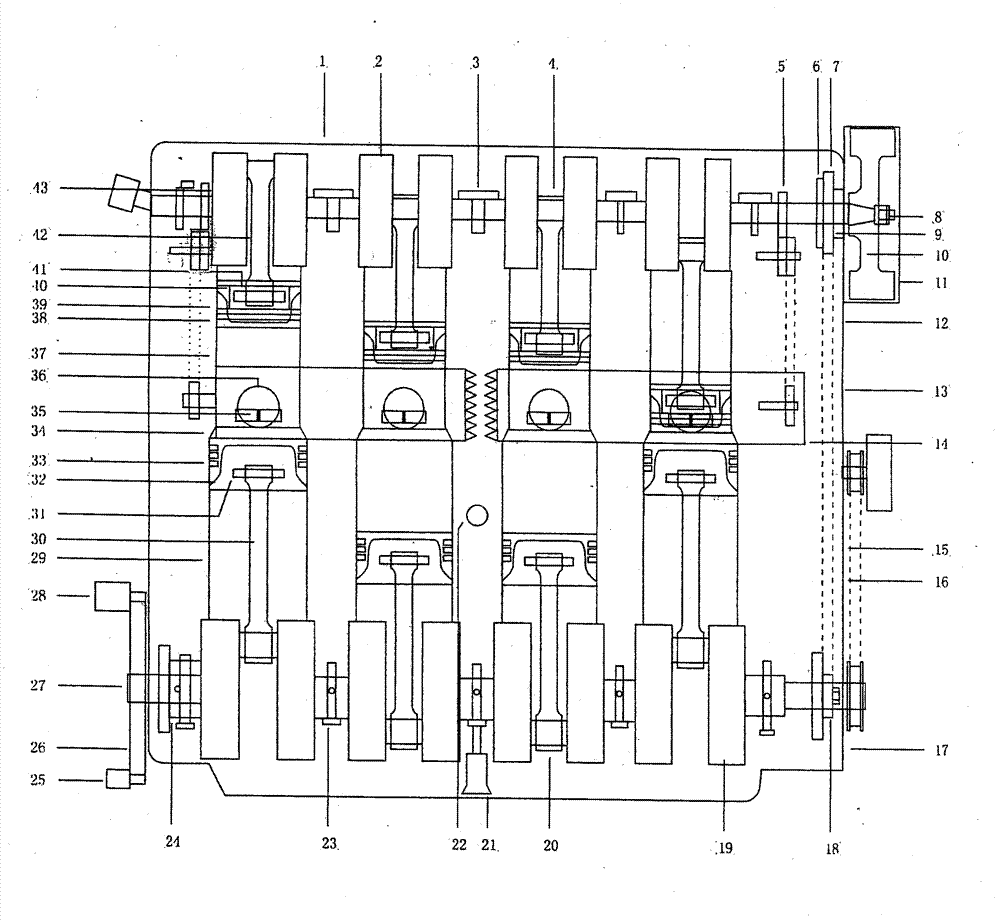

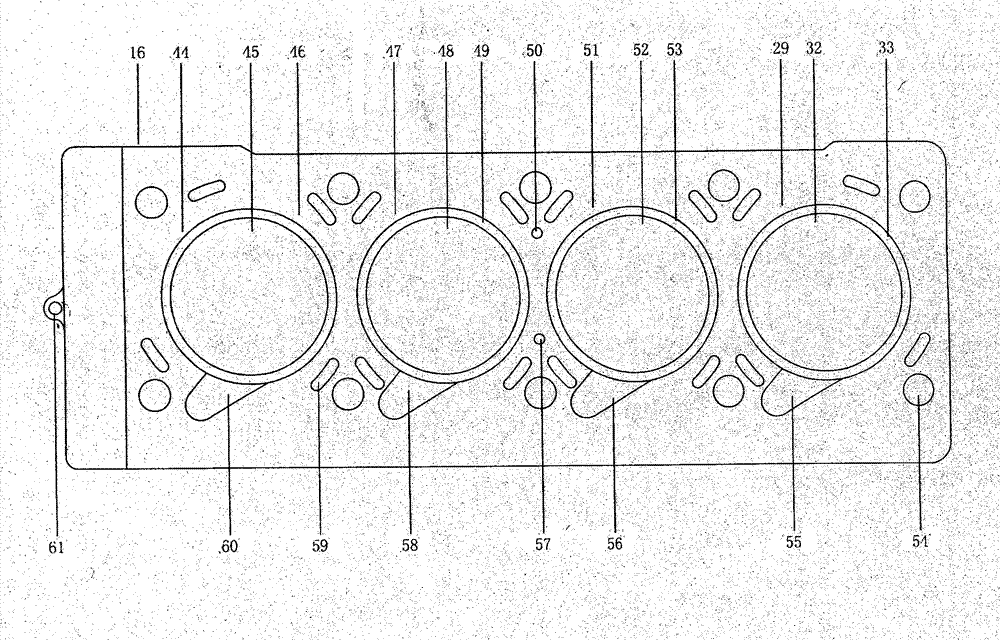

Novel four-stroke four-cylinder layered dual-vortex combustion energy-saving internal combustion engine with new gas distribution mechanism

A gas distribution mechanism and four-stroke technology, which is applied to combustion engines, internal combustion piston engines, machines/engines, etc., can solve problems such as insufficient fuel saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

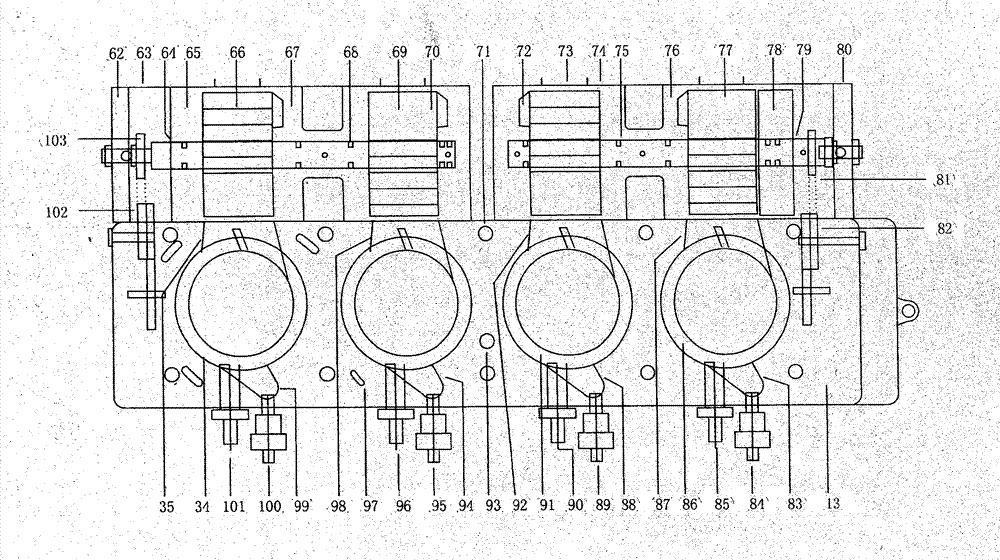

[0024] specific implementation plan

[0025] The facility scheme of the patent of the present invention is in image 3 Middle: first take eight small oil rings of turbine shafts (68, 75) and distribute them on the collar positions of the four inlet and exhaust turbines (66, 69, 73, 77), and install each of the turbine shafts on the collar positions Seat (67,76), load onto each turbine left and right seats again, load onto each turbine timing small sprocket wheel (81,103) again and fix with nuts, load onto each turbine timing small chain ( 82, 102). On the other side, two advance and discharge turbines (66, 69) are tightly fitted and fixed respectively on two shaft heads of two advance and discharge turbines, and then four advance and discharge turbines (66, 69, 73, 77) are installed in a distributed manner. Enter each one into the turbine outer cylinder (63,74), and then install each turbine head seat cover (72,70) on the shaft head of each one. A turbine left and right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com