Skewed gas flow electric bag composite dust remover

A technology of electric bag compounding and oblique air flow, which is applied in the direction of combined devices, chemical instruments and methods, and separation of dispersed particles, can solve the problems of low dust removal efficiency, short service life of cloth bags, and low operating speed, so as to improve dust removal efficiency and increase The effect of large utilization area and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The structure and working process of the present invention will be described in detail below in conjunction with the accompanying drawings, but the implementation and protection of the present invention are not limited thereto.

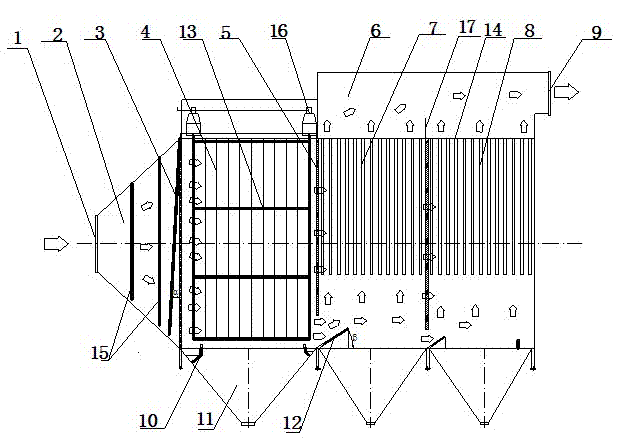

[0019] Such as figure 1 , oblique air flow type electrostatic bag composite dust collector, including air distribution area 2 distributed from left to right, electrostatic precipitator area 4 and bag dust removal area 7, dust collection area 11 is set below the electrostatic precipitator area 4 and bag dust removal area 7, There is a clean air area 6 above the bag dust removal area 7, and the five areas are installed in a housing; the air distribution area 2 includes two vertically placed air distribution plates 15 and an inclined air distribution plate 15 arranged at intervals from left to right. The airflow distribution plate 3 and the oblique airflow distribution plate 15 are located at the junction of the airflow distribution area 2 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com