Cavitation-erosion-preventing novel double-fuel injector and common-rail fuel system

A fuel injection and dual-fuel technology, applied in fuel injection devices, special fuel injection devices, charging systems, etc., can solve problems such as injector failure, noise, wall cavitation, etc., to improve reliability and optimize nozzle structure. , Solve the effect of cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

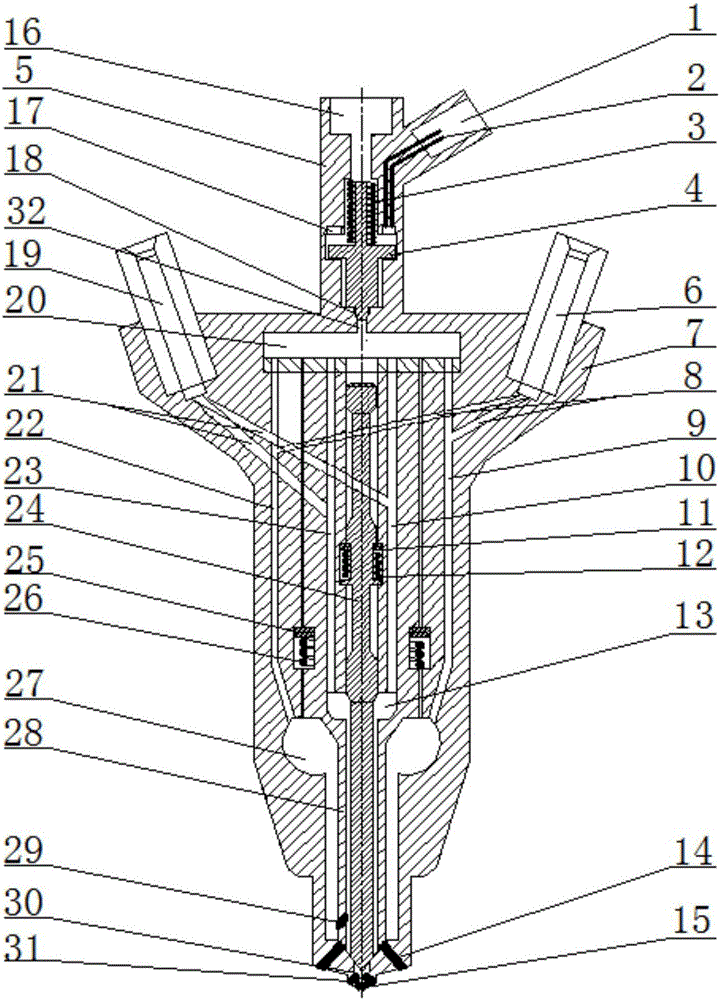

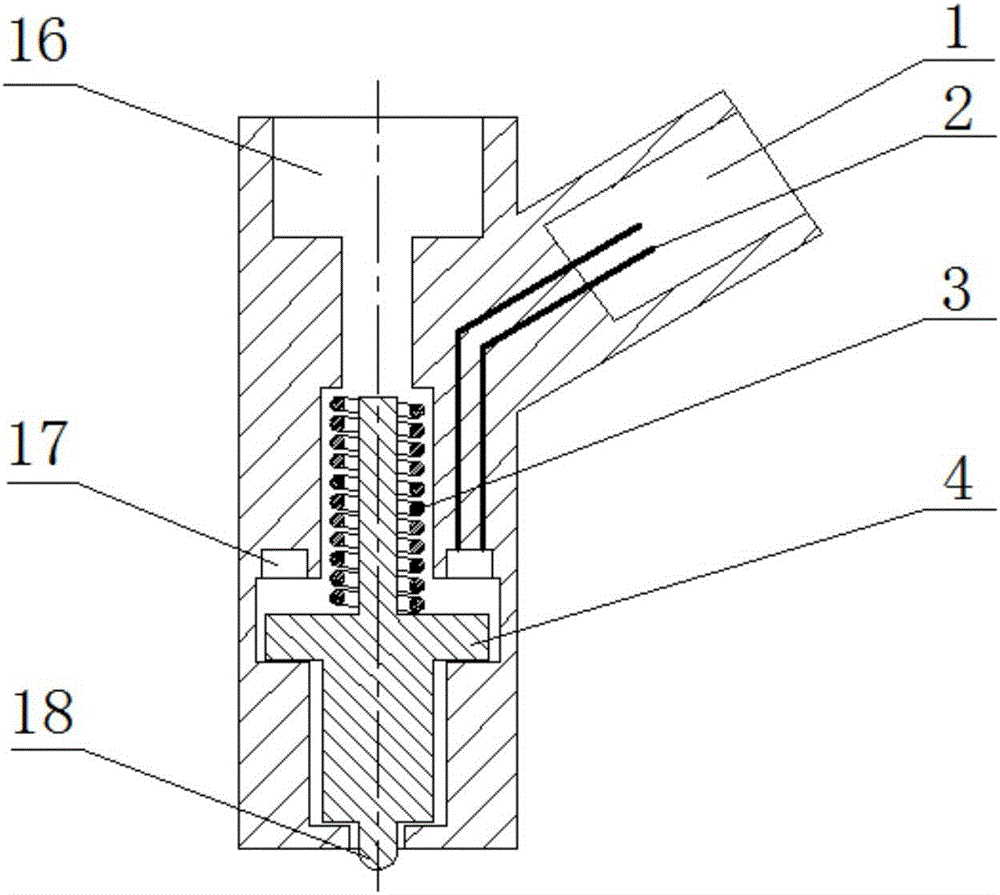

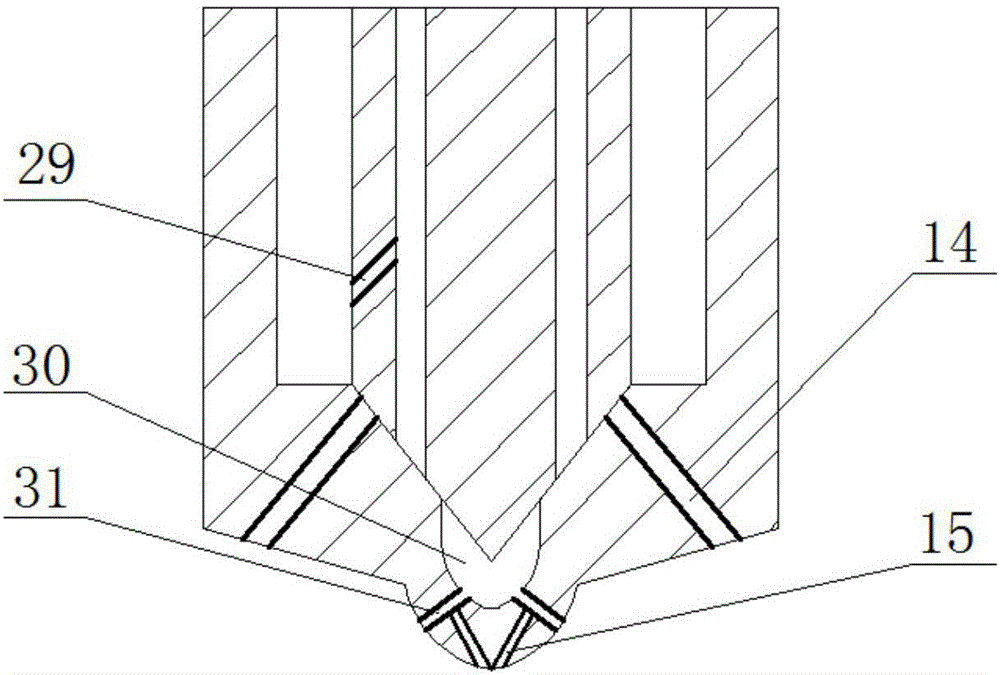

[0034] Such as figure 1 As shown, the novel anti-cavitation dual-fuel injector of the present invention includes an injector body 7 and an electromagnetic control device 5, and the injector body 7 includes a needle valve 24 arranged in the axial piston cavity of the injector body 7, The second return spring 12 sleeved on the needle valve 24 , the first fuel guide 6 and the second fuel guide 19 arranged at both ends of the tail of the injector body 7 . The needle valve 24 and the injector body 7 form a pair, the upper and lower ends of the second return spring 12 are respectively close to the protruding end of the needle valve 24 and the injector body 7, and the middle and lower parts of the needle valve 24 A second high-pressure fuel chamber 13 is provided on the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com