Patents

Literature

33results about How to "Play a supercharging role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

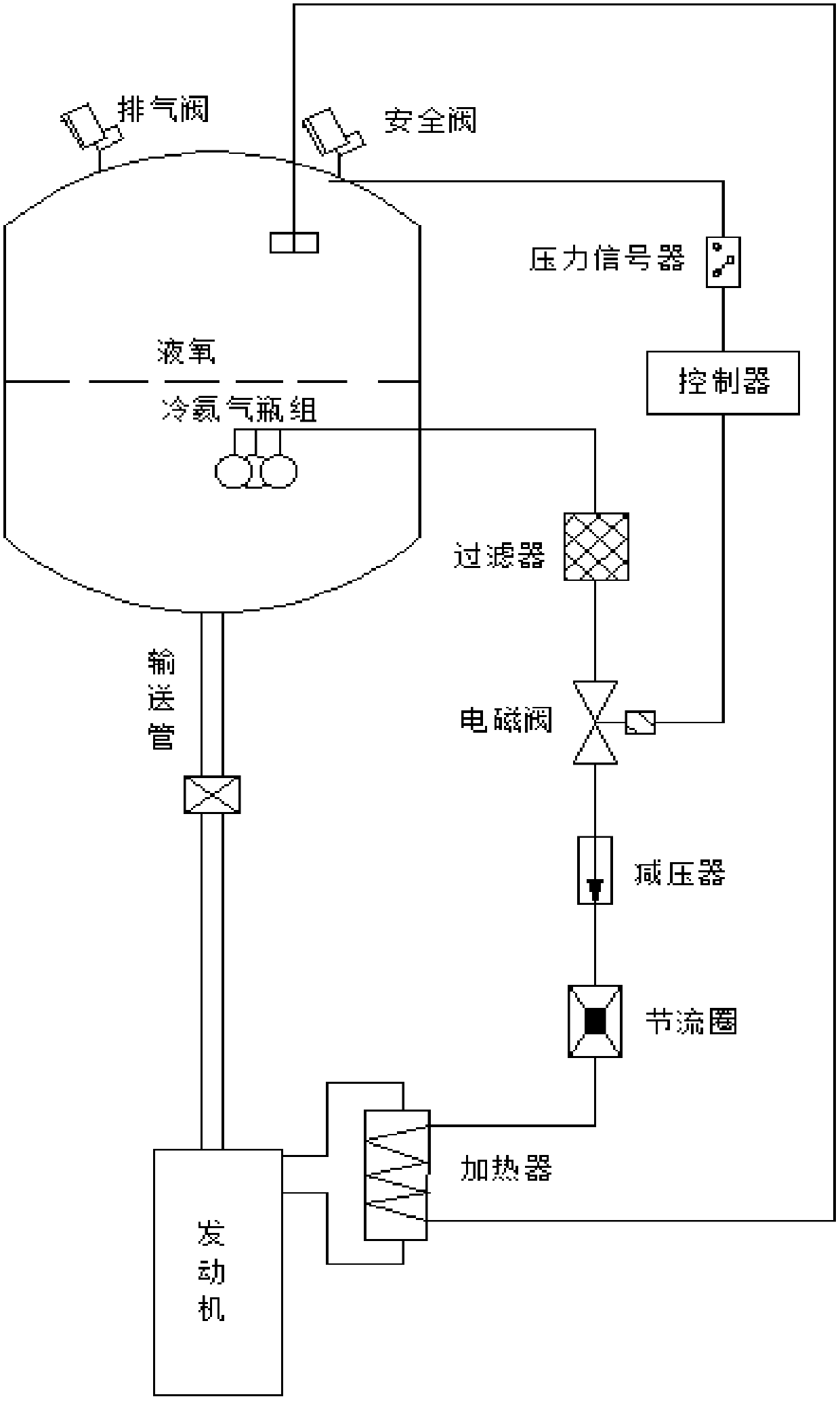

Cold helium heating and pressurizing system for rocket oxygen tank

InactiveCN107630769AIncrease carrying capacityReduce weightRocket engine plantsCarrying capacityOxygen tank

The invention discloses a cold helium heating and pressurizing system and method for a rocket oxygen tank. The cold helium heating and pressurizing method for the rocket oxygen tank comprises the steps that a certain number of cold helium cylinders are placed in the liquid oxygen storage tank, helium in the cold helium cylinders enters a gas pillow of the liquid oxygen storage tank after passing through a filter, an electromagnetic valve, a pressure reduction device, a throttling ring and a heater, and then liquid oxygen is pressurized. The cold helium heating and pressurizing system and method for the rocket oxygen tank have the advantages that helium in the cold helium cylinders enters the gas pillow of the liquid oxygen storage tank after being filtered, decompressed and heated, so thatliquid oxygen is pressurized, and the requirement for the pressure at an inlet of an engine is met. Through reasonable design of the cold helium heating and pressurizing system, it is ensured that under the normal operating condition of the cold helium heating and pressurizing system, the self weight of the heating and pressurizing system can be reduced, meanwhile, the effective utilization rateof helium can be increased, the carrying capacity of a rocket is improved accordingly; and meanwhile, the heating and pressurizing system has high safety and reliability.

Owner:SHANGHAI AEROSPACE SYST ENG INST +1

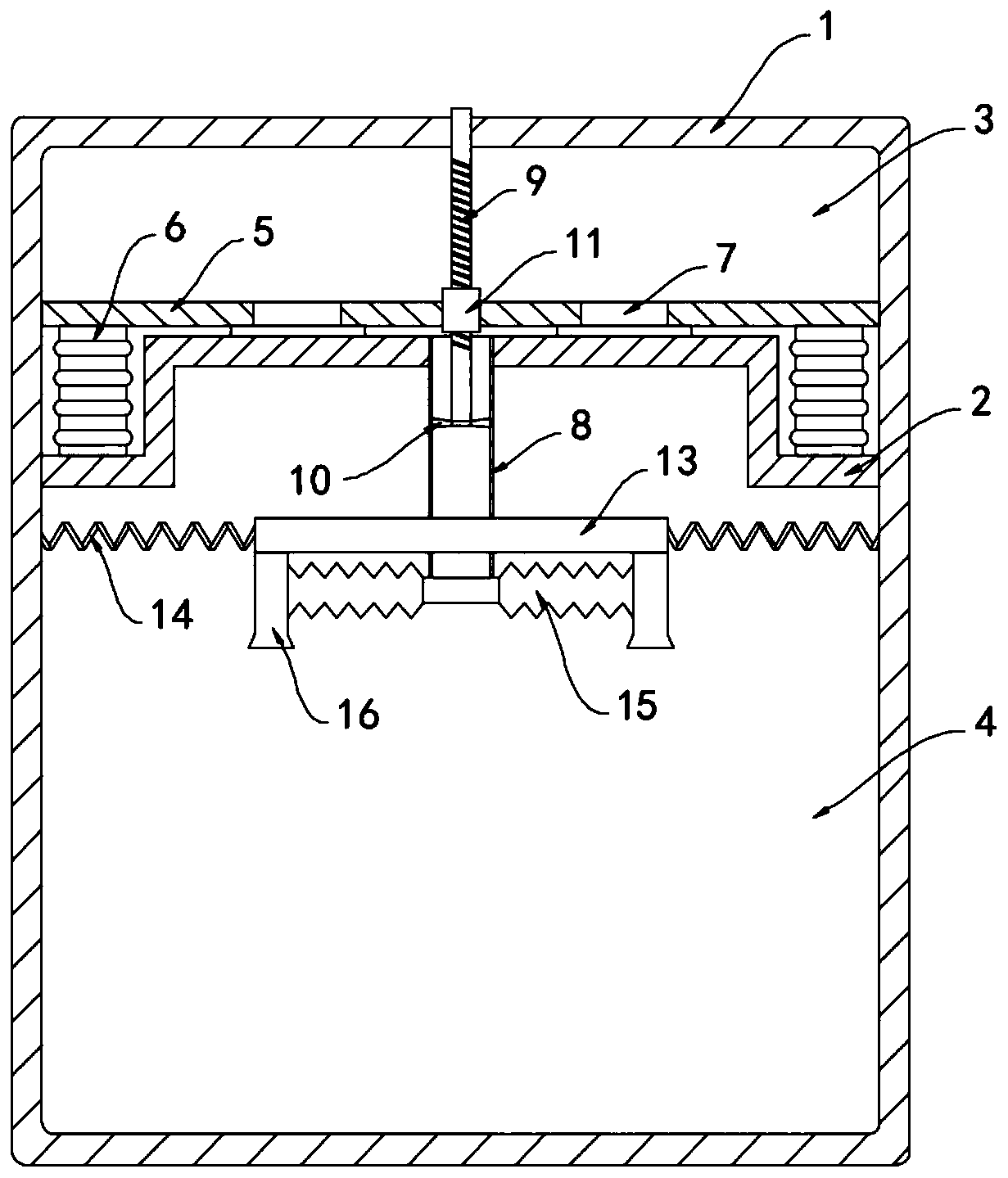

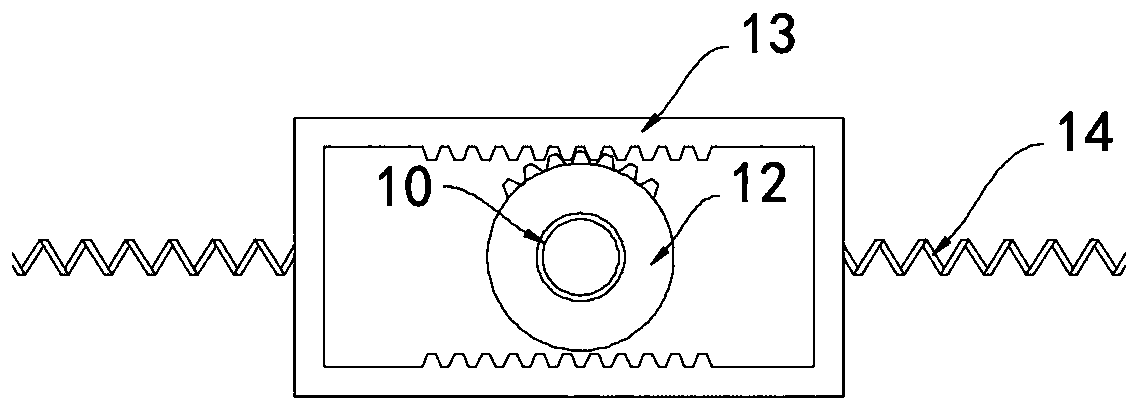

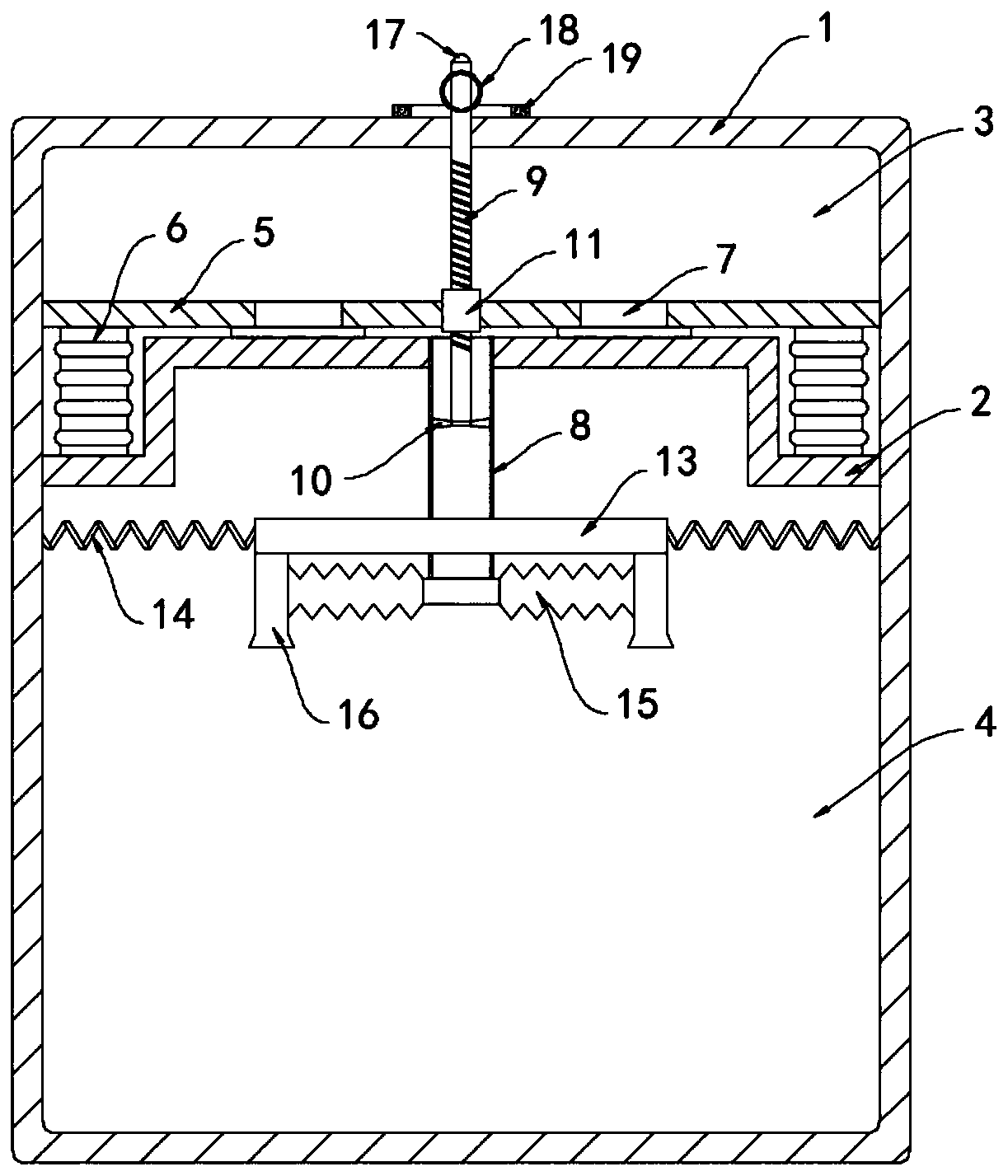

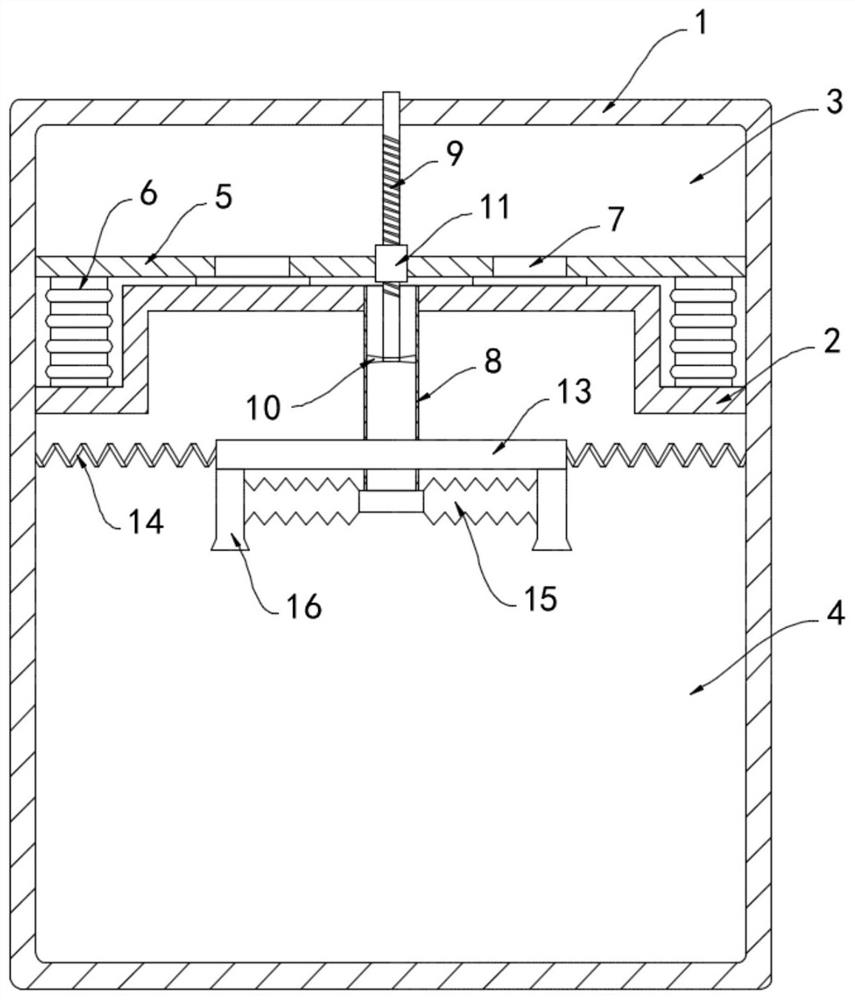

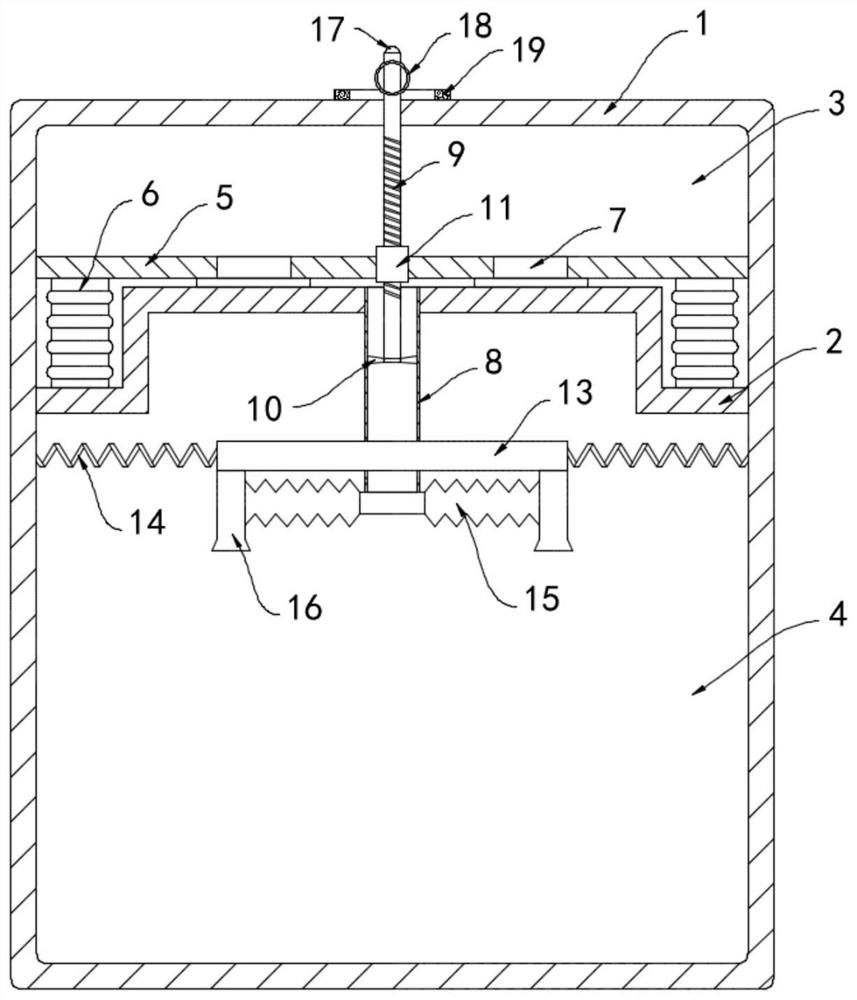

Outdoor power distribution cabinet with rapid self-extinguishing function

ActiveCN111555141AIncrease jet speedImprove fire extinguishing effectSubstation/switching arrangement casingsFire rescueStructural engineeringThreaded rod

The invention belongs to the field of power distribution cabinets, and especially relates to an outdoor power distribution cabinet with a rapid self-extinguishing function. The cabinet comprises a cabinet body, and a partition plate which is horizontally arranged is fixedly mounted on the inner side wall of the cabinet body; the partition plate divides the cabinet body into a fire extinguishing cavity and a mounting cavity; and the inner side wall of the fire extinguishing cavity is connected with a horizontally-arranged sealing plate in a sealed and sliding mode. The lower surface of the sealing plate is fixedly connected with a partition plate through an elastic air bag. The elastic air bag is filled with a thermal expansion and cold contraction medium, two through holes are formed in the sealing plate, and a vertically-arranged flow guide pipe rotationally penetrates through the partition plate, the flow guide pipe and the two through holes are arranged in a staggered mode, and a threaded rod arranged in the axial direction of the flow guide pipe is arranged in the flow guide pipe. When a fire occurs in the power distribution cabinet, a fire extinguishing agent in the fire extinguishing cavity can be automatically sprayed to electrical equipment in the mounting cavity, so that an automatic fire extinguishing effect is achieved, the fire in the cabinet body can be quickly controlled, and the possibility of economic loss and dangerous accidents is reduced.

Owner:胜利油田大源节能设备有限公司

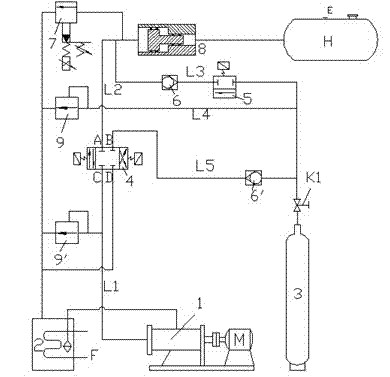

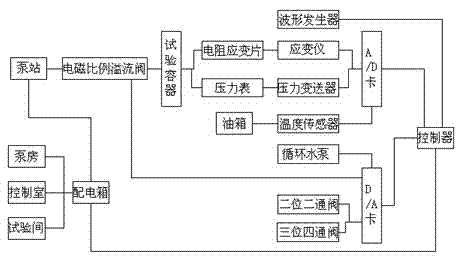

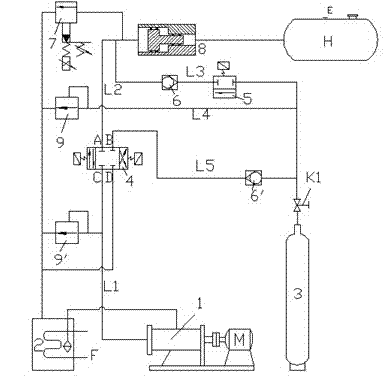

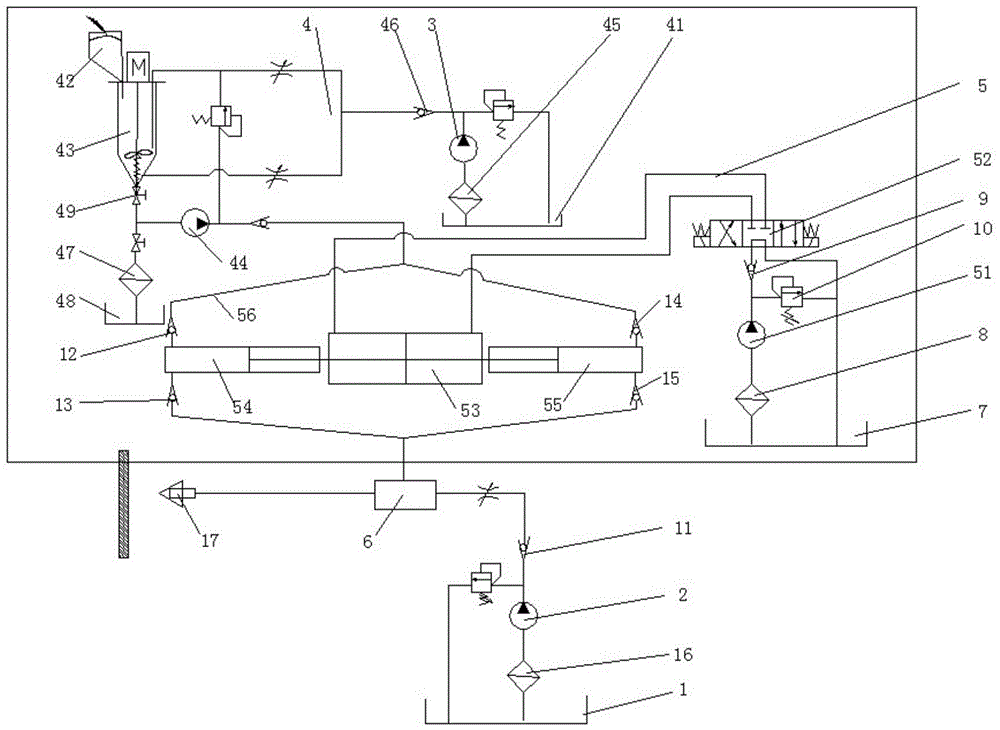

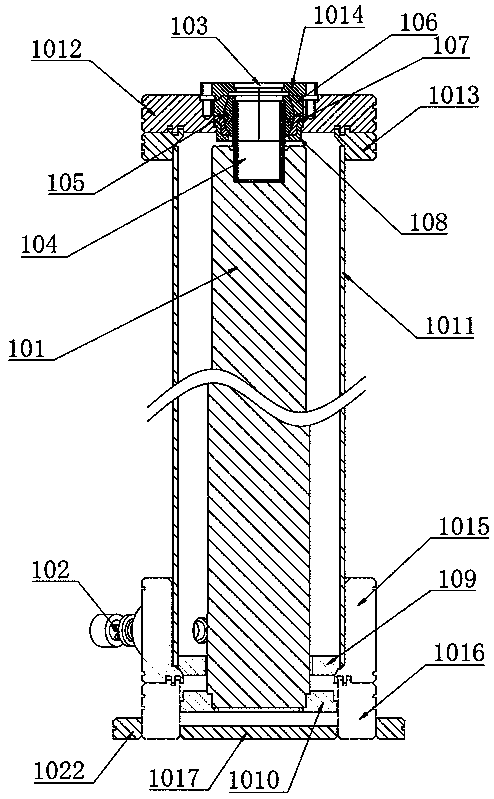

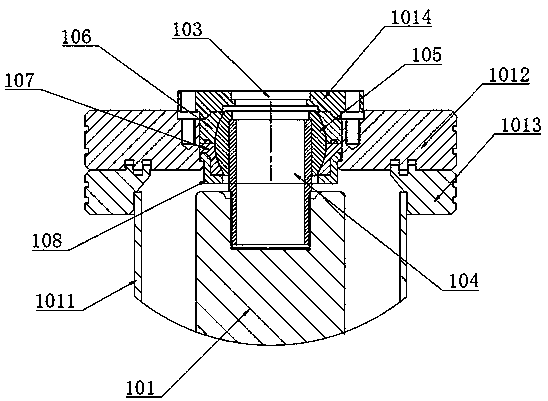

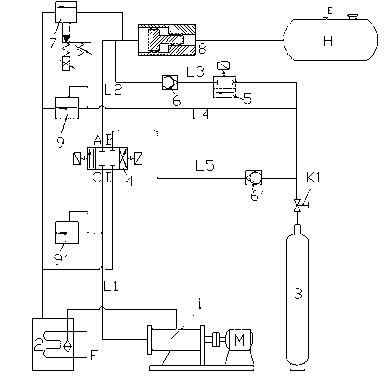

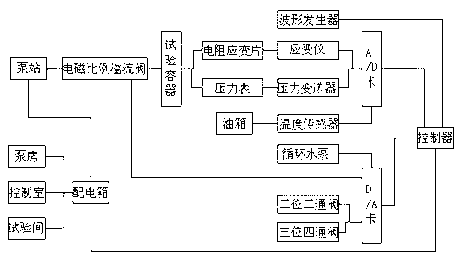

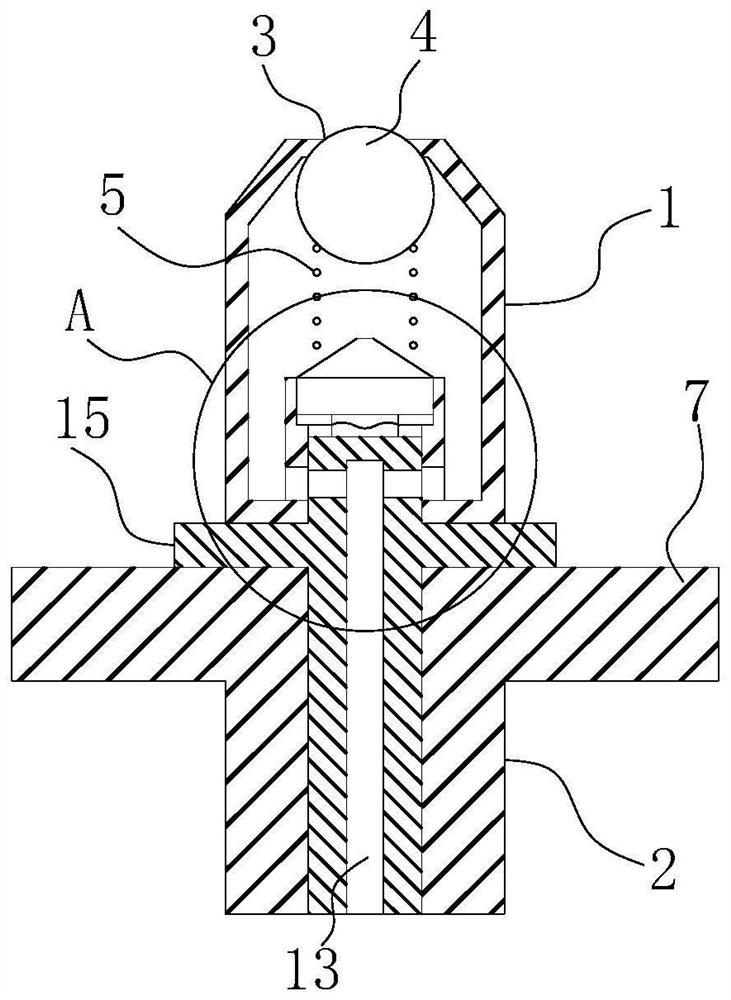

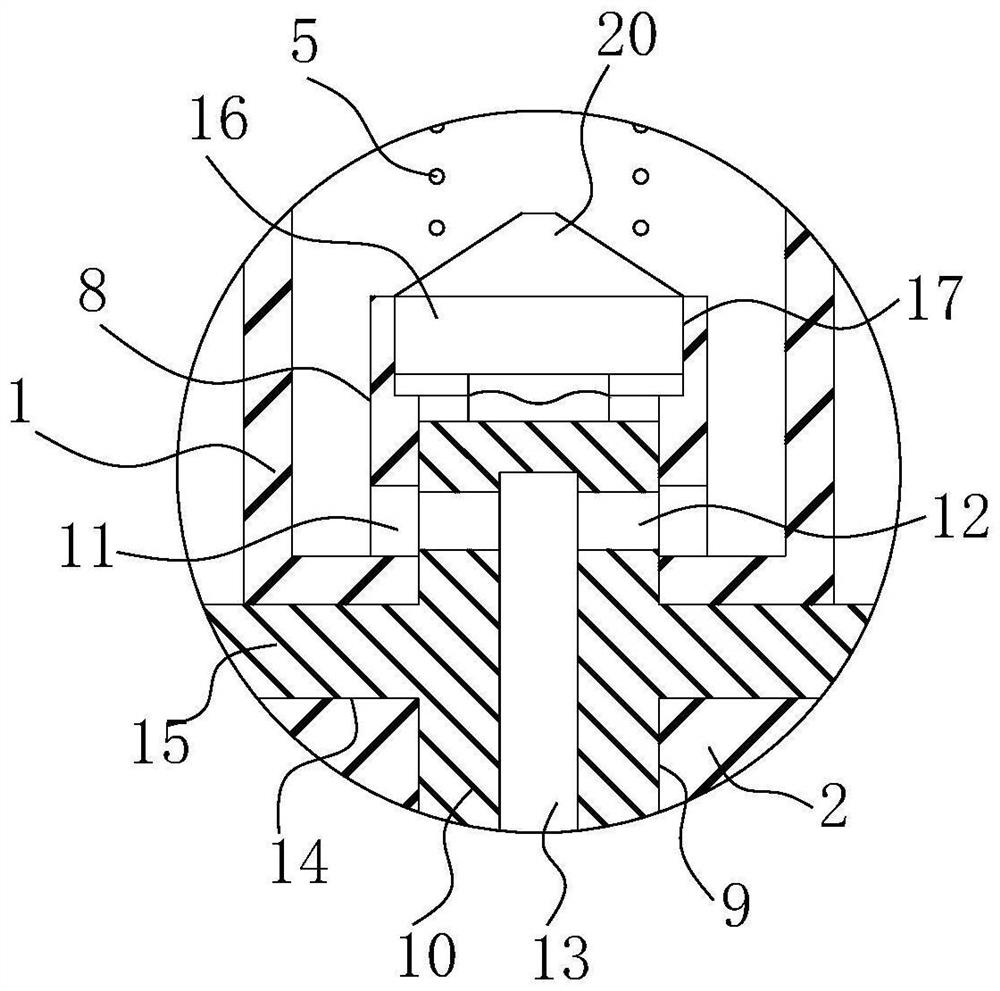

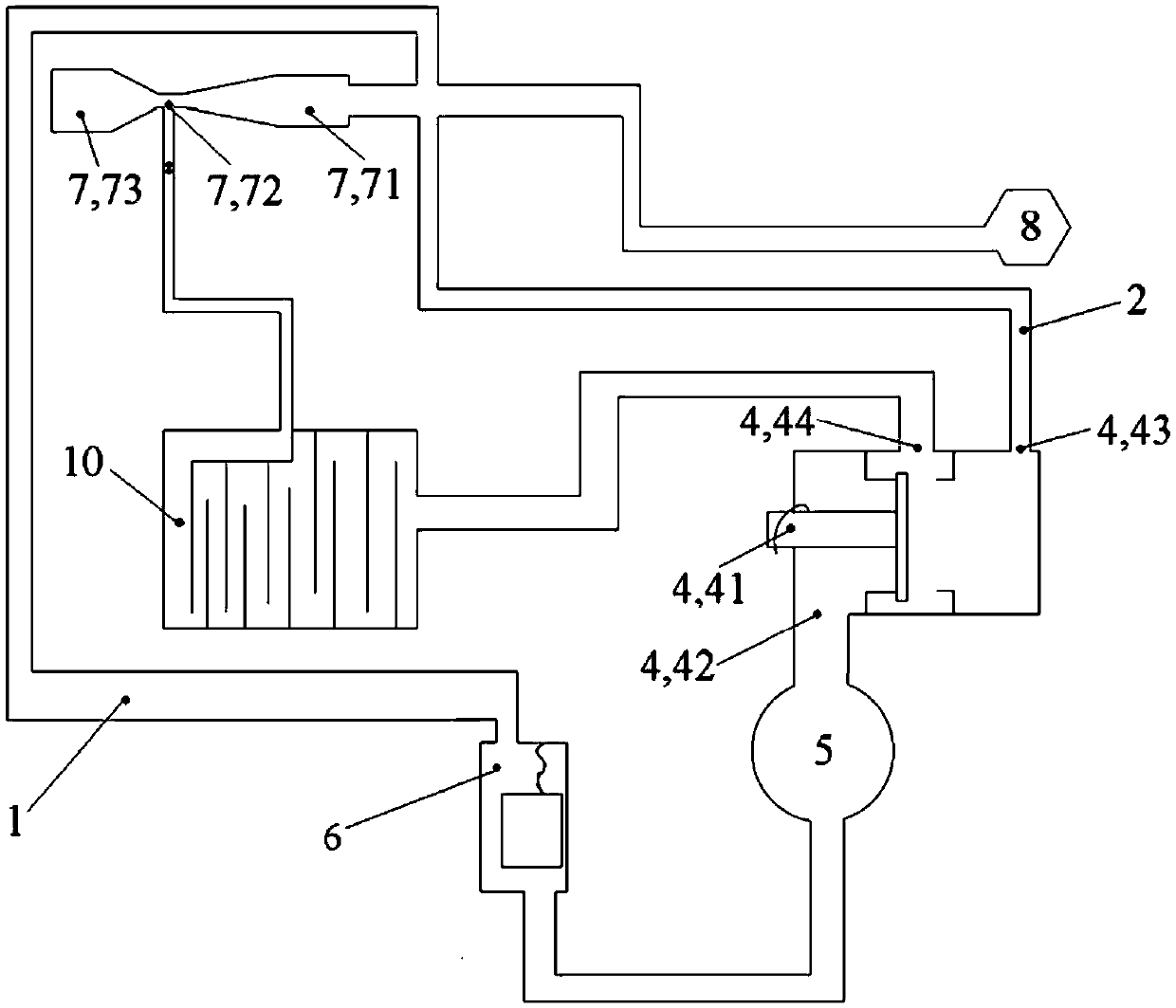

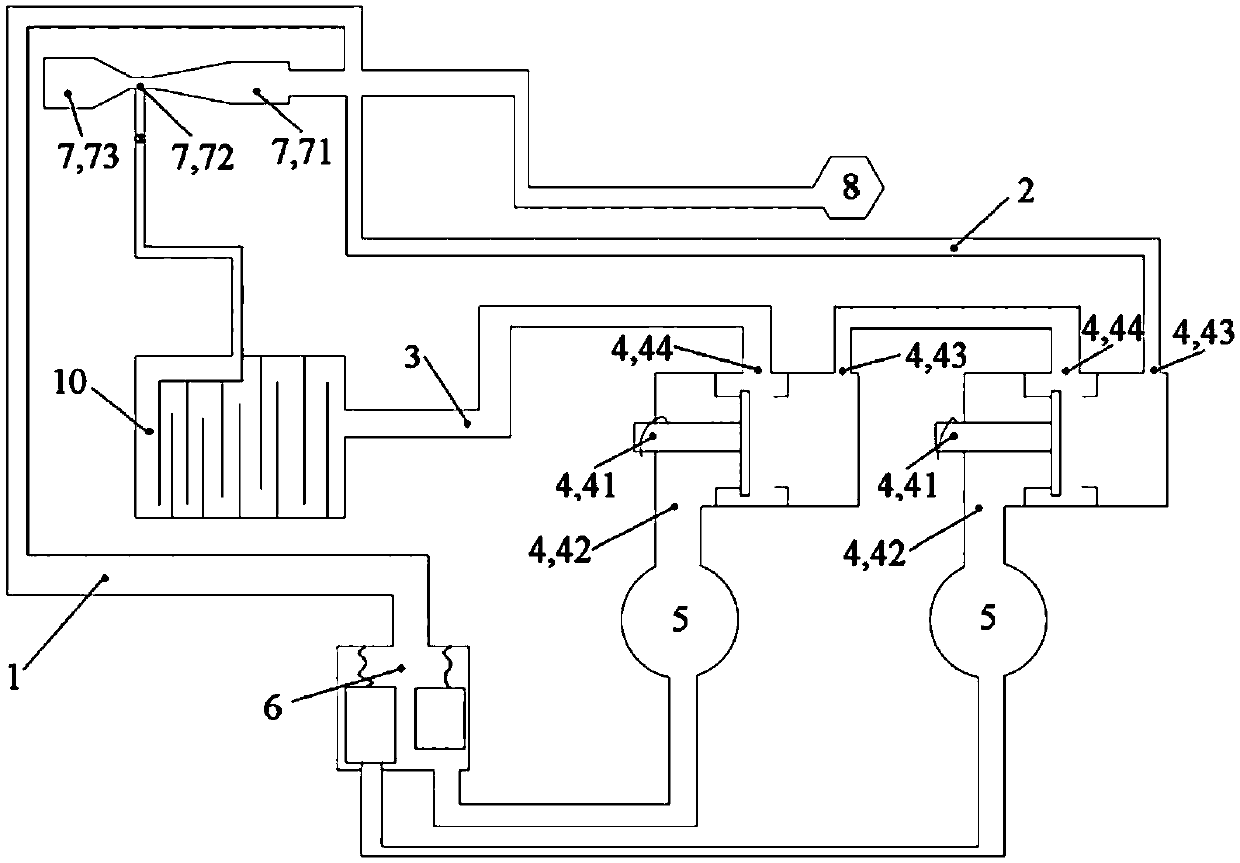

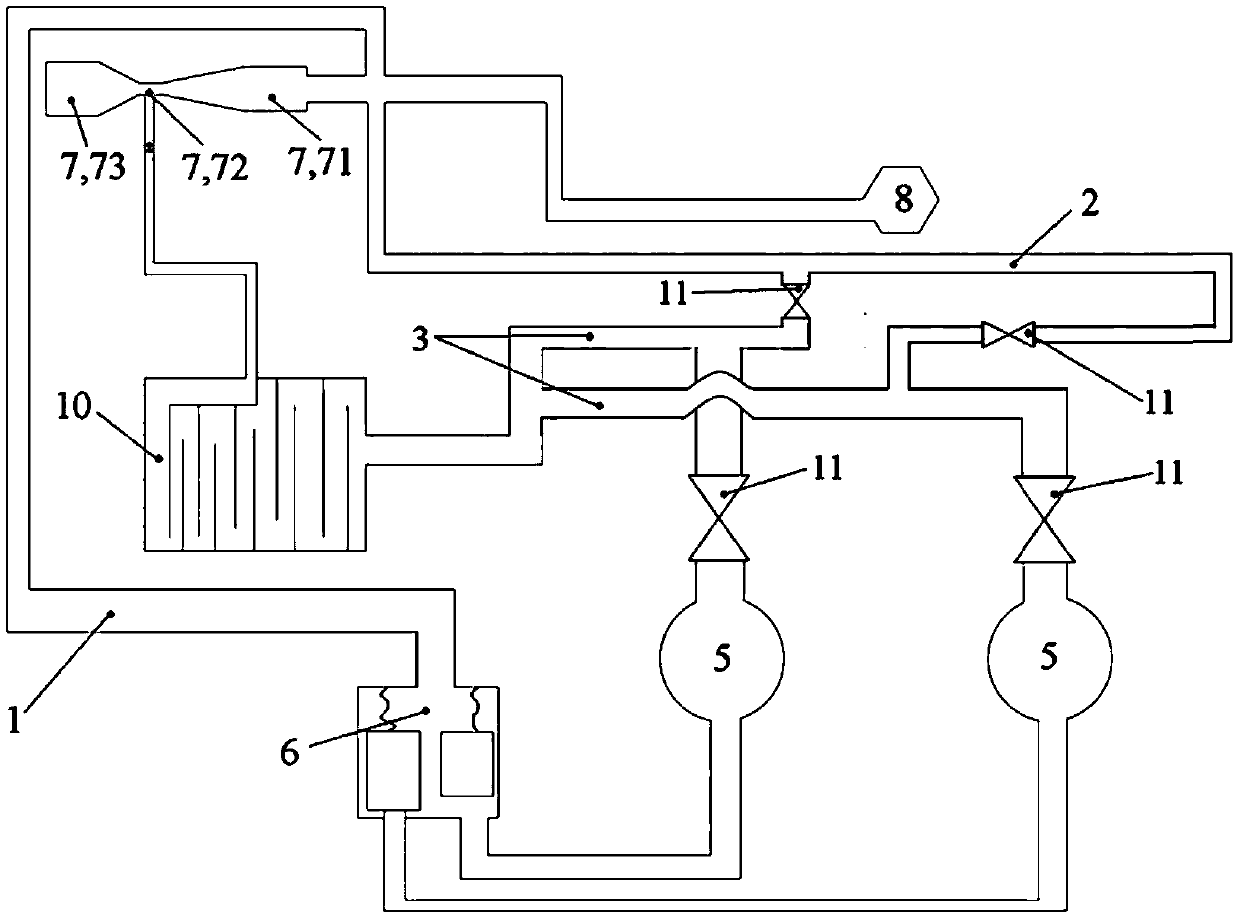

Pressure container corrosion fatigue testing device with closed-loop control

ActiveCN102192859APlay a supercharging roleAvoid corrosionWeather/light/corrosion resistanceElectrical/magnetic solid deformation measurementAutomatic controlFour-way valve

The invention discloses a pressure container corrosion fatigue testing device with closed-loop control, and the device provided by the invention comprises a high-pressure pump station (1), an oil tank (2), an energy accumulator (3), overflow valves (9, 9'), an electromagnetic proportion overflow valve (7), check valves (6, 6'), a corrosion medium isolation pressurized cylinder (8) and a resistance strain gauge E, wherein the hydraulic oil of a pump station system is separated from the corrosion medium in a test container through the corrosion medium isolation pressurized cylinder (8); the resistance strain gauge E is bonded on a test container H and connected with a controller through a dynamic strain instrument and an A / D (analog / digital) card; a pressure gauge is installed in the test container H and connected with the controller through a pressure transmitter and the A / D card; and the electromagnetic proportion overflow valve (7), a two-position two-way valve (5) and a three-position four-way valve (4) are respectively connected with the controller through a D / A (digital / analog) card. The device disclosed by the invention can be used for preventing the corrosion medium from corroding the pump station system, reducing the manufacturing cost and safety of the pump station system and realizing the automatic control on a corrosion fatigue test with high accuracy.

Owner:溧阳常大技术转移中心有限公司

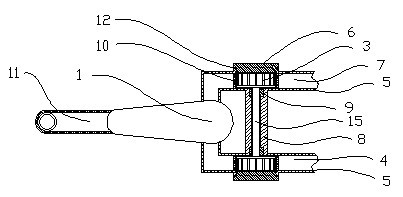

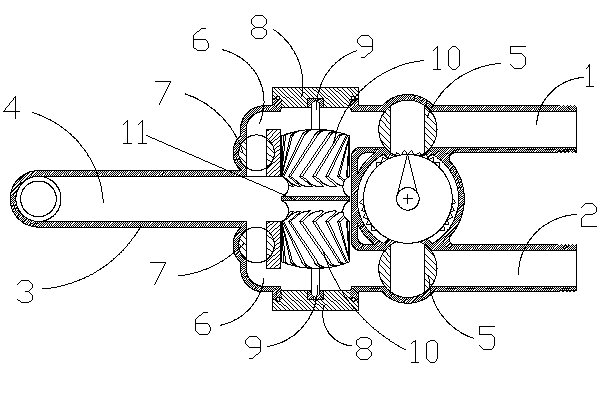

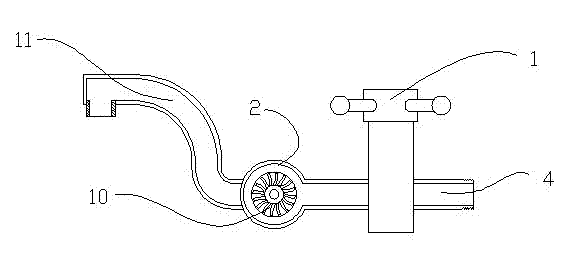

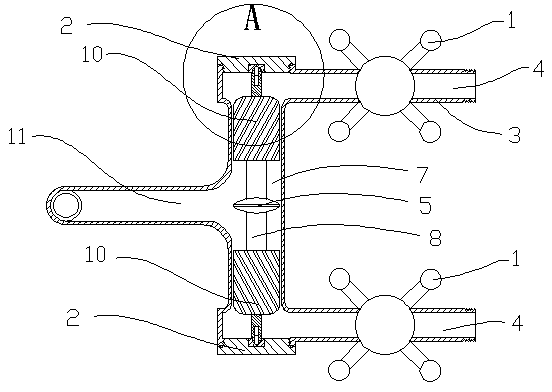

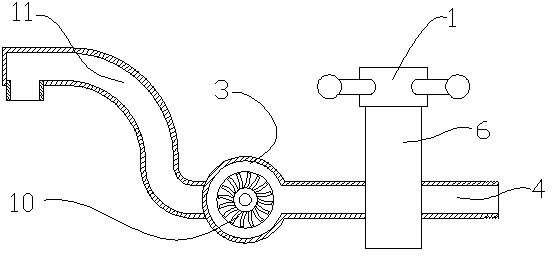

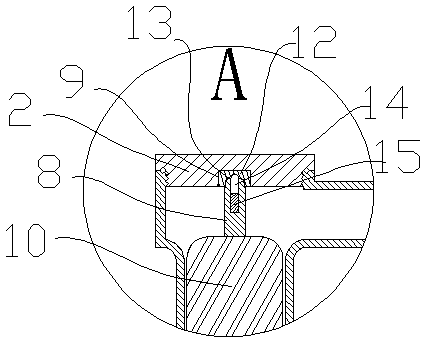

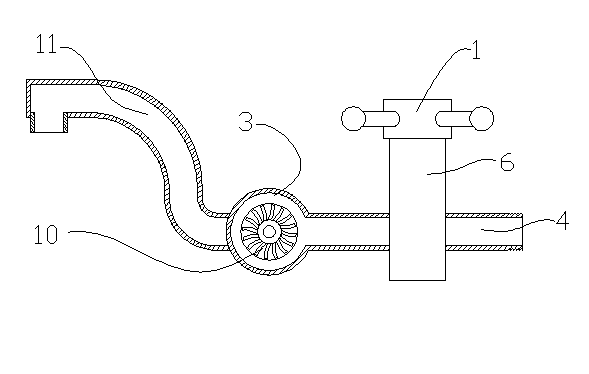

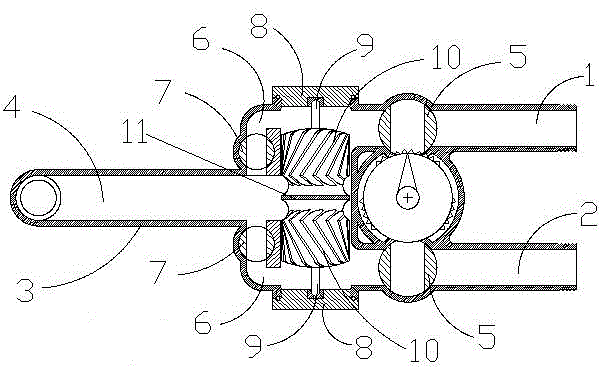

Cold-hot water tap

ActiveCN102305299AControl water temperatureGood stabilityOperating means/releasing devices for valvesMultiple way valvesImpellerEngineering

The invention discloses a cold-hot water tap which comprises a cold-hot water tap shell, a cold water feeding channel, a hot water feeding channel, a water discharge channel and a switch capable of regulating the flow rates of cold water and hot water. The cold-hot water tap is characterized in that the cold water feeding channel and the hot water feeding channel are respectively integrally provided with an impeller cavity, an impeller is arranged in each impeller cavity, an impeller shaft and a shaft sleeve are arranged between the impellers arranged in the impeller cavities of the cold water feeding channel and the hot water feeding channel, and the impellers are respectively fixedly coupled at two ends of the impeller shafts. The cold-hot water tap has the advantages that the cold-hot water tap is not influenced by the pressure difference of the cold water and the hot water, a user regulates the water temperature in bath and the cold-hot water tap with regulated water temperature is not influenced when other persons opens other water taps on the same pipeline.

Owner:黄小敏

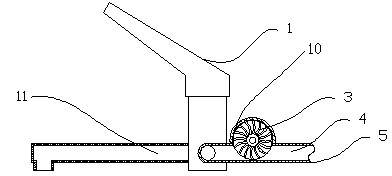

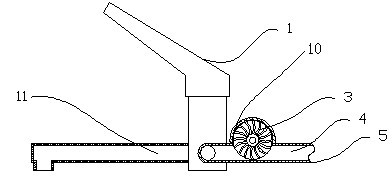

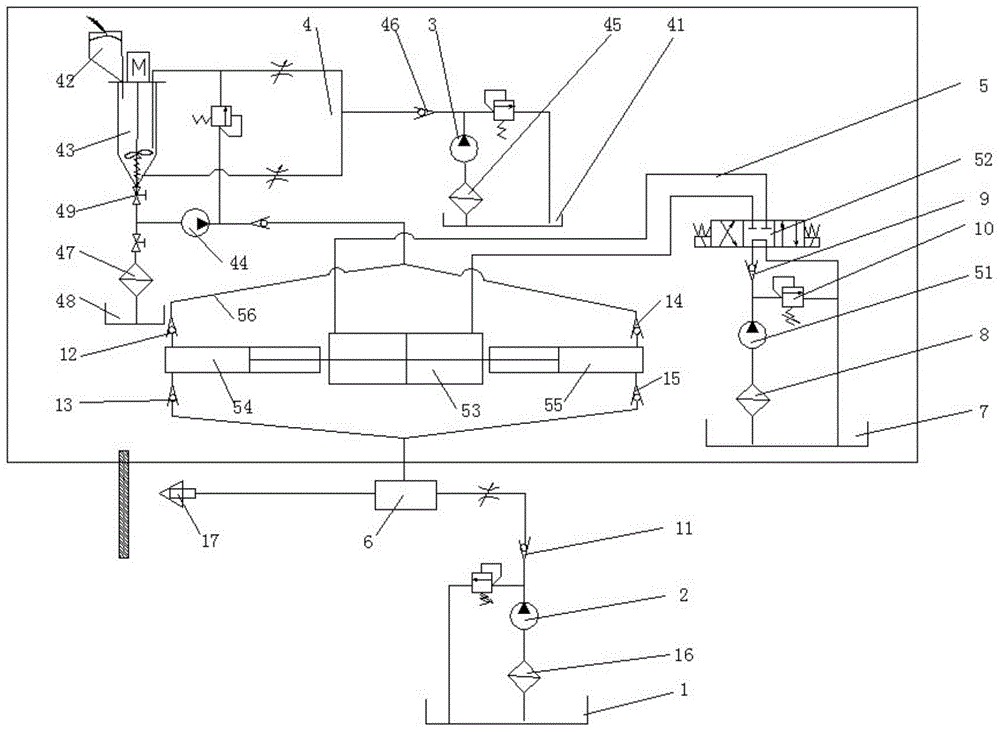

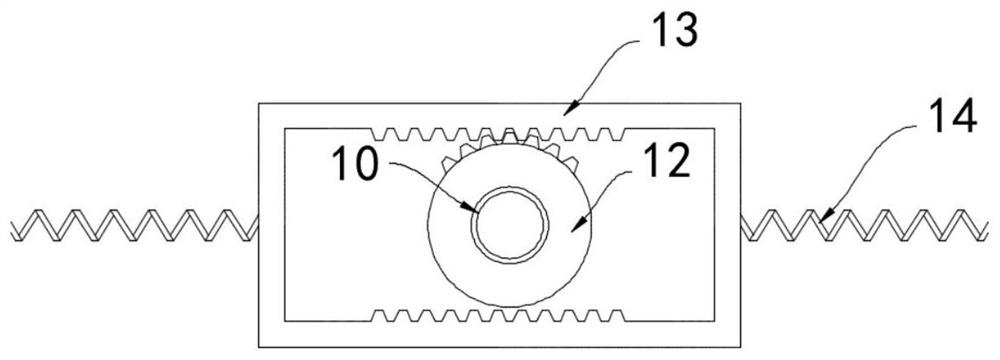

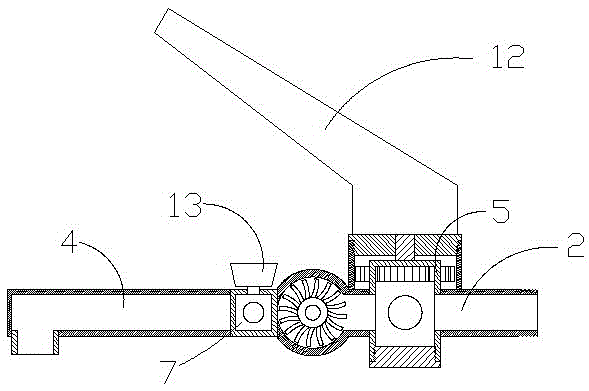

Front mixing grinding material jet-flow continuous feeding system

ActiveCN104552027AImprove work efficiency and work qualityLow priceAbrasive feedersJet flowHigh pressure

The invention discloses a front mixing grinding material jet-flow continuous feeding system. The front mixing grinding material jet-flow continuous feeding system comprises a main water tank, a high pressure pump, a low pressure pump, a continuous feeding system, and a mixing chamber, wherein one end of the main water tank is communicated with the high pressure pump; an outlet of the high pressure pump is connected with an inlet of the mixing chamber; an inlet of the low pressure pump is connected with the inlet of the mixing chamber through the continuous feeding system; the continuous feeding system comprises a feeding system and a pressurization system; the feeding system is communicated with the pressurization system; an outlet of the mixing chamber is communicated with a nozzle. The front mixing grinding material jet-flow continuous feeding system realizes the truly significant continuous feeding, overcomes the phenomena that the continuous working time is short and the grinding material is short of supply in the working process, can greatly improve the working efficiency and the work quality of the system, and facilitates industrialized popularization of the front mixing grinding material jet flow technology; secondly, the difference between the piston areas on the two sides of a piston rod can play the pressurization effect.

Owner:苏州峰启科教设备有限公司

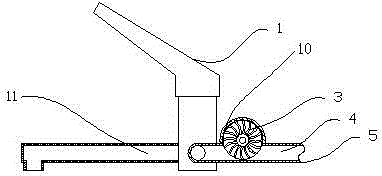

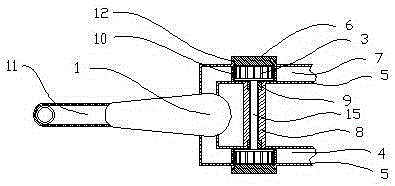

Spiral winding device for stripy article

InactiveCN107815906AAvoid damageIncrease the effective working rangeRope making machinesMotor shaftWorking range

The invention discloses a spiral winder for strip objects, which includes a support base plate, one side of the upper surface of the support base plate is fixed with a support seat by bolts, a motor installation shell is installed on the top of the support base, and the motor installation shell An electric motor is installed inside, a turbo air booster mechanism is installed at the end of the motor shaft in the motor, and a support rod fixed on the upper surface of the support substrate is installed at the bottom of the turbo air booster mechanism, and a turbo air booster mechanism is installed at the center of one end surface of the turbo air booster mechanism first axis of rotation. The present invention utilizes the driving function of the rotary type to wind a plurality of strip objects. In addition, the device has an independent winding tension control mechanism during winding, which can effectively prevent damage to objects and components caused by winding. Moreover, the device has a turbo air supercharging mechanism, which can play a role of supercharging, thereby increasing the effective working range of the device, improving the practicability of the device, and improving the yield.

Owner:李少许

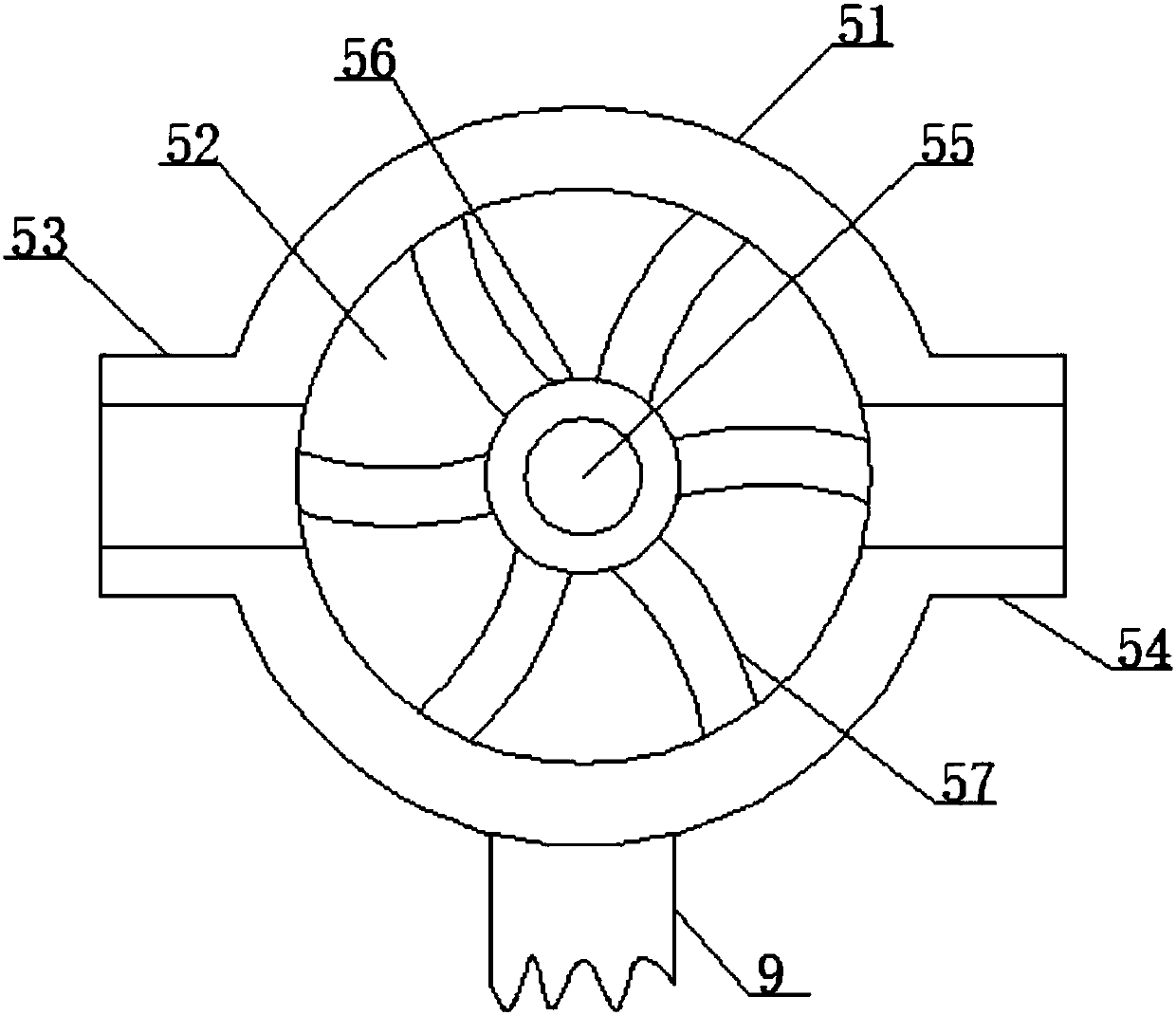

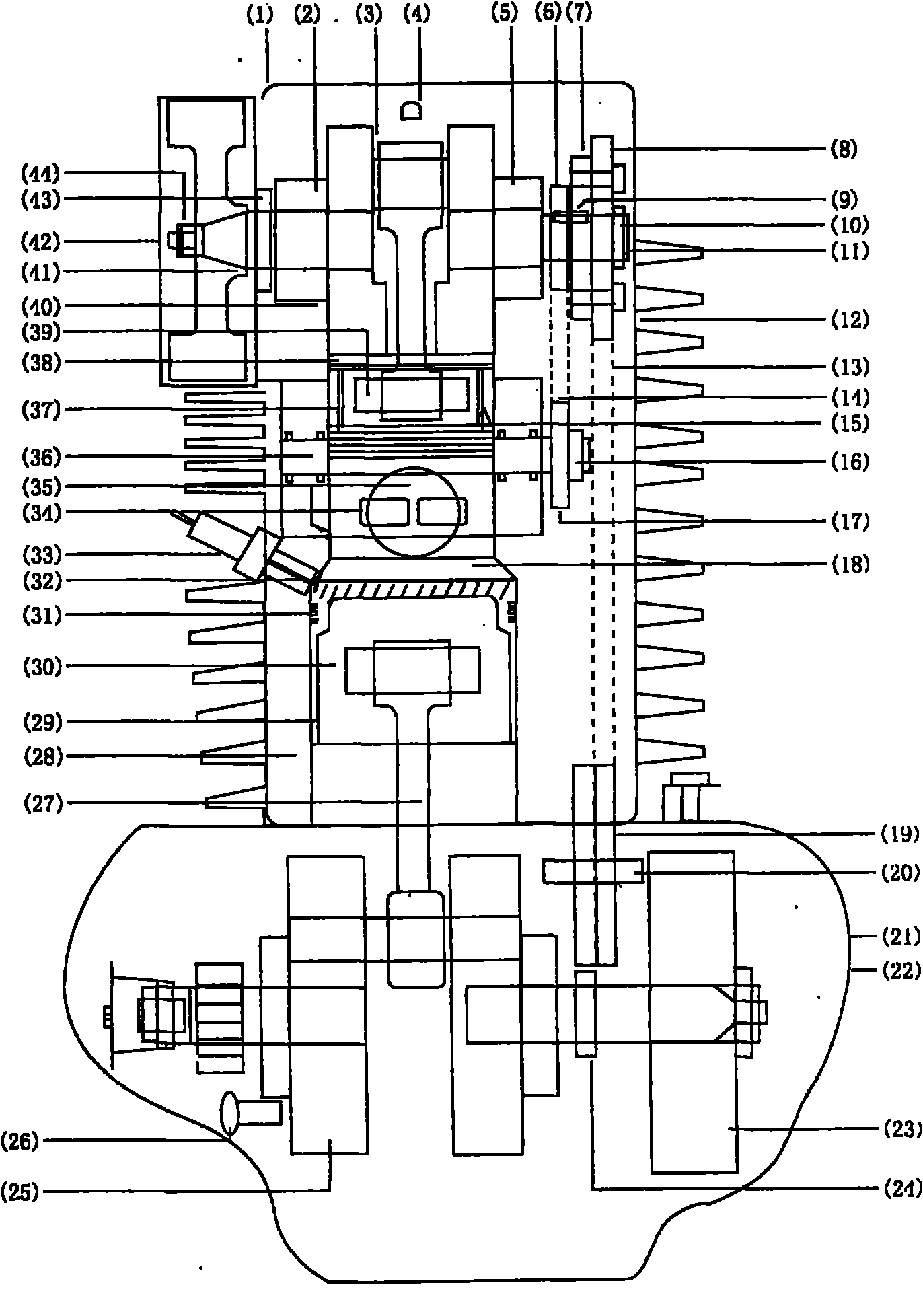

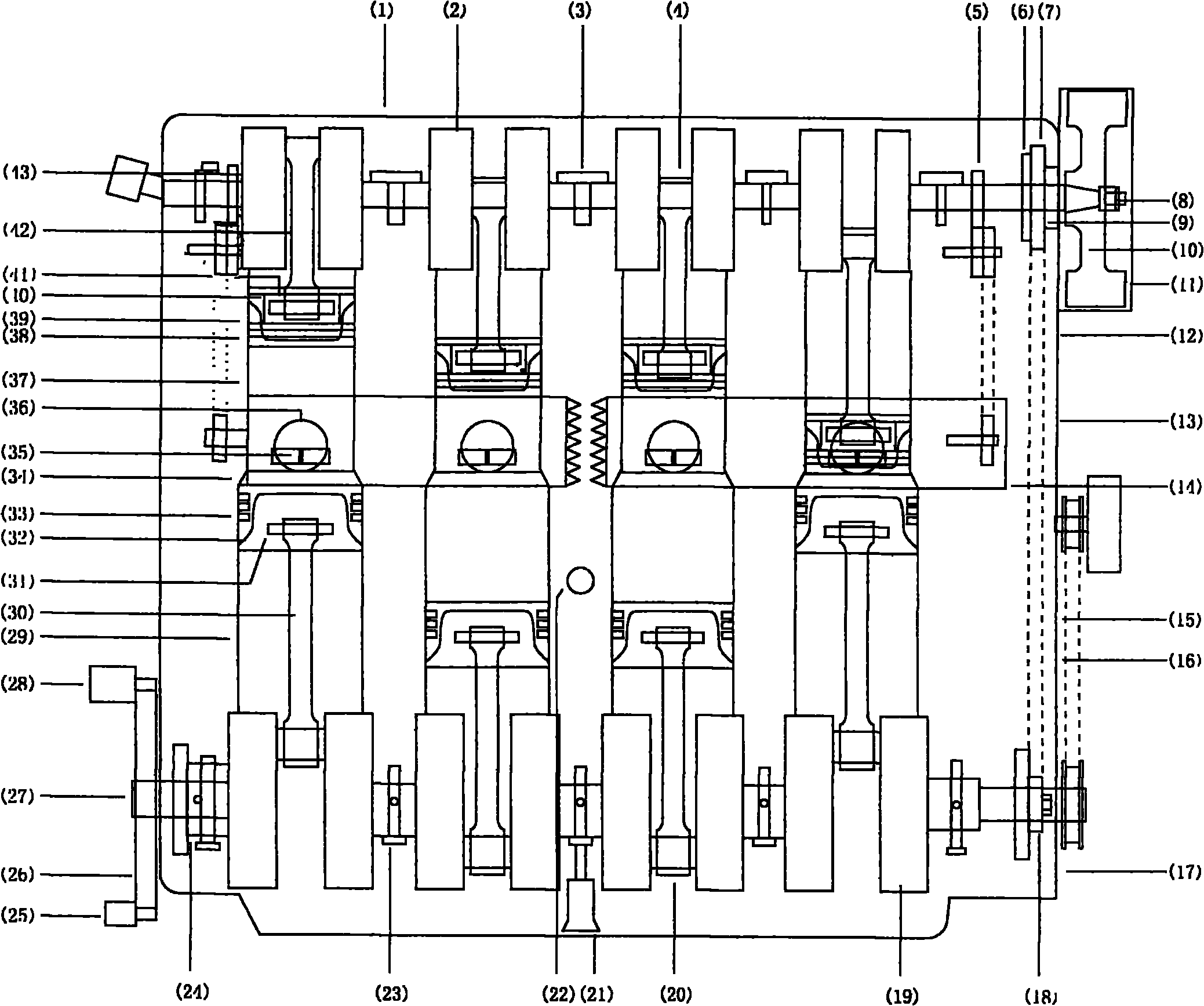

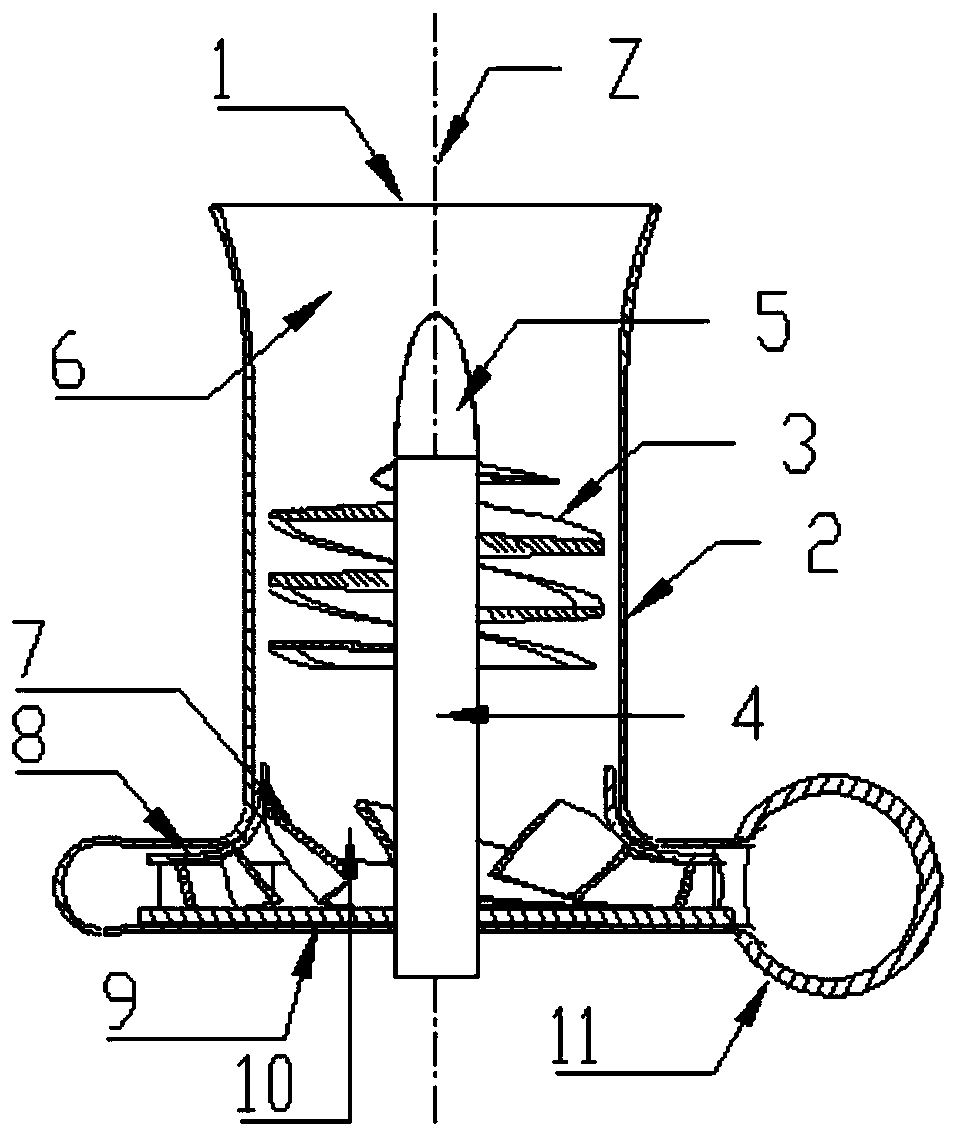

Novel four-stroke layered double-swirling combustion energy-saving internal-combustion engine with new air distribution mechanism

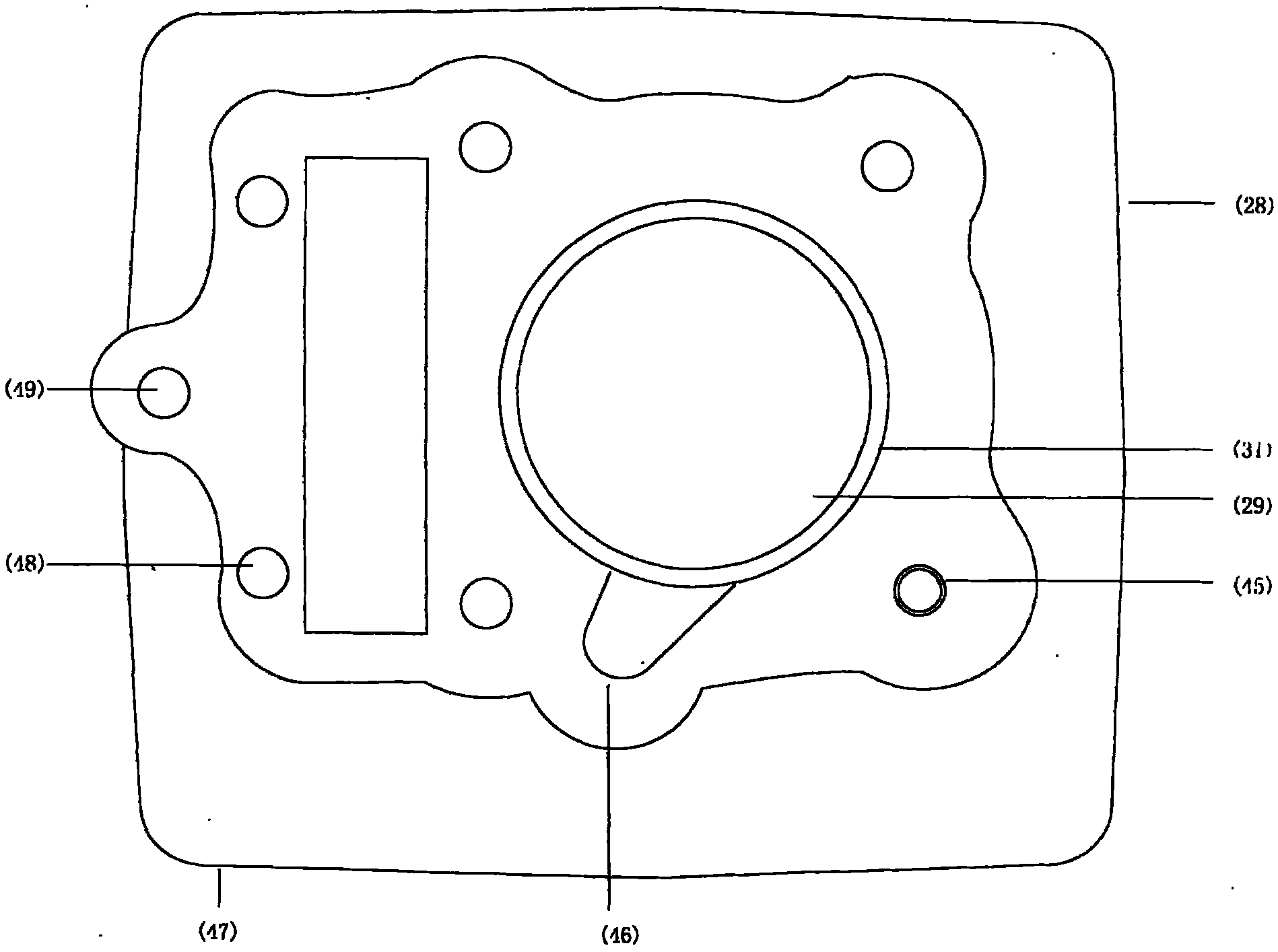

ActiveCN102094702AStable jobImprove qualityInternal combustion piston enginesElectric ignition installationPistonFuel oil

The invention relates to a four-stroke layered double-swirling combustion energy-saving internal-combustion engine with a new air distribution mechanism, and is particularly suitable for various internal-combustion engines for seas, land and space. A cylinder (28) and a cylinder oil nozzle gasket (32) are arranged on a crankcase (85) of a conventional four-stroke single-cylinder gasoline rod ejector, the new air distribution mechanism is arranged in a small cylinder head (12), and a small cylinder (40) is arranged inversely. The front of the wall of the small cylinder (40) is provided with two ports (34), and a small piston (38) slides up and down to suck air and exhaust air. The sucked air rotationally enters along the walls of the big cylinder (28) and the small cylinder (40), the inlet fuel oil rotationally enters, the big and the small pistons apply work at the same time, and the exhausted air pushes a suction-exhaust turbine (51) to apply first work. The internal-combustion engine has the advantages of simple structure, good lubricating condition, long service life, stable work, high revolution rate and no noise; and the engine realizes layered double-swirling combustion of the fuel oil swirled in the middle of an hot air interlayer, and realizes three-time work application in one-time combustion, so that the engine has higher high-power output, saves the fuel oil by about 50 percent and reduces the emission by 85 percent.

Owner:杨成元

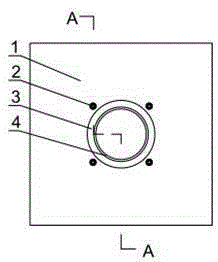

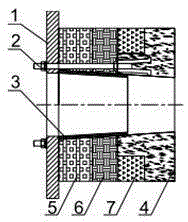

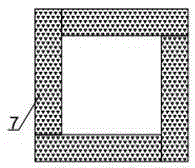

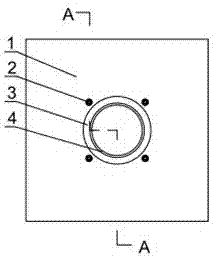

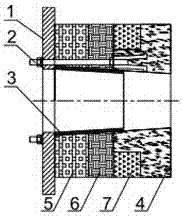

Composite burner tile for heating furnace

ActiveCN105387720AGood heat insulationCombining heavy fire resistance and corrosion resistanceFurnace componentsFiberHeating furnace

The invention relates to a composite burner tile for a heating furnace. The composite burner tile is characterized in that the shape of a composite insulating assembly is a quadrangular prism which sequentially consists of a glass state insulating fiber (5), a crystalline state insulating fiber (6), a square-hole insulating assembly (7) and a casting material prefabricated assembly (4). A through hole with a changeable diameter is formed in the center of the quadrangular prism, and a casing pipe (3) with a changeable diameter is inlaid in the through hole with the changeable diameter. Four bolt holes are symmetrically formed in the glass state insulating fiber (5) and the crystalline state insulating fiber (6) along the diagonal lines, and Y-shaped anchoring nails (8) of anchoring devices (2) are symmetrically arranged at four corners of a small square boss of the casting material prefabricated assembly (4); one ends of loop bars (9) of the anchoring devices (2) are connected with the Y-shaped anchoring nails (8), and the other ends of the loop bars (9) of the four anchoring devices (2) penetrate through the corresponding bolt holes and are connected with a stainless steel plate (1). The composite burner tile disclosed by the invention has the characteristics of being light in weight, good in insulating property, high in intensity, high in erosion resistance, easy in repair and maintenance, good in using effect and long in service life, and is suitable for various heating furnaces in petrifaction trades.

Owner:YIXING MORGAN THERMAL CERAMICS CO LTD

Pre-mixed abrasive jet continuous feeding system

ActiveCN104552027BOvercoming abrasive outagesImprove work efficiencyAbrasive feedersJet flowSpray nozzle

The invention discloses a front mixing grinding material jet-flow continuous feeding system. The front mixing grinding material jet-flow continuous feeding system comprises a main water tank, a high pressure pump, a low pressure pump, a continuous feeding system, and a mixing chamber, wherein one end of the main water tank is communicated with the high pressure pump; an outlet of the high pressure pump is connected with an inlet of the mixing chamber; an inlet of the low pressure pump is connected with the inlet of the mixing chamber through the continuous feeding system; the continuous feeding system comprises a feeding system and a pressurization system; the feeding system is communicated with the pressurization system; an outlet of the mixing chamber is communicated with a nozzle. The front mixing grinding material jet-flow continuous feeding system realizes the truly significant continuous feeding, overcomes the phenomena that the continuous working time is short and the grinding material is short of supply in the working process, can greatly improve the working efficiency and the work quality of the system, and facilitates industrialized popularization of the front mixing grinding material jet flow technology; secondly, the difference between the piston areas on the two sides of a piston rod can play the pressurization effect.

Owner:苏州峰启科教设备有限公司

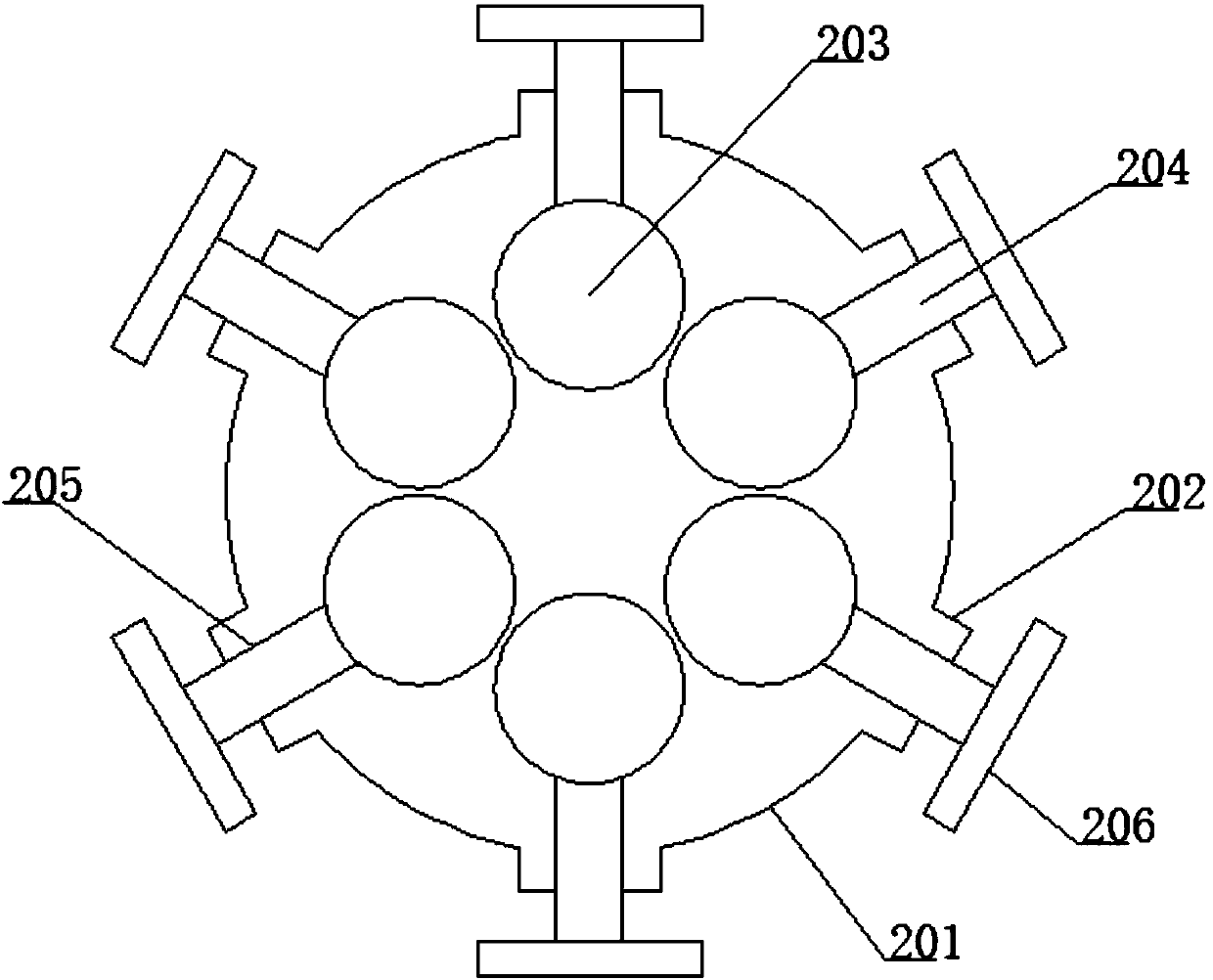

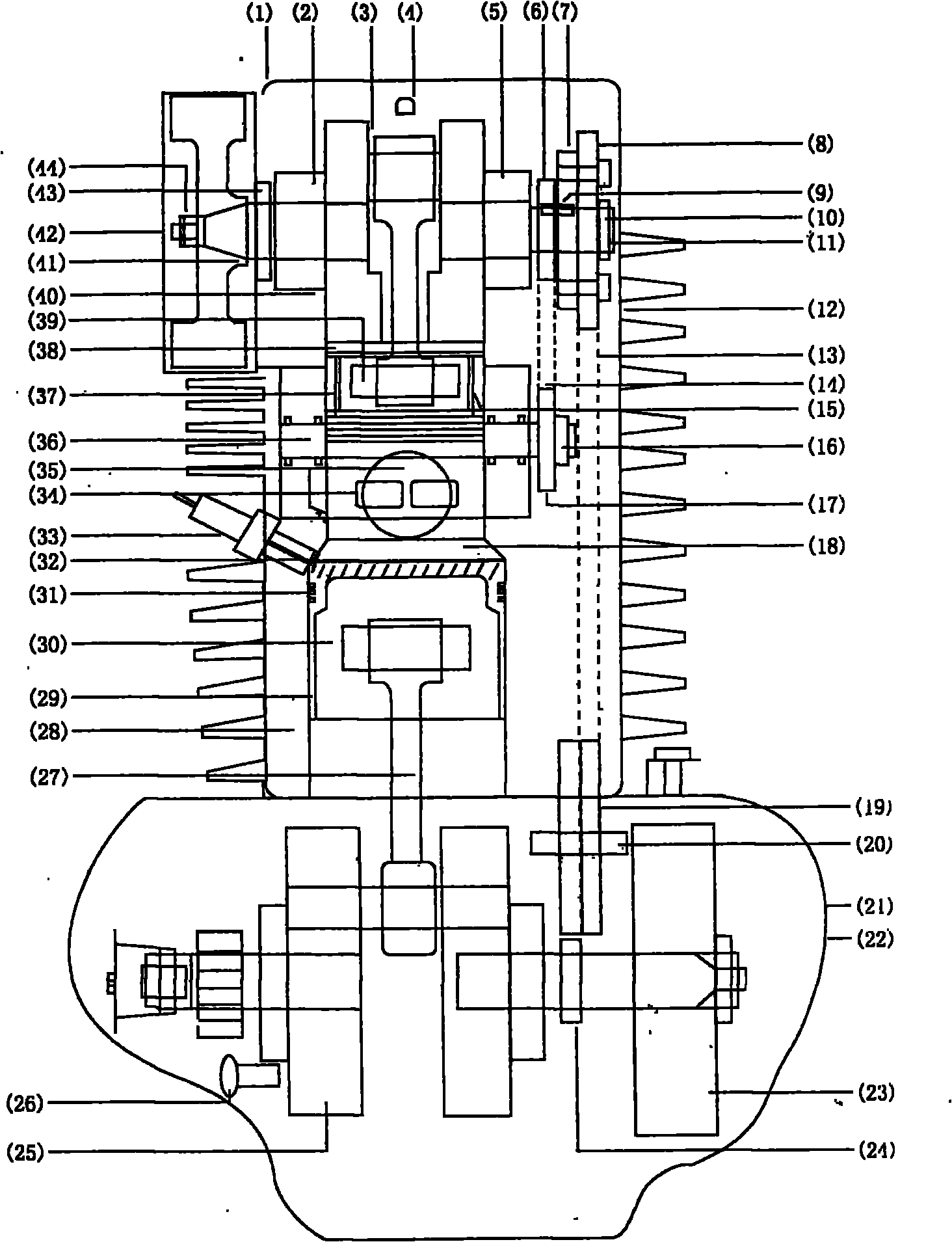

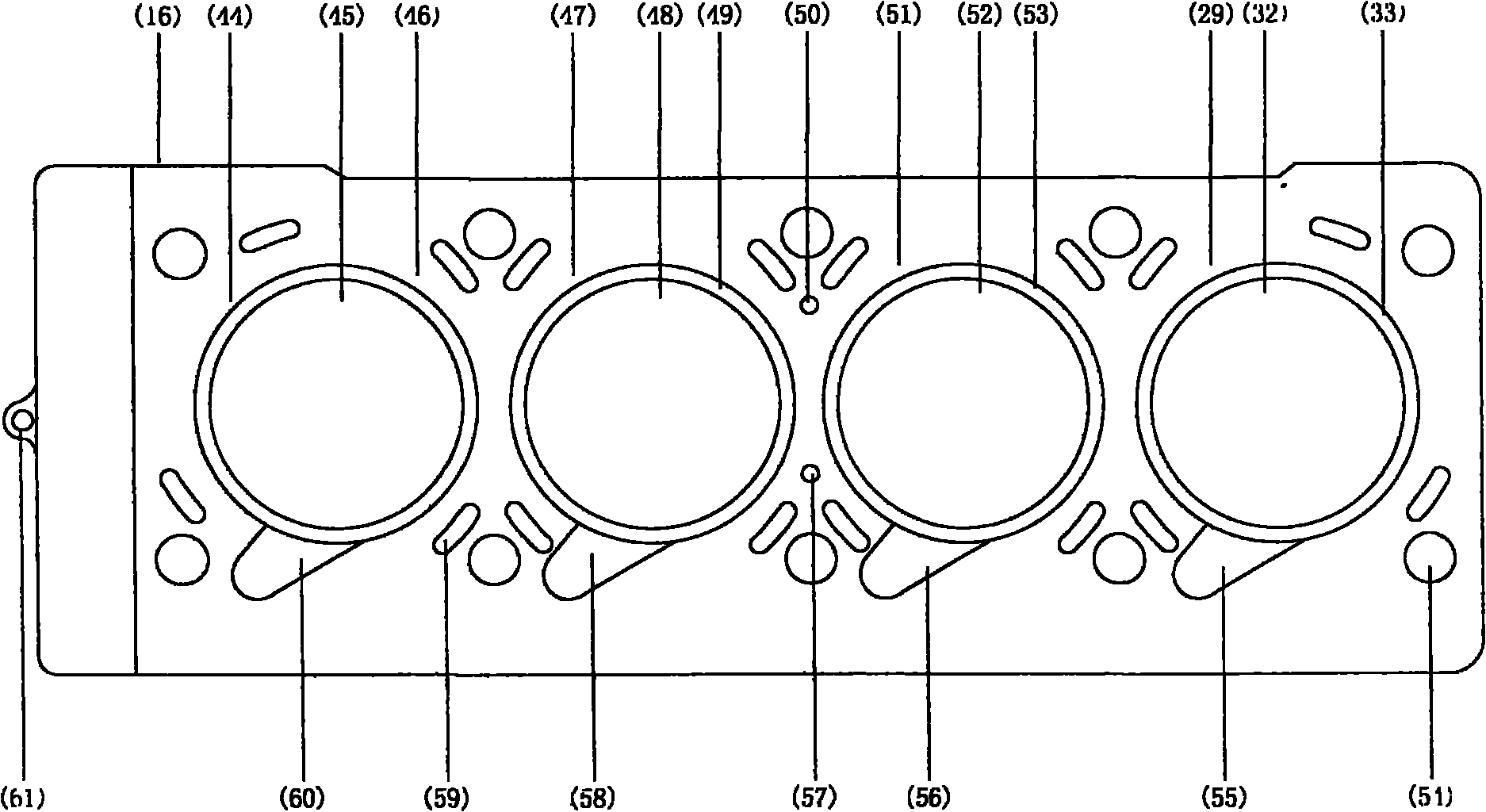

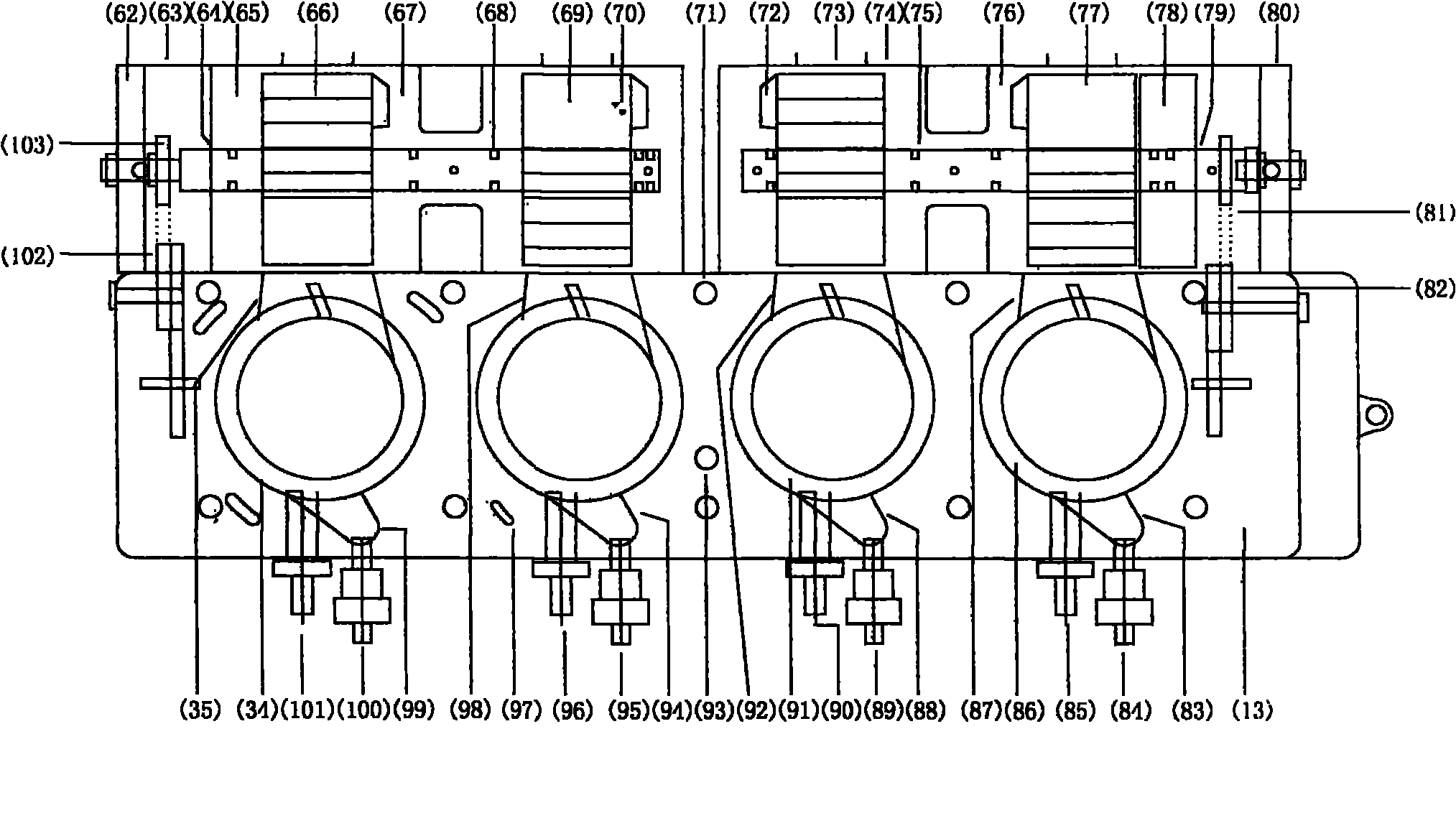

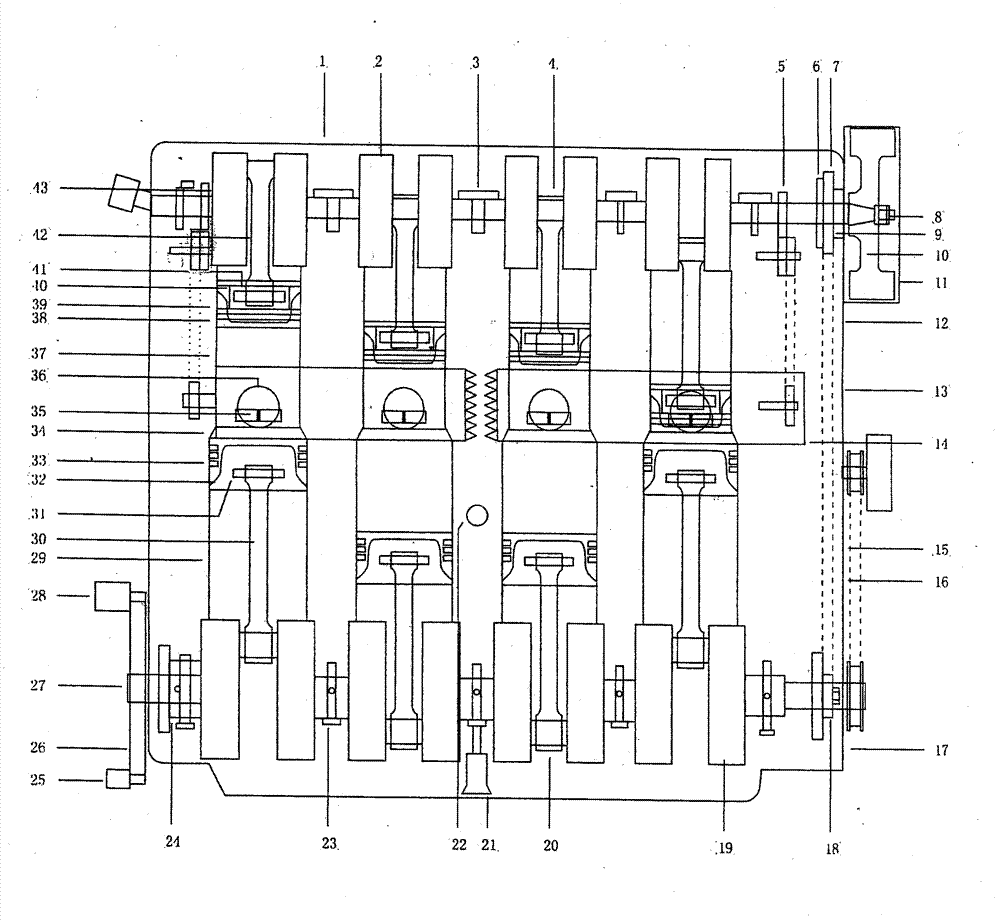

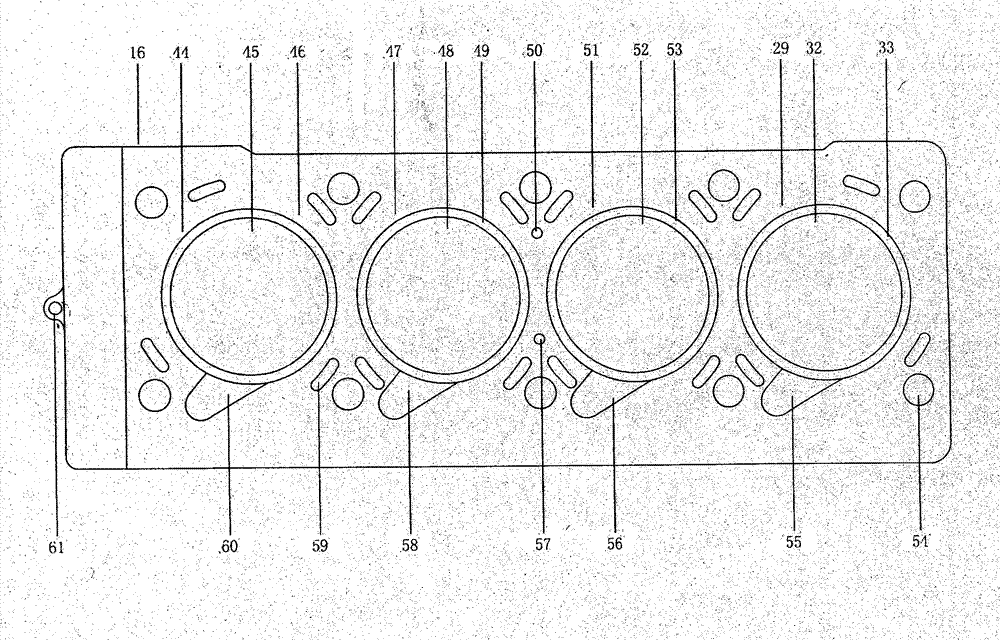

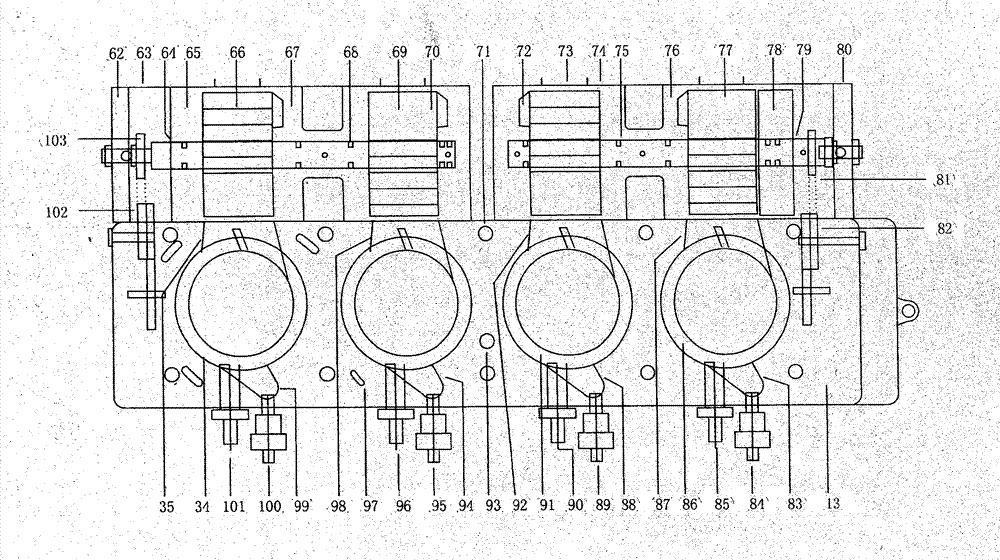

Novel four-stroke four-cylinder layered dual-vortex combustion energy-saving internal combustion engine with new gas distribution mechanism

ActiveCN102155285AImprove lubrication conditionsPowerfulInternal combustion piston enginesCylinder headsPistonEngineering

The invention provides a novel four-stroke four-cylinder layered dual-vortex combustion energy-saving internal combustion engine with a new gas distribution mechanism. In the internal combustion engine, four cylinder nozzle gaskets (14) and four small cylinder heads (13) with the new gas distribution mechanisms are arranged on four cylinders (28) of the conventional four-stroke vertical four-cylinder double overhead camshaft gasoline engine, and four small cylinders (37) are arranged inversely; two ports (35) are arranged in the front of the wall of each small cylinder (37); gas enters and is exhausted by up and down sliding of a small piston (39); and when big and small pistons (32, 45, 48, 52, 39) apply work simultaneously, gas exhaust is to push each small piston (39) and intake and exhaust turbines (66, 69, 73, 77) to apply work. The internal combustion engine has the advantages of simple structure, good lubricating condition, stable work, realizes that fuel vortex performs layered dual-vortex combustion in hot air interlayer, thereby having larger high-power output, saving fuel by about 50 percent, and reducing emission by 85 percent.

Owner:NANTONG YATAI ENG TECH

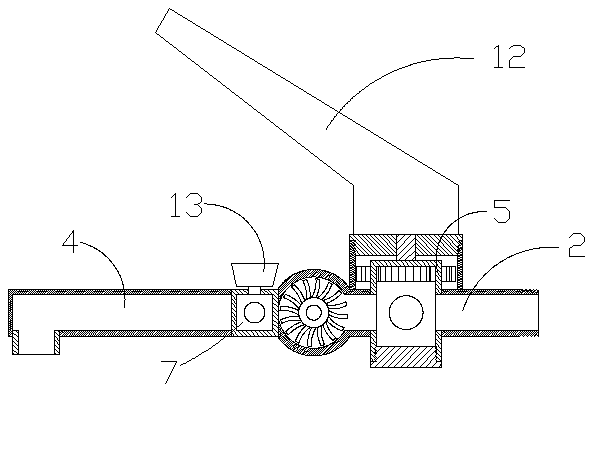

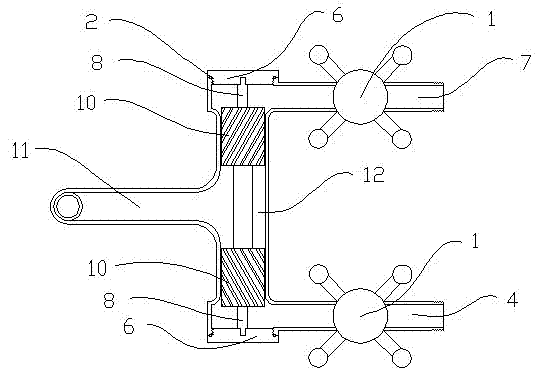

Cold and hot water tap

ActiveCN102996864AFlexible rotationPlay a role in decompressionOperating means/releasing devices for valvesMultiple way valvesFiberInlet channel

The invention discloses a cold and hot water tap which comprises a cold and hot water tap body; a cold water channel, a hot water channel, a water outlet channel and valves for adjusting the fluxes of the cold water and the hot water are arranged on the cold and hot water tap body; and the cold water channel and the hot water channel are respectively provided with sub channels between the valves and the water outlet channel; and second valves are respectively arranged on the sub channels. When the valve of only one water inlet channel is opened, a secondary valve at the same side can be opened so as to avoid the resistance to the water flow from bevel wheels. When the valves of the cold water inlet channel and the hot water inlet channel are both opened, the second valves on the sub channels can be closed, so that when hemp threads or raw material tapes or other fibers enter the cold and hot water channels, the hemp threads or raw material tapes or other fibers cannot entangle the bevel wheels, so flexible rotation of the bevel wheels is guaranteed. When cold water and hot water respectively flow from the channels in which the bevel wheels are arranged, the bevel wheel in the channel with bigger water pressure rotates initiatively and the bevel wheel in the channel with smaller water pressure is driven to rotate, so the pressure difference between the cold water and the hot water can be effectively adjusted.

Owner:浙江杭海新城控股集团有限公司

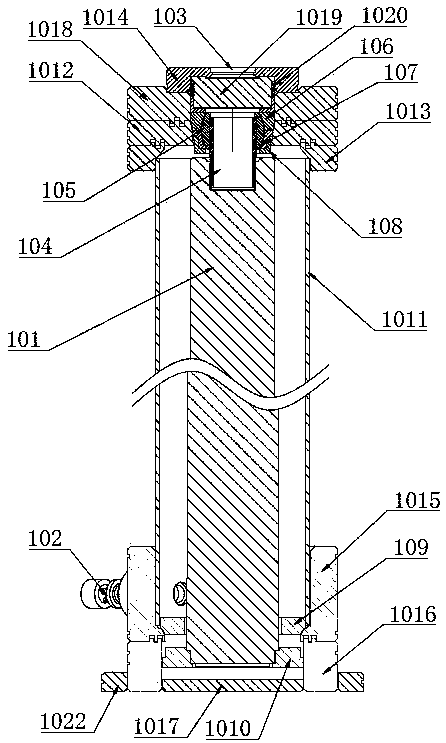

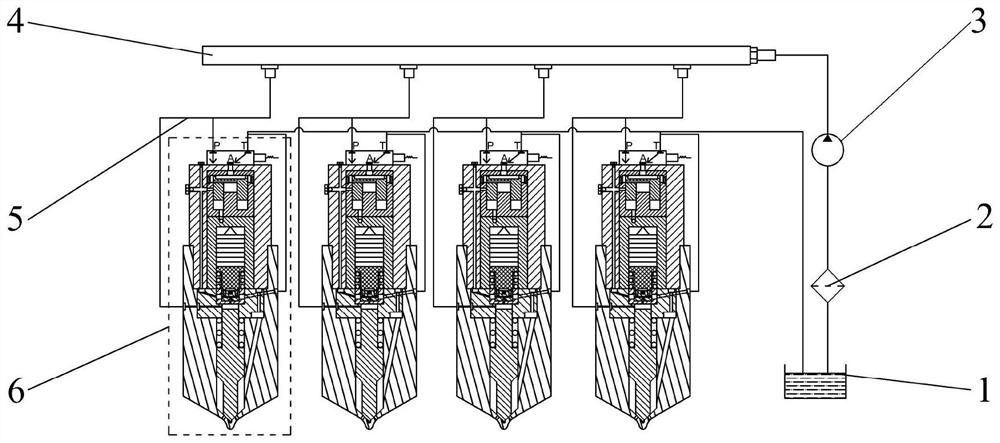

Mute high-speed pipe-interior pump and complete-set pressurizing device

PendingCN108050080AAvoid shakingPrevent up and down movementPump componentsCheck valvesPulp and paper industrySubmersible pump

The invention discloses a mute high-speed pipe-interior pump and a complete-set pressurizing device and belongs to the technical field of environment protection. The pipe-interior pump comprises a pump shell and an immersible pump, a water inlet is formed in the side face of the pump shell, and a water outlet is formed in the top of the pump shell. The immersible pump is mounted in the pump shell,a positioning shaft is arranged at the top of the immersible pump, and a positioning shaft through hole is formed in the positioning shaft and communicates with the immersible pump. A first positioning seat is arranged at the upper end of the pump shell, a second positioning seat is arranged at the lower end of the pump shell, and the first positioning seat comprises a ball bowel and a linkage ball. The periphery of the ball bowel is connected with the pump shell, the linkage ball is mounted in the ball bowel, and a vertical through hole is formed in the linkage ball. The positioning shaft isarranged in the vertical through hole of the linkage ball in a penetrating mode, the positioning shaft through hole communicates with the water outlet, and the lower end of the immersible pump is mounted in the second positioning seat. The complete-set pressurizing device comprises the four mute high-speed pipe-interior pumps which are combined in series-connection and parallel-connection modes.According to the pipe-interior pumps, operation is stable, noise is low, and the service life is long; and according to the complete-set pressurizing device, the pressure is high, the flow is large, and the application range is wide.

Owner:宙斯流体系统(上海)有限公司

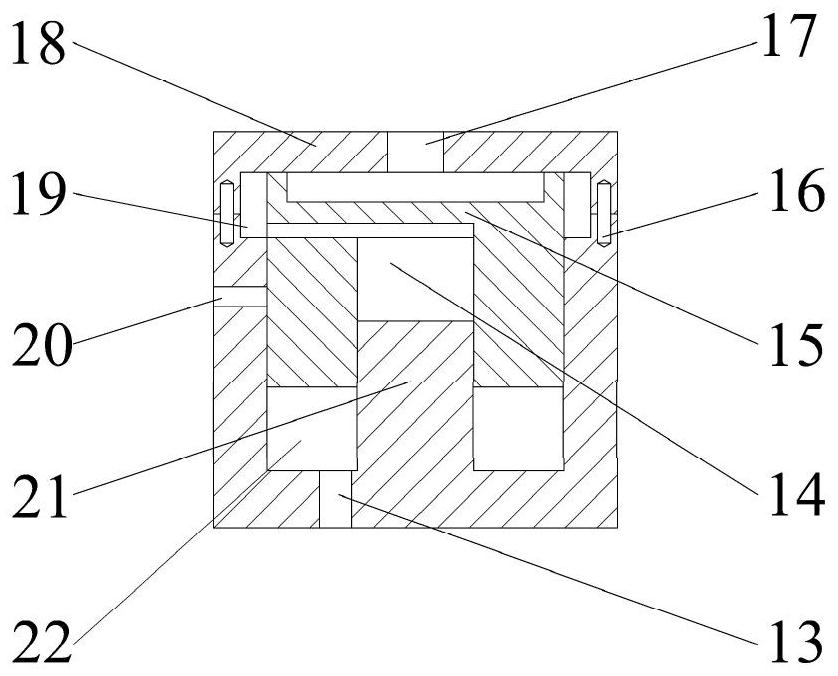

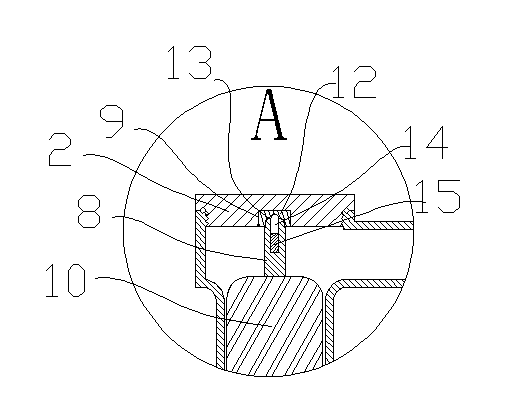

Grease distributor, grease lubricating system and lubricating grease changing system

PendingCN113915512ACompact layoutEasy to processDistribution equipmentLubrication check valvesOil and greaseThermodynamics

The invention relates to a grease distributor, a grease lubricating system and a lubricating grease changing system. The grease distributor comprises a distributor shell, wherein grease distribution units are arranged on the distributor shell; when grease storage cavities store grease, a grease supply channel supplies the grease to grease supply cavities to enable grease supply valve elements to plug grease outlets, the grease enters the grease storage cavities through a one-way grease passing structure, and grease pressing pistons extrude power cavities to reduce the size of the power cavities; and when the grease is discharged from the grease storage cavities, the grease pressing channel supplies fluid media to the power cavities to enable the grease supply valve elements to open the grease outlets, and the grease pressing pistons extrude the grease in the grease storage cavities to be discharged from the grease outlets. Due to the fact that the grease storage cavities do not depend on a spring to apply pressure in the process of injecting the grease outwards, the problem that the grease cannot be accurately supplemented due to fatigue of the spring can be avoided, meanwhile, the grease injection pressure in the process of injecting the grease into the grease storage cavities is small, and the technical problem that according to an existing distributor, grease supplementing of an grease storage cavity is achieved through reset of a spring, accordingly, the grease supplementing precision is low, and the lubricating quality of a lubricating part is poor is solved.

Owner:AUTOL TECH

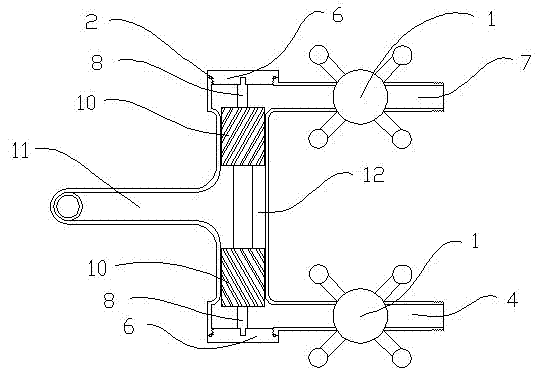

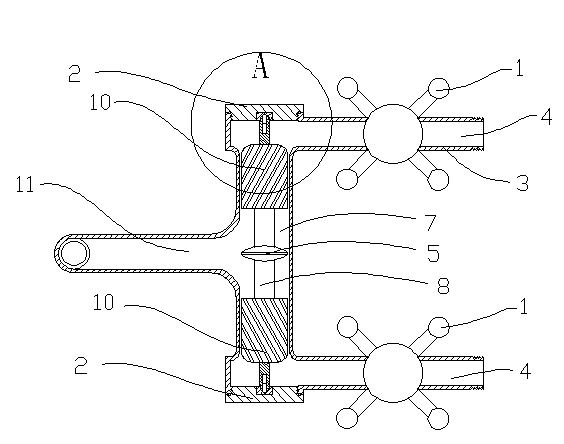

Cold-hot water faucet

InactiveCN102242822APlay a role in decompressionPlay a supercharging roleMultiple way valvesImpellerWater channel

The invention disclose a cold-hot water faucet which comprises a cold-hot water faucet body, wherein a cold water channel, a hot water channel, a water outlet channel and valves for adjusting the cold water flow and the hot water flow are arranged on the cold-hot water faucet body. The cold-hot water faucet is characterized in that the cold water channel and the hot water channel are respectively provided with one valve, the cold water channel, the hot water channel and the water outlet channel are converged, and the converged parts of the cold and hot water channels and the water outlet channel are respectively provided with an impeller and an impeller shaft. The cold-hot water faucet has the advantages that the pressure difference of the cold water and hot water is effectively adjusted; when other people opens the other water faucet in the same pipeline, only the total flow is reduced, the modulated cold-hot water proportion is basically not changed, and the water temperature is effectively controlled.

Owner:NINGBO ZHENHAI JIEDENG APPL TECH INST

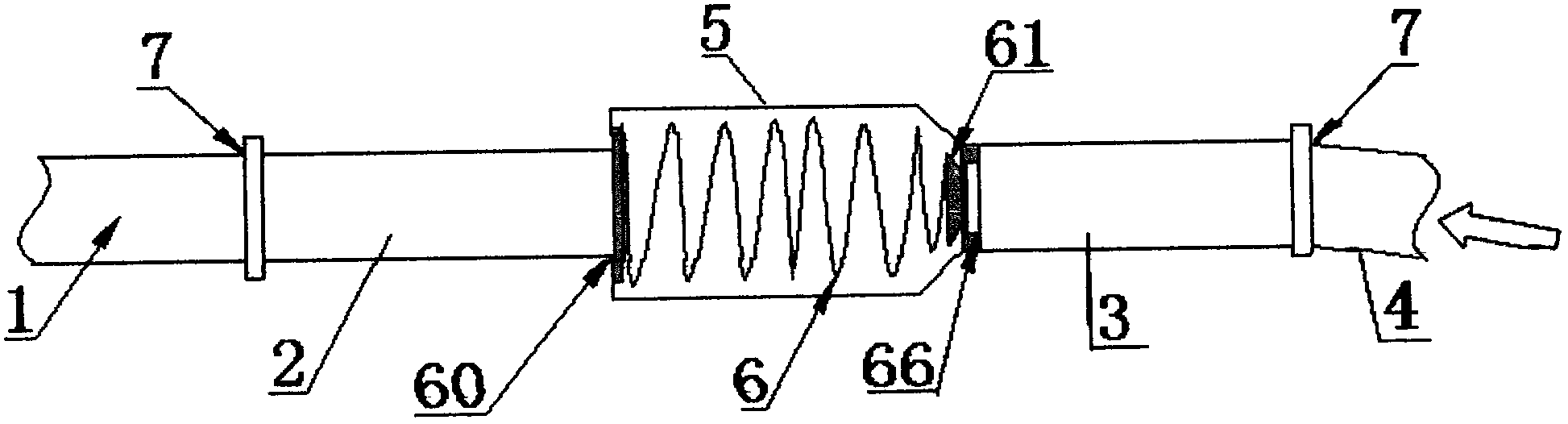

Multifunctional energy-saving buffering supercharger

InactiveCN103452577AWater injection benefitsPlay a supercharging roleDust removalFire preventionHigh pressure waterHigh pressure

The invention relates to a multifunctional energy-saving buffering supercharger which solves the problem of poor water running performance of the existing device. The multifunctional energy-saving buffering supercharger comprises a water injection pipe connector for connecting a water injection pipe and a water supply pipe connector for connecting a high pressure water supply pipe. A casing pipe or a section of a reducing pipe body with front end large and rear end small is connected between the water injection pipe connector and the water supply pipe connector, a supercharging spring is arranged in the reducing pipe body or the casing pipe, a supercharging blocking sheet with a water through hole in the middle is assembled at the front end of the supercharging spring, and a valve block matched with the small-diameter end of the reducing pipe body, or the rear end of the casing pipe or the end of the water supply pipe contactor is assembled at the rear end of the supercharging spring. An annular seat in sealing match with the valve block is manufactured or arranged on the inner periphery of the small-diameter end of the reducing pipe body or the end of the water supply pipe contactor. The multifunctional energy-saving buffering supercharger has the advantages that the structure is simple, the operation is convenient, water injection pressure can be enlarged, wear of devices and power consumption are reduced, water cannot flow back when a pump stops, low-pressure thick flow of water injection is changed into high-pressure thin flow, water can easily enter gaps of coal seams to evenly wet coal, and good liquid injection effect can be achieved to the coal seams with compact structures.

Owner:刘艺鹏

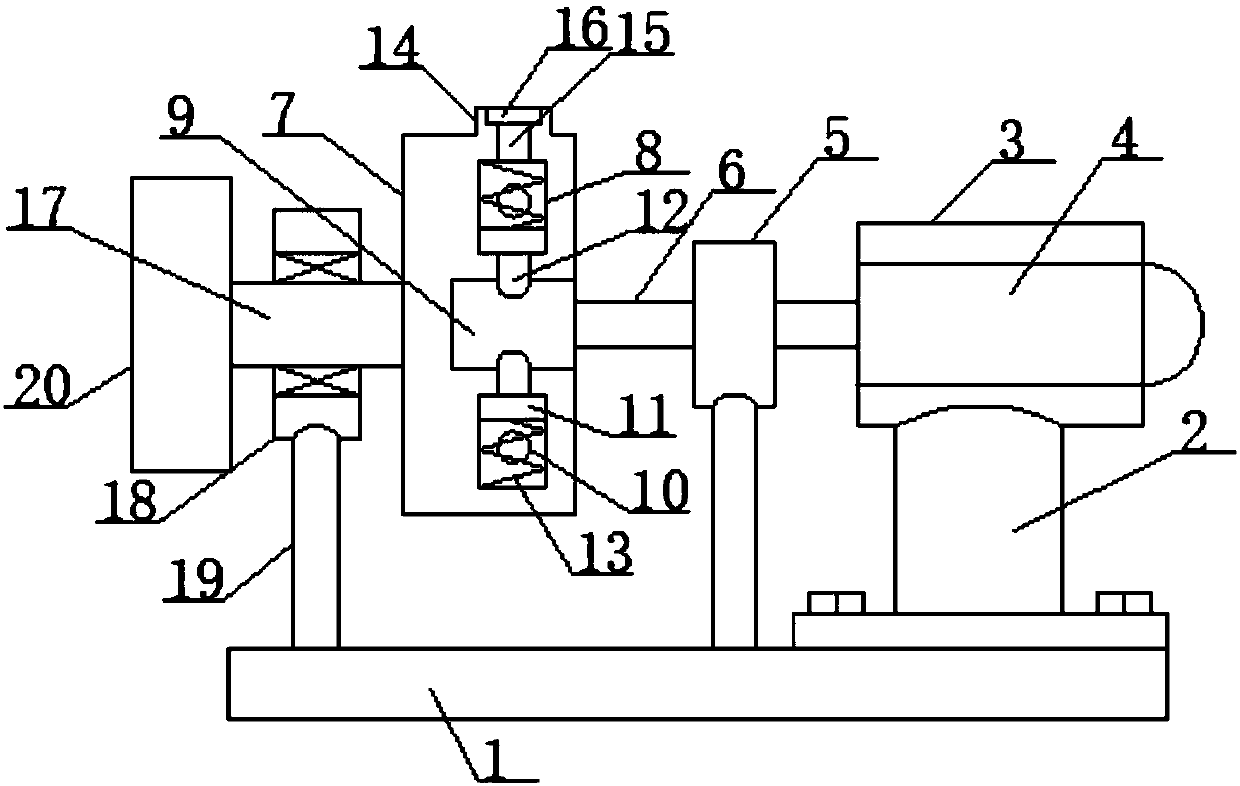

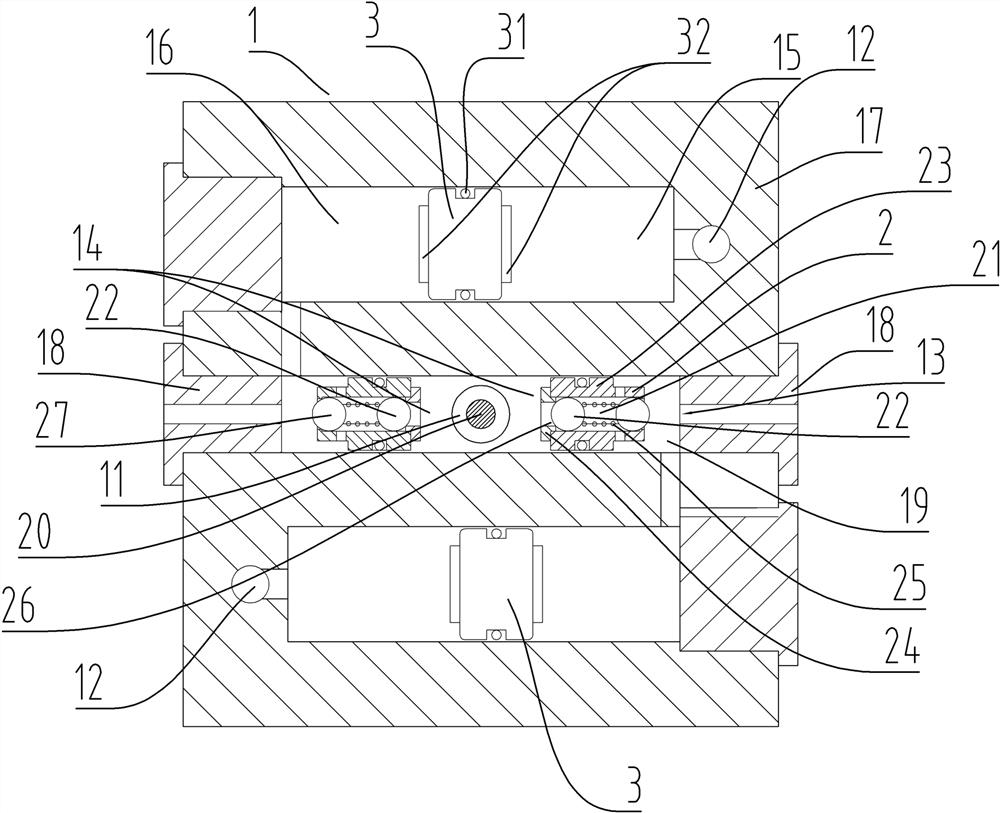

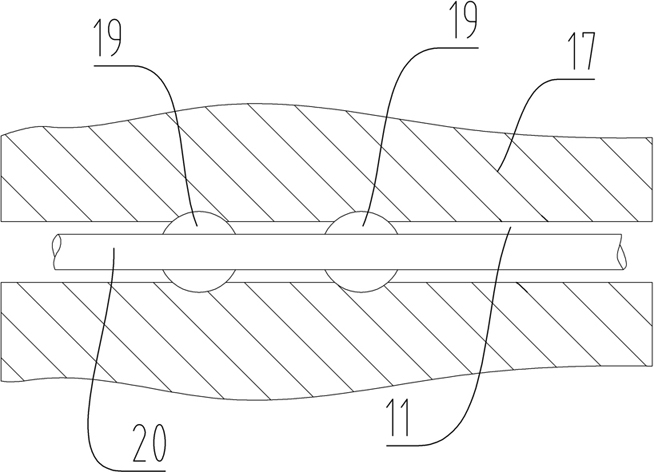

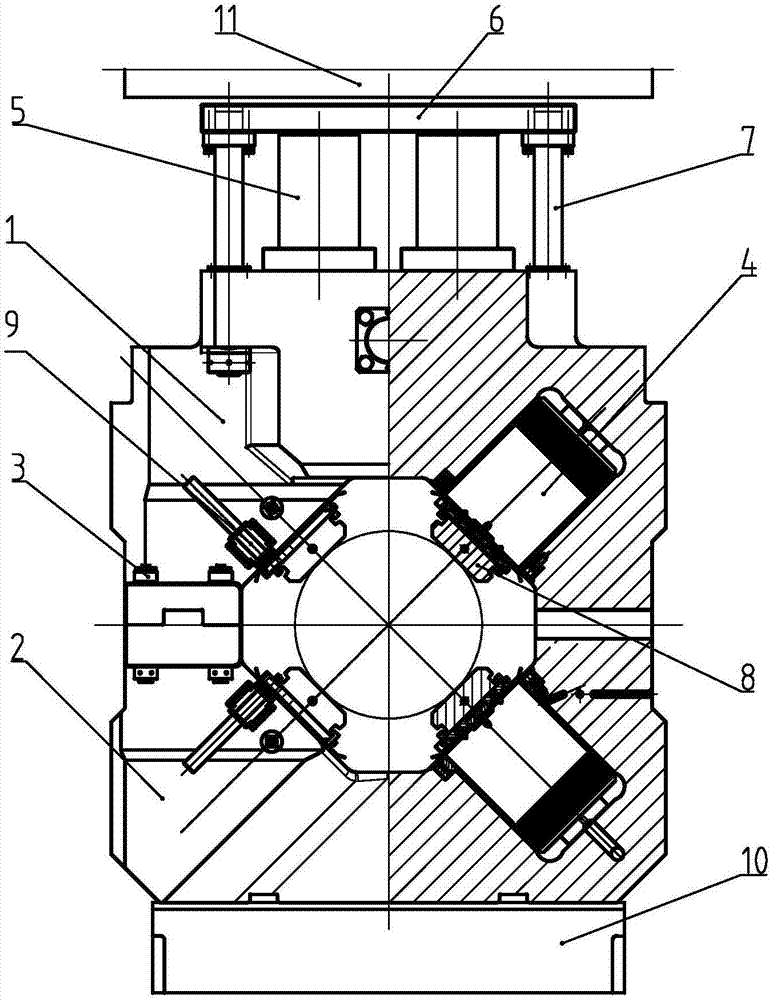

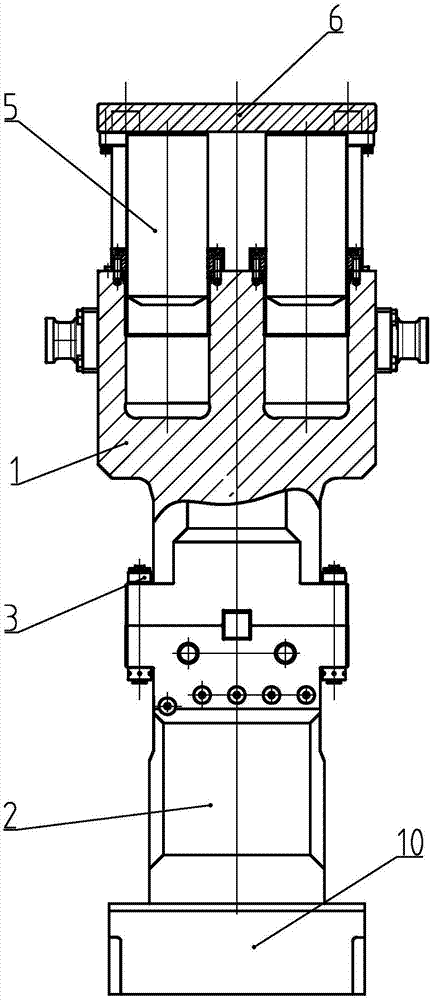

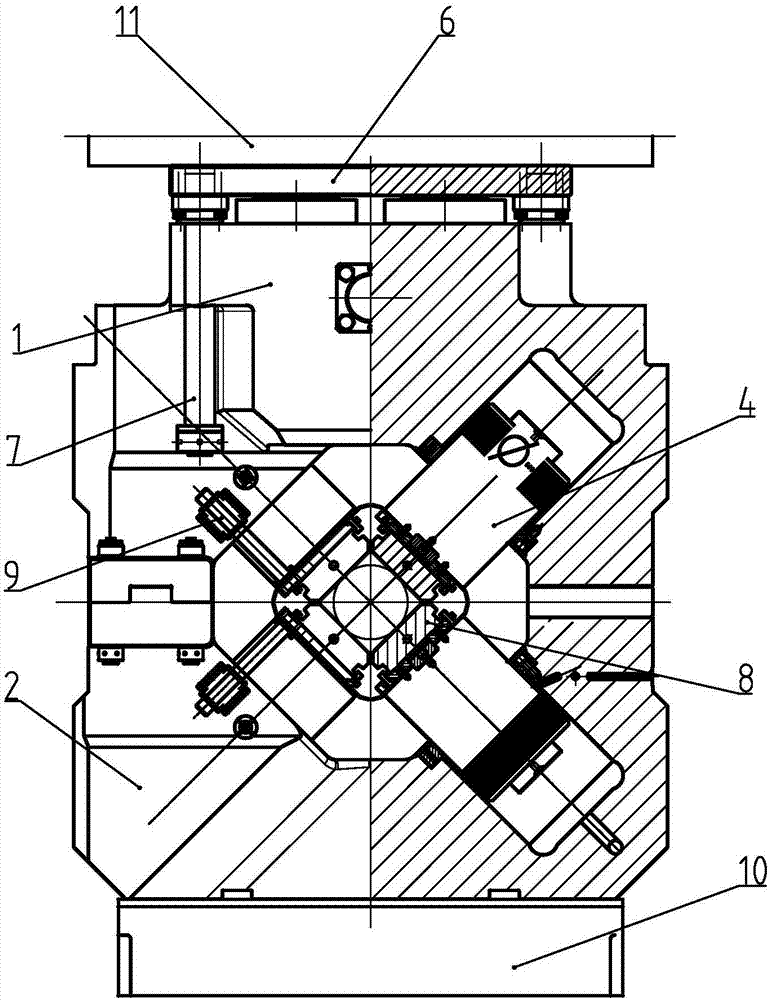

Heavy hydraulic four-hammer radial forging tool

InactiveCN107052208AImprove forging forcePlay a supercharging roleForging press detailsForging press drivesRadial forgingEngineering

The invention discloses a heavy-duty hydraulic four-hammer radial forging tool, which comprises an upper frame, a lower frame, 4 plunger cylinders, 4 hammerhead cylinders, 4 hammerheads, a plunger guide device and a hammerhead anti-rotation device ; The upper frame and the lower frame are connected by pre-tightening bolts to form a closed frame, and the 4 hammer heads are respectively connected with the 4 hammer head cylinders, and are respectively arranged on the upper frame and the lower frame in an "X shape". The force generated in the forging process; the cross-sectional area ratio of the hammer head cylinder and the plunger cylinder is determined according to the magnification of the forging force. Compared with the upper and lower anvil forging method of the original hydraulic press, the present invention adopts four hammerheads to apply load to the forging at the same time, and can complete the forming process of the heavy-duty shaft more quickly, so that the forging precision and forging of the heavy-duty shaft are improved. The quality and forging efficiency are significantly improved, and the machining allowance after forging is significantly reduced. While saving materials, it can save man-hours to the greatest extent and reduce production costs.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

Cold and hot water faucet

InactiveCN102954254BFlexible rotationReduce frictionValve members for absorbing fluid energyMultiple way valvesWater flowEngineering

The invention discloses a cold and hot water faucet. The cold and hot water faucet comprises a cold and hot water faucet body, a cold water channel, a hot water channel, a water outlet channel, a cold water flow adjusting valve and a hot water flow adjusting valve. Valves are respectively arranged on the cold and the hot water channel. Screws and a screw shaft are respectively arranged on sections, intersected with the water outlet channel, of the cold water channel and the hot water channel. The screws are respectively coupled and fixed on the same screw shaft or the screws are integrated with the screw shaft. A guide wheel is arranged between the two screws and on a section, intersected with the water outlet channel, of the cold water channel and the hot water channel. When the valves are all switched on, flows of cold water and hot water are basically identical, pressure difference between the cold water and the hot water is effectively adjusted. When a user turns on other faucets on a same pipeline, only total flow is reduced, adjusted proportion between the cold water and the hot water is basically not changed, thus the temperature of water is effectively controlled.

Owner:杨翠超 +3

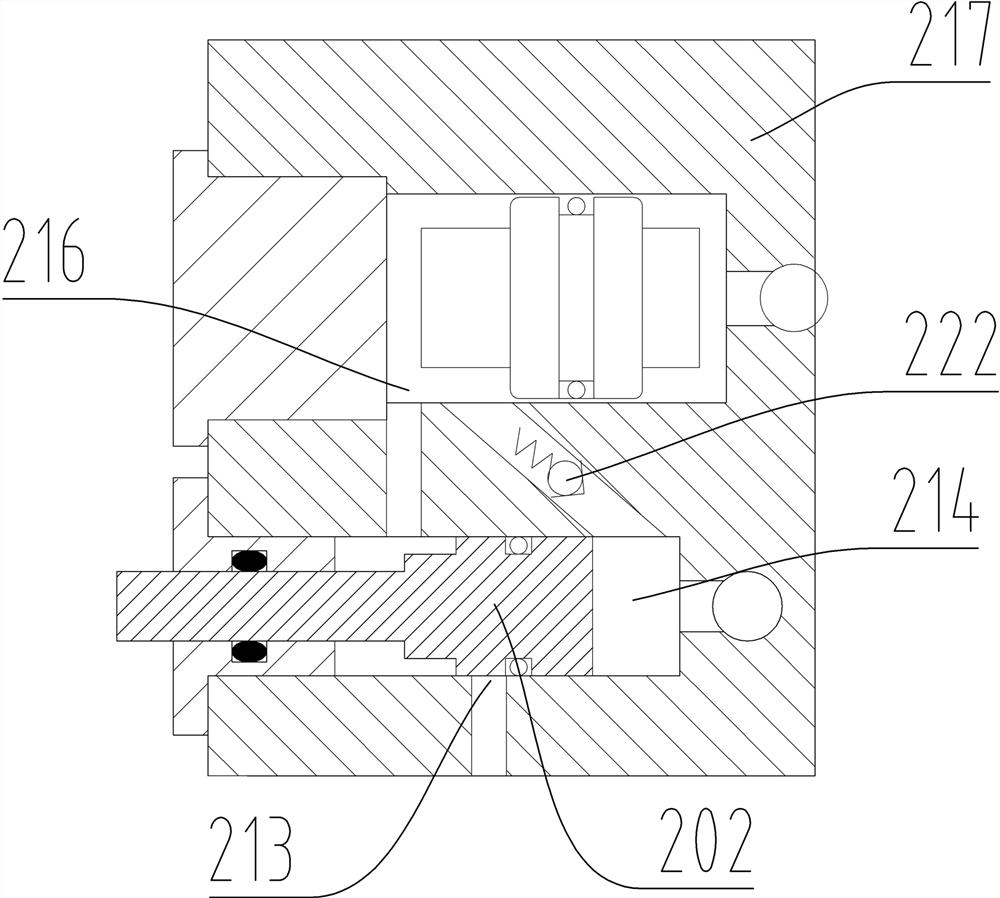

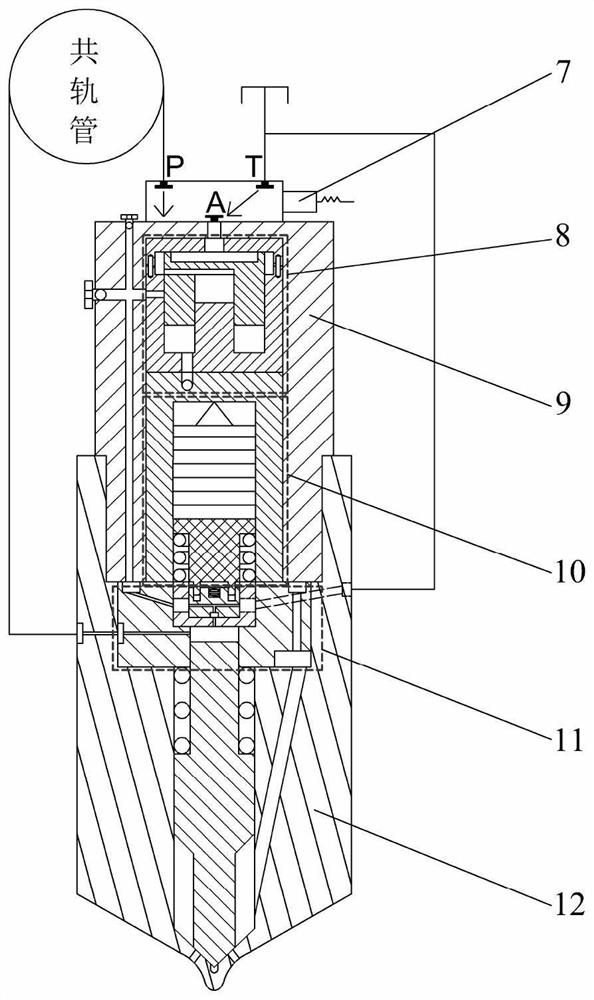

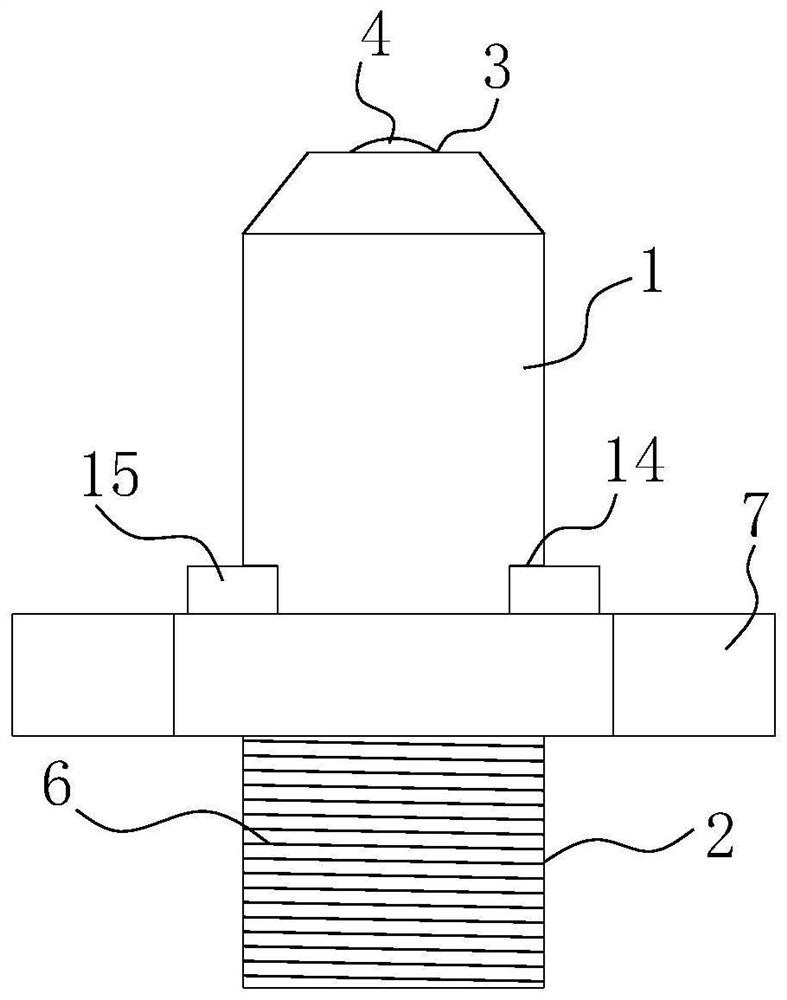

Modular diesel engine double-valve common rail system with flexible and adjustable oil injection rule

InactiveCN112761838AImprove the quality of workReduce complexityFuel injection apparatusMachines/enginesCommon railDieseling

The invention aims to provide a modular diesel engine double-valve common rail system with the flexible and adjustable oil injection rule. A high-pressure oil pump is connected with an oil tank and a common rail pipe, the common rail pipe is connected with an electronic control oil injector through a high-pressure oil pipe, and the electronic control oil injector is connected with the oil tank through an oil return pipe. The electronic control oil injector comprises a pressurization control valve module, a pressurization module, a fastening module, a piezoelectric driving module, an oil injection control module and a nozzle module. The pressurization control valve module is located above the pressurization module, the pressurization module and the piezoelectric driving module are installed in the fastening module, and the lower portion of the fastening module is located in the nozzle module. The oil injection control module is located in the nozzle module. The plunger sleeve plays a role in pressurizing and also plays a role in controlling of the opening and closing of an oil way, so that the complexity of the system structure is reduced. And a control cavity is always communicated with the common rail pipe, so that the system has the capability of realizing a slow-first and fast-second oil injection rule form, and the overall working quality of the diesel engine can be better improved.

Owner:HARBIN ENG UNIV

An outdoor power distribution cabinet with rapid self-extinguishing function

ActiveCN111555141BIncrease jet speedImprove fire extinguishing effectSubstation/switching arrangement casingsFire rescueEngineeringGuide tube

The invention belongs to the field of power distribution cabinets, and in particular relates to an outdoor power distribution cabinet with fast self-extinguishing function, comprising a cabinet body, and a horizontally arranged partition plate is fixedly installed on the inner side wall of the cabinet body, and the baffle plate The cabinet is divided into a fire-extinguishing cavity and an installation cavity. The inner side wall of the fire-extinguishing cavity is sealed and slidably connected with a sealing plate arranged horizontally. The lower surface of the sealing plate is fixedly connected to the partition through an elastic air bag, and the elastic air bag is filled There is a thermal expansion and cold contraction medium, two through holes are arranged in the sealing plate, and a vertically arranged guide pipe rotates through the baffle plate, and the position of the guide pipe and the two through holes are arranged alternately, The guide tube is provided with a threaded rod arranged along the axial direction thereof. The invention can automatically spray the fire extinguishing agent in the fire extinguishing chamber to the electrical equipment in the installation chamber when a fire occurs in the power distribution cabinet, so as to realize the function of automatic fire extinguishing, which is beneficial to quickly control the fire in the cabinet and reduce economic losses. and the possibility of dangerous accidents.

Owner:胜利油田大源节能设备有限公司

Cold and hot water faucet

InactiveCN102954254AFlexible rotationReduce frictionValve members for absorbing fluid energyMultiple way valvesWater flowEngineering

The invention discloses a cold and hot water faucet. The cold and hot water faucet comprises a cold and hot water faucet body, a cold water channel, a hot water channel, a water outlet channel, a cold water flow adjusting valve and a hot water flow adjusting valve. Valves are respectively arranged on the cold and the hot water channel. Screws and a screw shaft are respectively arranged on sections, intersected with the water outlet channel, of the cold water channel and the hot water channel. The screws are respectively coupled and fixed on the same screw shaft or the screws are integrated with the screw shaft. A guide wheel is arranged between the two screws and on a section, intersected with the water outlet channel, of the cold water channel and the hot water channel. When the valves are all switched on, flows of cold water and hot water are basically identical, pressure difference between the cold water and the hot water is effectively adjusted. When a user turns on other faucets on a same pipeline, only total flow is reduced, adjusted proportion between the cold water and the hot water is basically not changed, thus the temperature of water is effectively controlled.

Owner:杨翠超 +3

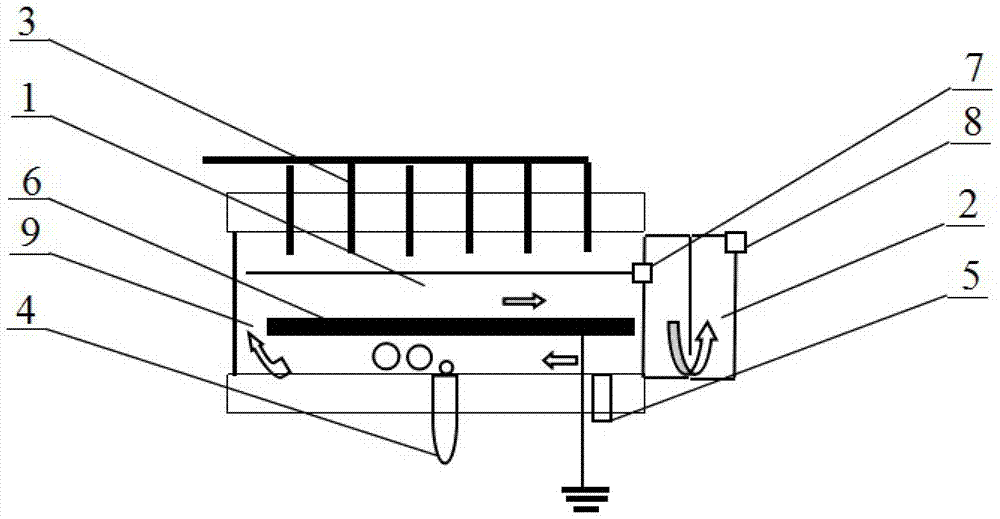

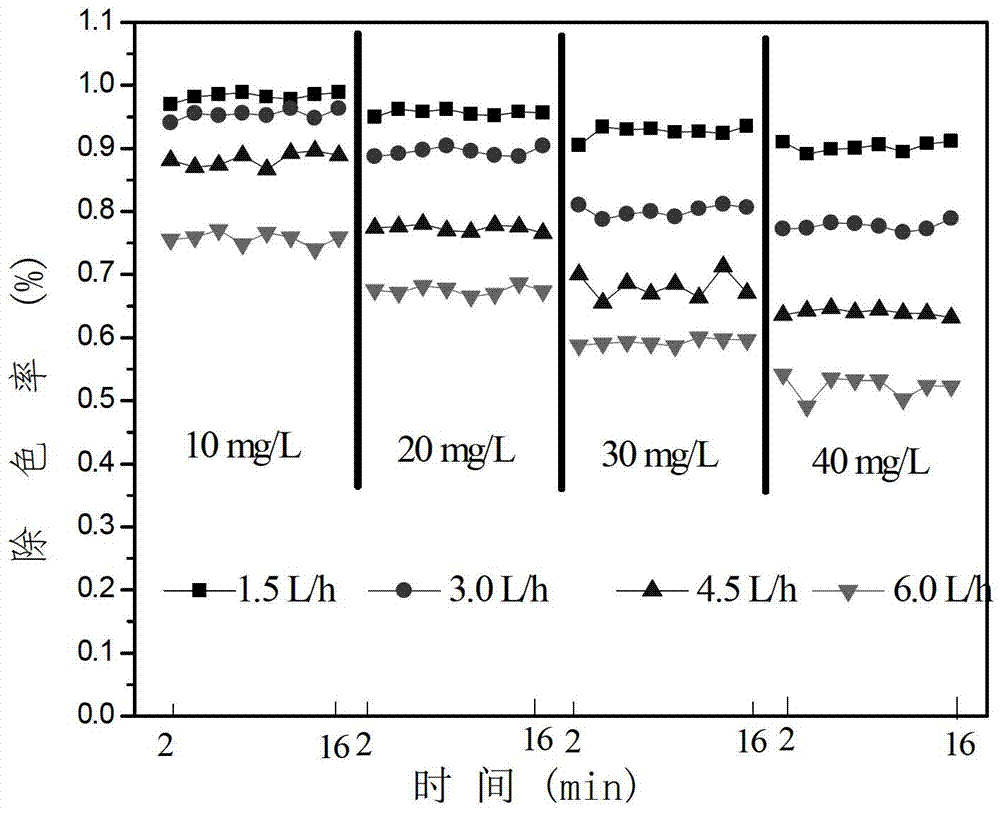

Continuous flow closed gas phase high-voltage pulse discharge water treatment device

ActiveCN103435141BImprove degradation efficiencyPlay a supercharging roleWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsGas phasePlasma technology

The invention relates to a device applying a non-equilibrium plasma technology to the field of water treatment, in particular to a continuous flow closed gas phase high-voltage pulse discharge water treatment device which mainly comprises a high-voltage pulse discharge reactor and a secondary reactor, wherein the high-voltage pulse discharge reactor is a cylindrical closed container; a plurality of high voltage electrodes are hung at the upper end of the high-voltage pulse discharge reactor at equal intervals; a gas inlet hole and a liquid inlet hole are formed at the lower end of the high-voltage pulse discharge reactor; a circular plate grounding electrode is arranged in the middle of the high-voltage pulse discharge reactor; the secondary reactor is a rectangular closed container; a vertical baffle is arranged in the middle of the secondary reactor; a reaction space is in a U-shaped structure; one side of the secondary reactor is communicated with the high-voltage pulse discharge reactor by a liquid outlet a; and the other side of the secondary reactor is communicated with an outside container by a liquid outlet b. The device has the advantages that the discharge device is simple in structure, can efficiently degrade organic matters in waste water, and meets requirements on efficient and energy-saving waste water treatment.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Pressure container corrosion fatigue testing device with closed-loop control

ActiveCN102192859BPlay a supercharging roleAvoid corrosionWeather/light/corrosion resistanceElectrical/magnetic solid deformation measurementAutomatic controlFour-way valve

The invention discloses a pressure container corrosion fatigue testing device with closed-loop control, and the device provided by the invention comprises a high-pressure pump station (1), an oil tank (2), an energy accumulator (3), overflow valves (9, 9'), an electromagnetic proportion overflow valve (7), check valves (6, 6'), a corrosion medium isolation pressurized cylinder (8) and a resistance strain gauge E, wherein the hydraulic oil of a pump station system is separated from the corrosion medium in a test container through the corrosion medium isolation pressurized cylinder (8); the resistance strain gauge E is bonded on a test container H and connected with a controller through a dynamic strain instrument and an A / D (analog / digital) card; a pressure gauge is installed in the test container H and connected with the controller through a pressure transmitter and the A / D card; and the electromagnetic proportion overflow valve (7), a two-position two-way valve (5) and a three-position four-way valve (4) are respectively connected with the controller through a D / A (digital / analog) card. The device disclosed by the invention can be used for preventing the corrosion medium from corroding the pump station system, reducing the manufacturing cost and safety of the pump station system and realizing the automatic control on a corrosion fatigue test with high accuracy.

Owner:溧阳常大技术转移中心有限公司

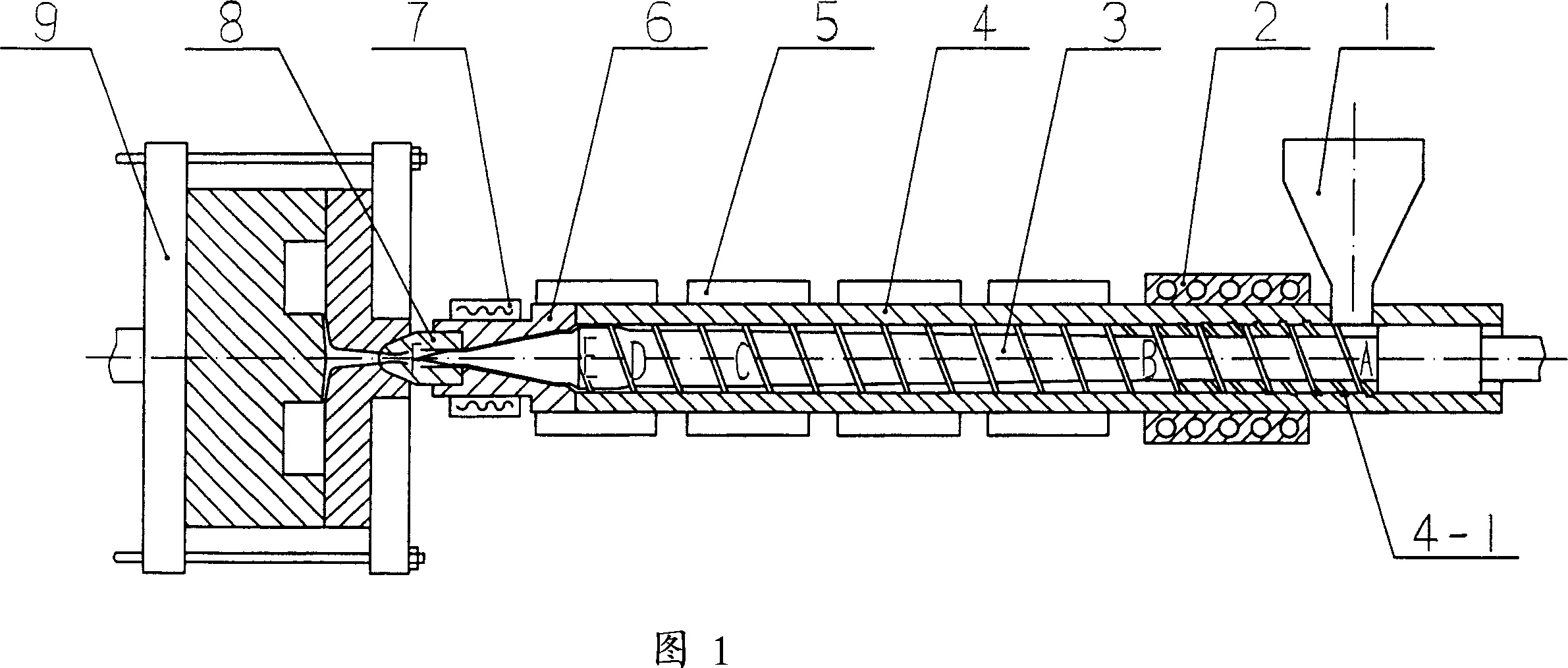

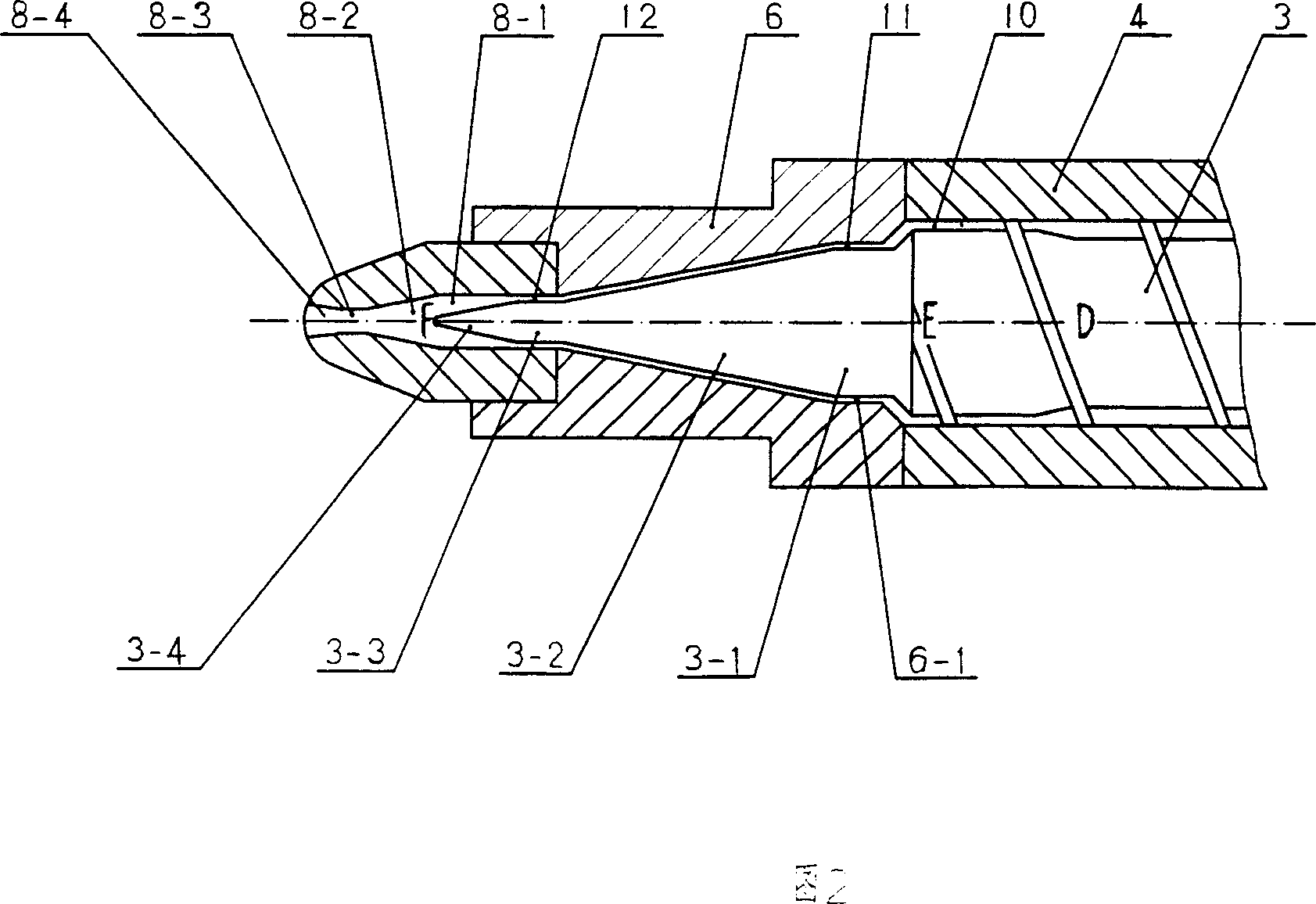

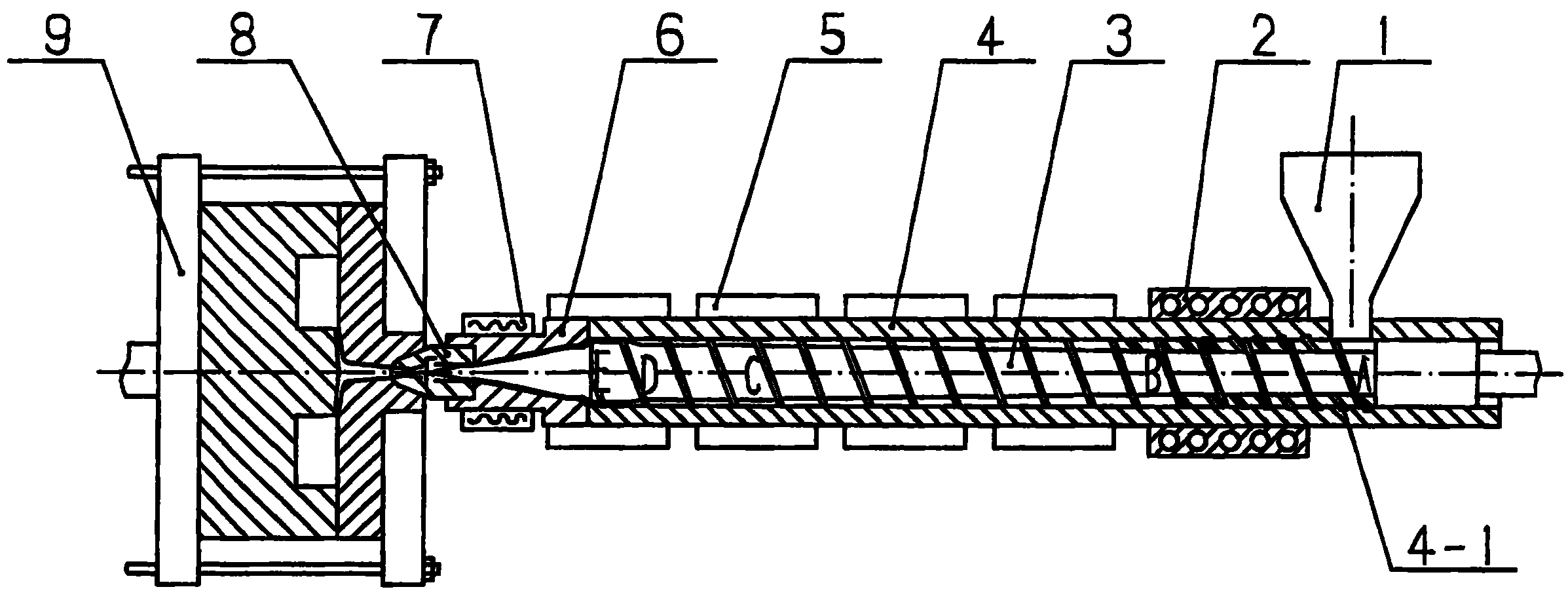

Ultrahigh molecular weight polyethylene injection moulding machine

InactiveCN1301843CPrevent slippingIncrease the effective coefficient of frictionEngineeringInjection moulding

The invention relates to a the super high molecule weight polyethylene inject molding machine, its average segment of screw is composed by the first average segment and the second average segment, the second average segment composes a loop screw stop domain with the inner wall of the machine canister, the head of the screw includes the first grade column, the first grade cone, the second grade column and the second grade cone, the first grade column outer diameter and the column inner diameter of the injection composes the former stop domain, the second grade column outer diameter and spray mouth composes the spray mouth stop domain, the spray has a store room which is composed with column cavity and prick cavity, this invention can prevent the material be returned effectively, decrease the resistance of plastics, improve the screw pull power and the inject capacity, so the difficult work of super high molecule weight polyethylene inject molding can be done by the mould with the normal construction.

Owner:BEIJING UNIV OF CHEM TECH

Novel four-stroke four-cylinder layered dual-vortex combustion energy-saving internal combustion engine with new gas distribution mechanism

ActiveCN102155285BReduce torqueReduce resistanceInternal combustion piston enginesCylinder headsGasolineEngineering

Owner:NANTONG YATAI ENG TECH

Pressure-regulating grease nipple

PendingCN114791080AHigh oil injection pressureWith plugging performanceConduits/junctionsThermodynamicsEngineering

The invention relates to the technical field of lubrication. The pressure-regulating grease nipple comprises a grease nipple body, the grease nipple body is composed of a hollow head section located on the upper portion and a root section located on the lower portion, an oil filling opening is formed in the top end of the head section, a plugging ball is arranged in the portion, on the inner side of the oil filling opening, of the head section, and the plugging ball is pressed against the oil filling opening through a plugging spring; an external thread is arranged on the circumferential face of the lower portion of the root section, and a screwing head is arranged on the circumferential face of the upper portion of the root section. According to the grease nipple, the grease injection pressure of the grease nipple can be effectively increased, so that the grease nipple has certain unblocking performance, and is particularly suitable for being used on machines for long-term field operation.

Owner:ZHUJI SAKURA SNOW MACHINERY

Composite burner brick for heating furnace kiln

ActiveCN105387720BGood heat insulationCombining heavy fire resistance and corrosion resistanceFurnace componentsFiberBrick

Owner:YIXING MORGAN THERMAL CERAMICS CO LTD

A hot and cold faucet

ActiveCN102996864BFlexible rotationPlay a role in decompressionOperating means/releasing devices for valvesMultiple way valvesFiberInlet channel

The invention discloses a cold and hot water tap which comprises a cold and hot water tap body; a cold water channel, a hot water channel, a water outlet channel and valves for adjusting the fluxes of the cold water and the hot water are arranged on the cold and hot water tap body; and the cold water channel and the hot water channel are respectively provided with sub channels between the valves and the water outlet channel; and second valves are respectively arranged on the sub channels. When the valve of only one water inlet channel is opened, a secondary valve at the same side can be opened so as to avoid the resistance to the water flow from bevel wheels. When the valves of the cold water inlet channel and the hot water inlet channel are both opened, the second valves on the sub channels can be closed, so that when hemp threads or raw material tapes or other fibers enter the cold and hot water channels, the hemp threads or raw material tapes or other fibers cannot entangle the bevel wheels, so flexible rotation of the bevel wheels is guaranteed. When cold water and hot water respectively flow from the channels in which the bevel wheels are arranged, the bevel wheel in the channel with bigger water pressure rotates initiatively and the bevel wheel in the channel with smaller water pressure is driven to rotate, so the pressure difference between the cold water and the hot water can be effectively adjusted.

Owner:浙江杭海新城控股集团有限公司

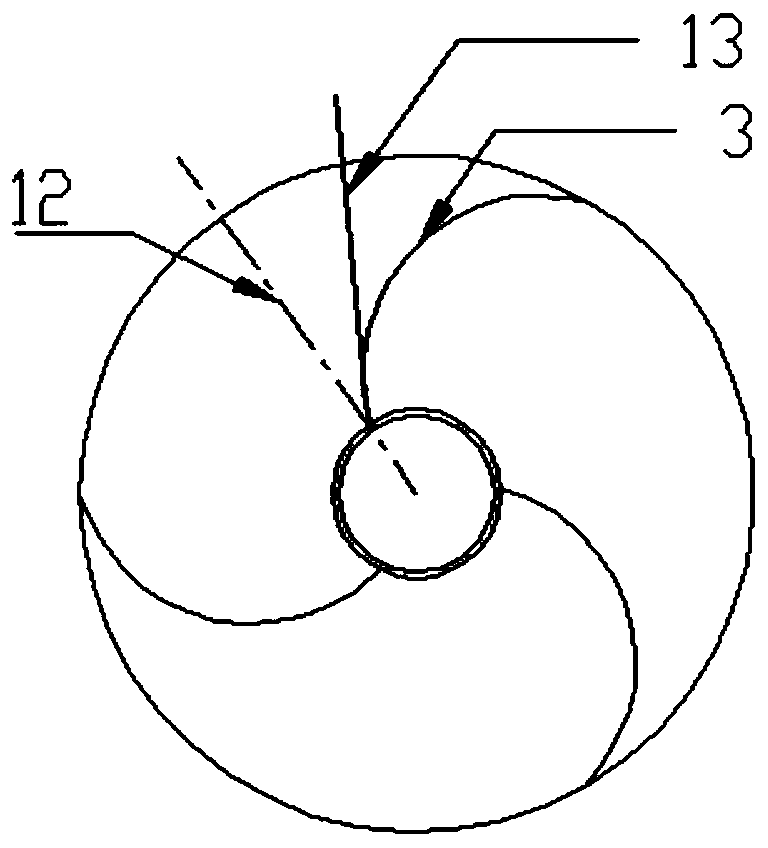

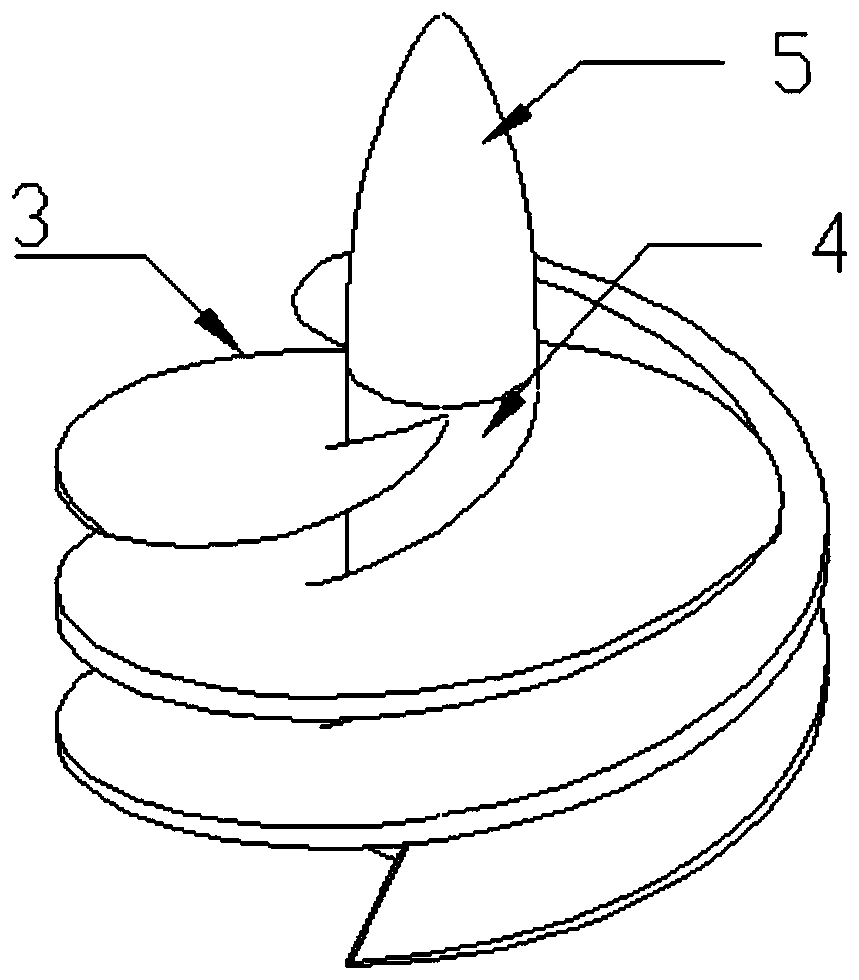

A centrifugal pump impeller and LNG submersible pump comprising the centrifugal pump impeller

InactiveCN108361205BSimple structureEasy to processSpecific fluid pumpsPump componentsEngineeringCavitation erosion

The invention belongs to the field of centrifugal pump type mechanical devices, and specifically relates to a centrifugal pump impeller. The centrifugal pump impeller comprises a front cover plate, arear cover plate, main blades and splitter blades, wherein the main blades and the splitter blades are obliquely arranged between the front cover plate and the rear cover plate; the main blades and the splitter blades are centrifugally uniformly distributed and alternatively arranged; the main blades are longer than the splitter blades; a spiral passageway is formed between every two adjacent blades; the main blades and the splitter blades gradually narrow from an inlet to an outlet. The invention also discloses an LNG (Liquefied Natural Gas) immersed pump comprising the abovementioned centrifugal pump impeller. With the adoption of the centrifugal pump impeller and the LNG immersed pump, the efficiency and the cavitation erosion performance can be improved under the condition that the flow rate and the lift of the LNG immersed pump is ensured; and meanwhile, the centrifugal pump impeller and the LNG immersed pump have the advantages of being simple in structure, convenient to process,and low in cost.

Owner:HUAZHONG UNIV OF SCI & TECH

A cold and hot water faucet

ActiveCN102305299BPlay a role in decompressionPlay a supercharging roleOperating means/releasing devices for valvesMultiple way valvesImpellerEngineering

Owner:黄小敏

Automatic additive-feeding device and method and washing machine

ActiveCN110699927AAvoid wastingAchieve dissolutionOther washing machinesTextiles and paperLaundry washing machineWater flow

The invention discloses an automatic additive-feeding device and method and a washing machine; the automatic additive-feeding device comprises: a water supply passage that may deliver water to a wateroutlet; a liquid storage box containing an additive; a suction structure that can draw out the additive in the liquid storage box and convey the additive to the water outlet along with the water flowby generating negative pressure on the water flow flowing through the water supply passage; and a flushing passage, used for controllably connecting the water supply passage with the liquid storage box, and conveying the water flow in the water supply passage to the liquid storage box for flushing. The invention also provides the washing machine with the automatic additive-feeding device, and theresidual additive dissolved in the liquid storage box through the water flow in a flushing passage is fed into a washing drum along with the water incoming flow of the washing machine, so that the liquid storage box can be conveniently and efficiently washed without waste.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com