Ventilation system

a technology of ventilation system and air flow rate, which is applied in ventilation system, lighting and heating apparatus, heating types, etc., to achieve the effect of improving air flow rate, increasing flexibility in dimensioning the unit, and improving air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]Discussion will begin with a couple of simplified, not necessarily preferred embodiments of the present invention (shown in FIGS. 23-26) to illustrate some of the inventive concepts. Discussion will then proceed to a couple of preferred embodiments (shown in FIGS. 2 to 22).

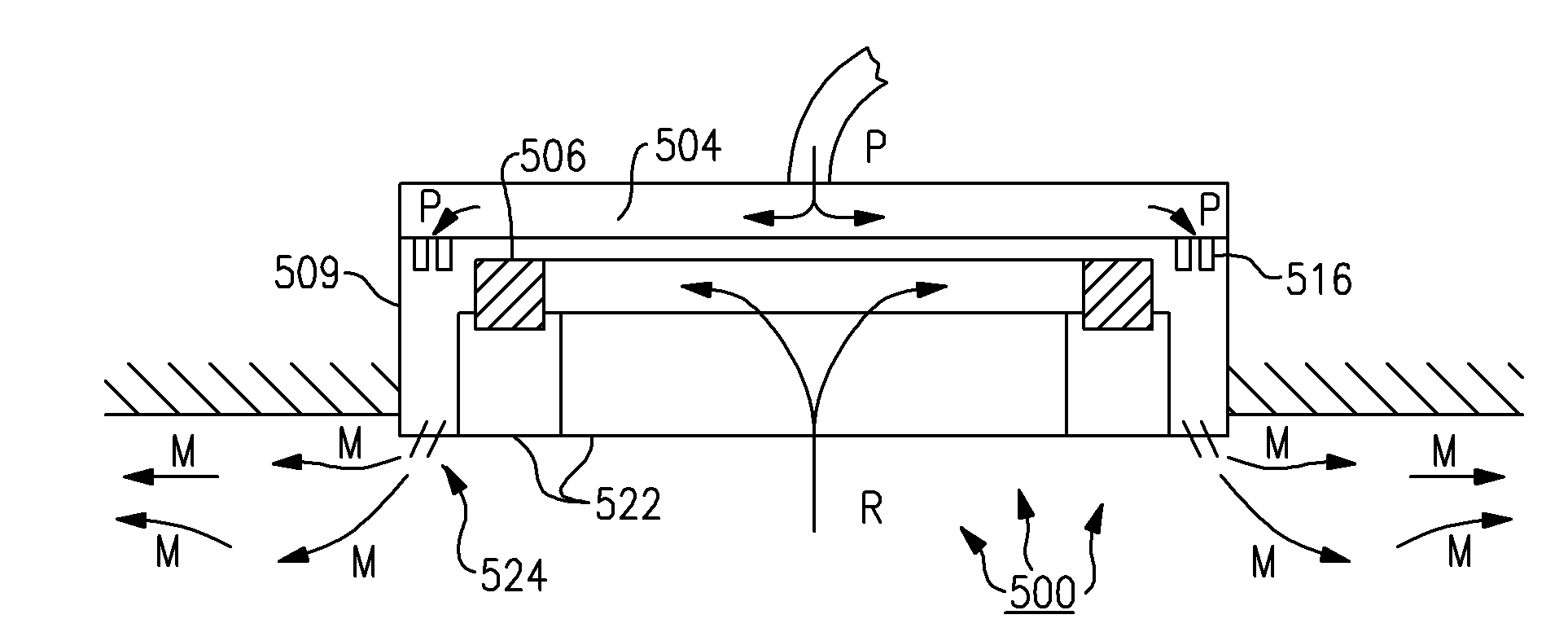

[0052]FIGS. 23a and 23b show ventilation system 400 according to the present invention, including: unitary plenum portion 404; heating / cooling unit 406; drainage base 407; mixing chamber outer wall 409; and venturi nozzles 416. Primary air P is blown into the unitary plenum portion from a primary air source (see DEFINITIONS section). The primary air is then forced through the nozzles 416 and down into the mixing chamber 406. Although only two nozzles are shown in FIGS. 23a and 23b, it is highly preferred that more nozzles be provided so that one or more rows of nozzles extend at least substantially all the way around the perimeter of system 400. In this embodiment, the mixing chamber is defined by the mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com