Full-automatic cold grinding and chambering equipment for bearing ring component and work method of full-automatic cold grinding and chambering equipment

A fully automatic technology for bearing rings, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as unmanned processing lines, and achieve the effects of ensuring stability, reliable feeding process, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

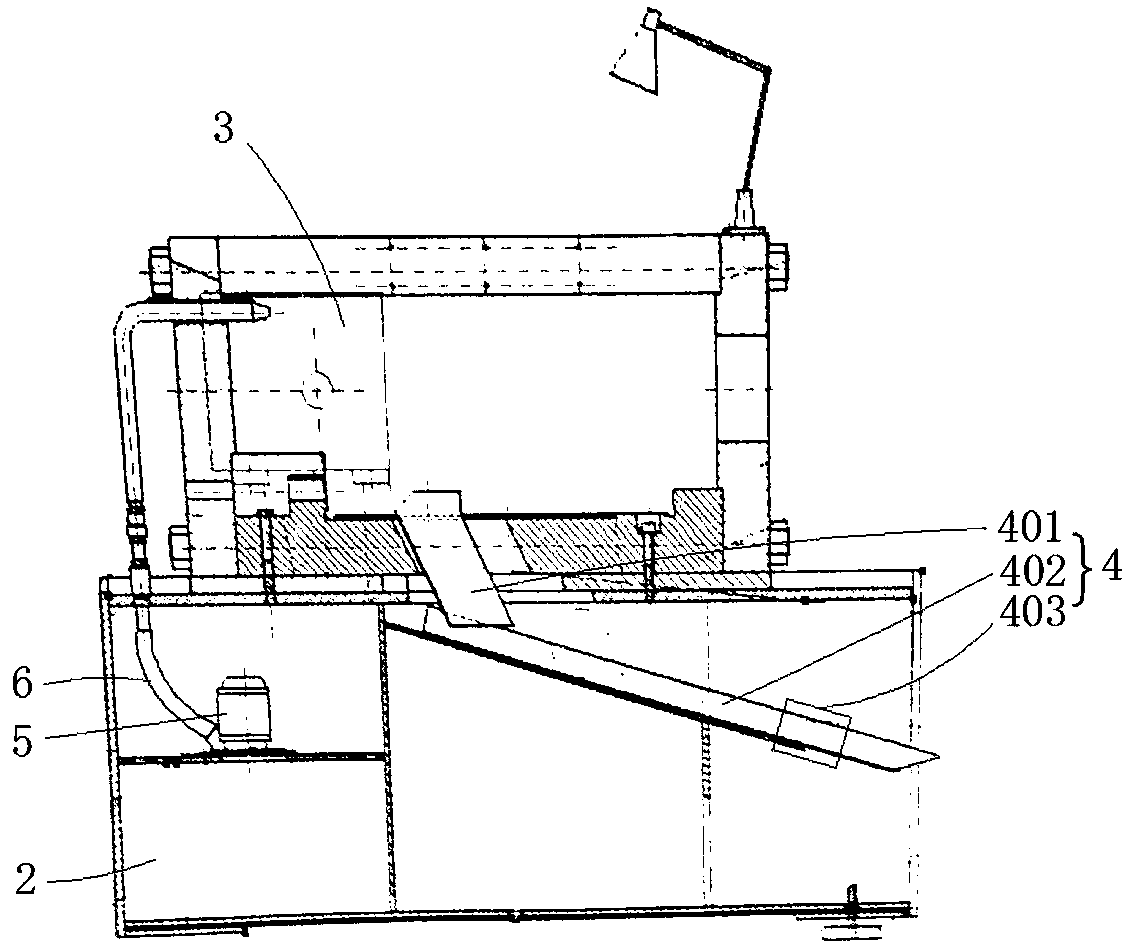

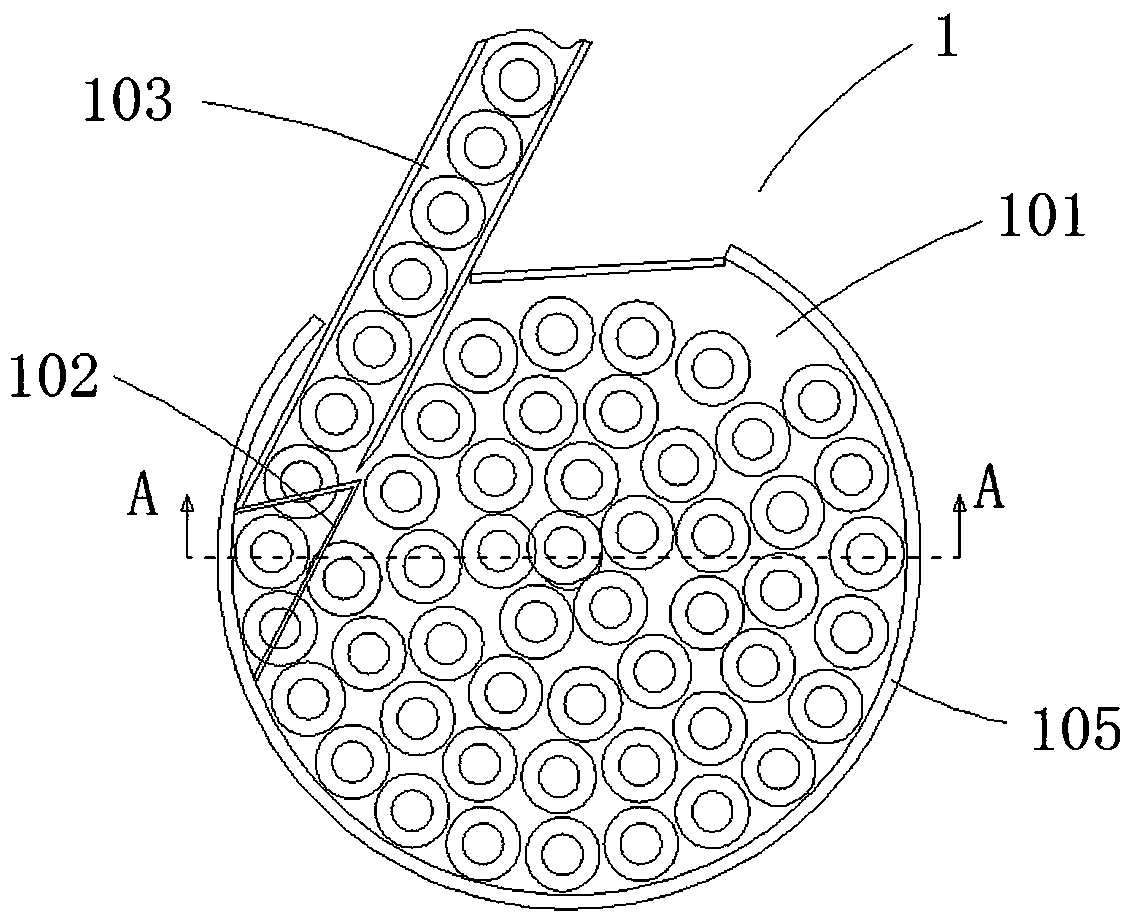

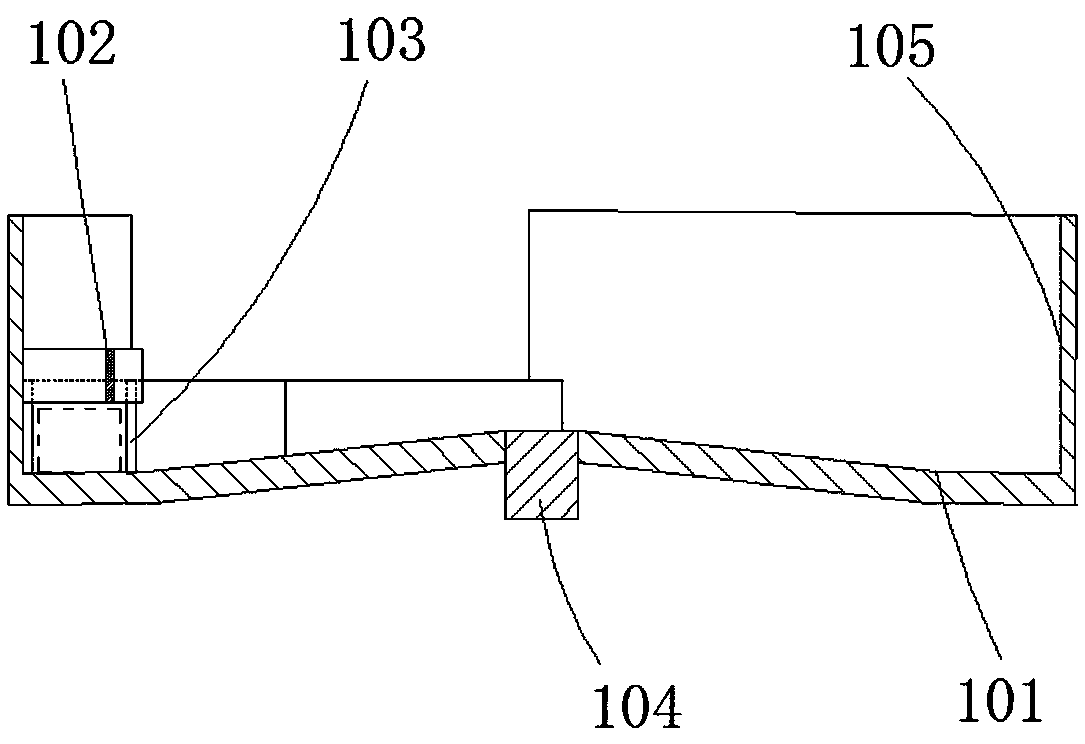

[0031] A kind of fully automatic cold rolling hole reaming equipment used for bearing ring parts of the present invention, such as Figure 1 to Figure 3 As shown, it includes an automatic feeding device 1, a base 2, a cold rolling reaming device 3 and a discharge device 4, the automatic feeding device 1 is arranged on one side of the base 2, and the cold rolling reaming device 3 and the unloading device 4 are installed On the base 2, the feed port of the cold rolling reaming device 3 is connected with the automatic feeding device 1, and the discharge port is connected with the unloading device 4; the automatic feeding device 1 includes a feeding turntable 101, and is arranged on the feeding turntable 101 The upper limit baffle 102 and the feeding regulation channel 103, the center of the feeding turntable 101 is provided with a rotating shaft part 104, and the rotating shaft part 104 is connected with a rotating drive device.

[0032] In this embodiment, one end of the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com