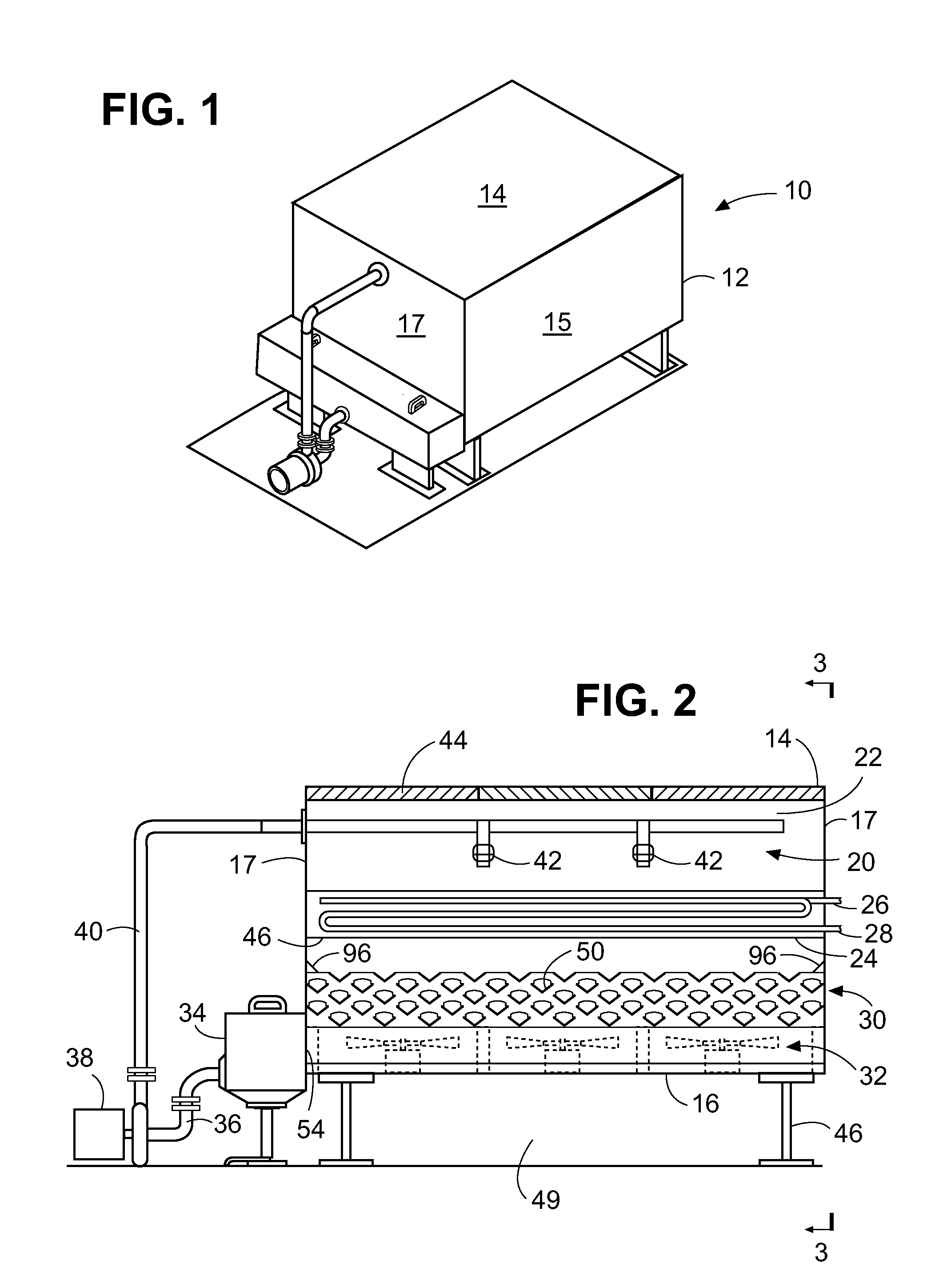

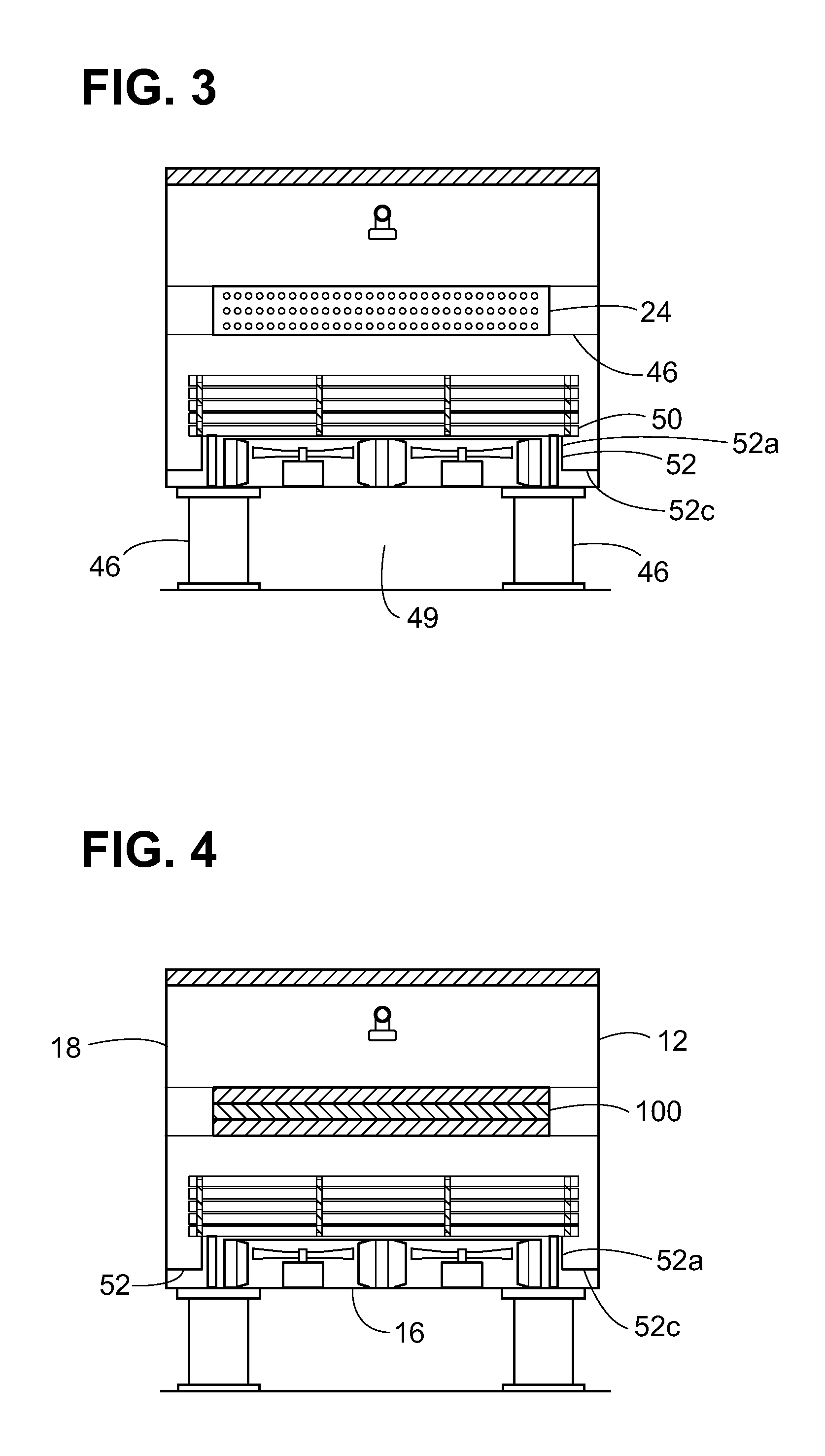

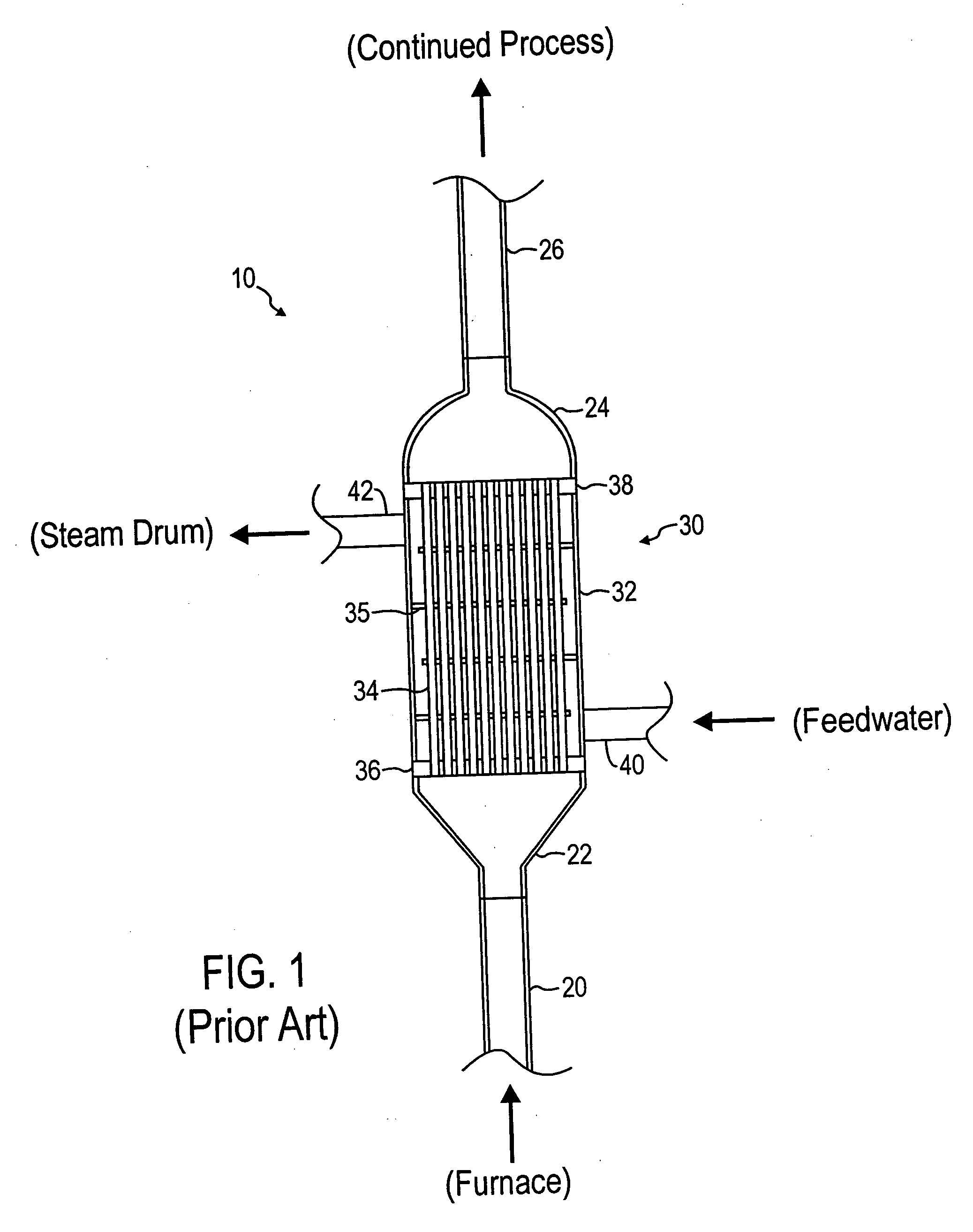

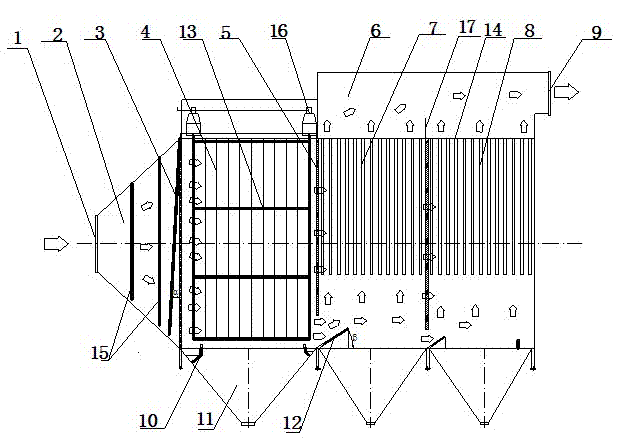

Direct forced draft fluid cooler/cooling tower and liquid collector therefor

InactiveUS20110315350A1Reduced initial construction costHeight of structurePipe supportsServomotor componentsCooling towerClosed loop

Direct forced draft fluid cooler / closed loop cooling towers and cooling towers are provided with fans at the bottom of the unit, and a plurality of layers of water collection troughs or channels above the fans to capture water droplets sprayed downwardly from the top of the device through a heat exchanger or fill media above the collection troughs. In one embodiment the collection troughs supply the collected water to one or more gutters inside the housing which lead the water to an external collection tank from which the water is recirculated through the system.

Owner:CURTIS HAROLD +1

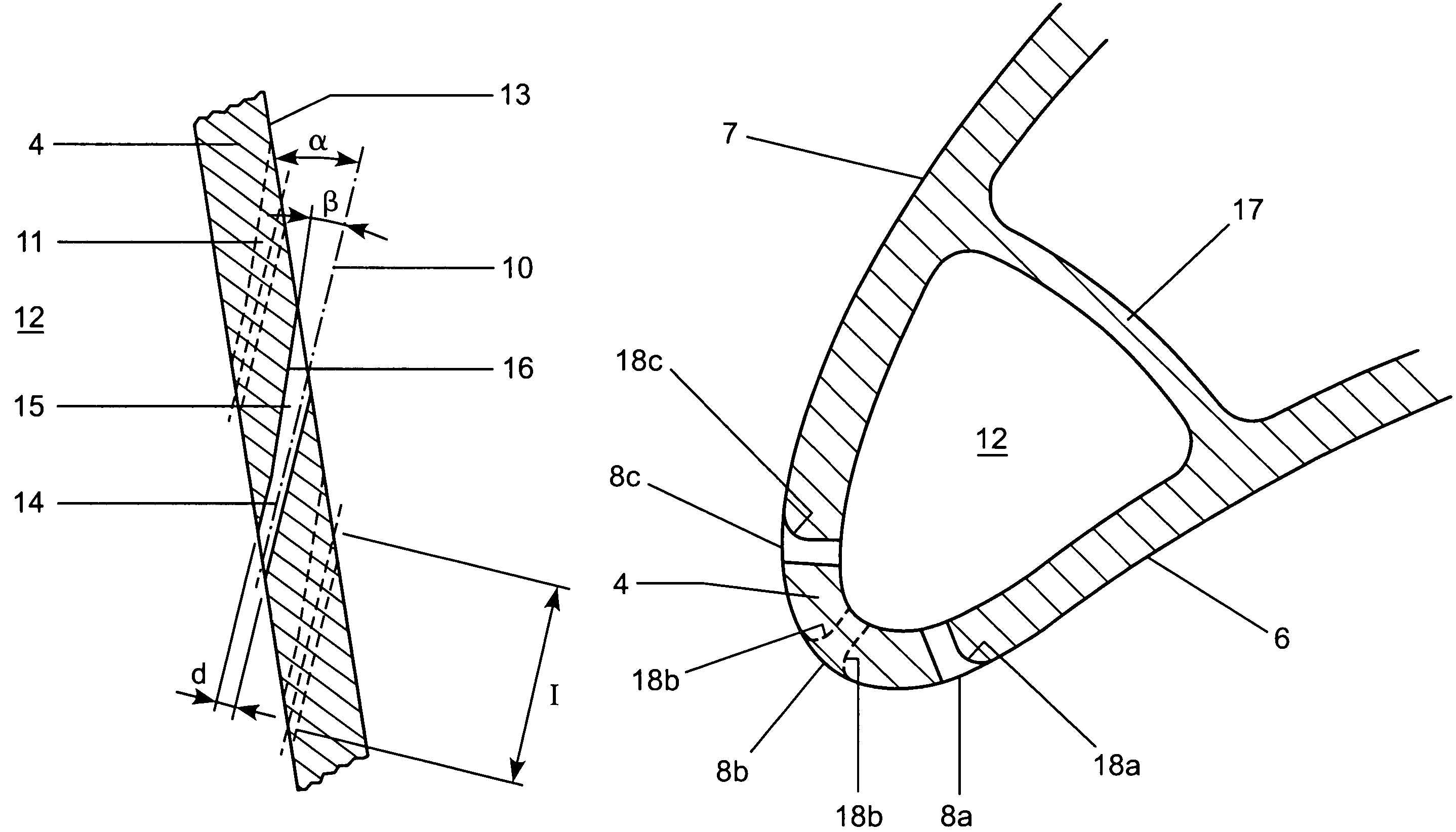

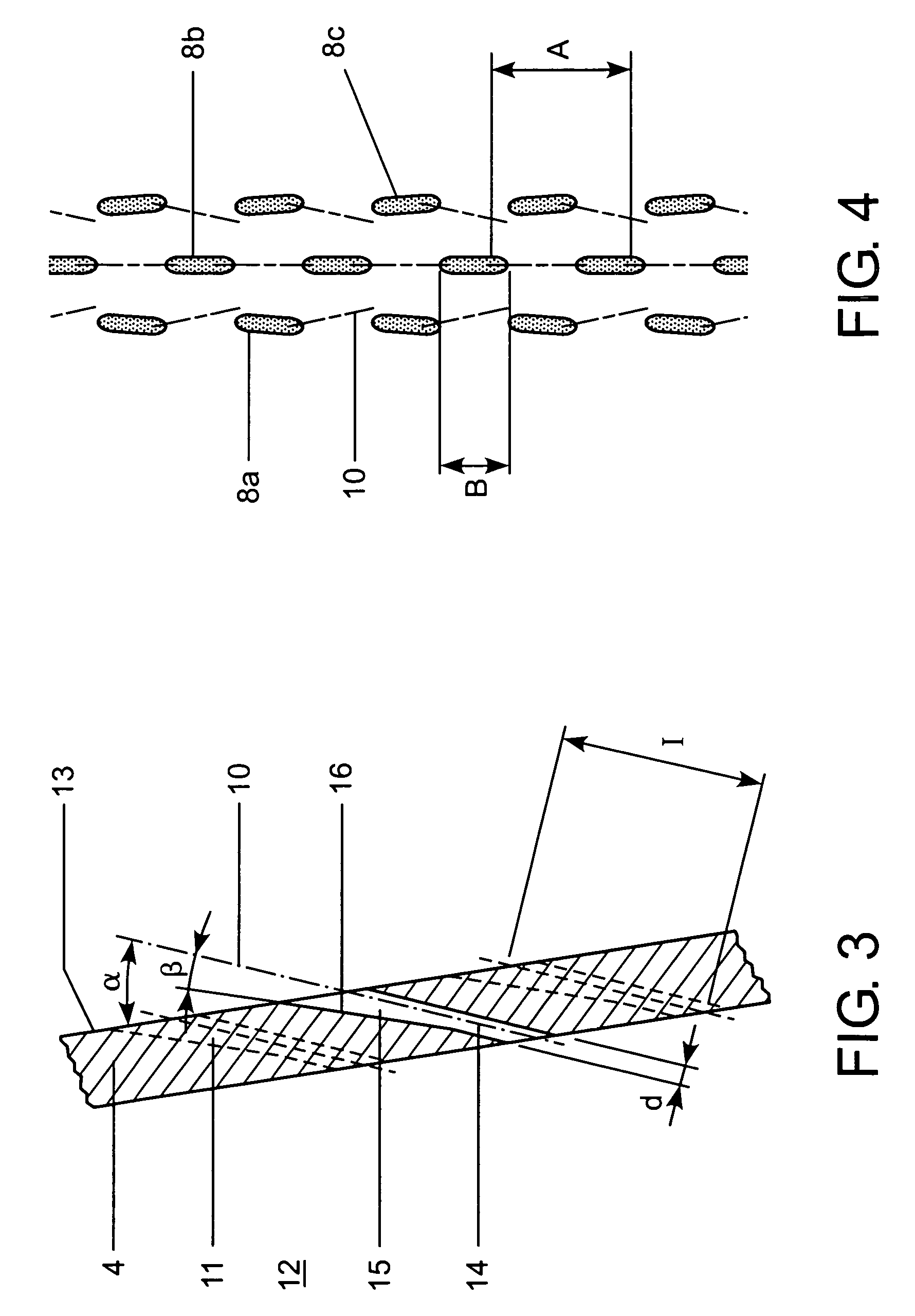

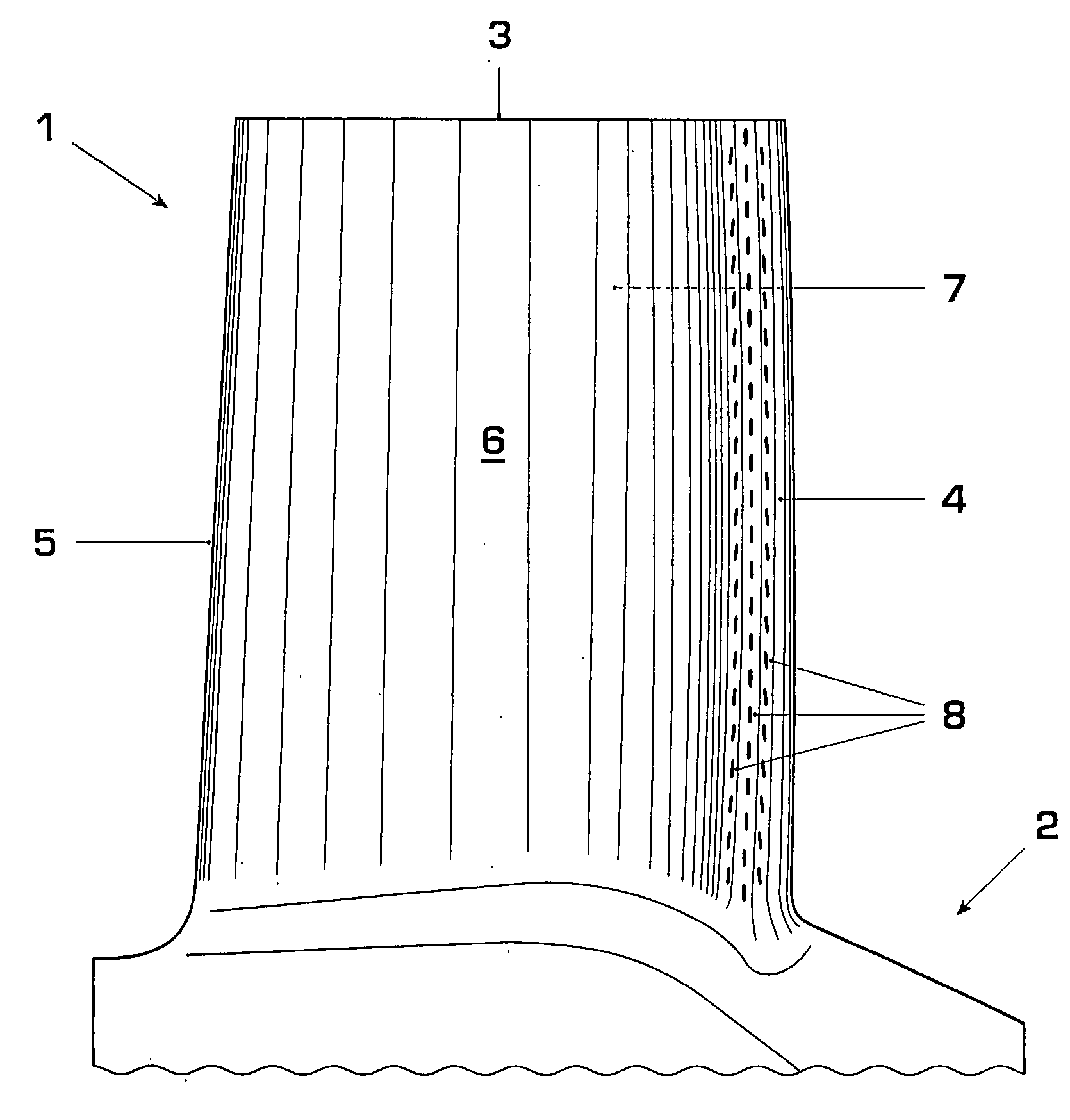

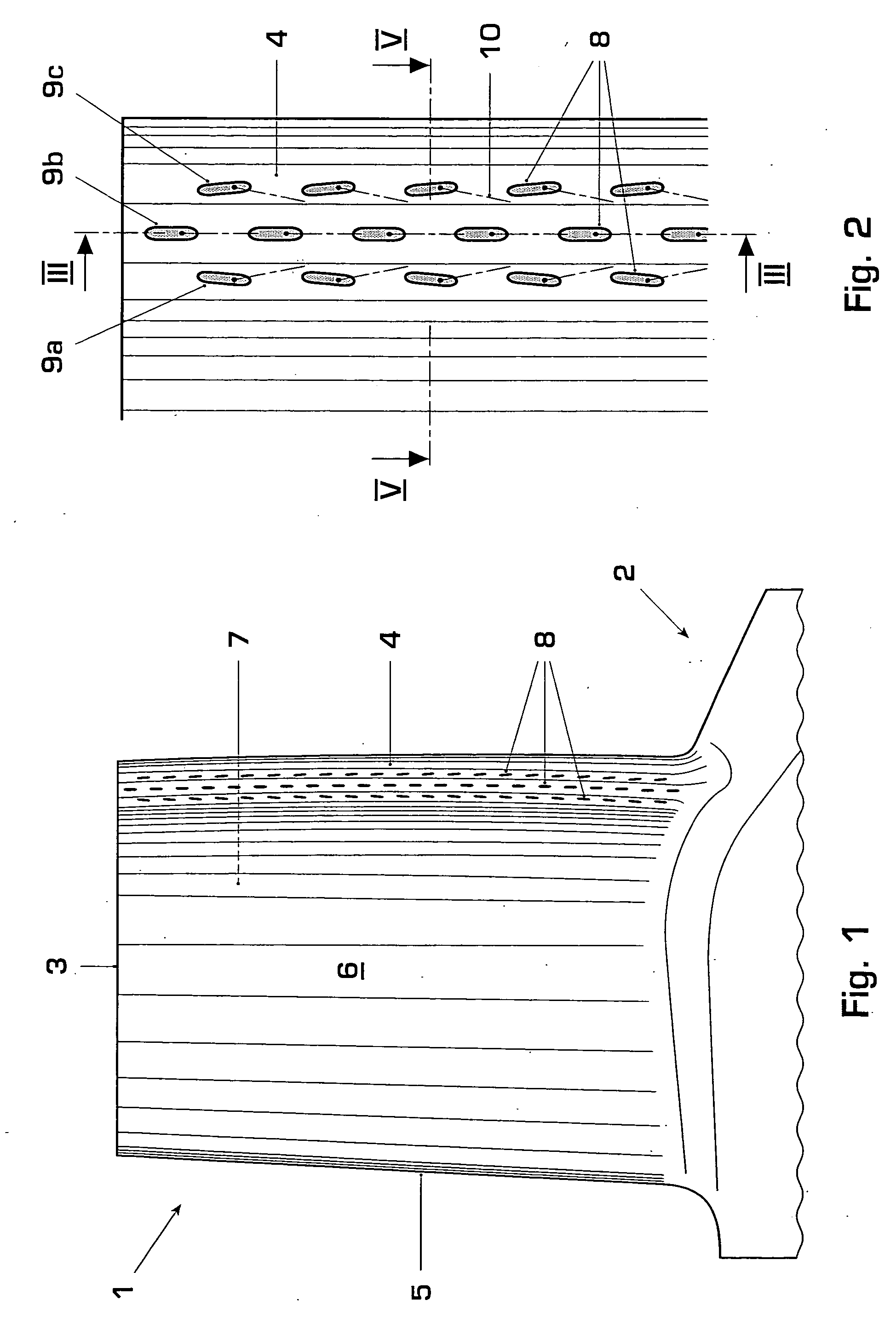

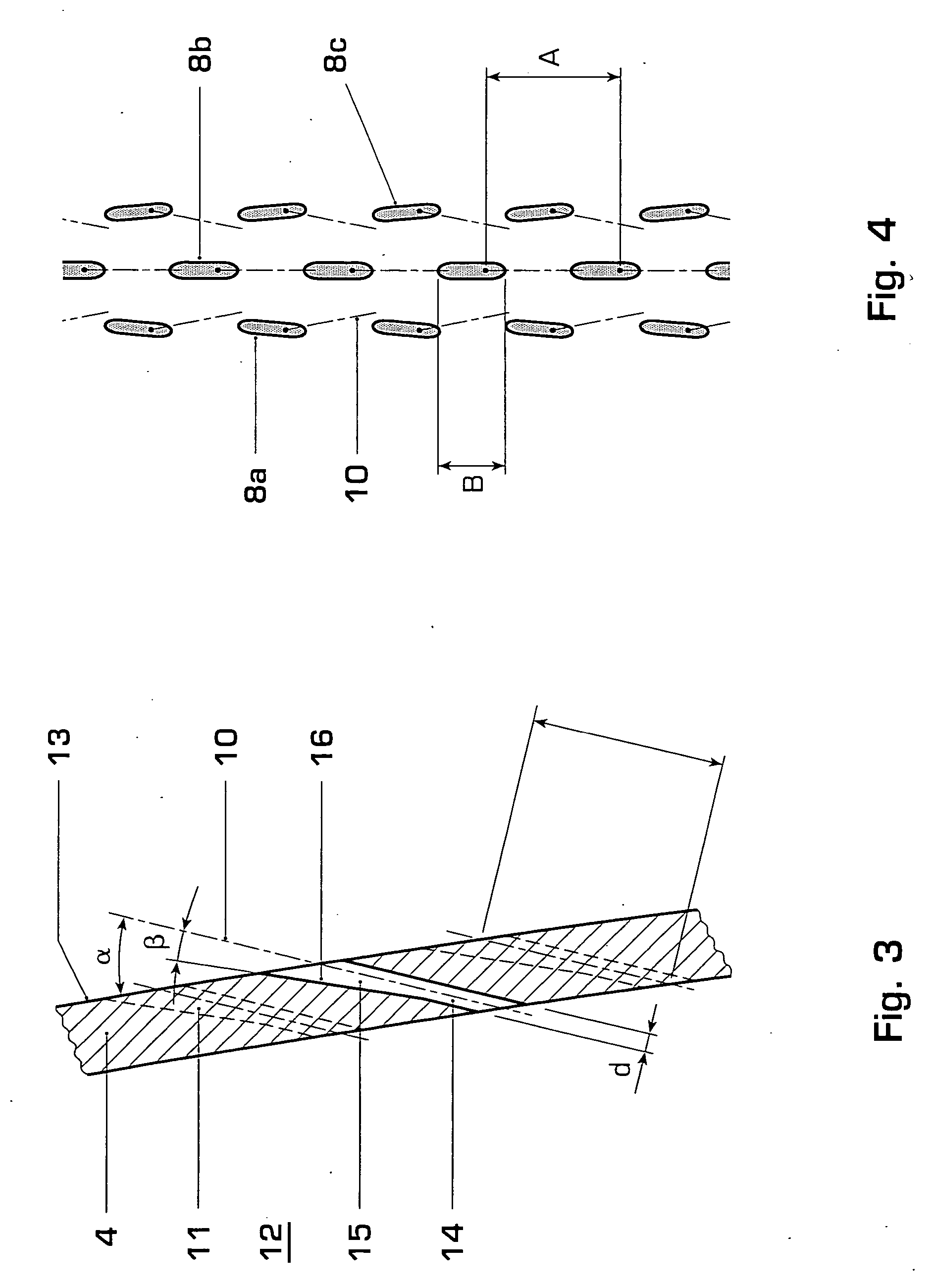

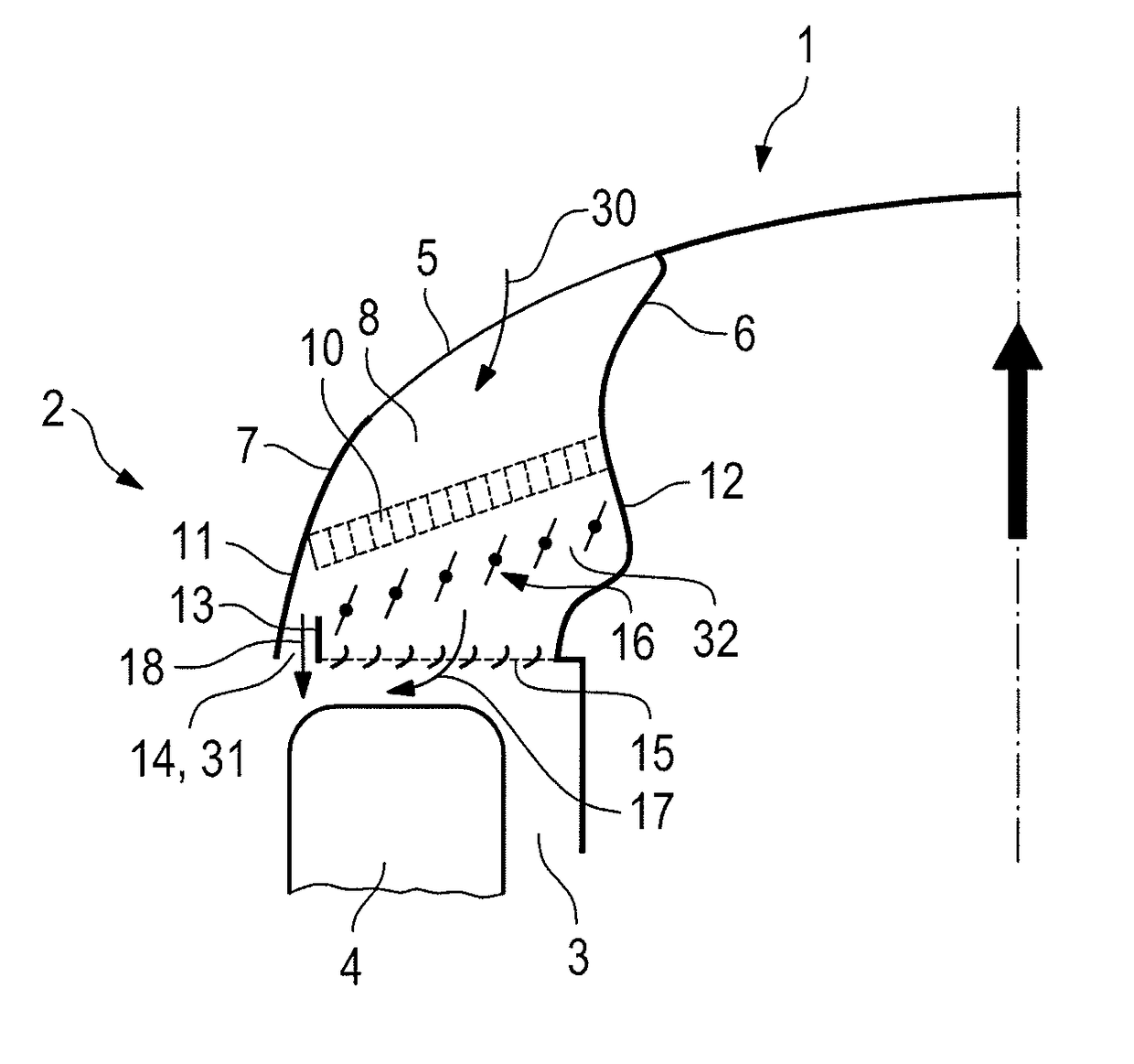

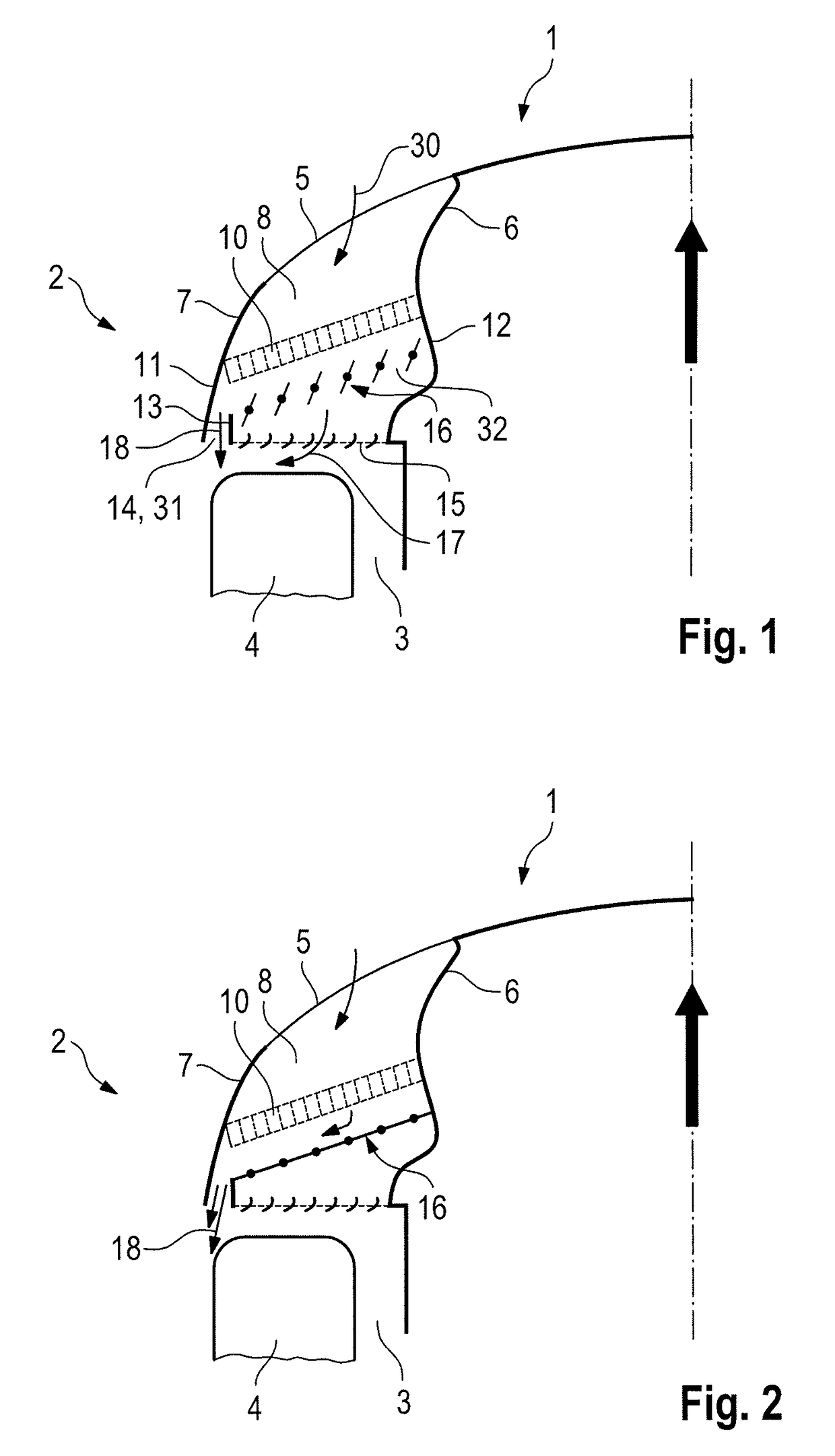

Gas turbine airfoil leading edge cooling construction

InactiveUS7300252B2Improved film coolingReduce formationBlade accessoriesMachines/enginesLeading edgeTrailing edge

A gas turbine airfoil with a pressure sidewall (6) and a suction sidewall (7) extends from a root (2) to a tip (3) and from a leading edge (4) to a trailing edge (5). It comprises several film cooling holes with exit ports (8). The film cooling holes have a sidewall that is diffused in the direction of the tip (3) of the airfoil (1) at least over a part of the film cooling hole. Furthermore, the film cooling holes each have flare-like contour near the outer surface of the leading edge (4). The film cooling holes according to the invention provide an improved film cooling effectiveness due to reduced formation of vortices and decreased penetration depth of the cooling air film.

Owner:ANSALDO ENERGIA IP UK LTD

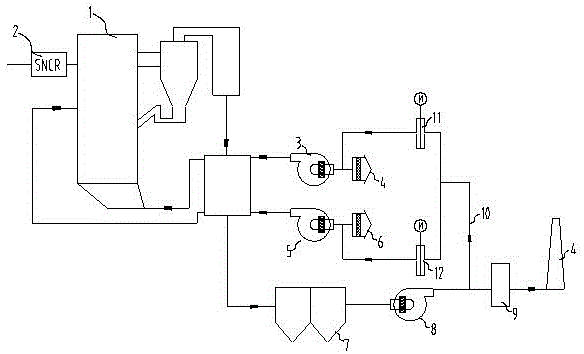

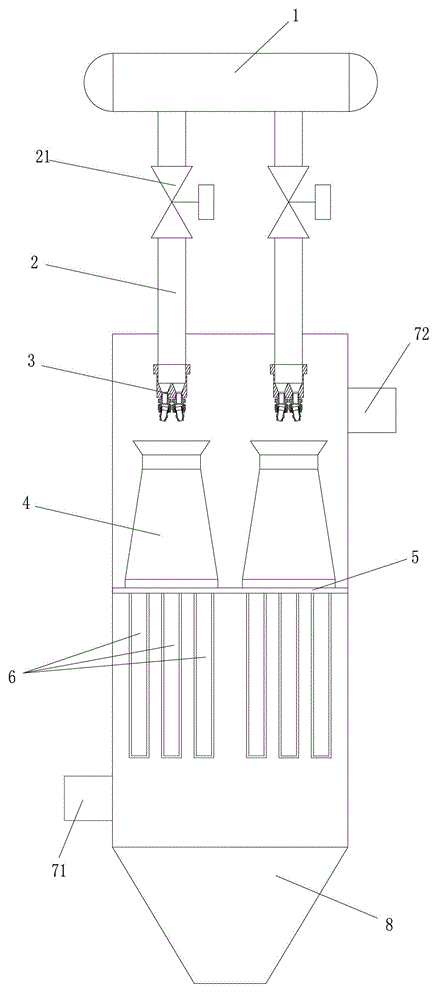

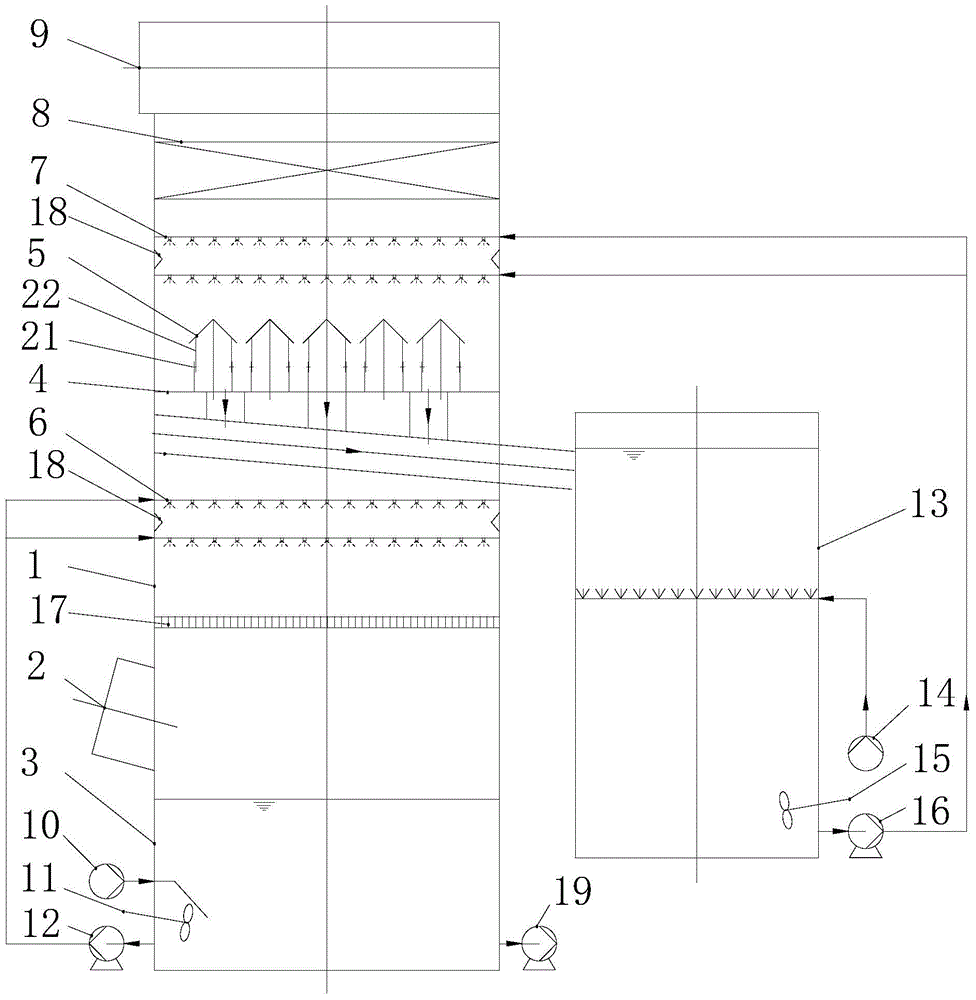

Flue gas recirculation-based wide load-wide coal deep denitrification system for CFB (circulating fluidized bed) boiler

InactiveCN105570883ALower combustion temperatureEmission reductionFluidized bed combustionFluegas recirculationCombustion chamberFlue gas

The invention provides a flue gas recirculation-based wide load-wide coal deep denitrification system for a CFB (circulating fluidized bed) boiler. The system comprises the boiler, an SNCR (selective non-catalytic reduction) system, a primary air blower, a secondary air blower, an induced draft fan, a recirculation flue, a primary air recirculation adjusting valve, a secondary air recirculation adjusting valve and the like. One end of the recirculation flue is connected with an outlet of the induced draft fan, the other end is connected with an inlet of the primary air blower and an inlet of the secondary air blower by the aid of the primary air recirculation adjusting valve and the secondary air recirculation adjusting valve, low-temperature flue gas is led out of the outlet of the induced draft fan, the low-temperature flue gas with the proper flow is sent to different positions of a combustion chamber by the blowers through control by the adjusting valves, distribution of temperature fields in the boiler is optimized by fine controlling content of oxygen of primary air and content of oxygen of secondary air on the basis of SNCR, pollutant emission is reduced, and the CFB boiler can realize low emission of NOx under wide load-wide coal conditions.

Owner:SICHUAN CHUANGUO BOILER

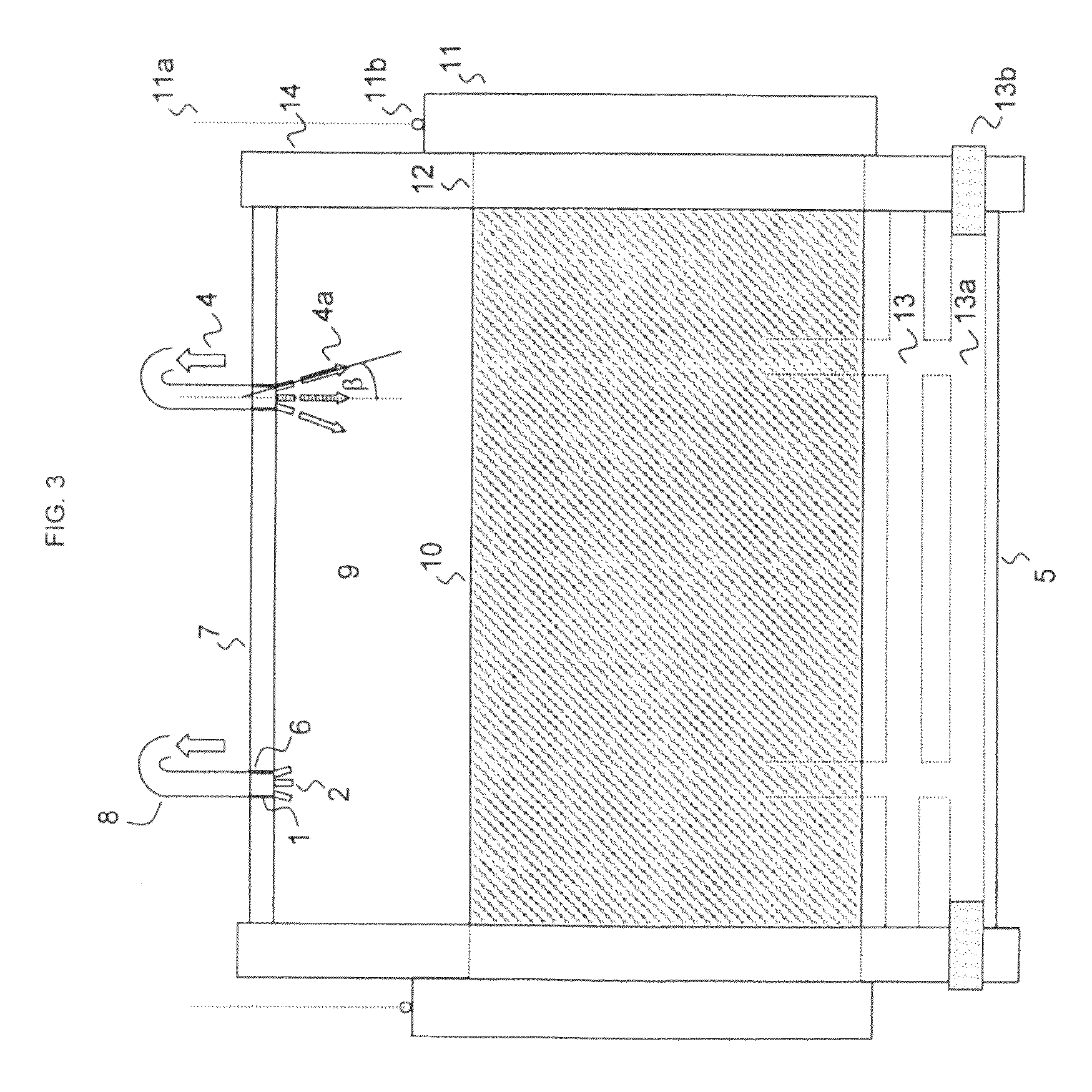

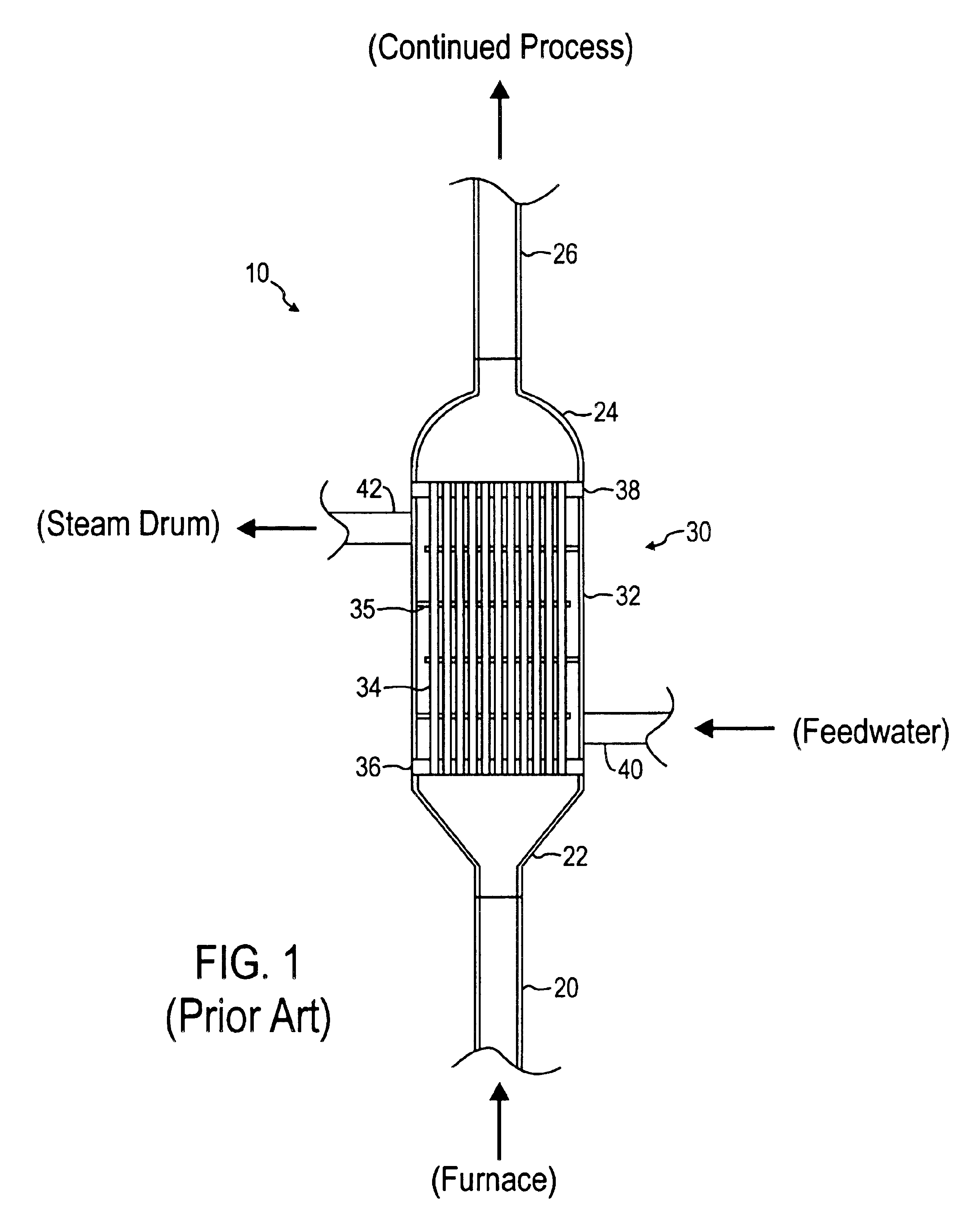

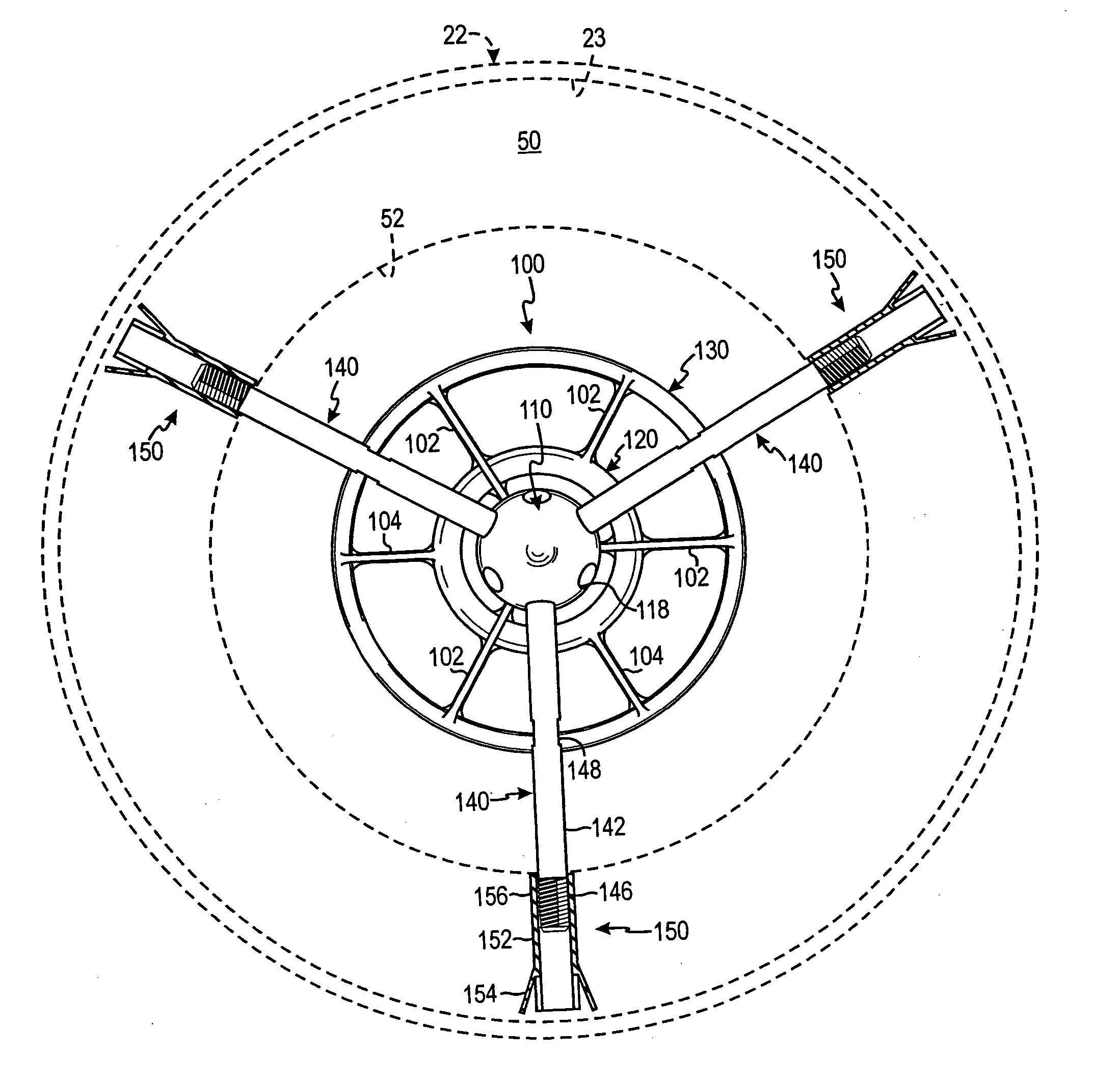

Intra-body flow distributor for heat exchanger

ActiveUS6845813B1Improved air distributionEasy to shapeCorrosion preventionChemical/physical/physico-chemical stationary reactorsAirflowEngineering

A flow distributor for mounting in an inlet of a heat exchanger includes a nose cone and one or more diverting rings. The nose cone is aerodynamically shaped to divert impingent gas flow around the nose cone. A first diverting ring is spaced outwardly from the nose cone and can be oriented such that at least a portion of the gas flow diverted by the nose cone is redirected into the wake of the nose cone. A second diverting ring can be spaced outwardly from the first diverting ring and can be oriented to divert gas flow impingent thereon. Struts connect the nose cone and one or more rings. Refractory on the wall of the inlet is shaped to reduce the recirculation at the outer perimeter thereof. The flow distributor is installed in the inlet with refractory to achieve substantially equal flow across the tube sheet of the heat exchanger.

Owner:KNIGHTHAWK ENG

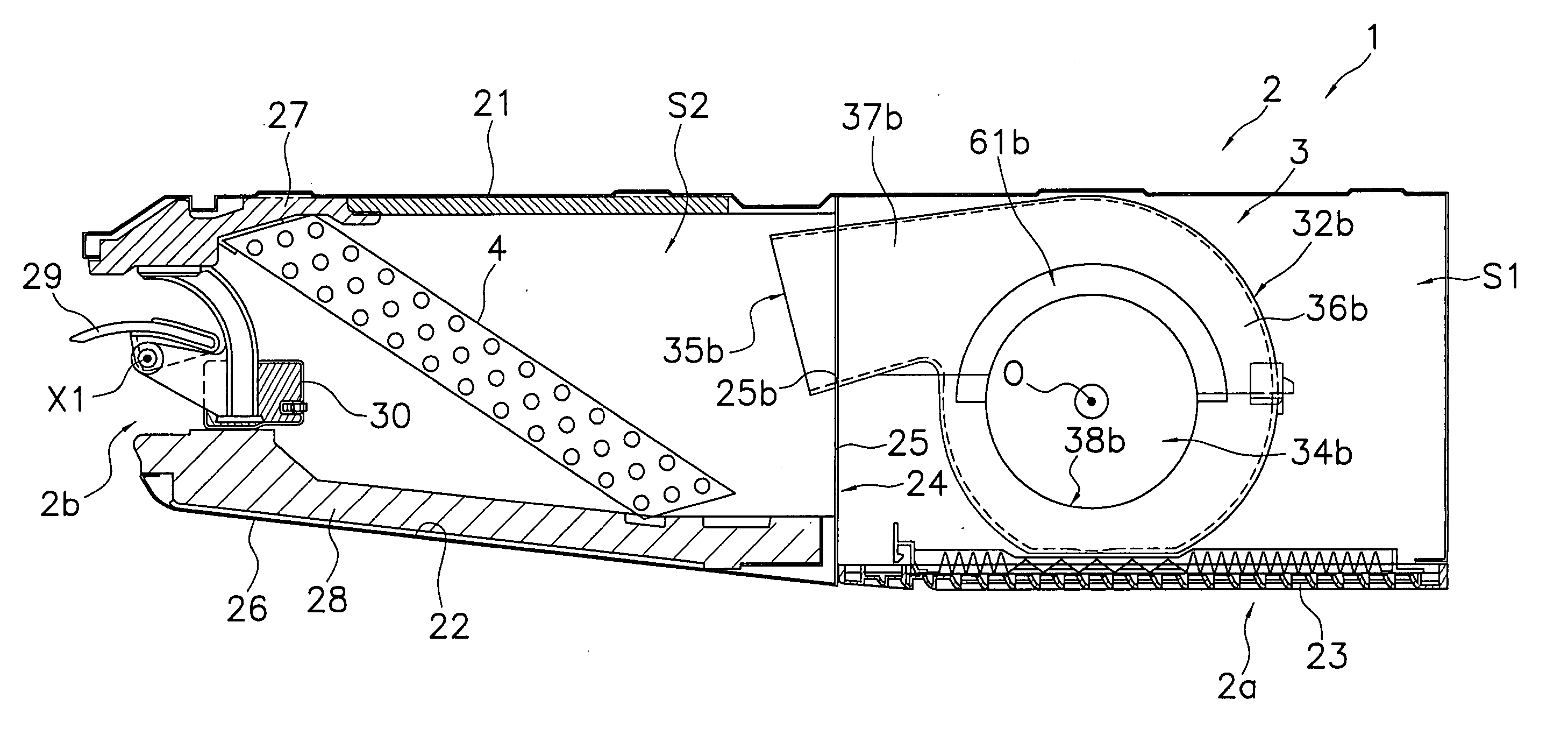

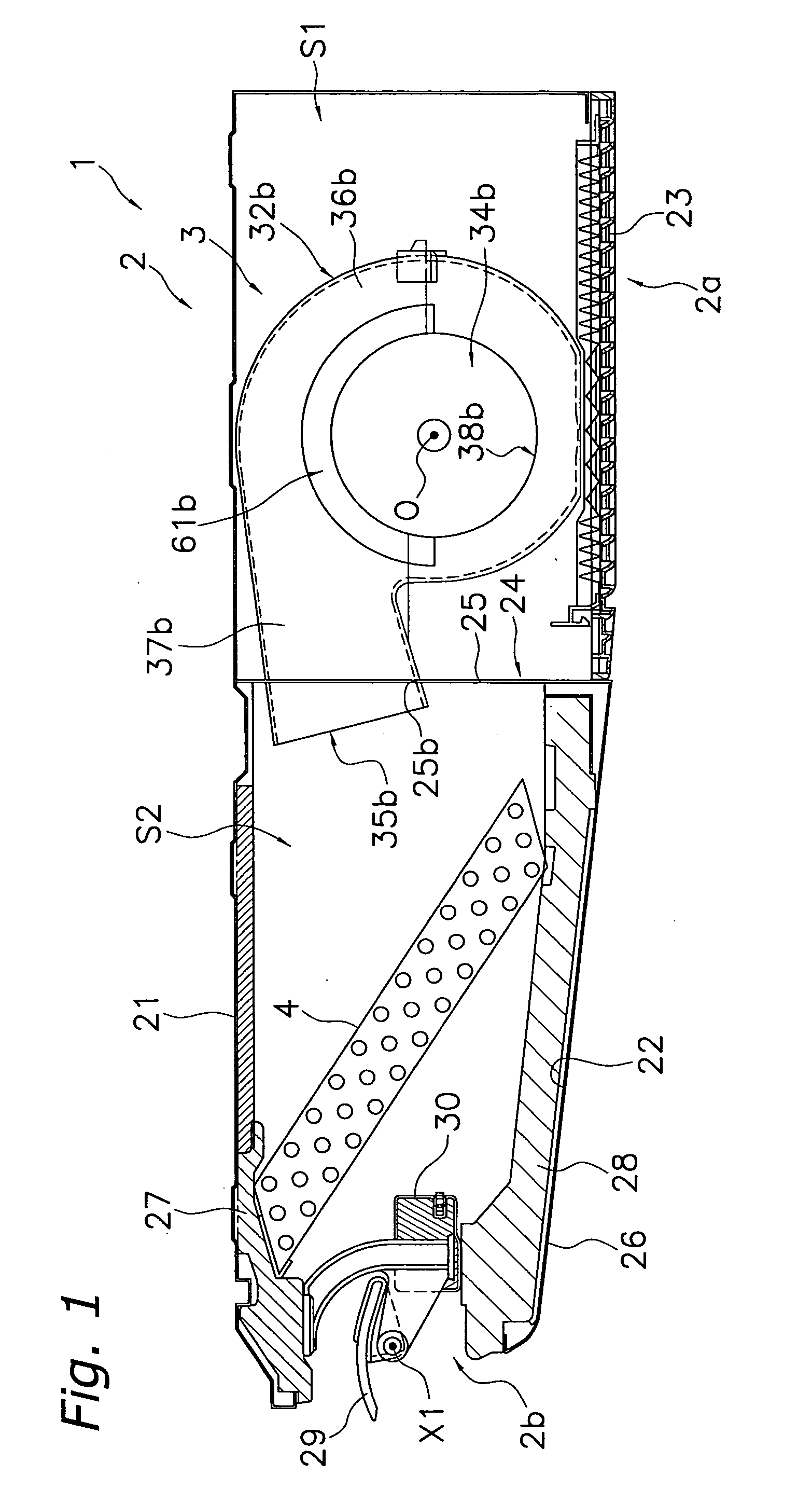

Fan and air conditioner

InactiveUS20070116559A1Convenient guidanceMaintain performancePump componentsLighting and heating apparatusImpellerEngineering

An air conditioner includes a centrifugal fan and a unit casing that houses the centrifugal fan. The centrifugal fan includes an impeller and a scroll casing that houses the impeller. The unit casing has a unit intake port that opens in a direction crossing an opening direction of a scroll intake port. At a circumferential portion of the scroll intake port of the scroll casing, there is formed a bulged portion with an inner surface that is formed evenly in a circumferential direction and an outer surface portion formed away from the unit intake port that bulges out to a side opposite the impeller.

Owner:DAIKIN IND LTD

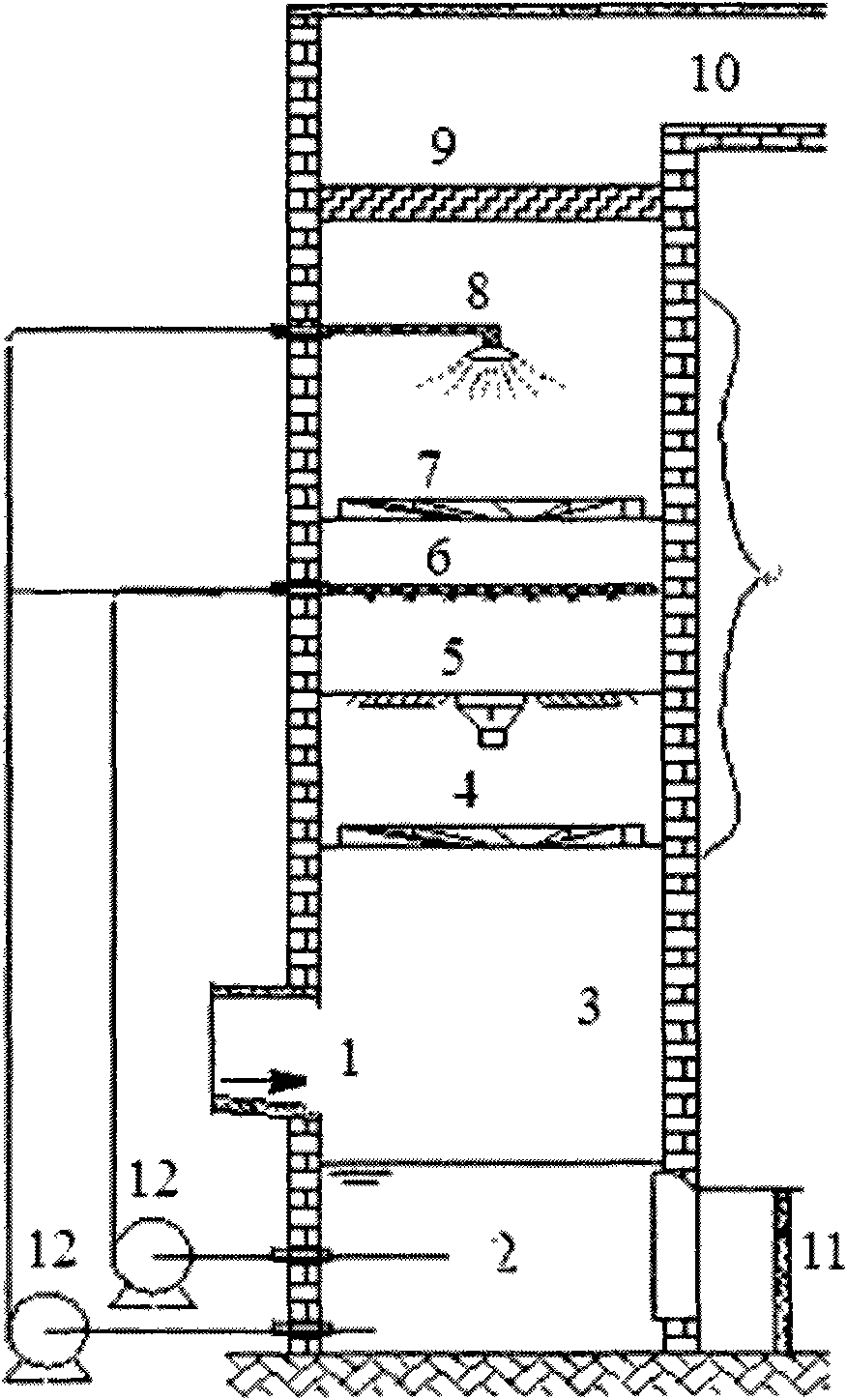

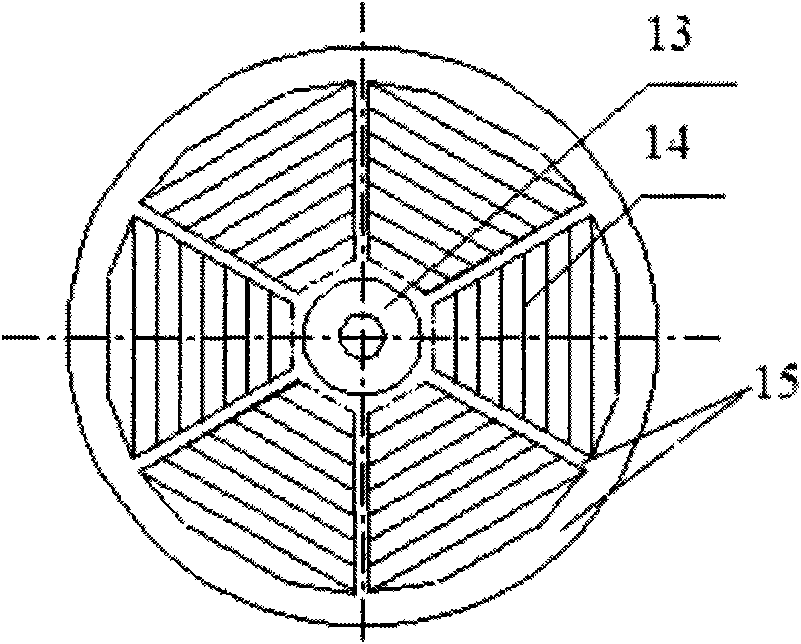

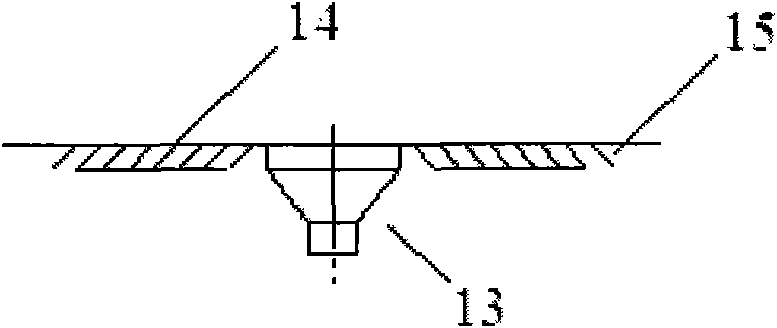

Integrated coupling device for flue gas desulfurization and dedusting

ActiveCN101584957AImproved air distributionEfficient desulfurization and dust removalCombination devicesAirflowFlue gas

The invention, which belongs to the field of flue gas desulfurization technique, provides an integrated coupling device for flue gas desulfurization and dedusting, which includes: a tower body, a tangential intake port, a flue gas exit port, a bottom layer rotational flow board, a inward sprinkler plate, a spraying layer, a lower defogging board and a upper defroster, wherein a central overflow tube is located in the center of the inward sprinkler plate, several injection blades are fixed and equipped on the outer edge of the central overflow tube angularly from layer to layer in a regular polygon mode, and the support plate tendon is connected with double ends of every piece of injection blade in a fixed connection. The invention uses the inward sprinkler plate in an unique design, and couples the spraying method and the rotational flow method in an organic combination, the inward sprinkler plate has multiple efficacies of desulphurization, dedusting, air flow distribution improvement as well as doctor solution influx, thereby the device provided by the invention has high-efficient desulphurization and dedusting functions, moreover reduces the liquid-gas ratio and airflow resistance obviously.

Owner:SHANGHAI JIAO TONG UNIV

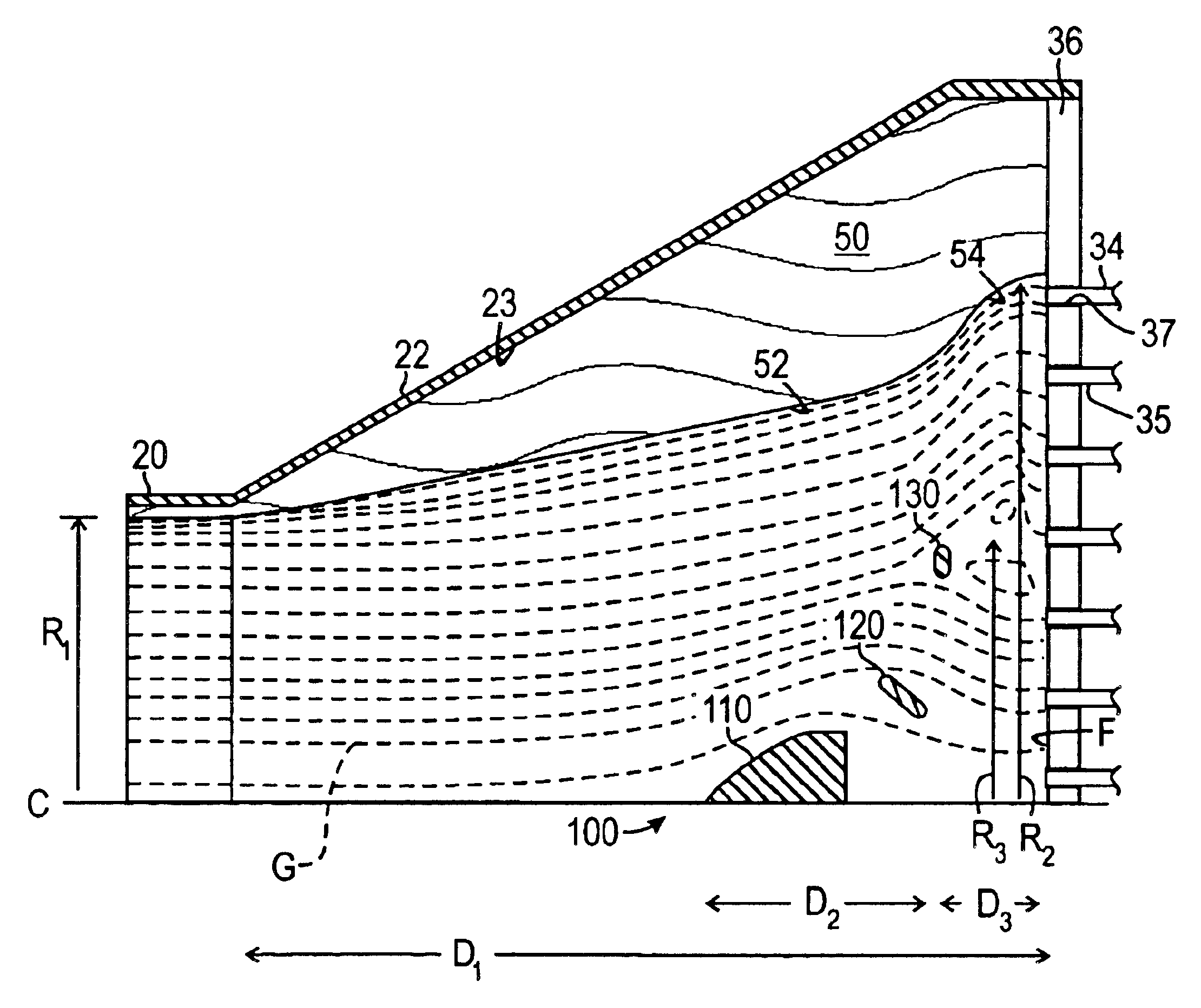

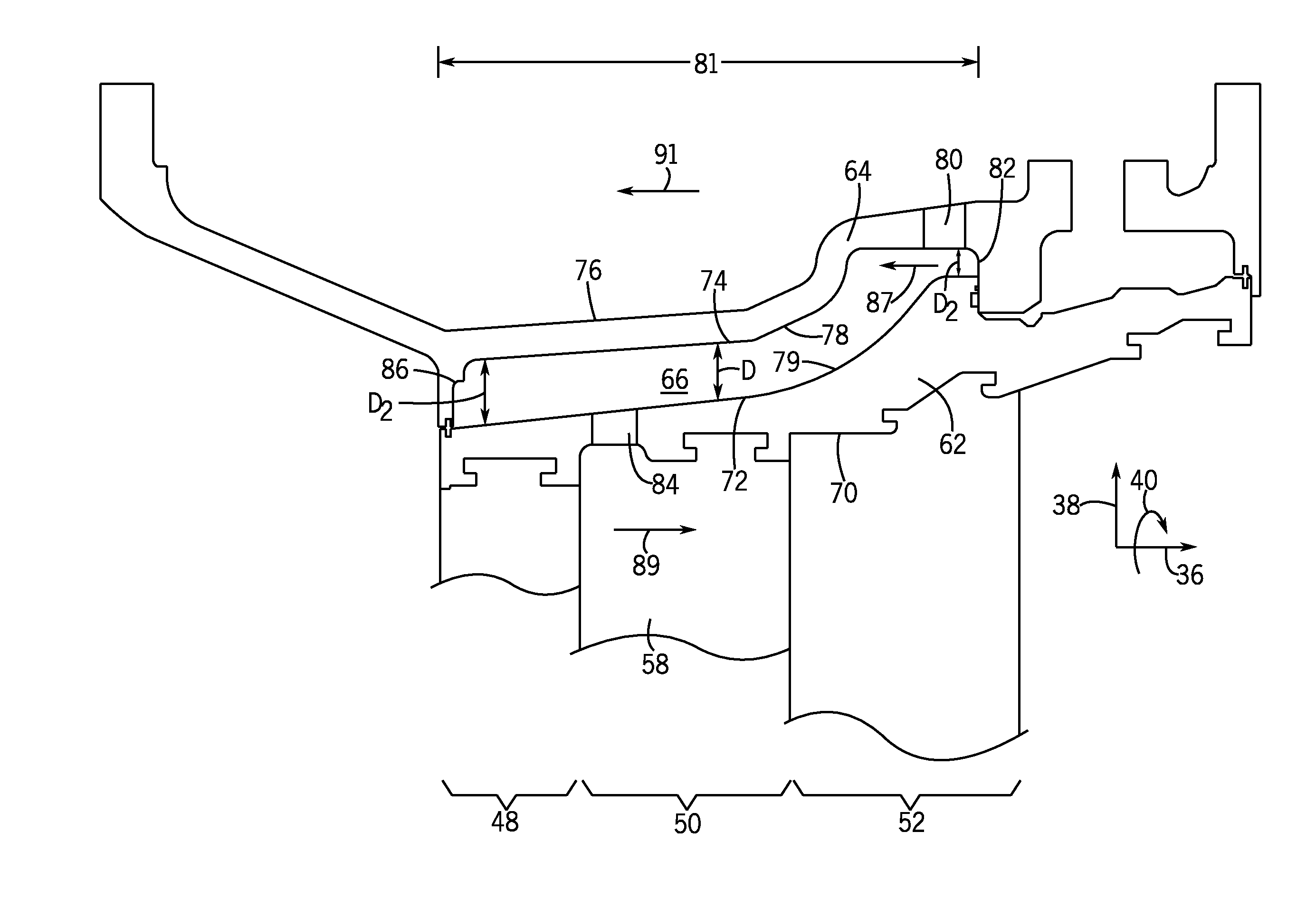

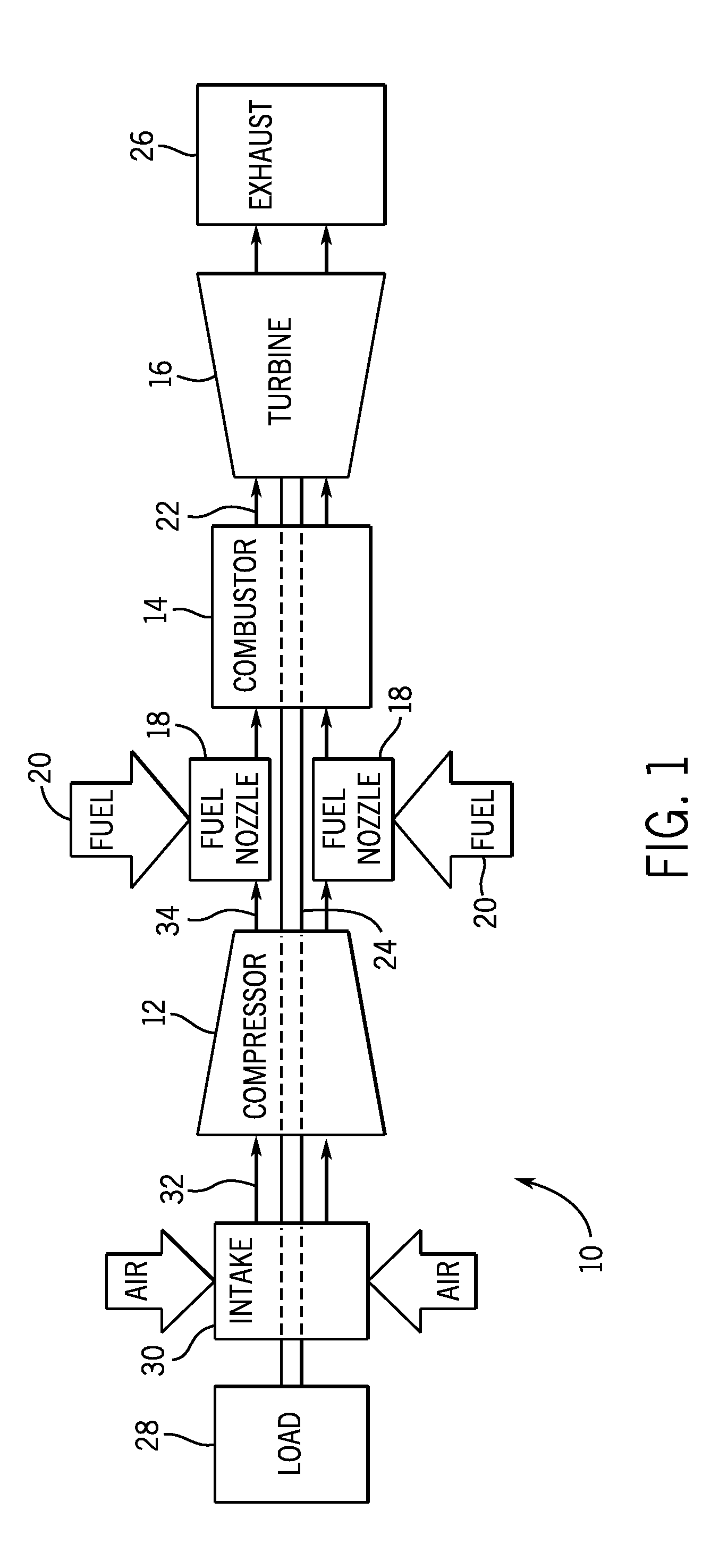

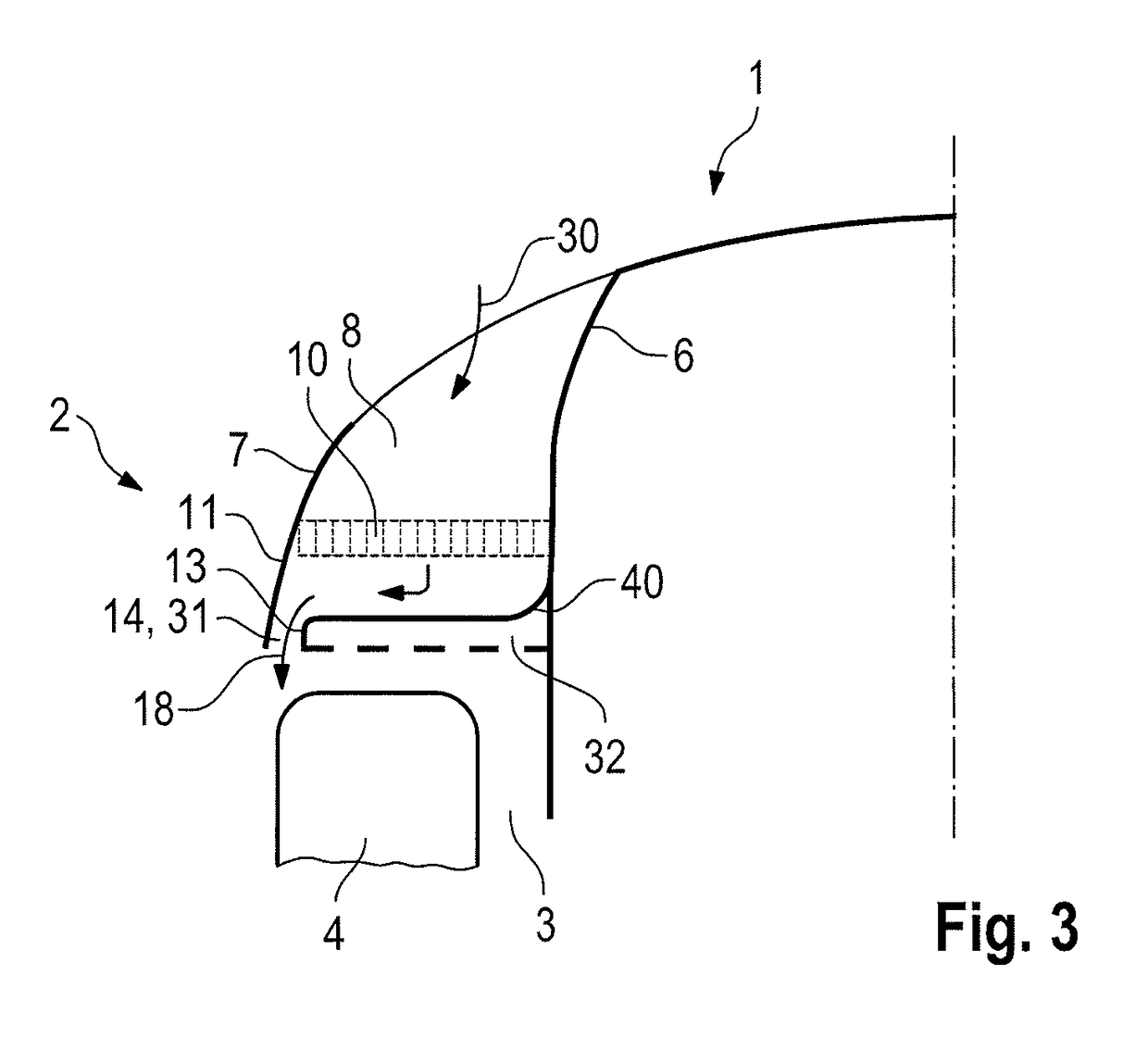

Method and apparatus to improve heat transfer in turbine sections of gas turbines

ActiveUS20140271111A1Improved air distributionImprove cooling effectEngine fuctionsEfficient propulsion technologiesTurbine bladeGas turbines

A gas turbine engine system having a combustion section and a turbine section is provided. The turbine section includes at least one turbine stage having a plurality of turbine blades coupled to a rotor and an inner casing circumferentially disposed about the plurality of turbine blades. The turbine section includes an outer casing circumferentially disposed about at least a portion of the inner casing. The inner casing and the outer casing define a cavity comprising a volume configured to facilitate the distribution of air within the cavity to cool an outer surface of the inner casing and an inner surface of the outer casing. The outer casing comprises at least one air inlet and the inner casing comprises at least one air outlet. At least one flange is provided within the cavity, and the at least one flange flanks the air inlet and at least one flow guide.

Owner:GENERAL ELECTRIC CO

Cambered vane for use in turbochargers

InactiveUS20070107426A1Improved air distributionEasy to operateWind motor controlPump componentsLeading edgeImpeller

Cambered vanes of this invention are constructed for use within a vaned turbocharger and comprise an inner airfoil surface oriented adjacent a turbine wheel, and an outer airfoil surface oriented opposite the inner airfoil surface. The inner and outer airfoil surfaces define a vane airfoil thickness. A cambered vane leading edge or nose is positioned along a first inner and outer airfoil surface junction, and a vane trailing edge positioned along a second inner and outer surface junction. The vane inner and outer airfoil surfaces are specially configured to provide a vane camberline having a curved section. Specifically, the vane camberline curved section has a measure of curvature is defined within a degree of tolerance by a vane placement or pivot diameter, as generally measured between diametrically opposed vanes mounted in the turbocharger, for providing improved gas flow distribution, thereby increasing the effective operating range of the turbocharger.

Owner:HONEYWELL INT INC

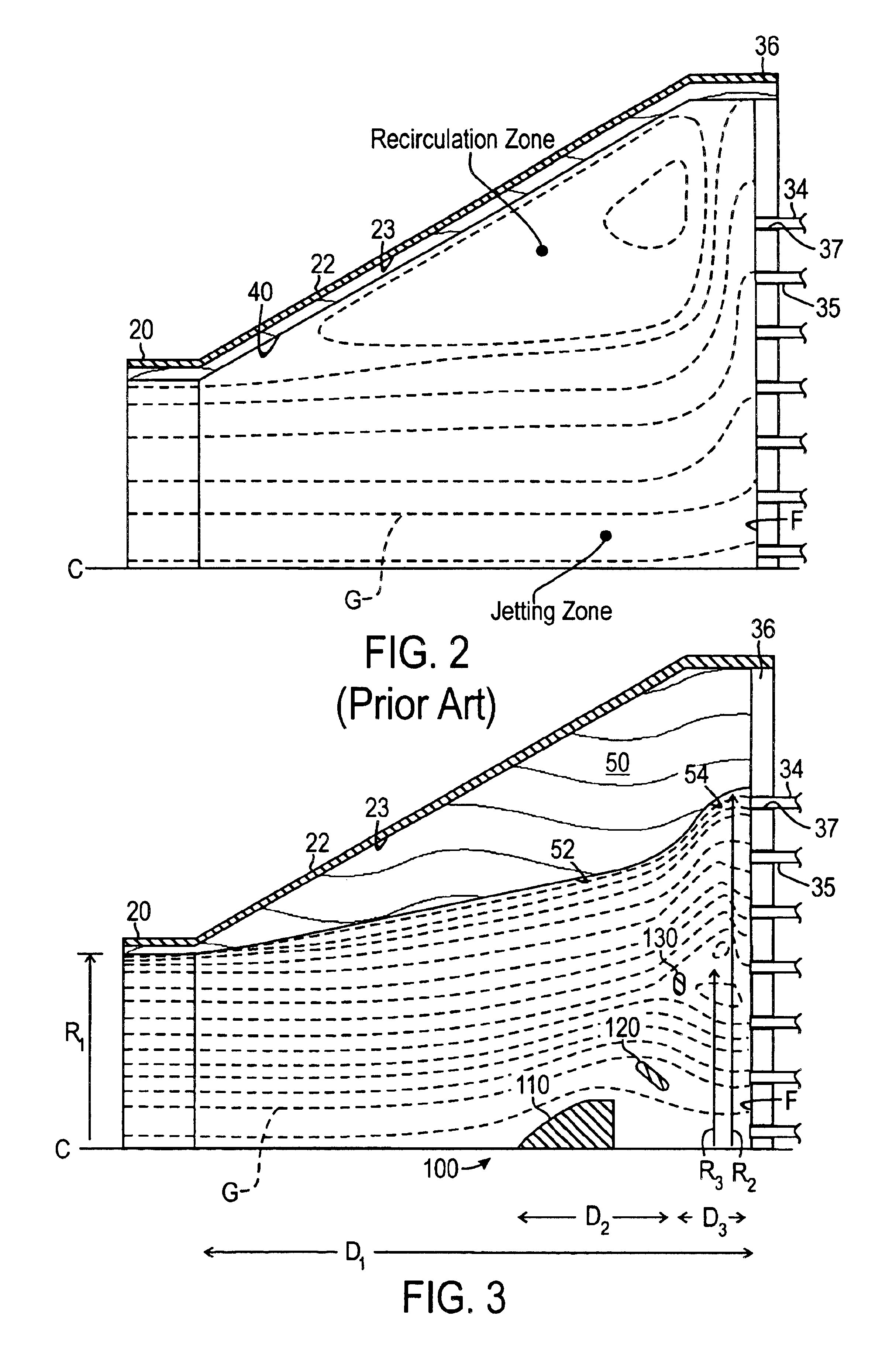

Intra-body flow distributor for heat exchanger

InactiveUS20050262850A1Improved air distributionEasy to shapeGas turbine plantsChemical/physical/physico-chemical stationary reactorsRefractoryEngineering

A flow distributor for mounting in an inlet of a heat exchanger includes a nose cone and one or more diverting rings. The nose cone is aerodynamically shaped to divert impingent gas flow around the nose cone. A first diverting ring is spaced outwardly from the nose cone and can be oriented such that at least a portion of the gas flow diverted by the nose cone is redirected into the wake of the nose cone. A second diverting ring can be spaced outwardly from the first diverting ring and can be oriented to divert gas flow impingent thereon. Struts connect the nose cone and one or more rings. Refractory on the wall of the inlet is shaped to reduce the recirculation at the outer perimeter thereof. The flow distributor is installed in the inlet with refractory to achieve substantially equal flow across the tube sheet of the heat exchanger.

Owner:KNIGHTHAWK ENG

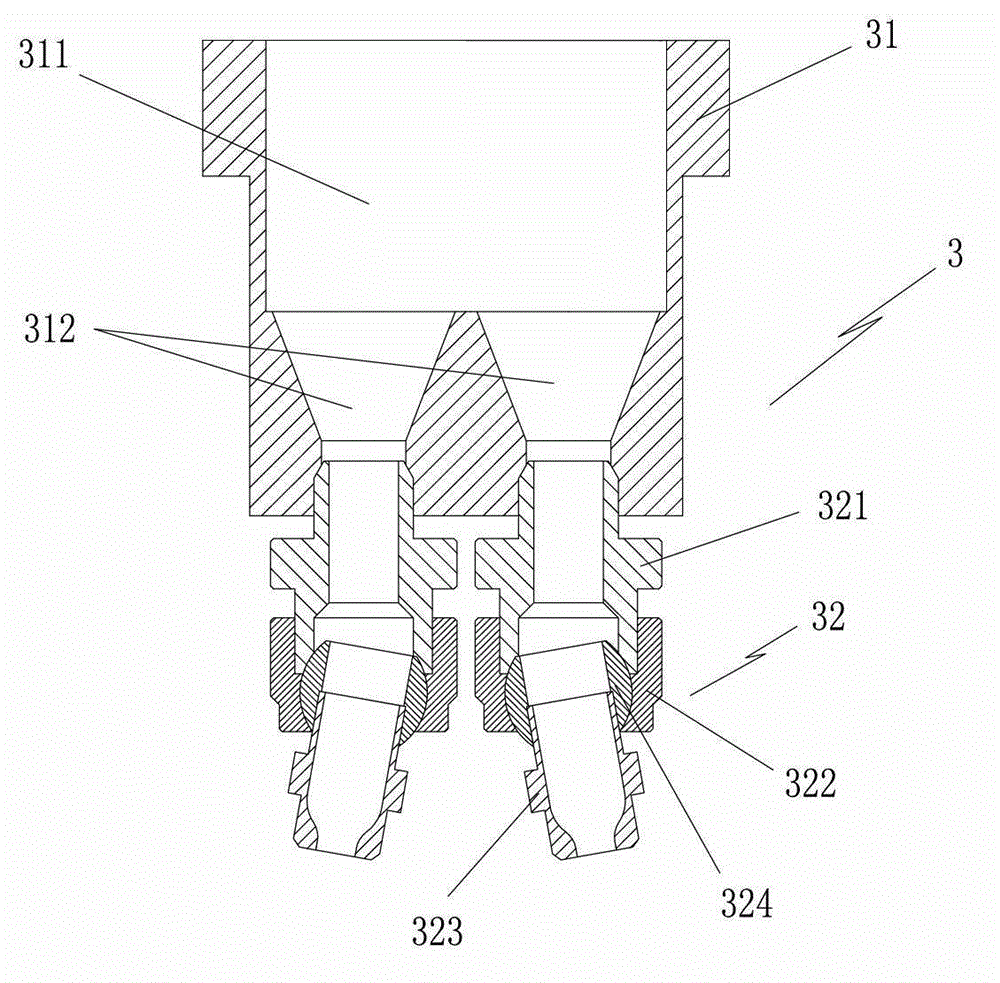

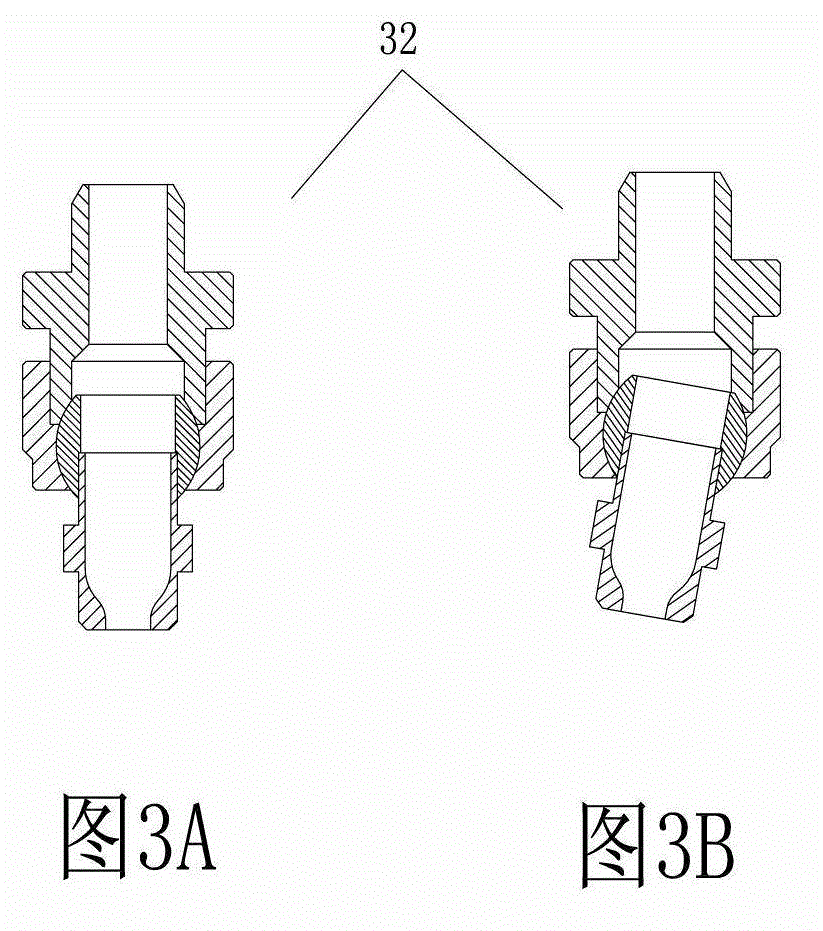

Pulse backflush deashing device for filter

ActiveCN102908840AOvercome airflow eccentricityOvercome defects such as vibrationDispersed particle filtrationJet flowDiffusion loss

The invention discloses a pulse backflush deashing device for a filter. Filtering units are arranged on a pipe plate of the filter, and the pipe plate divides the filter into a clean gas cavity and a dusty gas cavity in a sealing manner. The pulse backflush deashing device comprises ejectors arranged at the upper parts of the filtering units, and backflush pipelines matched with the ejectors, wherein one end of each backflush pipeline is communicated with a backflush gas storage tank through a pulse backflush valve, and a direction-adjusting multi-hole jet nozzle according to the top part of each ejector is arranged at the other end of each backflush pipeline. As the pulse backflush deashing device adopts the direction-adjusting multi-hole jet nozzles with the jet directions being adjustable, the jet direction of backflush gas can be adjusted, the jet length can be extended, and a primary jet flow and a secondary jet flow are mixed uniformly by multiple high speed jet flows, so that the distribution statuses of backflush gas flows entering the ejectors can be improved, the diffusion loss is reduced, the energy transmission efficiency can be improved, and the deficiencies, such as non-uniformity of pulse backflush, as well as gas flow eccentricity and filter pipe vibration that are brought by the existing jet nozzles, are overcome.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Gas turbine airfoil leading edge cooling construction

InactiveUS20060073016A1Uniform film effectivenessConstant surface distanceBlade accessoriesMachines/enginesLeading edgeTrailing edge

A gas turbine airfoil with a pressure sidewall (6) and a suction sidewall (7) extends from a root (2) to a tip (3) and from a leading edge (4) to a trailing edge (5). It comprises several film cooling holes with exit ports (8). The film cooling holes have a sidewall that is diffused in the direction of the tip (3) of the airfoil (1) at least over a part of the film cooling hole. Furthermore, the film cooling holes each have flare-like contour near the outer surface of the leading edge (4). The film cooling holes according to the invention provide an improved film cooling effectiveness due to reduced formation of vortices and decreased penetration depth of the cooling air film.

Owner:ANSALDO ENERGIA IP UK LTD

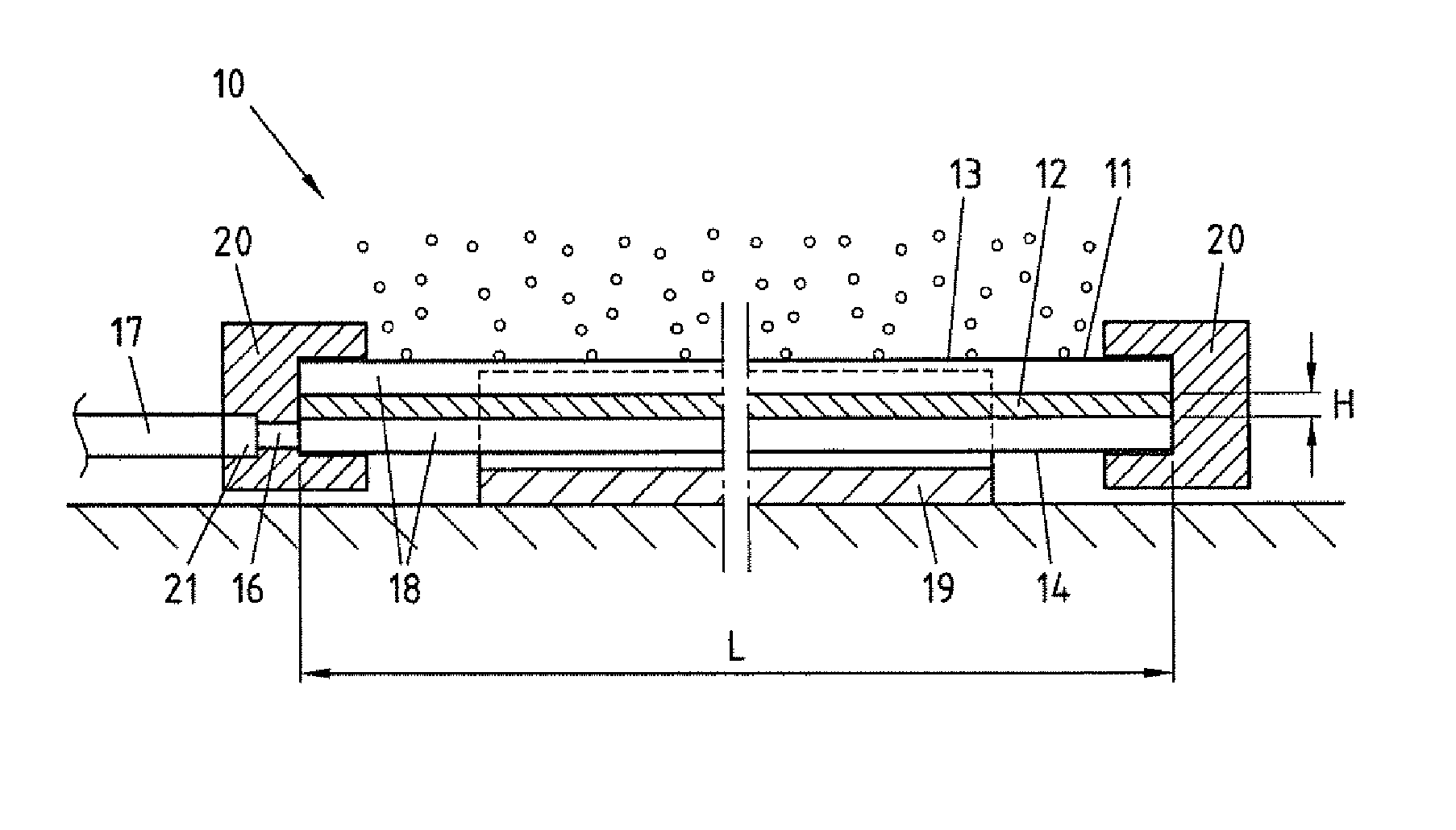

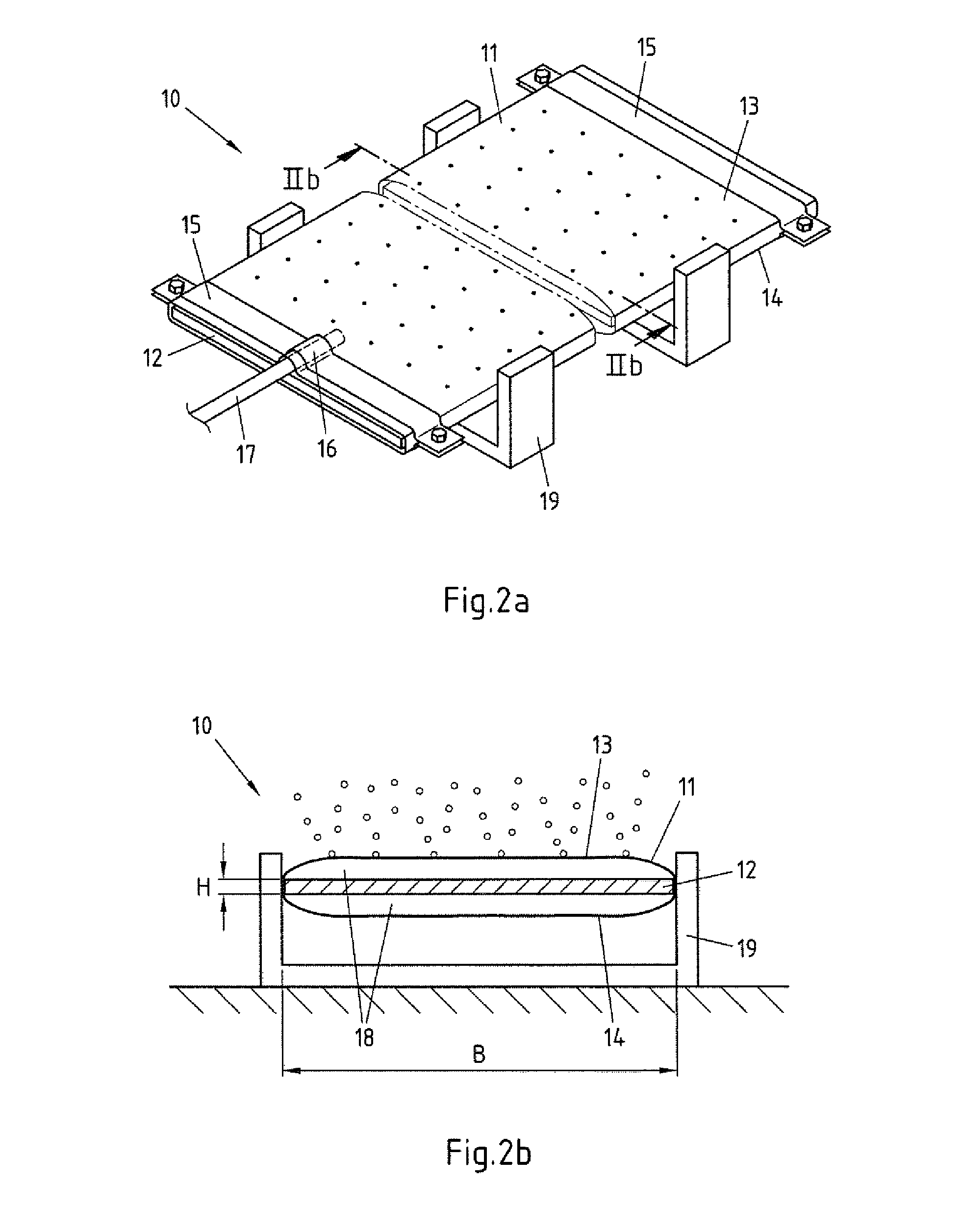

Device for Distributing Gases in Liquids

ActiveUS20150001744A1Improve sealingUniform bubble distributionCarburetting airTransportation and packagingMaterial PerforationMechanical engineering

A device for distributing gases in liquids, comprising: an aerating element made out of plastic, with an upper side and a lower side joined with the upper side, a support element, and a gas inlet, wherein the aerating element comprises at least one cavity that can be filled with gas through the gas inlet, wherein at least the area of the upper side of the aerating element comprises holes, perforations or the like as the gas outlet, and wherein the support element is situated in the cavity of the aerating element. In order to enable a uniform and reliable aeration of larger water surfaces in a cost-effective manner, it is proposed that the width of the support element be greater than its height.

Owner:NORRES SCHLAUCHTECHNIK GMBH

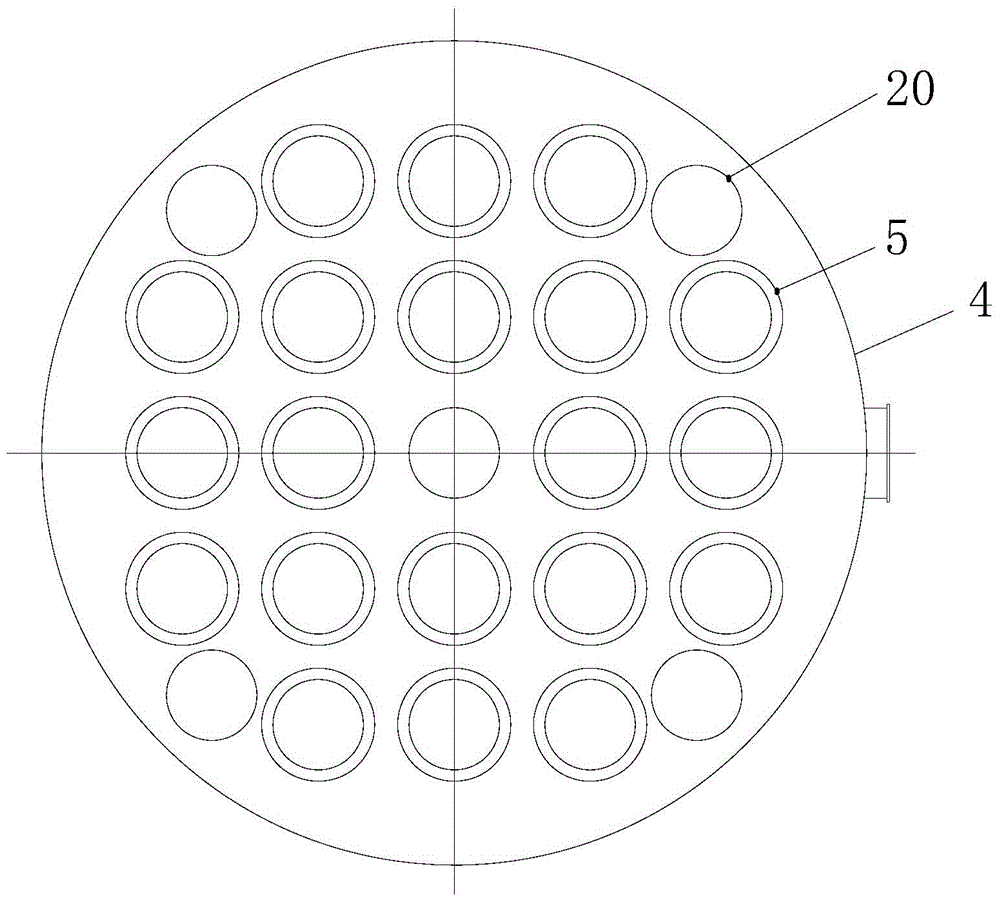

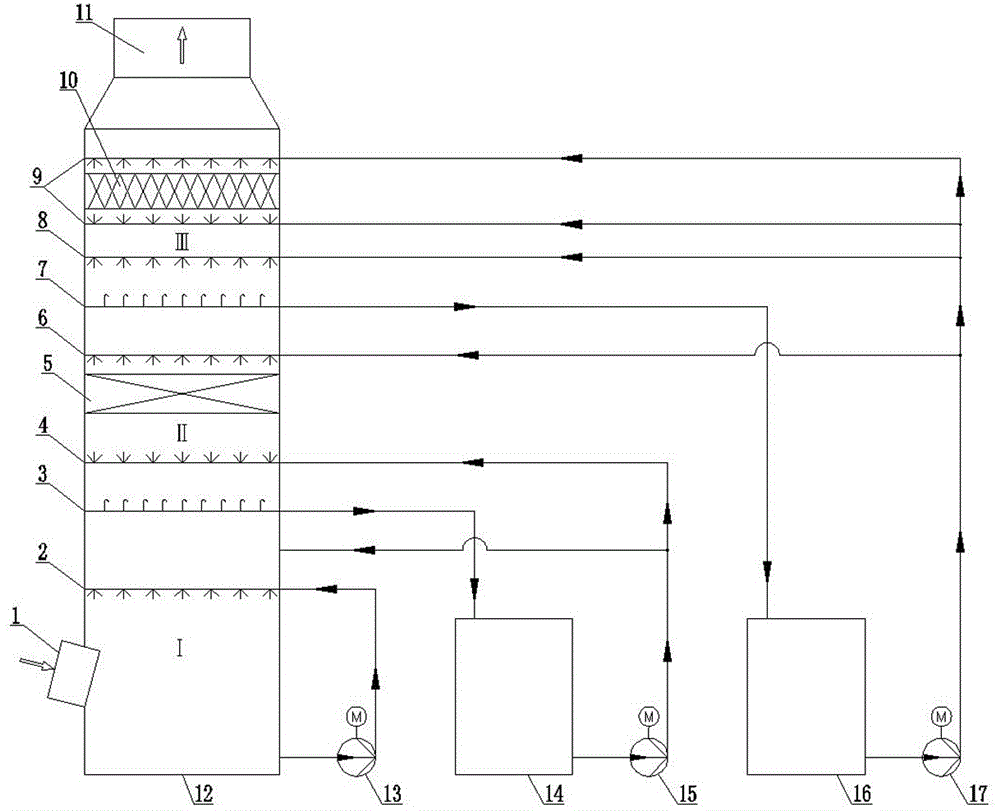

Porous partition spray equipped desulfurization tower

InactiveCN104959017AGuaranteed fluencyImprove solubilityCombination devicesUsing liquid separation agentSulfurFlue gas

The invention discloses a porous partition spray equipped desulfurization tower. The lower part in the tower body is a first order absorption zone, the upper part in the tower body is a second order absorption zone, and a porous air flow distribution plate is disposed between the first order absorption zone and the second order absorption zone. The porous air flow distribution plate includes a plate body, the plate body is provided with liquid leakage holes, the plate body is also provided with upward ventilation columns, each ventilation column is equipped with an air cap, the tower body is externally provided with a tower outside slurry pool of the second order absorption zone, and the tower outside slurry pool is connected to the liquid leakage holes through a seal pipeline. According to the porous partition spray equipped desulfurization tower provided by the invention, the first order spray operates at a low Ph value, the second order spray operates at a high Ph value, the energy consumption of a circulating pump is greatly reduced, the porous air flow distribution plate is used for separating the two order absorption systems, the rising flue gas and falling slurry can pass separately, thus ensuring smooth flue gas rising and uniform flue gas distribution. The desulfurization tower is especially suitable for high sulfur coal flue gas desulfurization, can lower the investment and operation cost, and is applicable to current ultra-clean emission reconstruction of power plants.

Owner:浙江菲达环保科技股份有限公司

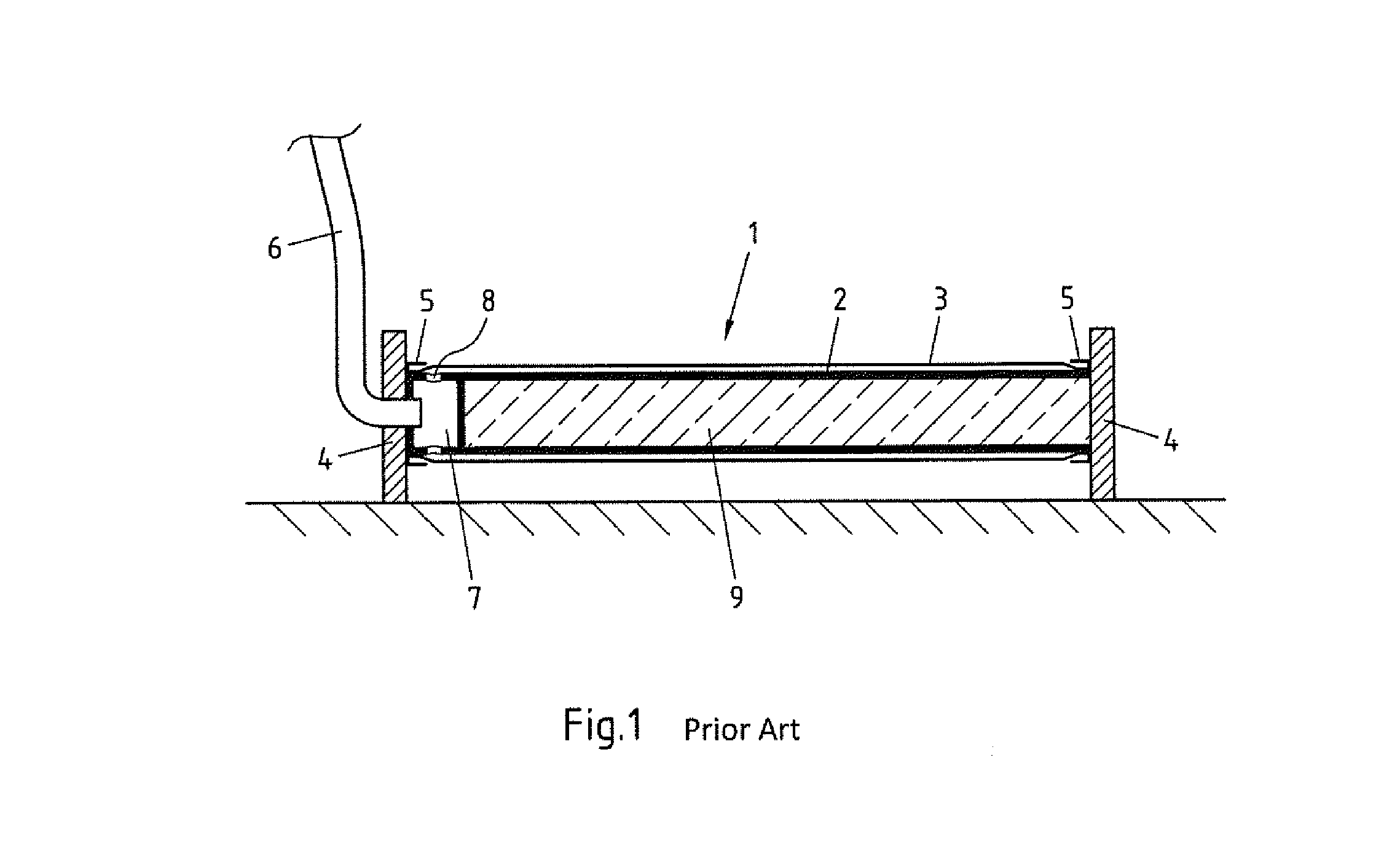

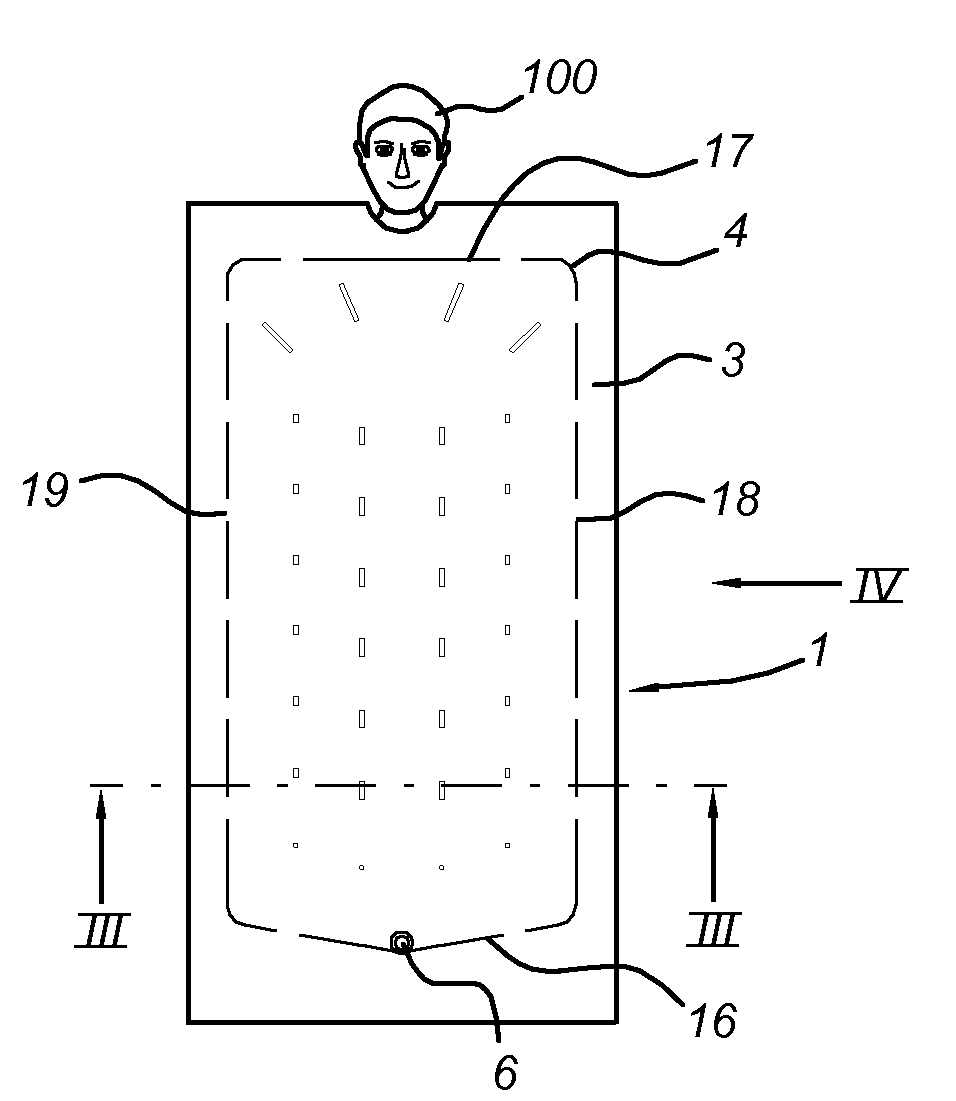

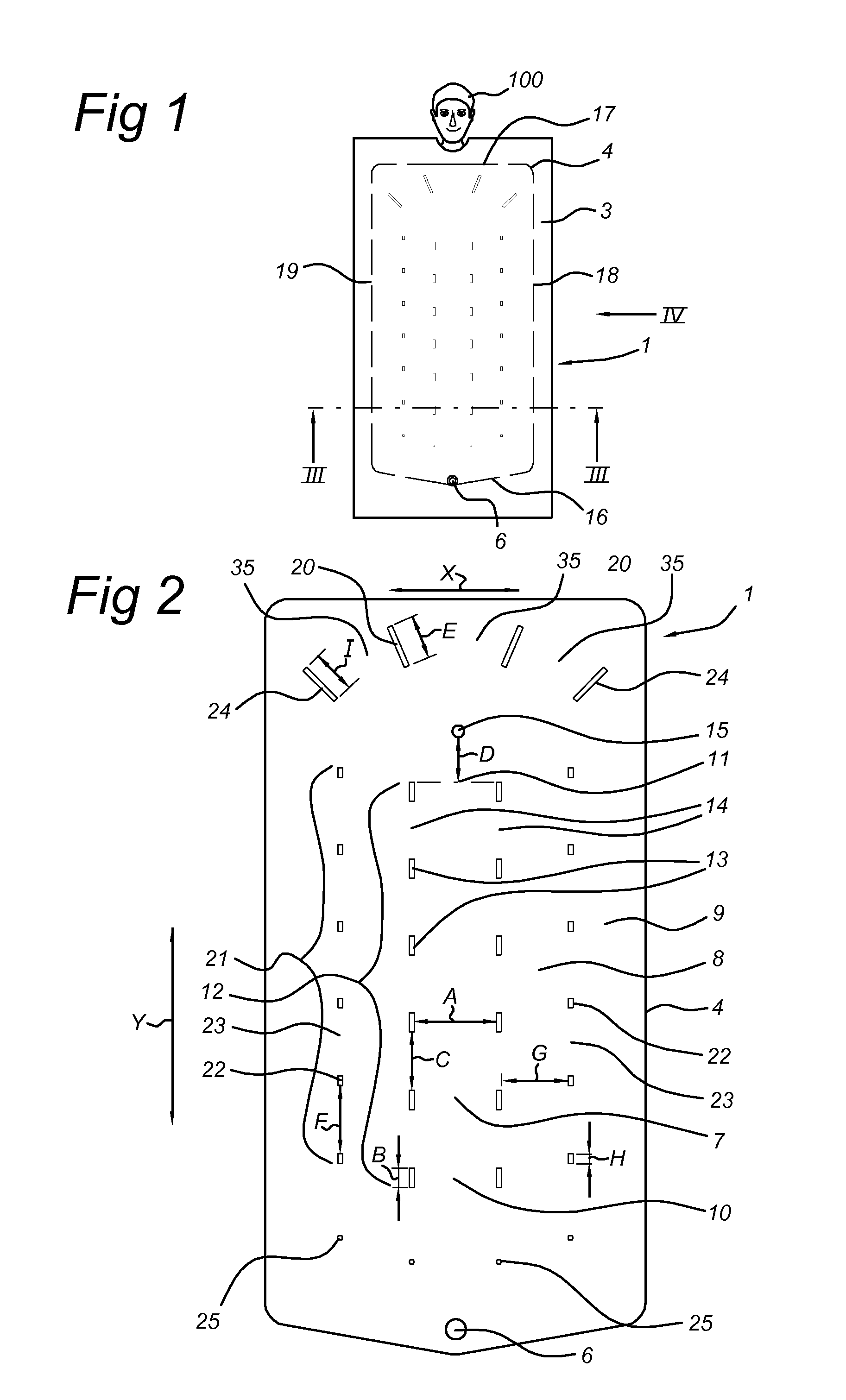

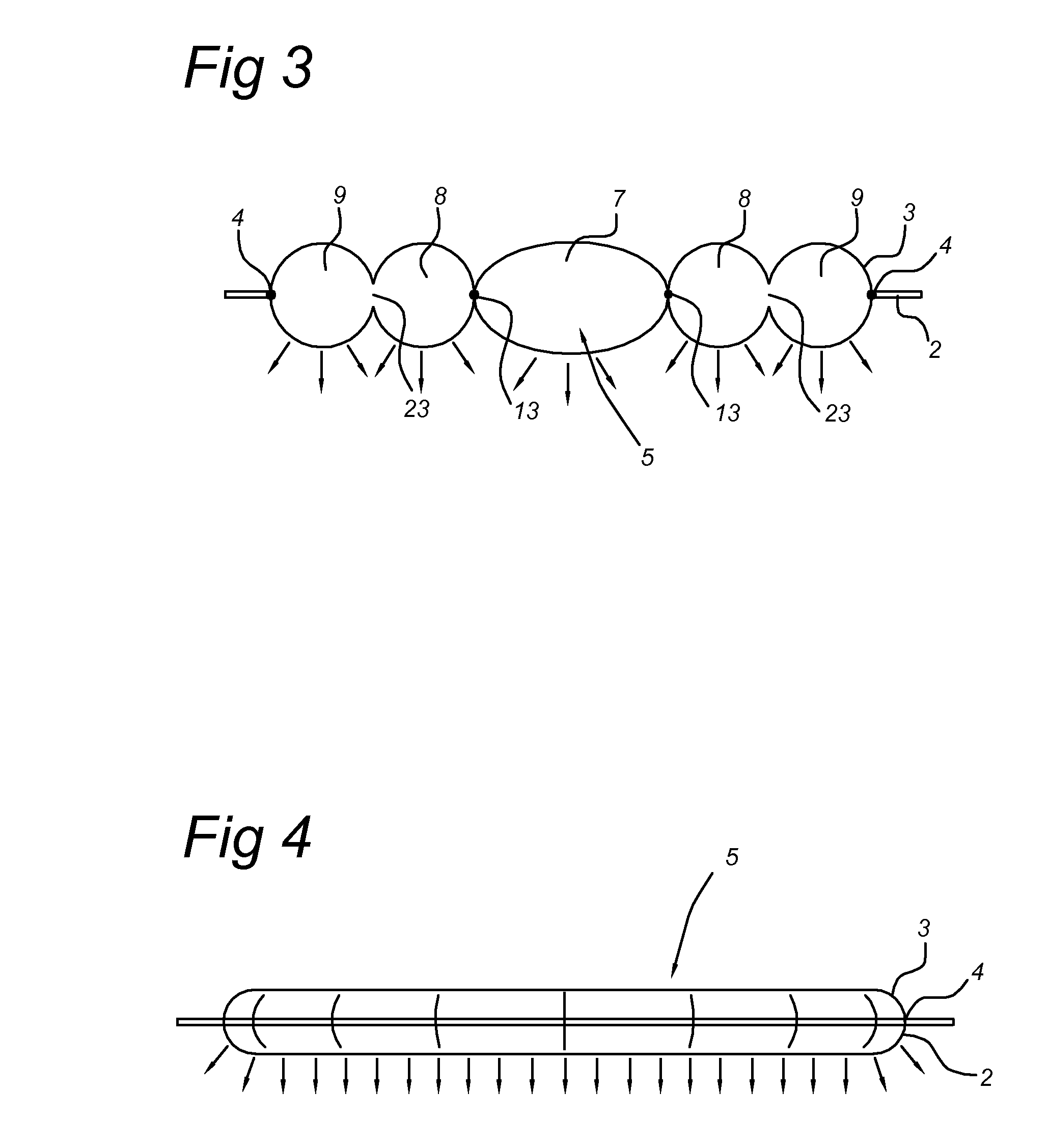

Device for conveying air to a person

ActiveUS20100161012A1Distribute quicklyImprove quickLight therapyTherapeutic coolingEngineeringMain duct

The invention relates to a device for conveying heated air to a person and comprises an air-permeable inner sheet and an air-impermeable outer sheet which are connected to one another by welds in order to form a panel-like shape in the inflated state. The welds produce a main duct having, viewed at the inlet end and in the non-inflated state, a main duct width. The main duct is delimited by at least one first series of elongate first welded strips, the first intermediate spaces which are in line with one another. The length of each of these first intermediate spaces, viewed in the non-inflated state, is in each case smaller than the main duct width. The length of each first welded strip is at least 15% of the main duct width and at most 80% of the main duct width.

Owner:THE SURGICAL INT

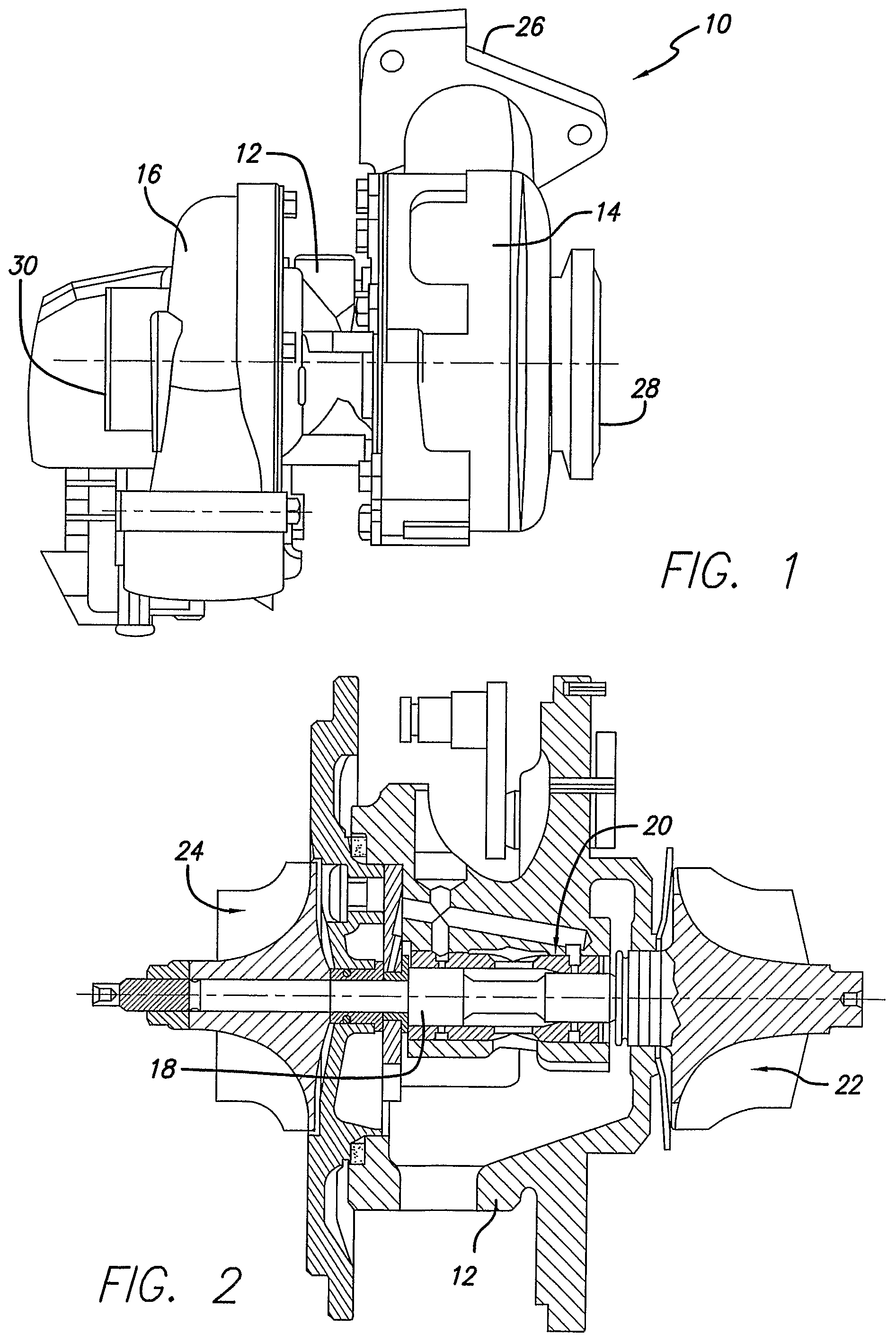

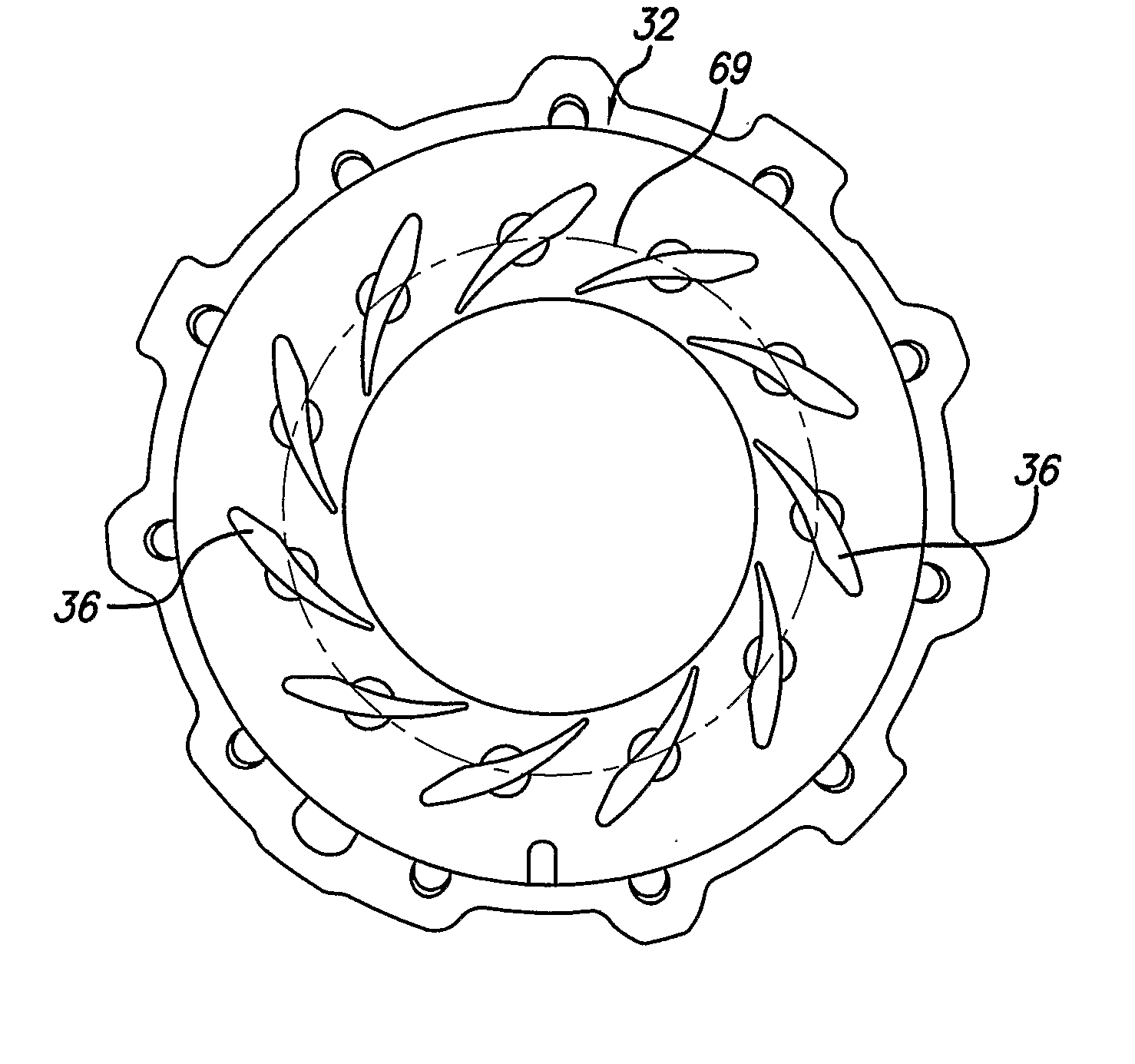

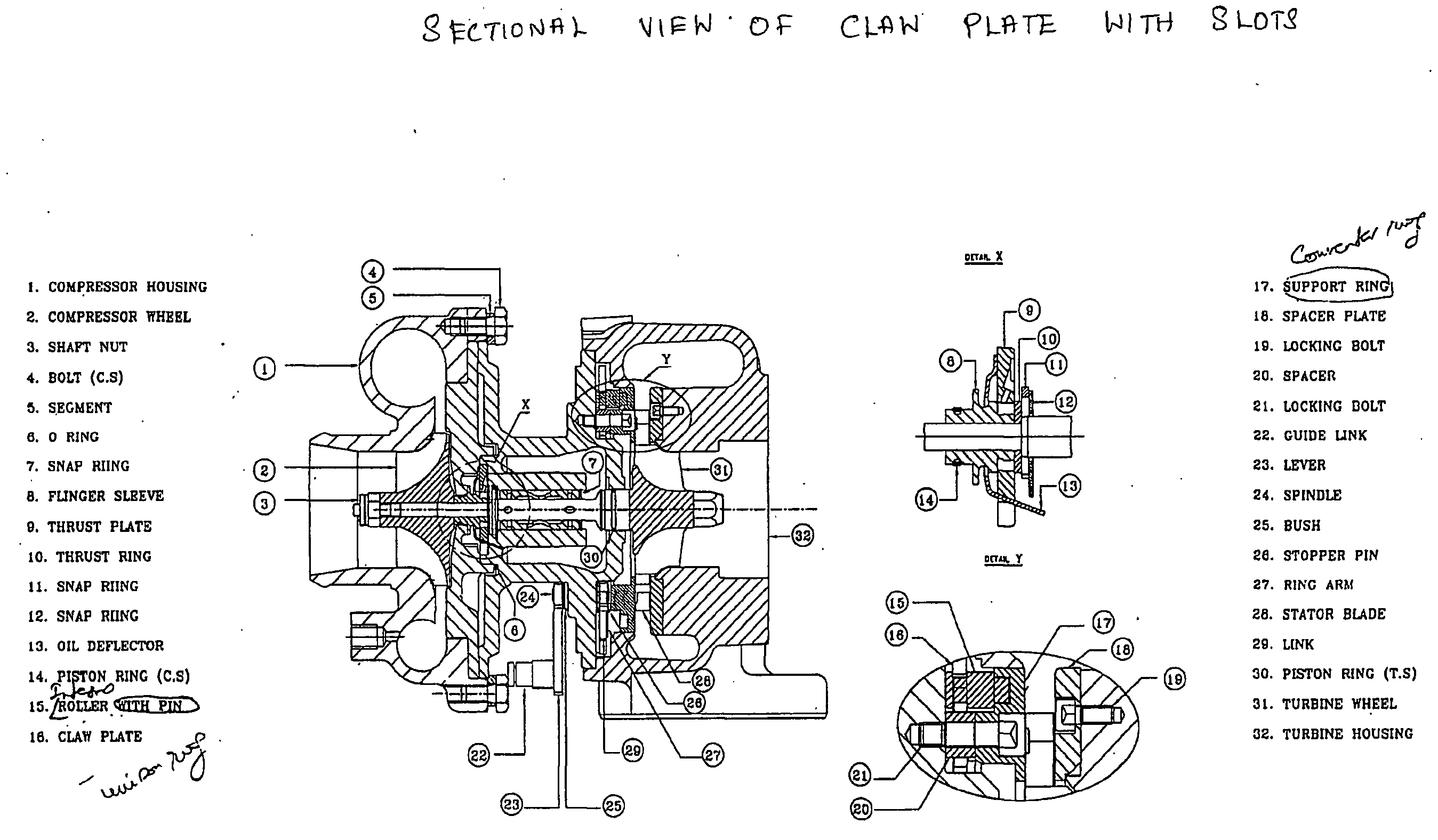

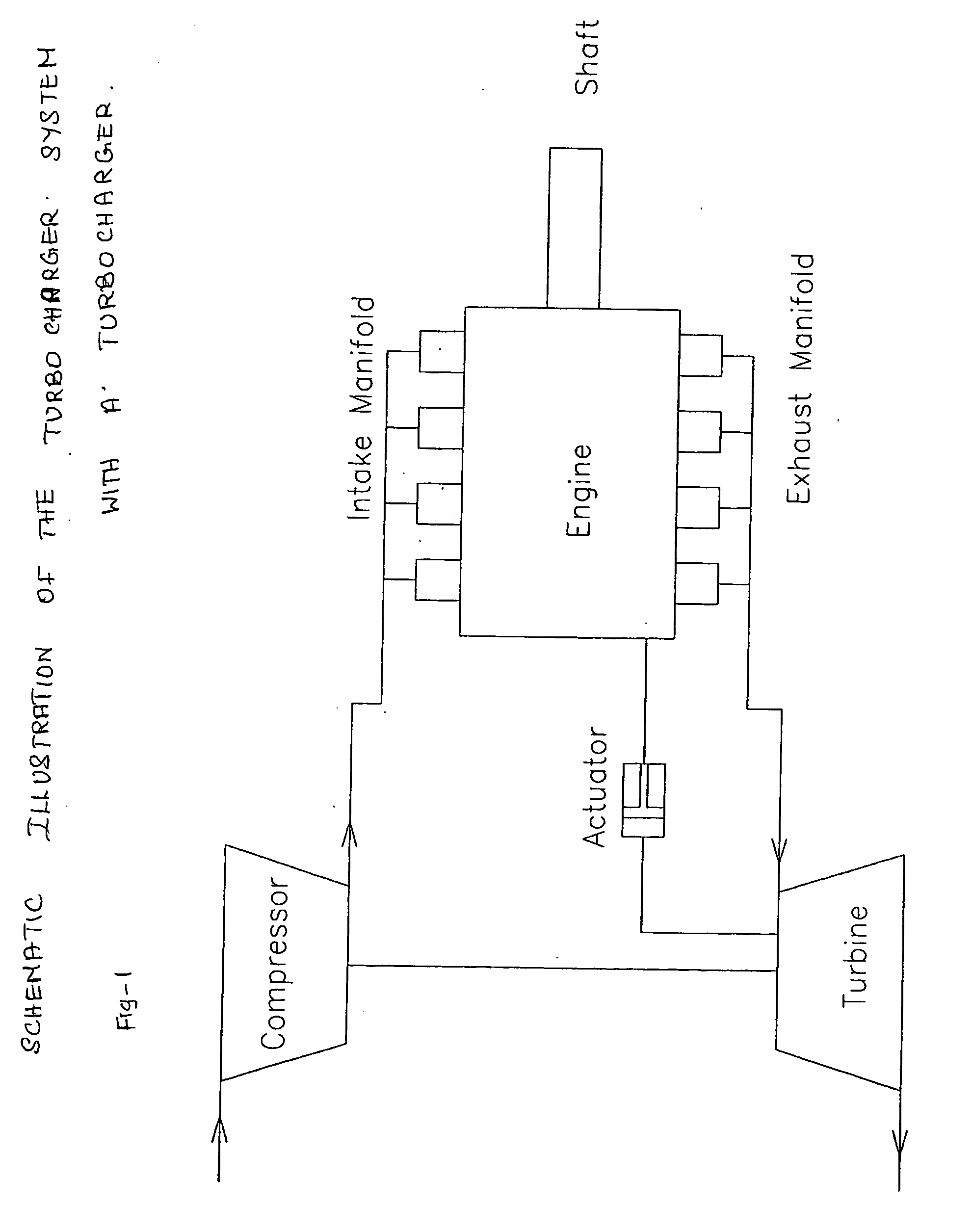

Variable stator blade mechanism for turbochargers

InactiveUS20100166542A1Improved air distributionMinimize and eliminate unwanted airflow effectEngine manufactureInternal combustion piston enginesImpellerTurbine wheel

A turbocharger with variable turbine geometry comprising of a turbine housing having an exhaust gas inlet and an outlet, a volute connected to the inlet, and a nozzle wall adjacent the volute, carrying a turbine wheel and is attached to a shaft with a plurality of improved aerodynamic profiled stator blades that are disposed within the turbine housing between the exhaust gas inlet and turbine wheel.

Owner:TURBO ENERGY

Front-end structure of a motor vehicle

ActiveUS9637180B2Improved air distributionReduce air resistanceSuperstructure subunitsBumpersMotorized vehicleHeat exchanger

A front-end structure of a motor vehicle, having an air inlet opening and having an air duct which extends from the air inlet opening and in which there is arranged a heat exchanger through which air can flow, wherein the air duct conducts an air flow into the wheel arch and / or laterally with respect to the wheel arch, wherein the air duct is divided, downstream of the heat exchanger, into a first duct part and a second duct part, wherein the first duct part conducts air laterally with respect to the wheel arch and the second duct part conducts air into the wheel arch, wherein an air flow control device is provided in the air duct, which air flow control device controls the air flow through the first duct part and / or through the second duct part.

Owner:DR ING H C F PORSCHE AG

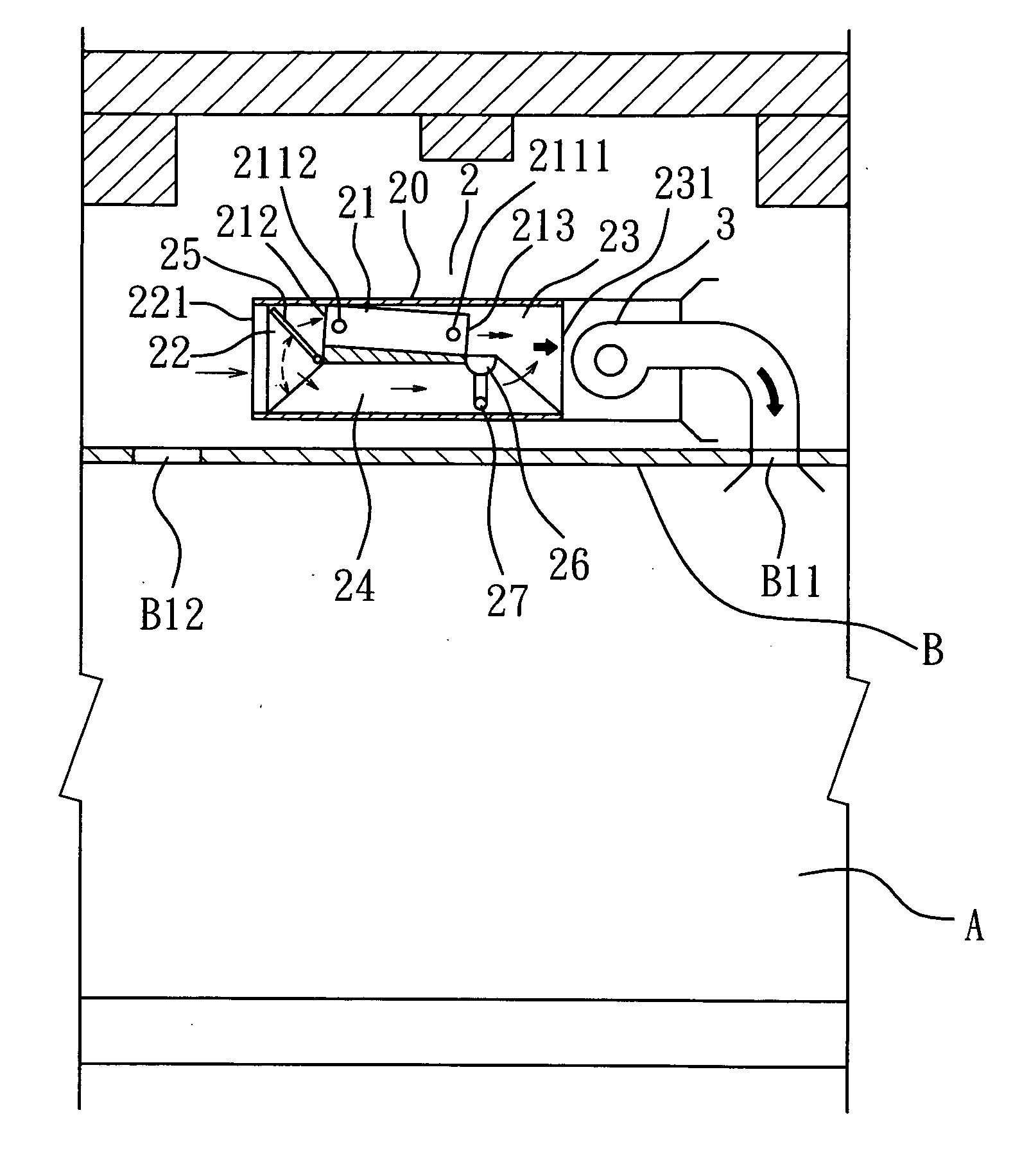

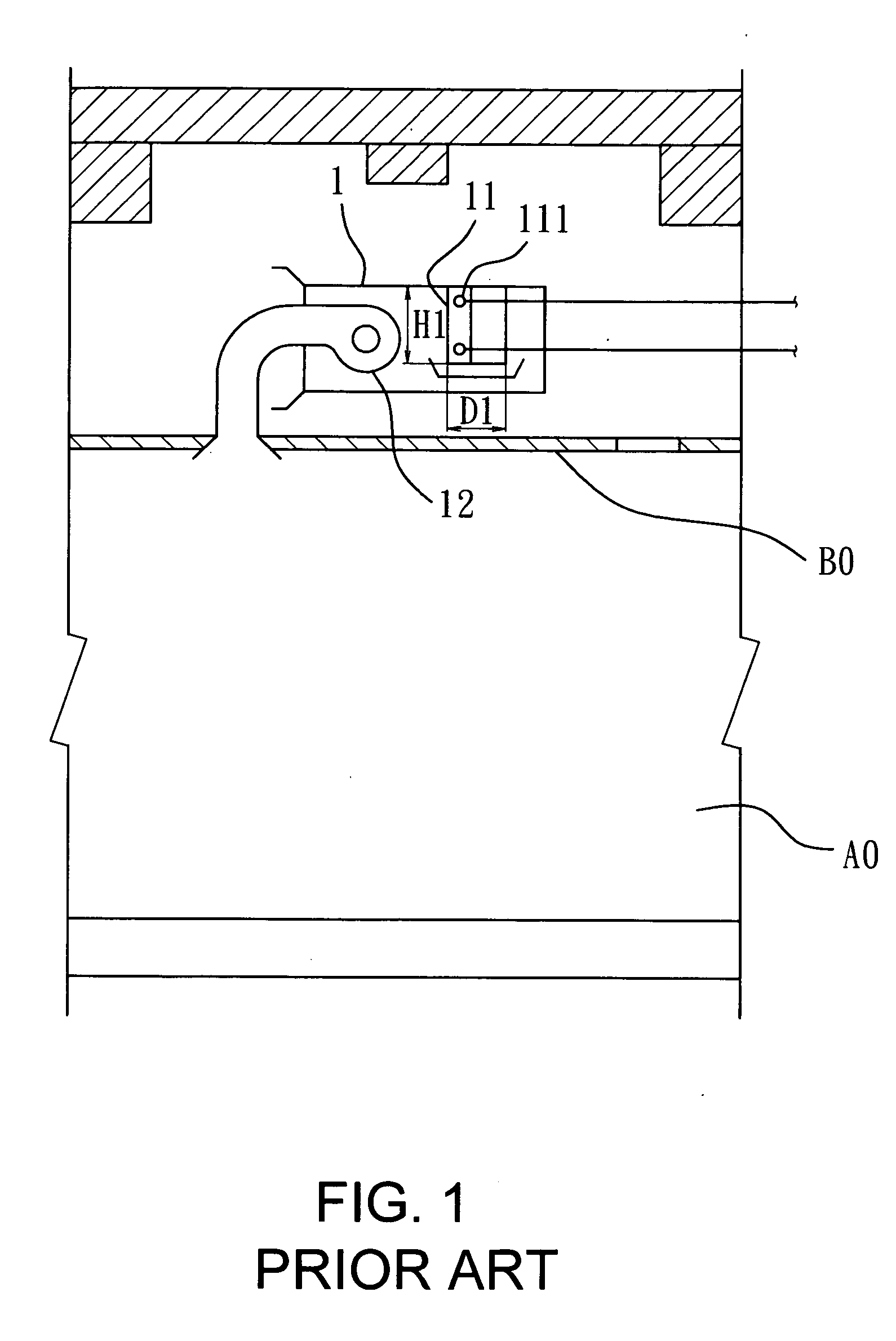

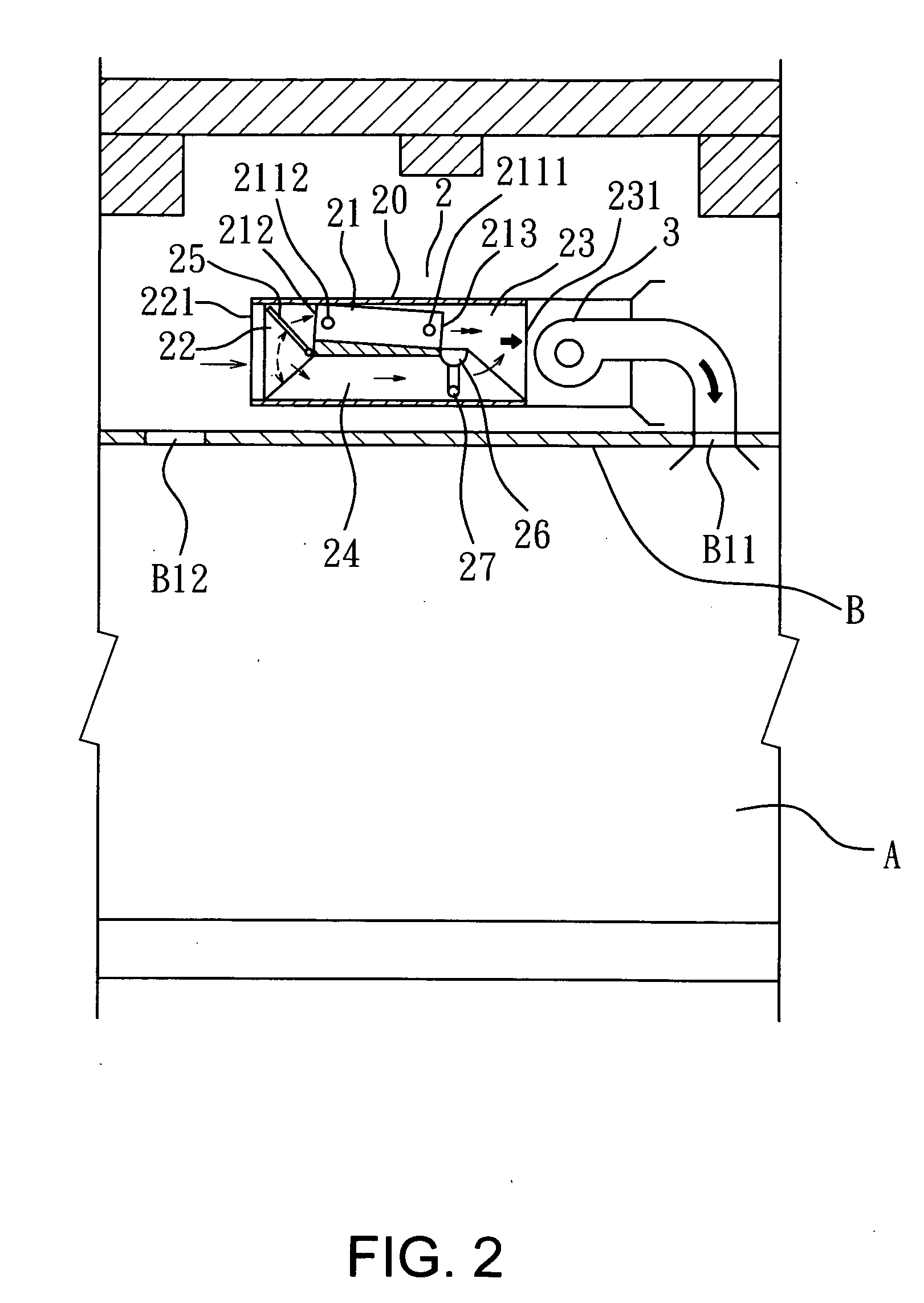

Thin refrigeration air conditioner having a greater temperature difference

InactiveUS20070163292A1Improves airflow distributionGreat temperature differenceLighting and heating apparatusSpace heating and ventilation detailsTraffic volumeRefrigerant

A thin refrigeration air conditioner has a casing which houses a thin heat exchanger, an air intake chamber, an air exit chamber, a side chamber and an air port baffle. The thin heat exchanger in cooperative with the air port baffle or a return air branch port can control airflow to maintain a high temperature difference and low flow rate operation while the air and refrigerant flow through the thin heat exchanger to perform heat exchange process. Return airflow and airflow delivery can be maintained in an optimal temperature difference condition according to energy requirement of the air conditioning zone. Thus it can provide a most comfortable condition and also save energy. It also takes less installation space and improves airflow distribution.

Owner:COHAND TECH

Skewed gas flow electric bag composite dust remover

InactiveCN102824804AImprove dust removal efficiencyReduce dust concentrationCombination devicesFlow diversionRe entrainment

The invention discloses a skewed gas flow electric bag composite dust remover, which comprises a gas flow distribution region, an electric dust removing region and a bag dust removing region from left to right, wherein the lower parts of the electric dust removing region and the bag dust removing region are provided with dust collecting regions; a clean gas region is positioned on the upper part of the bag dust removing region; the gas flow distribution region comprises two gas flow distribution plates which are arranged vertically, and a skewed gas flow distribution plate; the electric dust removing region comprises a cathode line, an anode plate and a high-pressure electric device; the joint between the electric dust removing region and the bag dust removing region is provided with an electric bag bonding plate; the bag dust removing region comprises a gas flow diversion plate, a bag, a framework and a tube nest; the framework and the bag construct a whole body which is arranged on the tube nest; each dust collecting region consists of an ash hopper and an ash hopper baffle plate; and the clean gas region mainly comprises clapboards. Optimal gas flow distribution in the electric bag composite dust remover is realized, the generation of eddy current in the electric dust removing region is reduced, the running resistance of the bag dust removing region is reduced, re-entrainment is reduced, and low-resistance efficient running of the electric bag composite dust remover is ensured.

Owner:SOUTH CHINA UNIV OF TECH

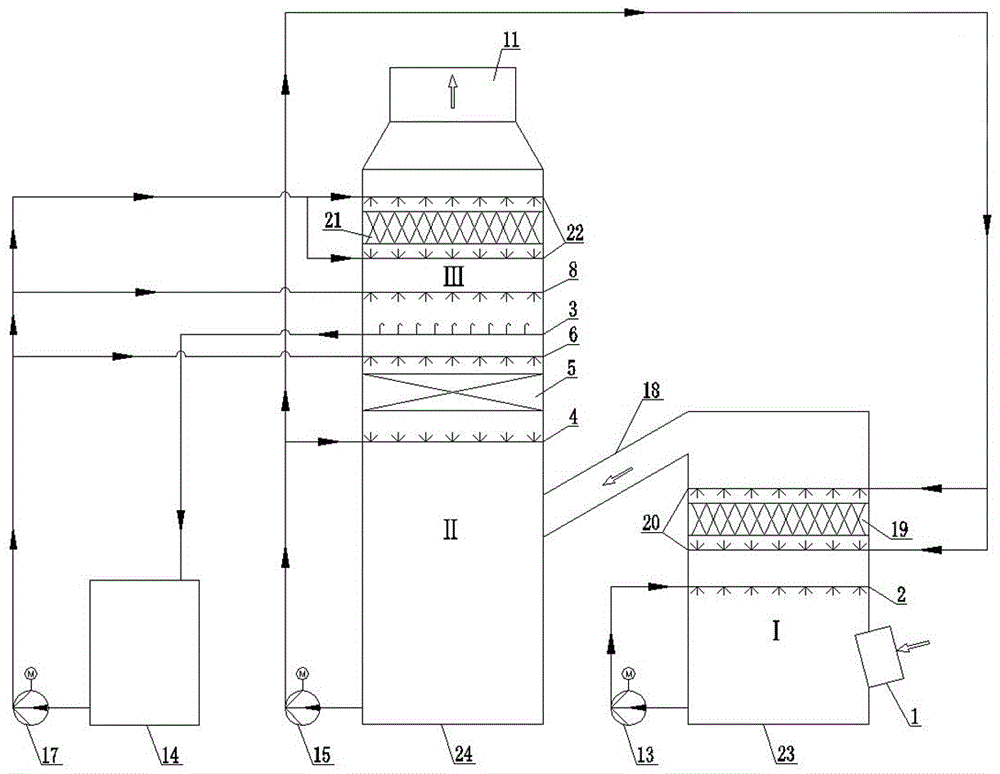

Three-cycle desulphurization method for wet type ammonia-process desulphurization and flue gas desulfurization tower or system

InactiveCN105727723AGuaranteed oxidationGuaranteed crystallizationGas treatmentUsing liquid separation agentFlue gasProcess engineering

The invention relates to the field of environmental protection and discloses a three-cycle desulphurization method for wet type ammonia-process desulphurization. The desulphurization method is implemented with a first slurry circulating loop, a second slurry circulating loop and a third slurry circulating loop, wherein in the first slurry circulating loop, slurry having mass concentration of 10%-20% and a pH value of 4.0-5.0 is used for carrying out cycle spraying treatment on flue gas, and the temperature of the flue gas treated by the slurry is 50-60 DEG C; in the second slurry circulating loop, slurry having mass concentration of 10%-15% and a pH value of 5.0-6.0 is used for carrying out cycle spraying treatment on the flue gas; and in the third slurry circulating loop, slurry having mass concentration of 3%-10% is used for carrying out cycle spraying treatment on the flue gas. The invention also discloses a flue gas desulfurization tower or system using the three-cycle desulphurization method. According to the three-cycle desulphurization method, the three independent circulating loops are divided according to the concentration of the slurry, the circulating loops separately control the slurry having different concentrations and pH values for treatment of the flue gas, and the contradiction of high desulphurization efficiency and high oxygenation efficiency of by-products is solved.

Owner:SICHUAN JUNHE ENVIRONMENTAL PROTECTION

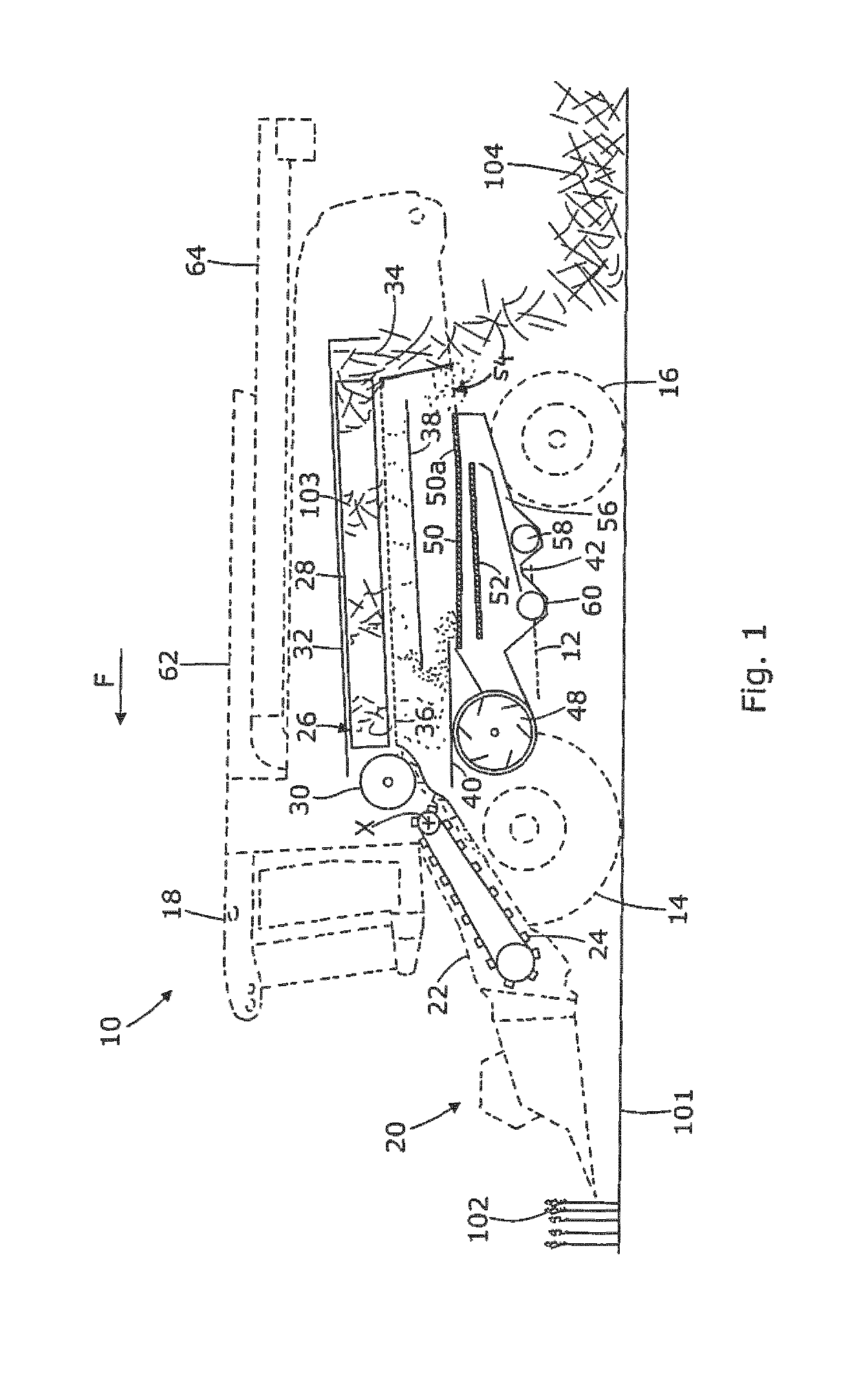

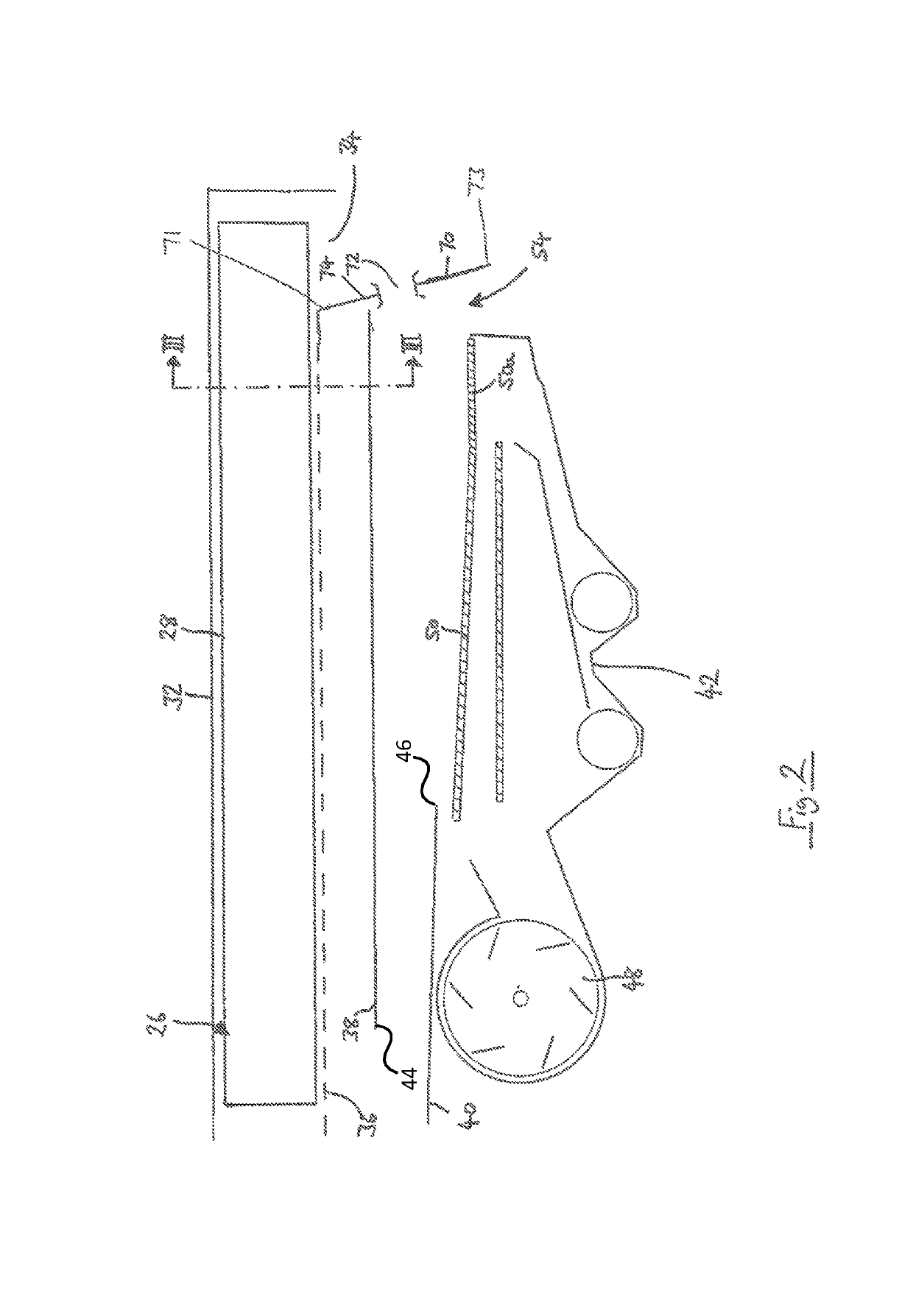

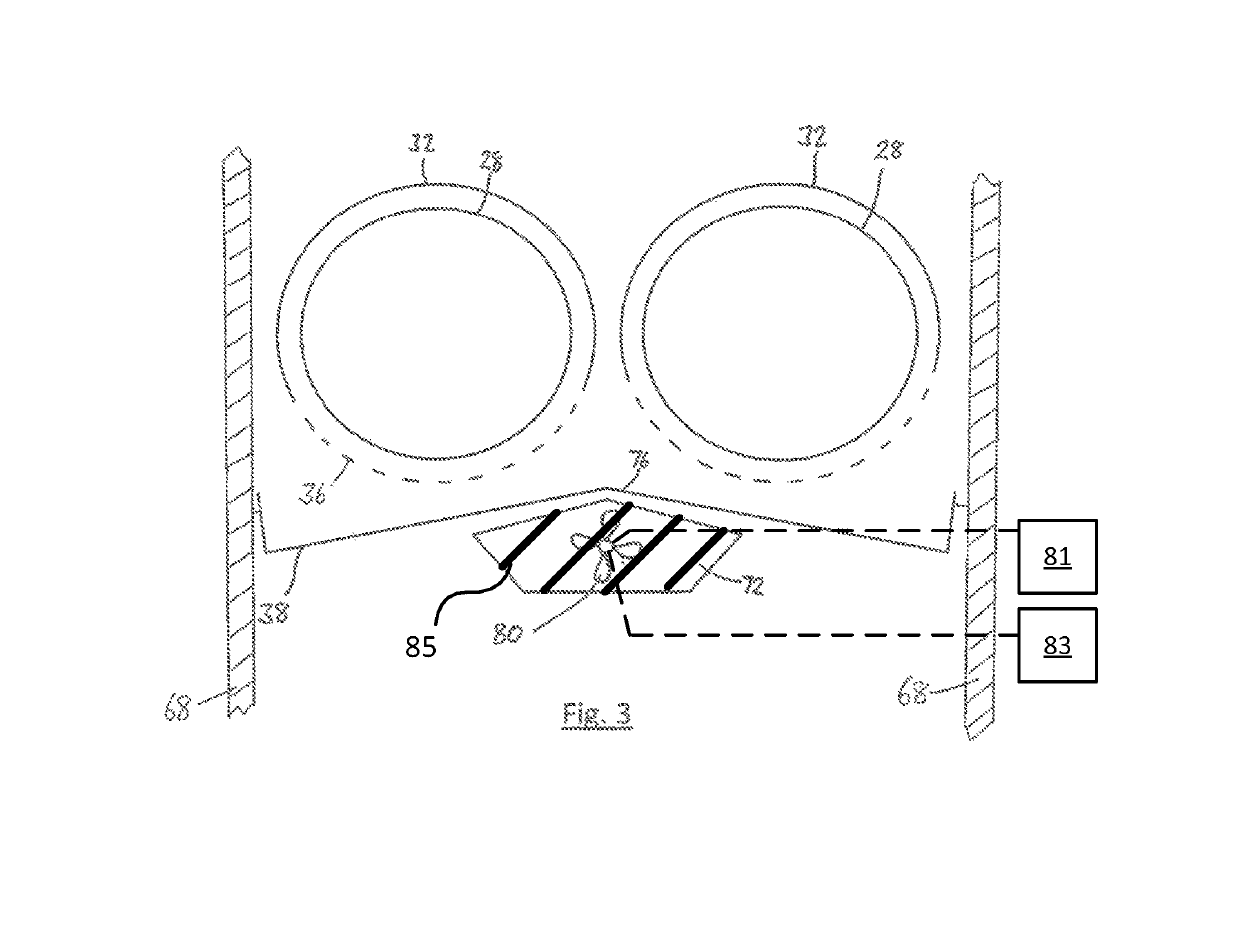

Combine harvester grain cleaning system

A grain cleaning system in a combine harvester including a pair of side walls, a rear wall that extends between the side walls, a sieve that oscillates in a fore-and-aft path between the side walls, a fan unit for generating a cleaning airstream, and an outlet for discharging residue from a grain-cleaning process. The outlet is framed in part by a lower edge of the rear wall. An aperture is provided in the rear wall to provide air relief to enhance the fore-to-aft flow of the cleaning airstream. Optionally, an auxiliary fan may drive air through the aperture.

Owner:AGCO INT GMBH

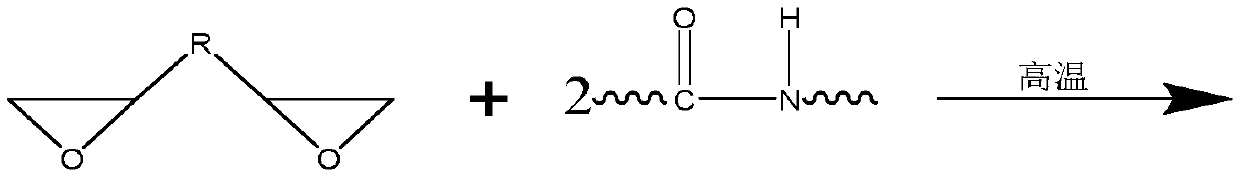

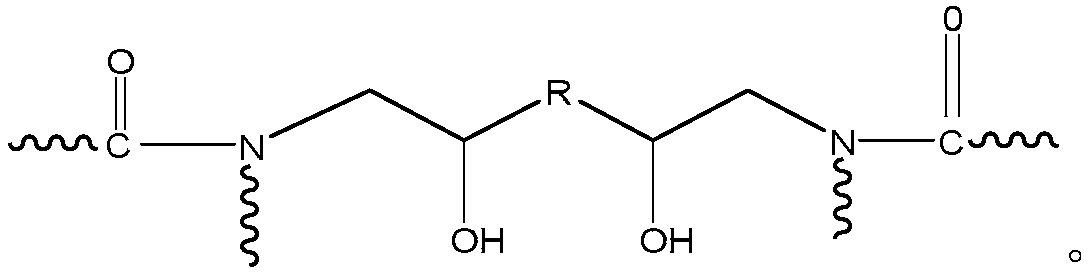

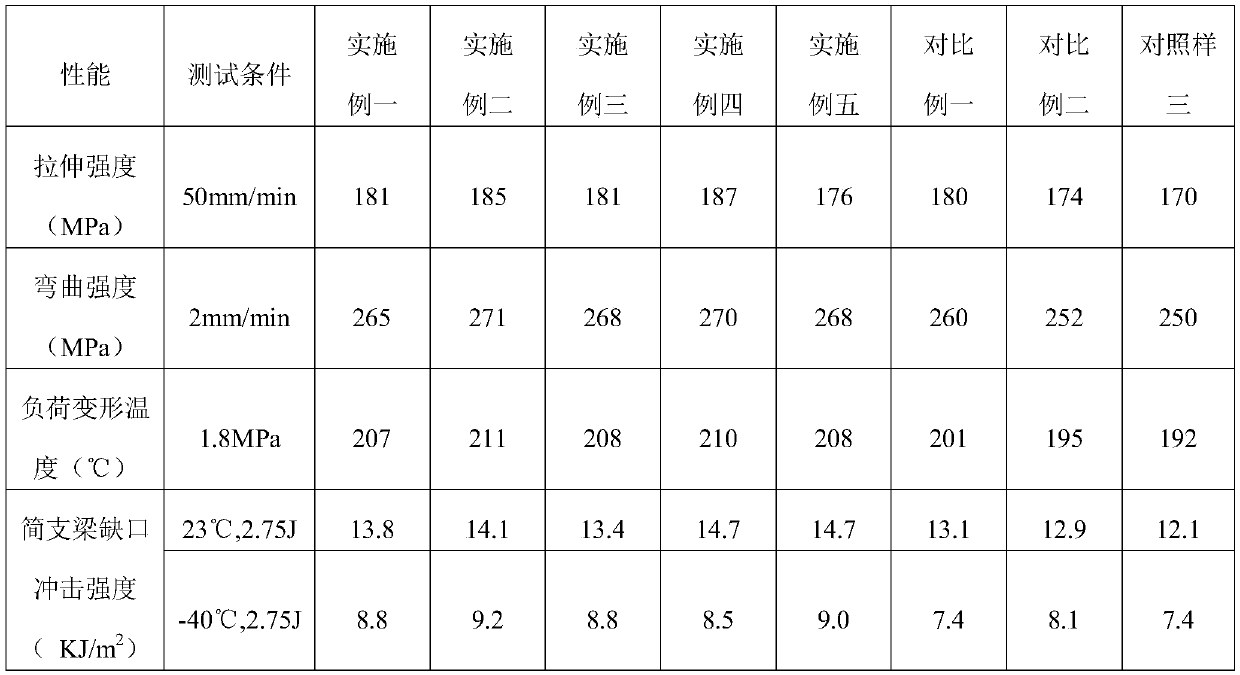

Glass fiber reinforced nylon material for engine intake manifold and preparation method thereof

The invention discloses a glass fiber reinforced nylon material for an engine intake manifold and a preparation method thereof. The glass fiber reinforced nylon material comprises the following raw materials: 20-40 parts of nylon resin No. 1, 20-40 parts of nylon resin No. 2, 30-35 parts of glass fibers, 0.5-1 part of a coupling agent, 0.2-0.5 part of a main antioxidant, 0.2-0.5 part of an auxiliary antioxidant, 0.2-0.5 part of a heat stabilizer, 3-5 parts of metal microbeads, 0.1-0.3 part of a nucleating agent, 0.3-0.8 part of a lubricant, 1.0-1.5 parts of a hydrolysis-resistant agent, 0.5-2.5 parts of epoxy resin and 1-2 parts of black masterbatch. The invention also discloses the preparation method for the above-mentioned nylon material. According to the invention, the epoxy resin is adopted for coating pretreatment of the metal microbeads, and the metal microbeads flow onto the surface of the material during the subsequent processing of the nylon material, thereby improving the gloss of the obtained product and reducing the phenomenon of emergence of glass fibers on the surface. Thus, the prepared intake manifold has a smooth surface and good use performance.

Owner:QINGDAO GON TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com