Patents

Literature

493 results about "Cavitation erosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

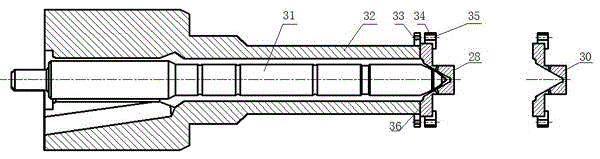

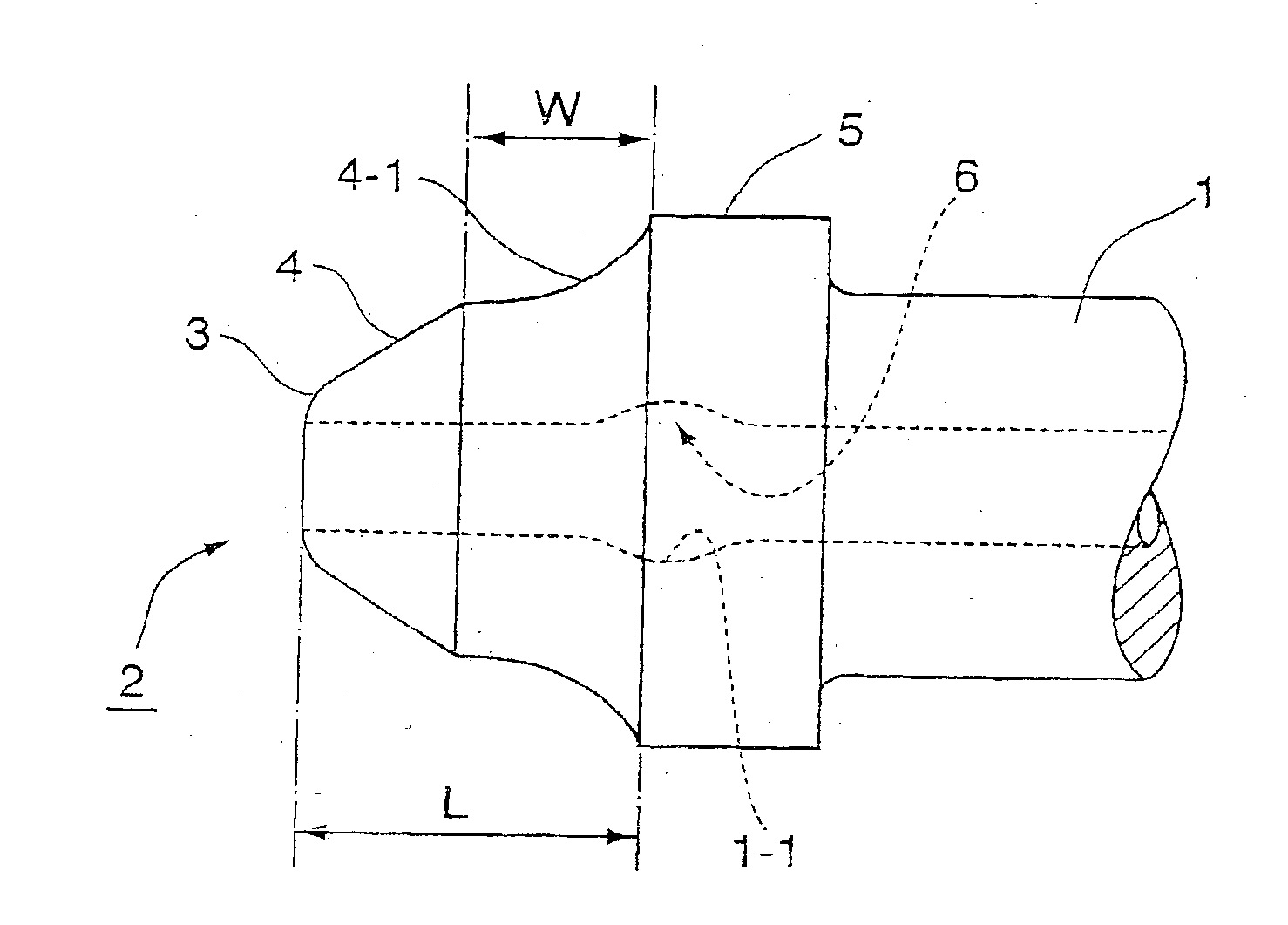

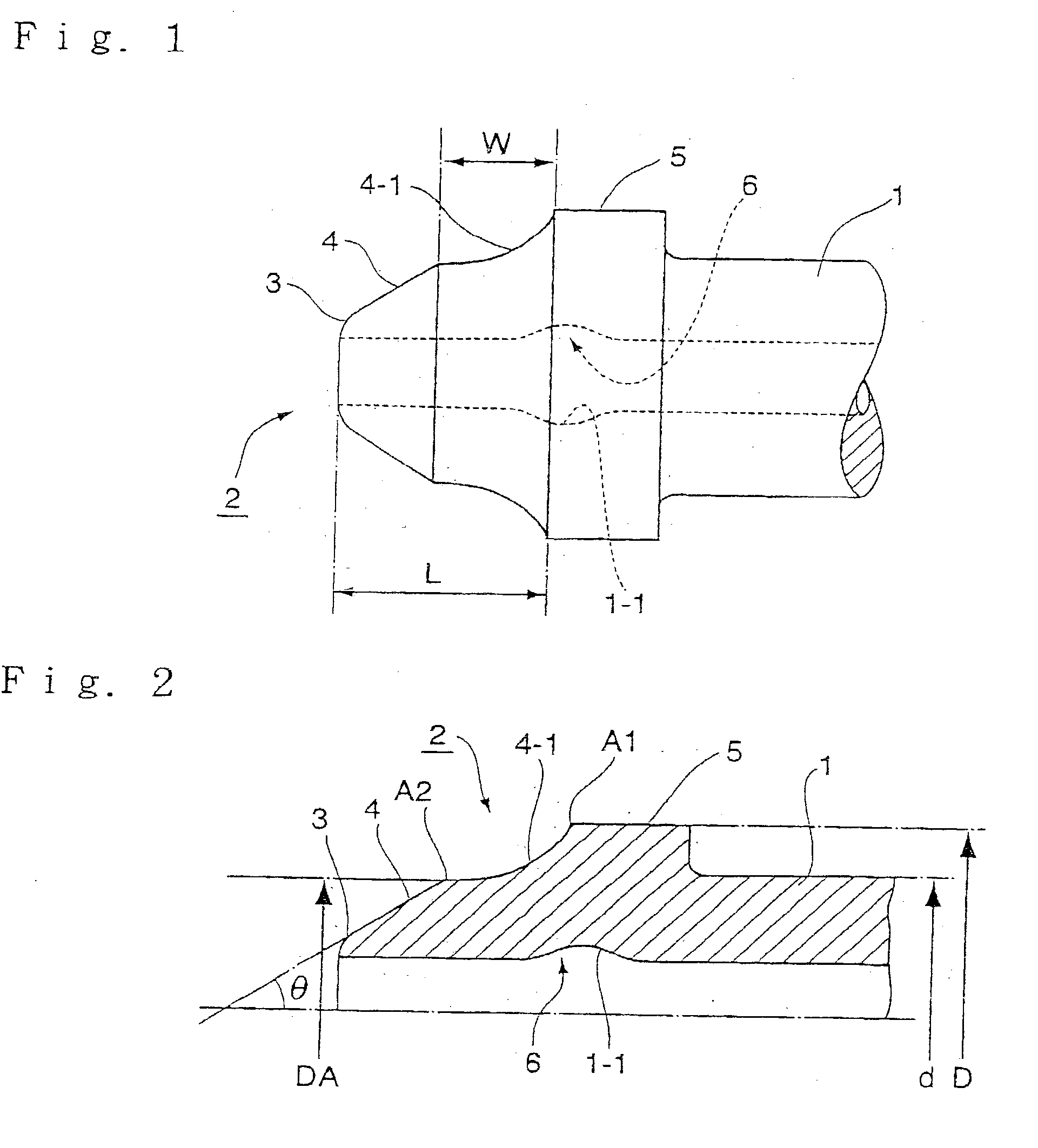

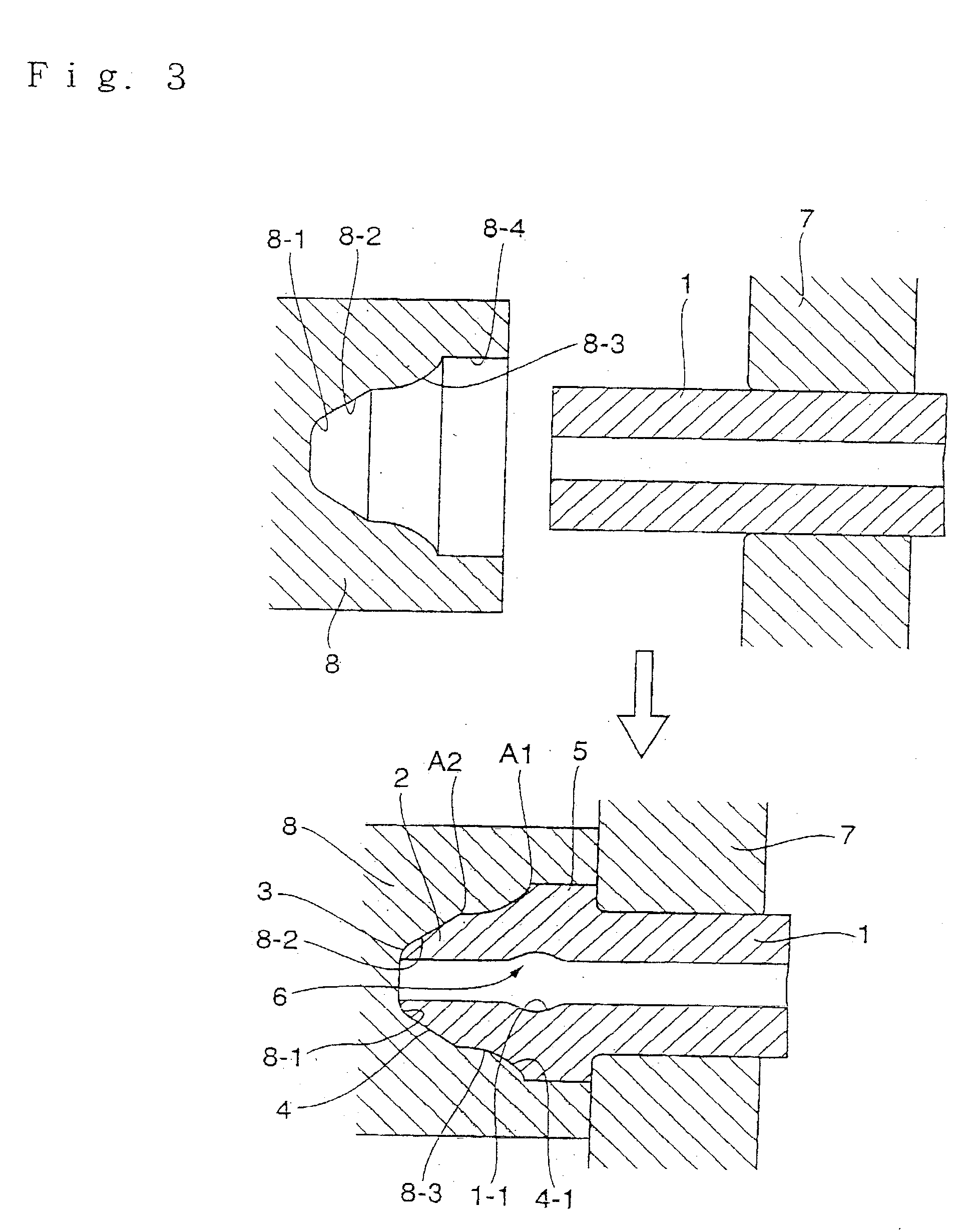

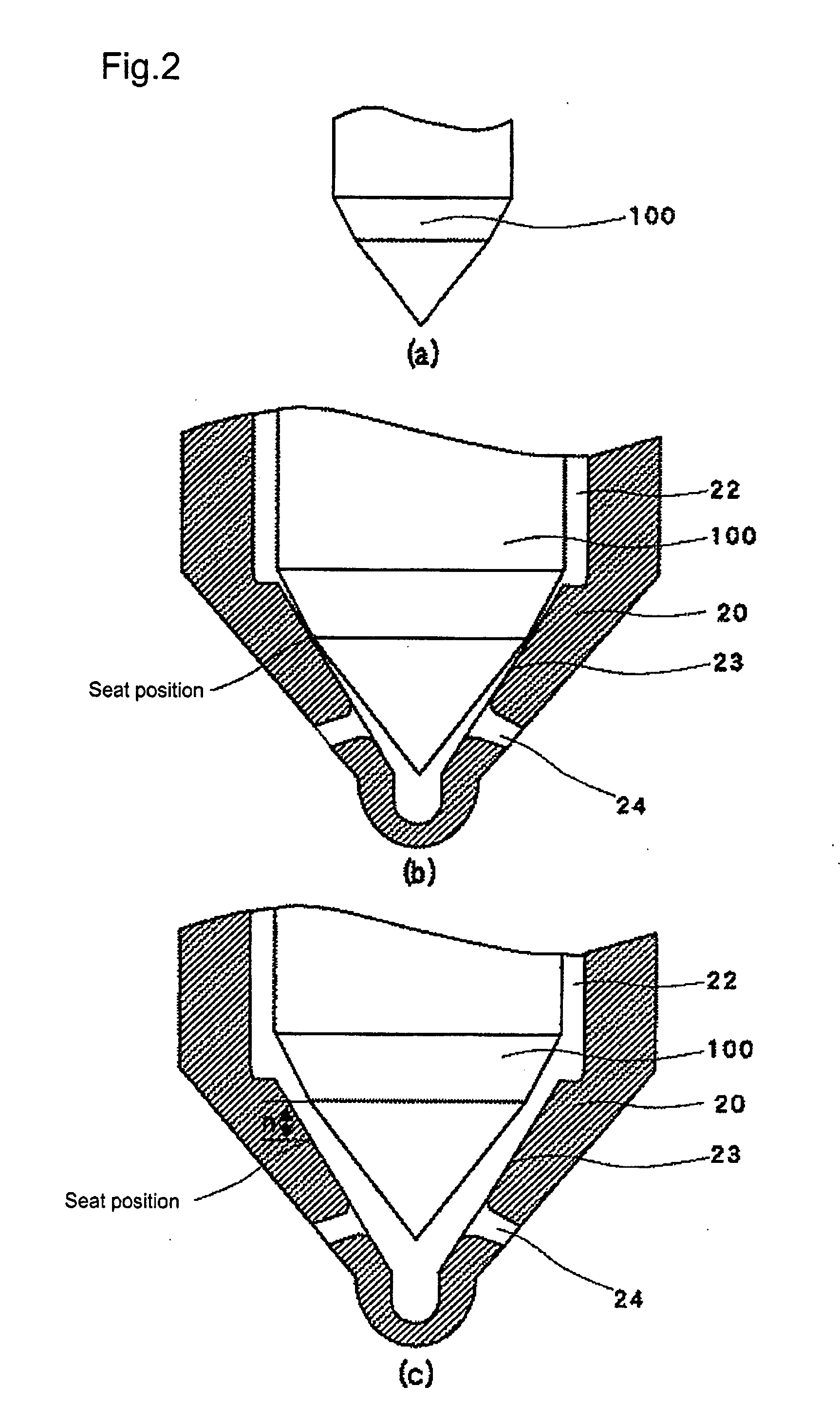

High-pressure fuel injection pipe having connecting head portion

InactiveUS6840283B2Eliminate fearReduce fatigue failureJoints with sealing surfacesMetal-working apparatusThick wallEngineering

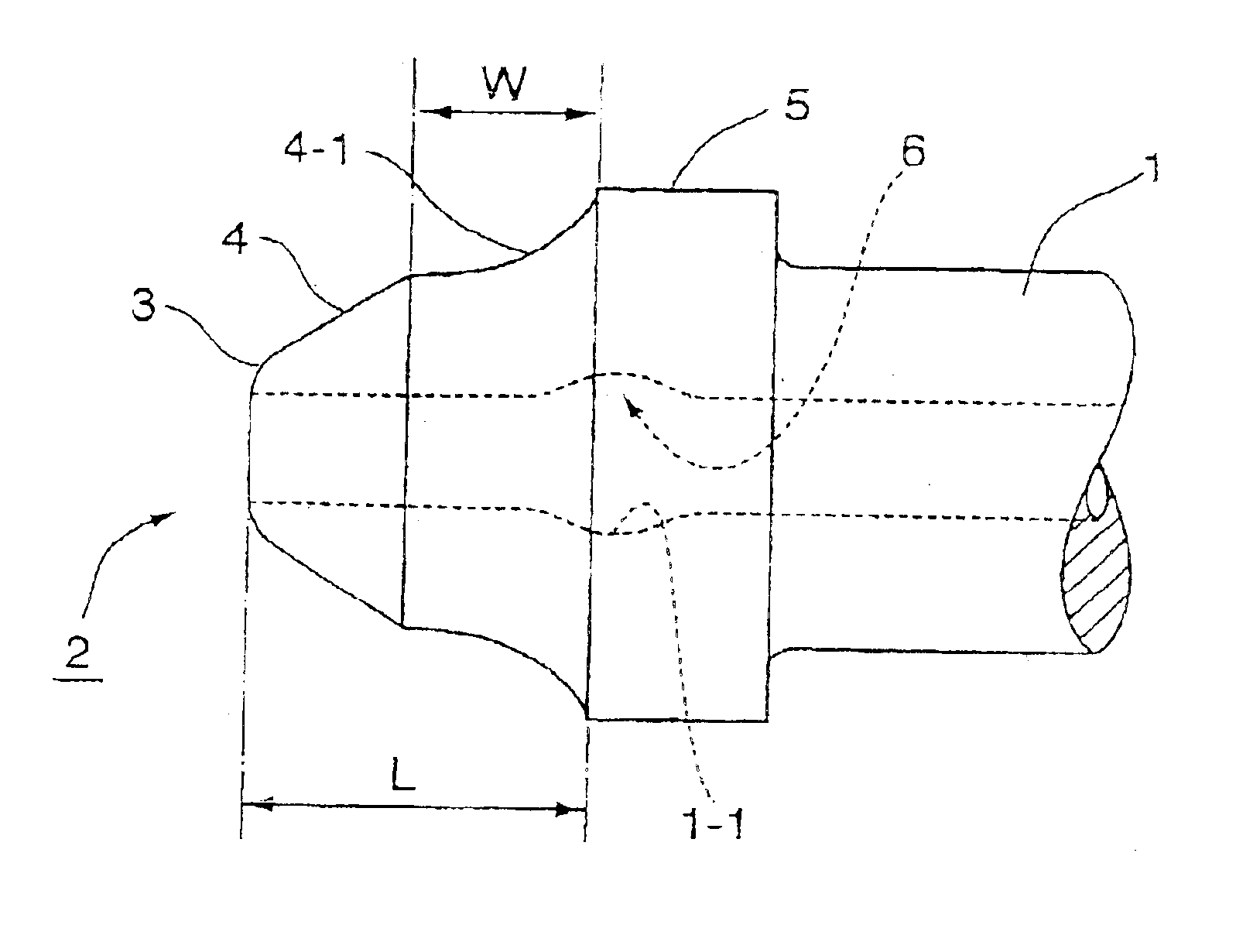

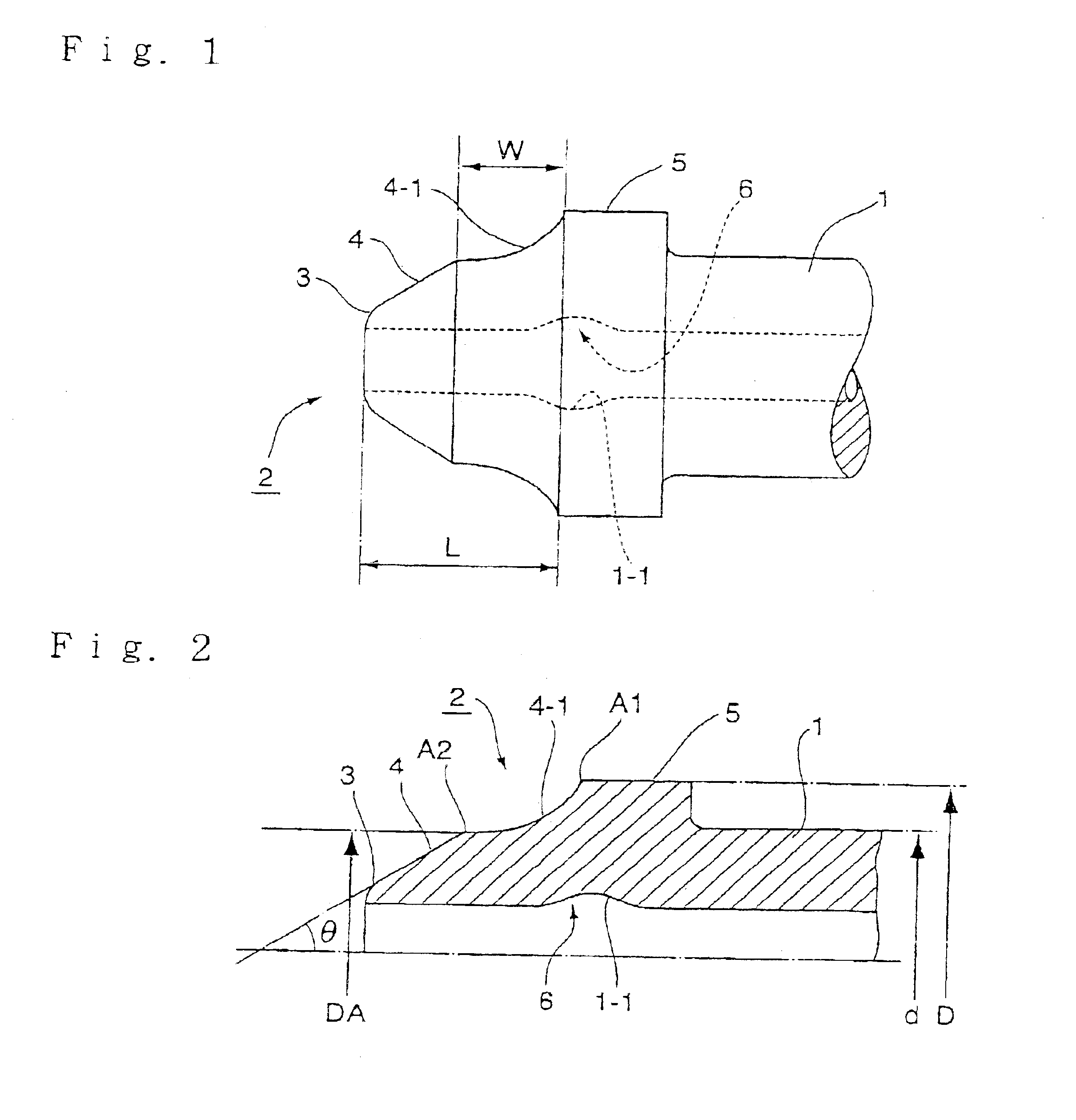

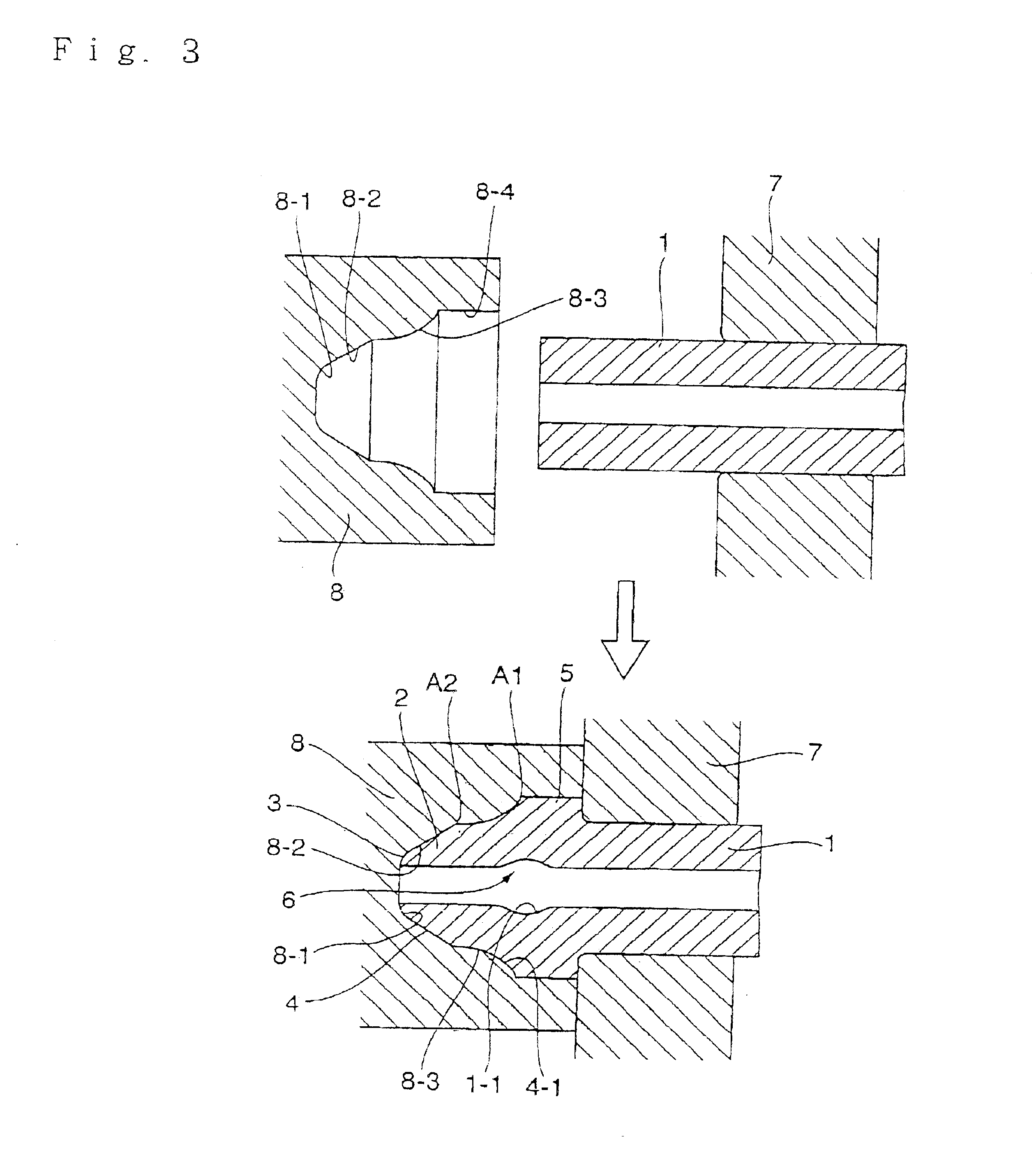

A high-pressure fuel injection pipe having connecting head portion is provided which is capable of eliminating a fear of the occurrence of cavitation erosion of the inner surface of the connecting head portion and a fatigue failure of the same head portion by having a contour of a cross section of an annular pocket occurring in an inner part of the connecting head portion during a head portion processing operation extend shallowly and gently. This fuel injection pipe has at a connecting end portion of a thick-walled steel pipe having a relatively small diameter, including a seat surface, an annular flange formed so that the flange is axially spaced from the seat surface, and a conical surface connected to the seat surface, extending therefrom to the annular flange and tapering off to a free end of the connecting head portion, wherein the conical surface is provided at a part thereof with an annular, shallow, cross-sectionally curved recess.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

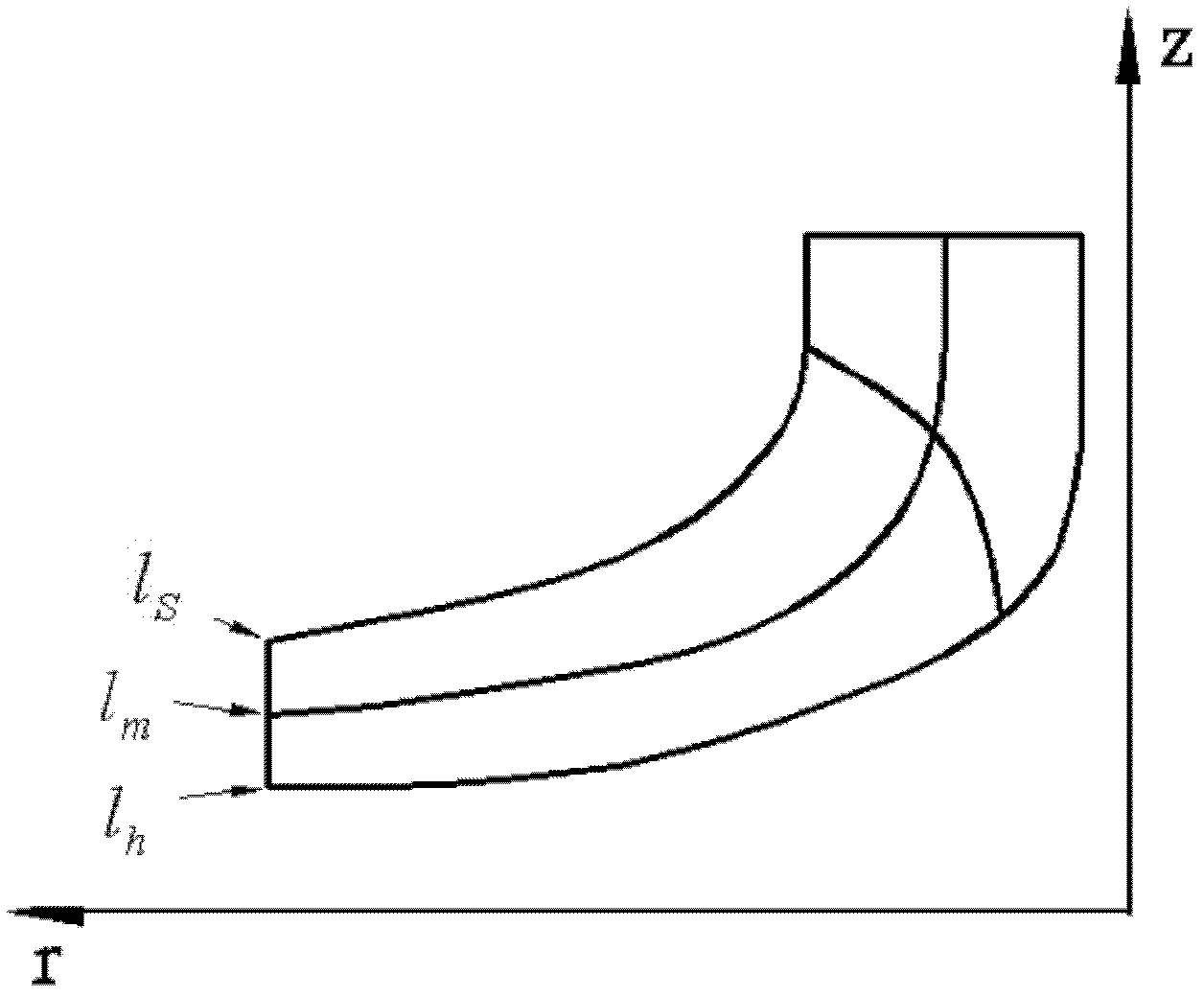

Optimization design method of impellor for cavitation-erosion-resistant centrifugal fan

InactiveCN102251983AReasonably constructedImprove efficiencyPump componentsPumpsEngineeringThree dimensional shape

Owner:XIAN UNIV OF TECH

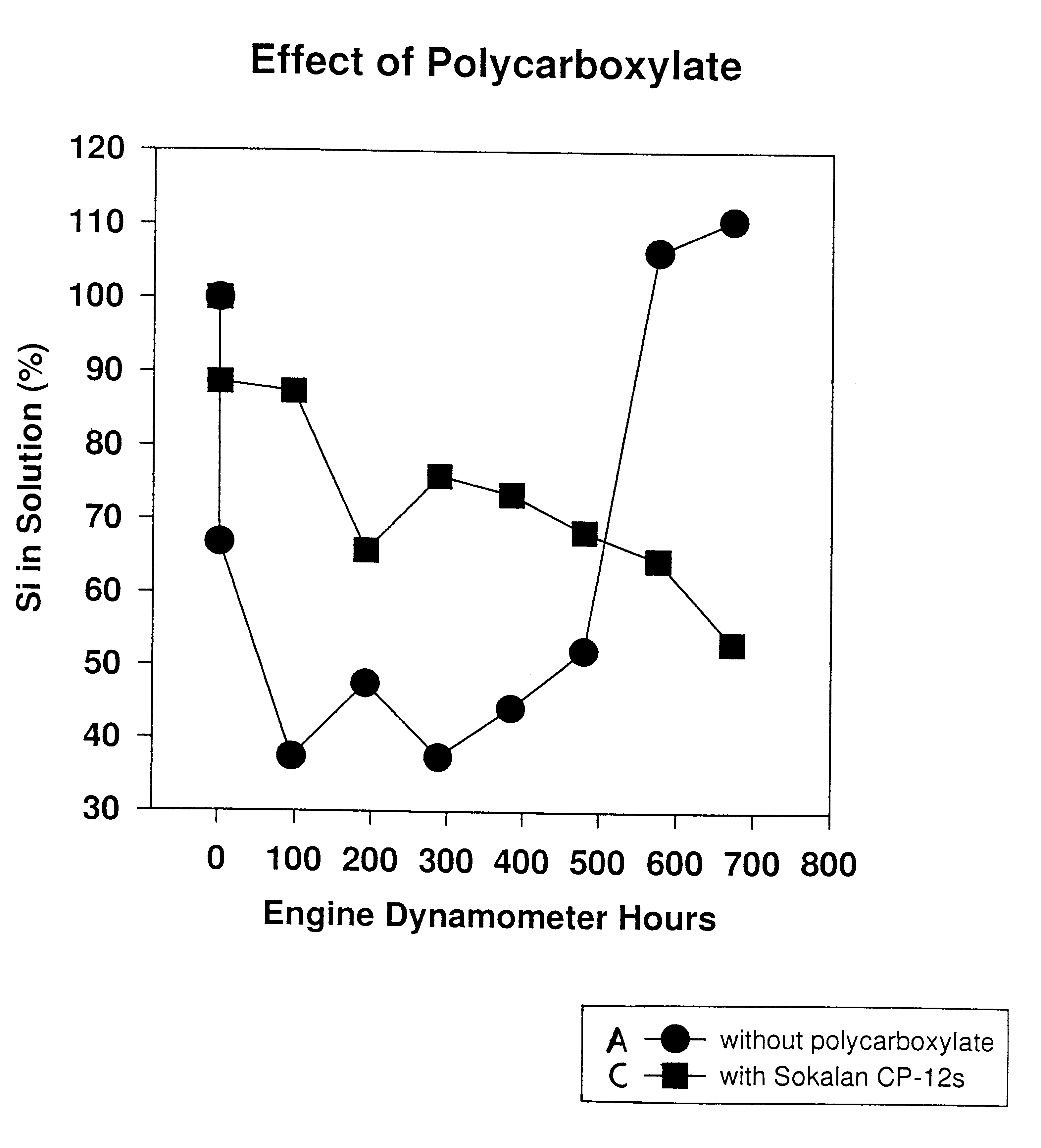

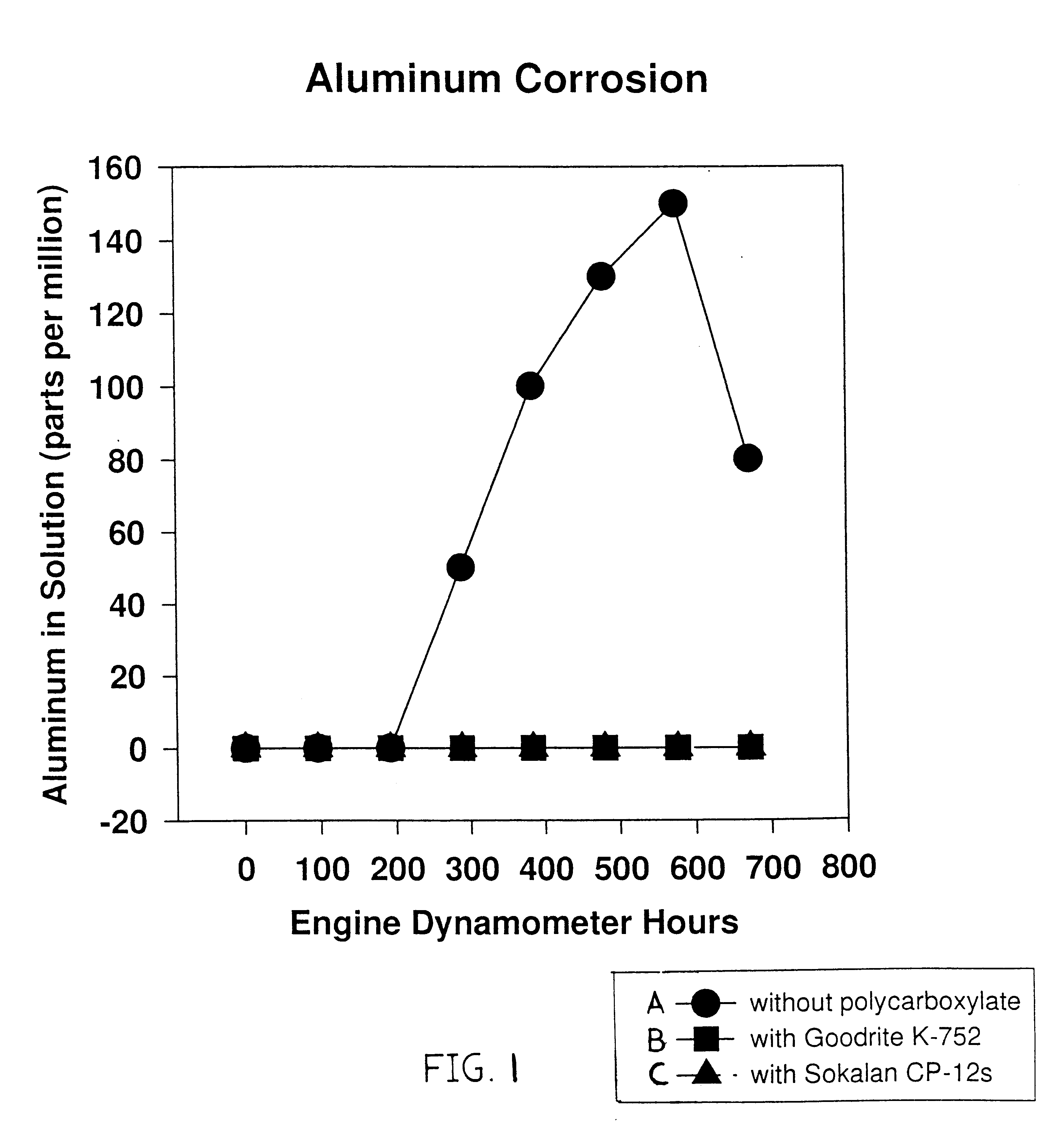

Extended engine coolant lifetime through polymeric polycarboxylate secondary silicate stabilization

InactiveUS6203719B1Inhibiting cavitation-erosion corrosionOther chemical processesHeat-exchange elementsPhosphateNitrate salts

The present invention provides corrosion inhibition formulations and compositions for inhibiting mineral scale and the corrosion of metals particularly the cavitation corrosion of aluminum in the presence of aqueous liquids. The combination of a mixture of polymeric polycarboxylates, azoles, nitrate salts, phosphates, stabilized silicates and transition metal compounds provide a synergistic protective effect against the cavitation corrosion of aluminum in aqueous liquids reducing the corrosion rate and is effective at relatively low concentrations and varying pH ranges. The addition of selected polymeric polycarboxylates not only significantly reduces glycol based coolant cavitation erosion-corrosion, heat rejecting aluminum corrosion, and hard water precipitates and scale, it has been discovered that polymeric polycarboxylates in combination with siloxane stabilized silicates enhance secondary silicate stabilization leading to improvement in aluminum corrosion protection and coolant life when utilized with selected amounts of the above-identified additives. The formulations are particularly suitable for automotive applications.

Owner:VALVOLINE LICENSING & INTPROP LLC

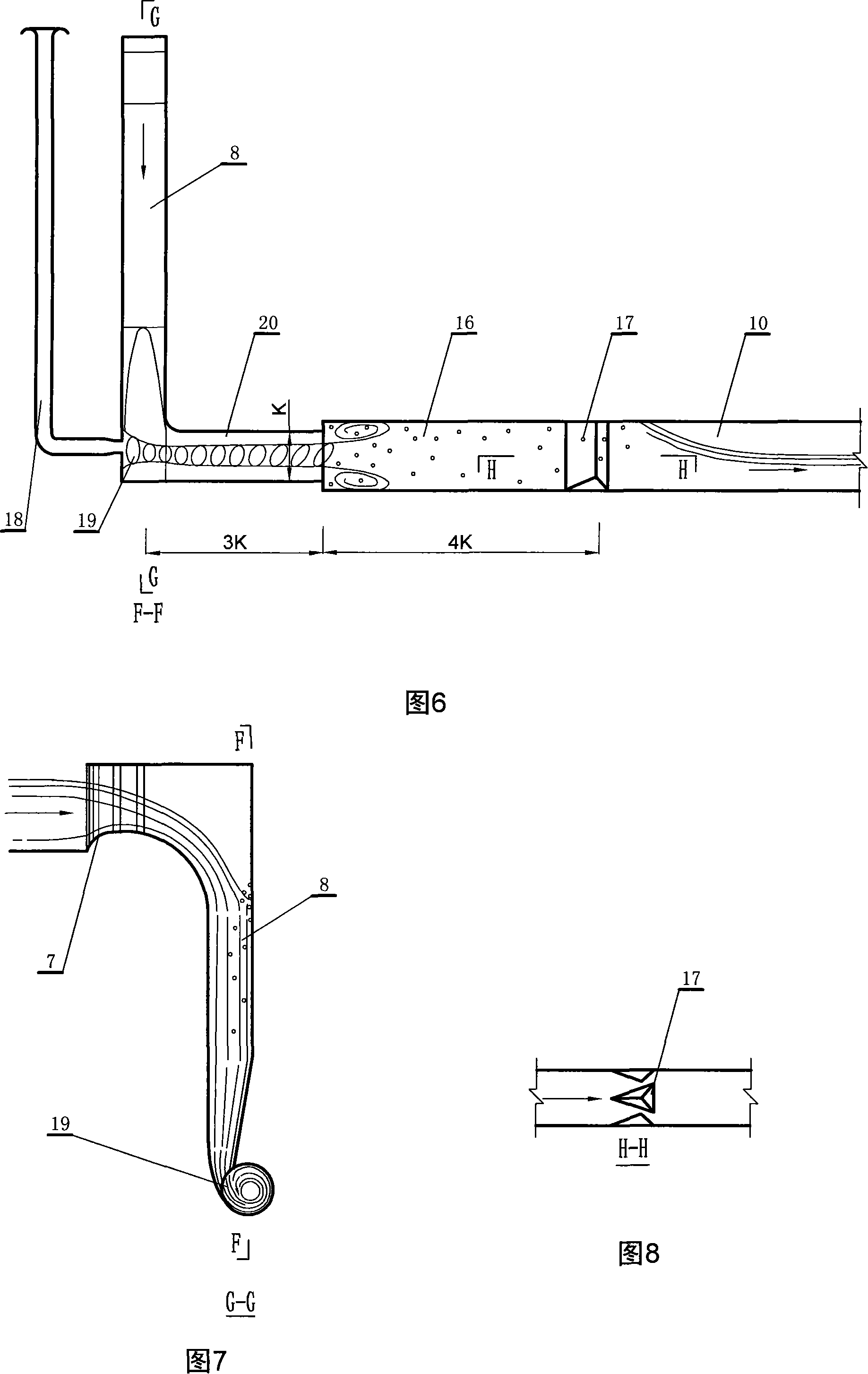

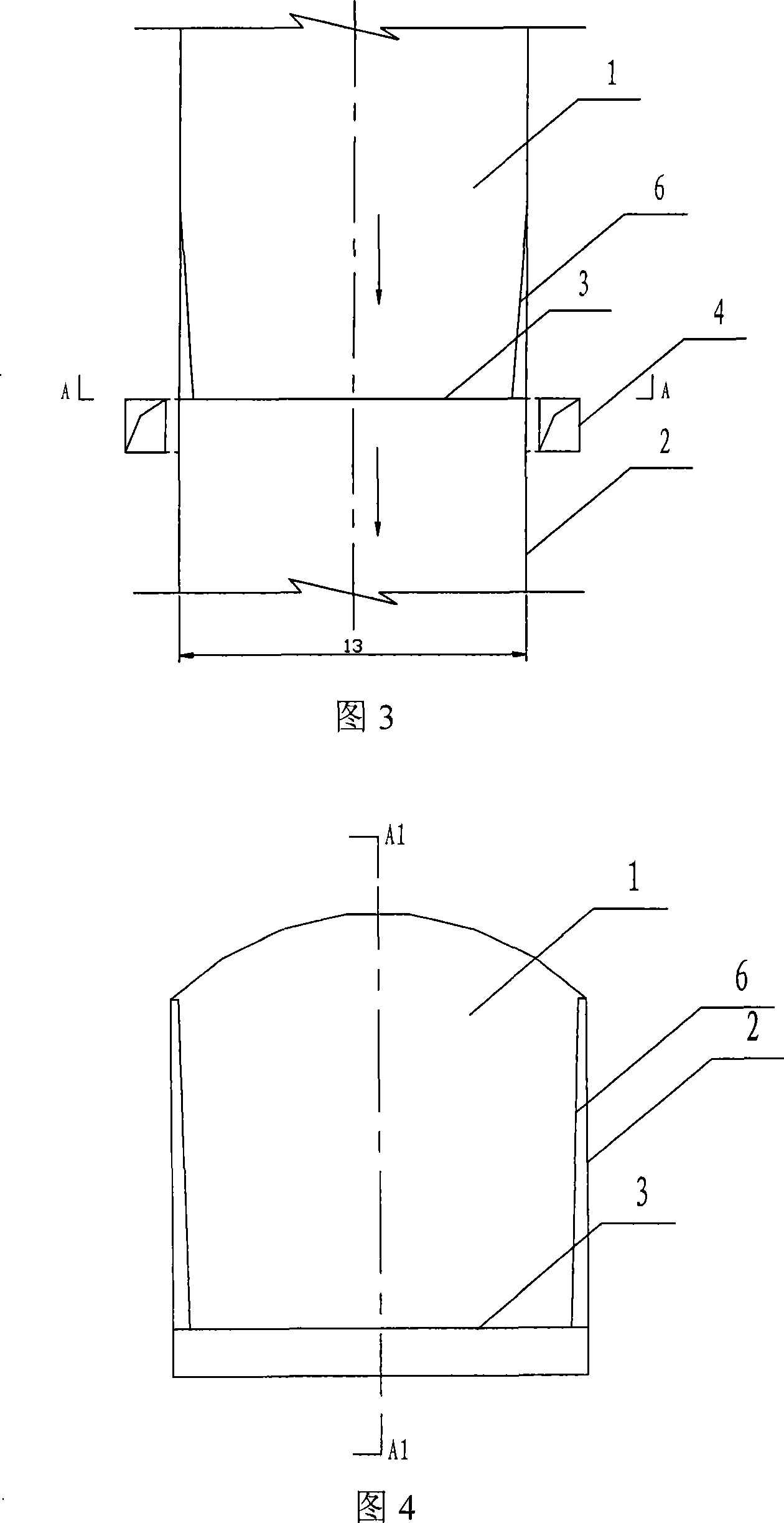

Rotational flow silo equipped with air entrainment ridge

The invention discloses a gyrating drilled shaft provided with an aeration ridge. The invention is characterized in that the gyrating drilled shaft is provided with an aeration ridge on the wall surface at the middle lower part of the drilled shaft section, the aeration ridge is formed by gradually shrinking the drilled shaft connected with the upper flat section of a flood discharging tunnel from the middle part to the middle lower part and then suddenly expanding the wall surface, and at least two aeration holes are distributed on the annular aeration ridge formed by the sudden expansion, each of the aeration holes is spliced with a vent pipe communicating with the atmosphere. The vent pipes can be selectively buried on the outer side of the gyrating drilled shaft. The gyrating drilled shaft disclosed by the invention enables near-wall water layers at the lower reaches of the aeration ridge to become into aerated water flows, thereby increasing the flow cavitation number, playing the effects of air entrainment and cavitation prevention, preventing the overflowing section at the middle lower part of the drilled shaft from being damaged by cavitation erosion, and ensuring the safe flood discharging operation of the gyrating drilled shaft.

Owner:SICHUAN UNIV

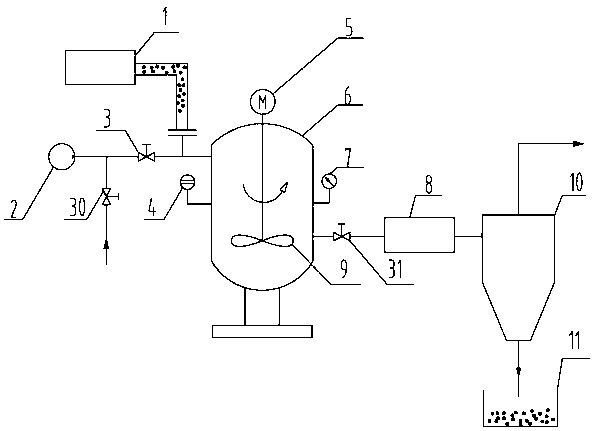

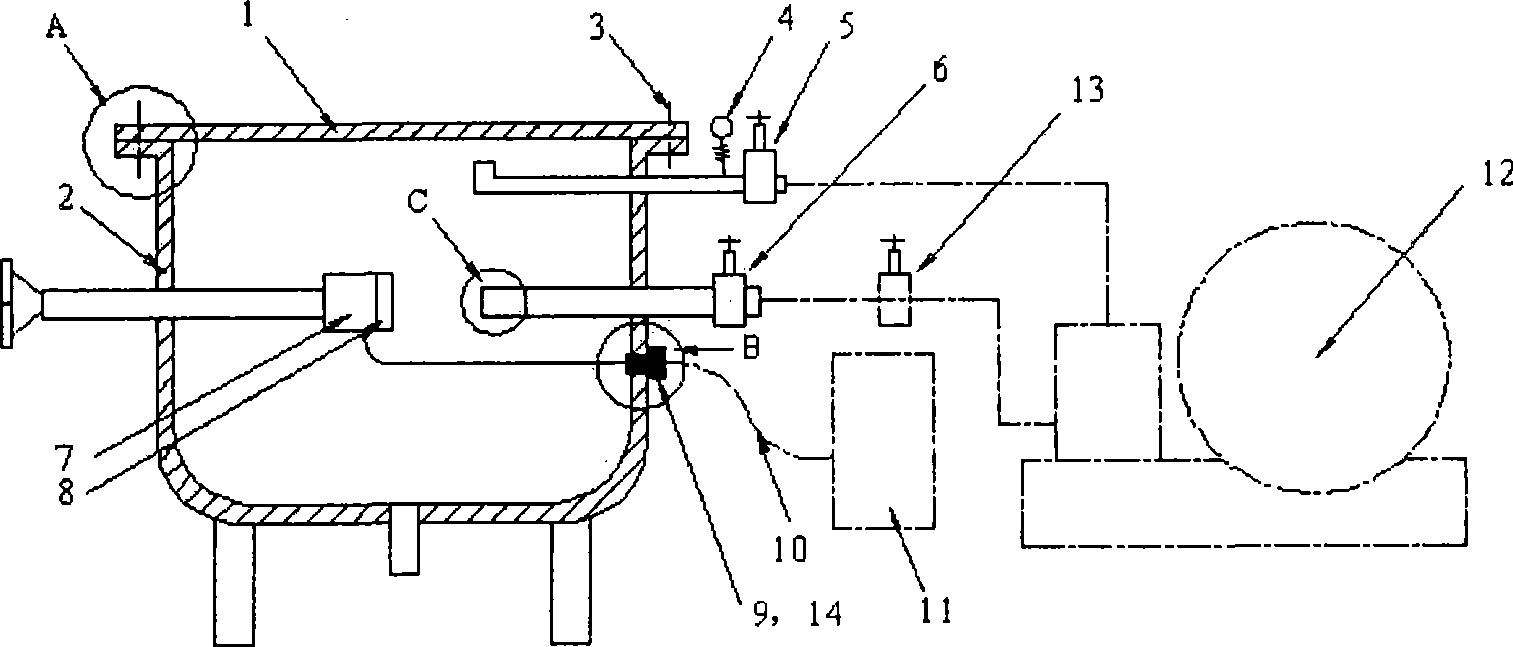

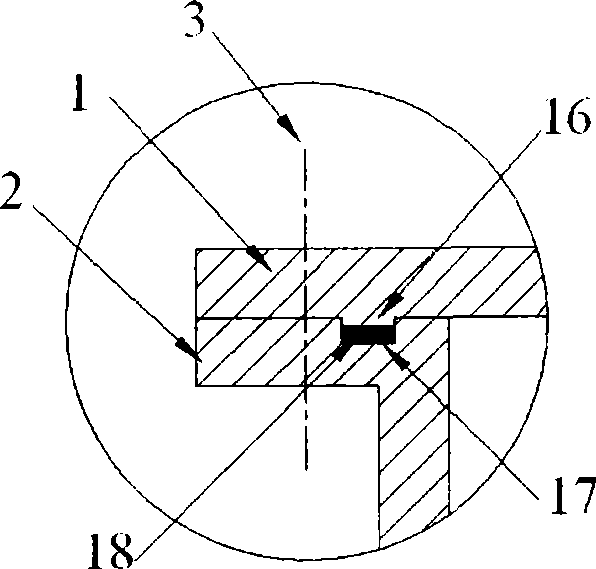

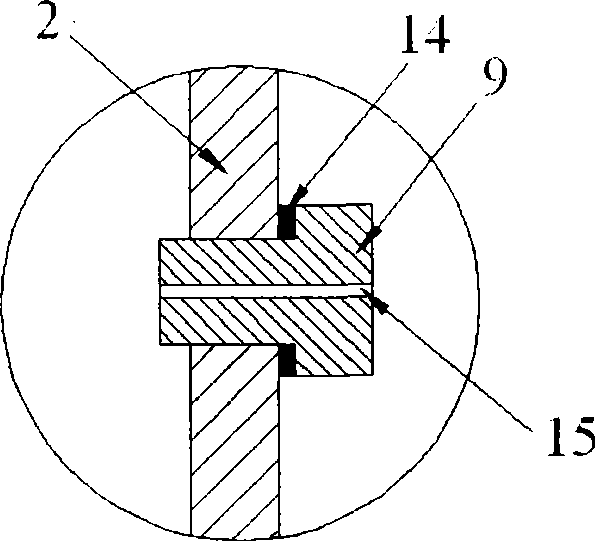

Cavitation erosion-erosion wearing cooperative test device

ActiveCN103323356AReduce or avoid unplanned downtime accidentsExtend the safe and stable operation periodInvestigating abrasion/wear resistanceGas phaseDouble phase

The invention discloses a cavitation erosion-erosion wearing cooperative test device. A slurry tank inlet is formed by a convergence of three branches which are a gas inlet, a water inlet, and a solid particle inlet. A transmission shaft of a motor extends into the slurry tank, and drives stirring blades to rotate. The outlet of the slurry tank is connected to an inlet of a separator through a stop valve and a cavitation erosion-erosion wearing test valve, and a pipeline. A gas phase outlet is provided on the top of the separator. A solid-liquid double-phase outflow port on the bottom of the separator communicates with a recovery tank. A liquid level gauge and pressure gauge are arranged on the side of the slurry tank. With the device provided by the invention, the flow state of a multiphase flow medium can be observed, and particle motion trajectory can be observed. With a valve core pressure sensor on the top of the test valve core, the determination of flow cavitation number is realized. The device is suitable to be used for researching cavitation erosion and erosion wearing, and weight loss law of a metal material under the cooperative effect of cavitation erosion-erosion under different influencing facts. With the device, a functional relationship between a corresponding failure mode and weight loss can be established. The relationship can be used in guiding design of pipes, valves, and pipe fittings, and in optimization operations of operation conditions.

Owner:ZHEJIANG SCI-TECH UNIV

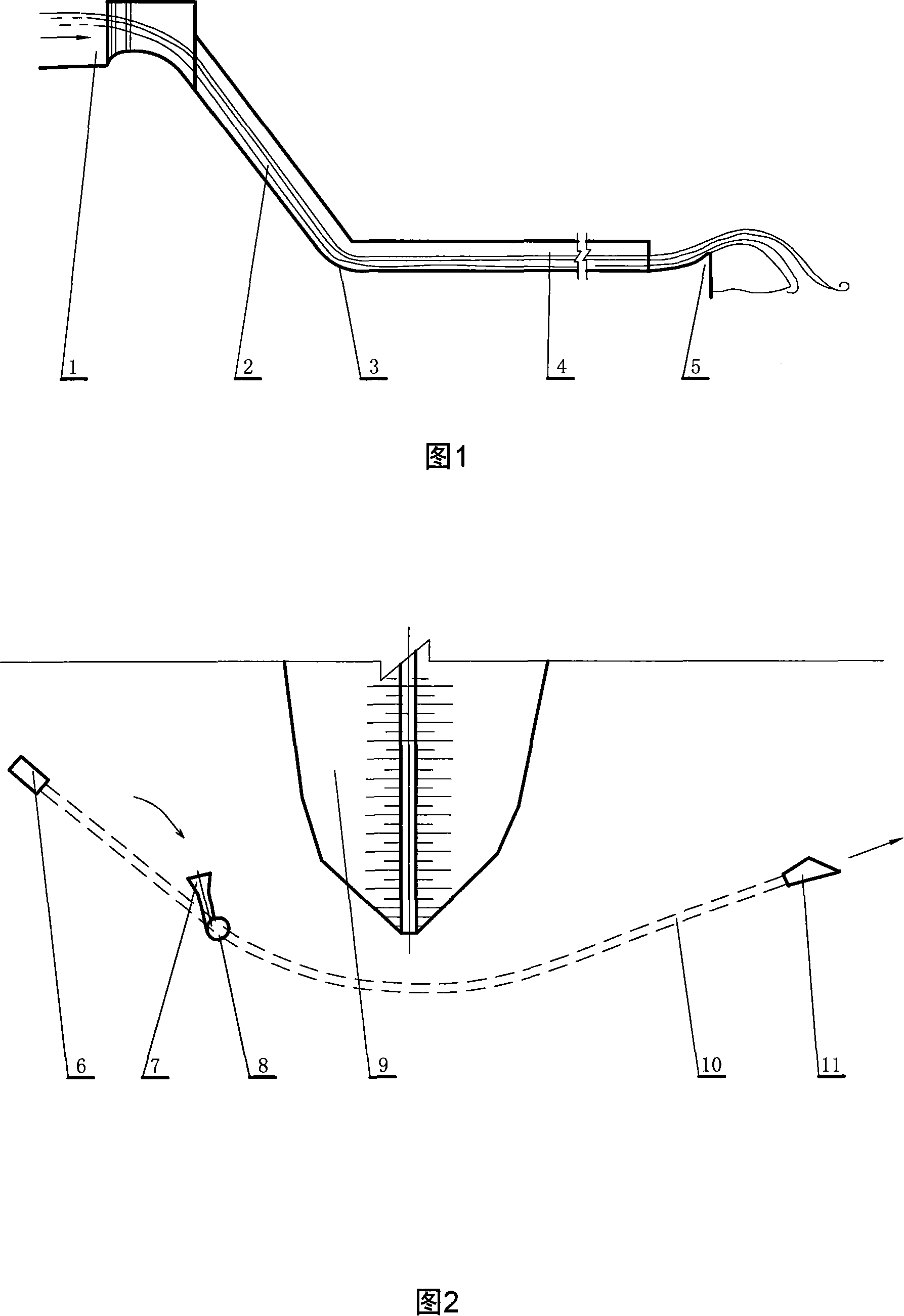

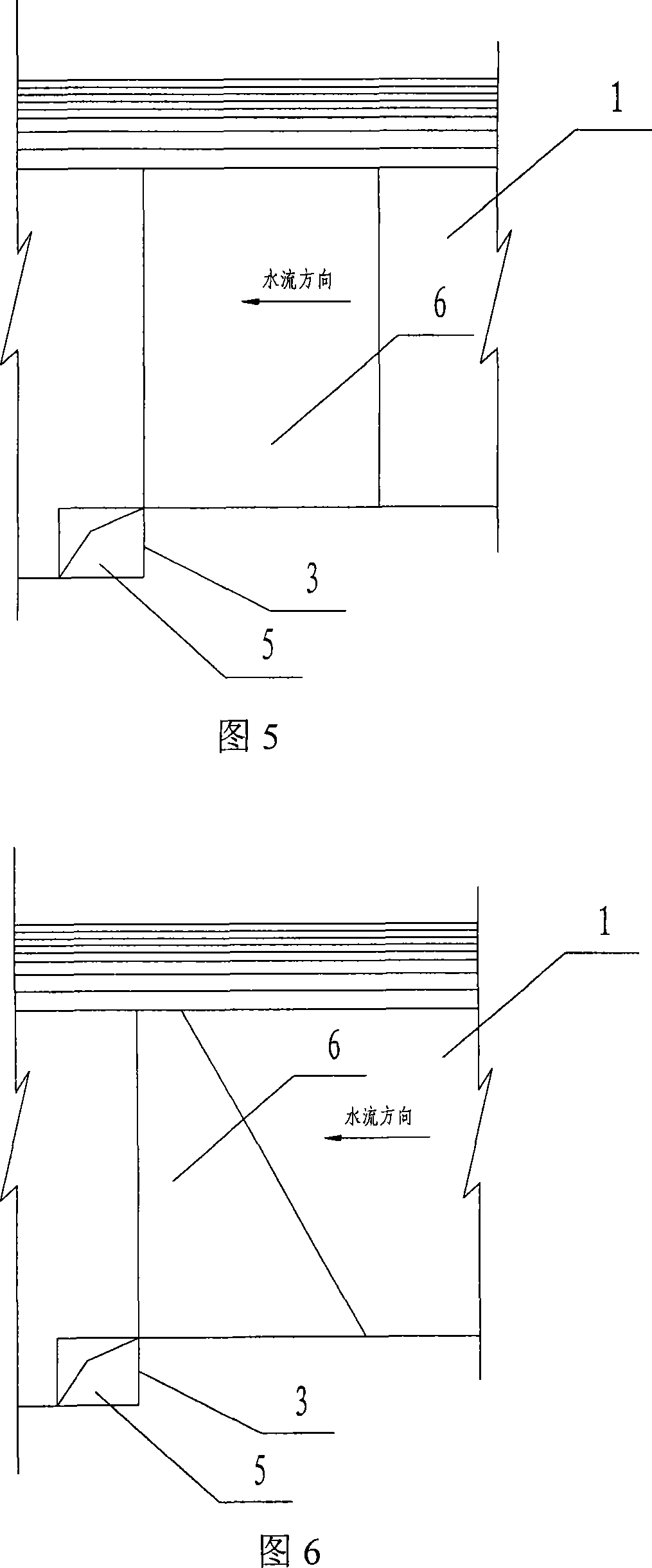

Flood discharging method and flood discharging tunnel employing rotational flow and strong moisture mixing energy dissipation

The present invention relates to flood discharge method and flood discharge tunnel dissipating energy by means of eddying flow and intense water-air mixing, and is especially one flood discharge tunnel for high water head large hydraulic power project. The flood discharge tunnel includes one water inlet in the upstream of dam, one eddy flow and fall head energy dissipating facility connected to the water inlet and provided with well, one water cushion pond with one waterproofing pier in the exit for further energy dissipating, one water output tunnel connected to the water cushion pond and one water outlet. The flood discharge tunnel has one energy dissipating rate as high as 90 %, and can control the outlet flow rate and prevent cavitation erosion, scouring and atomizing effectively.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

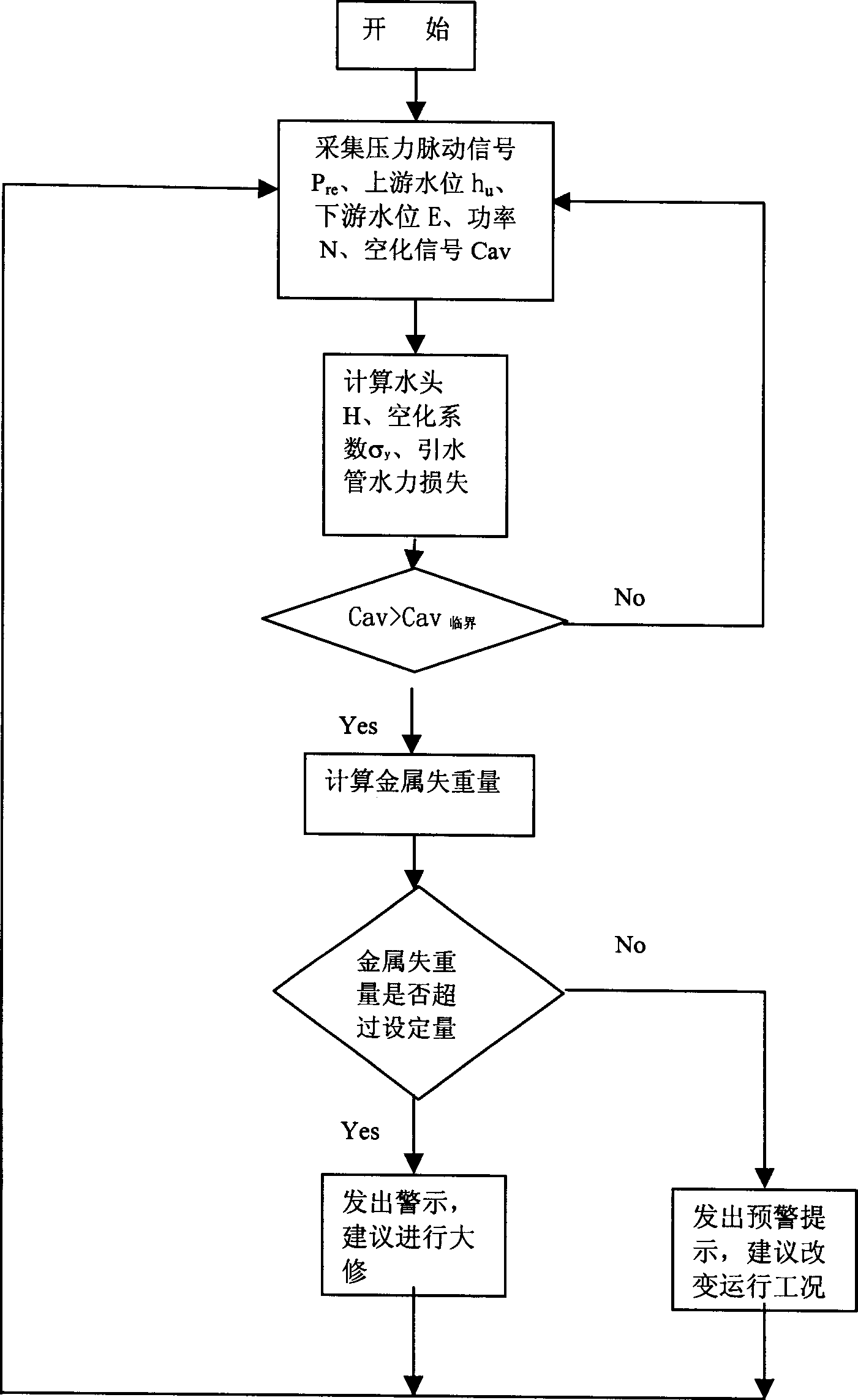

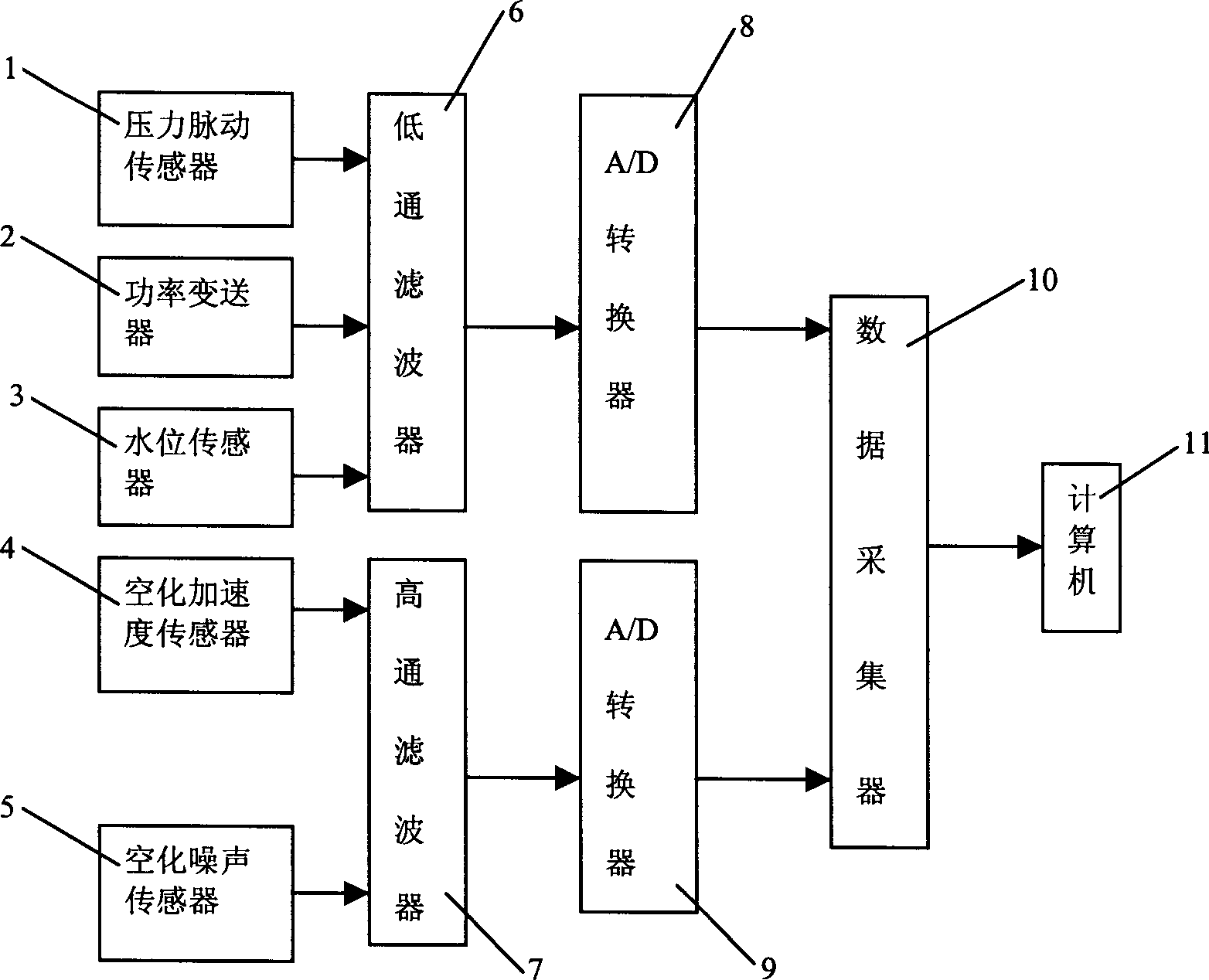

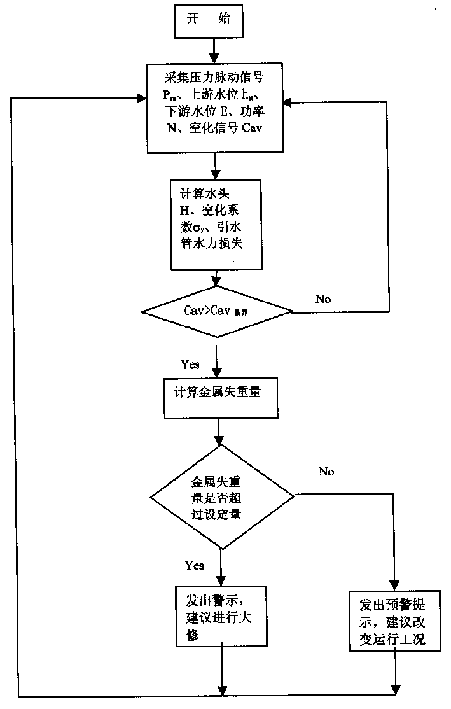

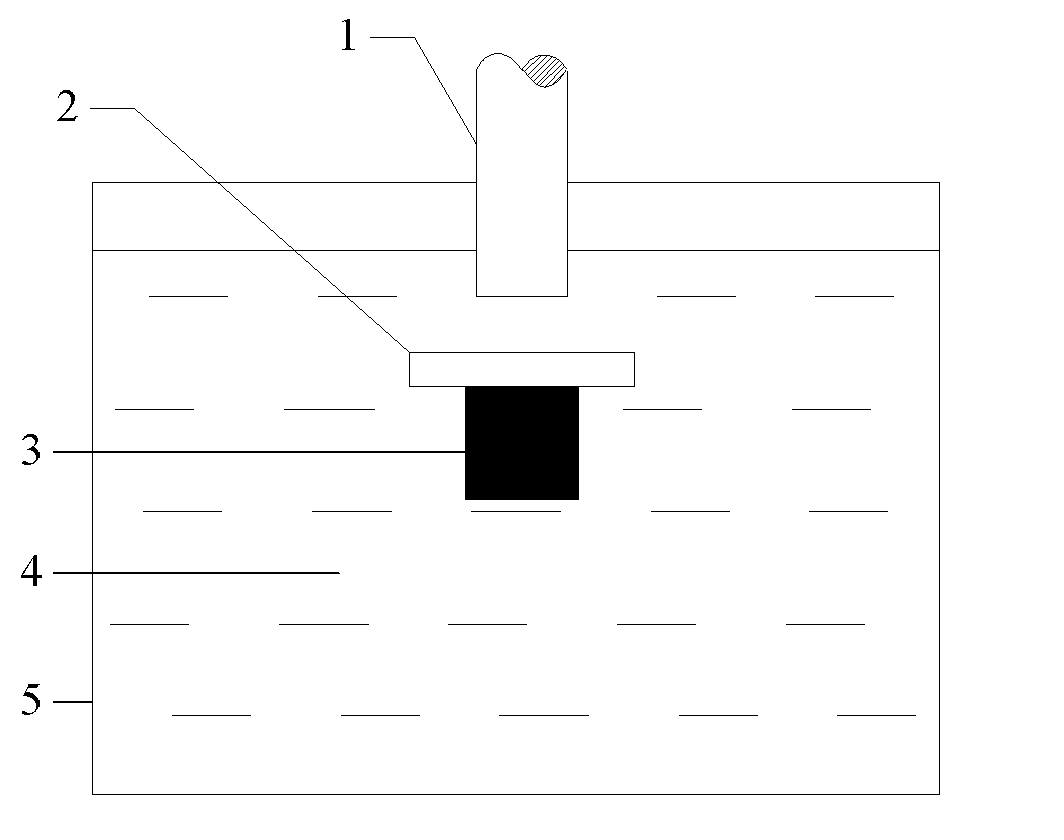

Hydraulic machinery cavitation destruction on-line monitoring method and diagnosis apparatus

InactiveCN1401986AImprove securityExtended service lifeStructural/machines measurementHydro energy generationHydraulic machineryEngineering

An in-line monitor method and diagnosing apparatus for the damage of cavitation and cavitation erosion of hydraulic machinery is characterized by that the cavitation coefficient, pressure pulse, energy characteristics of hydraulic machinery, working water head, and the cavitation impact signals are measured, the lost metal weight is calculated out and the intensity of cavitation and cavitation erosion and damaged legree are analyzed.

Owner:TSINGHUA UNIV

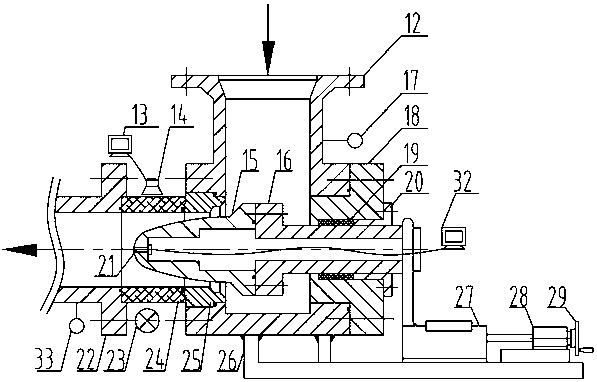

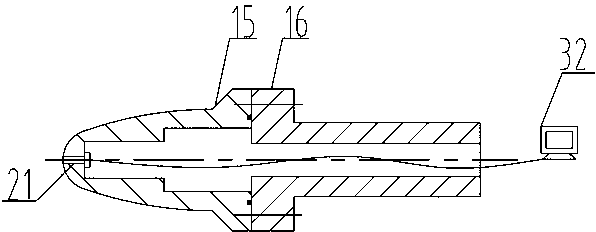

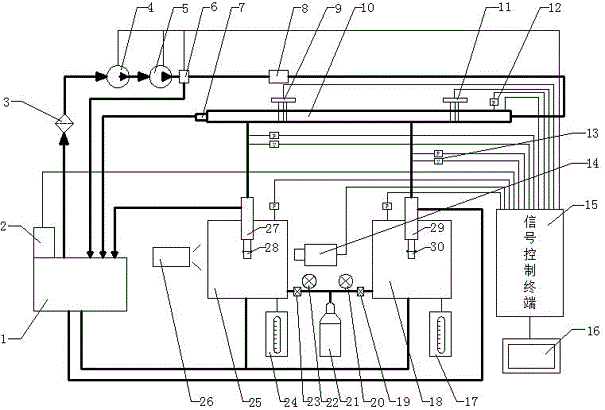

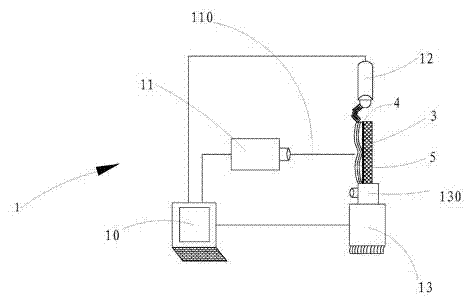

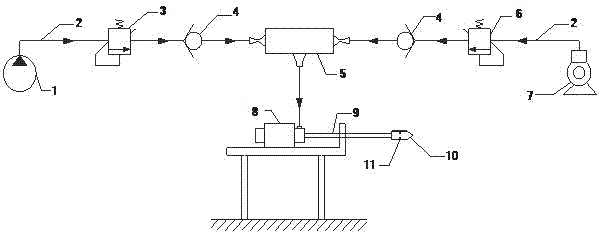

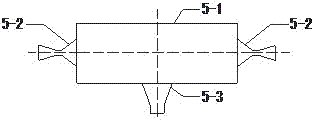

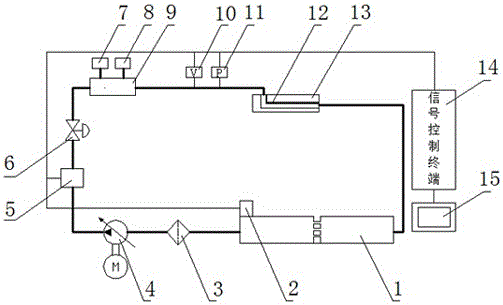

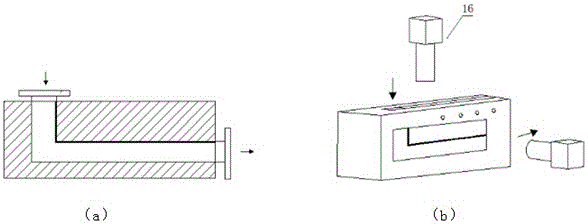

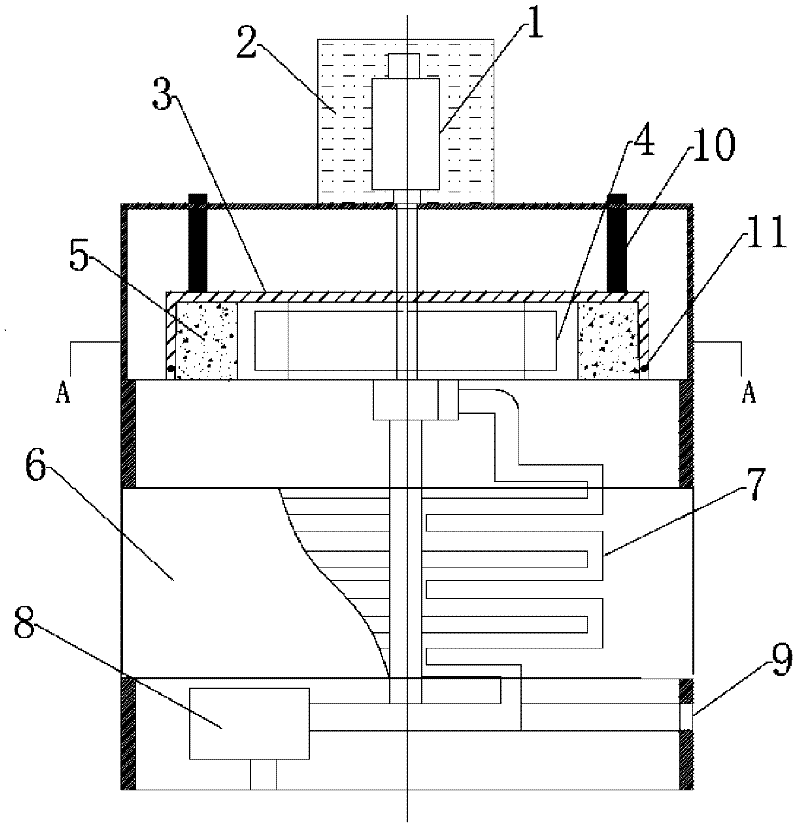

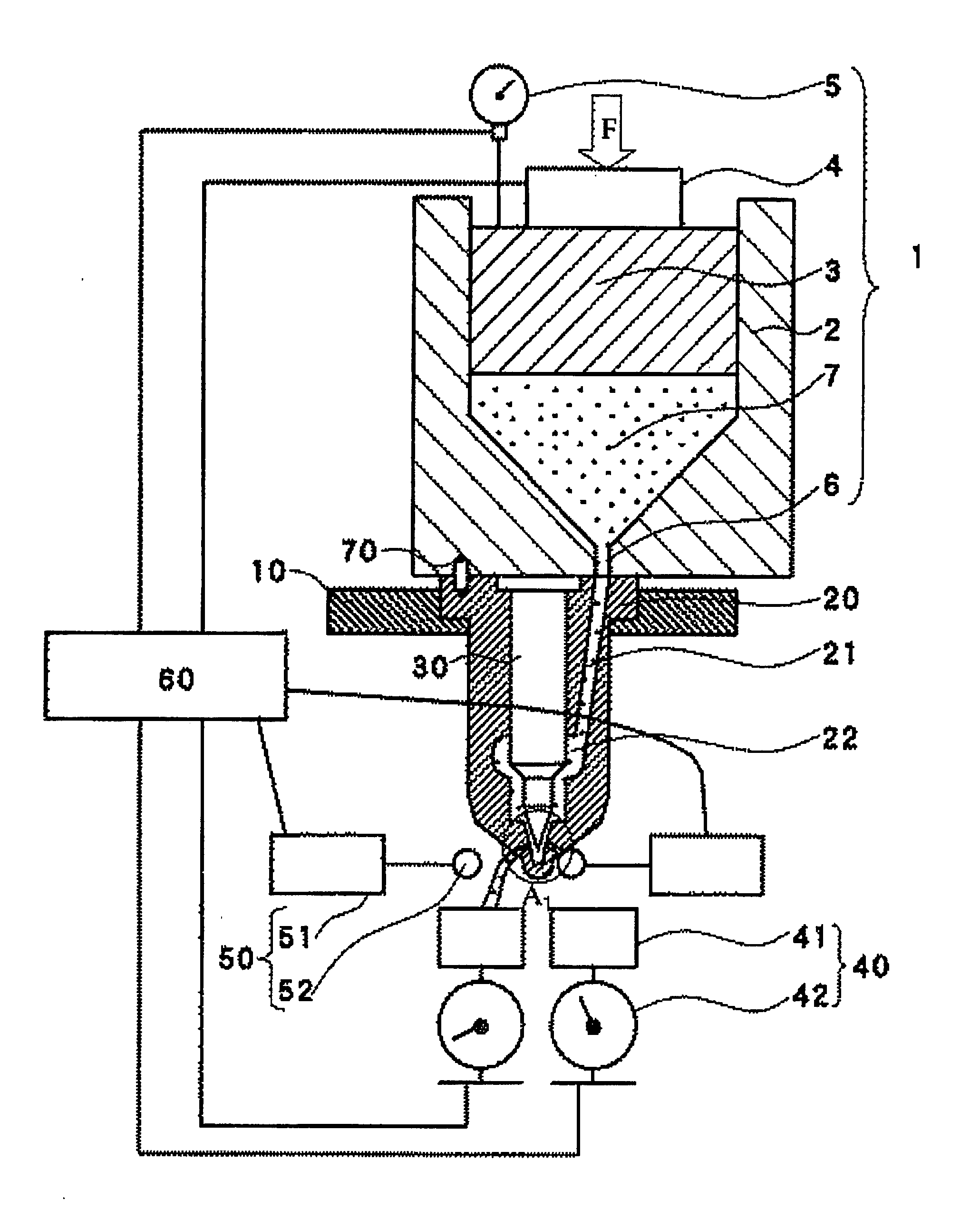

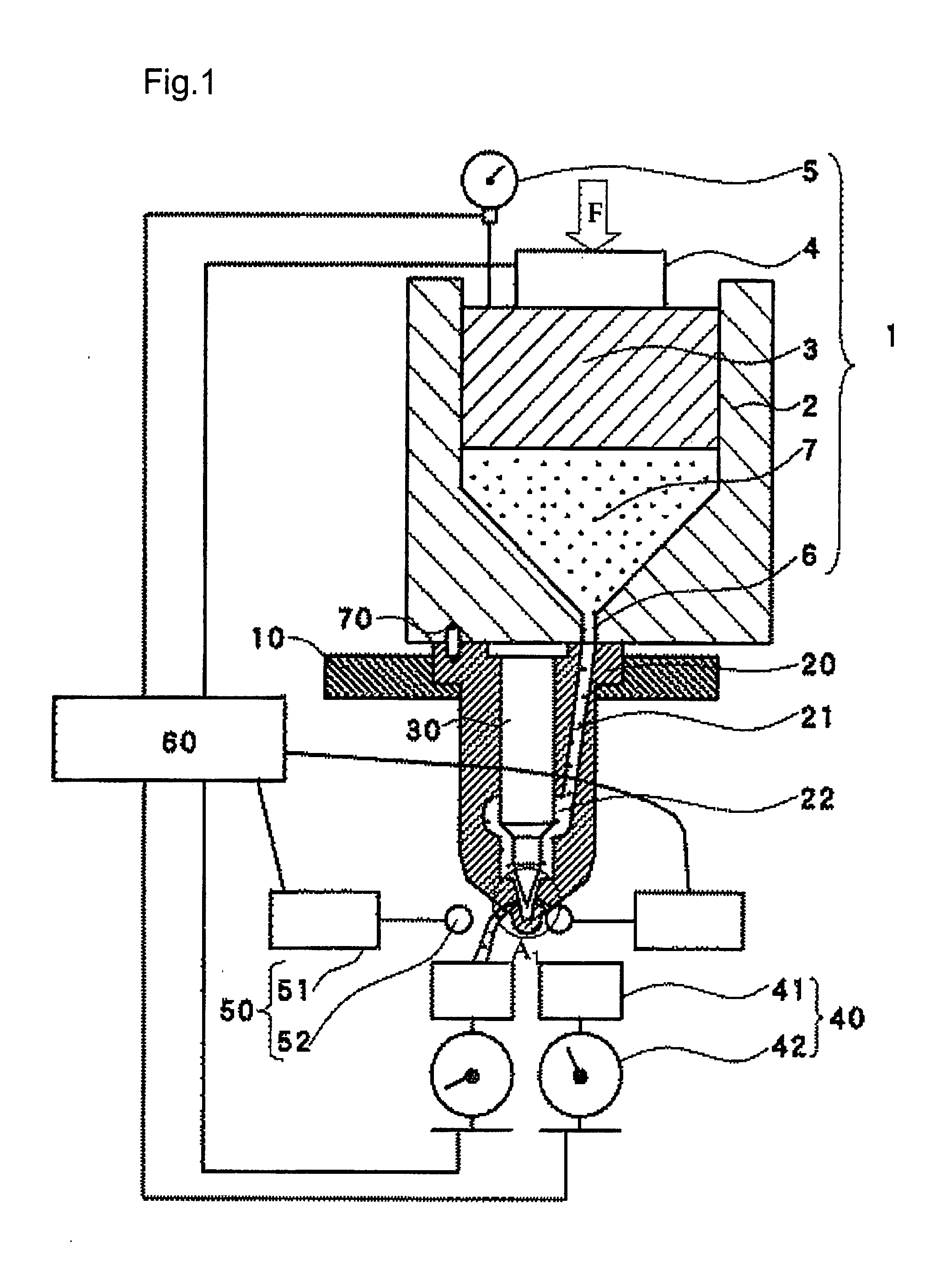

Testing device and method for measuring relationship between nozzle inside flow and cavitation erosion under multiple working conditions

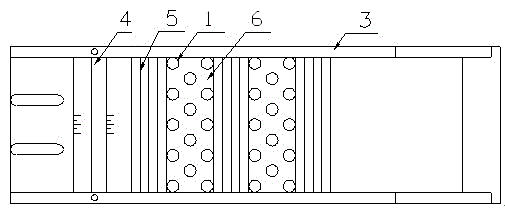

ActiveCN105604755AMeet the actual working conditionsChange flow stateEngine testingFuel injection apparatusFuel oilFuel supply

The invention discloses a testing device and method for measuring the relationship between nozzle inside flow and cavitation erosion under multiple working conditions. The testing device comprises a pressure control system, a signal testing system, an injection system and a fuel supply system; the pressure control system comprises a first electromagnetic oil pressure control valve, a second electromagnetic oil pressure control valve, a pressure regulating valve, a pressure limiting valve and a back pressure cavity; the signal testing system comprises pressure sensors, flow sensors, a signal control terminal, a CCD high-speed digital camera and a computer; the injection system comprises oil atomizers and nozzle head caps; the fuel supply system comprises an oil tank, a heating tile, a fuel oil filter, an electric fuel pump, a high-pressure oil pump, a turbulator and a common-rail oil pipe. By means of the testing device, test research on influences on nozzle inside cavitation caused by nozzle inside cavitation flow generated by different injection pressures, back pressure, the fuel spray nozzle structure, the fuel temperature and the pipe inside flow state can be carried out, and measurement of influence factors of nozzle inside cavitation caused by nozzle inside cavitation flow of a diesel engine under multiple working conditions is achieved.

Owner:JIANGSU UNIV

Laser shock method

ActiveCN102212655AReduce porosityImprove corrosion resistanceVacuum evaporation coatingSputtering coatingComputer control systemHigh power lasers

The invention discloses a laser shock method. The method comprises the following steps: (A) providing a laser shock device and a vacuum ion plating machine, wherein the laser shock device comprises a computer control system, a high-power laser, an automatic water sprayer and a worktable, the worktable is equipped with a first fixture and the vacuum ion plating machine is equipped with a second fixture; (B) covering an aluminum foil absorbing layer on the surface of a metal material; (C) controlling the automatic water sprayer to spray water to the surface of the aluminum foil absorbing layer by means of the computer control system; (D) controlling the worktable to move by means of the computer control system; (E) controlling the high-power laser to emit laser beams to the aluminum foil absorbing layer by means of the computer control system; and (F) finally removing the aluminum foil absorbing layer, placing the metal material in the vacuum ion plating machine and forming a graphite coating on the surface of the metal material by utilizing a physical vapor deposition method. By utilizing the laser shock method, surface strength and hardness of the metal material can be improved and cavitation erosion can be effectively avoided.

Owner:ZHANGJIAGANG FURUI SPECIAL EQUIP CO LTD

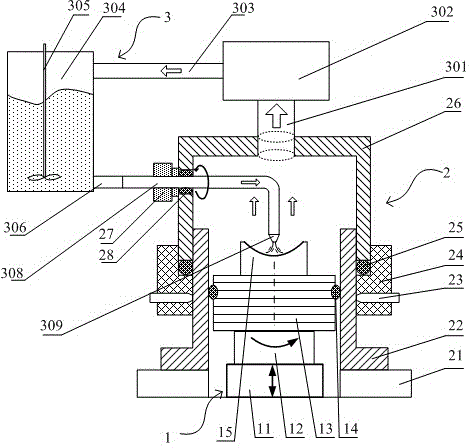

Multifunctional base injection type cavitation corrosion test device

InactiveCN101451940AEasy to adjustAchieve corrosiveInvestigating abrasion/wear resistanceMaterial ErosionMetallic materials

The invention belongs to a multifunctional submerged jet type cavitation test device in the fields of cavitation erosion resistance and erosion corrosion resistance of metal materials, a detachable upper end cover arranged closely is provided on top of a tank, a pressure valve and a pressure release valve are arranged on a side wall of the sealed tank, a nozzle is detachably arranged on an inner end of the tank of the same tube of the pressure valve, a testing bracket and a testing sample wafer are arranged on the other side wall of the sealed tank, a plug screw and a traverse education through hole for testing thereon are arranged at a lower part of the same side wall of the sealed tank and the pressure valve, the traverse and the education through hole are sealed through sealant; a pressure gauge is arranged on an upper part of the sealable tank matching with the pressure release valve; the plug screw and the sealed tank are sealed through a seal ring. The device is reliable in structure theory, low in manufacturing cost, handy in working use, precise in experiment effect, long in service life and reduced in energy consumption.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

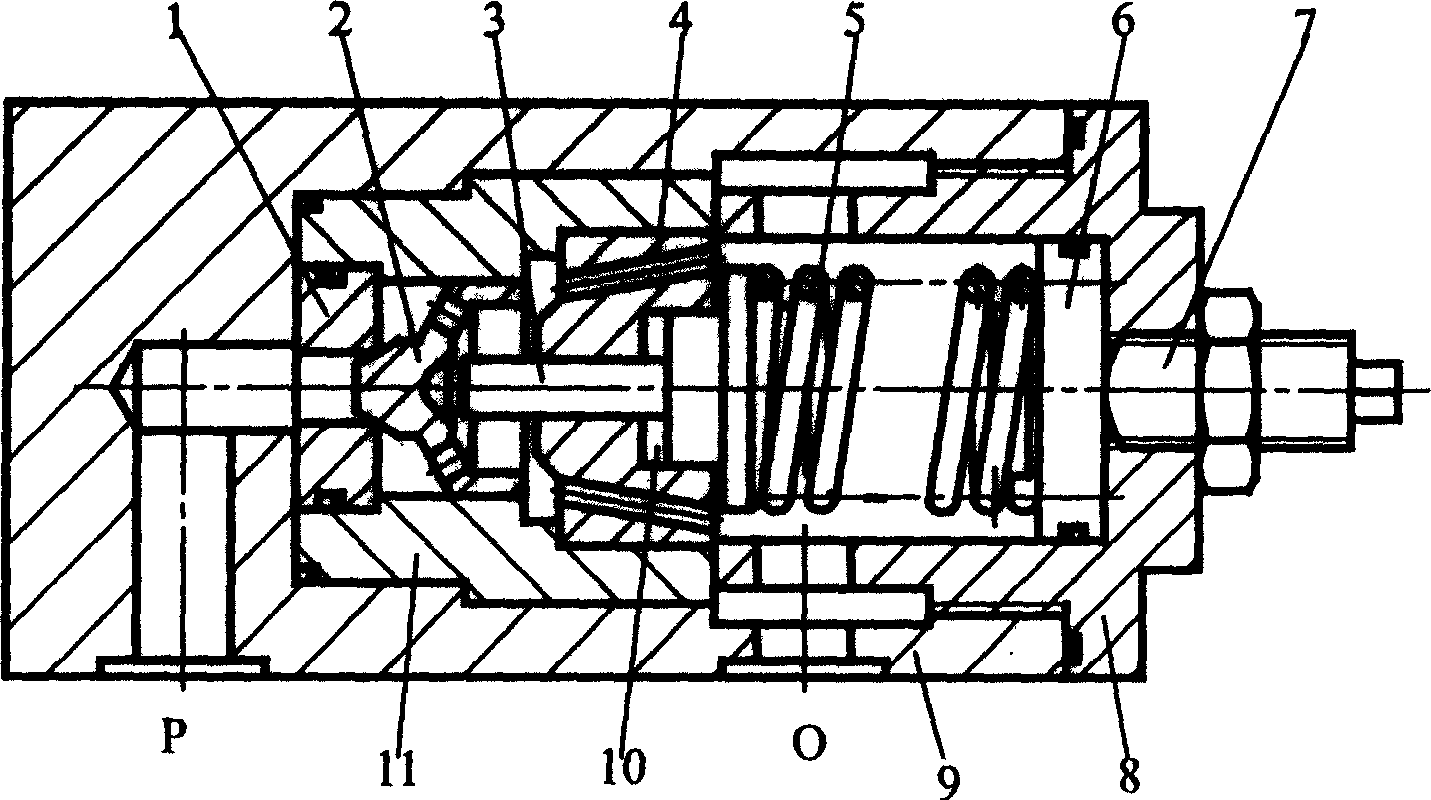

Middle high pressure directly-acting hydraulic overflow valve

ActiveCN1563764AReduce leakageImprove cavitation resistanceEqualizing valvesSafety valvesLow noiseWater based

The present invention relats to pressure control element in hydraulic system and belongs to the field of valve. The present invention includes valve seat, valve core, damping rod, damping sleeve, valve sleeve, pressure regulating spring, spring seat, end cap and regulating screw. The valve core is one cavity; the damping rod and the damping sleeve have their inner holes form fitting interval and damping cavity; the valve seat and the valve core form one conic valve structure; and the valve core has small holes in its shoulder and tail end forming guide surface to the inner hole of the valve sleeve. The present invention is suitable for use as pressure controlling valve in high and medium pressure hydraulic system with water-based work medium. Compared with similar overflow valves, the present invention has the advantages of less leakage, high cavitation erosion resistance, less vibration, low noise and stable work performance.

Owner:WUHAN MAJOR DAY DIGITAL MACHINERY MFG CO LTD

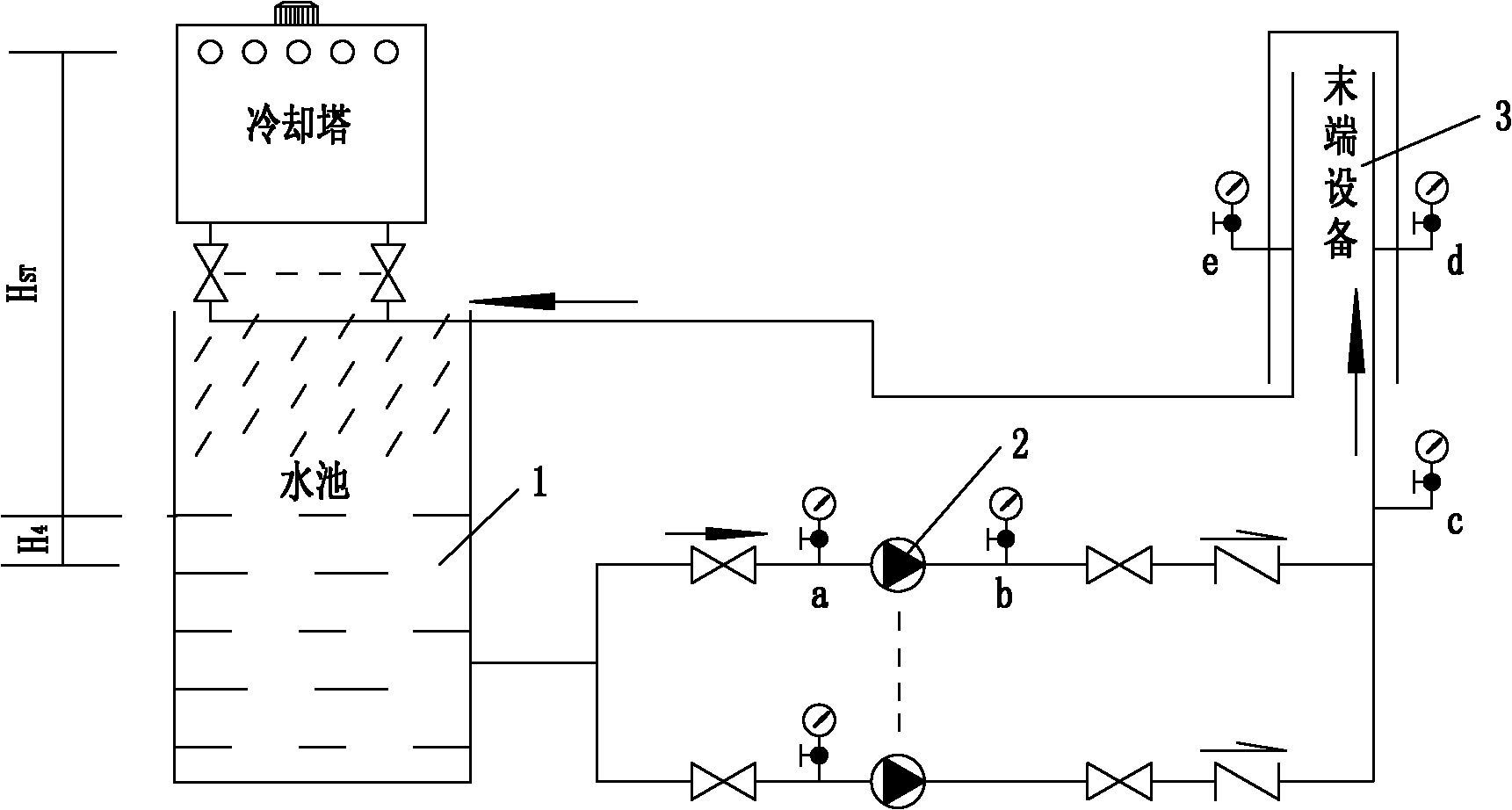

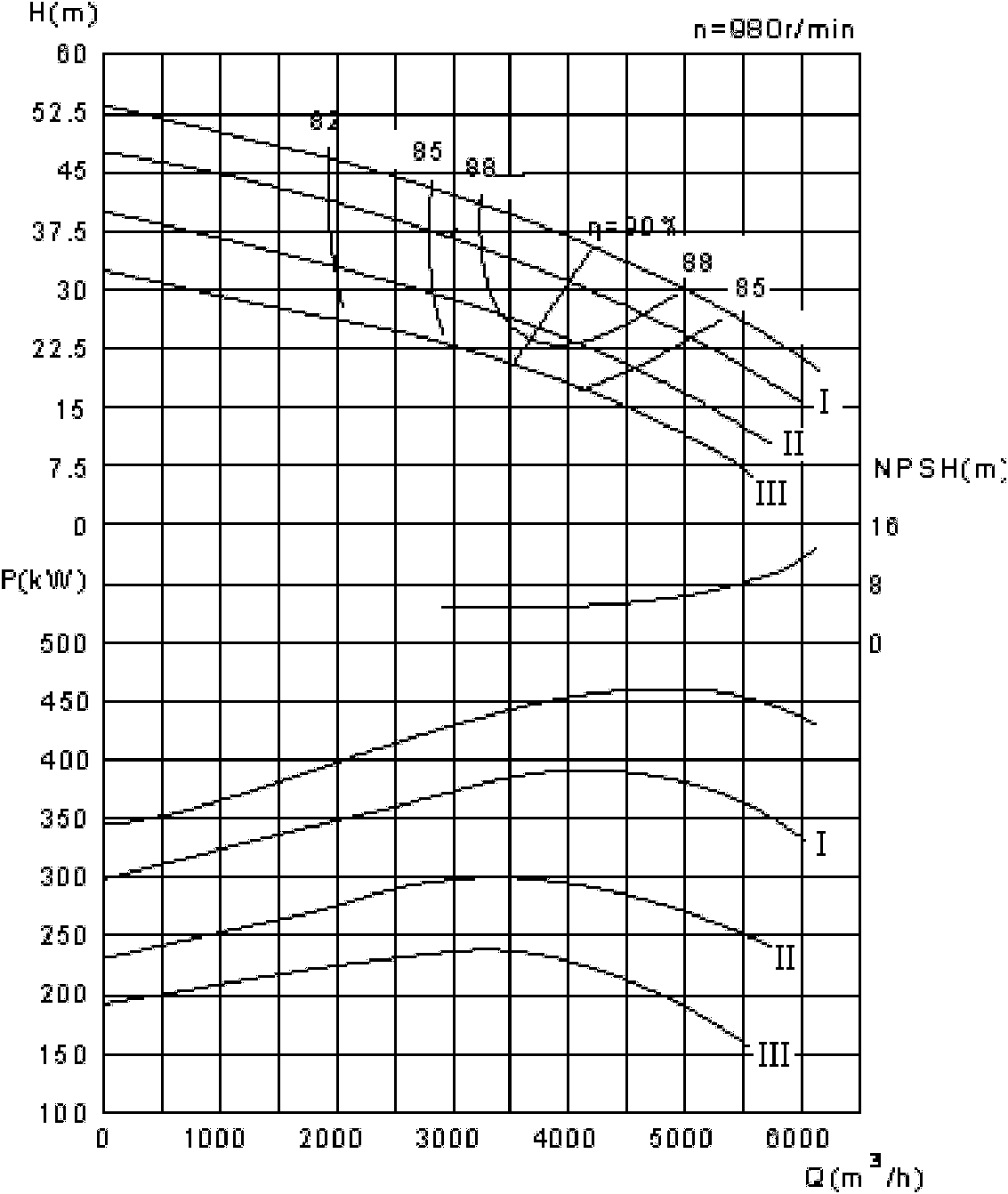

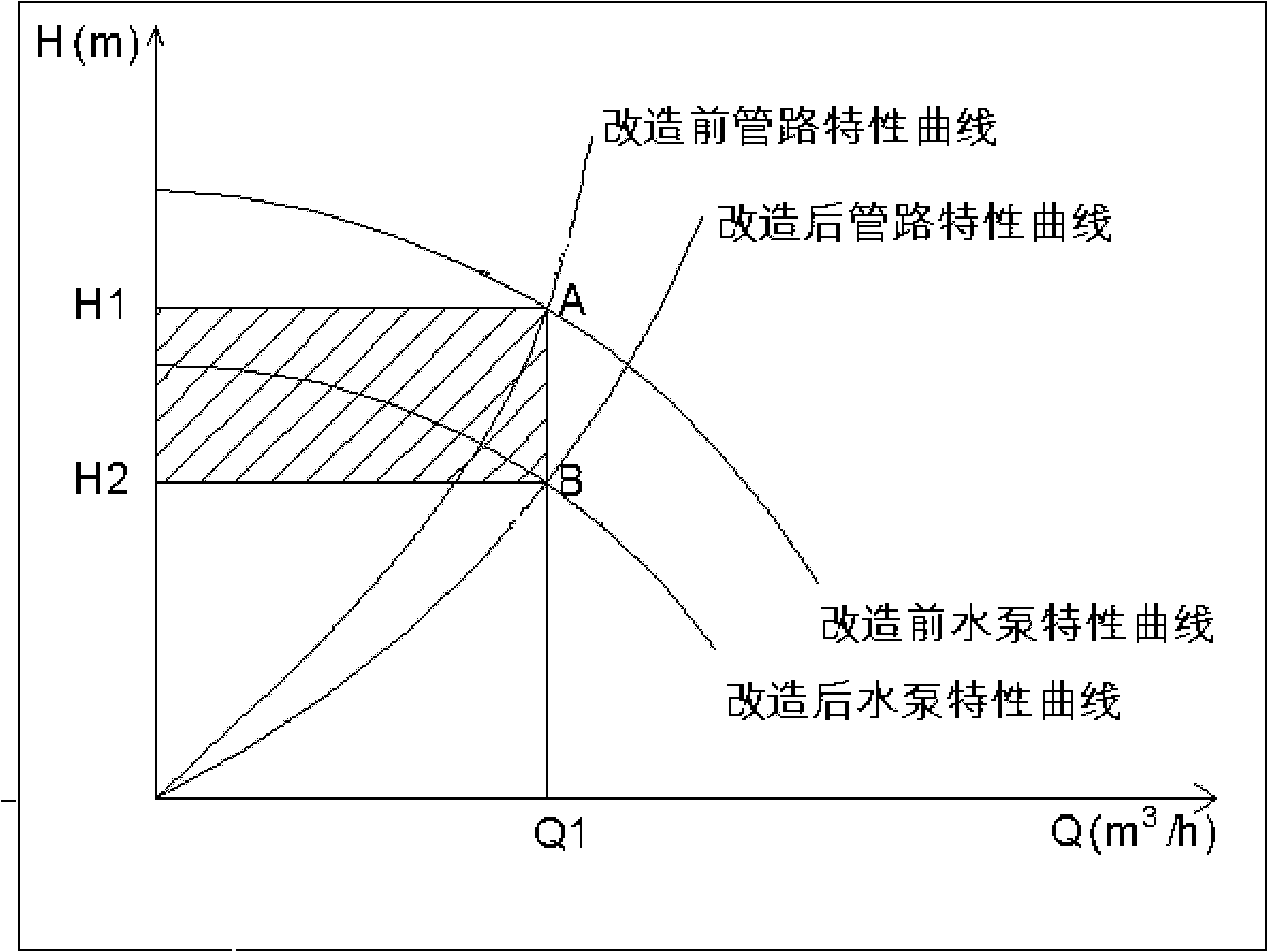

Method for optimizing circulating cooling water convey system

InactiveCN102052564ASolution to short lifeTroubleshoot feature matching issuesPipeline systemsData acquisitionModel Number

The invention belongs to the field of circulating cooling water conveying systems and particularly relates to a method for optimizing a circulating cooling water convey system. The method comprises acquisition of date in all procedures of the circulating cooling water system, date analysis, and system optimization. The model number of a water pump actually needed in the system is determined through data acquisition and analysis, and valve loss, local circumfluence, high-low pressure blending, pipeline blockage and unnecessary loss in the system are correspondingly eliminated. By adopting the method, unfavorable working conditions caused by overlarge resistance of the circulating cooling water system, such as overlarge electric motor power, over temperature, cavitation erosion on a water pump, low operation efficiency and the like are improved, and most importantly, the pipeline characteristic matching problem in the circulating cooling water system is solved. By adopting the tailor-made water pump to meet actual needs, the efficiency of the machine set is more than 15% higher than that of the original pump, the cavitation erosion phenomenon is remarkably relieved, the electric motor is protected, the service life is longer, the energy saving effect is greatly improved to reach above 25%, and the actual operation efficiency of the system is greatly improved.

Owner:杨宝良

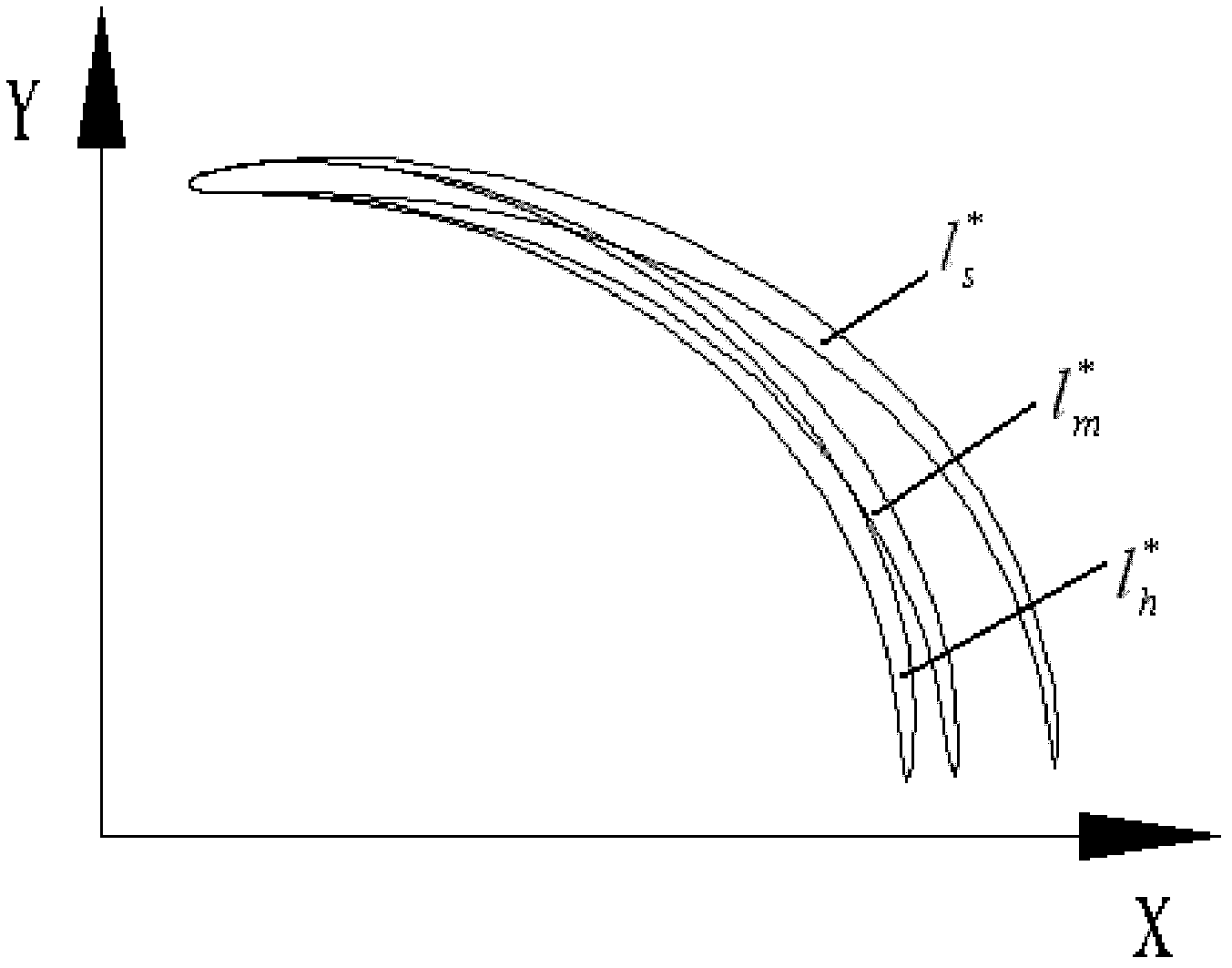

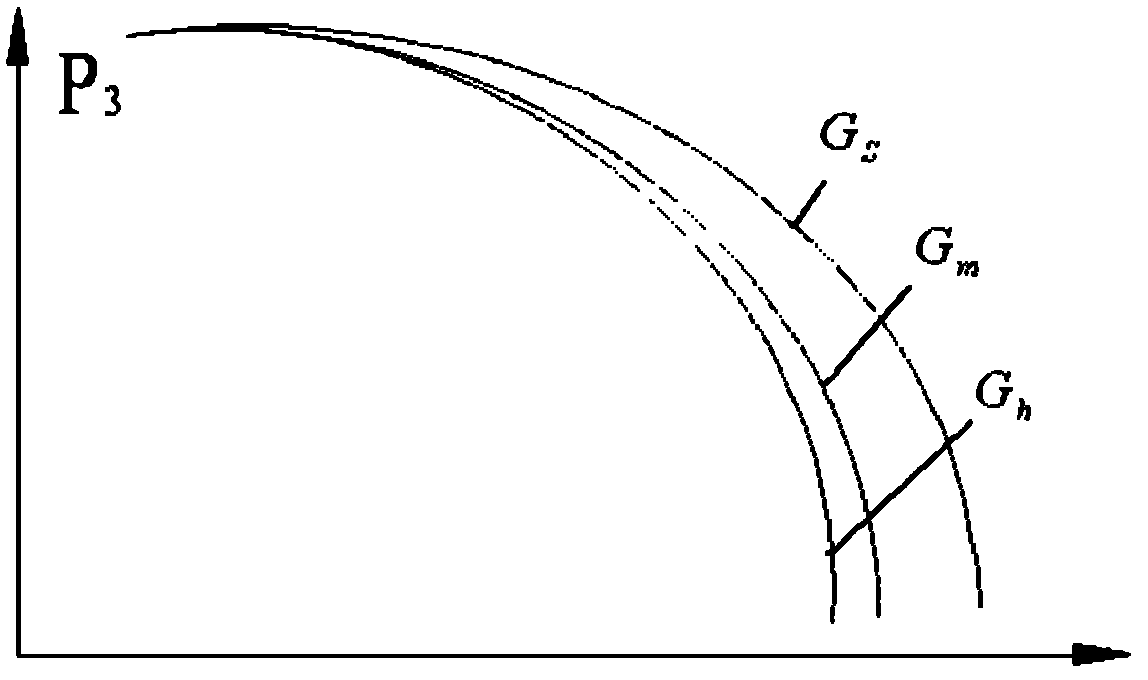

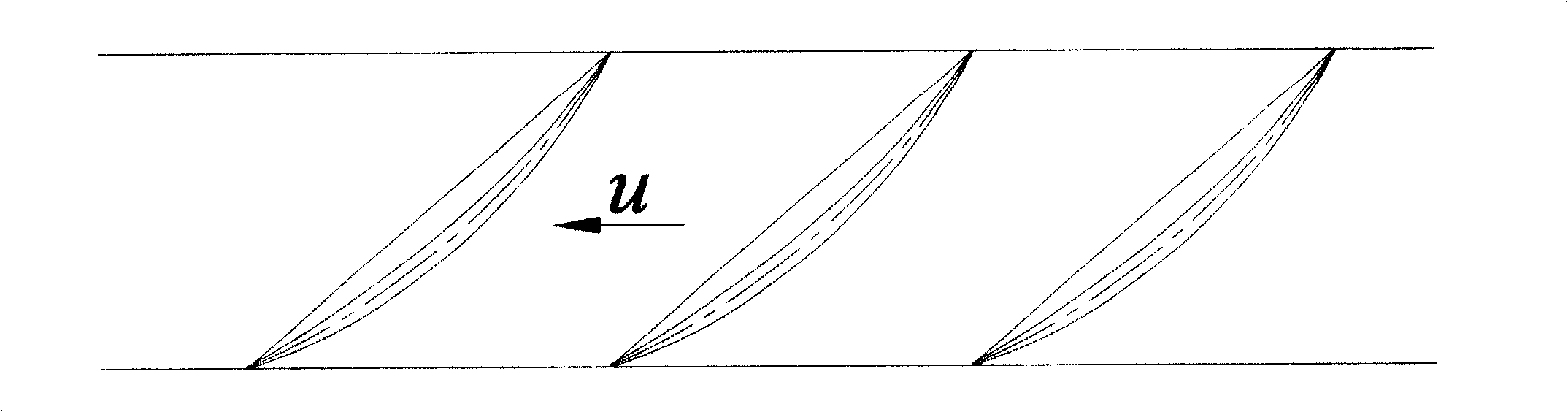

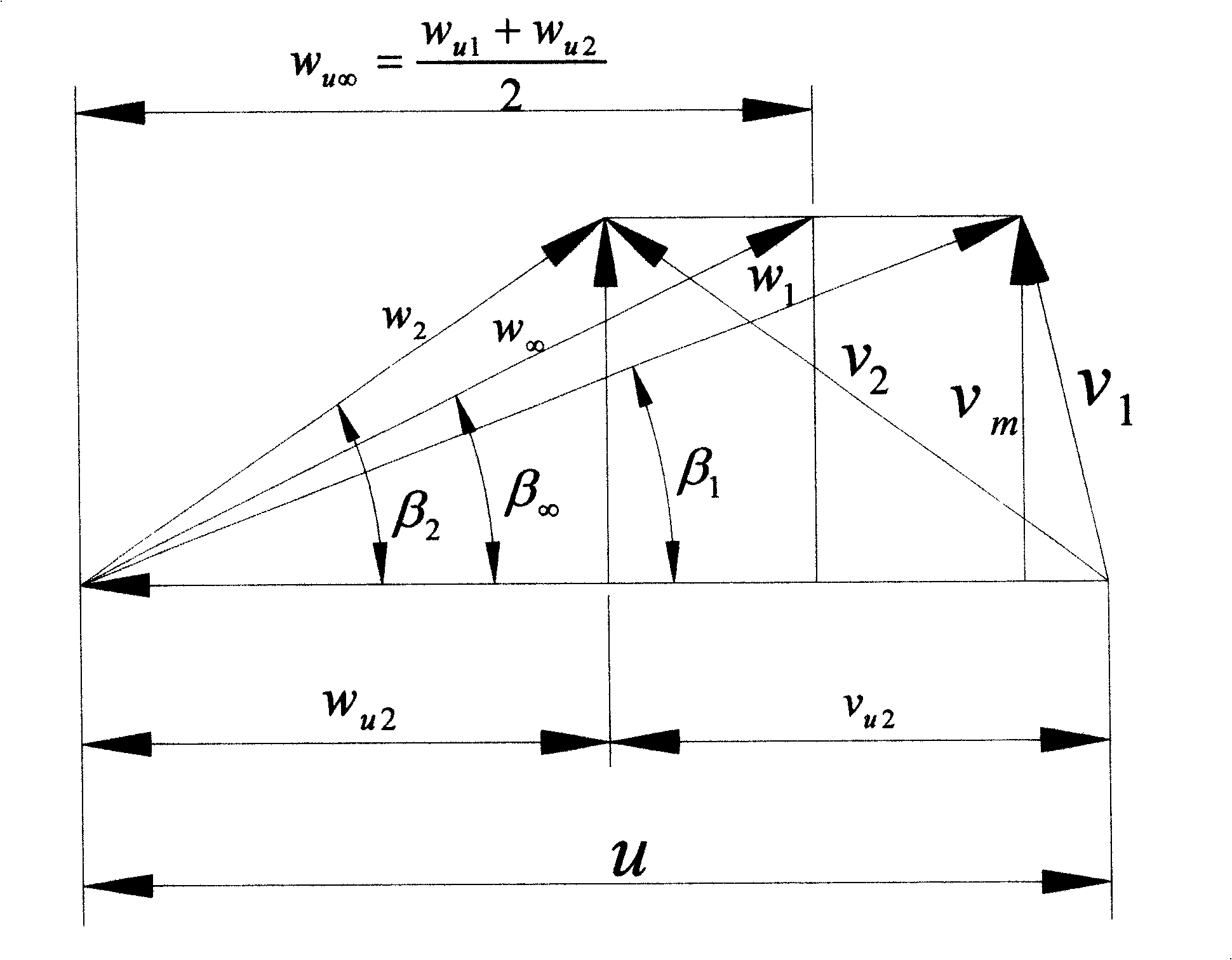

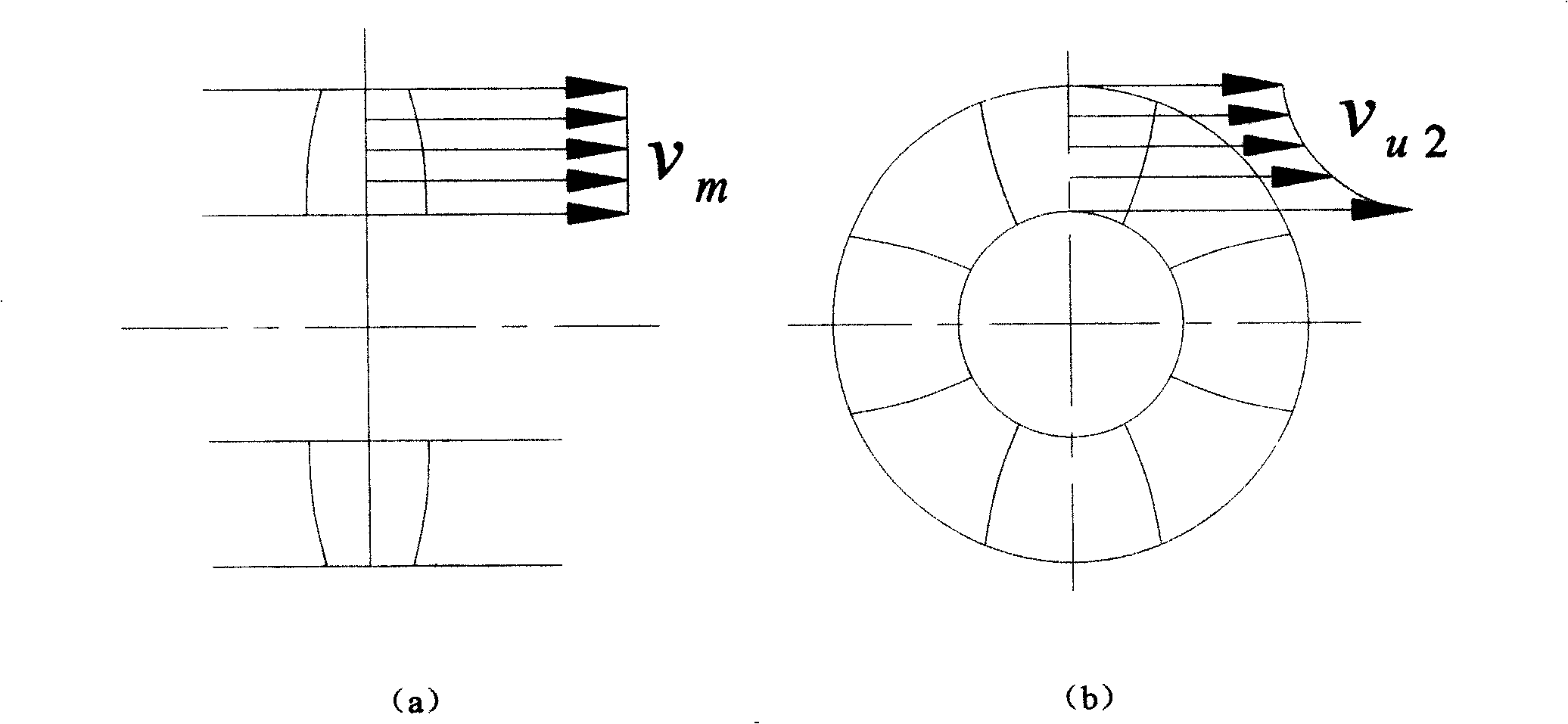

Axial flow impeller machine design method and blade

InactiveCN101245711AImprove efficiencyIncrease pressurePump componentsBlade accessoriesImpellerEngineering

The invention provides a design method for an axial flow impeller machine for confirming the flow model of the axial flow impeller machine. The method at least includes the circle component of vu2 and axial plane speed of vm2 which are at the exit of a vane and are distributed in a way of linearity along the radius of the vane, and the circle component and axial plane at the hub side is small while the circle component and axial plane at the wheel edge side is larger; the distribution functions of the circle component vu2 and axial plane speed vm2 at the exit of the vane are confirmed according to the external characteristic parameters and structure parameters as well as the flow model of the axial flow impeller machine; the axial flow impeller machine is designed according to the confirmed distribution functions of the circle component vu2 and axial plane speed vm2 at the exit of the vane. The invention also provides the vane of the designed axial flow impeller machine; wherein, the difference of the mounting angles for the wing models of the hub side and wheel edge side of the vane Delta Beta is equal to Beta h minus Beta s and is between minus 3 degrees to 10 degrees. The equipressure area at the back of the vane is distributed along the radial direction of the vane in strip. The invention can improve the efficiency of the impeller machine to reach 91 percent and improve the anti-cavitation erosion capacity.

Owner:任明琪

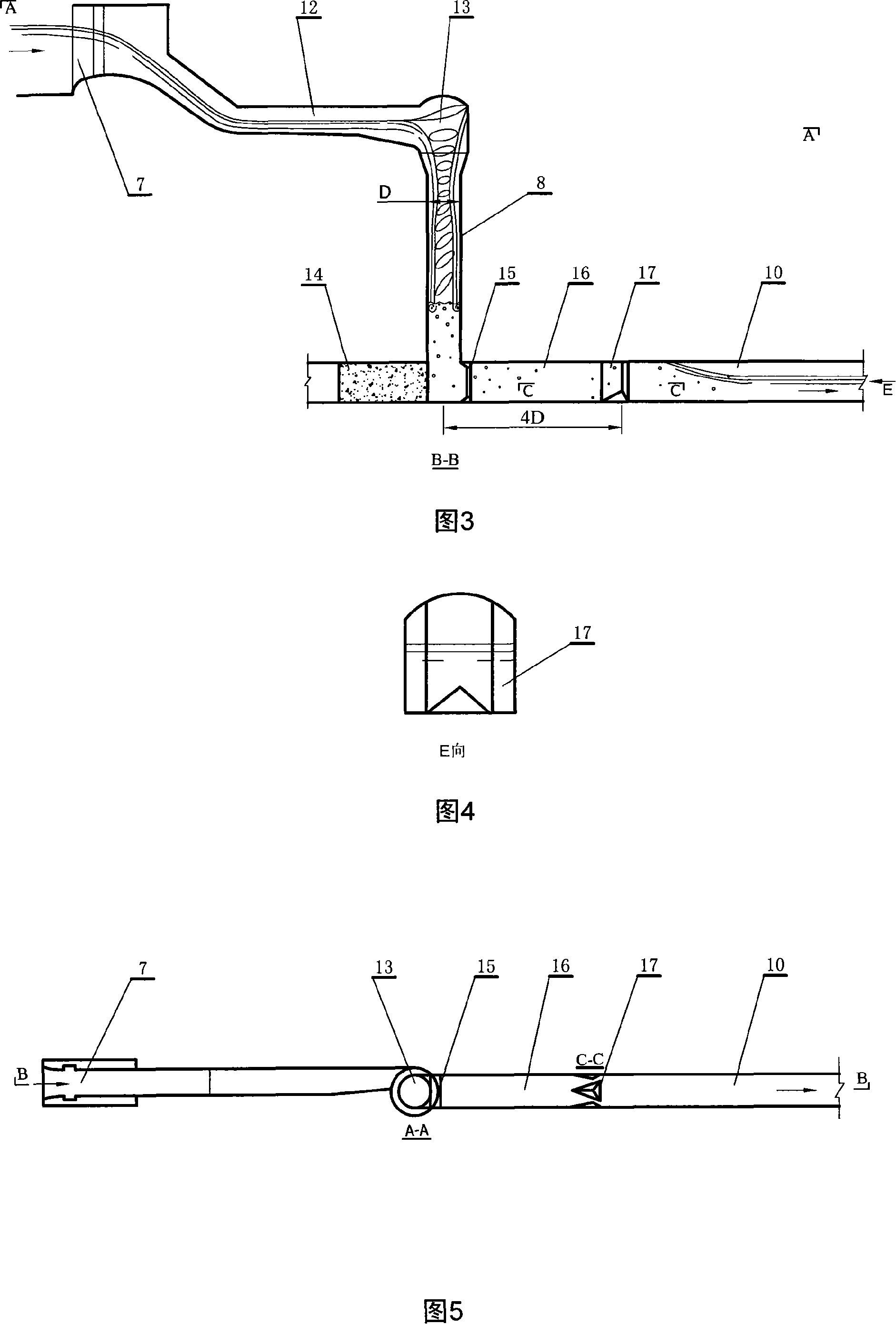

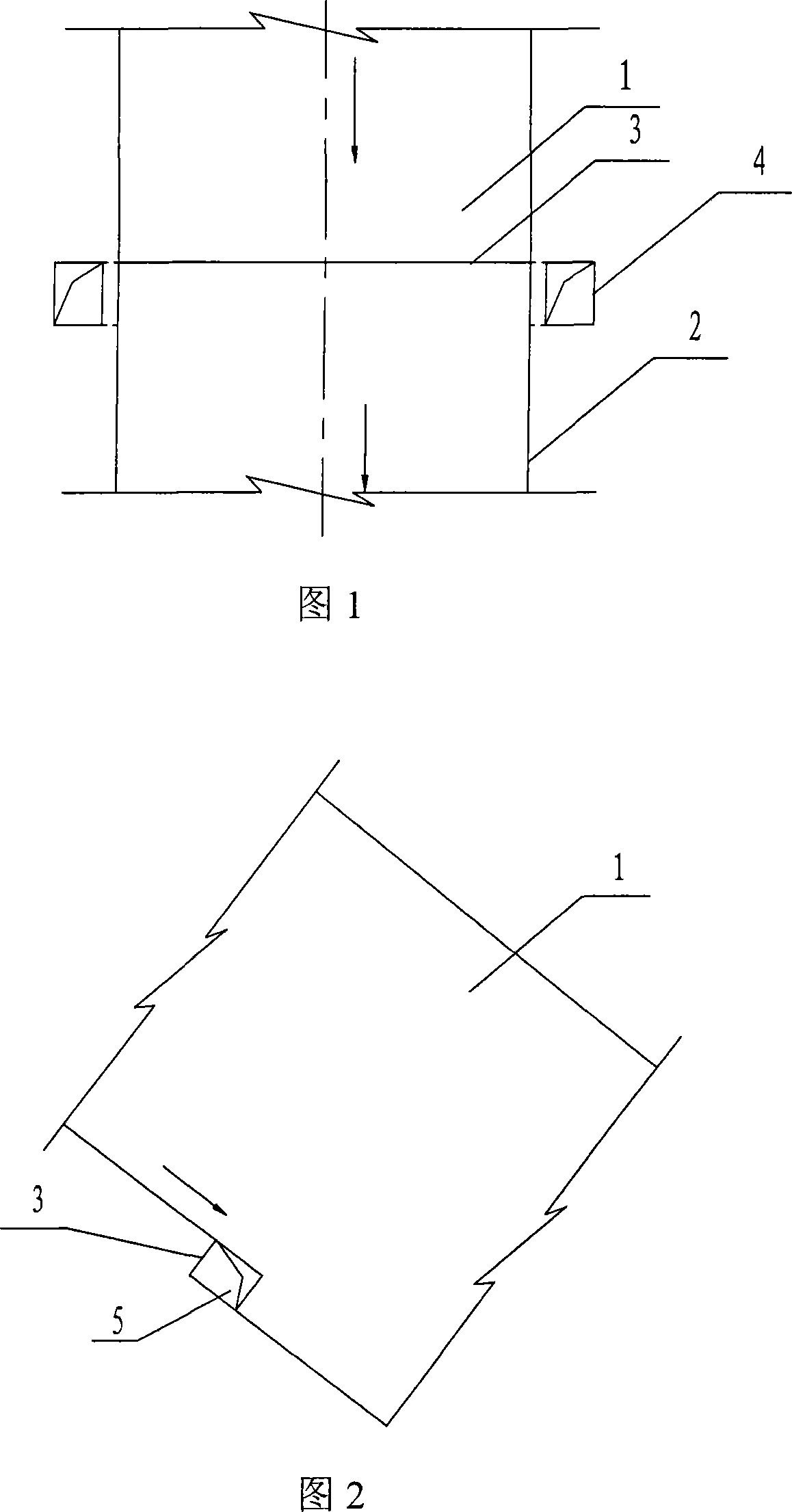

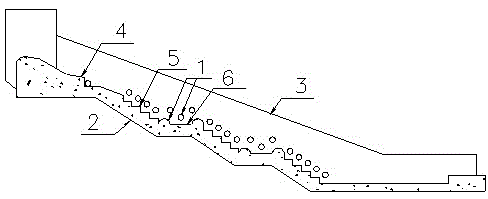

Spillway tunnel whole-section aeration method and spillway tunnel having whole-section aeration structure

InactiveCN101177937AGuaranteed air entrainmentAvoid cavitation damageBarrages/weirsCavitationEngineering

The invention discloses a whole section aeration method of a flood discharging tunnel. The bottom part of a free flow flood discharging tunnel is provided with a backward step and a ventilation shaft, which form bottom cavity aeration, based on which a lateral deflector is respectively arranged at side walls on two sides of the upstream of aeration backward step, therefore, an aeration side cavity is formed and the whole section aeration is further formed at the aeration backward step. The deflector inside the flood discharging tunnel with the whole section aeration structure designed according the method is a wedge deflector. Since the whole section aeration changes the former simplex method of bottom cavity aeration and guarantees the necessary aeration quantity when the flood discharging tunnel in normal operation, thus eliminating large-area fresh water flooding district at the side walls of the flood discharging tunnel and effectively avoiding the cavitation eroding damage of the side walls.

Owner:SICHUAN UNIV

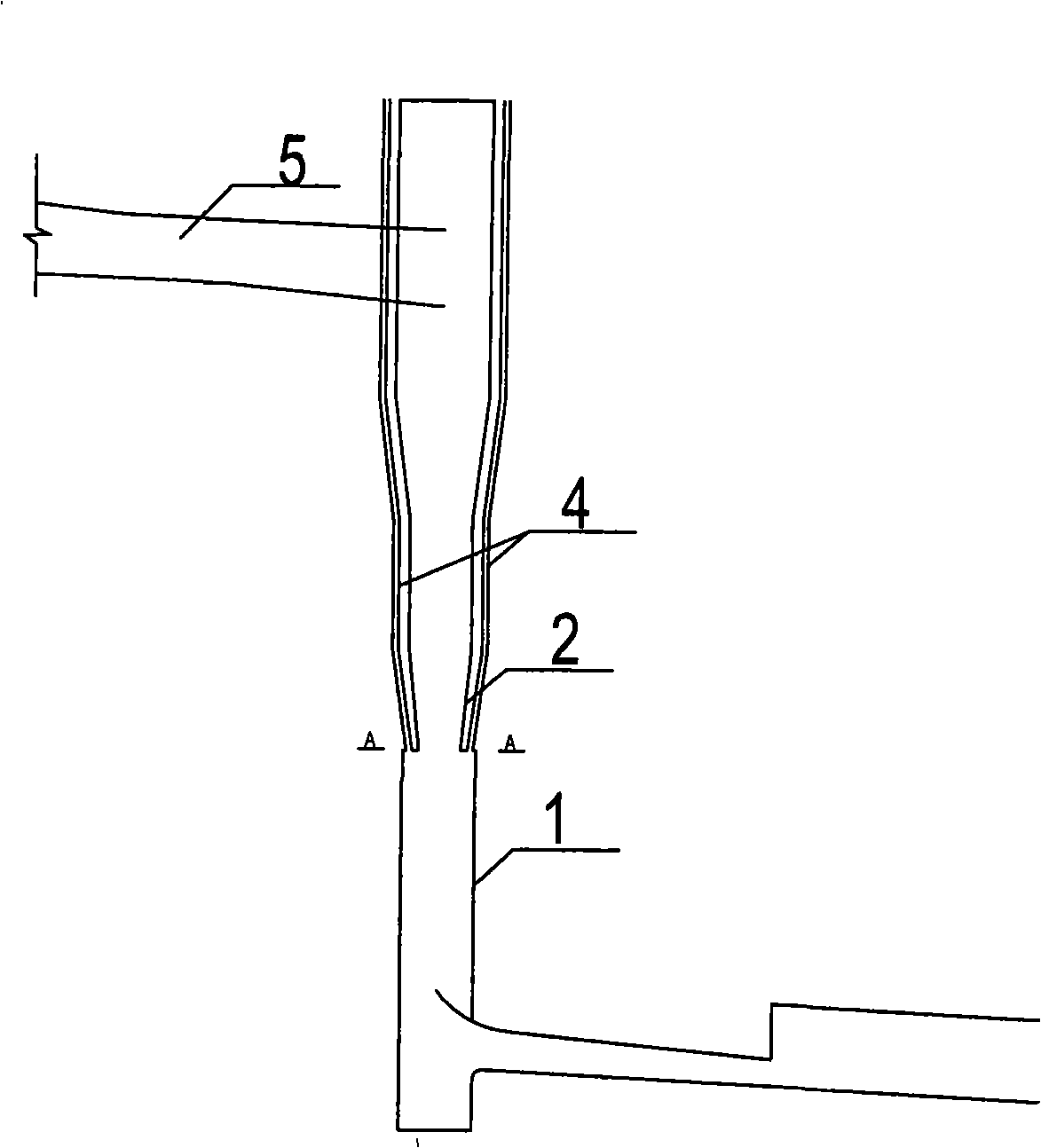

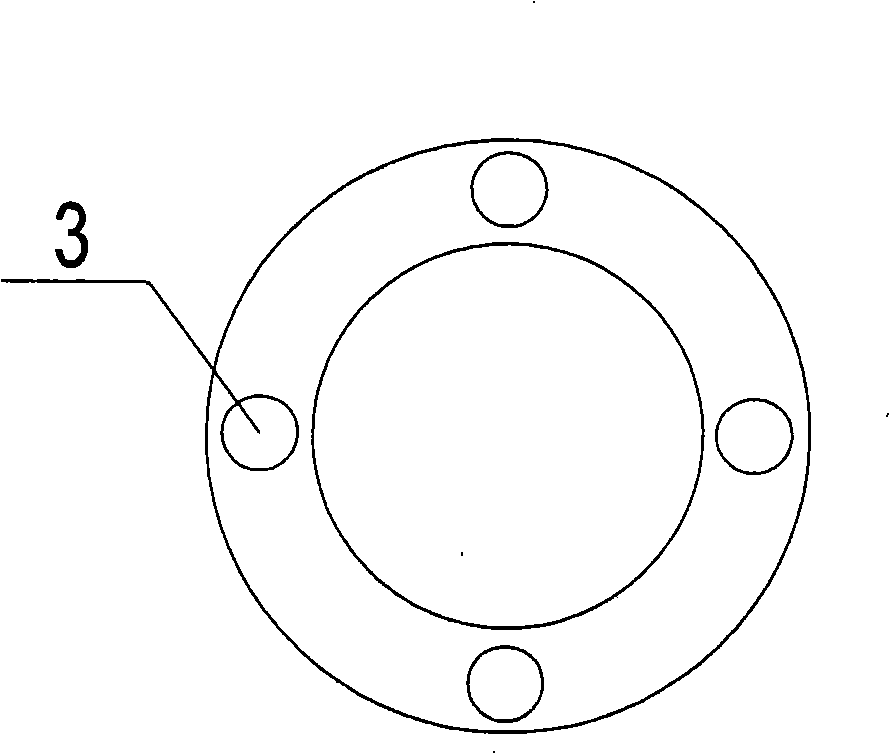

High-pressure fuel injection pipe having connecting head portion

InactiveUS20030230349A1Eliminate fearReduce fatigue failureJoints with sealing surfacesMetal-working apparatusThick wallHigh pressure

A high-pressure fuel injection pipe having connecting head portion is provided which is capable of eliminating a fear of the occurrence of cavitation erosion of the inner surface of the connecting head portion and a fatigue failure of the same head portion by having a contour of a cross section of an annular pocket occurring in an inner part of the connecting head portion during a head portion processing operation extend shallowly and gently. This fuel injection pipe has at a connecting end portion of a thick-walled steel pipe having a relatively small diameter, including a seat surface, an annular flange formed so that the flange is axially spaced from the seat surface, and a conical surface connected to the seat surface, extending therefrom to the annular flange and tapering off to a free end of the connecting head portion, wherein the conical surface is provided at a part thereof with an annular, shallow, cross-sectionally curved recess.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Cavitation erosion test equipment for testing material performance and test method thereof

Owner:DALIAN MARITIME UNIVERSITY

Bias gas-liquid two-phase jet-flow slotting permeability-increasing device and method

ActiveCN103046949AIncreased disturbance rangeImprove breathabilityFluid removalGas removalAir pumpHigh pressure water

A bias gas-liquid two-phase jet-flow slotting permeability-increasing device comprises a gas-liquid two-phase fluid generating system and a drilling and slotting integrated system, wherein the gas-liquid two-phase fluid generating system is composed of a high pressure water pump, a high pressure resistant hose, a pressure regulating valve, a check valve, a gas-liquid mixer, a pressure regulating valve, a high pressure air pump, a drilling rig, a drill pipe, a pressure control drill and a side nozzle. The side nozzle is used for spraying high-pressure bias gas-liquid two-phase jet flow to slot different sections of drilling walls. Two-beam gas-liquid two-phase jet flow acts on coal through impulses at a certain angle under the interaction of washout and cavitation erosion, 'water fight' in the slotting process is effectively avoided, the coal breakage threshold pressure is effectively reduced, the effective length of a slot in single slotting is enlarged, the coal disturbance range is increased obviously, the air permeability of the coal can be improved by about 250-400 times, and the gas extraction effect is improved substantially. Backflow gas can dilute the gushed gas density and operation safety is improved. The method is simple, the operation is easy, practicability is high, and time and labor are saved.

Owner:CHINA UNIV OF MINING & TECH

Vinyl resin paint muterial

The present invention discloses vinyl resin, and is especially one kind of paint mixture compounded with acrylate or methyl acrylate, and the paint mixture is painted onto the flow-passing surface of metal member to prevent cavitation erosion. The paint mixture consists of: vinyl resin as basic material, diluent, initiator and stuffing in the weight ratio of 100 to 20-70 to 0.5-2.5 to 0-500, with the vinyl resin is acrylate or methyl acrylate. The paint may be prepared into base liquid without stuffing or facing material with stuffing, and it may have increased supplementary material based on the requirement of engineering.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Device and method for polishing symmetrical optical component of small-caliber rotating shaft

ActiveCN102873643AReduce distractionsEnhanced frictionAbrasive feedersAbrasive machine appurtenancesShock wavePolishing

The invention discloses a device and a method for polishing a symmetrical optical component of a small-caliber rotating shaft. The device comprises a sealed container mechanism, a workbench drive system which is installed in an inner cavity of the sealed container mechanism and a polishing fluid circulating system which is connected with the sealed container mechanism; and a negative pressure space is formed in the upper part of the inner cavity of the sealed container mechanism. During the polishing, a suction effect of negative pressure difference is utilized for sucking and compositing polishing fluid, a negative pressure cavitation effect is utilized for machining a workpiece surface, a normal pressure environment of machining is changed into a negative pressure environment, air disturbance in an injection process is reduced, a polishing point can be reduced, and the sliding friction function and stability of micro and fine abrasive particles are increased; and moreover, the negative pressure cavitation effect forms strong cavitation shock wave and high speed micro jet, so that the removal efficiency of the workpiece surface is increased. Materials are removed under the combined action of abrasive particle cutting and cavitation erosion, so that the surface with high quality is obtained. The device is suitable for polishing various rotating symmetroid optical components, and has a high practicable value in automatic processing.

Owner:HUNAN UNIV

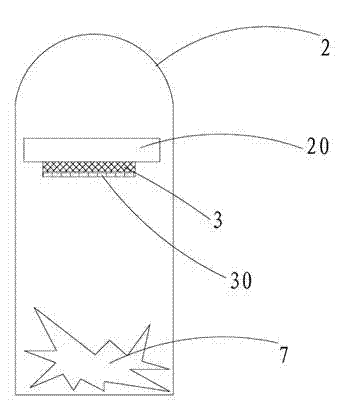

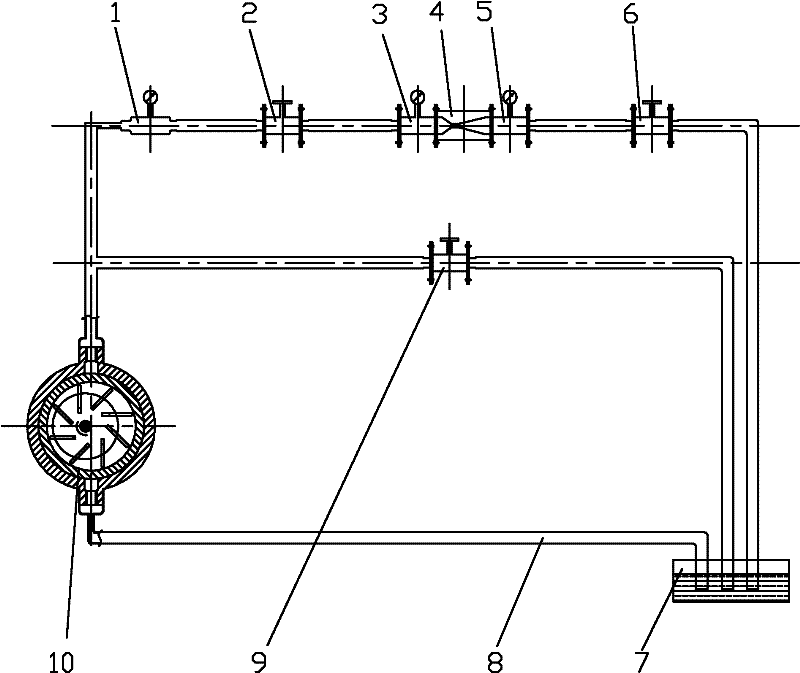

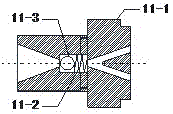

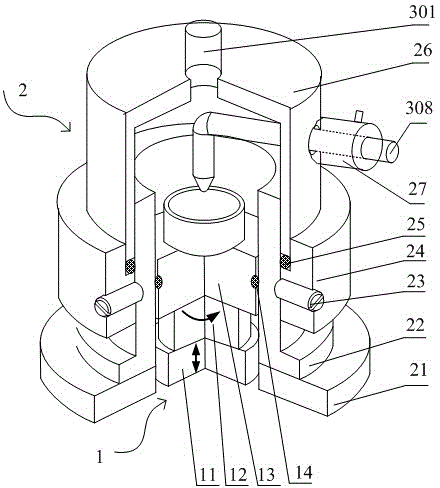

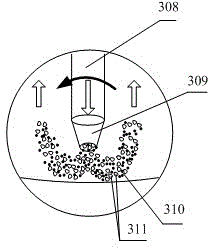

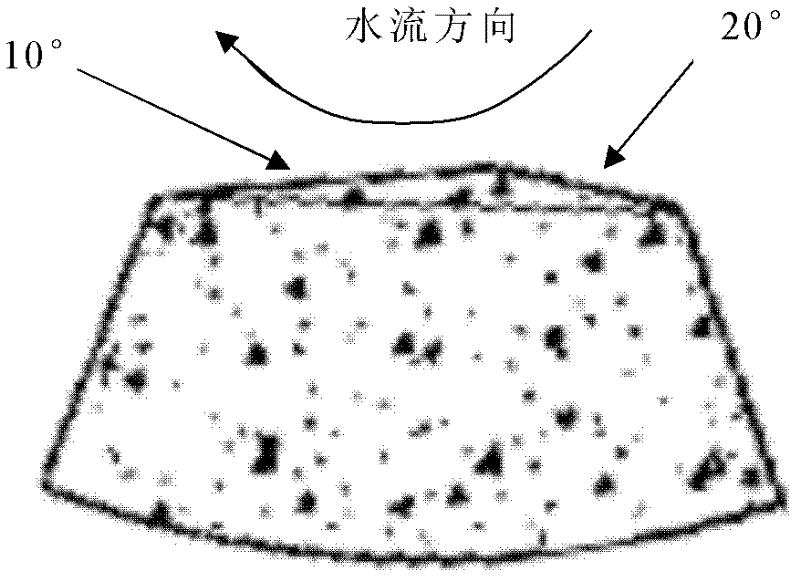

Visualized testing device for cavitation-cavitation erosion relation measurement

InactiveCN105891034ARealize automatic cycleFlow can be adjusted arbitrarilyInvestigating abrasion/wear resistanceMetal foilFuel tank

The invention discloses a visualized testing device for cavitation-cavitation erosion relation measurement. The device comprises a fuel oil supply system, a reaction system and a measurement system, the fuel oil supply system comprises a fuel tank, a heating device, a diesel filter, a pump station, an oil pressure adjusting valve, an adjustable butterfly valve, a buffer section, a compressor and a vacuum pump; the reaction system comprises a test section and a metal foil piece; the measurement system comprises a pressure sensor, a flow sensor, a signal control terminal and a computer. The visualized testing device has the advantages that the structure is simple, the device runs stably, cavitation erosion intensity is continuously adjustable, test operation is simple, the induced cavitation performance effect of the test section is good, and the generation areas of vacuole clusters adjacent to the test section and cavitation erosion characteristics on the metal foil piece are easy to observe.

Owner:JIANGSU UNIV

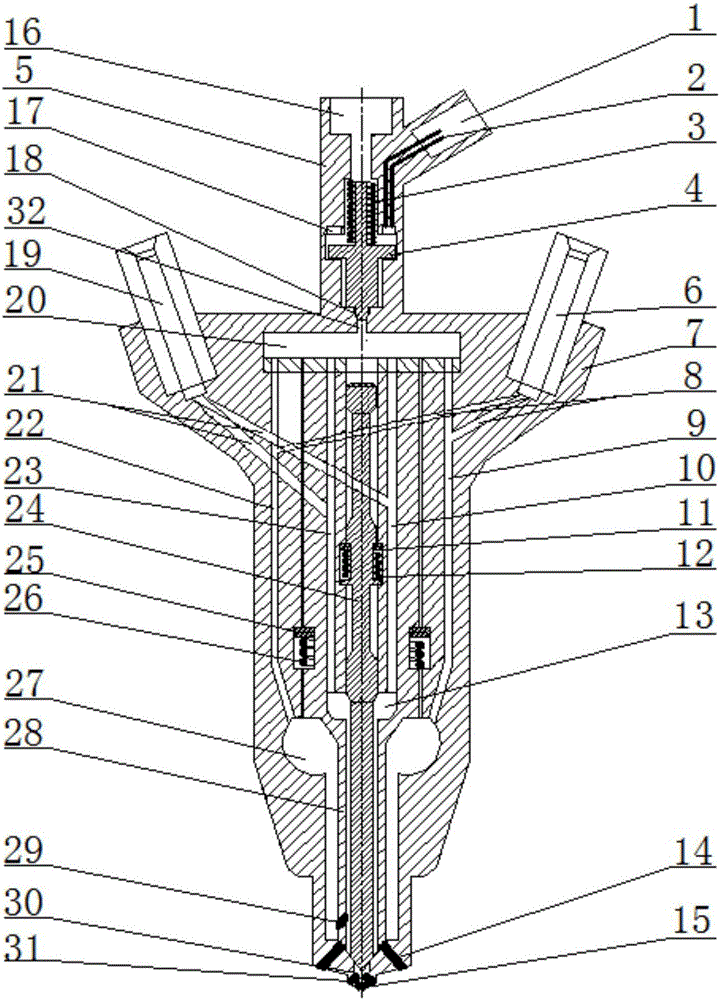

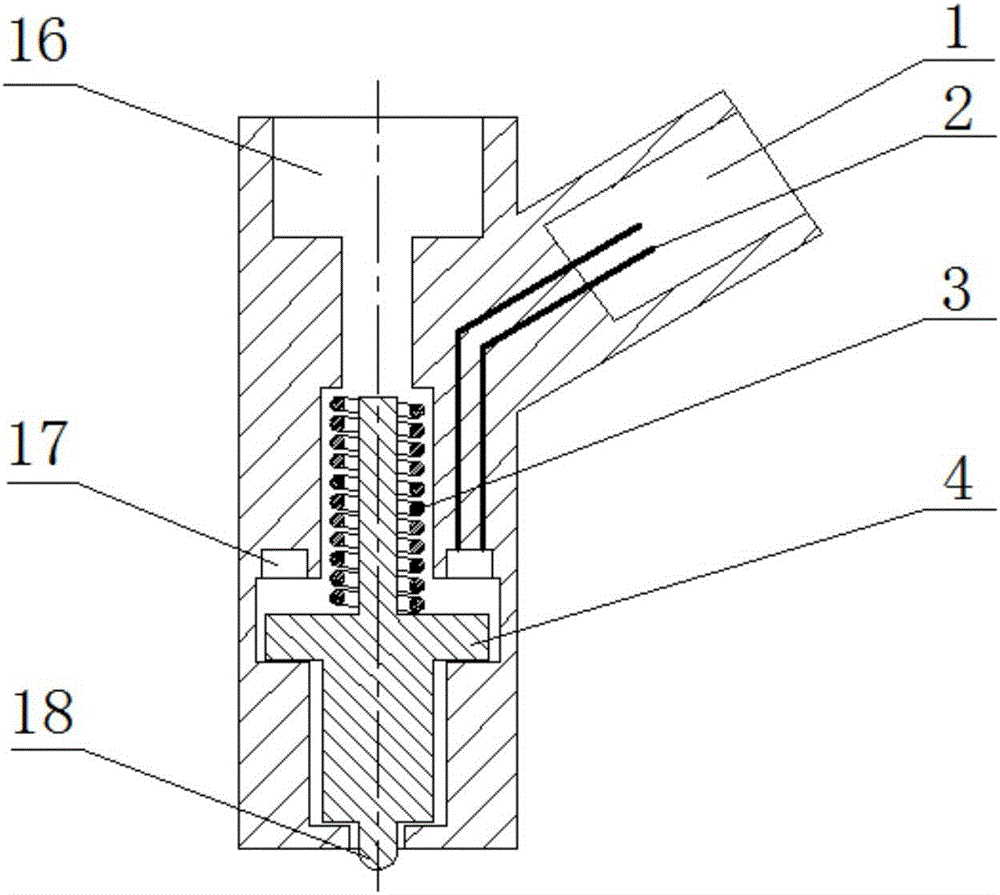

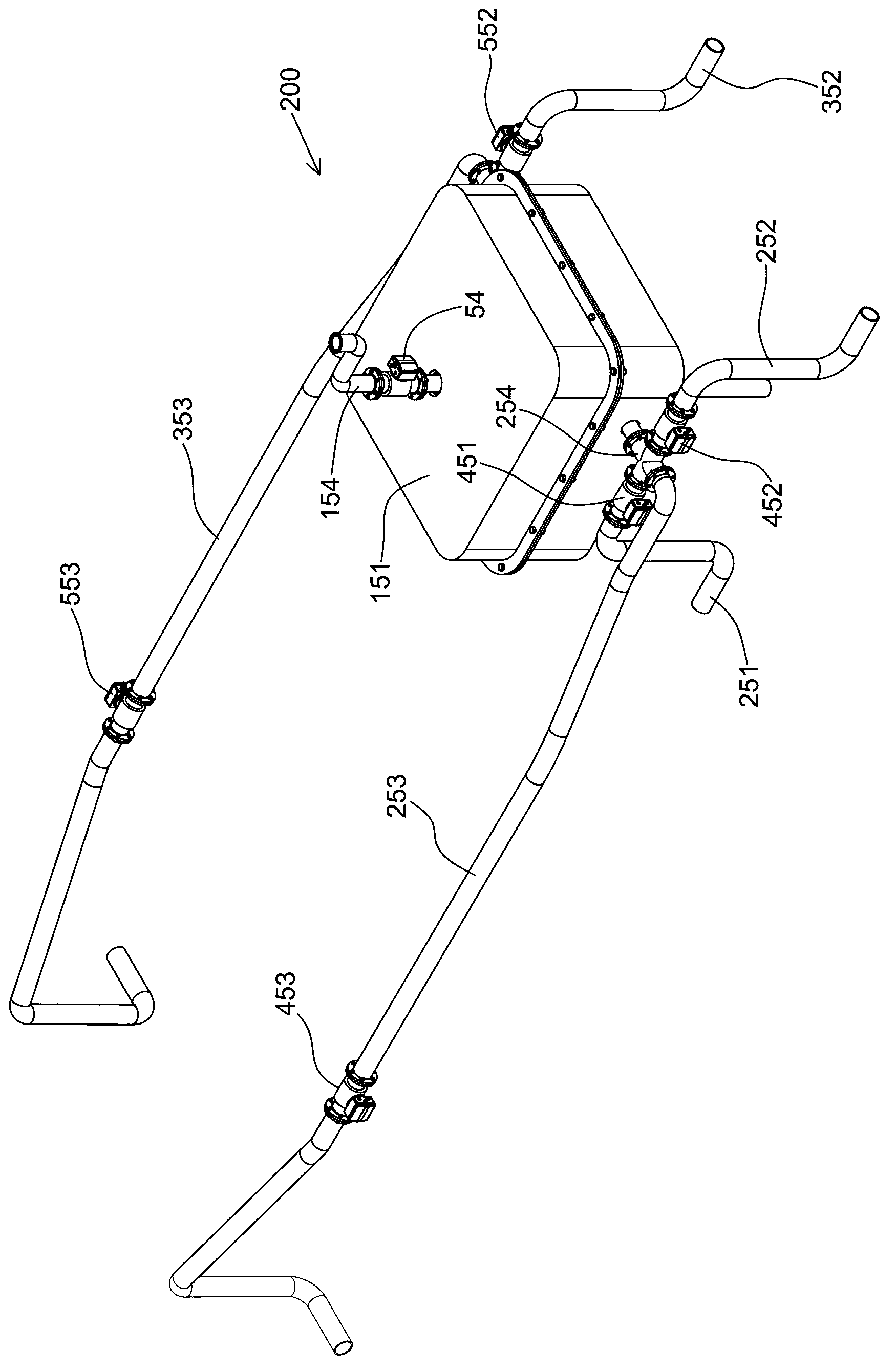

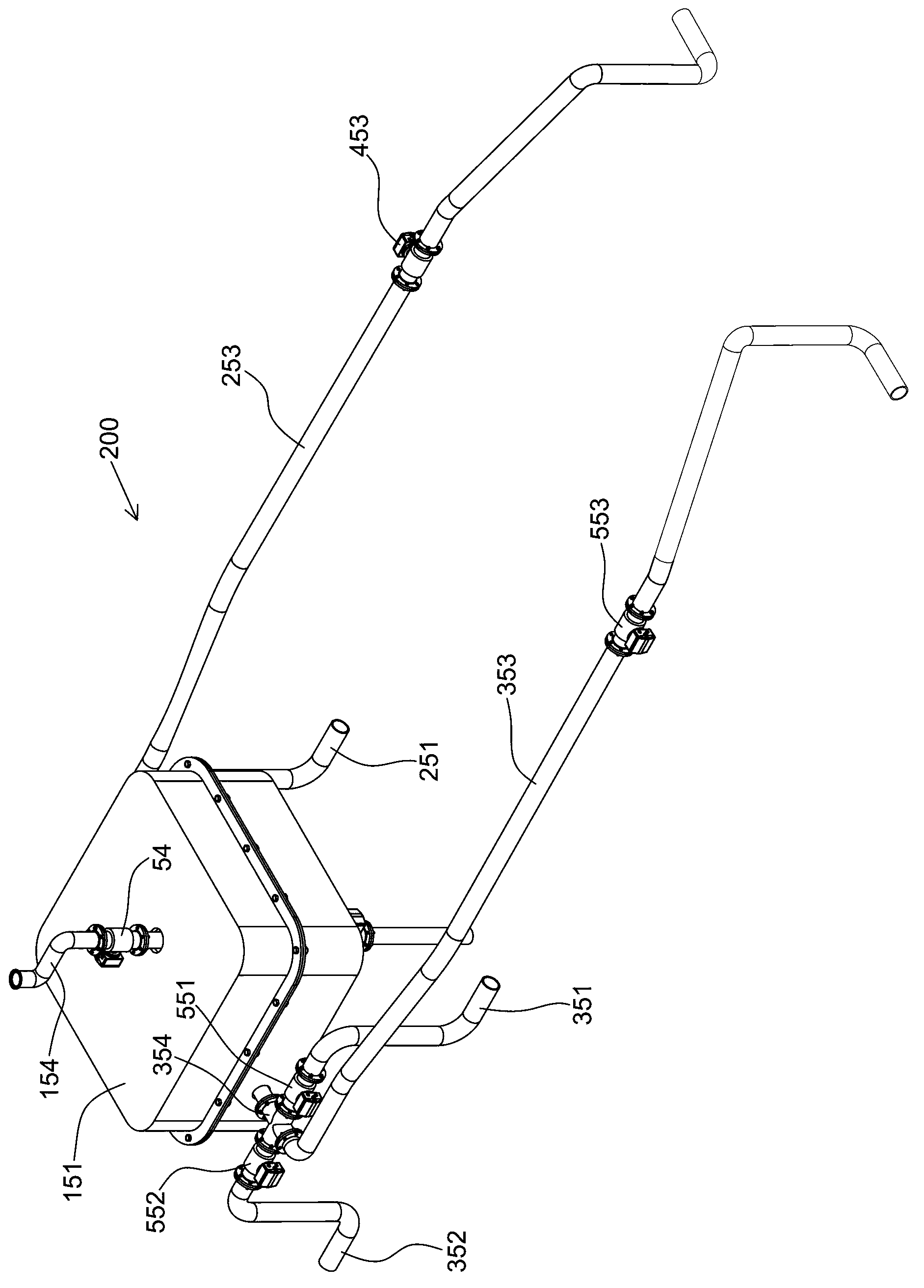

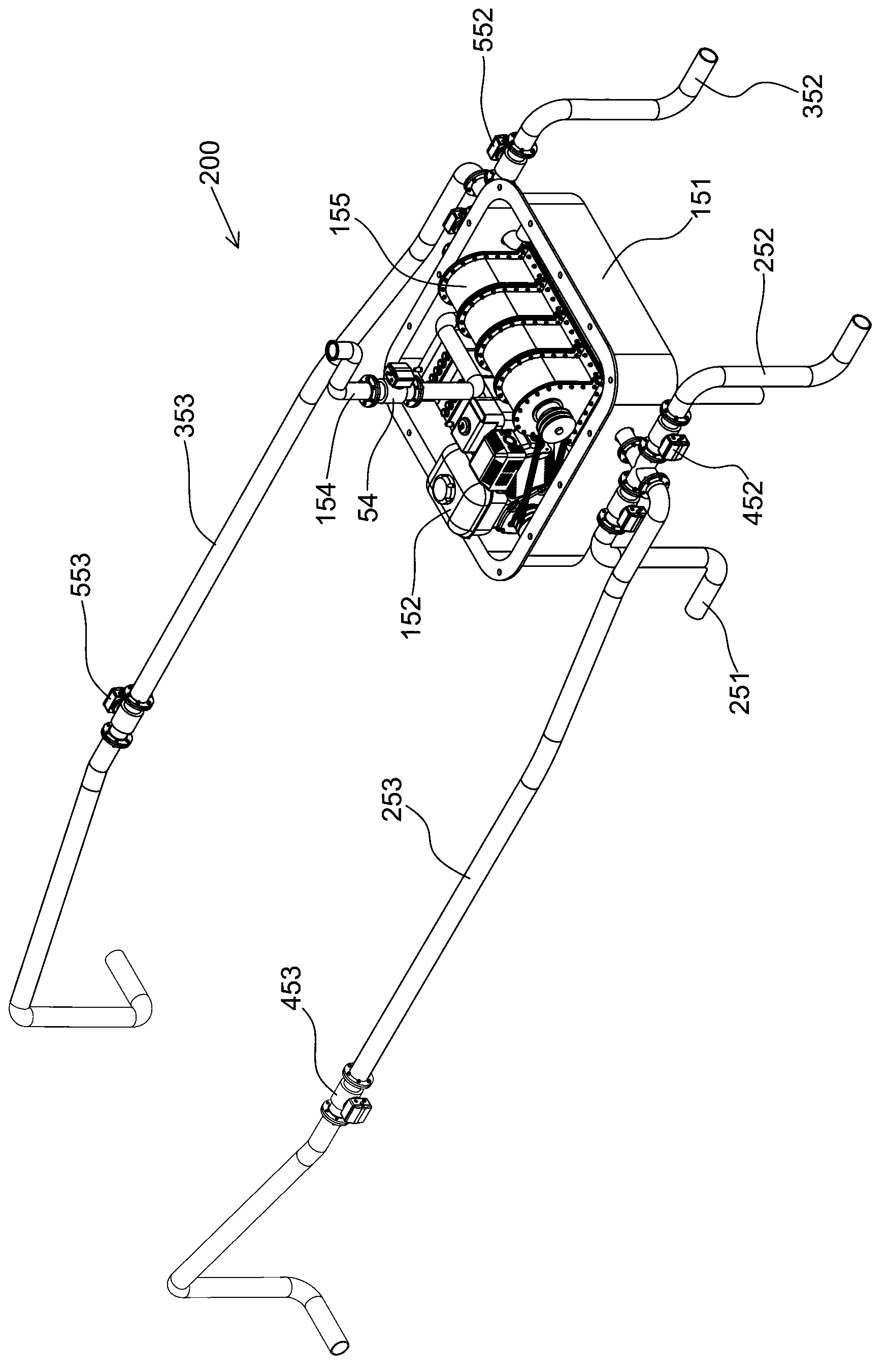

Cavitation-erosion-preventing novel double-fuel injector and common-rail fuel system

InactiveCN106762276ASolve the problem of direct injection in the cylinderSolve the cavitation problemMachines/enginesSpecial fuel injection apparatusBody axisCommon rail

The invention provides a cavitation-erosion-preventing novel double-fuel injector and a common-rail fuel system. The cavitation-erosion-preventing novel double-fuel injector comprises an injector body and an electromagnetic control device. The injector body comprises a needle valve arranged in an injector body axis piston cavity, a second reset spring arranged on the needle valve in a sleeving manner, a first fuel guiding device and a second fuel guiding device, wherein the first fuel guiding device and the second fuel guiding device are arranged at the two ends of the tail of the injector body. The electromagnetic control device is assembled at the tail of the injector body. A cable, a first reset spring, an armature and an electromagnetic valve are arranged in the electromagnetic control device. A common rail fuel system is connected with the two fuel guiding devices of the injector through two fuel high-pressure common-rail pipes to send fuel to the injector. The cavitation-erosion-preventing novel double-fuel injector and the common-rail fuel system are used for achieving in-cylinder direct injection of two different kinds of fuel, and the problem about in-cylinder direct injection of a diesel induced ignition natural gas engine is solved; and the nozzle structure is optimized, and the problem of insufficient lubrication existing in the gas fuel injection process is effectively solved through lubricating injection holes.

Owner:JIANGSU UNIV

Water spray propulsion unit for ship

ActiveCN102795325AWide efficiency rangeImprove efficiencyRotary piston pumpsRotary piston liquid enginesPropulsive efficiencyHigh lift

The invention relates to a water spray propulsion unit for a ship, consisting of a case, a motor, a liquid inlet tube, a gas inlet tube, a rotation type volume pump and six nozzles. The six nozzles are respectively a left forward nozzle, a left backward nozzle, a left lateral nozzle, a right forward nozzle, a right backward nozzle and a right lateral nozzle, wherein the left forward nozzle and the left backward nozzle are installed at the left side of the tail part of the ship body; the right forward nozzle and the right backward nozzle are installed at the right side of the tail part of the ship body; the left lateral nozzle is installed at the left side of the front part of the ship body; and the right lateral nozzle is installed at the right side of the front part of the ship body. A dynamic shaft of the motor is connected with a central shaft of the rotation type volume pump through a decelerating mechanism, the liquid inlet tube is connected with a liquid inlet tube connector of the rotation type volume pump, and the gas inlet tube is connected with a gas inlet tube connector of the rotation type volume pump. By taking the rotation type volume pump as a core part, the water spray propulsion unit for the ship has the advantages of small volume, light weight, high flow, high lift and great suction, and the problems of cavitation and cavitation erosion of a vane pump are effectively solved. According to the water spray propulsion unit, gas-liquid two-phase propulsion is adopted so that the propulsion efficiency is high.

Owner:徐世友

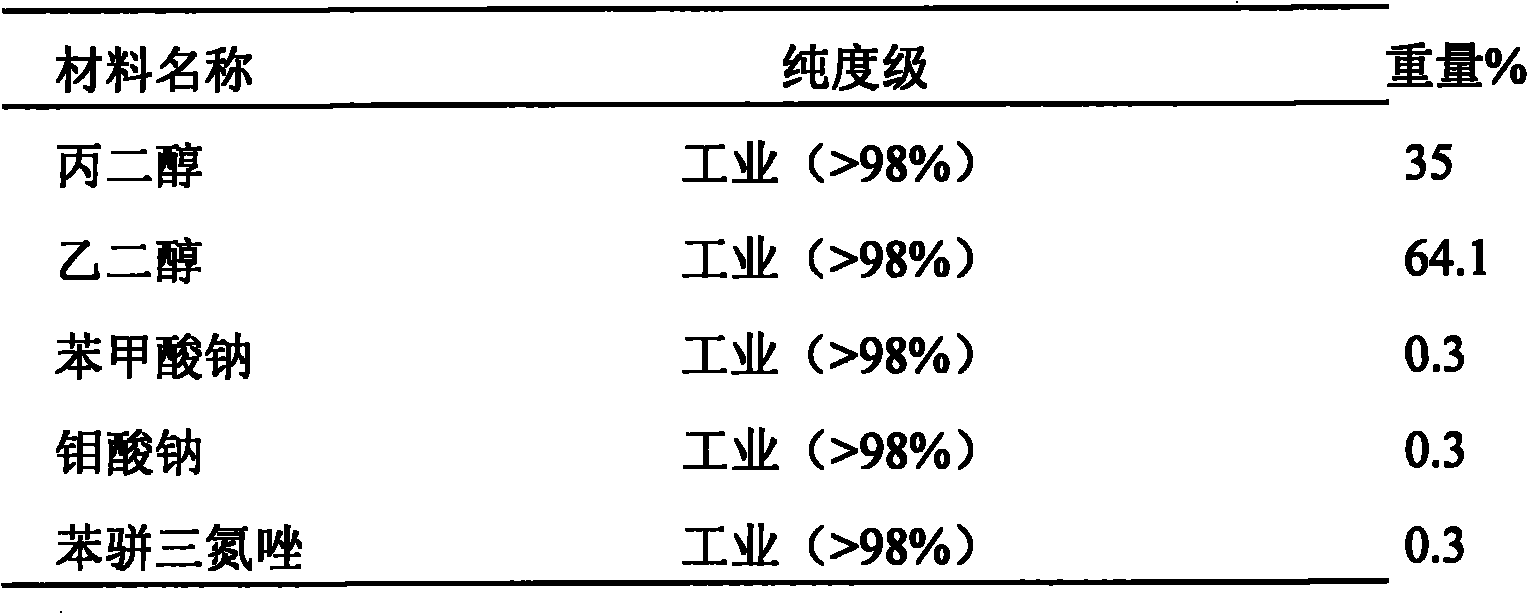

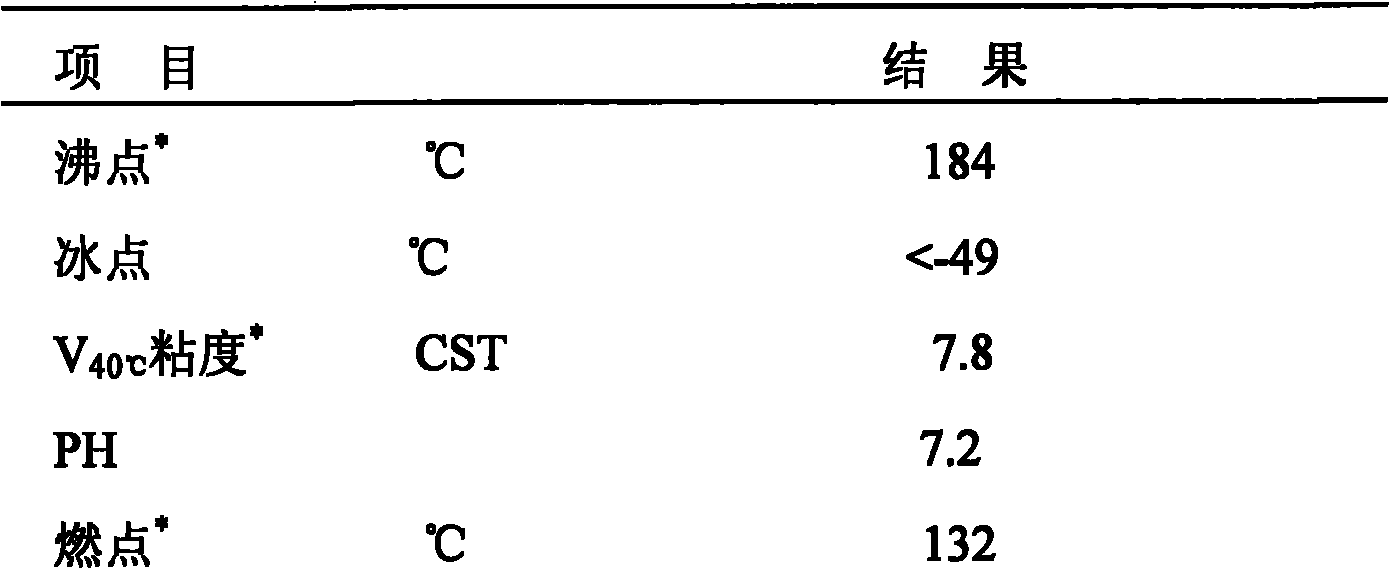

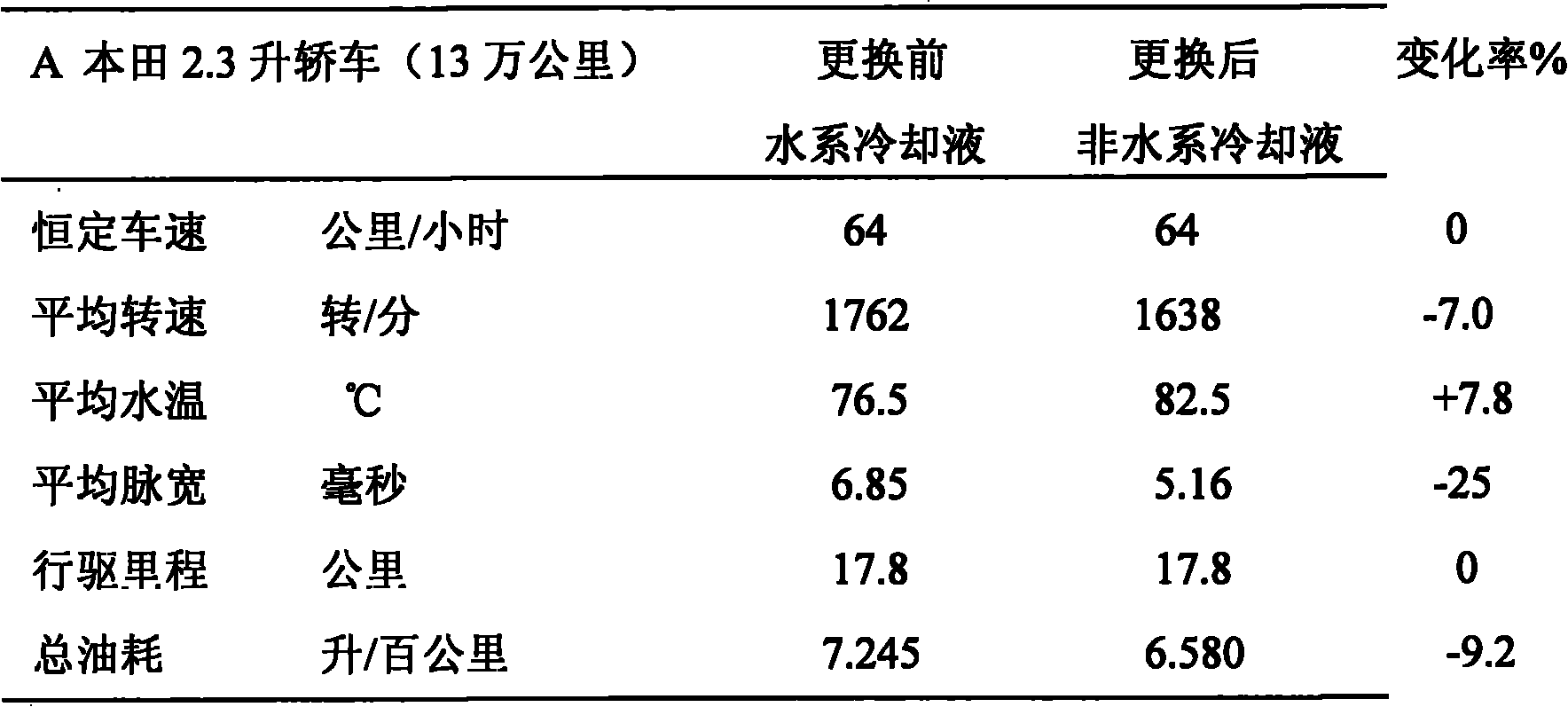

Non-aqueous system internal-combustion engine cooling liquid

The invention relates to the field of chemical engineering heat transfer, in particular to a non-aqueous system cooling medium used as internal-combustion engine cooling liquid. The invention particularly discloses non-aqueous system internal-combustion engine cooling liquid. The non-aqueous system internal-combustion engine cooling liquid contains propylene glycol, glycol, sodium benzoate, sodiummolybdate and benzotriazole, and is characterized in that the content of the propylene glycol is less than 40 percent. The freezing point of the non-aqueous system internal-combustion engine coolingliquid is below 49 to 13 DEG C below zero, so that the non-aqueous system internal-combustion engine cooling liquid can be widely used in gasoline engines and diesel engines. For the non-aqueous system internal-combustion engine cooling liquid, the corrosion resistance and the cavitation erosion resistance are far beyond those of the aqueous system cooling liquid, the boiling point is over 180DEGC, the normal-pressure operation is achieved, the combustion efficiency is improved, the oil consumption is lowered, and the emission of waste gas is reduced. The non-aqueous system internal-combustion engine cooling liquid does not contain heavy metals, amines, phosphides and chlorides, and meets the ROHS standard of the EU.

Owner:郝克强 +1

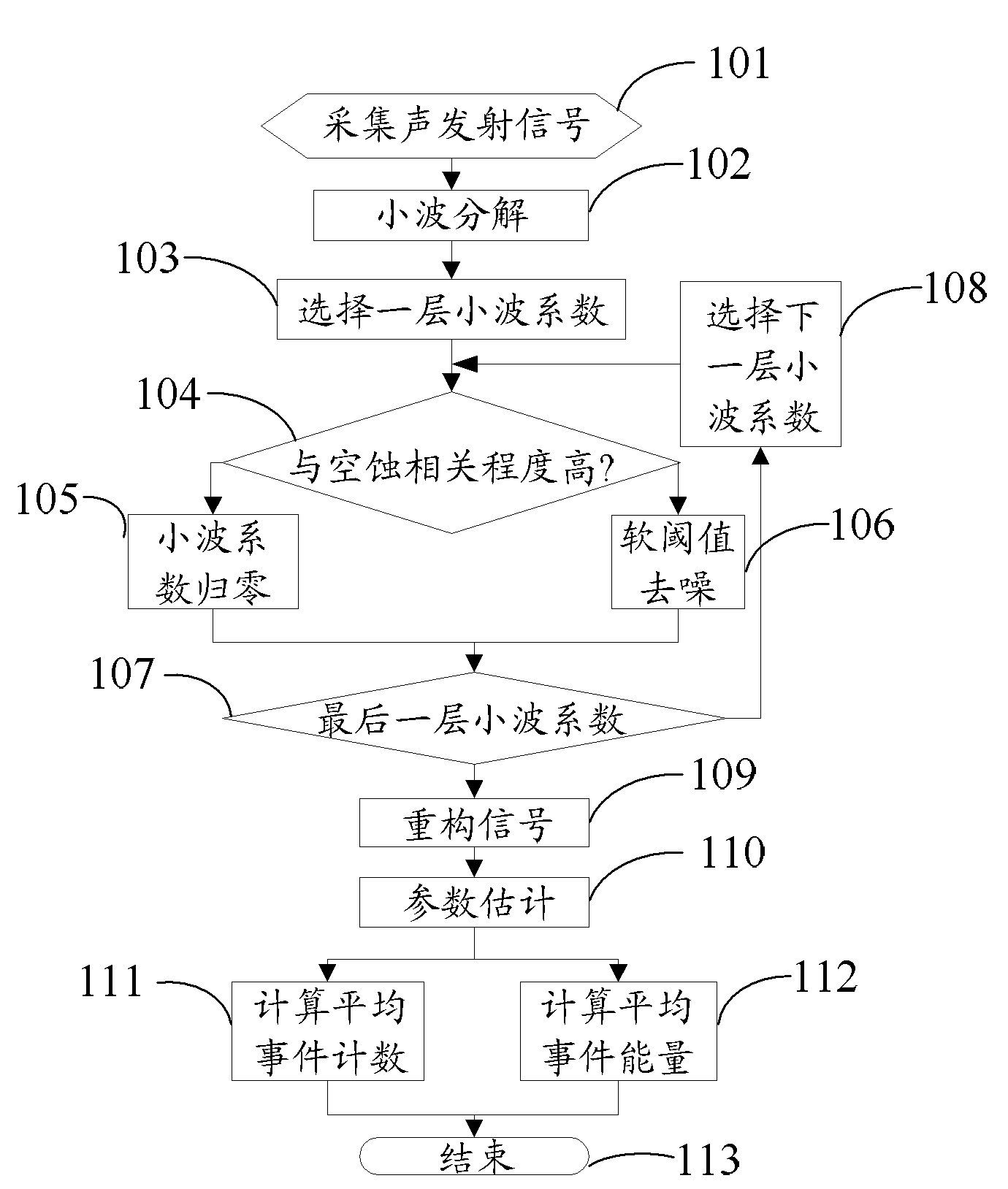

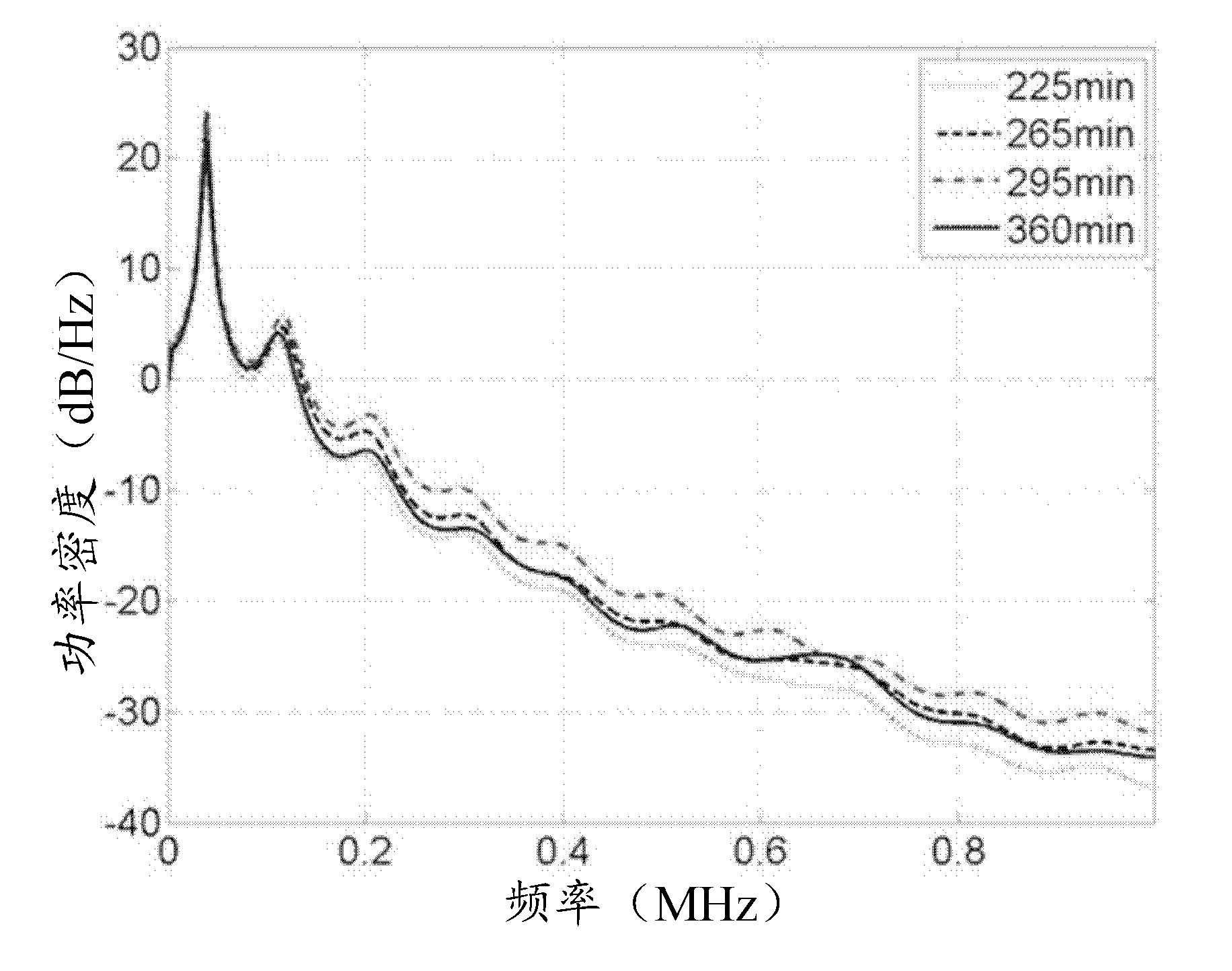

Cavitation erosion detection method based on acoustic emission

InactiveCN102539539AMaterial analysis using acoustic emission techniquesProcessing detected response signalAcoustic emissionWavelet decomposition

The invention discloses a cavitation erosion detection method based on acoustic emission, which comprises the following steps: utilizing an acoustic emission sensor to collect an acoustic emission signal in unit time length during cavitation erosion development; performing wavelet decomposition on the acoustic emission signal according to set layer number to obtain a wavelet coefficient and relevant degree of the cavitation erosion and frequency range where the wavelet coefficient is located, and denoising the wavelet coefficient according to the relevant degree and the set layer number; performing signal reconstruction by utilizing the wavelet coefficient after denoising, and obtaining a reconstruction signal; setting parameter estimating threshold and counting time interval of the reconstruction signal; calculating acoustic emission event number and acoustic emission even average energy of the reconstruction signal; and judging plastic deformation and mass loss condition during cavitation erosion development according to the acoustic emission even number and the acoustic emission even average energy. The cavitation erosion detection method based on the acoustic emission performs denoising according to the characteristics of the acoustic emission signal and utilizes a simple estimating parameter to represent the development condition of plastic deformation and mass loss during cavitation erosion.

Owner:TSINGHUA UNIV

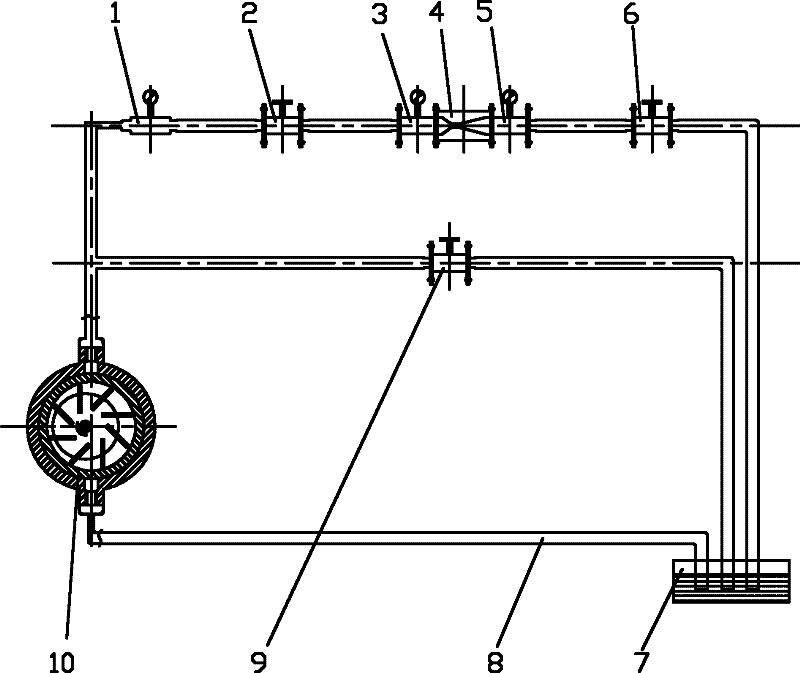

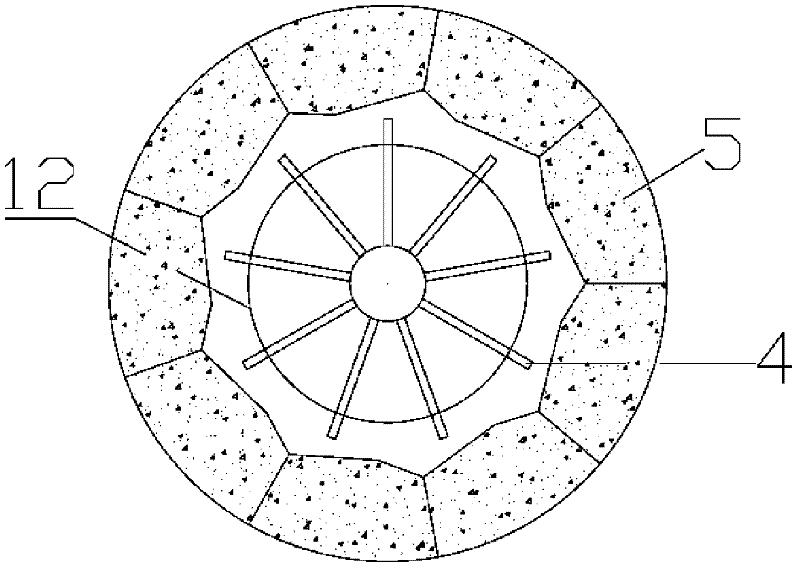

Rotating scaling type abrasion-cavitation erosion coupling test method and device

ActiveCN102331380AIncrease speedLow flow resistanceInvestigating abrasion/wear resistanceImpellerElectric machine

The invention relates to a rotating scaling type abrasion-cavitation erosion coupling test method and device. The test method comprises the following steps: manufacturing the inner edge of a tested piece into a bulge, placing the bulge in a sealed abrasion-cavitation erosion chamber and forming a scaling type flow channel by matching the bulge with a rotating impeller in the abrasion-cavitation erosion chamber; filling water flows containing sands; starting a rotating driving motor and a water circulating pump, spraying the water flows containing sands from a hollow blade and rotating and flowing at a high speed; forming rushing-abrasion damage and cavitation erosion damage to the surface of a concrete tested piece; after testing, taking out and weighting the tested piece and measuring anabrasion depth; and discharging the water flows containing sands. The abrasion-cavitation erosion coupling test device is provided with the abrasion-cavitation erosion chamber, wherein a rotating water-sand spraying impeller with a hollow structure is arranged in the abrasion-cavitation erosion chamber; the bulge of the inner edge of the tested piece is matched with the rotating impeller; and thescaling type flow channel is formed in the abrasion-cavitation erosion chamber. The test method and device can be used for testing the abrasion-cavitation erosion resisting capability of concretes under the abrasion-cavitation erosion coupling action of the high-speed water flows containing sands and have the advantages that the maximum flow speed reaches 40m / s-60m / s, the occupied area is small, the rushing-abrasion efficiency is high, the energy conservation and environmental friendliness are realized.

Owner:NANJING HYDRAULIC RES INST

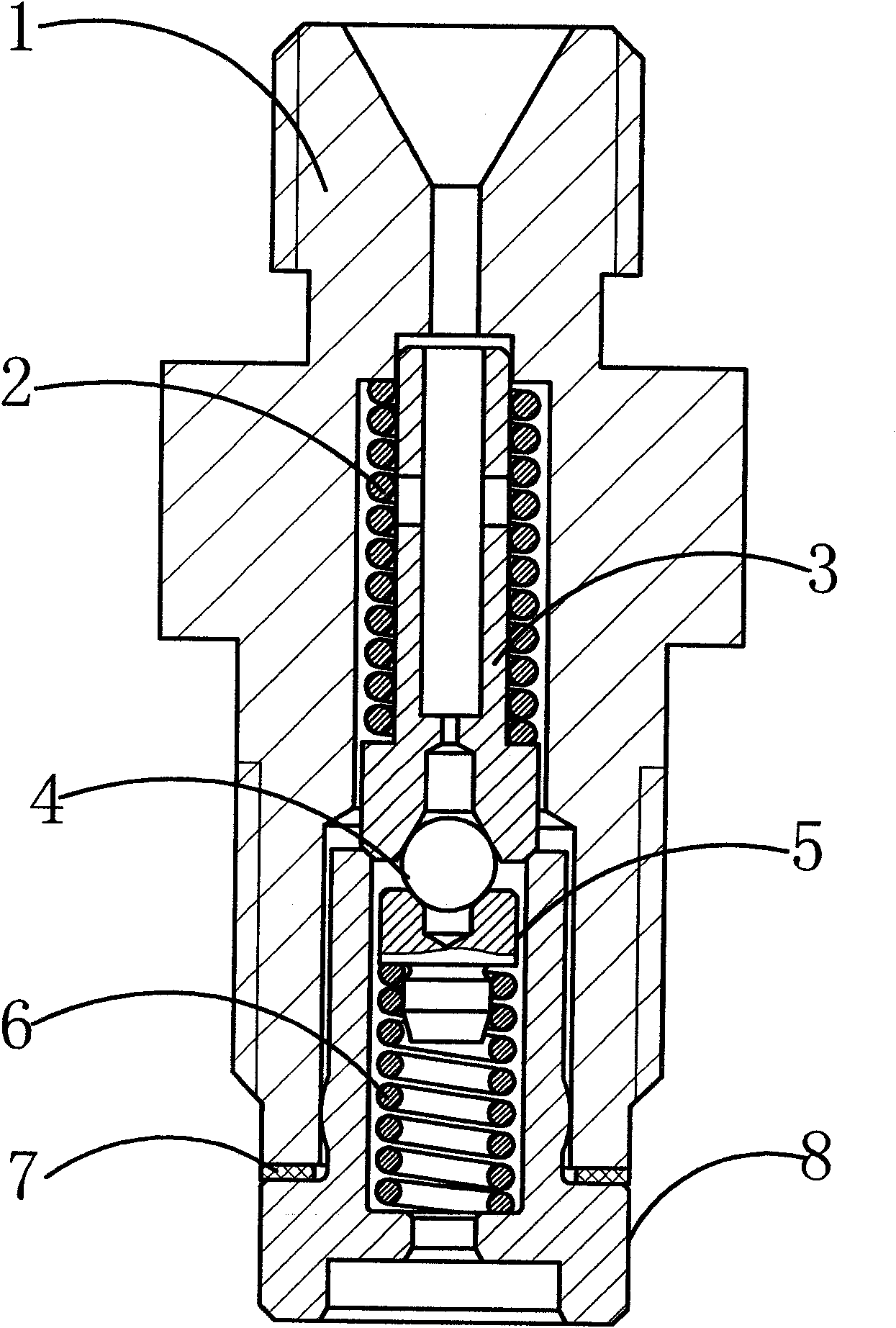

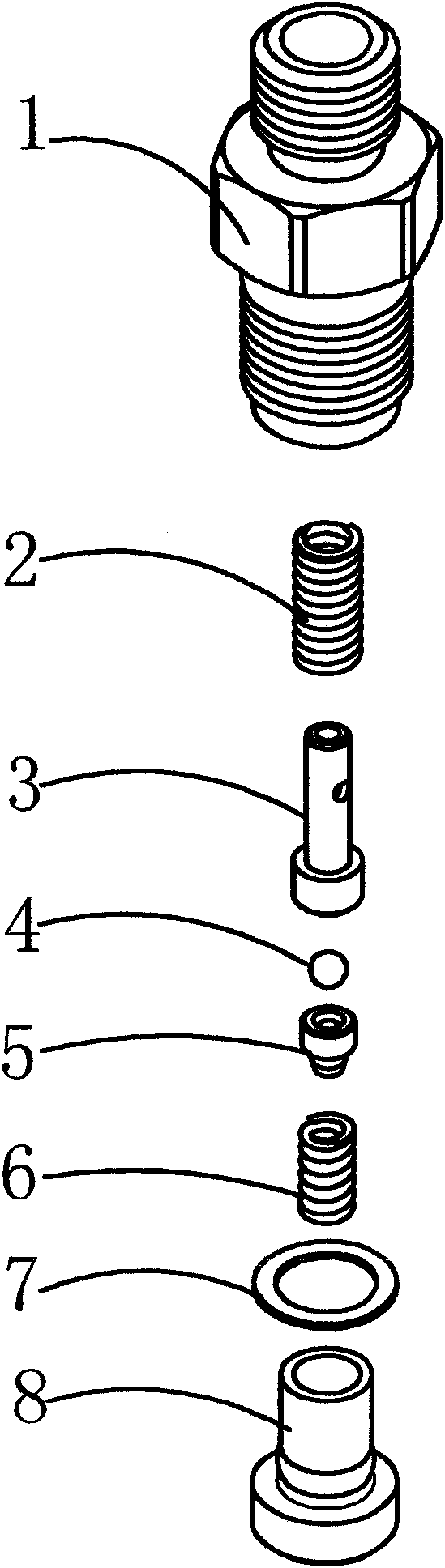

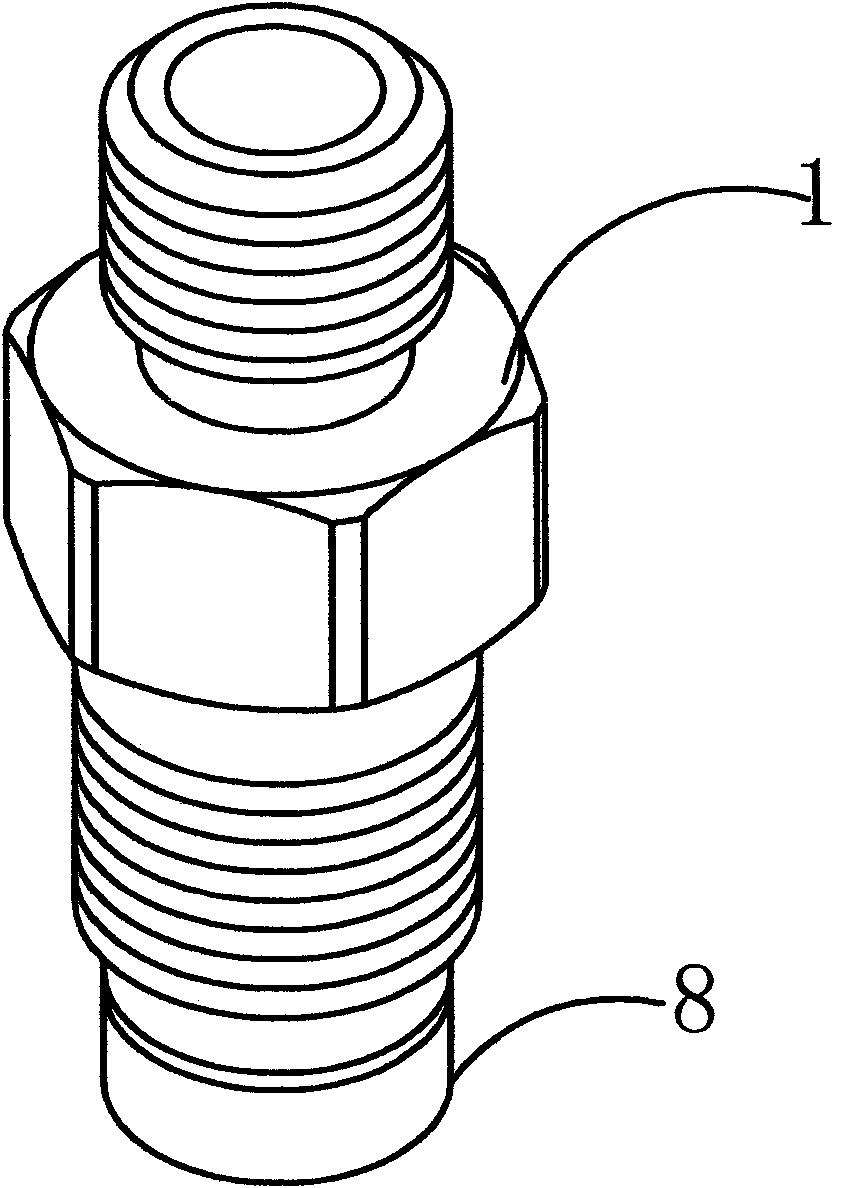

Constant pressure oil outlet valve

InactiveCN101865062AReduce consumption ratePressure wave intensifiesMachines/enginesFuel injecting pumpsManufacturing technologyLow speed

The invention relates to the manufacturing technology of a single cylinder high speed diesel engine with a small cylinder diameter, in particular to a constant pressure oil outlet valve suitable for a diesel engine fuel oil system. The constant pressure oil outlet valve comprises an oil outlet valve tightening seat, an oil outlet valve spring, an oil outlet valve core, an oil outlet valve seat, a steel ball, a spring seat and a pressure relief valve spring, wherein the oil outlet valve spring, the oil outlet valve core and the oil outlet valve seat are mounted in the oil outlet valve tightening seat, the steel ball, the spring seat and the pressure relief valve spring are sequentially assembled in the oil outlet valve tightening seat, the oil outlet valve tightening seat is provided with a lift-range limiting cavity capable of controlling the lift-range of the oil outlet valve, the oil outlet valve core and the oil outlet valve seat are tangentially matched to form a one-way oil supply valve, the oil outlet valve core and the steel ball are tangentially matched to form a constant pressure relief valve, and the lift-range limiting cavity can influence the throttle flow and the initial pressure of the fuel oil in the oil outlet valve through controlling the jumping height of the oil outlet valve core. The constant pressure oil outlet valve has the functions of limiting the lift-range and relieving pressure, can eliminate the secondary injection, the unstable injection generated easily due to low speed and the cavitation erosion easily occurring to a high pressure chamber, and the like, and has the characteristics of simple structure, skillful process, favorable performance, low fuel oil consumption rate, low discharge, stable injection, an the like.

Owner:宁波舜田良源油嘴油泵有限公司

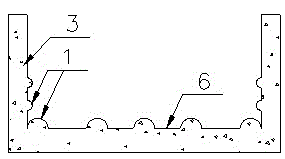

Discharge chute

ActiveCN102912772AIncrease roughnessIncrease frictional resistanceBarrages/weirsWater flowFlood discharge

The invention discloses a discharge chute which comprises a bottom plate and side walls at two sides of the bottom plate, wherein the bottom plate comprises a plurality of stepped bottom plates and a plurality of smooth bottom plates; the stepped bottom plates and the smooth bottom plates are alternately arranged; and a plurality of convex bodies are arranged on the smooth bottom plates and / or the side walls. According to the discharge chute, the convex bodies are arranged on the smooth bottom plates and / or the side walls, so that the roughness of the discharge chute is improved, the frictional resistance is increased, the turbulent energy dissipation rate is improved, a mass of water flow energy is dissipated, the risks of the cavitation erosion destroy of the discharge chute and the erosion destroy are reduced and the flood discharge safety is improved.

Owner:POWERCHINA ZHONGNAN ENG

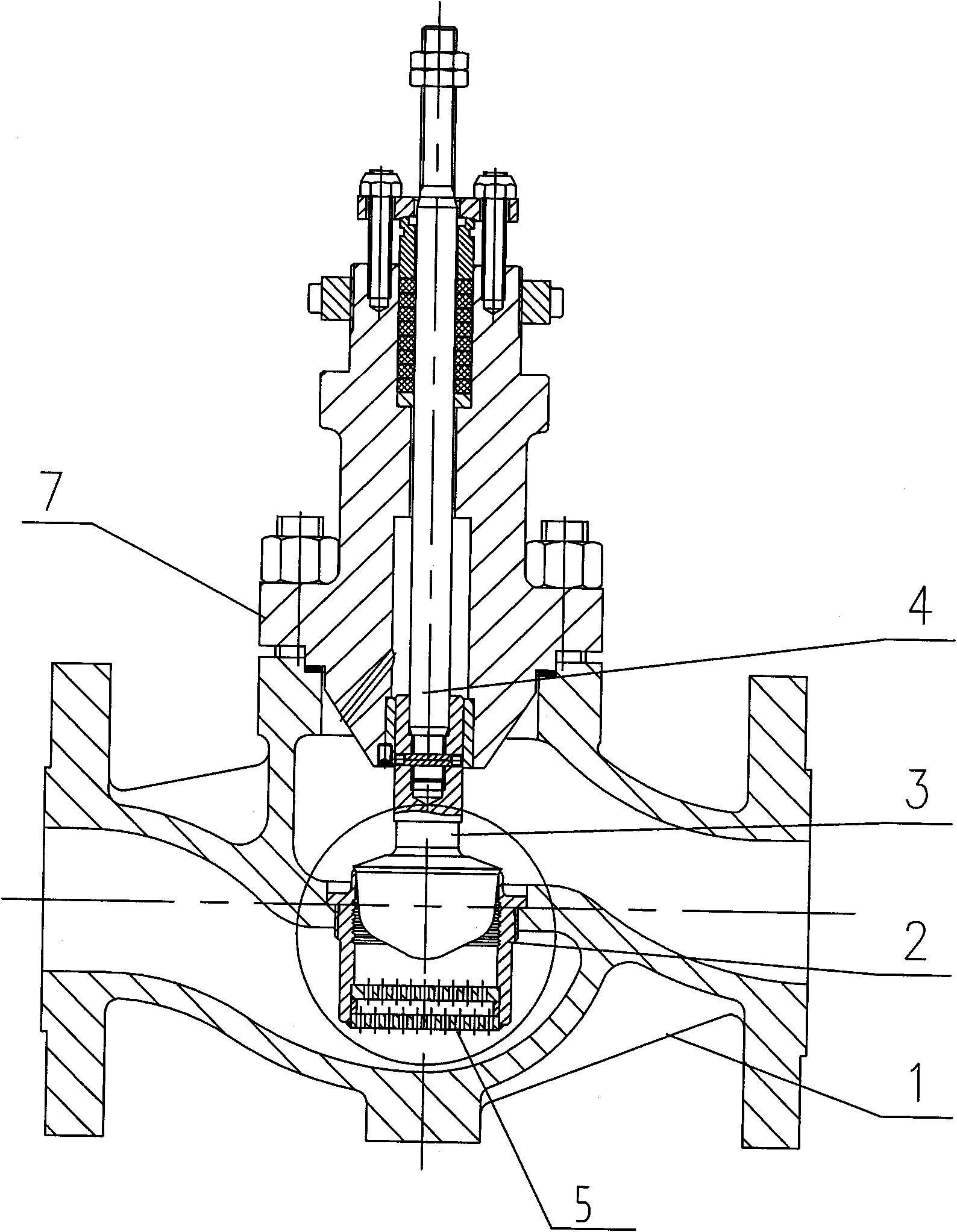

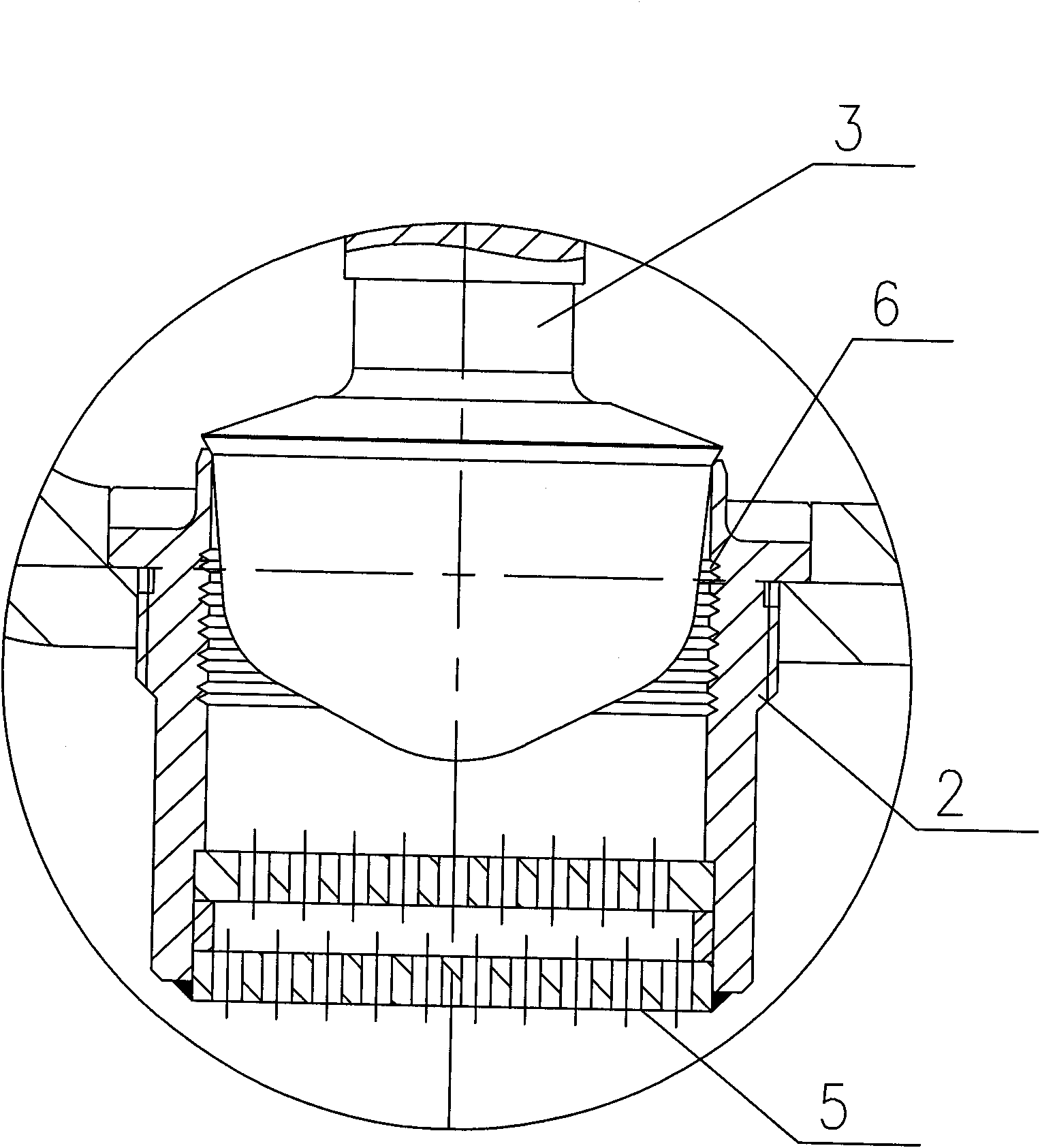

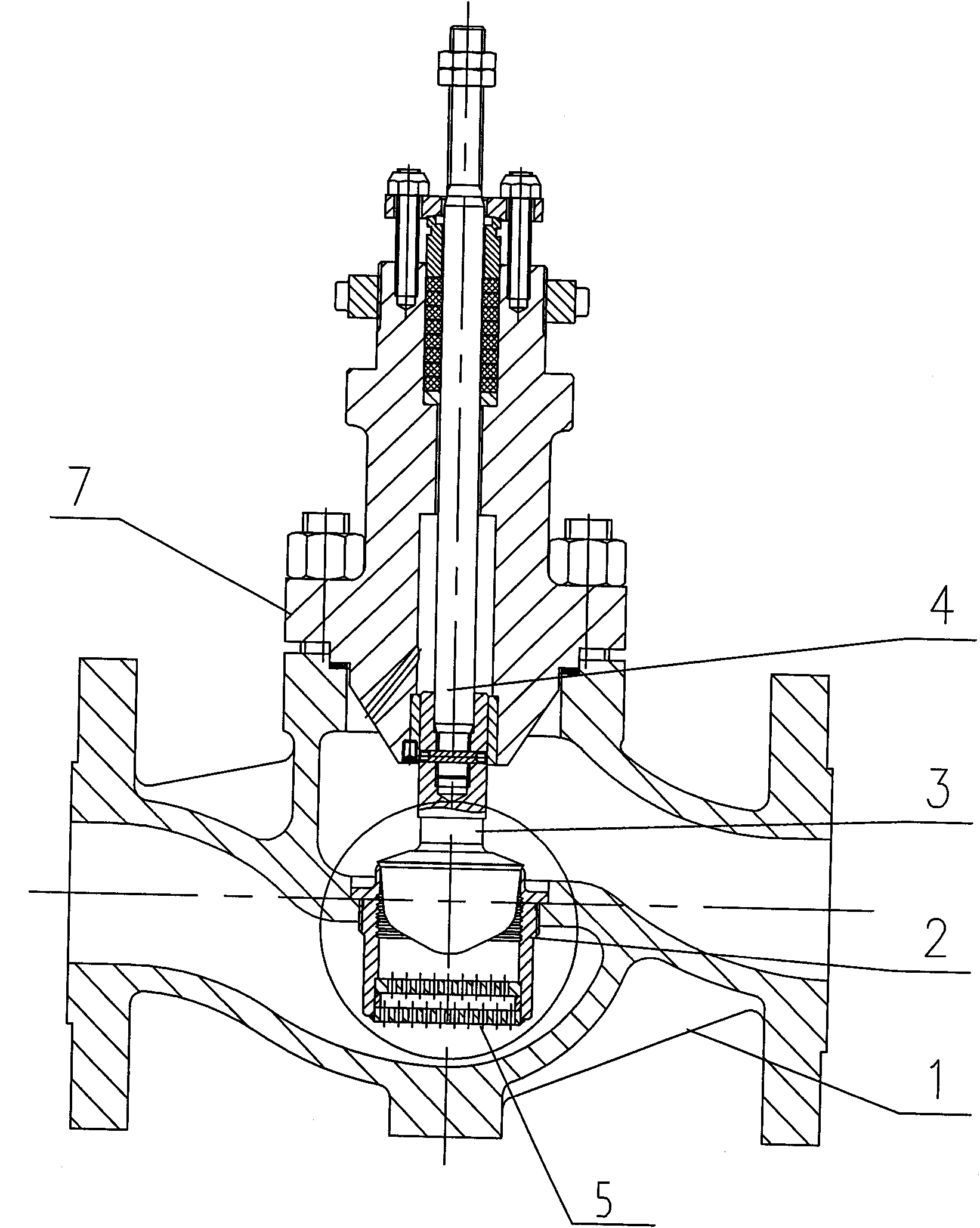

Anti-cavitation erosion adjusting valve capable of cutting

InactiveCN101865297AGuaranteed tightnessEliminate cavitationValve members for absorbing fluid energyLift valveEngineeringSmall hole

The invention relates to an anti-cavitation erosion adjusting valve capable of cutting, which comprises a valve body, a valve seat, a valve core and a valve rod. The invention is characterized in that the sealed face of the valve seat is provided with a cut, the upper side of the sealed face of the valve core is provided with the cut, the valve core sealed face tightly contacts with the valve seat sealed face and the lower part of the valve seat is provided with two or more than two layers of parallel restriction orifices which are provided with small holes. The inner wall at the lower part of the valve seat sealed face is provided with a zigzag groove so that a zigzag swirl chamber is formed between the valve seat and the valve core. The invention adopts the valve seat cutting technology and cuts air bubbles generated by flash evaporation through the sharp cut of the valve seat sealed face, consequently the cavitation erosion is avoided and the damage of the cavitation erosion on the interior components of the valve is eliminated thoroughly.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

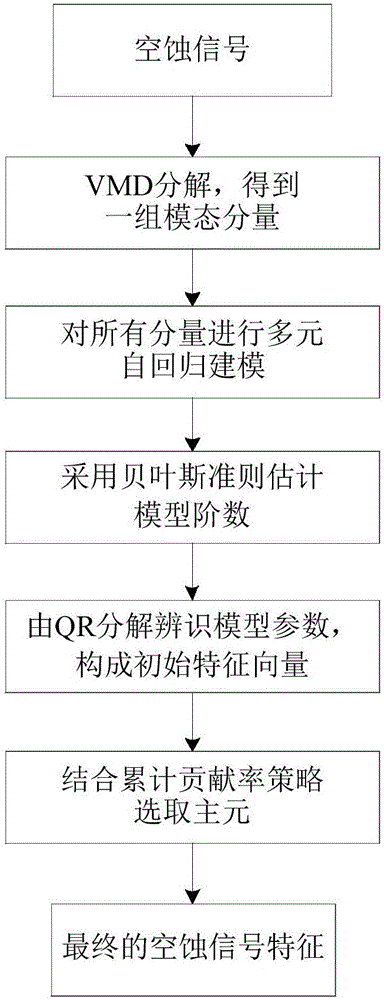

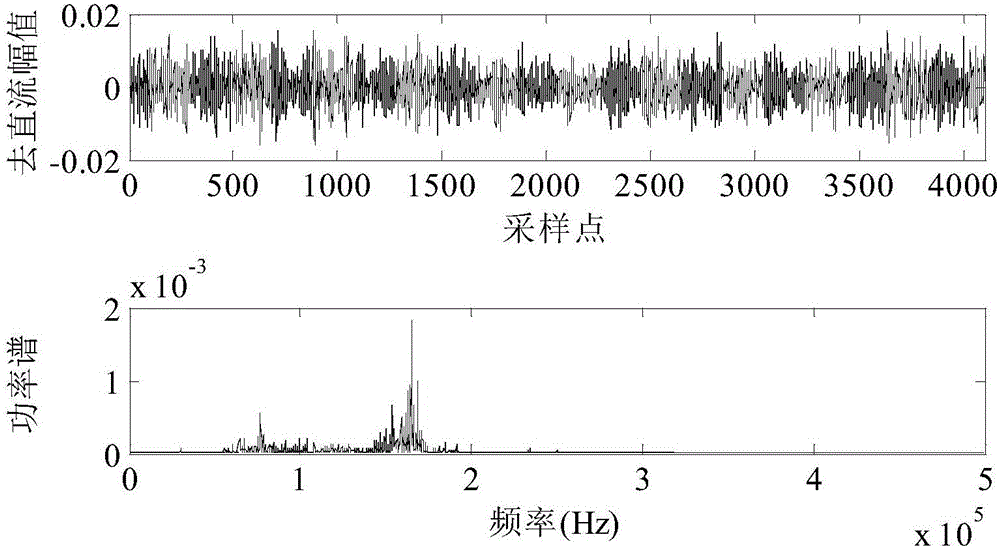

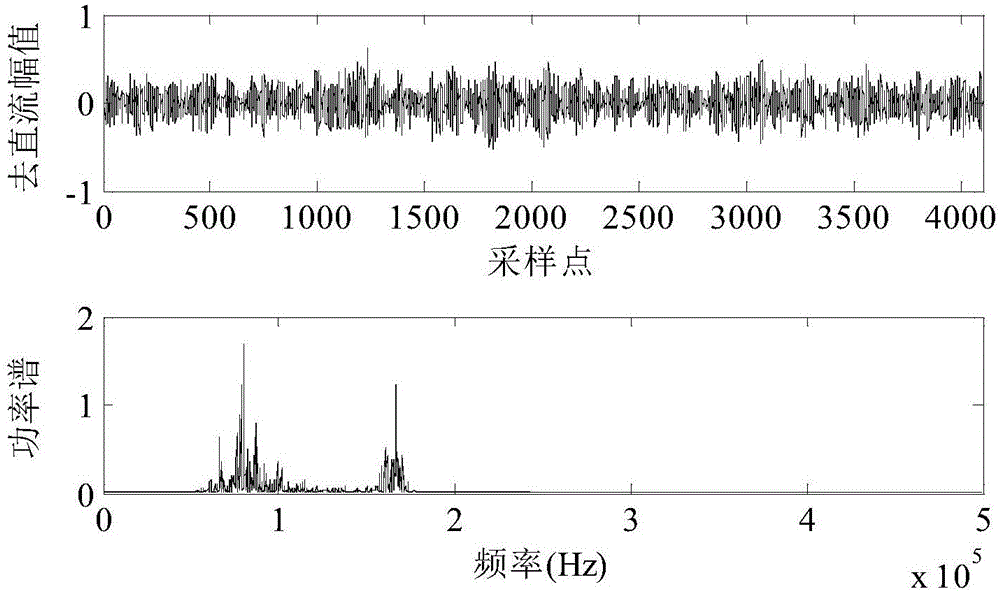

Multi-modal regression analysis based hydroelectric generating set's cavitation erosion signal feature extraction method

InactiveCN106407944AFully featuredEfficient separationGeometric CADCharacter and pattern recognitionRegression analysisPrincipal component analysis

The invention relates to a multi-modal regression analysis based hydroelectric generating set's cavitation erosion signal feature extraction method, which comprises the following steps: 1) obtaining the cavitation erosion signal measuring data from a monitoring system; 2) establishing variation modal decomposition (VMD) parameters and decomposing the cavitation erosion signal into a series of modal components; 3) carrying out multivariate autoregressive modeling to all components; and using the Bayesian criterion to determine the order of the model; 4) constructing the model parameters identified by the QR decomposition method for the initial feature of the cavitation signal; and 5) using the principal component analysis to extract the main element for the final signal characteristics. The technical scheme of the invention realizes the adaptive separation of the intrinsic mode of the cavitation signal, and the characteristic vector obtained by the multimodal regression analysis embodies the important information of the system state, and realizes the full representation of the cavitation signal.

Owner:CHINA THREE GORGES UNIV

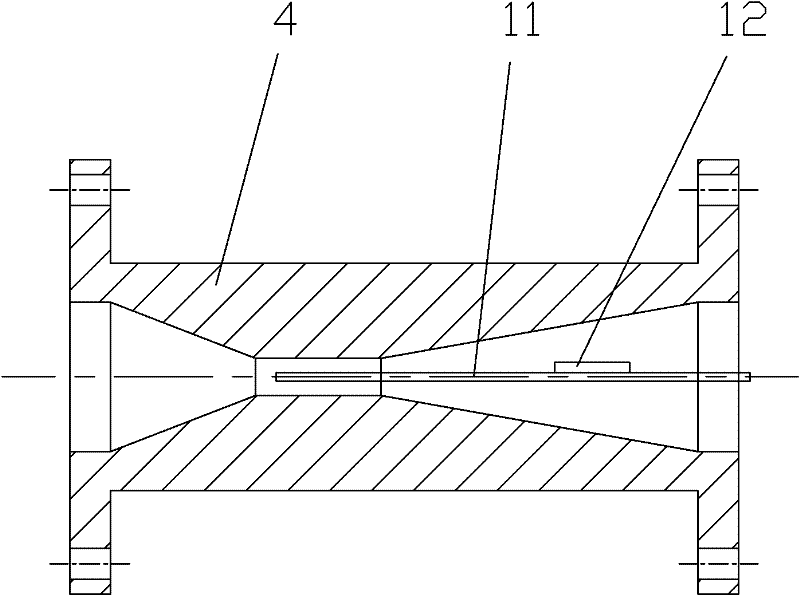

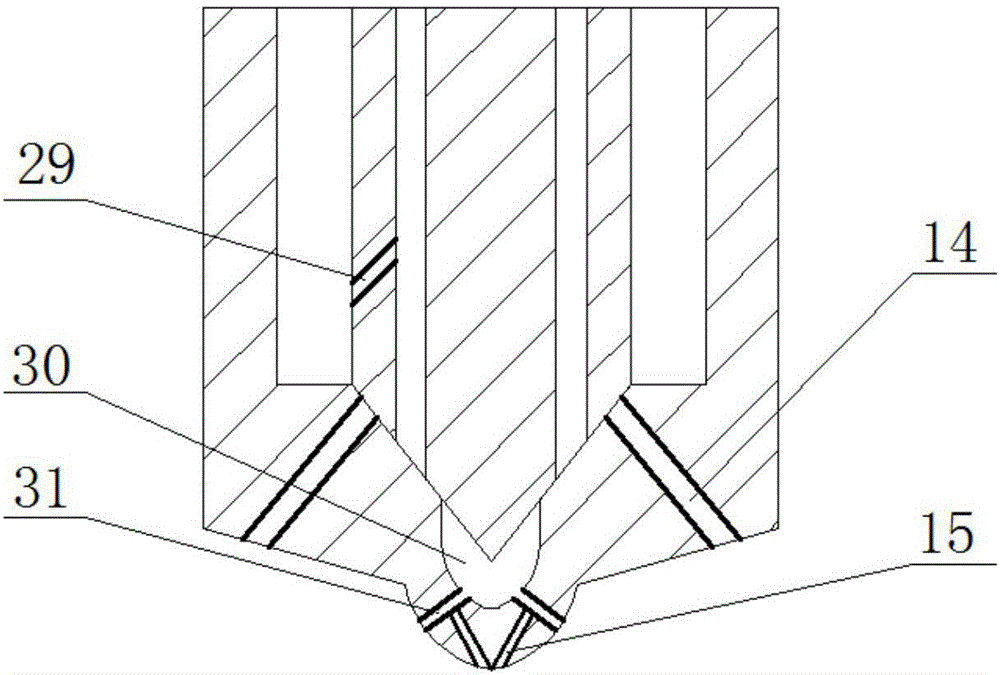

Method of machining injection hole in nozzle body, apparatus therefore, and fuel injection nozzle produced using the method and apparatus

The object of the invention is to provide a fuel injection nozzle with which occurrence of cavitation erosion due to occurrence of separation of fuel flow near the needle valve and injection holes is suppressed and variation in fuel injection characteristic is reduced, a method of machining injection holes, and an apparatus therefore to attain the object. An insert tool shaped like the needle valve or an insert tool having a conical surface similar to the needle valve and a groove or grooves are on the conical surface to introduce abrasive fluid to the injection holes, is inserted in the central hollow of the nozzle body when performing abrasive fluid flowing processing to round entrance corners of the injection holes, and the processing of each of the injection holes is stopped when flow rate of abrasive fluid flowing out through relevant injection hole reaches a predetermined value.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com