Tower crane

A technology of tower cranes and tower cranes, which is applied in the direction of cranes, etc., and can solve the problems of difficult processing and transportation, large superstructure size, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

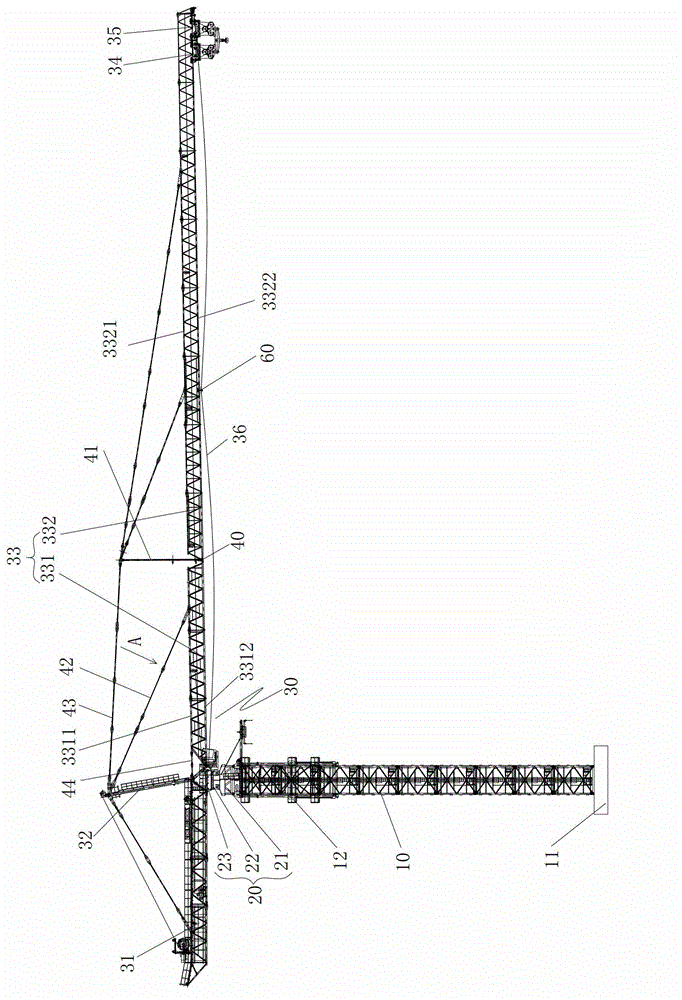

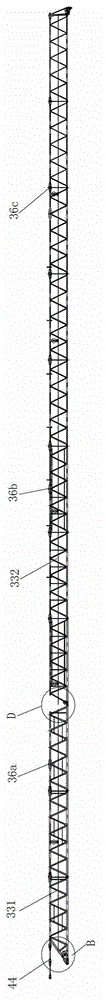

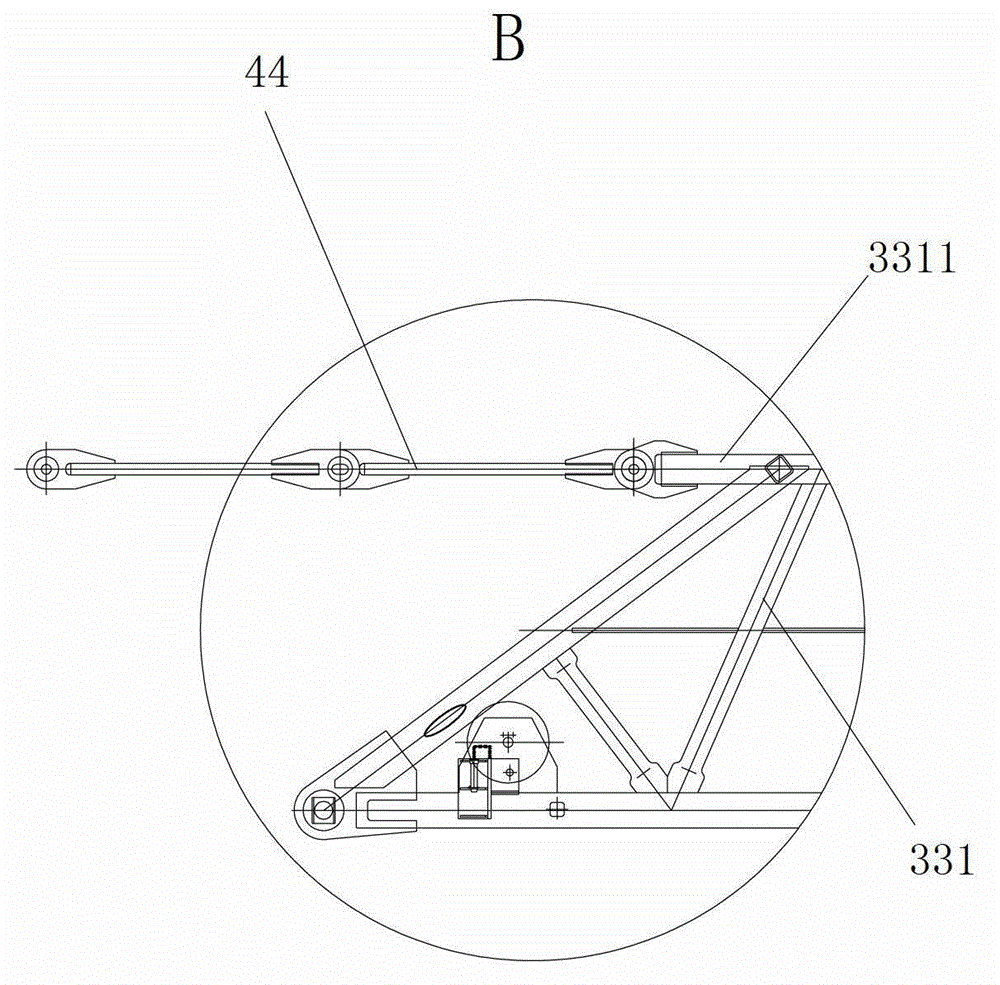

[0043] Such asfigure 1 As shown, according to an embodiment of the present invention, a tower crane is provided, including a tower body 10, a slewing mechanism 20 arranged on the top of the tower body 10, and an upper structure 30 arranged on the slewing mechanism 20, wherein the tower body 10 The bottom of the tower is fixed on the ground through a fixed foundation 11. The tower body 10 includes a plurality of standard sections fixedly connected together. The top of the tower body 10 is provided with a jacking mechanism 12 for adding standard sections. The jacking mechanism 12 includes a surrounding The climbing frame outside the standard section can jack up the upper structure 30 of the tower body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com