Patents

Literature

54results about How to "Increase the effective working range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

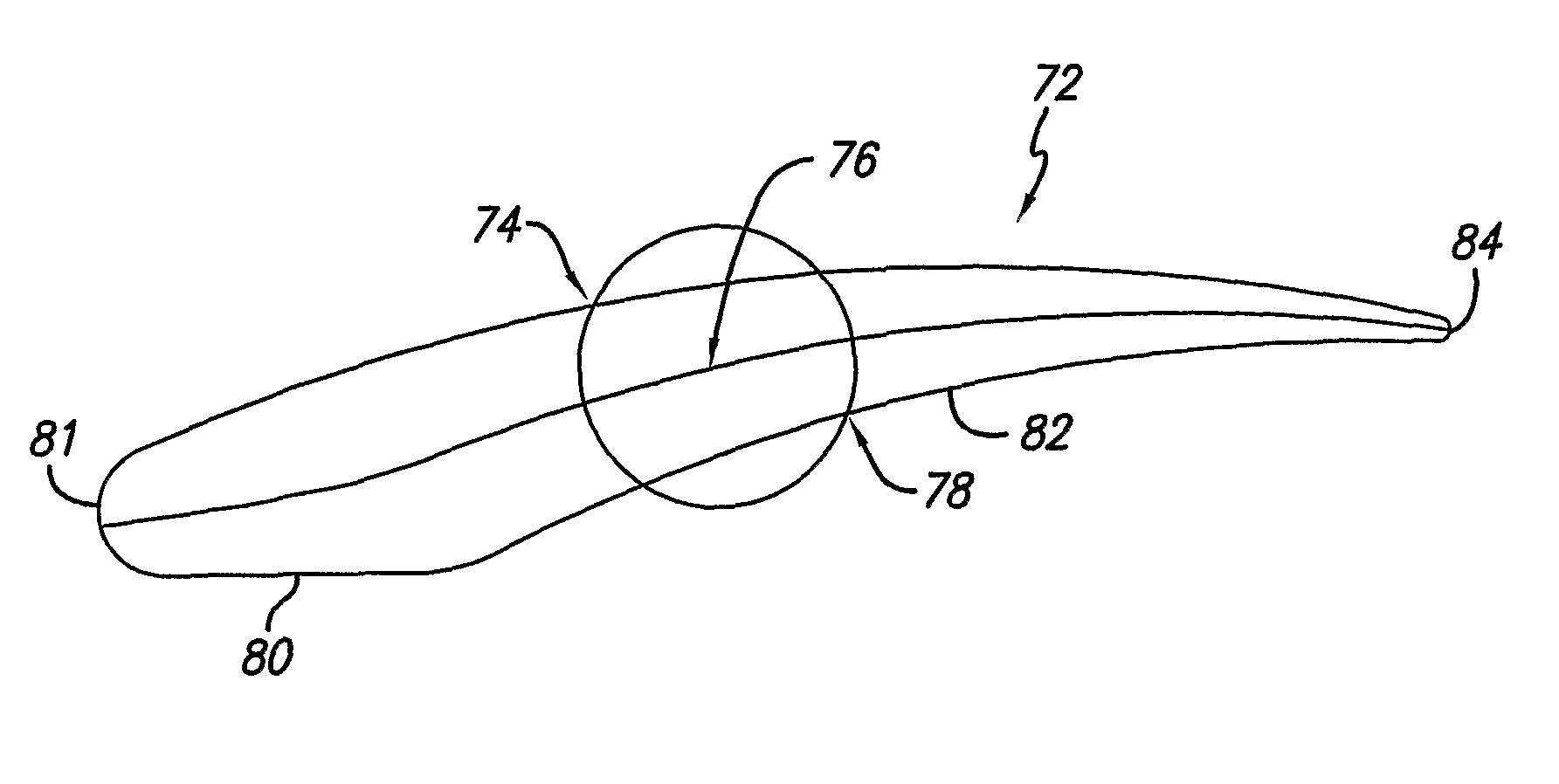

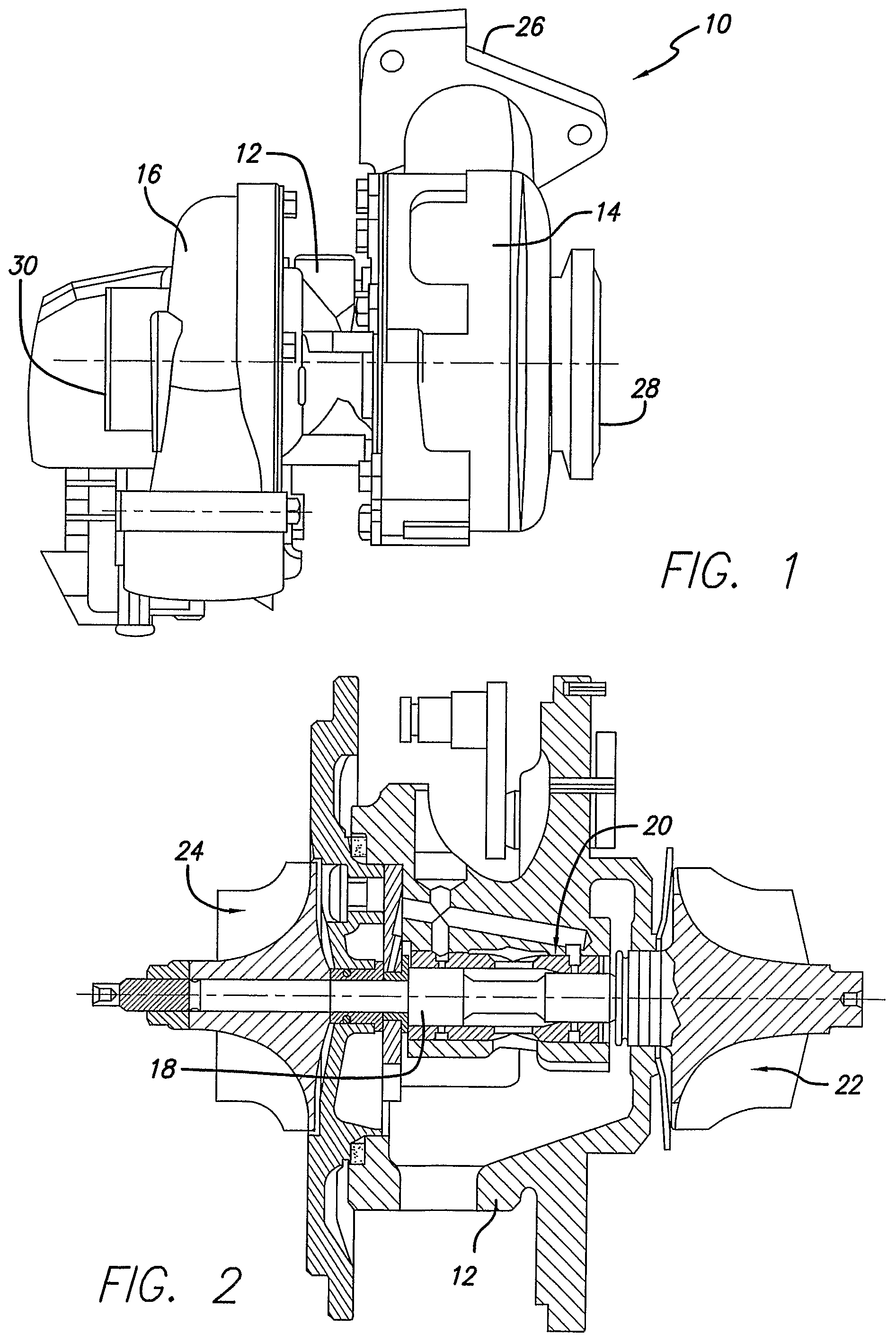

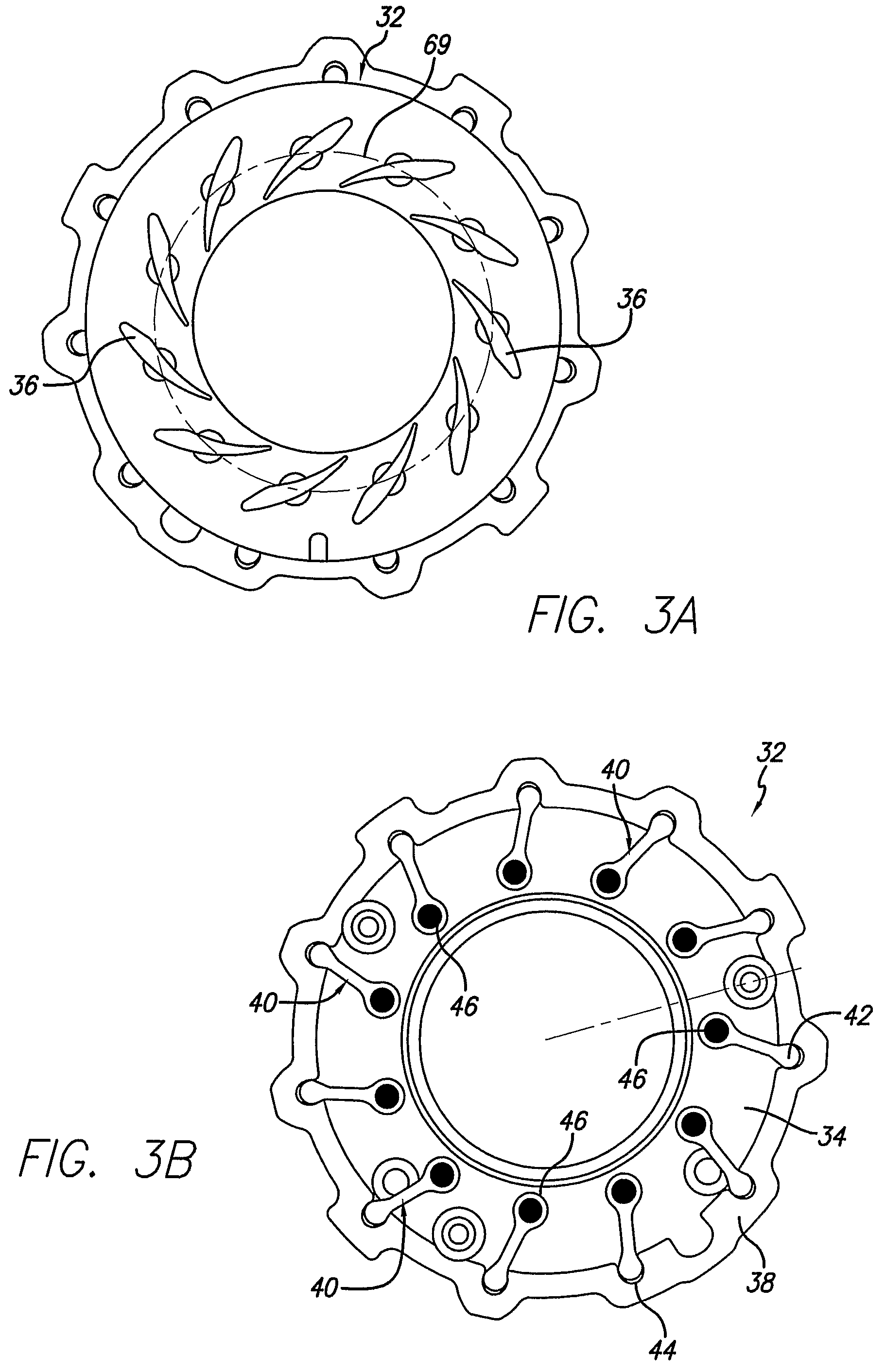

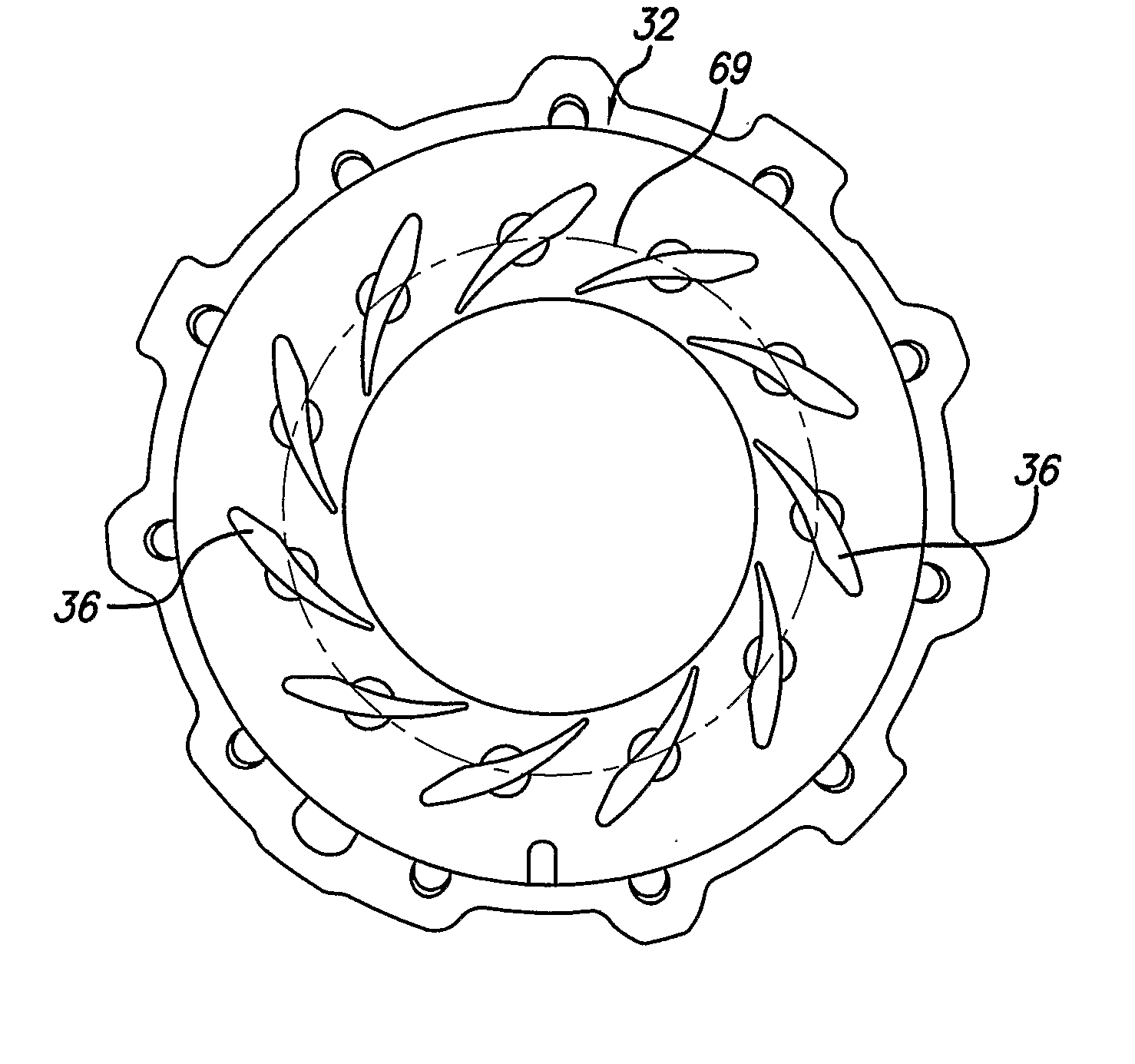

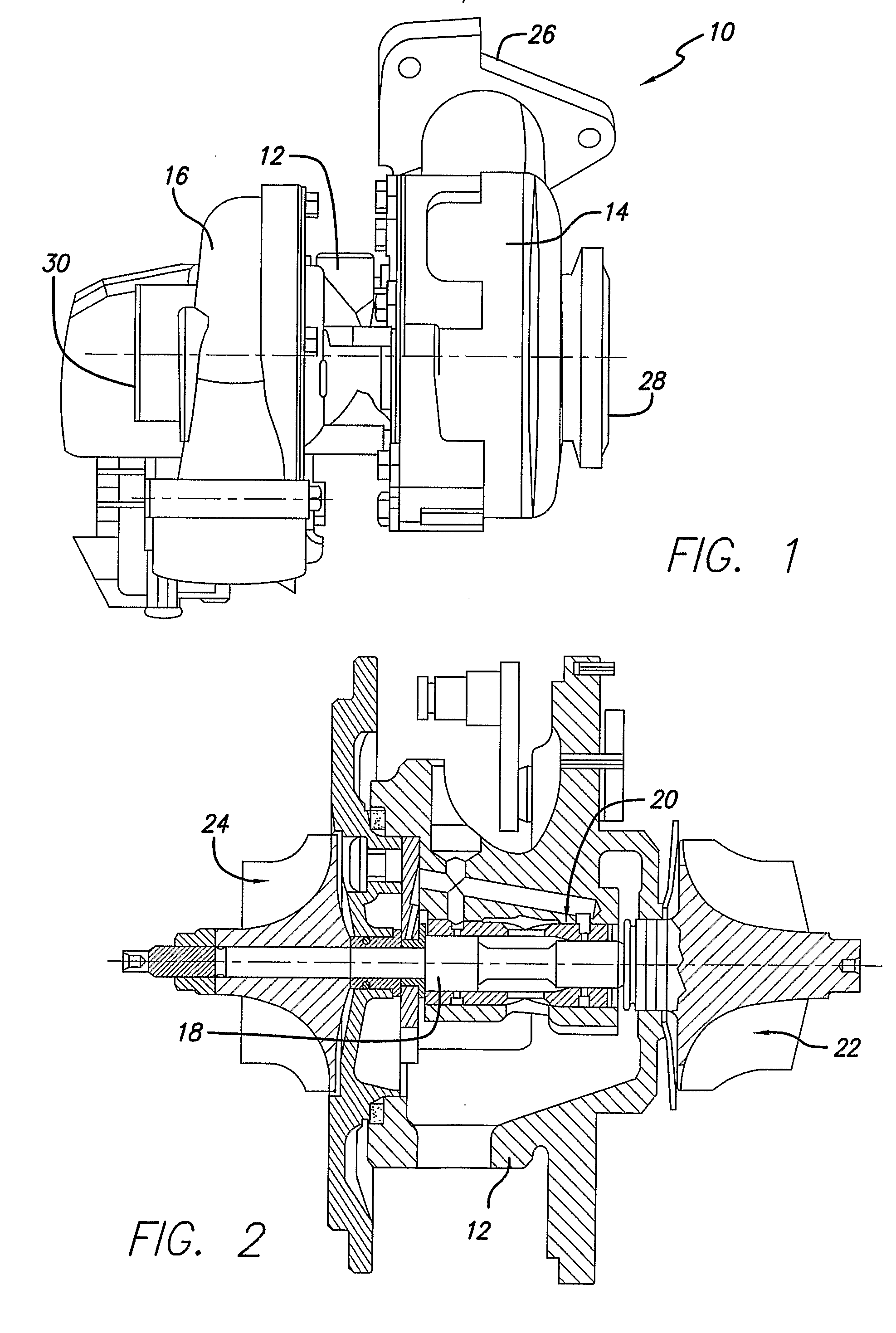

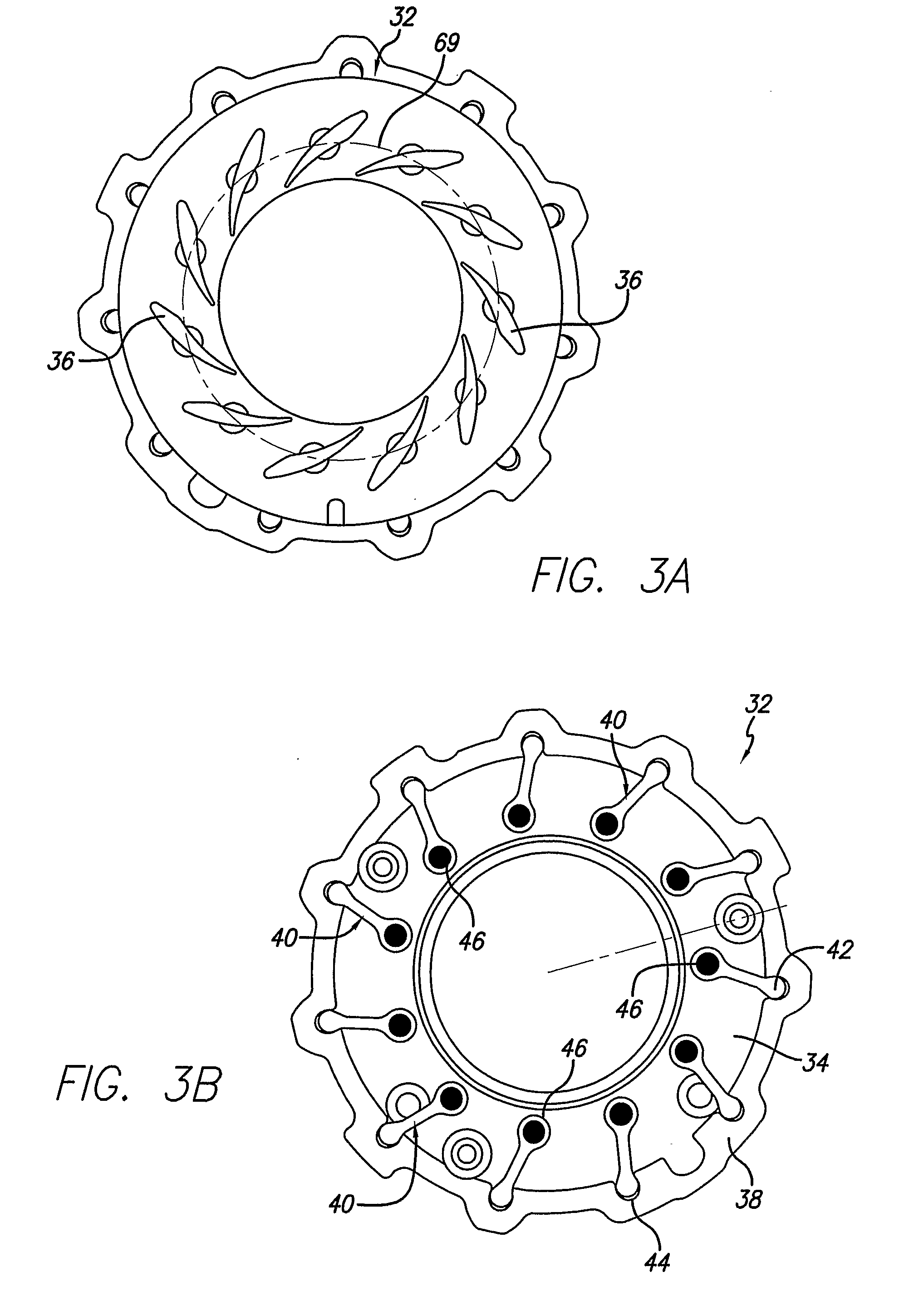

Cambered vane for use in turbochargers

InactiveUS7771162B2Increase the effective working rangeImproved air distributionWind motor controlPump componentsLeading edgeImpeller

Various cambered vanes are constructed for use within a vaned turbocharger and include an inner airfoil surface oriented adjacent a turbine wheel, and an outer airfoil surface oriented opposite the inner airfoil surface. The inner and outer airfoil surfaces define a vane airfoil thickness. A cambered vane leading edge or nose is positioned along a first inner and outer airfoil surface junction, and a vane trailing edge positioned along a second inner and outer surface junction. The vane inner and outer airfoil surfaces are specially configured to provide a vane camberline having a curved section, which can. provide for improved gas flow distribution, thereby increasing the effective operating range of the turbocharger.

Owner:HONEYWELL INT INC

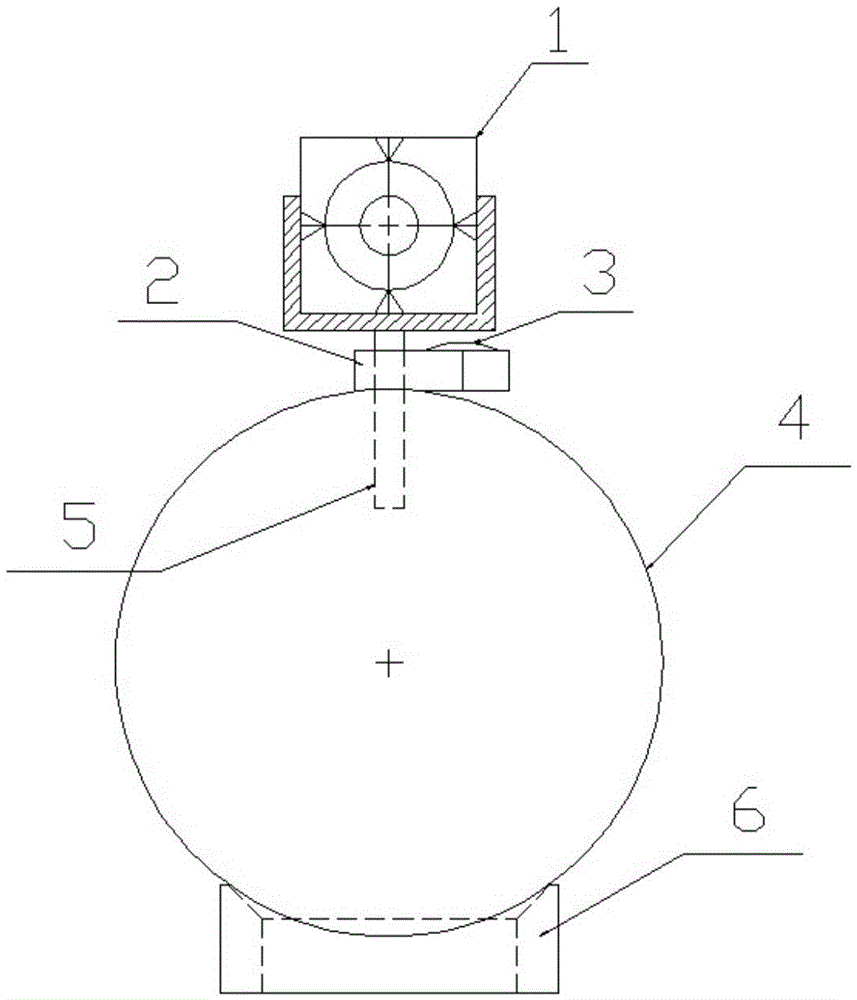

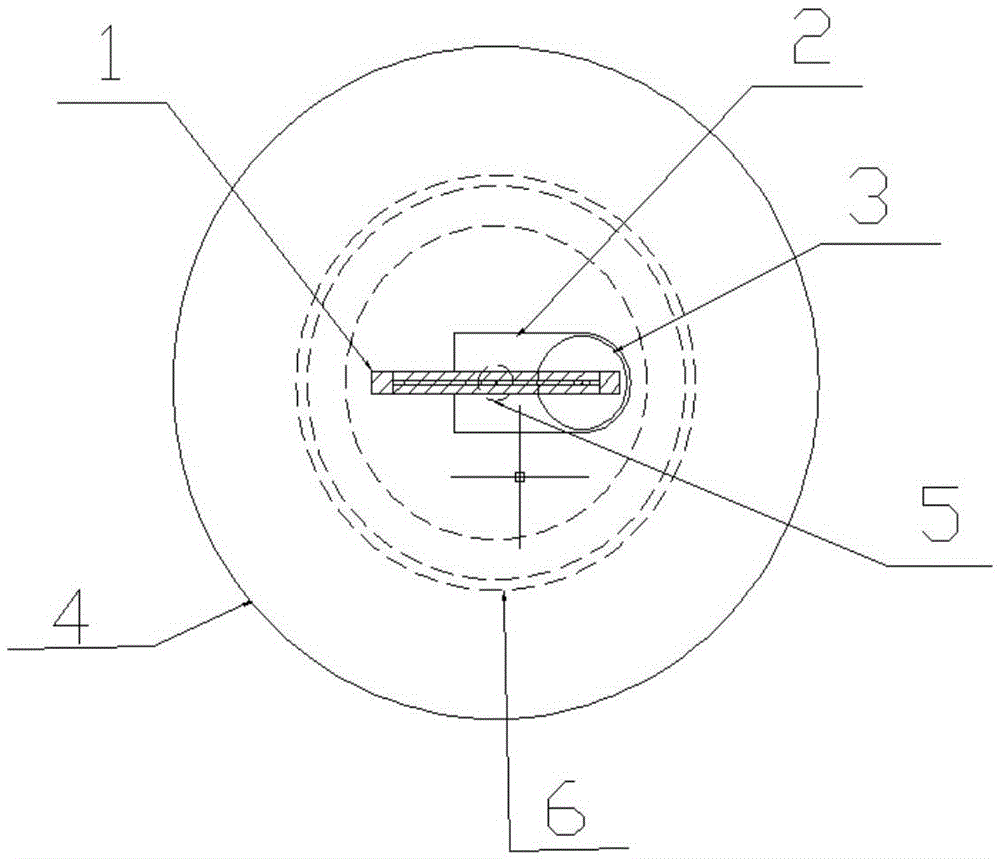

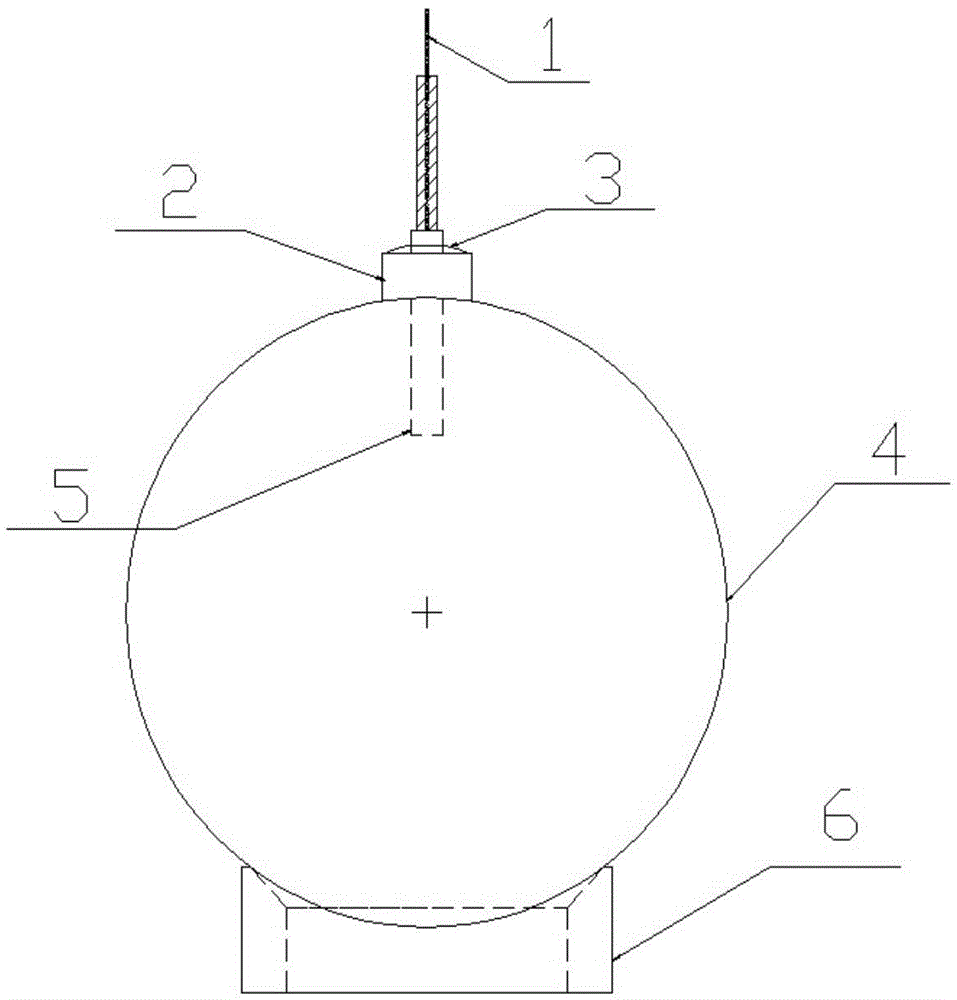

Multifunctional three-dimensional laser scanning target

InactiveCN105547269ASimple designNovel and reasonable designMeasuring points markingUsing optical meansLaser scanningOptoelectronics

The invention discloses a multifunctional three-dimensional laser scanning target. The multifunctional three-dimensional laser scanning target comprises a total station reflection plate, a horizontal platform and a three-dimensional laser scanning ball, wherein the lower end of the total station reflection plate is connected with the upper end of a supporting rod, the total station reflection plate is used for providing a clear target for total station observation, the horizontal platform is arranged in the middle of the supporting rod, a water level is arranged on the horizontal platform, the upper end of the three-dimensional laser scanning ball is connected with the lower end of the supporting rod, the three-dimensional laser scanning ball is used for a three-dimensional laser scanner to determine a central point coordinate of the three-dimensional laser scanning ball, and a fixed distance exists between the center of the three-dimensional laser scanning ball and the central height of the total station reflection plate. The total station reflection plate, the horizontal platform, the three-dimensional laser scanning ball and a supporting rod axis are located on the same straight line. The multifunctional three-dimensional laser scanning target is simple in structure, reasonable in design, convenient to use and operate and low in cost. In addition, the total station reflection plate and the three-dimensional laser scanning ball are combined, the size of an apparatus is decreased, the laser scanning target is convenient to carry, good in practicability and convenient to popularize and apply, and meanwhile the acquisition efficiency and accuracy of data are improved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Cambered vane for use in turbochargers

InactiveUS20070107426A1Improved air distributionEasy to operateWind motor controlPump componentsLeading edgeImpeller

Cambered vanes of this invention are constructed for use within a vaned turbocharger and comprise an inner airfoil surface oriented adjacent a turbine wheel, and an outer airfoil surface oriented opposite the inner airfoil surface. The inner and outer airfoil surfaces define a vane airfoil thickness. A cambered vane leading edge or nose is positioned along a first inner and outer airfoil surface junction, and a vane trailing edge positioned along a second inner and outer surface junction. The vane inner and outer airfoil surfaces are specially configured to provide a vane camberline having a curved section. Specifically, the vane camberline curved section has a measure of curvature is defined within a degree of tolerance by a vane placement or pivot diameter, as generally measured between diametrically opposed vanes mounted in the turbocharger, for providing improved gas flow distribution, thereby increasing the effective operating range of the turbocharger.

Owner:HONEYWELL INT INC

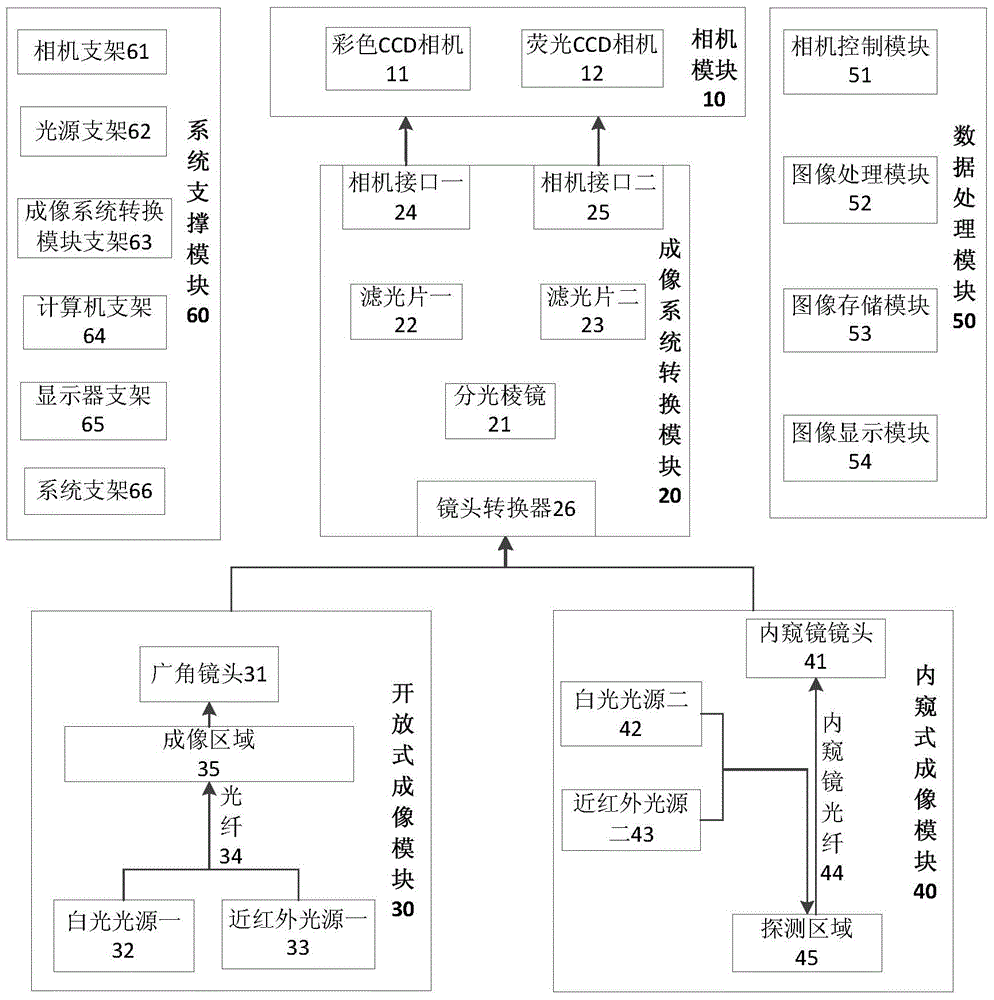

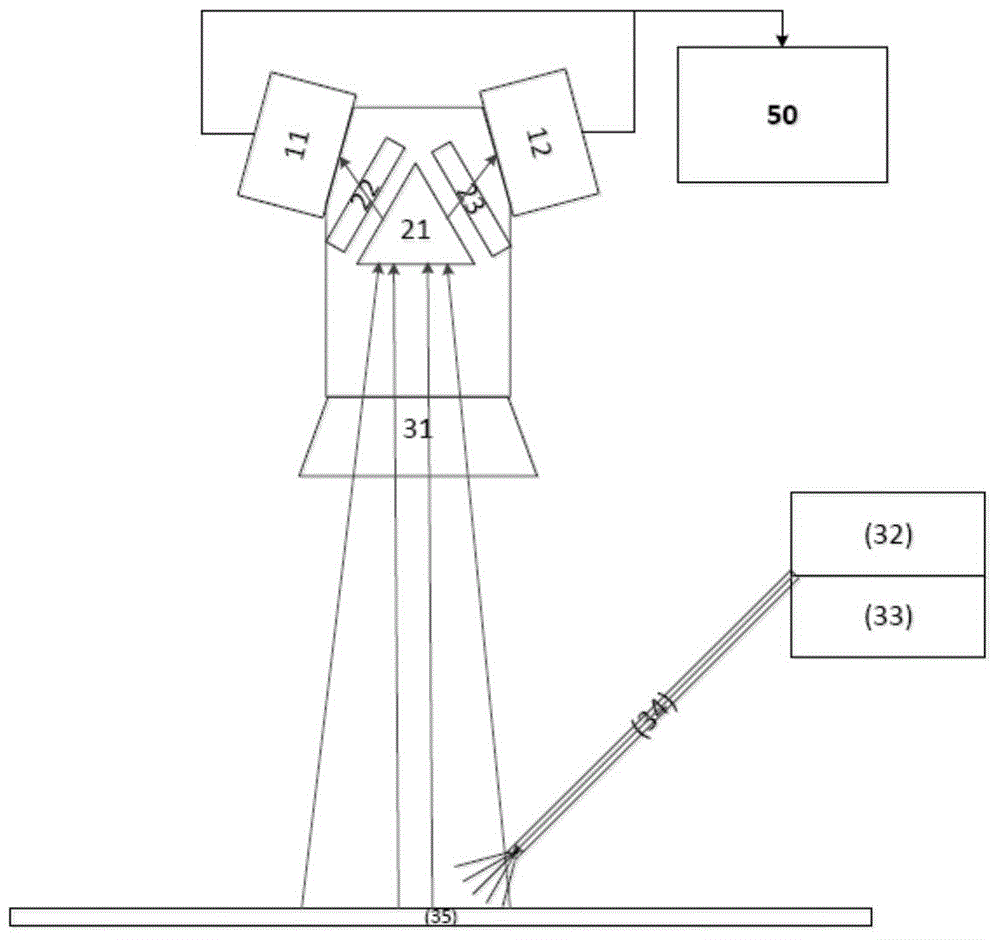

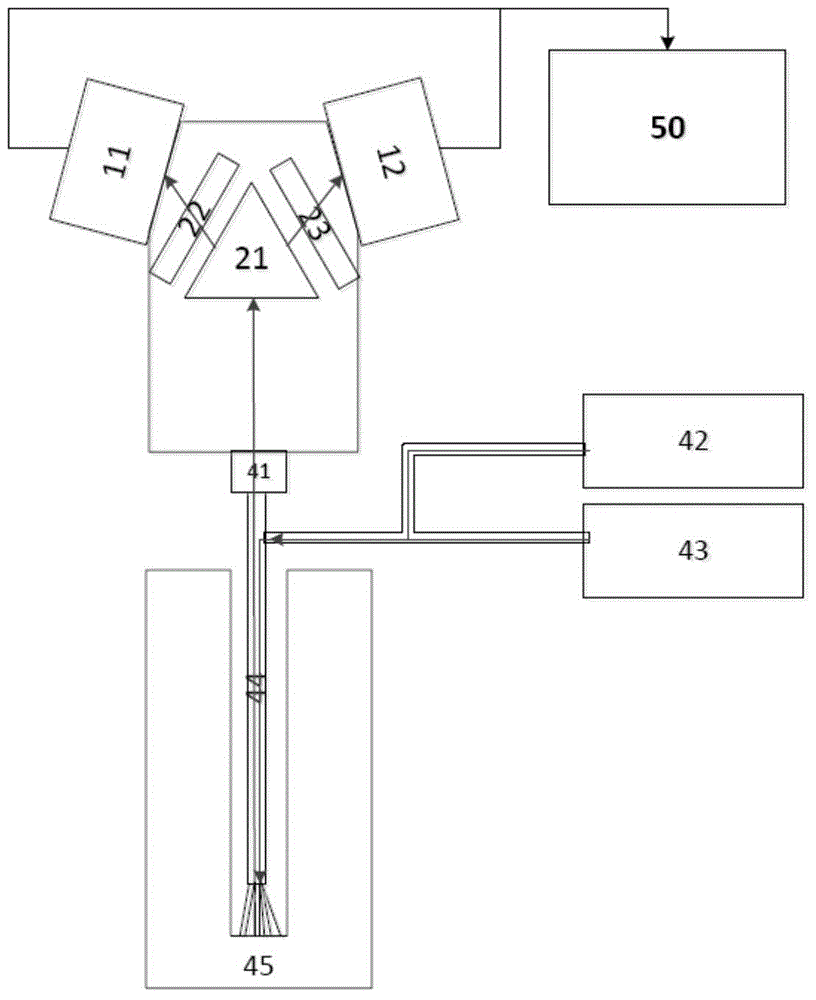

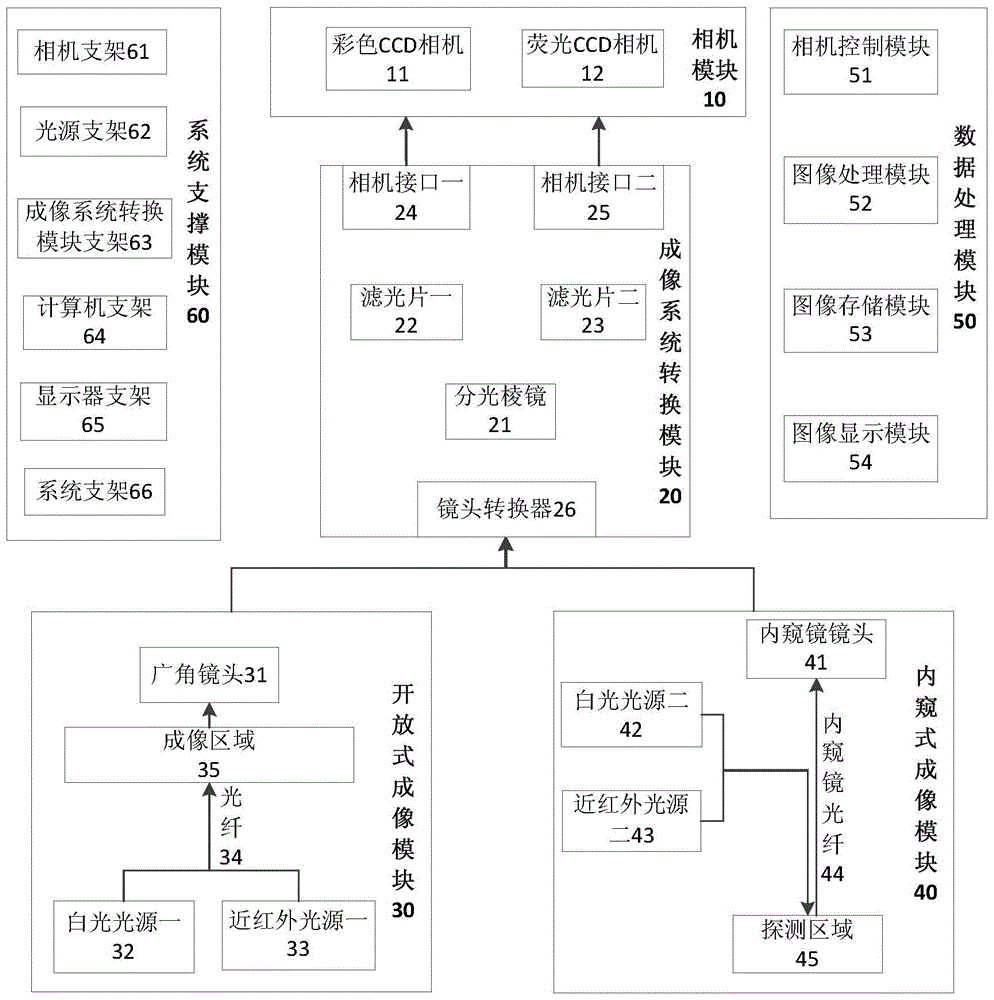

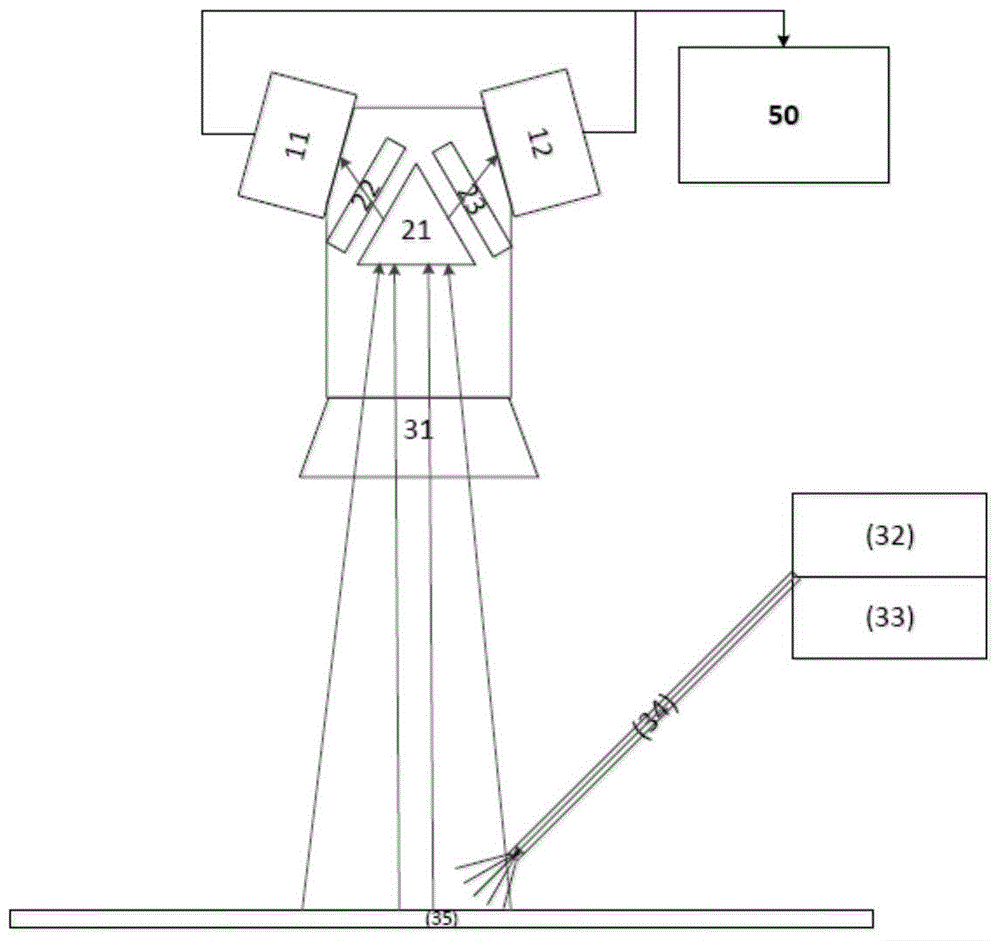

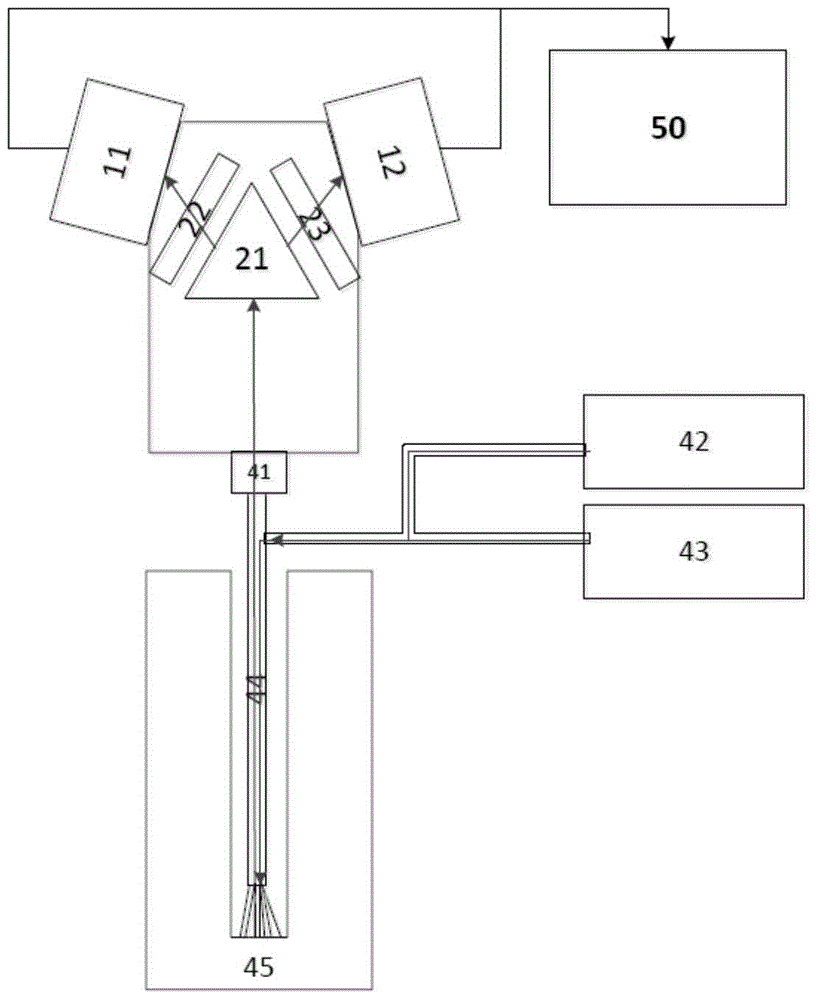

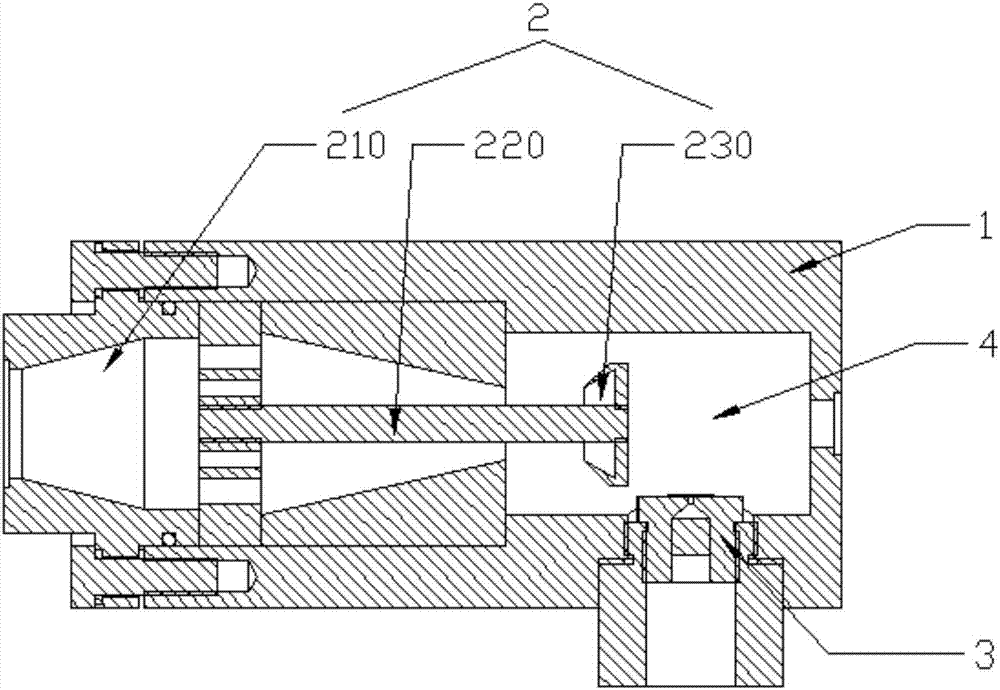

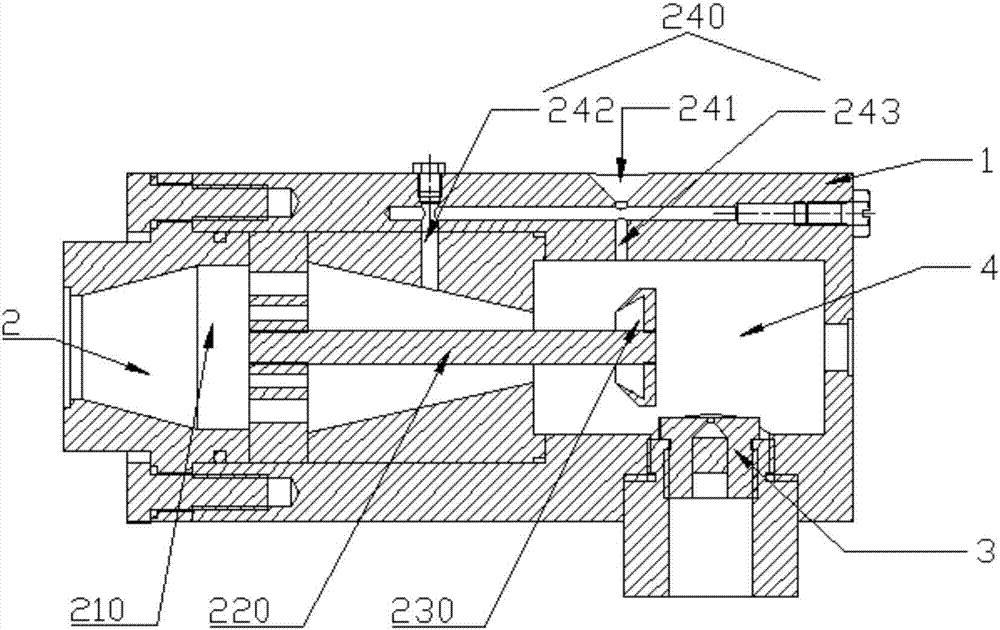

View-switchable dual-optical-path molecular image navigation system and imaging method

ActiveCN104367380AIncrease the effective working rangeSurgeryDiagnostic recording/measuringCamera controlFluorescence

The invention discloses a view-switchable dual-optical-path molecular image navigation system and an imaging method. The view-switchable dual-optical-path molecular image navigation system comprises a camera module, an imaging system switching module, an open-type imaging module, an endoscopic-type imaging module, a data processing module and a system support module. The camera module is used for color imaging and fluorescence imaging. The imaging system switching module is used for switching an open-type imaging mode or an endoscopic-type imaging mode according to imaging need. The open-type imaging module is used for large-view observation imaging. The endoscopic-type imaging module is used for deep-view detection imaging. The data processing module is used for providing camera control software and image acquisition, processing and display methods. The system support module is used for providing support and connection for navigation equipment.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

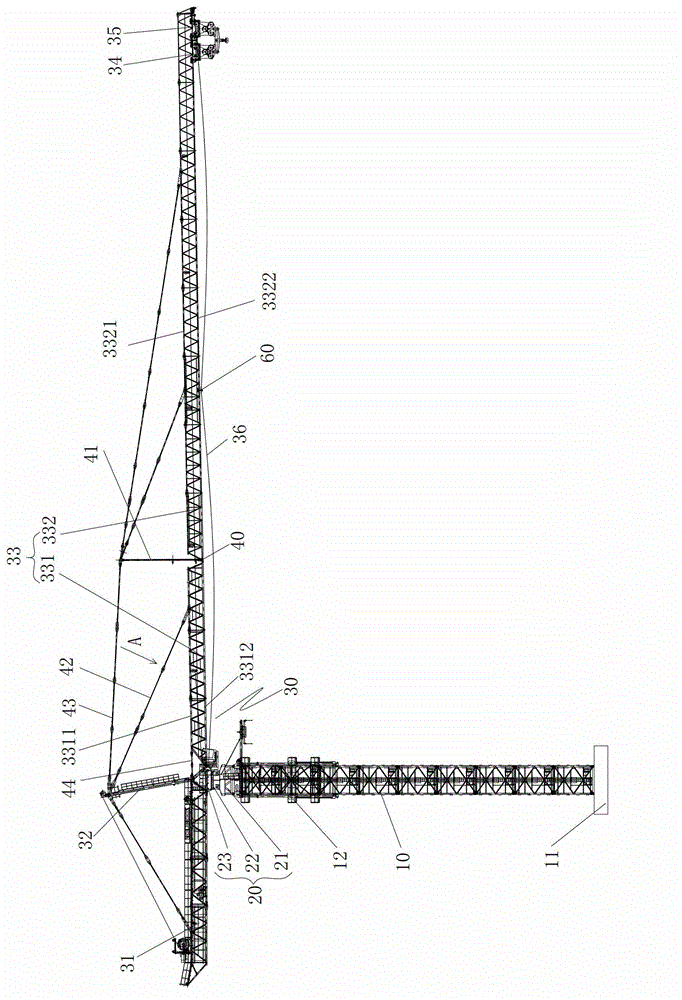

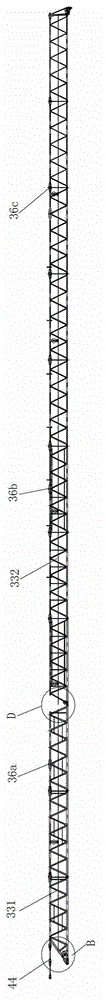

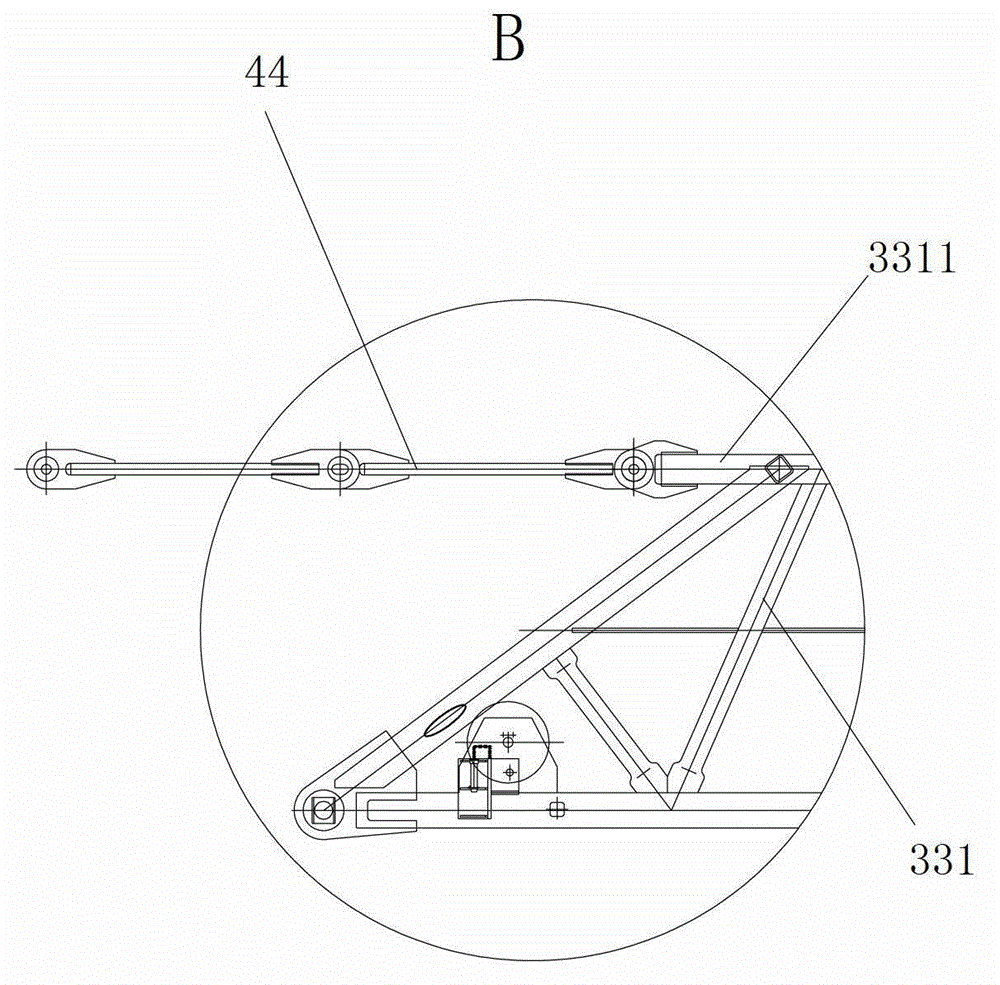

Tower crane

The invention provides a tower crane, which comprises a tower body, a slewing mechanism which is arranged at the top of the tower body, and a superstructure which is arranged on the slewing mechanism. The superstructure comprises a tower crane jib, a top mast and a balance arm. The tower crane is characterized in that the tower crane jib comprises a jib frame, the jib frame comprises a jib root and a jib tip, the section of the jib root is quadrilateral, the section of the jib tip is triangular, the jib root is fixedly connected with the slewing mechanism, the jib tip lower chord of the jib tip is rotatably connected with the jib root lower chord of the jib root, the jib tip upper chord of the jib tip is disconnected from the jib root upper chord of the jib root, the jib root is connected to the top mast through a first draw bar and the jib tip is connected to the top mast through a second draw bar. The tower crane has the advantages that the lateral bearing capacity of the tower crane jib can be obviously improved, the stability of the tower crane jib is improved, the superstructure of the tower crane is reduced and the cost of the tower crane is decreased.

Owner:ZOOMLION HEAVY IND CO LTD

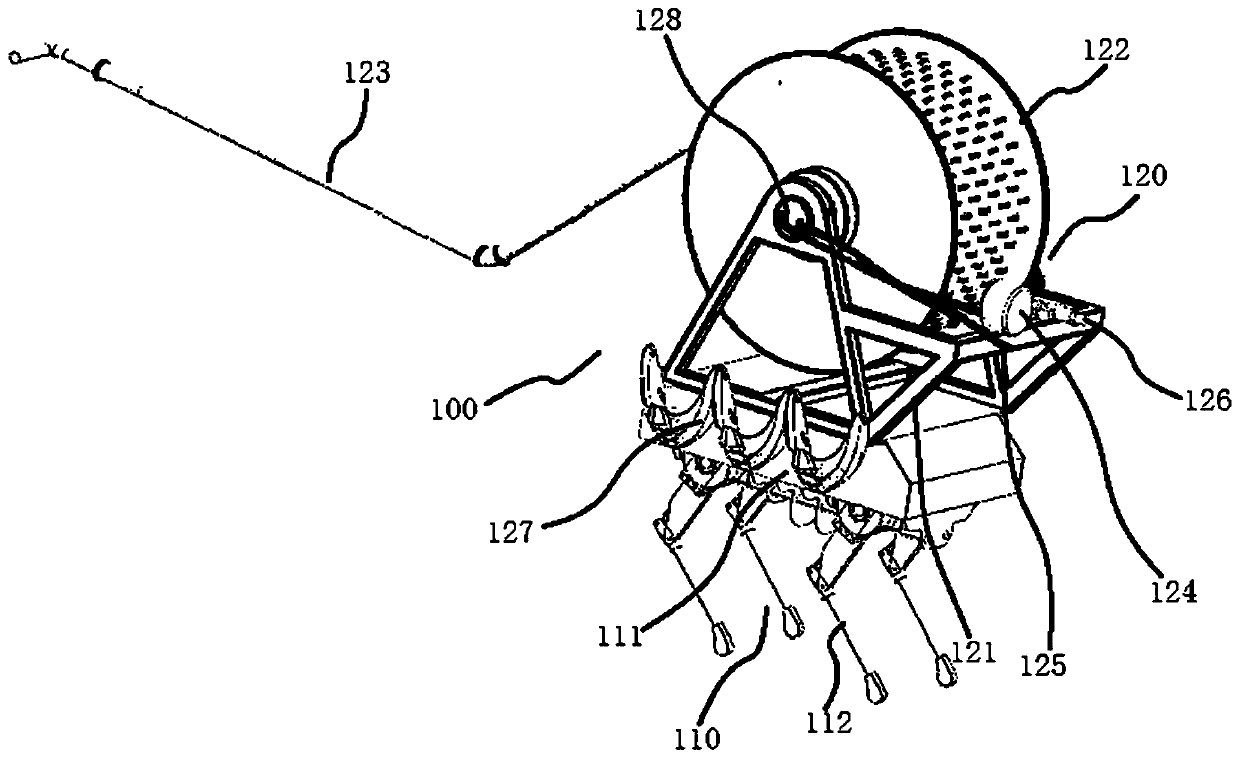

Spiral winding device for stripy article

InactiveCN107815906AAvoid damageIncrease the effective working rangeRope making machinesMotor shaftWorking range

The invention discloses a spiral winder for strip objects, which includes a support base plate, one side of the upper surface of the support base plate is fixed with a support seat by bolts, a motor installation shell is installed on the top of the support base, and the motor installation shell An electric motor is installed inside, a turbo air booster mechanism is installed at the end of the motor shaft in the motor, and a support rod fixed on the upper surface of the support substrate is installed at the bottom of the turbo air booster mechanism, and a turbo air booster mechanism is installed at the center of one end surface of the turbo air booster mechanism first axis of rotation. The present invention utilizes the driving function of the rotary type to wind a plurality of strip objects. In addition, the device has an independent winding tension control mechanism during winding, which can effectively prevent damage to objects and components caused by winding. Moreover, the device has a turbo air supercharging mechanism, which can play a role of supercharging, thereby increasing the effective working range of the device, improving the practicability of the device, and improving the yield.

Owner:李少许

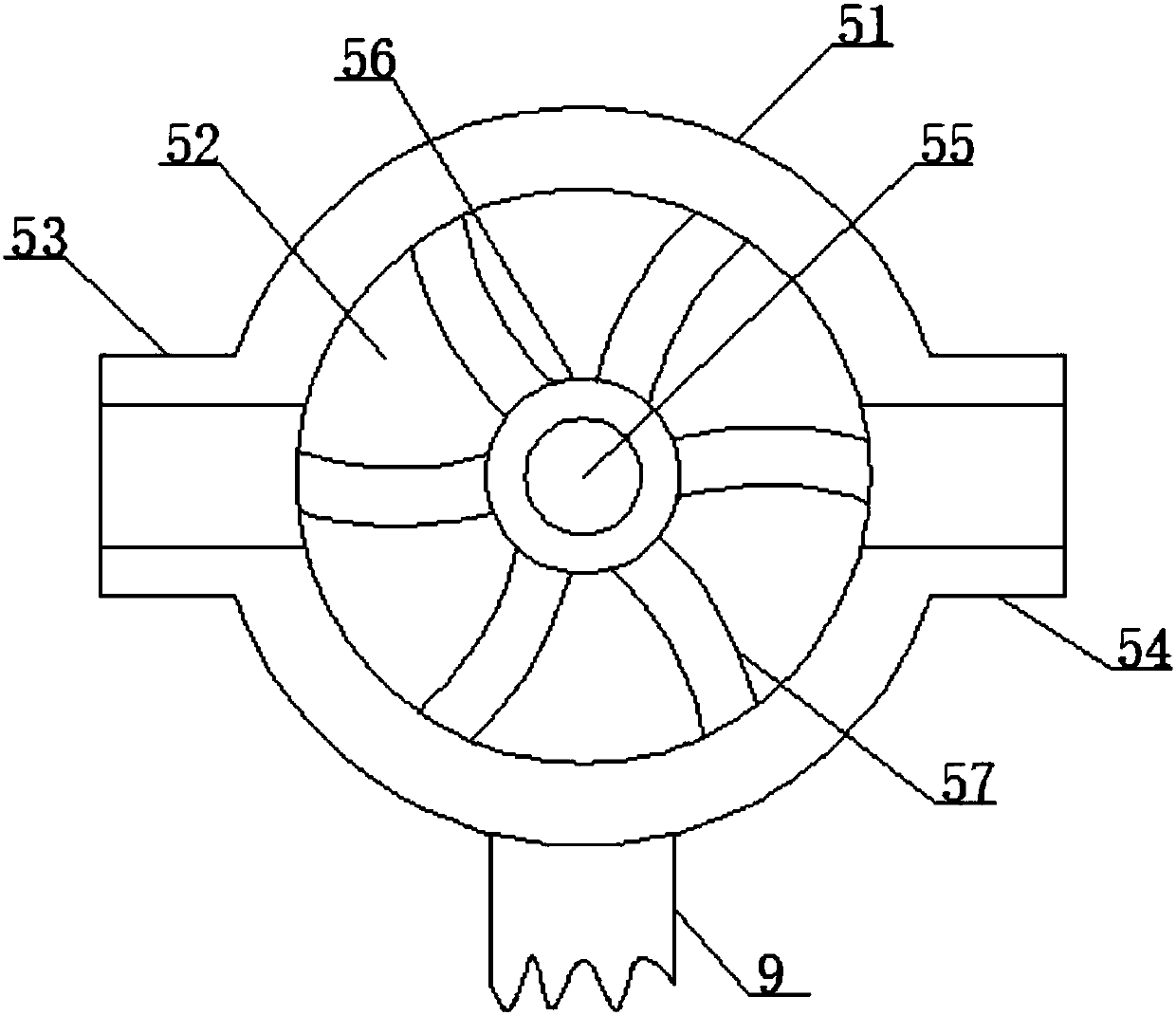

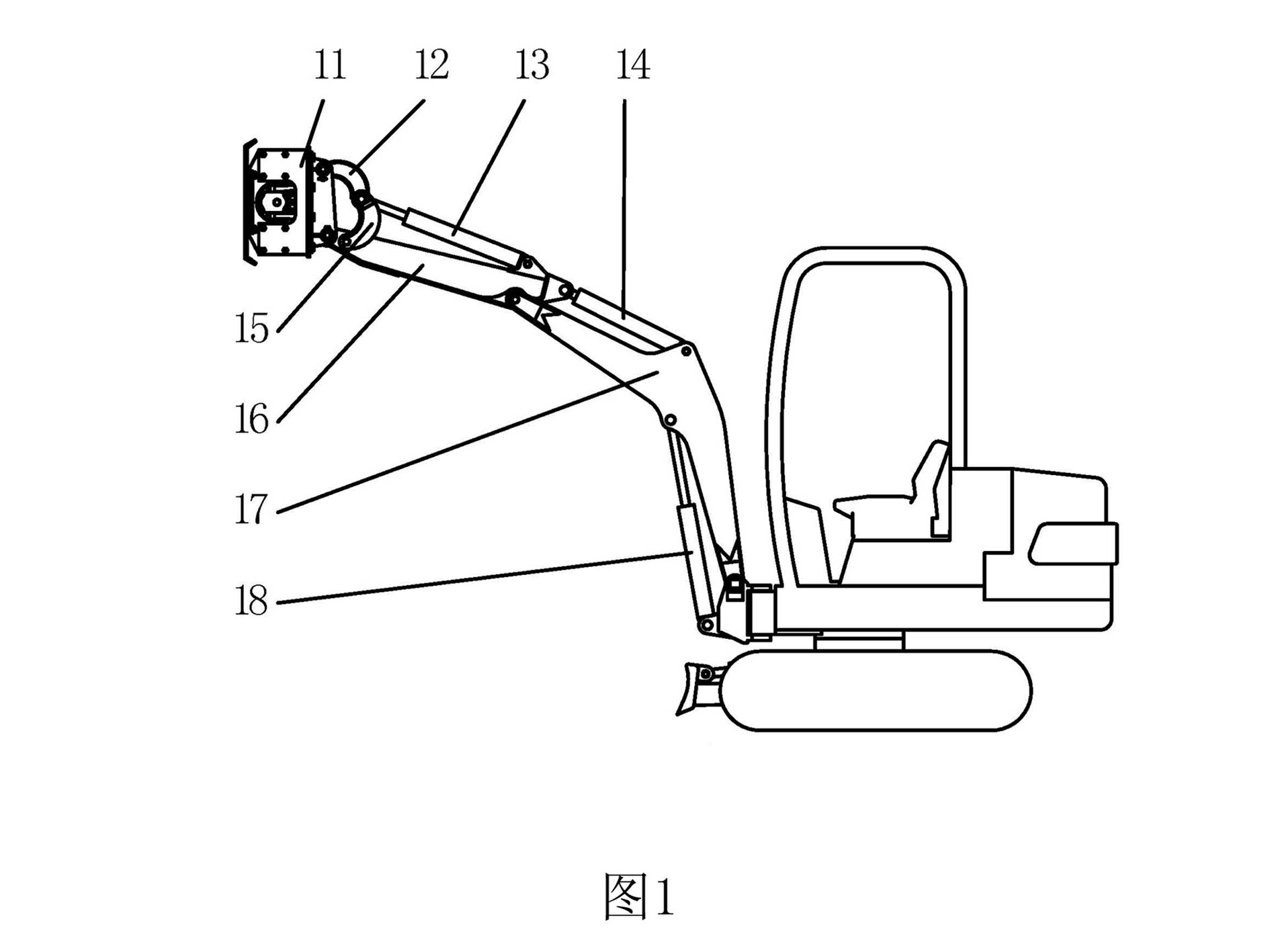

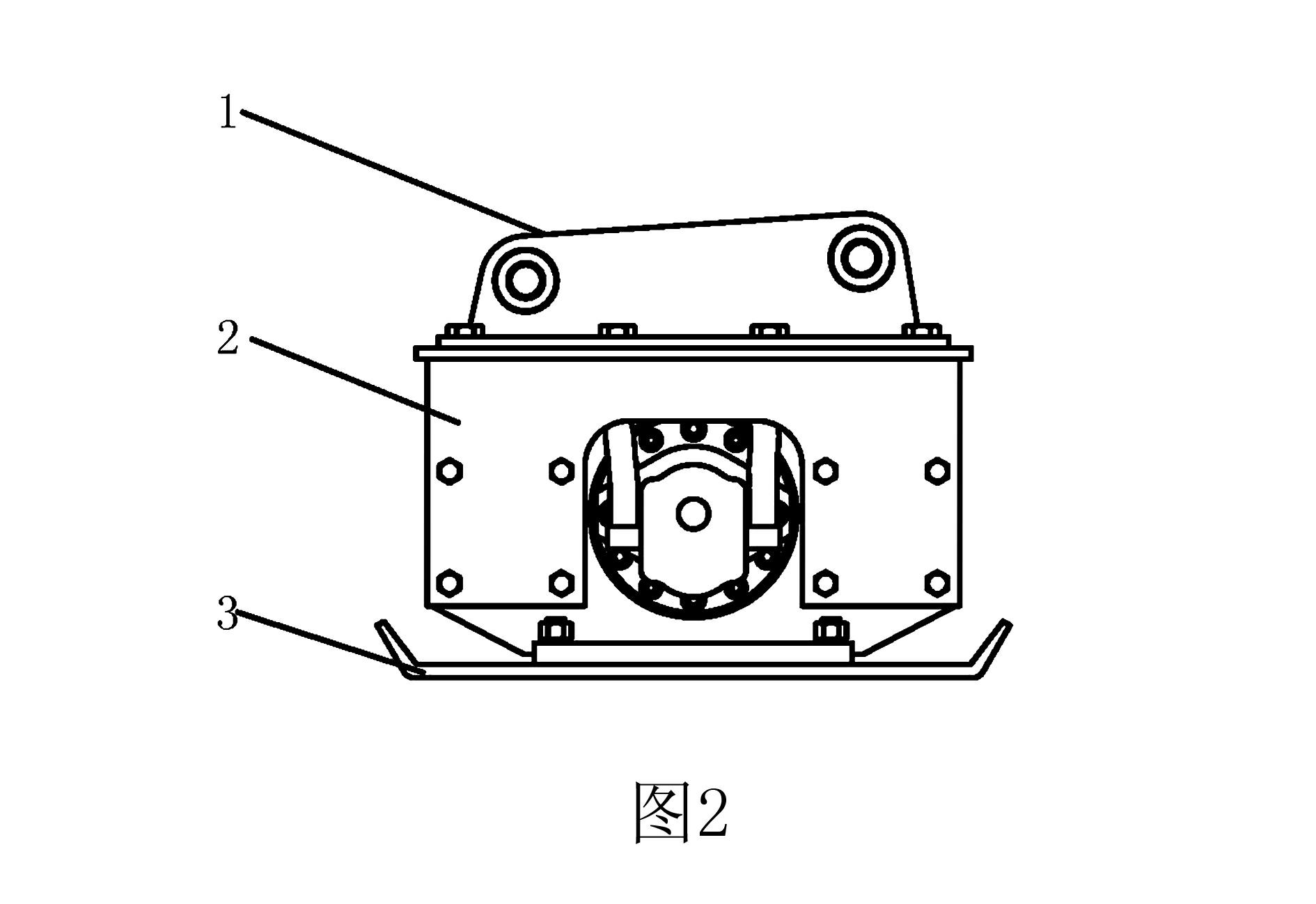

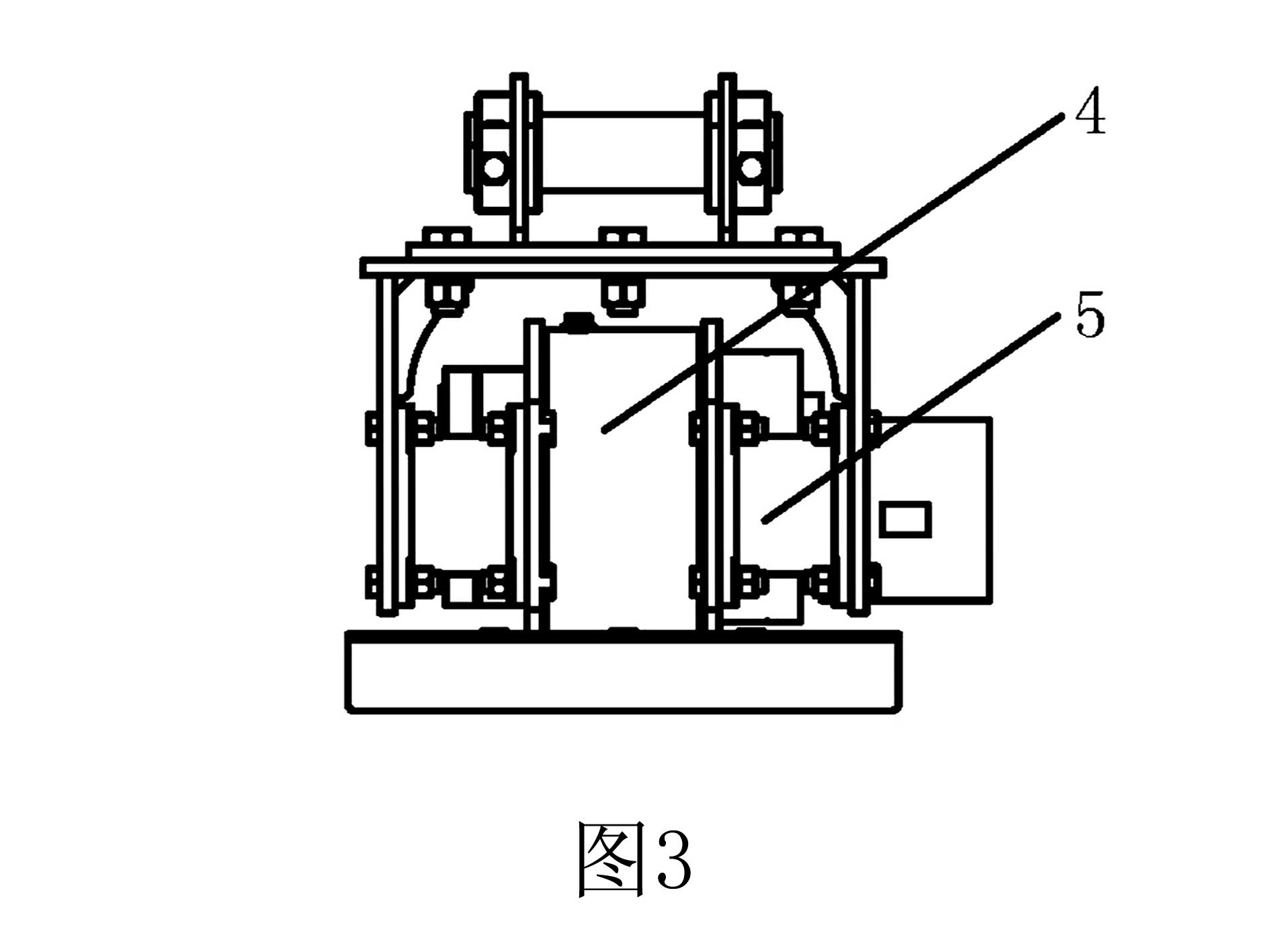

Vibration rammer with horizontal vibration function

InactiveCN102277970AWith horizontal vibration functionIncrease the effective working rangeBuilding material handlingHydraulic motorVertical vibration

A vibrating rammer with a horizontal vibration function is composed of a connecting frame and a supporting frame to form a casing, a vibration exciter is installed in the casing through a vibration-damping rubber block, and a tamping plate is installed on the lower part of the casing. The vibration exciter is composed of an output main shaft installed in the tamper shell through a stop bearing, the output main shaft is connected with a hydraulic motor, and a polarizing block is arranged on the output main shaft. The connecting frame is connected to the hydraulic excavator through sticks and connecting rods. The vibratory rammer with horizontal vibration function has a larger working range and vertical vibration capability. During the construction of raw earth buildings, the defects of low safety and low work efficiency of operators working at high places are overcome. The vibration rammer provided by the invention has the function of horizontal vibration, has simple structure and easy operation, and can perform vertical and horizontal compaction work.

Owner:建研机械检验检测(北京)有限公司 +1

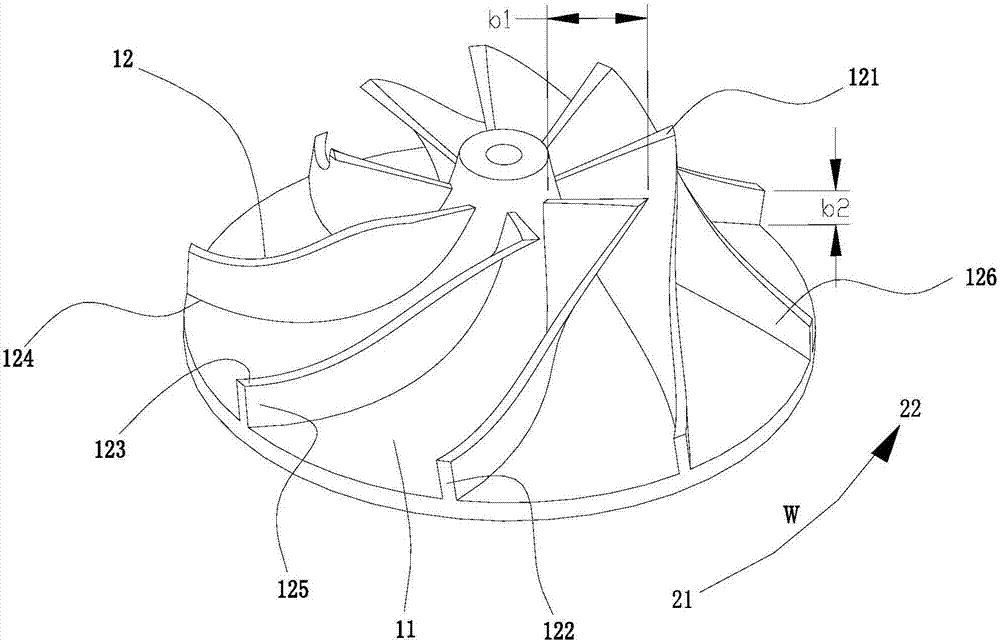

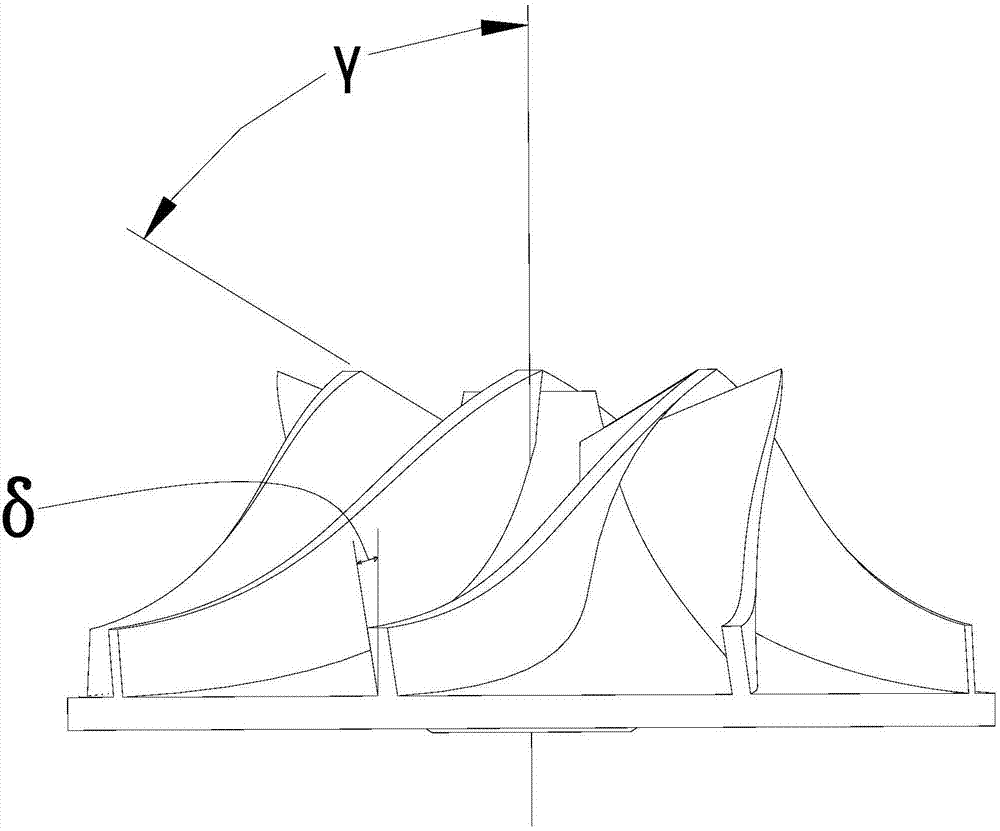

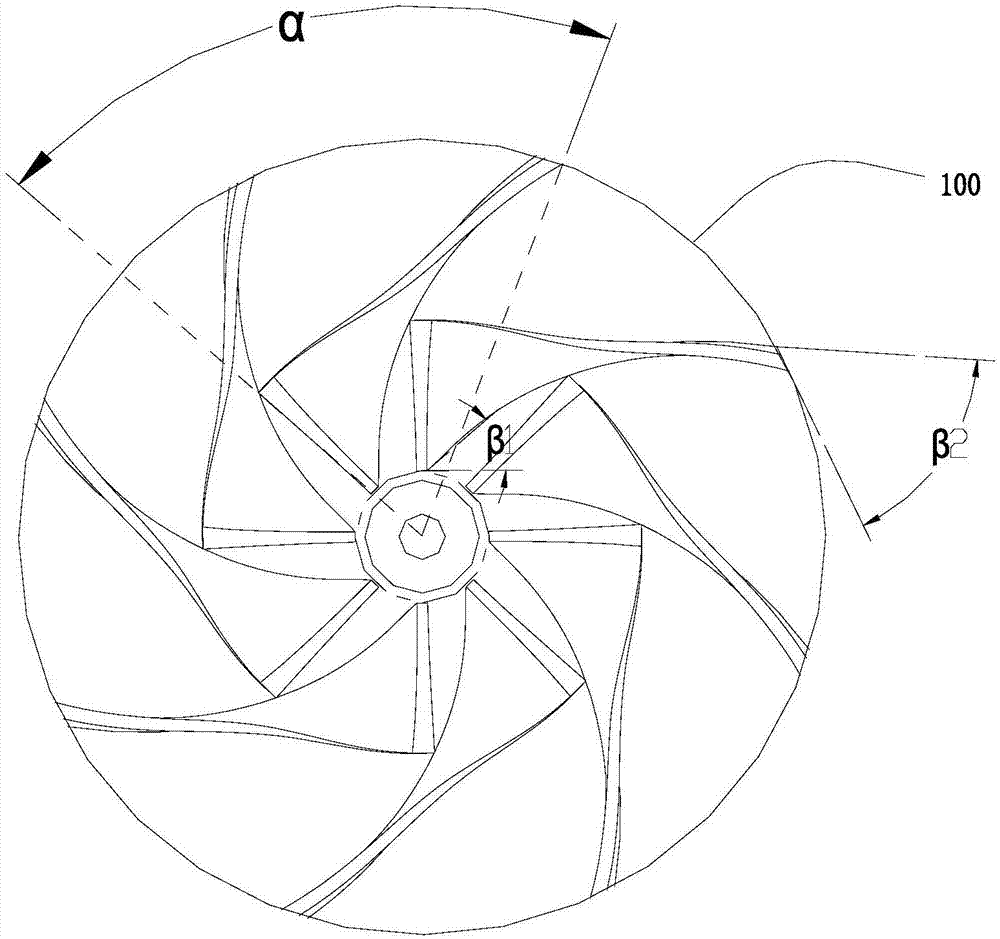

Impeller, fan and motor

PendingCN107143523AIncrease the effective working rangeImprove work performancePump componentsPumpsImpellerClassical mechanics

The invention discloses an impeller, a fan and a motor. The impeller (100) comprises an approximately-conic hub (11) and multiple blades (12) arranged on the outer circumferential face of the hub (11) at intervals in the circumferential direction. Each blade comprises a front edge face located at the inlet end and a rear edge face located at the outlet end. Each blade is a flat plate twisted blade. The blade rear edge segment of each blade is rotationally twisted and inclined relative to the circumferential direction. In the impeller, the shapes of the blades are subjected to optimization design, especially on the rear edge segments, the rear edge segments of the flat plate twisted blades are rotationally twisted and inclined by a certain angle relative to the circumferential direction, so that a concave face and a convex face are formed on the two side faces of the rear edge segment of each blade correspondingly, fluid losses at the outlet ends of the blades can be effectively reduced, the effective working range of the impeller can be expanded, and the working performance of the impeller can be greatly improved.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

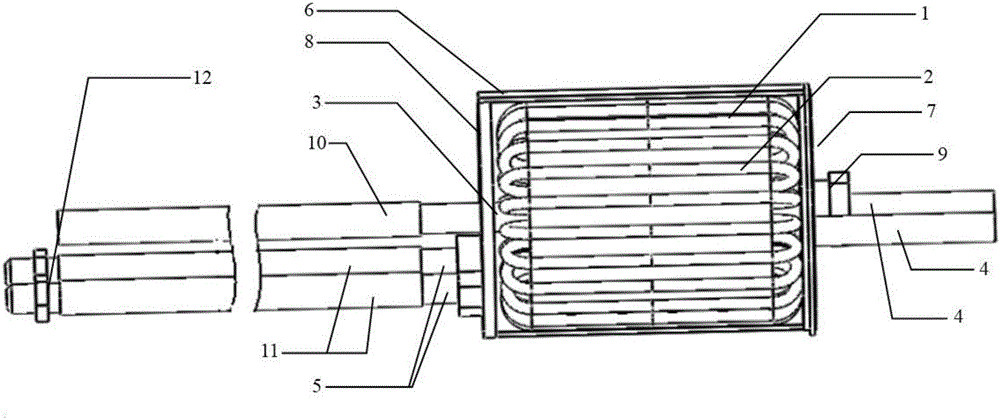

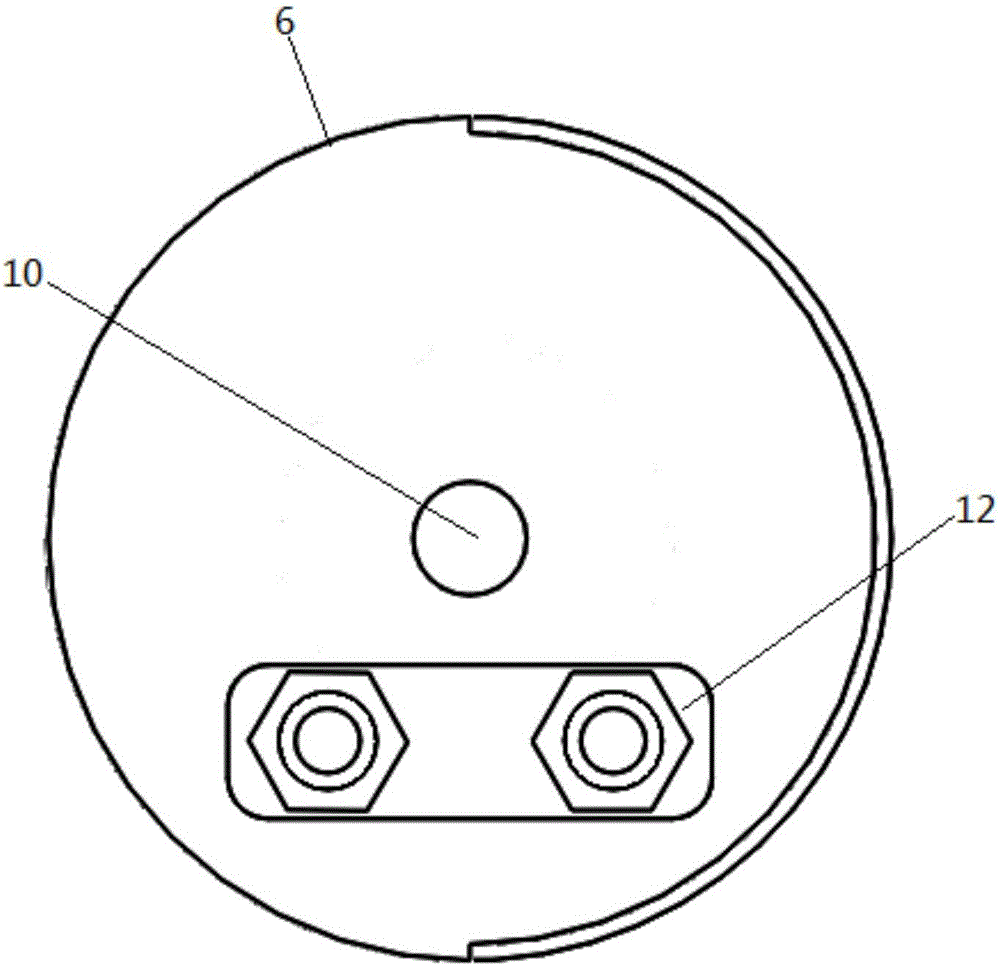

Induction-heating portable hand-held transformer

ActiveCN106653335ALow failure rateNo generationTransformers/inductances coolingTransformers/inductances casingsTransformerHand held

The invention discloses an induction-heating portable hand-held transformer comprising a hand-held housing. The transformer is arranged in the hand-held housing and comprises an external metal cylindrical body; the front and back ends of the external metal cylindrical body are respectively provided with a front end cover plate and a back end cover plate for sealing; an annular magnetic core is disposed in the external metal cylindrical body; the annular magnetic core is provided with a primary side lead to form a primary side winding set; one end of the primary side lead is connected to a water-electricity separation joint; a central hollow rod is disposed in the external metal cylindrical body; and the central hollow rod passes through the annular magnetic core to be connected with an auxiliary side joint of the front end cover plate and a water inlet pipe of the back end cover plate to form an auxiliary side loop to output power. The transformer is simply structured, has light weight and can be easily moved; functions, such as welding, quenching and metal melting of old water-cooled transformers can be realized; and the transformer has unparallel advantages in the field of metal tube wall powder re-melting.

Owner:西安北辰亿科电子科技有限公司

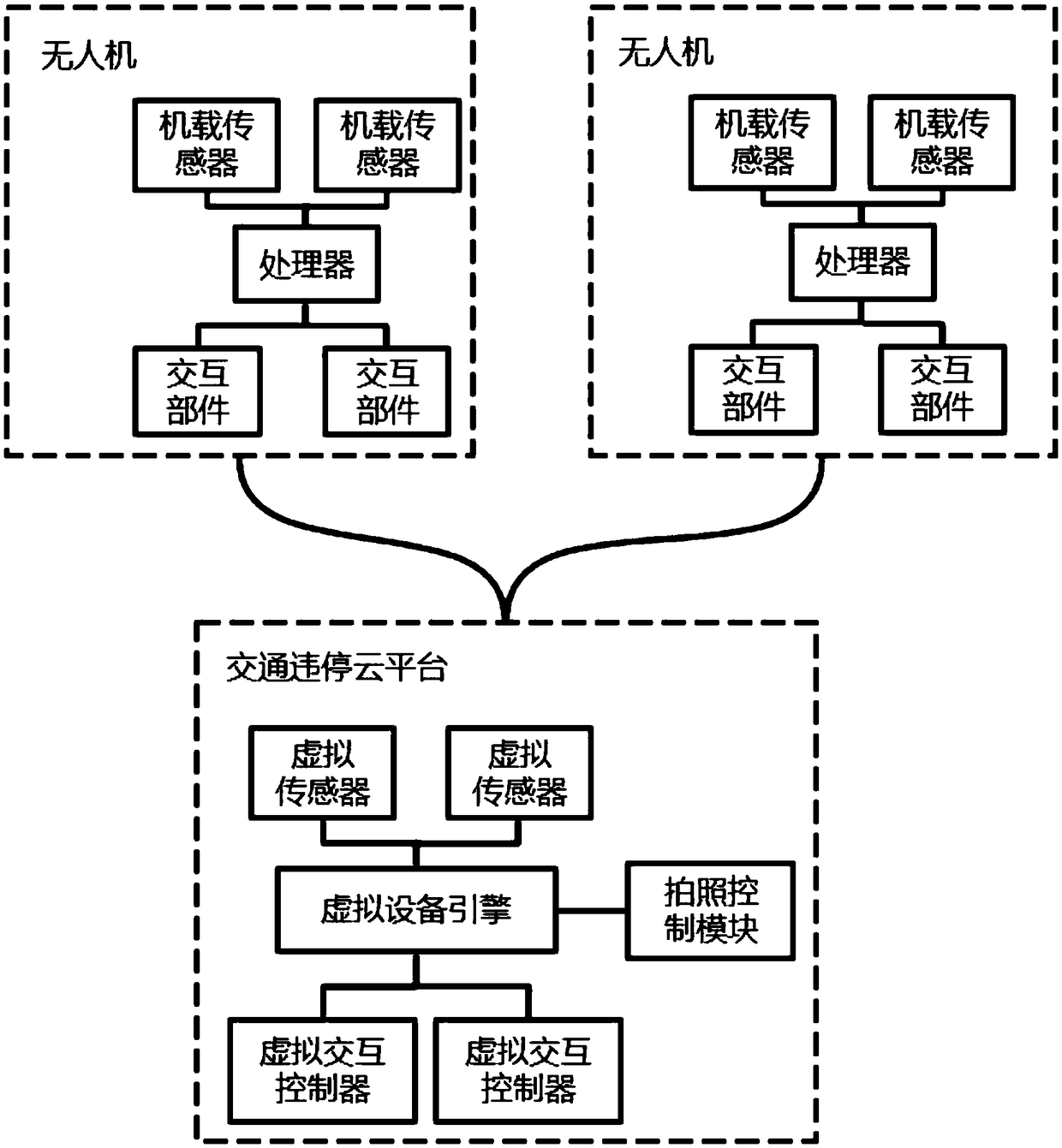

Illegal parking surveillance system based on cloud computing

ActiveCN109360423AReduced Power RequirementsReduce processing requirementsRoad vehicles traffic controlCamera controlVirtual sensors

The invention relates to an illegal parking surveillance system based on cloud computing. The illegal parking surveillance system comprises an illegal parking cloud platform and a plurality of drones.Each of the drones comprises a processor, an onboard sensor, and an interaction component. The illegal parking cloud platform comprises a virtual device engine, a camera control module, a virtual sensor, and a virtual interaction controller. The drone transmits initial data collected by the onboard sensor to the illegal parking cloud platform; the virtual sensor converts the initial data into initial redirect data; the virtual device engine converts and sends the initial redirect data to the camera control module; the camera control module generates a virtual action command after performing image recognition and analysis on the converted data; the virtual device engine receives the virtual action command and sends it to the virtual interaction controller; and the virtual interaction controller converts the virtual action command into an actual action command compatible with the interaction component of each of the drones, and transmits the actual action command via the network to enable the interaction component of each of the drones to execute an illegal parking photographing task.

Owner:ZHEJIANG FANGDA COMM

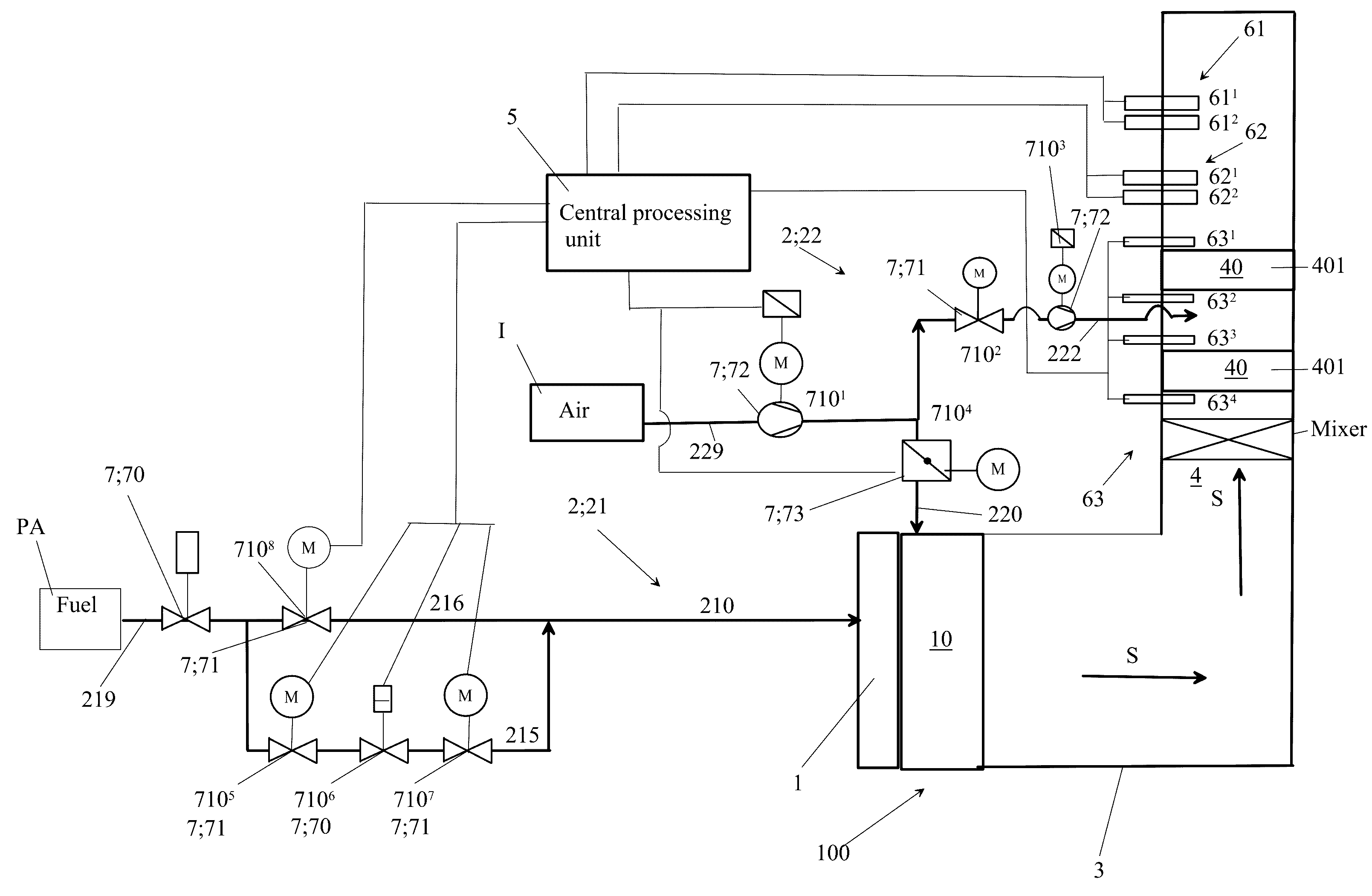

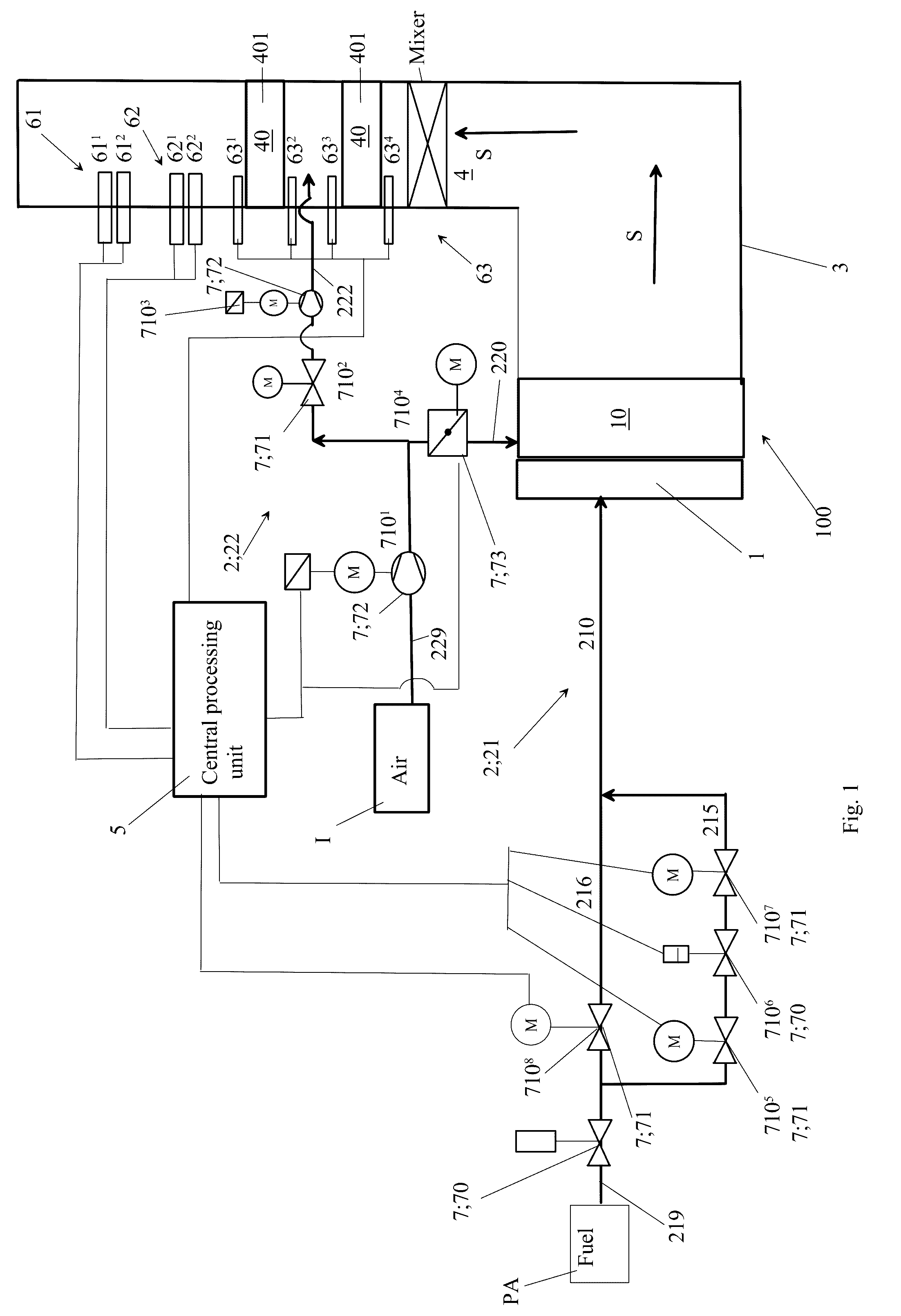

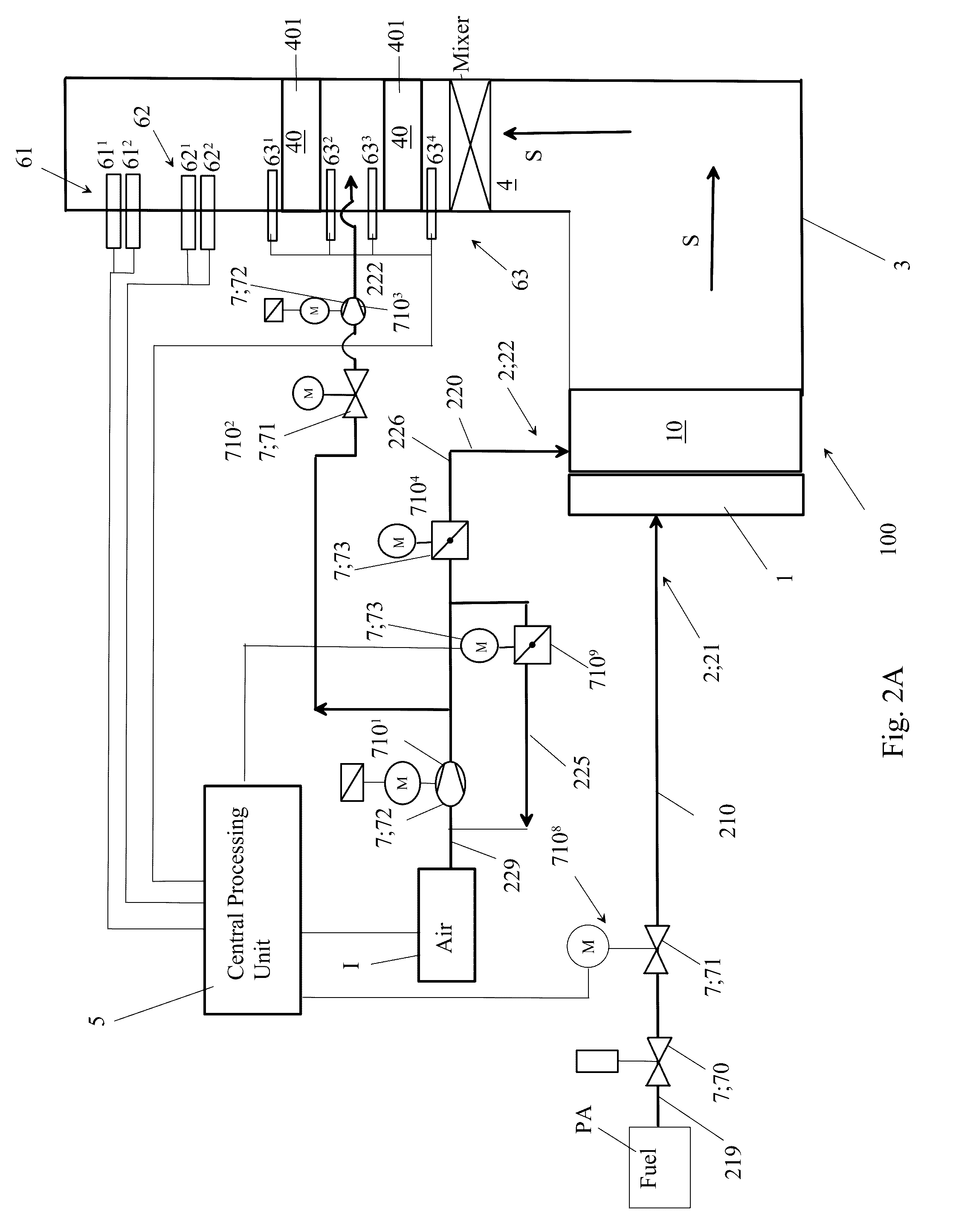

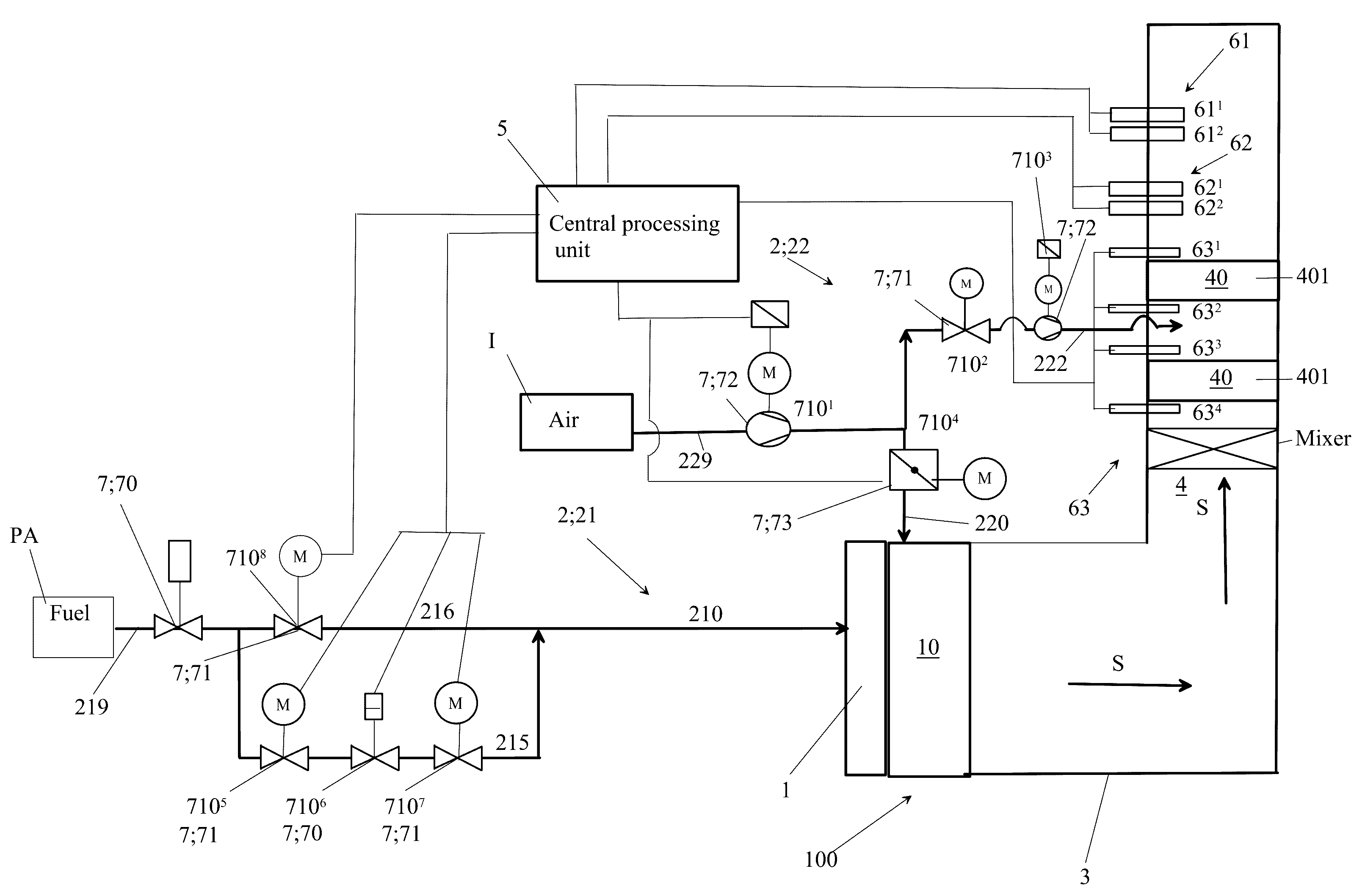

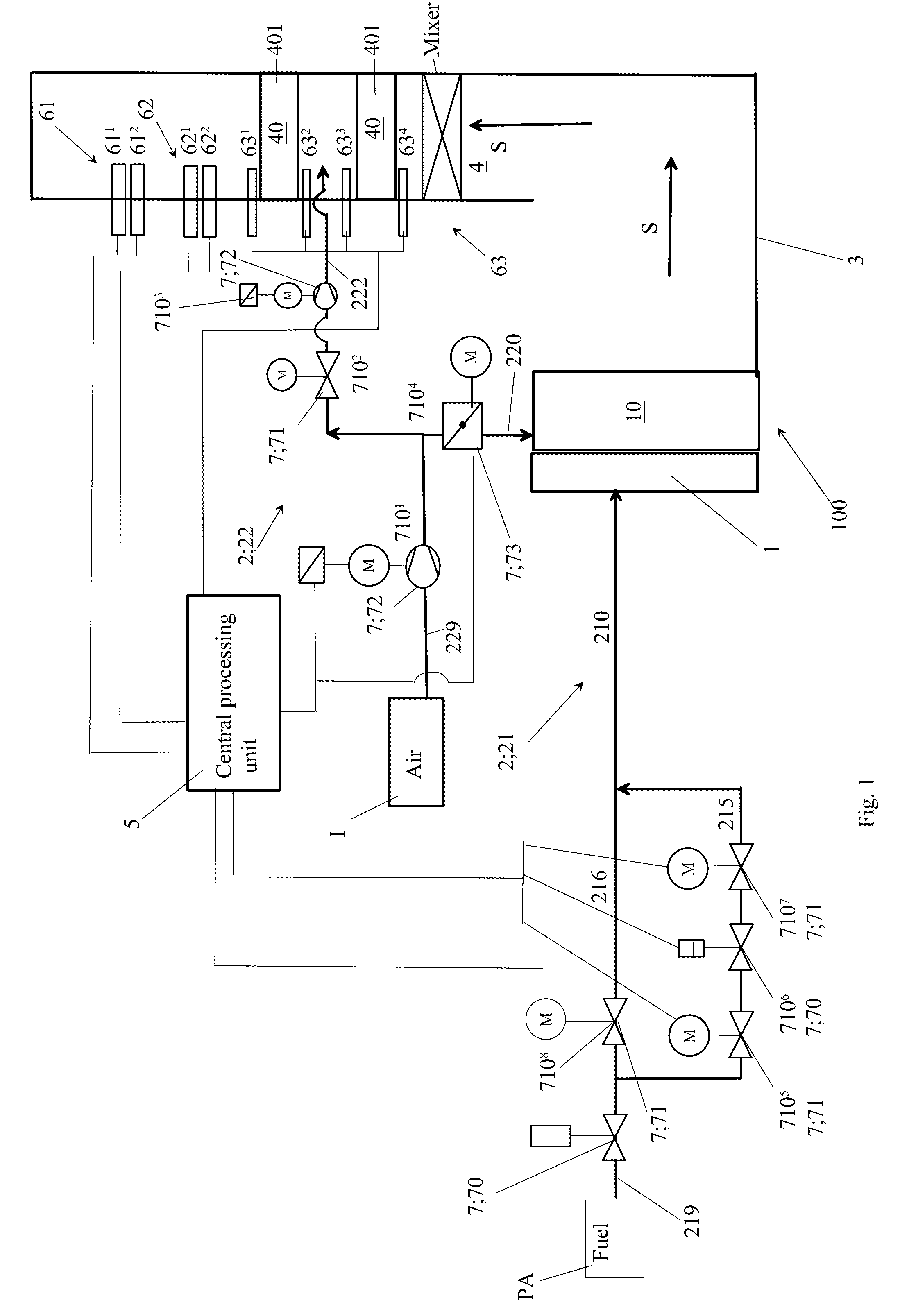

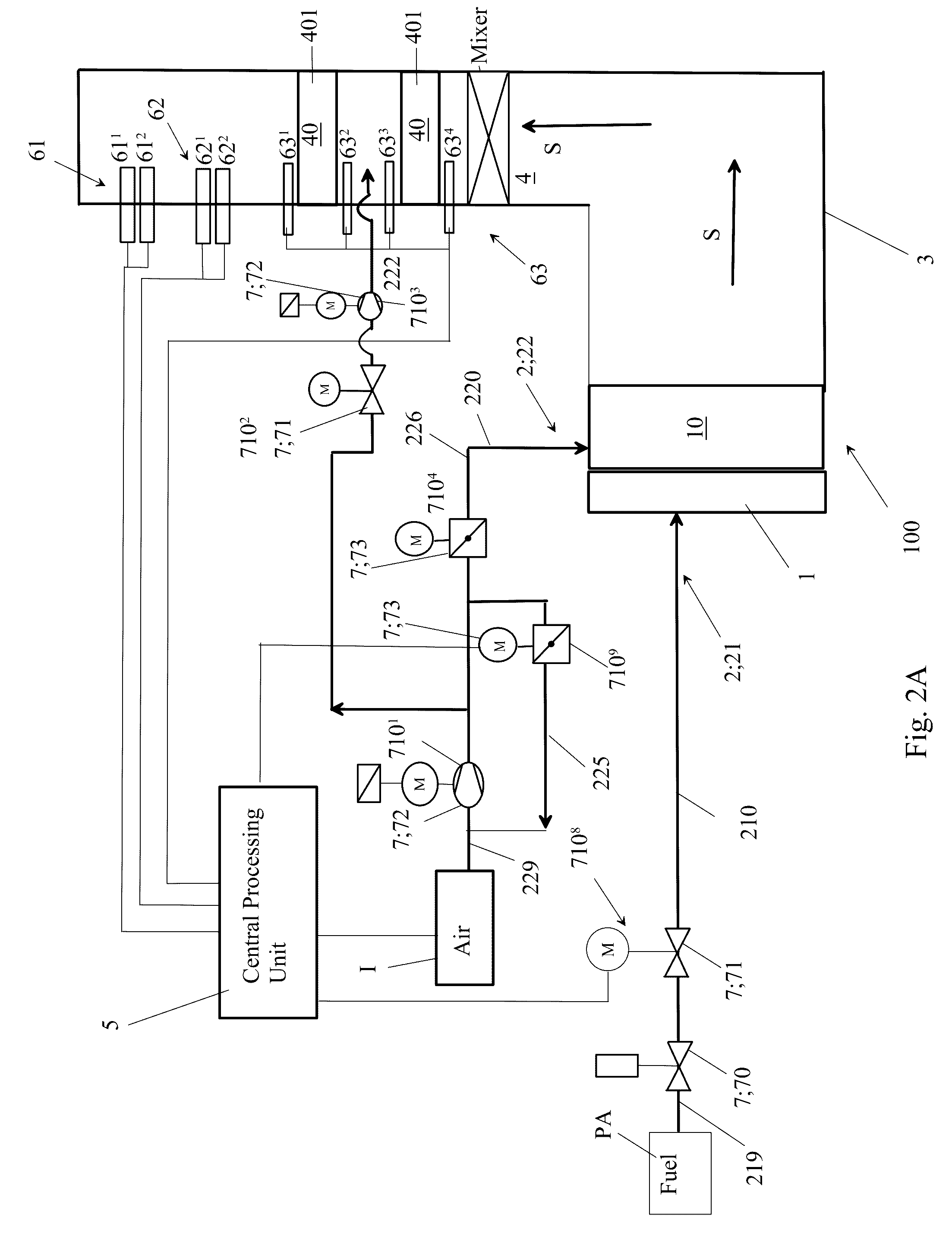

Arrangement and burner automation for adjusting the ratio between supplied amounts of fuel and air in an industrial burner

InactiveUS20160305659A1Increase the effective working rangeResidue reductionFuel supply regulationAir supply regulationCombustion chamberMeasuring instrument

An arrangement for adjusting the ratio between supplied amounts of fuel (PA) and air (I) in a burner, which is intended for a gaseous and / or liquid fuel is disclosed. The burner comprises a fuel and air mixing zone, a fuel supply conduit adapted to supply the mixing zone with a given inlet flow of fuel, a combustion air supply means adapted to supply the mixing zone with a given inlet flow of combustion air, and burner automation. The burner automation contains measuring instruments. The burner has its mixing zone accompanied by a combustion chamber which is in communication with a flue gas conduit. The combustion chamber or flue gas conduit has at least one catalytic zone. In the arrangement, the measuring instruments include at least one sensor, such as a lambda sensor, measuring the amount of residual oxygen in flue gases (flue gas oxidation / reduction potential). In the arrangement adjustment for an inlet flow (QI, QItot) of combustion air generated by the combustion air (I) supply means (determined as a volume flow per unit time), as well as the adjustment for an inlet flow (QPA, QPAtot) of fuel arriving in the mixing zone by way of the fuel supply conduit (determined as a volume flow per unit time), by means of burner automation, is based on the amount of residual oxygen measured from flue gases (S) with the measuring instrument, by way of which the burner automation adjusts the relative ratio between said inlet flow (QI, QItot) of combustion air as well as the inlet flow (QPA, QPAtot) of fuel in such a way that the amount of residual oxygen is within the range of 0.05-0.5% in flue gases prior to the catalytic zone.

Owner:OILON TECH OY

Water spraying type internal combustion engine exhaust system

InactiveCN107288743AExtended service lifeIncrease gas pressureInternal combustion piston enginesExhaust apparatusExternal combustion engineSoot particles

The invention relates to an internal combustion engine exhaust system, in particular to a water spraying type internal combustion engine exhaust system. The water spraying type internal combustion engine exhaust system solves the problems that in an existing internal combustion engine exhaust system, the diameter of gas soot particles is large, the soot discharge quantity is high, and the combustion efficiency is low. The number of water spraying nozzles is consistent with that of exhaust branch pipes of an internal combustion engine combustion chamber. Each exhaust branch pipe of the internal combustion engine combustion chamber is provided with the corresponding water spraying nozzle. One end of each exhaust branch pipe communicates with a corresponding combustion chamber body. The other ends of the exhaust branch pipes communicate with a tail gas exhaust manifold. Each water spraying nozzle communicates with a water pipe through a pipeline. The water pipe is connected with a water tank through a water pump. A control unit is connected with the water pump and the multiple water spraying nozzles. A signal sensor is electrically connected with the control unit. An exhaust opening of the tail gas exhaust manifold sequentially communicates with a tail gas catalysis device and a noise elimination device through a turbocharging device. The water spraying type internal combustion engine exhaust system is used on an internal combustion locomotive.

Owner:HARBIN INST OF TECH

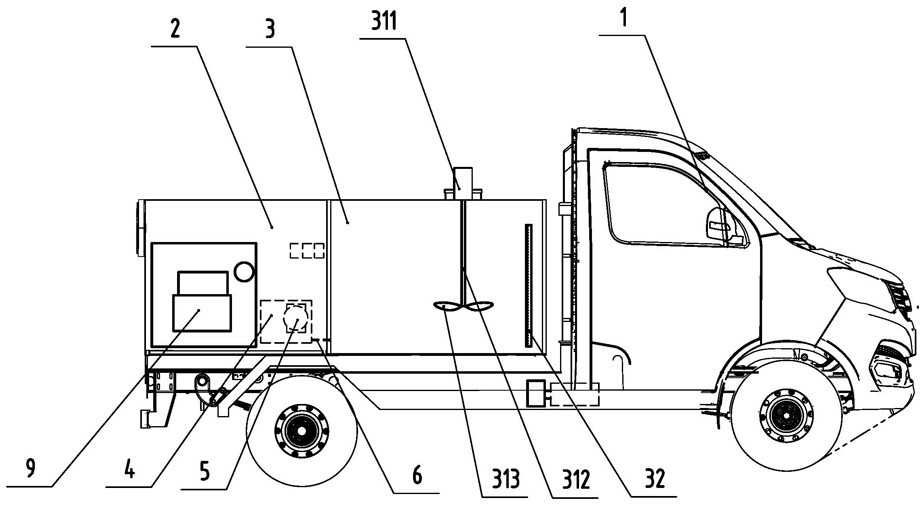

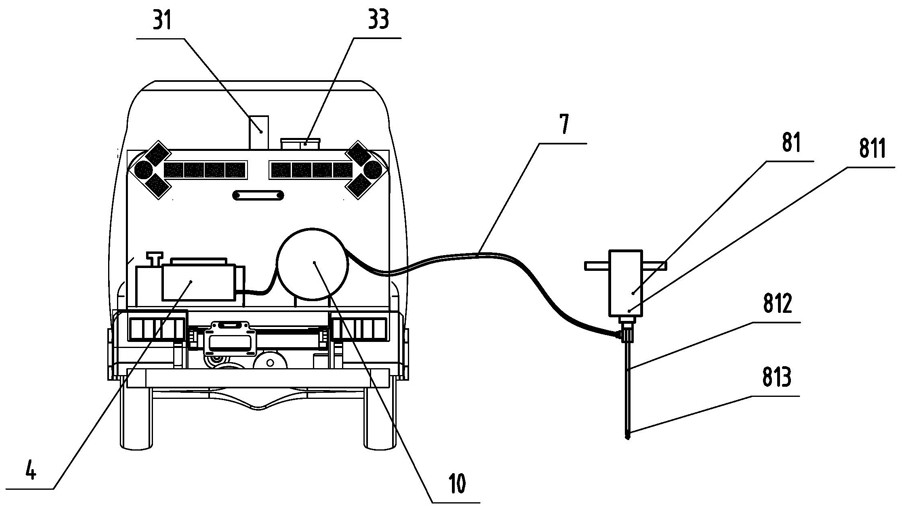

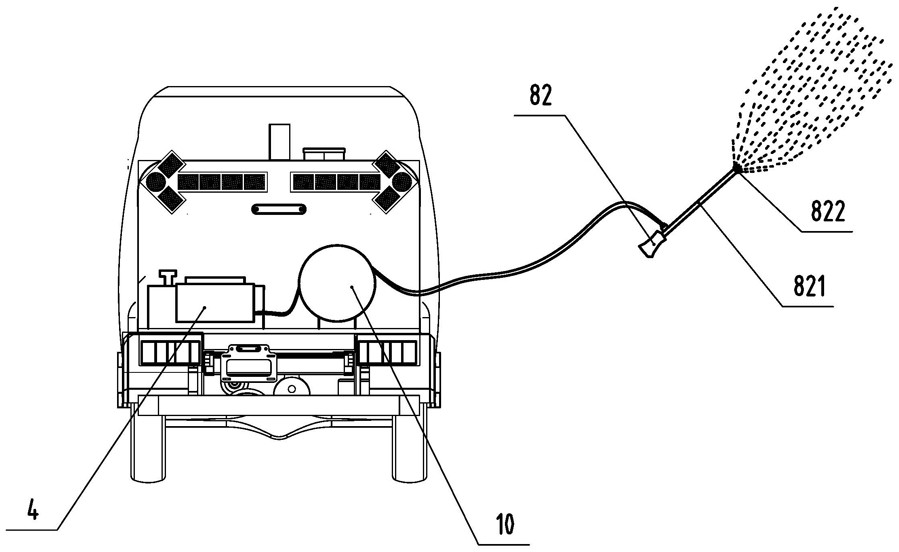

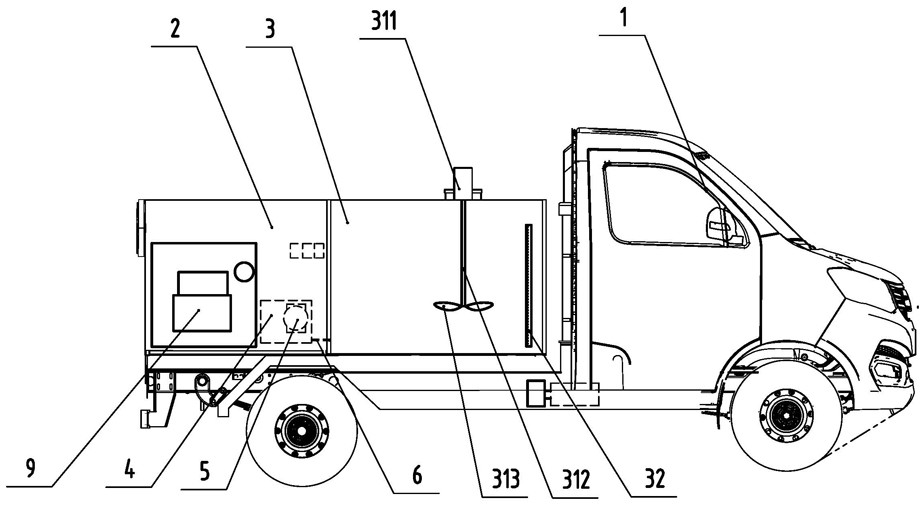

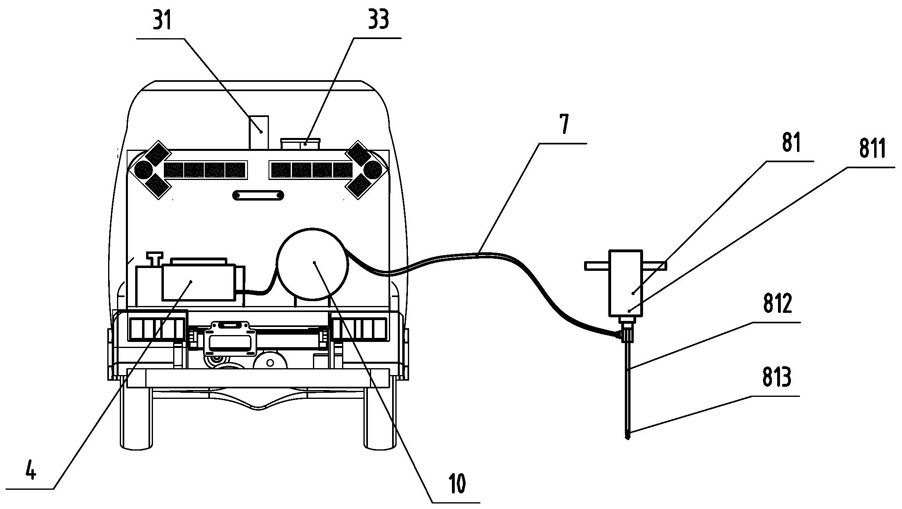

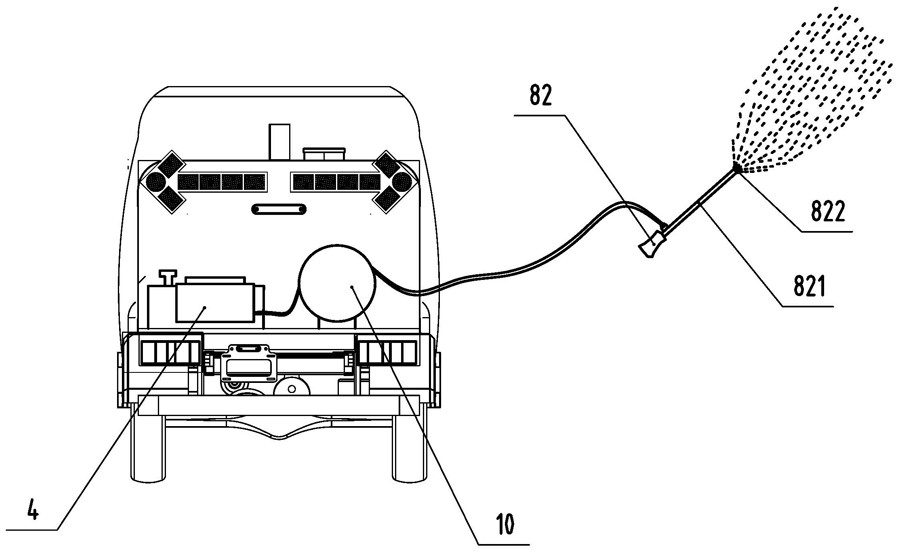

Garden greening comprehensive maintenance vehicle

PendingCN112352526AIncrease the effective working rangeMeet the needs of different working environmentsRoot feedersSpraying apparatusAgricultural scienceAgricultural engineering

The invention relates to a garden greening comprehensive maintenance vehicle which is characterized by comprising a chassis, a carriage, a spray tank, a high-pressure water pump, a water pump drivingdevice, a first water pipe, a second water pipe, a pesticide feeding device and a controller. According to the connecting manner of the components, the carriage is installed on the chassis, the spraytank is arranged in the carriage or arranged on the chassis in parallel with the carriage, the water pump driving device is connected with the chassis, the high-pressure water pump is connected with the water pump driving device, the high-pressure water pump is communicated with the spray tank through the first water pipe, the high-pressure water pump is communicated with the pesticide feeding device through the second water pipe, the controller is electrically connected with the water pump driving device, the pesticide feeding device can be rapidly switched, and therefore underground deep-root fertilization and overground foliage spraying can both be conducted. The garden greening comprehensive maintenance vehicle has the advantages of being uniform in pesticide effect, high in fertilization efficiency and large in operation range. The garden greening comprehensive maintenance vehicle belongs to the technical field of fertilization and pesticide spraying equipment.

Owner:SHANGHAI SHENZHOU VEHICLE ENERGY SAVING & ENVIRONMENTAL PROTECTION

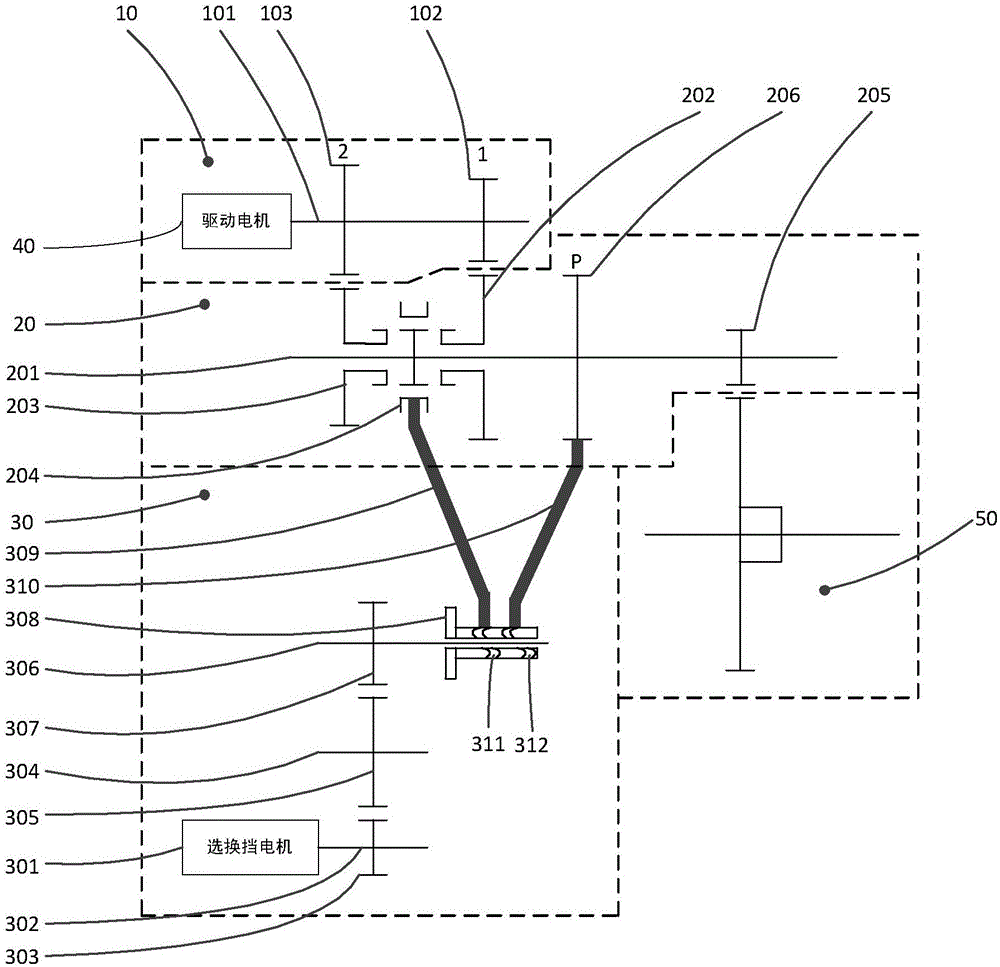

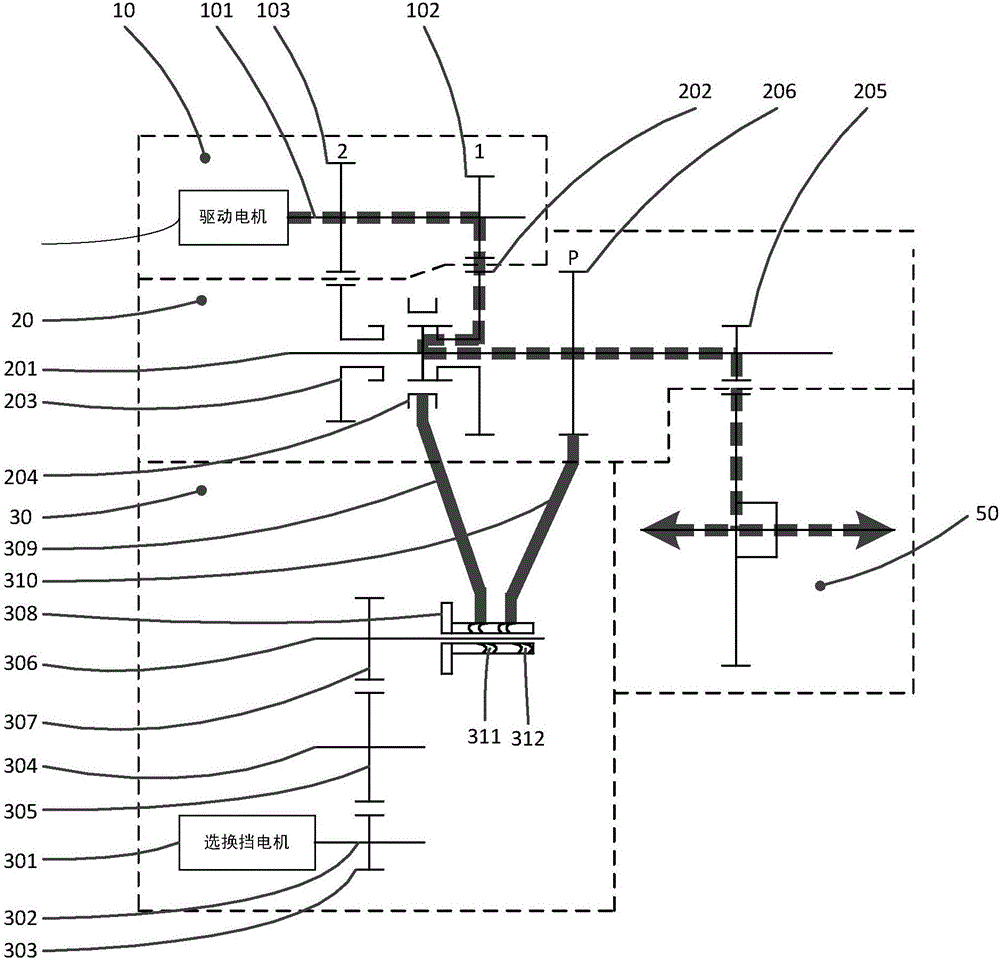

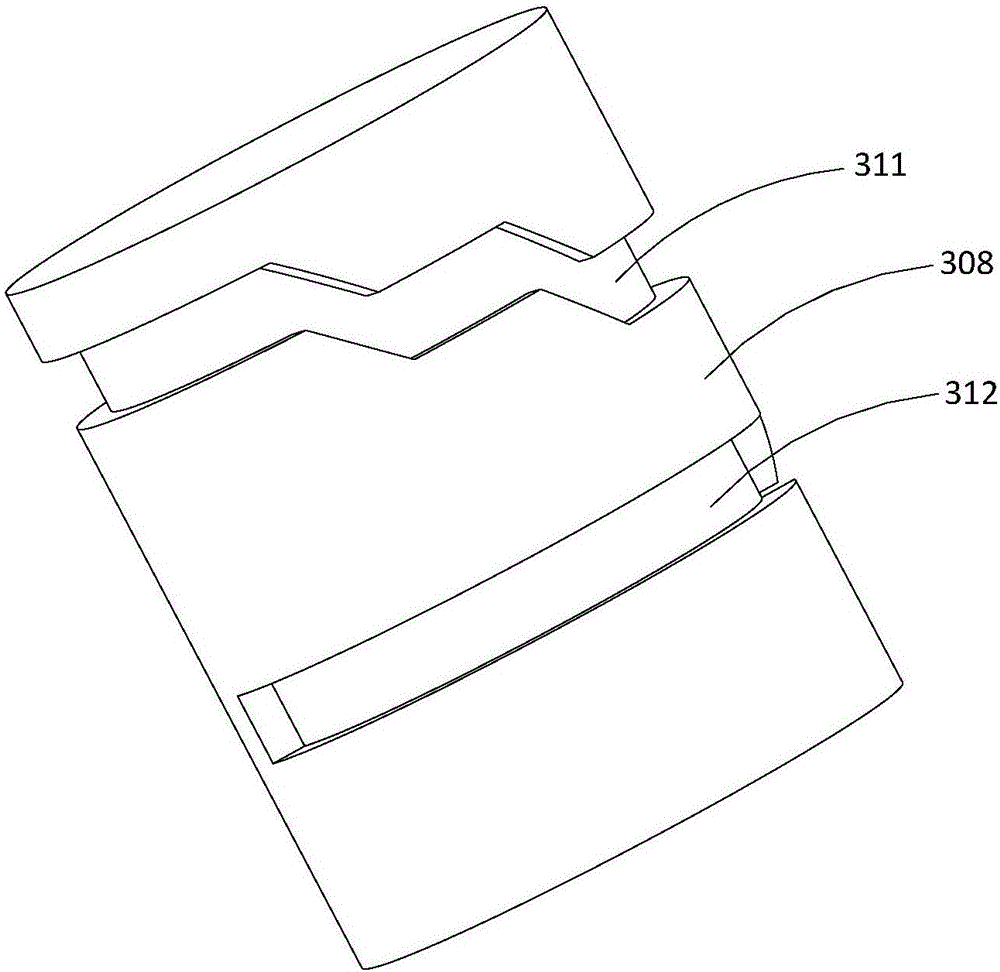

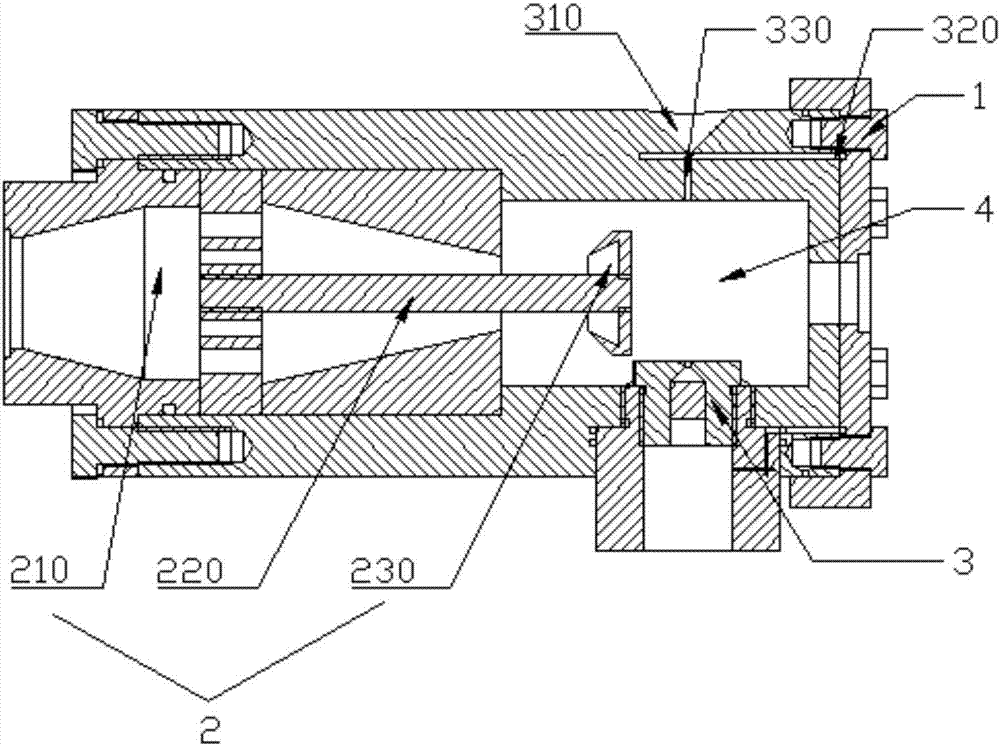

Electric automobile transmission

InactiveCN106151488AIncrease the effective working rangeSmooth shiftingGearing controlElectric power transmissionElectric machinery

The invention relates to the related field of transmissions and discloses an electric automobile transmission. The electric automobile transmission comprises an input shaft assembly, wherein the input shaft assembly is in driving connection to an output shaft assembly; the output shaft assembly is connected to a shift selecting mechanism assembly; the input shaft assembly is connected to a driving motor; and the output end of the output shaft assembly is connected to a differential mechanism assembly. By arranging the shift selecting mechanism assembly, two-shift driving of the driving motor can be realized so as to improve the effective working range of the driving motor. By virtue of a shift selecting mechanism, stable shifting can be quickly realized; by virtue of pure electric driving, purposes of simplifying the structure of a transmission device and alleviating the weight of the transmission device are achieved, so that the shifting mechanism is further simplified; by arranging a shift selecting drum, the driving gear and the parking gear can be realized in the same shift selecting mechanism, and various gears can be selected, so that energy integrated optimization of the whole system can be realized in various working conditions.

Owner:HEBEI UNIV OF TECH

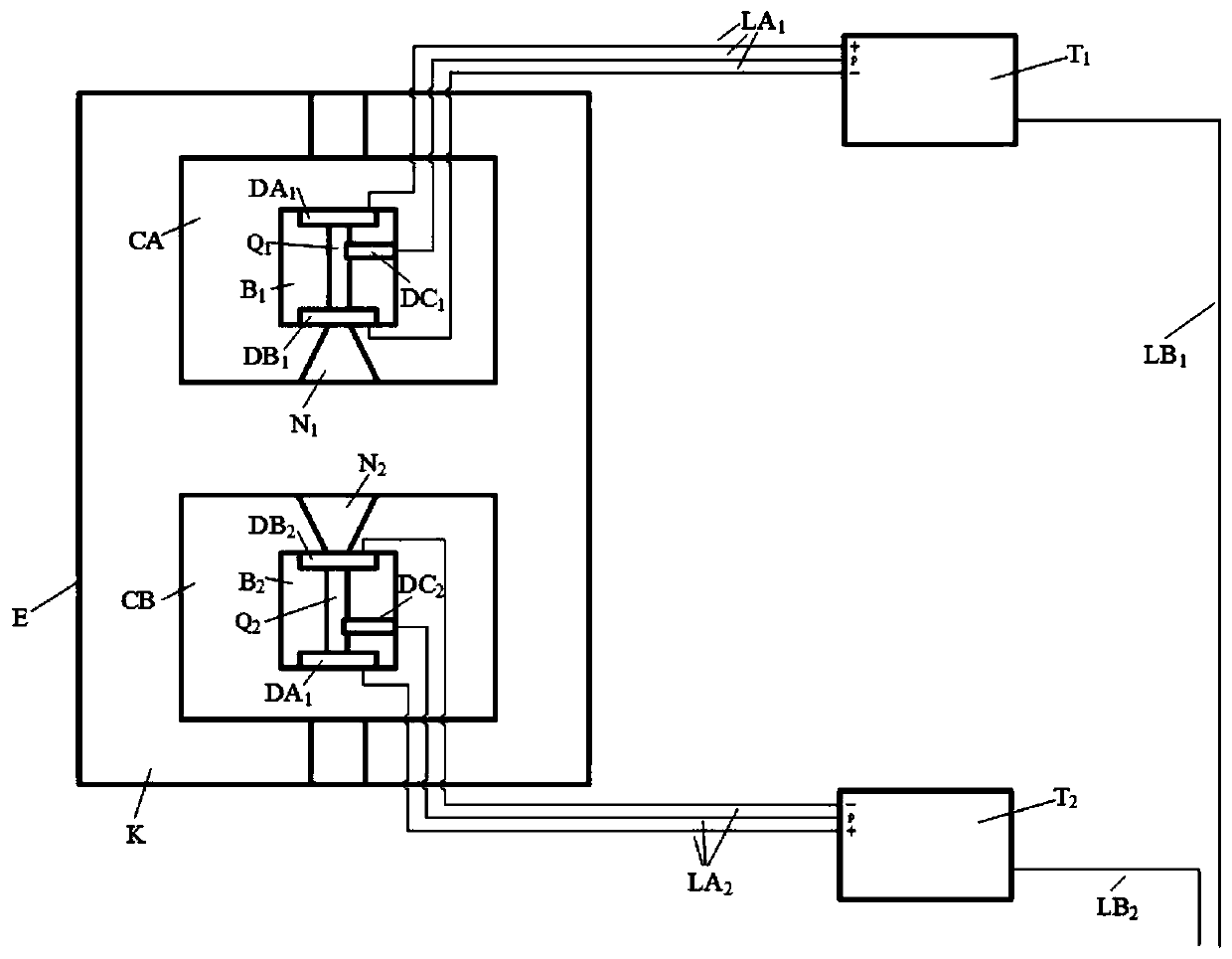

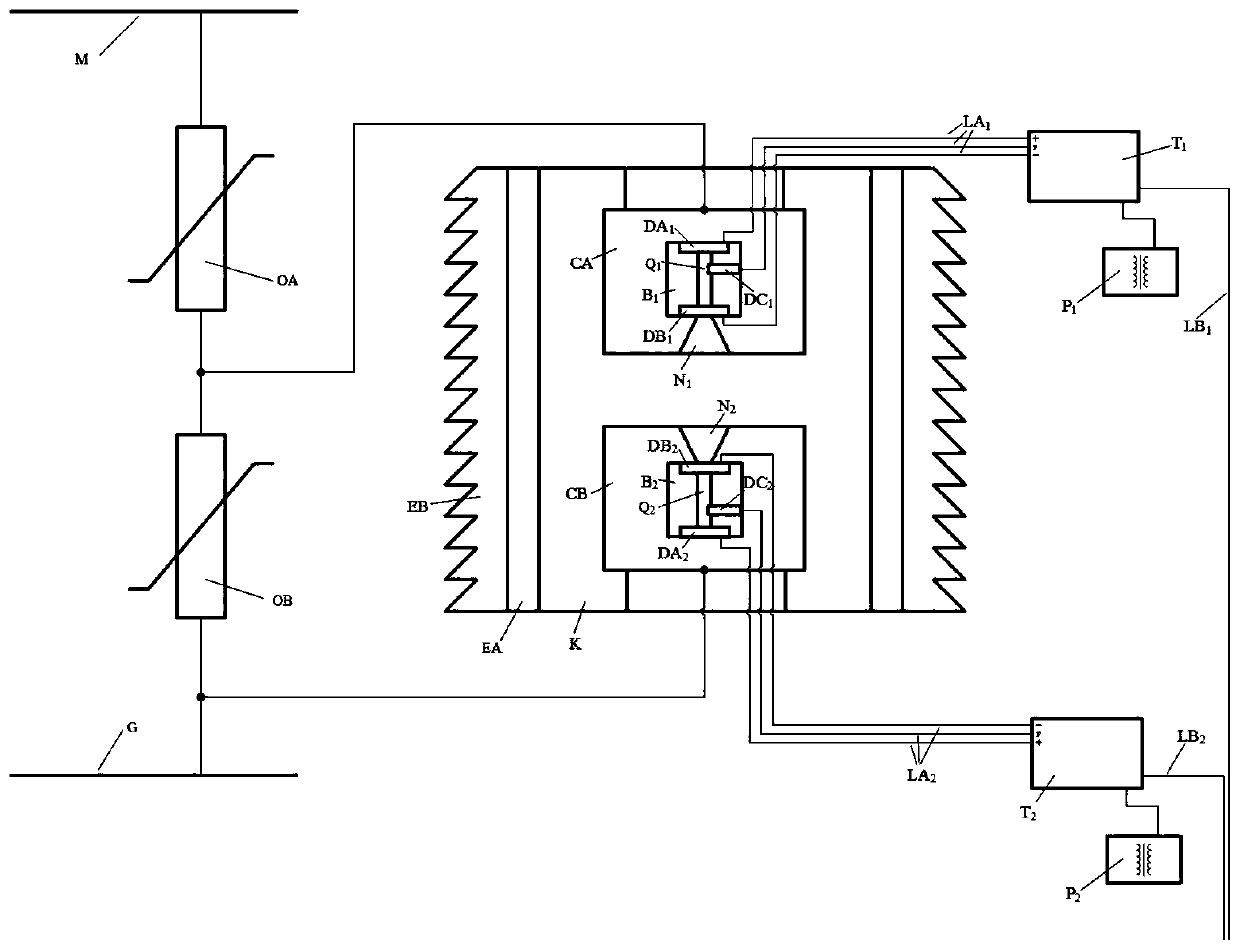

Closed discharge gap triggered by plasma jet and application thereof

PendingCN110430655AReliable actionImprove controlSpark gap detailsPlasma techniquePlasma jetHigh pressure

The invention discloses a closed discharge gap triggered by a plasma jet and an application thereof. The closed discharge gap comprises a plasma spraying unit comprising an injection device and a plasma trigger T, wherein the injection device is arranged in a contact unit, generates plasmas and ablate the ablation materials through pulse voltages and currents and generates a plasma jet by adoptinga capillary action of an elongated cavity, the injection device is connected with a plasma trigger T through the high voltage wire LA, the contact unit is arranged in the cavity unit for tolerance ofarc ablation, the cavity unit is used for providing a closed high-pressure gaseous medium environment. The closed discharge gap can ensure the reliable operation in the low work parameters, improvesthe control performances of the discharge gap, increases the work range and service life of the discharge gap, solves the problems that the arc is extinguished due to the small gap current, avoids thegap breaking, and replaces the complex and high-cost energy storage and freewheeling device.

Owner:西安西交瑞力电气研究院有限公司

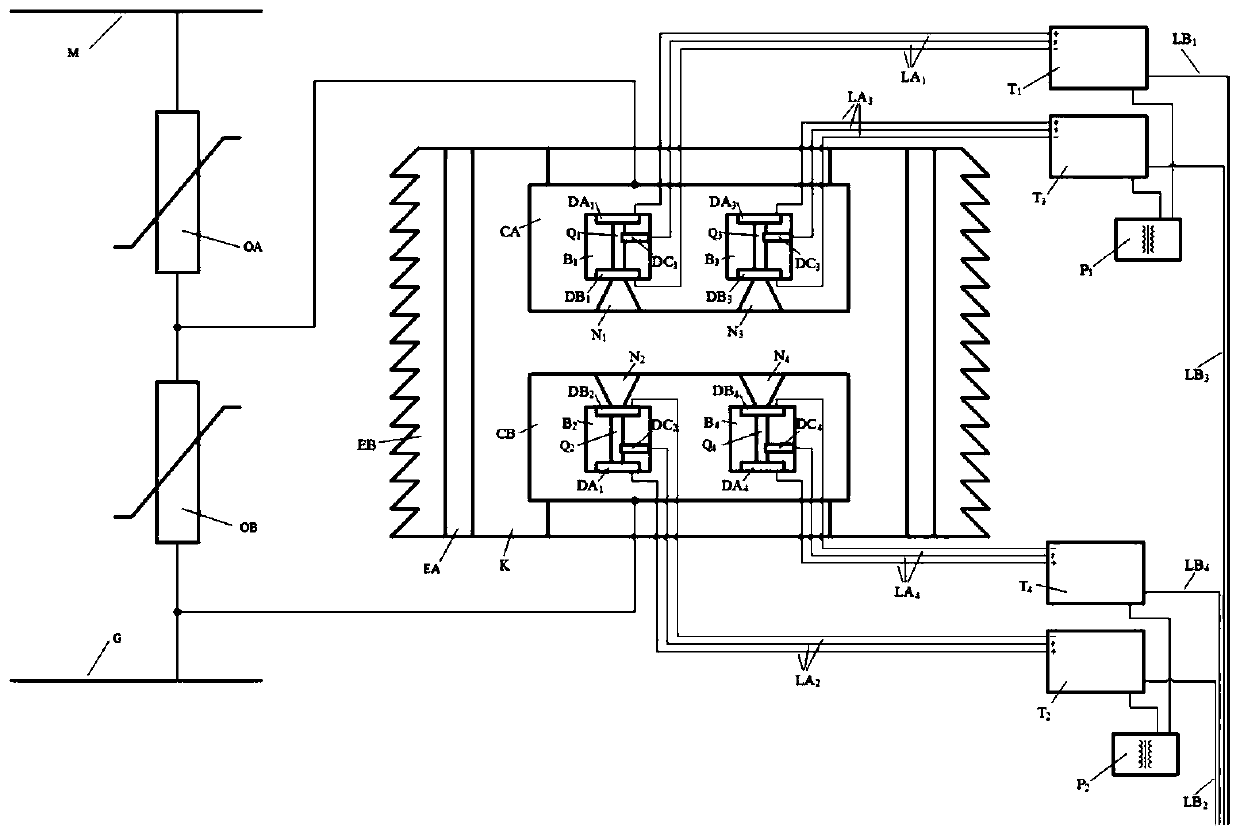

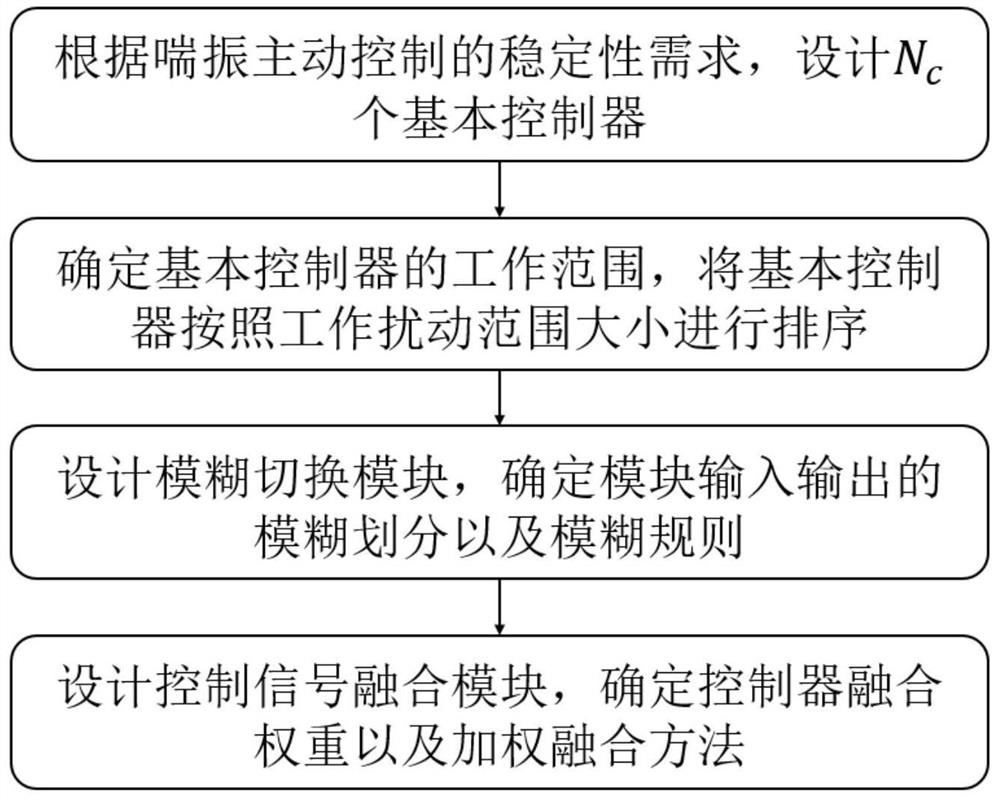

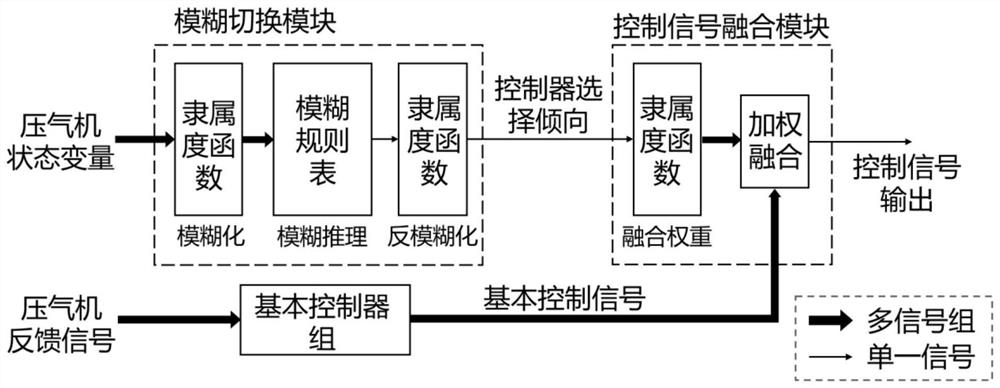

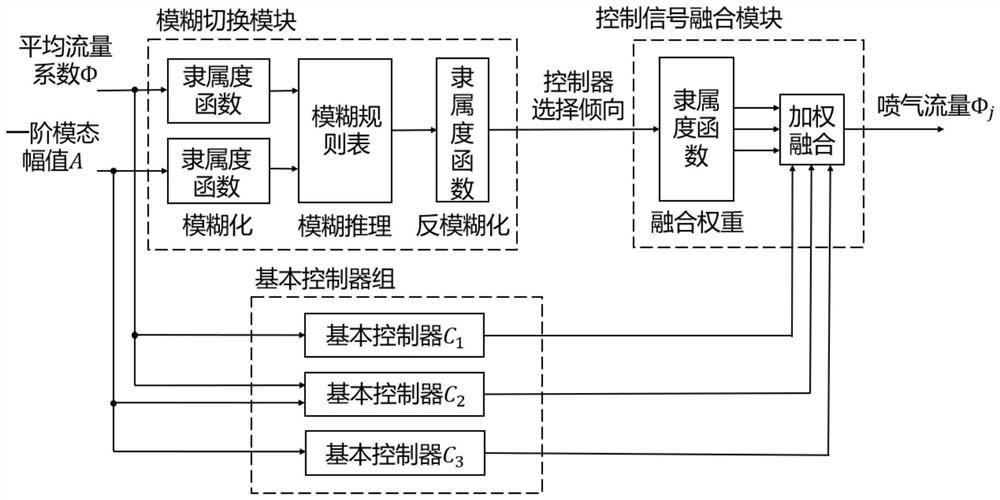

Aero-engine surge active control system based on controller fuzzy switching

ActiveCN113279997ASolve the problem of not being able to achieve multiple perturbationsImprove stabilityGas turbine plantsPump controlControl systemGas compressor

The invention discloses an aero-engine surge active control system based on controller fuzzy switching. The active control system is based on the fuzzy switching principle, according to the working state of a gas compressor, a basic controller most suitable for the current state is selected for switching control, and large-range, self-adaptive and performance-optimized surge active control can be achieved. According to the active control system, through a fuzzy switching mode, large-range surge active control is realized, the effective working range of the controller is expanded, and the reliability of the controller is improved; the designed controller can be suitable for active control over surge caused by various inducements, the self-adaptability of the controller is improved, and the controller is closer to the actual working condition of an engine; a certain optimization index is added in the design process of the controller, so that optimal control under a corresponding optimization target can be realized; and the needed control effect can be achieved by slightly changing an existing controller, and compared with an existing intelligent control method, the active control system is simpler, more convenient and easier to implement.

Owner:DALIAN UNIV OF TECH

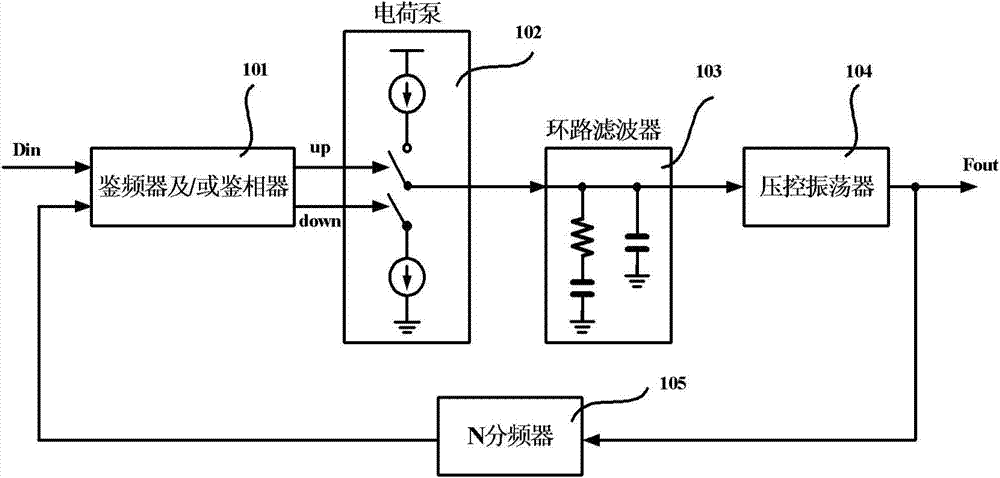

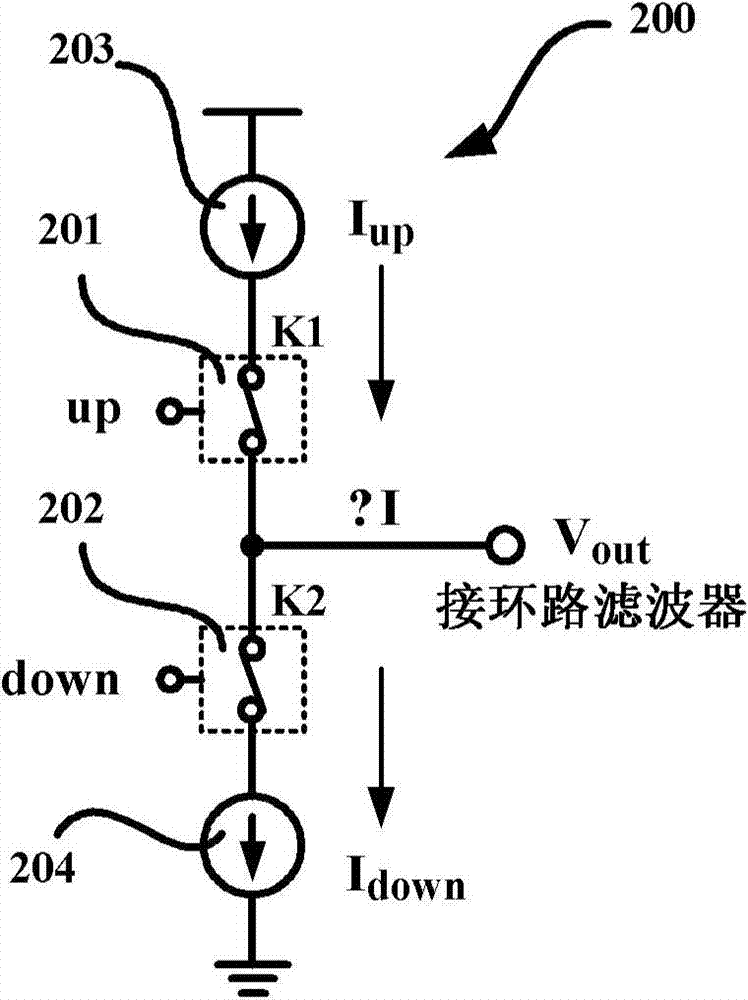

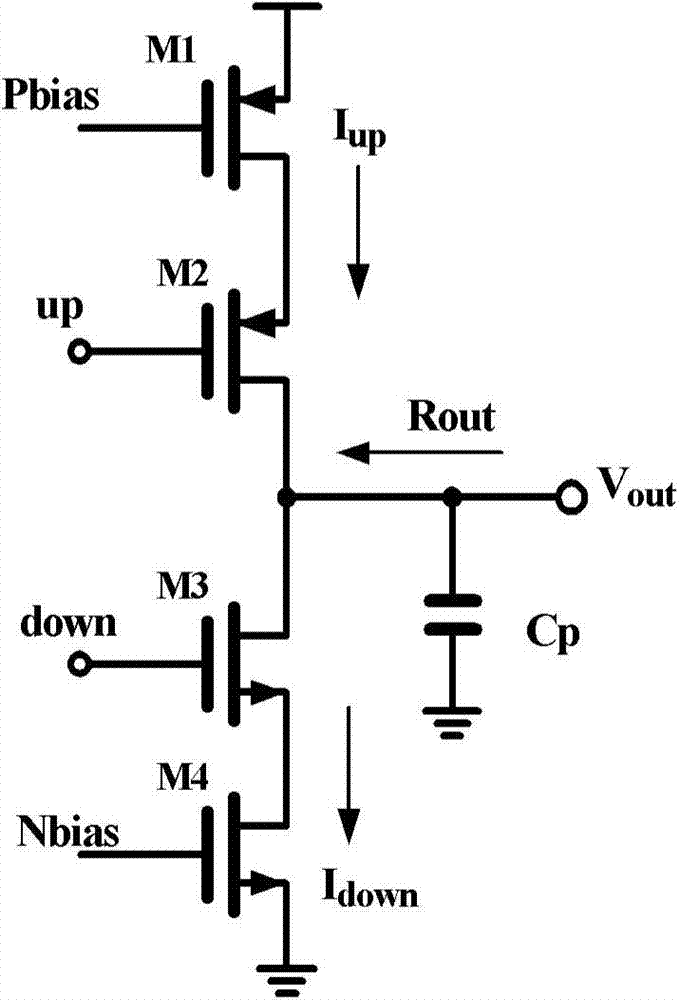

Charge pump

ActiveCN104734493AIncrease the effective working rangeCompensation mismatchApparatus without intermediate ac conversionPower flowCurrent limiting

The invention provides a charge pump. The charge pump is detected by a feedback module to output the voltage, and power source current values mirrored by charging and discharging power sources of the charge pump are adjusted according to the value of the output voltage of the charge pump, so that charging and discharging current mismatching caused by changes of the output voltage is compensated.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

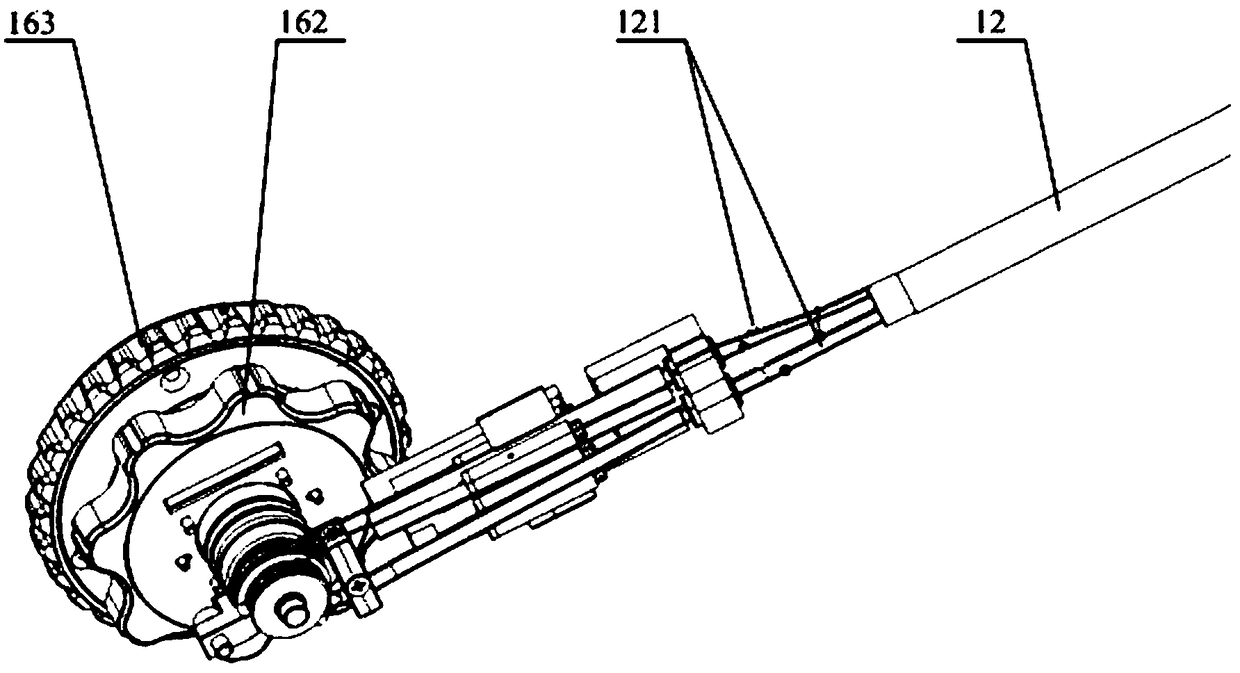

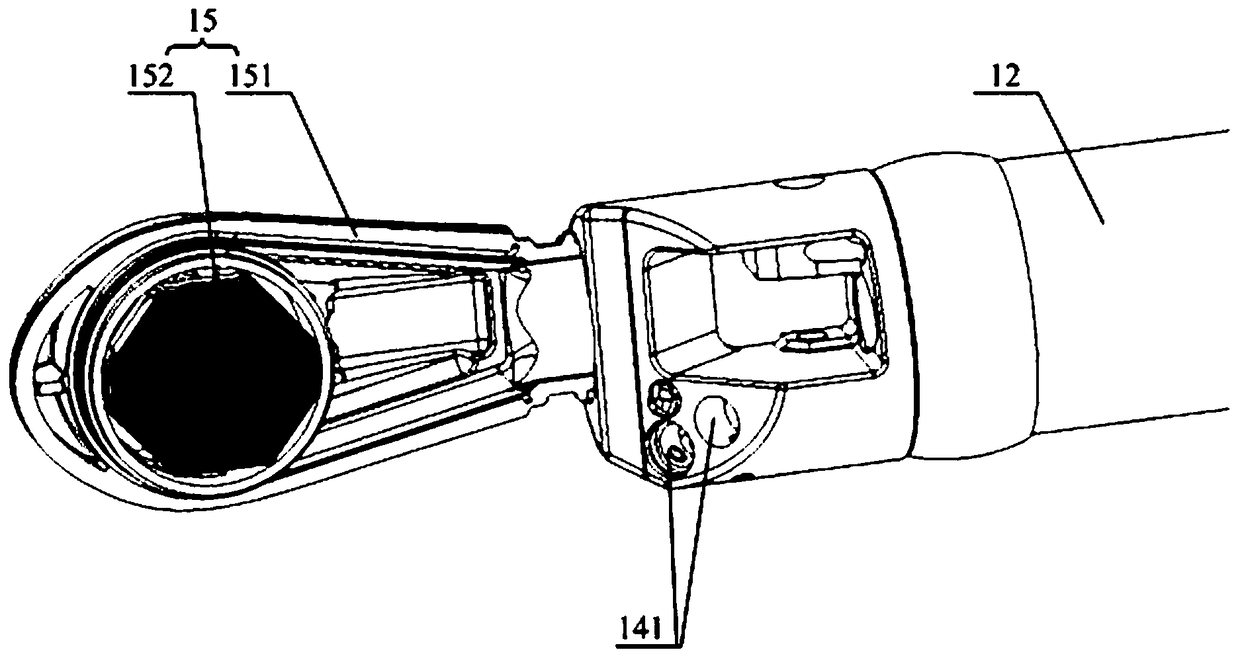

Ultrasonic endoscope and operation method thereof

PendingCN108714035AAvoid risk of injuryRealize the effect of diagnosis and treatmentUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsJoystickEndoscope

The invention discloses an ultrasonic endoscope. The ultrasonic endoscope comprises a control rod and an operation rod which are connected with each other, wherein the free end of the control rod is connected with an information feedback device; a probe component is arranged at the free end of the operation rod, and comprises a phase array ultrasonic probe and an optical endoscope; the phase arrayultrasonic probe comprises a shell and an ultrasonic vibrator positioned in the shell; and a control component is arranged at the joint of the control rod and the operation rod, and is used for controlling the phase array ultrasonic probe to make directional back-forth swinging and a dead axle to rotate. The ultrasonic endoscope can be used for efficiently and stably implementing multi-plane scanning diagnosis. The invention further discloses an operation method for the ultrasonic endoscope.

Owner:SONOSCAPE MEDICAL CORP

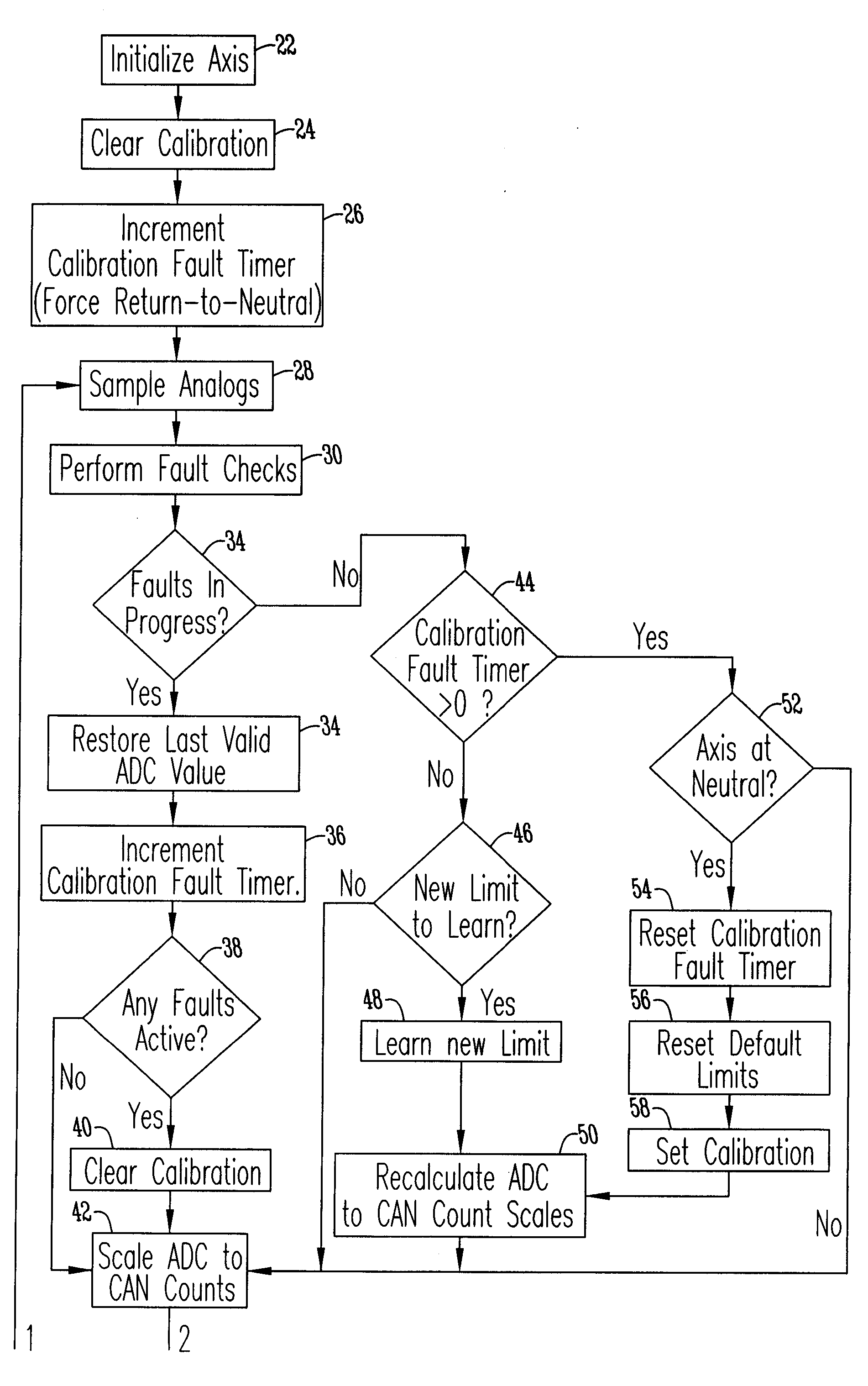

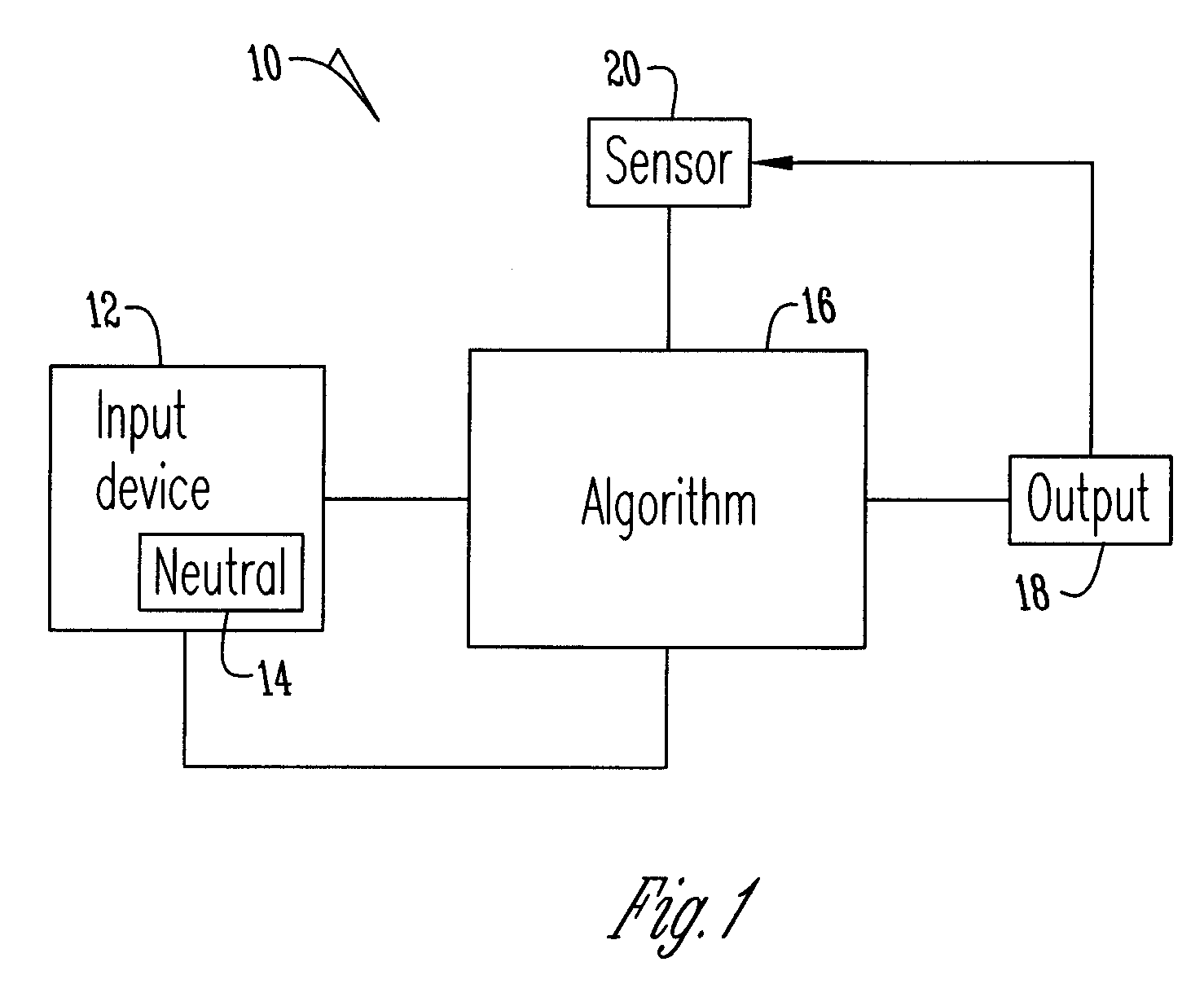

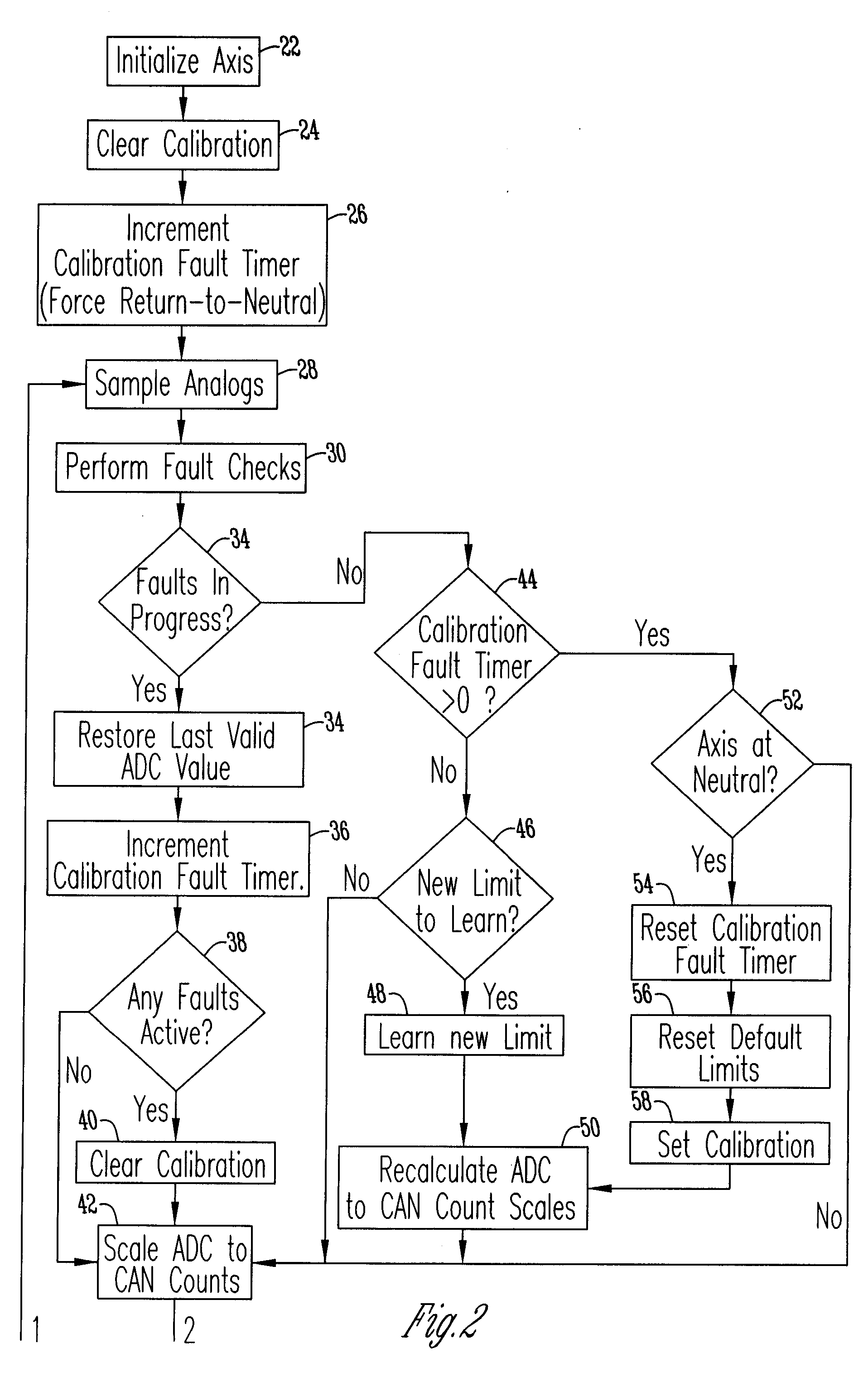

Method and means for self calibrating a valid operating range

InactiveUS20080228336A1Increase the effective working rangeExpand the scope of operationVehicle testingRegistering/indicating working of vehiclesComputer scienceInput device

A method of calibrating a valid operating range. The method includes loading a default calibration limit and then monitoring an input for new calibration limits provided by an input device. An algorithm then detects if the new calibration limits provide a fault and if not the algorithm rescales the output based upon the new calibration limits to increase the valid operating range.

Owner:DANFOSS POWER SOLUTIONS INC

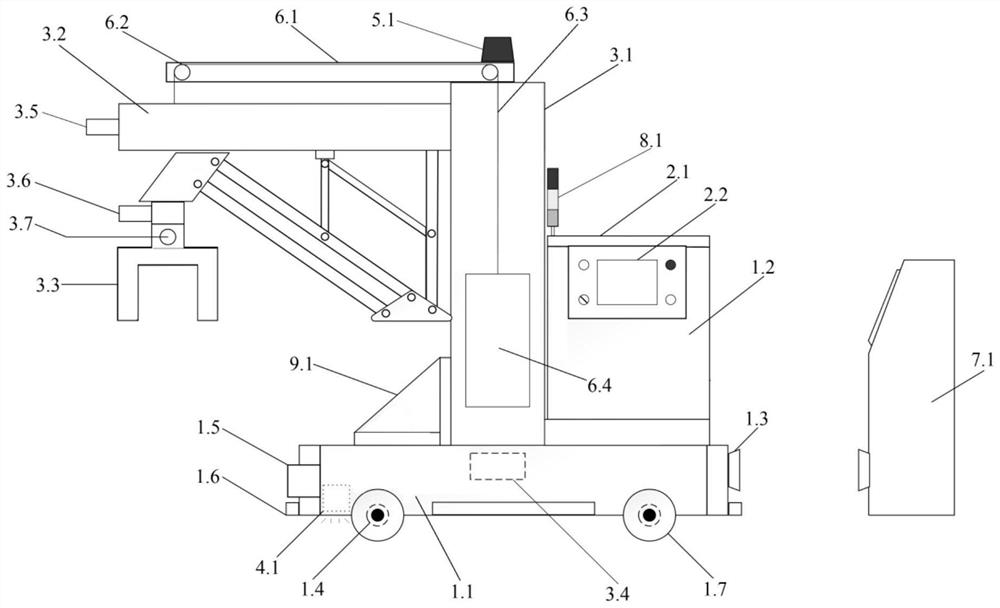

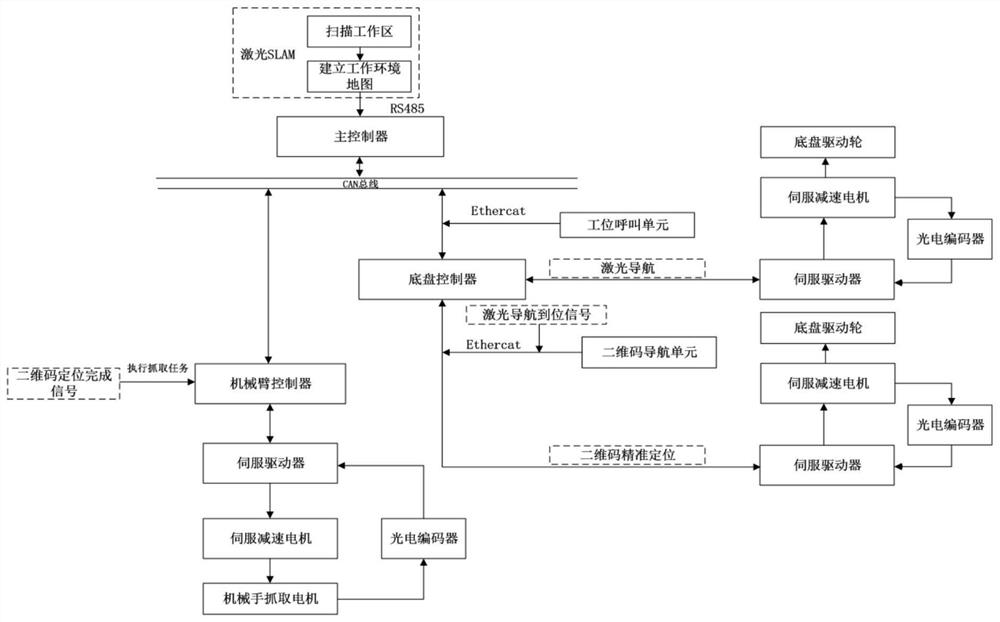

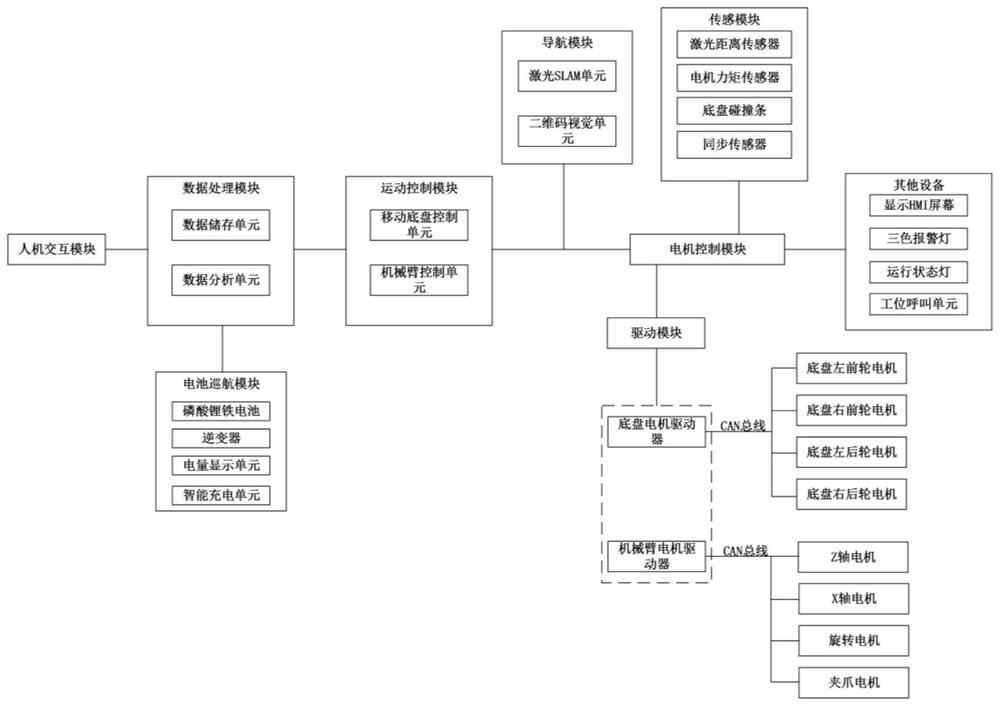

Mobile carrying robot system and control method thereof

PendingCN112093467ADoes not increase control difficultyIncrease the effective working rangeProgramme-controlled manipulatorBatteries circuit arrangementsRobotic systemsSimulation

The invention relates to the technical field of material carrying equipment, and particularly relates to a mobile carrying robot system and a control method thereof. The mobile carrying robot system comprises a robot mobile platform, a main control computer system, a manipulator device, a two-dimensional code visual positioning system and a laser slam system. A traditional mechanical arm type robot is limited in working range, and a mobile carrying robot effectively expands the X axis and the Y axis of a fixed mechanical arm to enlarge the working range, so that the enterprise investment costis saved. In addition, an existing mobile traction trolley is low in positioning precision, and the repeated positioning precision is mostly only 10 mm. The invention provides a layered combined navigation control method. A positioning mode of laser slam and close-range two-dimensional code visual composite navigation is adopted, the repeated positioning precision can reach 2mm, the control difficulty cannot be increased due to the existence of multiple navigation modes, and the mobile platform can be used as a movable base of the mechanical arm.

Owner:CHINA JILIANG UNIV

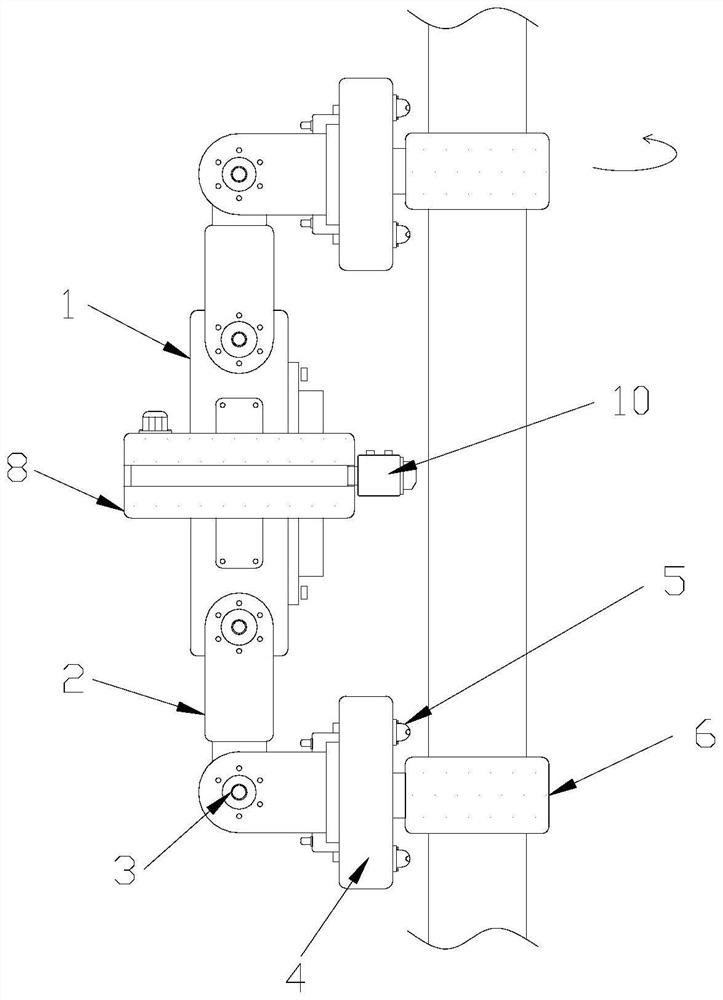

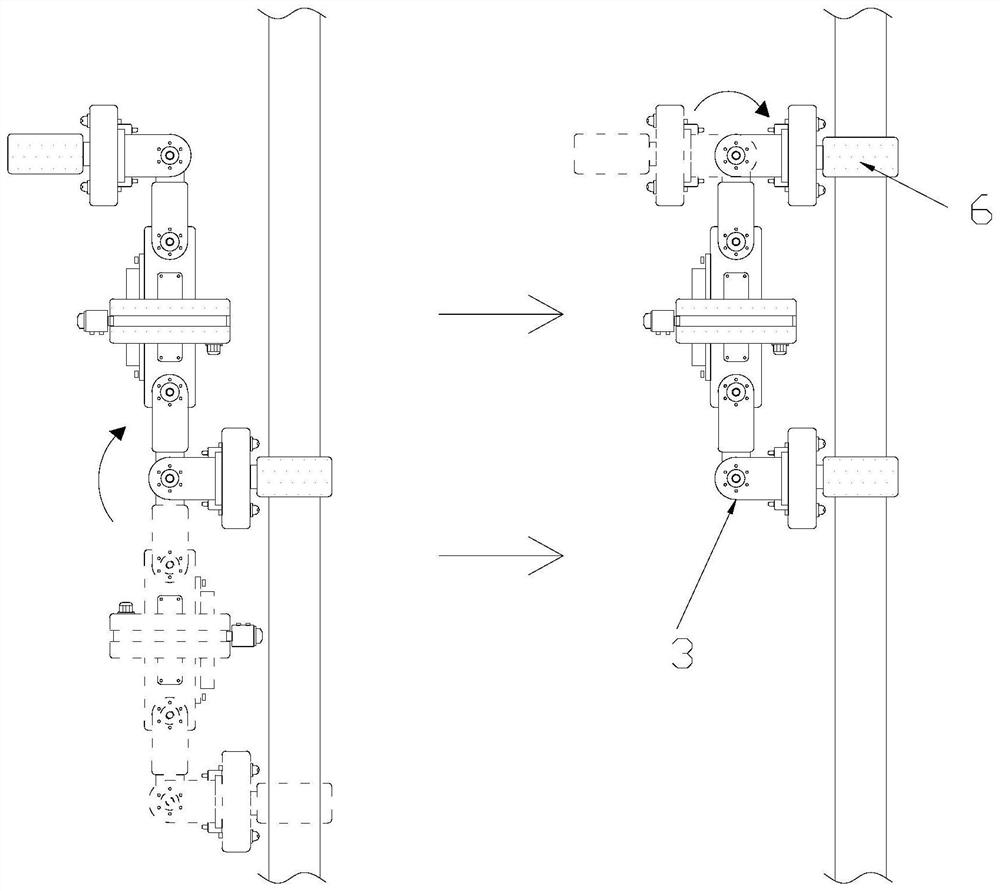

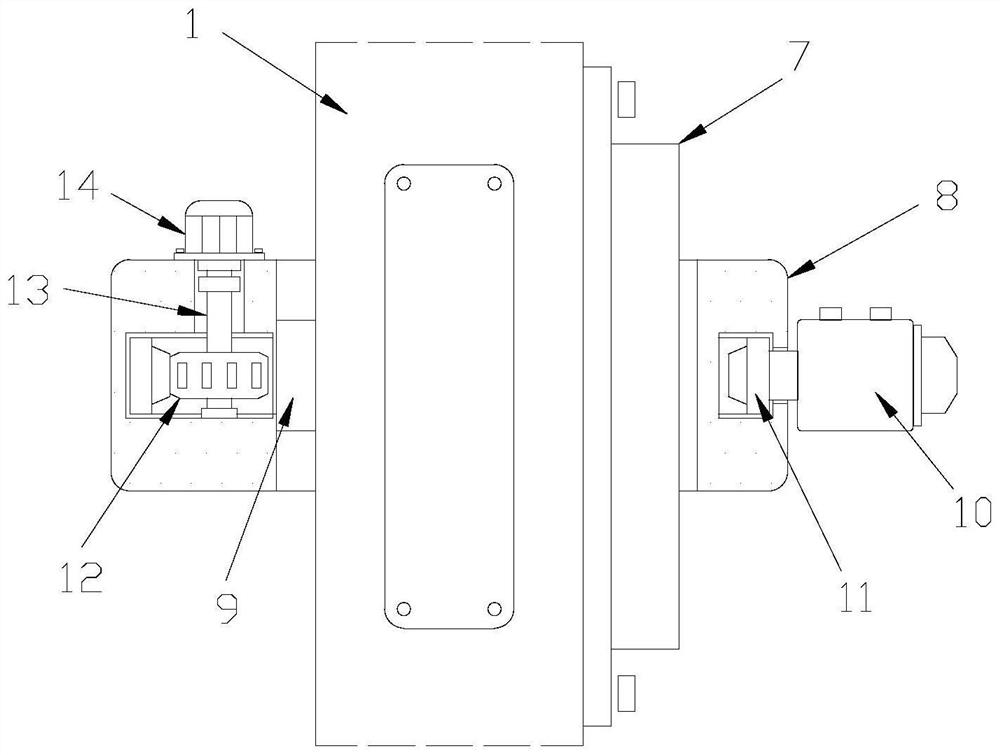

High-altitude climbing type welding robot based on AI visual identification

ActiveCN113478142AAchieve climbingIntelligent operation and applicationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachine

The invention discloses a high-altitude climbing type welding robot based on AI visual identification, and belongs to the field of welding robots. The high-altitude climbing type welding robot comprises a robot arm main body, wherein connecting frames are arranged at the upper end and the lower end of the robot arm main body; the connecting frames are connected with mounting bases through rotating control mechanisms respectively; the rotating control mechanisms are used for driving the robot arm main body and the mounting bases to turn over to achieve climbing; image collectors used for visual identification are arranged on the side edges of the mounting bases; a clamping portion used for clamping a structure is further arranged on the side edge of each mounting base; and a welding mechanism is arranged on the outer side of the middle of the robot arm main body. In order to solve the problems that in the prior art, the welding robot can only conduct welding operation on a plane, and the high-altitude welding risk is large, high-altitude automatic climbing welding can be achieved, the labor intensity of workers is effectively reduced, and safe production is guaranteed.

Owner:CHINA MCC17 GRP

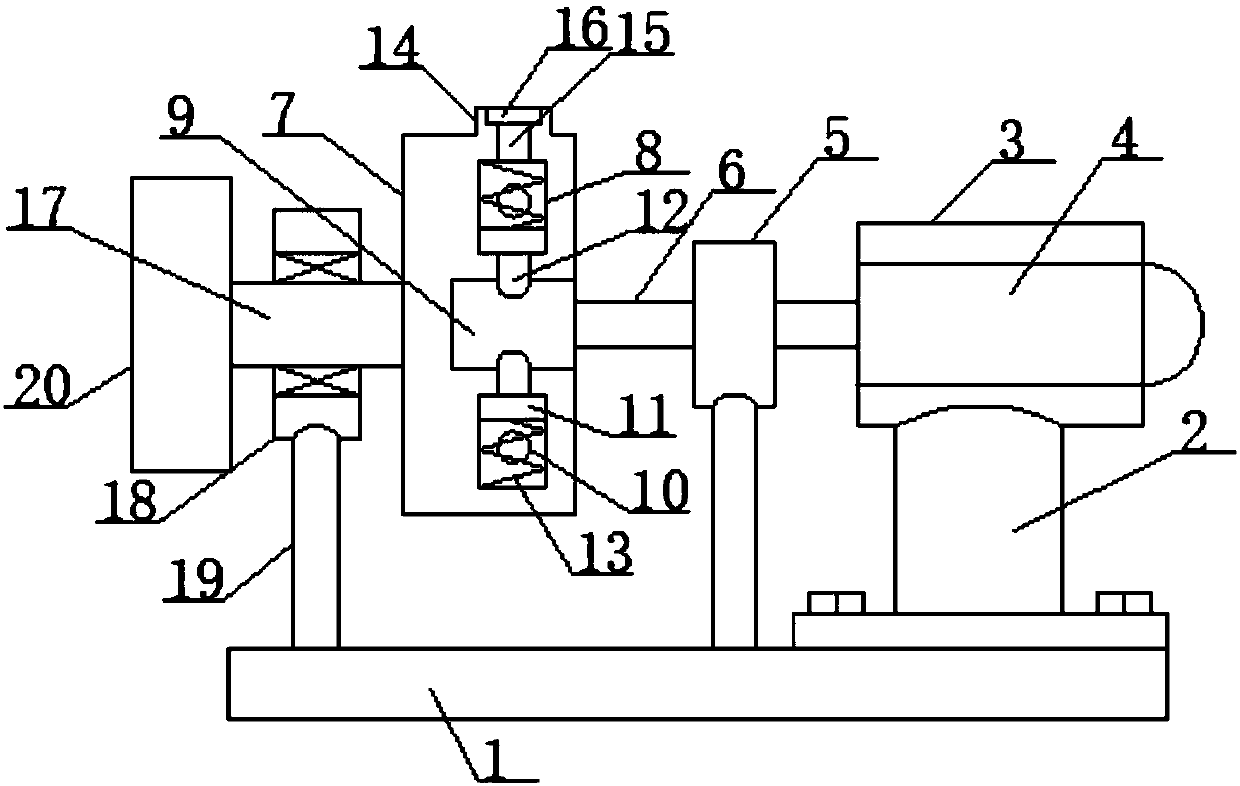

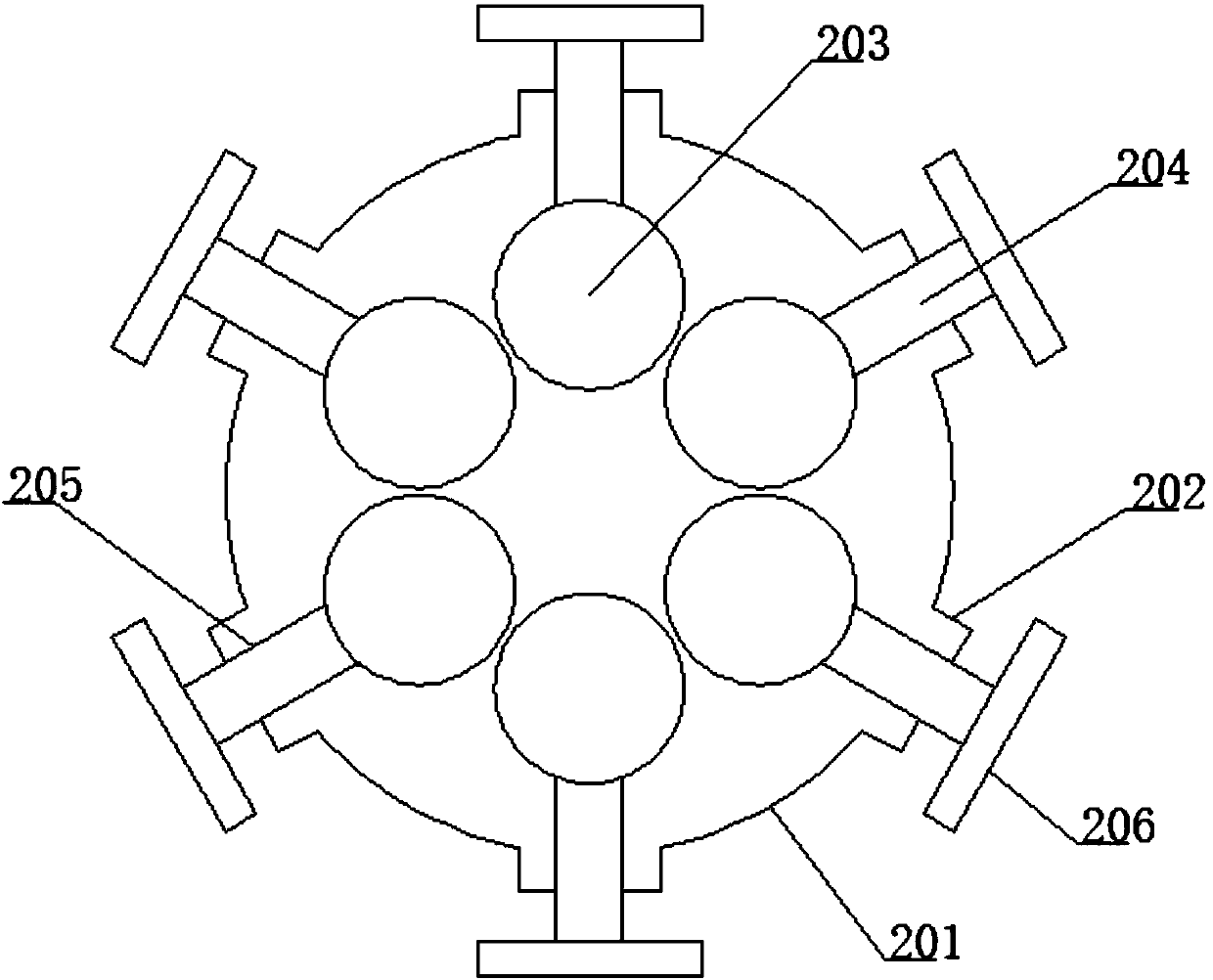

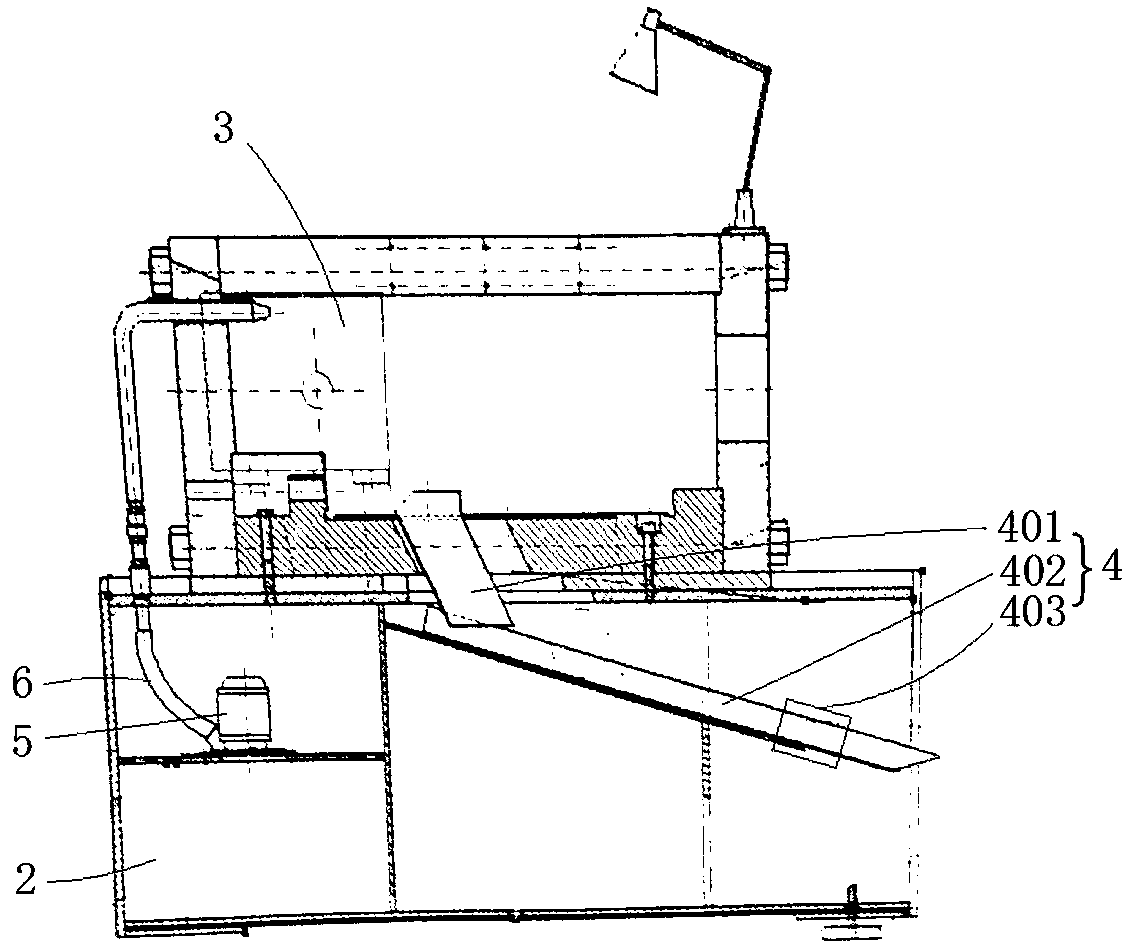

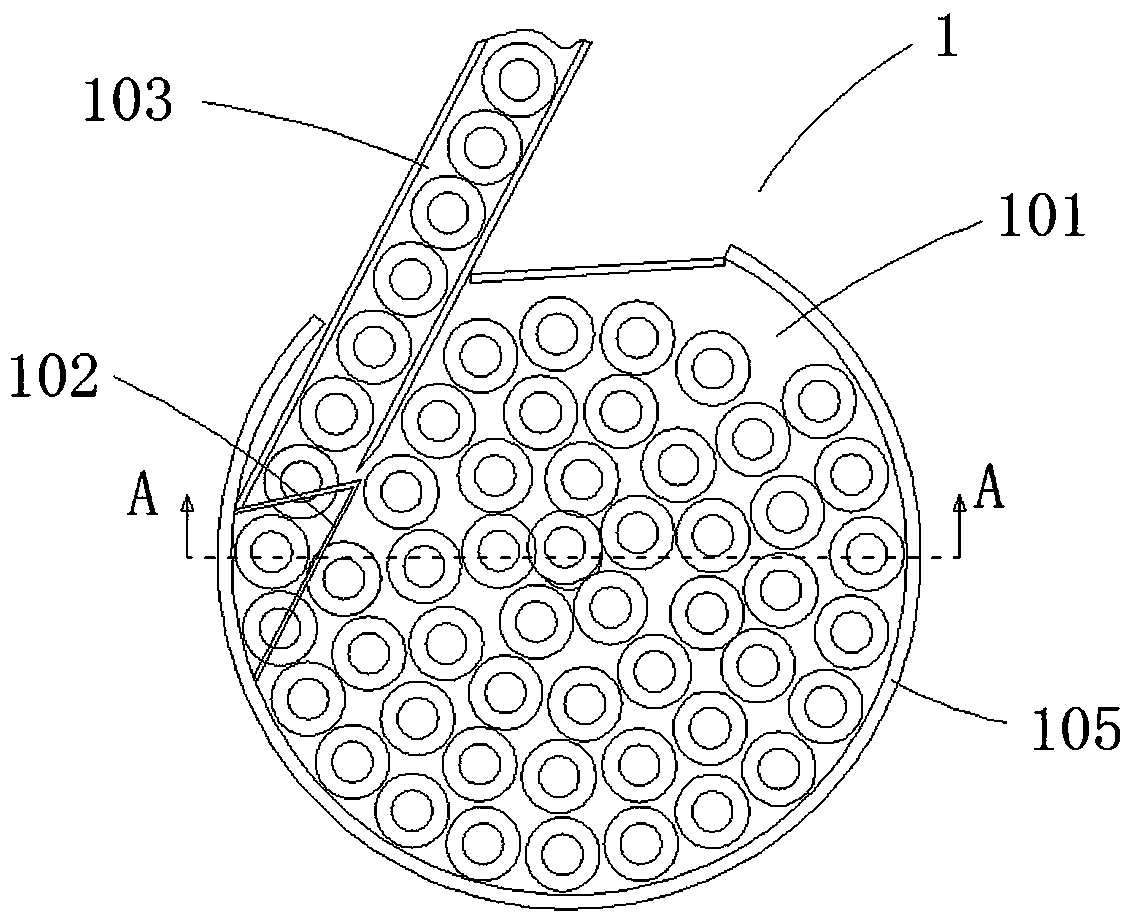

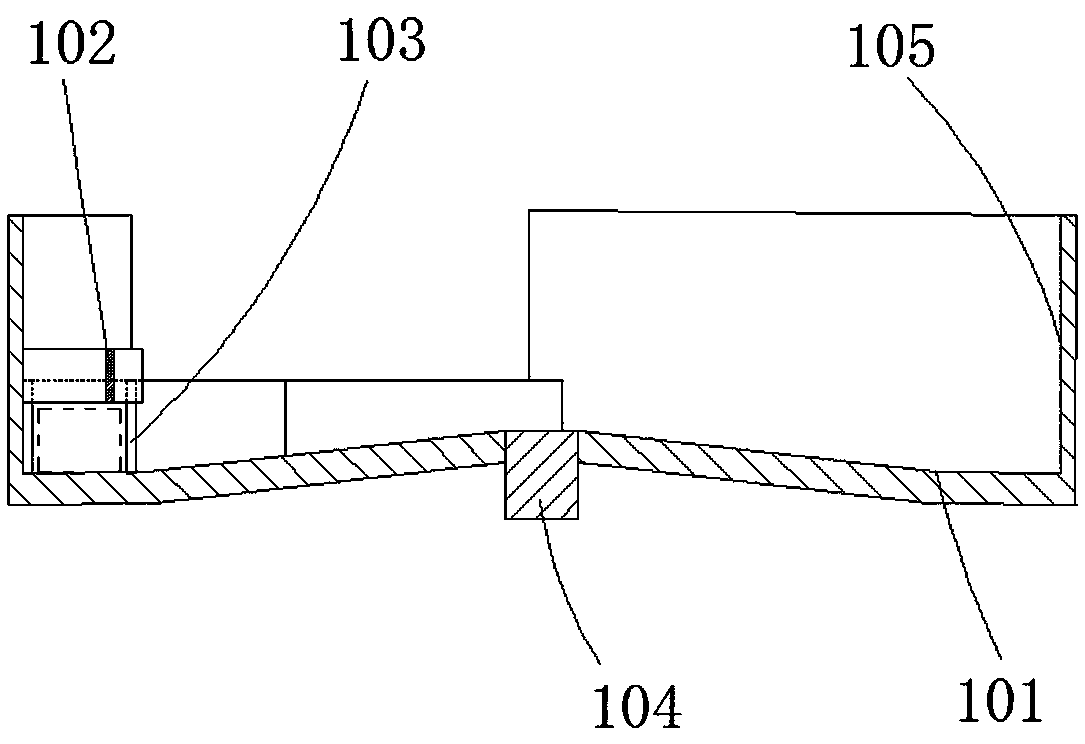

Full-automatic cold grinding and chambering equipment for bearing ring component and work method of full-automatic cold grinding and chambering equipment

InactiveCN108480532ASimple structureReliable feeding processMetal-working feeding devicesBearing componentsEngineeringMachining process

The invention discloses full-automatic cold grinding and chambering equipment for a bearing ring component, and relates to the technical field of advanced manufacturing and automation. The full-automatic cold grinding and chambering equipment comprises an automatic feeding device, a base, a cold grinding and chambering device and an unloading device. The automatic feeding device is arranged on oneside of the base. The cold grinding and chambering device and the unloading device are arranged on the base. A feeding port of the cold grinding and chambering device is connected with the automaticfeeding device, and a discharging port is connected with the unloading device. The automatic feeding device comprises a feeding rotary disc and further comprises a limiting baffle and a feeding regulation channel which are arranged on the feeding rotary disc. A rotation shaft part is arranged at the center of the feeding rotary disc and connected with a rotation driving device. A series of actionsincluding automatic feeding, cold grinding and chambering machining and automatic unloading are achieved, and unmanned producing and machining are achieved in the whole process. The automatic feedingdevice is simple in structure, the feeding process is stable and reliable, the repeated conveying preventing function is better achieved, and stability and safety of the integral machining process are guaranteed.

Owner:江苏保捷精锻有限公司

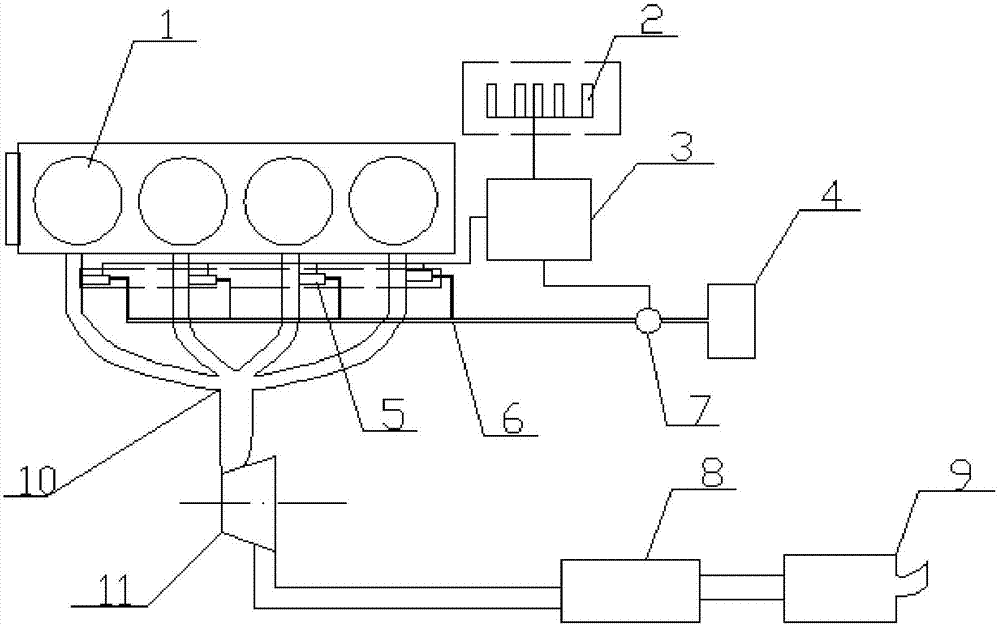

Method for reducing nitrogen oxide(s) and carbon monoxide from flue gases and flue gas composition

InactiveUS20160305655A1Residue reductionIncreasing burner efficiencyFuel supply regulationAir supply regulationCombustion chamberMeasuring instrument

A method for reducing nitrogen oxide(s) and carbon monoxide from flue gases of an industrial burner adapted to burn gaseous and / or liquid fuel is disclosed. The burner comprises burner automation containing measuring instruments, and a mixing zone accompanied by a combustion chamber. The burner automation is in communication with measurement instruments of flue gas conduit. The combustion chamber or flue gas conduit has two catalytic zones of at least one three-way catalytic converter(s). The catalytic zones are successive in progressing direction of flue gases. An inlet flow (QI, QItot) of combustion air and an inlet flow (QPA, QPAtot) of fuel is delivered into the mixing zone. The flue gases are generated in the combustion chamber by combusting air and fuel delivered into the mixing zone. The amount of residual oxygen is measured in flue gases by a lambda-sensor. The flue gases are directed to at least one three-way catalytic converter(s). The inlet flow (QI, QItot) of combustion air and the inlet flow (QPA, QPAtot) of fuel arriving in the mixing zone is adjusted by the burner automation, so that the mean amount of residual oxygen in moles compared to mean amount of carbon monoxide in moles, is 0.5 / 1 (mole / mole) and O2 within the range of 0.01-0.50 vol-% in flue gases prior to or at the first catalytic zone of the at least one three-way converter. Supplementary air is delivered between the first and the second catalytic zones of the three-way converter or between catalytic zones of two successive three-way catalytic converters, so that concentration in the flue gases after said catalytic zones is within range of 0-9 ppm for NOx and within a range of 0-100 ppm.

Owner:OILON TECH OY

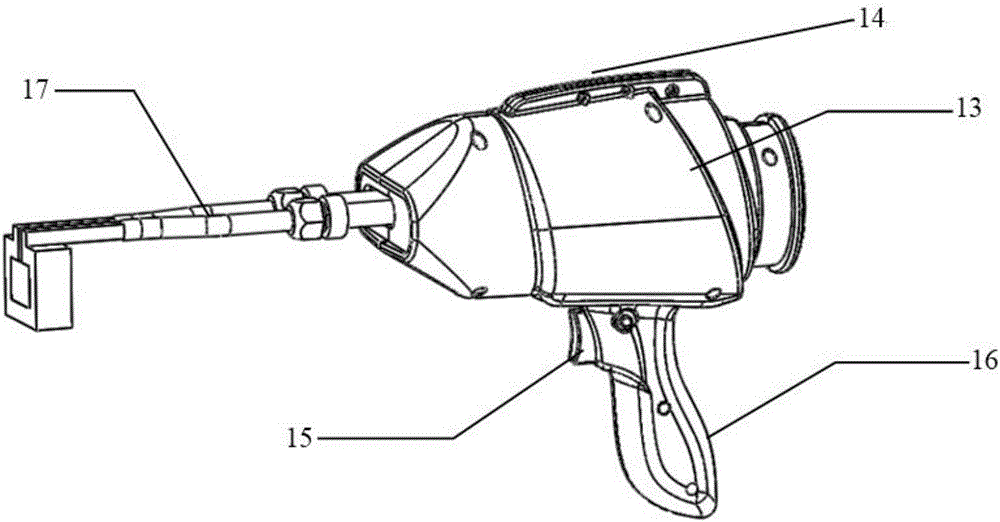

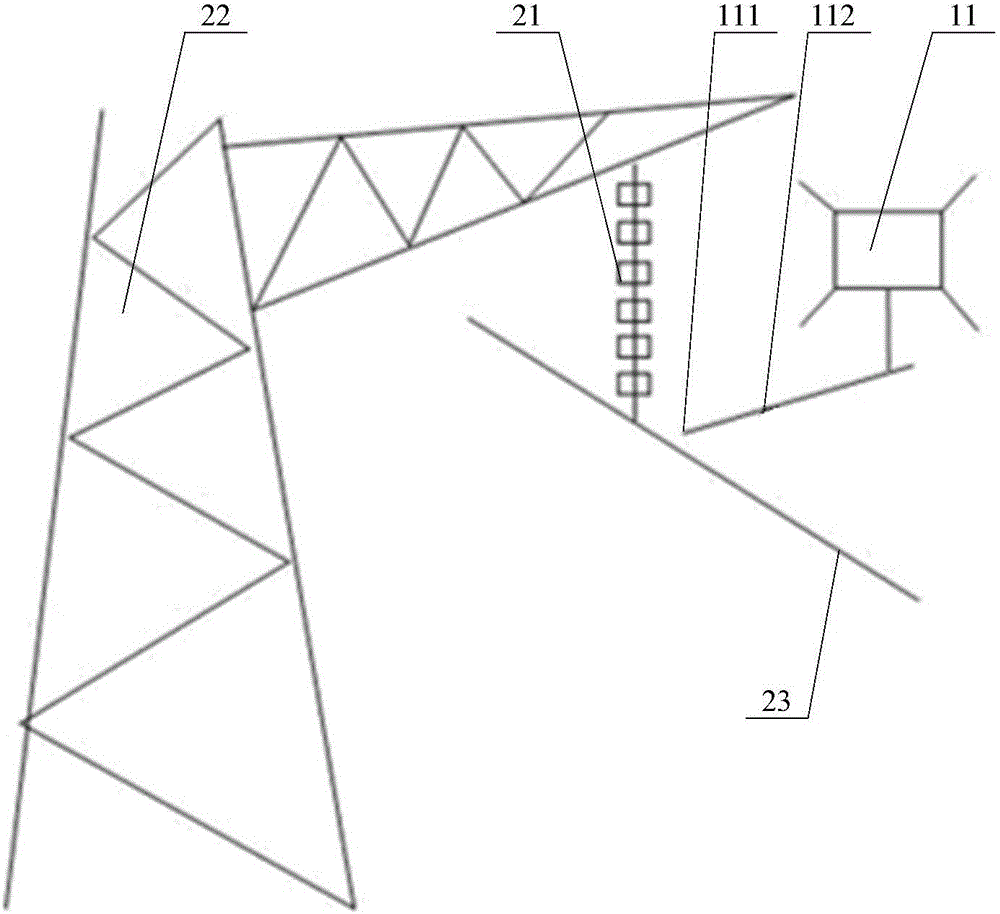

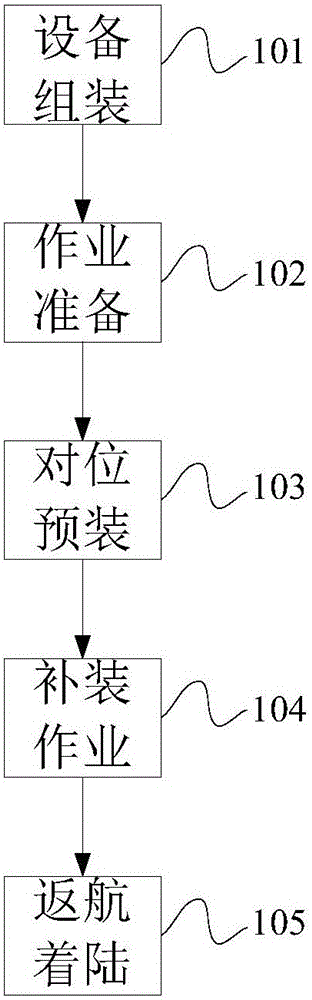

Unmanned aerial vehicle (UAV) live-line operation device and method

InactiveCN105720519APrecise and efficient replenishmentIncrease the effective working rangeApparatus for overhead lines/cablesUncrewed vehicleEmbedded system

The invention discloses an unmanned aerial vehicle live working equipment, which includes an unmanned aerial vehicle and a controller that cooperate with each other. The unmanned aerial vehicle is provided with an insulating operation head that matches the component to be reinstalled, and the insulating operation head is provided with a There are sensors matched with the controller, the drone is also provided with a detection device, and the controller is provided with a monitoring device matched with the detection device. During the working process, the staff controls the UAV to carry the insulating operation head equipped with the components to be replaced to fly to the live equipment where the corresponding components are missing through the controller, and uses the detection device and sensors to feed back the position information and working surface conditions to the controller, so that Through the monitoring device, the staff can understand the situation of the reinstallation work surface of the live equipment in real time, so that the components to be reinstalled can be accurately and efficiently reinstalled to the corresponding positions of the live equipment. The invention also discloses a live-working method of the unmanned aerial vehicle using the live-working equipment of the unmanned aerial vehicle.

Owner:STATE GRID CORP OF CHINA +1

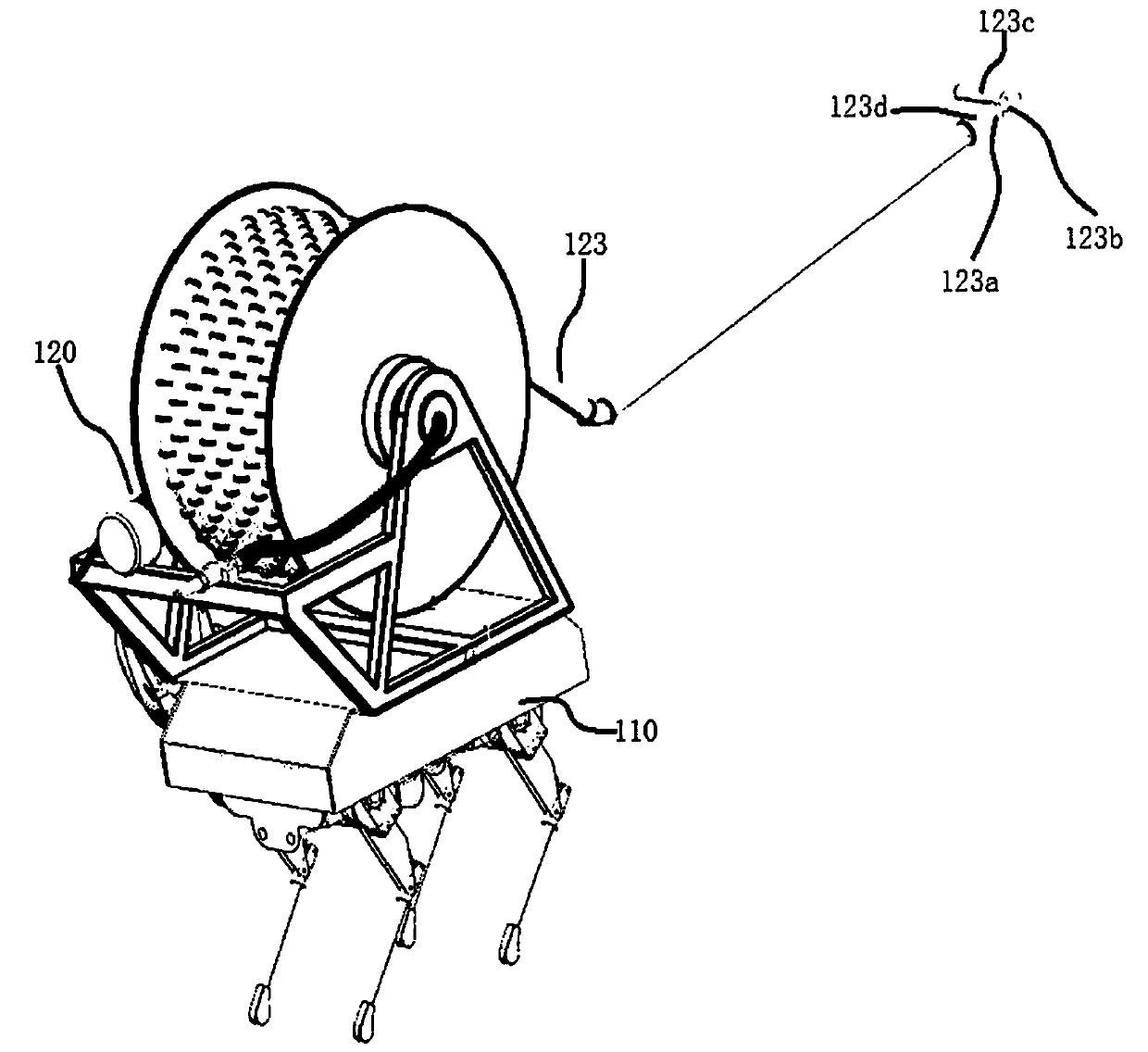

Foot-shaped reconnaissance fire-fighting rescue robot system and method

PendingCN110898357AIncrease the effective working rangePracticalFire rescueRescue robotControl system

The invention discloses a foot-shaped reconnaissance fire-fighting rescue robot system and method. The system includes a foot-shaped mobile chassis, a fire-fighting rescue component on the foot-shapedmobile chassis, and a background control system. The fire-fighting rescue component obtains on-site environmental data and / or on-site status data in real time, and implements fire extinguishing and / or rescue actions on the site. The background control system obtains the on-site environmental data and / or on-site status data obtained by the fire-fighting rescue component to form a fire-fighting rescue instruction to control the movement status of the foot-shaped mobile chassis and drive the fire-fighting rescue component to carry out fire extinguishing and / or rescue actions according to the movement status of the foot-shaped mobile chassis. The system and method can adapt to the scenes of various dangerous accidents, can perform real-time reconnaissance and fire extinguishing on the scene,have a very large effective working range and good practicability.

Owner:ZHEJIANG YUAN FIRE FIGHTING EQUIP +1

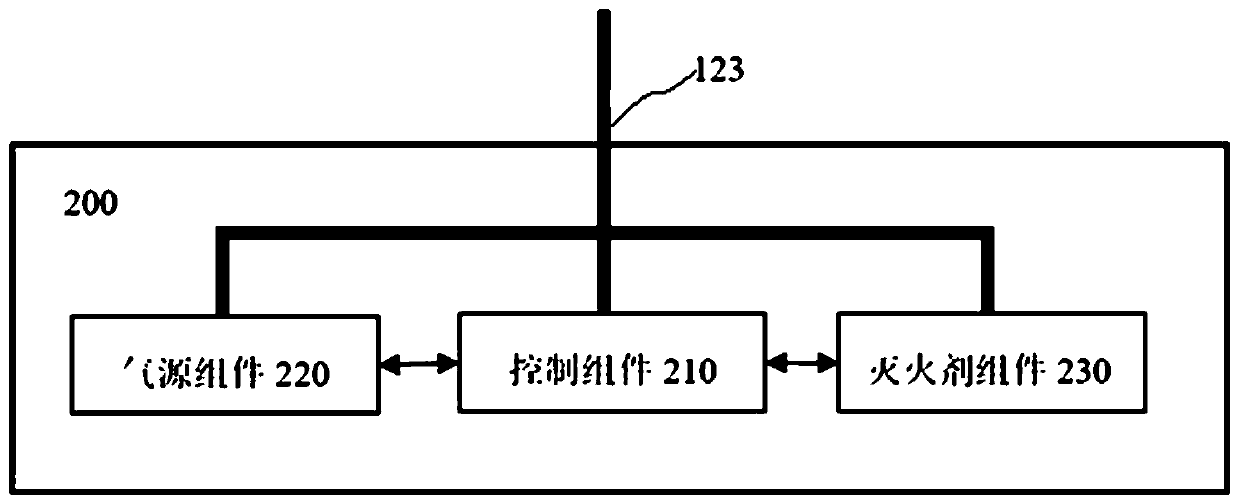

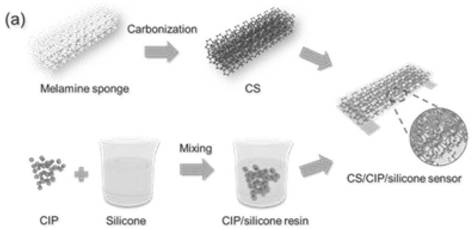

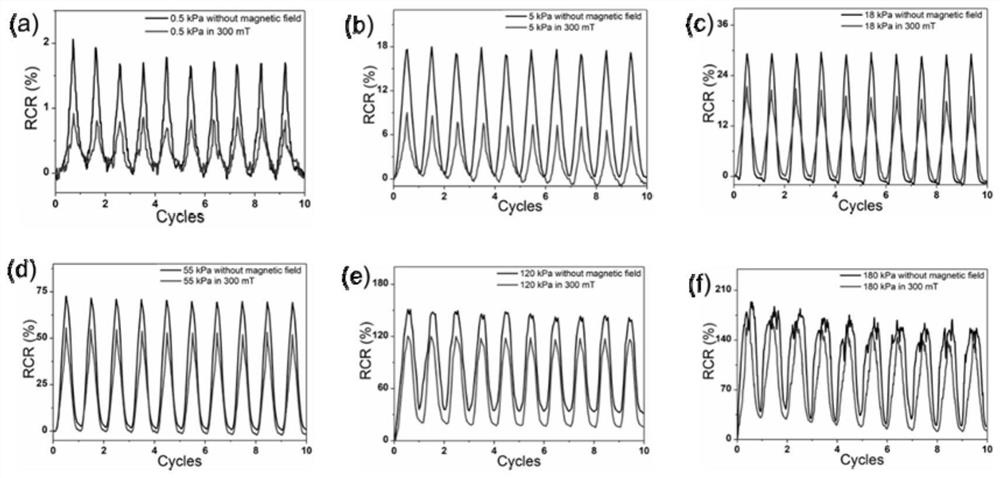

Flexible sensing material with adaptive piezoresistive performance and preparation method and application thereof

ActiveCN113444368AAdaptive piezoresistive performance tuningGood piezoresistive response performanceRespiratory organ evaluationSensorsResponse sensitivityChain structure

The invention provides a flexible sensing material with adaptive piezoresistive performance and a preparation method and application thereof. The flexible sensing material specifically comprises a conductive filler, a magnetic filler and an elastic high polymer material. The three-dimensional network structure of the conductive filler is damaged under the action of external force, and the resistivity of the material changes; when the stress is removed, the conductive network is recovered by depending on the elasticity of the high polymer material, and the resistivity of the material also returns to the initial state, so that the stress detection can be completed; under the action of a magnetic field, the magnetic filler in the material moves along the direction of the magnetic field to form a chain structure so that the compression modulus of the piezoresistive sensing material is increased, and the pressure detection range of the sensing material under the same compression strain is further adjusted. Compared with a traditional flexible piezoresistive material, the material keeps relatively high response sensitivity in a low stress range; and the working range is greatly enlarged after the magnetic field is applied. The material can realize the detection of micro stress and large stress, and is beneficial to the portable, integrated and intelligent design of the flexible stress sensor.

Owner:CHONGQING UNIV

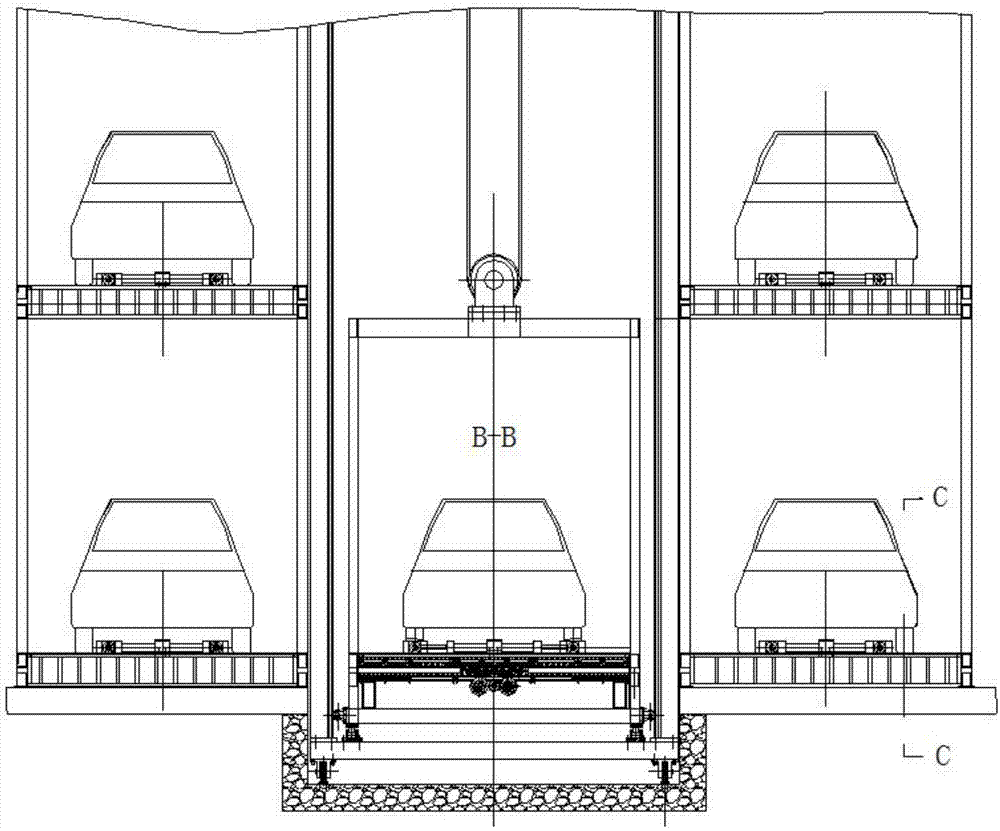

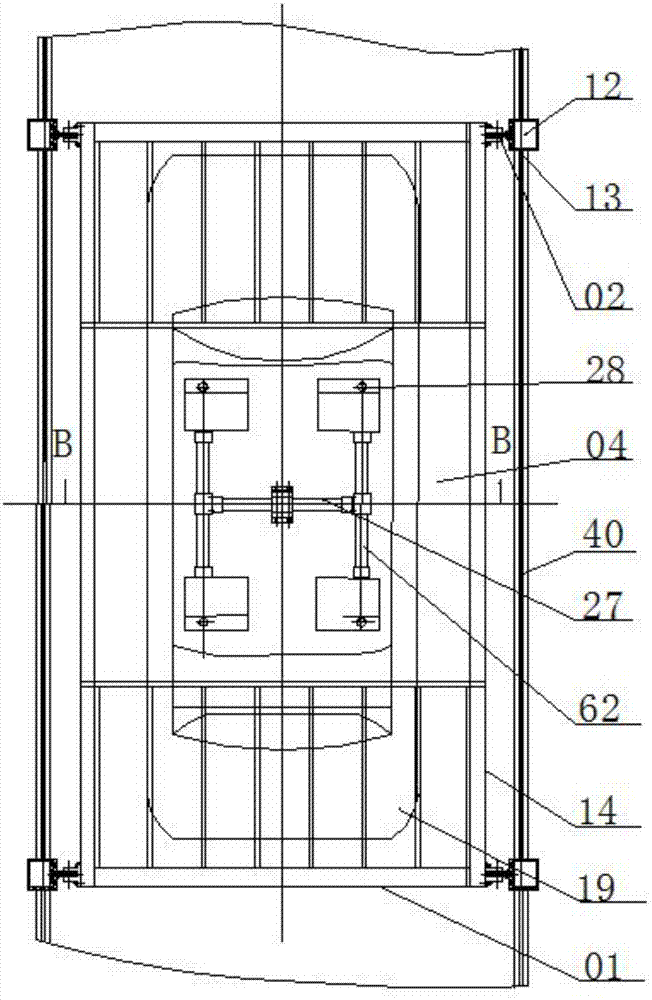

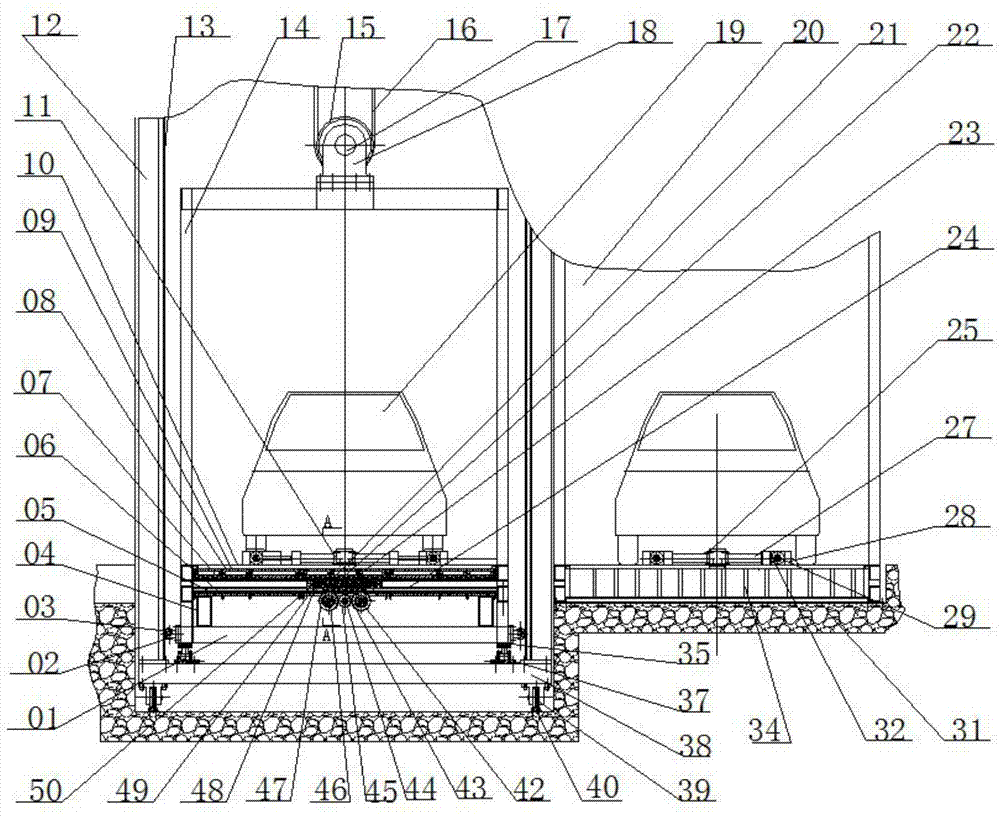

Gear transmission bi-directional multiplication telescopic transverse moving mechanism for a stereo garage

The invention provides a gear transmission bi-directional multiplication telescopic transverse moving mechanism for a stereo garage. The gear transmission bidirectional multiplication telescopic transverse moving mechanism comprises a lifting hanging box, and a lifting device is arranged at the upper end of the lifting hanging box, transverse telescopic mechanisms are arranged on the front position and the rear position of a hanging box bottom frame at the lower end of the lifting hanging box, and telescopic connecting plates are arranged at the upper ends of the transverse telescopic mechanisms on the front position and the rear position; and a wheel locating device is arranged on each telescopic connecting plate. According to the gear transmission bidirectional multiplication telescopictransverse moving mechanism for the stereo garage, bi-directional carrying between lanes can be realized without adding a reversing device, and effective conveying greater than the body width of a mechanism is obtained; the relative size is small, the structure is simple and reliable, integrated controlling is convenient, and the stereo garage gear transmission bidirectional multiplication telescopic transverse moving mechanism can be used as automation and intelligent transferring executive mechanism technique applied in lane occasion.

Owner:ANHUI SYNCHRONOUS AUTOMATION TECH

Landscaping comprehensive maintenance vehicle fertilization control system and using method

InactiveCN112492947AIncrease the effective working rangeMeet the needs of different working environmentsTransportation and packagingUsing liquid separation agentAgricultural scienceControl system

The invention relates to a landscaping comprehensive maintenance vehicle fertilization control system and a using method. The landscaping comprehensive maintenance vehicle fertilization control systemis characterized in that the landscaping comprehensive maintenance vehicle fertilization control system comprises a chassis, a carriage, a spray tank, a high-pressure water pump, a water pump drivingdevice, a first water pipe, a second water pipe, a pesticide applying device and a controller. According to the connecting manner of the landscaping comprehensive maintenance vehicle fertilization control system, the carriage is installed on the chassis, the spray tank is arranged in the carriage or arranged on the chassis in parallel with the carriage, the water pump driving device is connectedwith the chassis, the high-pressure water pump is connected with the water pump driving device, the high-pressure water pump is communicated with the spray tank through the first water pipe, and the high-pressure water pump is communicated with the spray tank through the second water pipe; and the high-pressure water pump is communicated with the pesticide applying device through the second waterpipe, and the controller is electrically connected with the water pump driving device. Operation is conducted according to the using method, underground deep-root fertilization can be conducted, overground foliage spraying can also be conducted, the beneficial effects of being uniform in pesticide effect, high in fertilization efficiency and large in operation range are achieved, and the landscaping comprehensive maintenance vehicle fertilization control system and the using method belong to the technical field of fertilization and pesticide spraying equipment.

Owner:上海神舟精宜汽车测控技术有限公司

Dual-optical path molecular image navigation system and imaging method with switchable field of view

ActiveCN104367380BIncrease the effective working rangeSurgeryDiagnostic recording/measuringCamera controlFluorescence

The invention discloses a view-switchable dual-optical-path molecular image navigation system and an imaging method. The view-switchable dual-optical-path molecular image navigation system comprises a camera module, an imaging system switching module, an open-type imaging module, an endoscopic-type imaging module, a data processing module and a system support module. The camera module is used for color imaging and fluorescence imaging. The imaging system switching module is used for switching an open-type imaging mode or an endoscopic-type imaging mode according to imaging need. The open-type imaging module is used for large-view observation imaging. The endoscopic-type imaging module is used for deep-view detection imaging. The data processing module is used for providing camera control software and image acquisition, processing and display methods. The system support module is used for providing support and connection for navigation equipment.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Gas Powered Ultrasonic Multiphase Mixer

ActiveCN106139460BImprove fire extinguishing efficiencyImprove fire extinguishing effectFire rescueMixed flowMicrometer

The invention discloses a pneumatic ultrasonic multiphase mixer. The pneumatic ultrasonic multiphase mixer comprises a body, a gas flow guide chamber for introducing inflowing gas in the horizontal direction and for accelerating the gas to generate ultrasonic waves through resonance, a liquid flow guide chamber and a mixing chamber. The gas flow guide chamber comprises a flow guide chamber body, a center rod and a resonant chamber. The liquid flow guide chamber is arranged in the vertical direction of the main body and used for rupturing liquid through liquid nozzles, wherein solid powder is added to the liquid of the liquid flow guide chamber or the gas of the gas flow guide chamber in advance. The resonant chamber is contained in the mixing chamber. The mixing chamber is arranged in the horizontal direction of the main body and comprises an inner chamber body and a mixing chamber outlet communicating with the inner chamber body. Gas-phase continuous multiphase mist flow or liquid-phase continuous multiphase bubble flow is output through the mixing chamber outlet. According to the pneumatic ultrasonic multiphase mixer, mixing of the gas phase, the liquid phase and the solid phase is strengthened through the ultrasonic waves, and uniform multiphase mixed flow is formed; and water mist with the diameter being lower than 10 micrometers can be generated, the misting effect is better, the liquid-phase continuous multiphase bubble flow can be output as well, and thus the fire extinguishing efficiency is improved.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com