A high-seal centrifugal sand pump and its working method for reducing water erosion

A technology of high sealing and sand pumps, which is applied to pumps for special fluids, parts of pumping devices for elastic fluids, pumps, etc., and can solve problems affecting the service life of equipment, equipment damage and destruction, and wear of centrifugal sand pumps , to achieve high practical life, reduce water erosion, and solve the effect of cavitation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

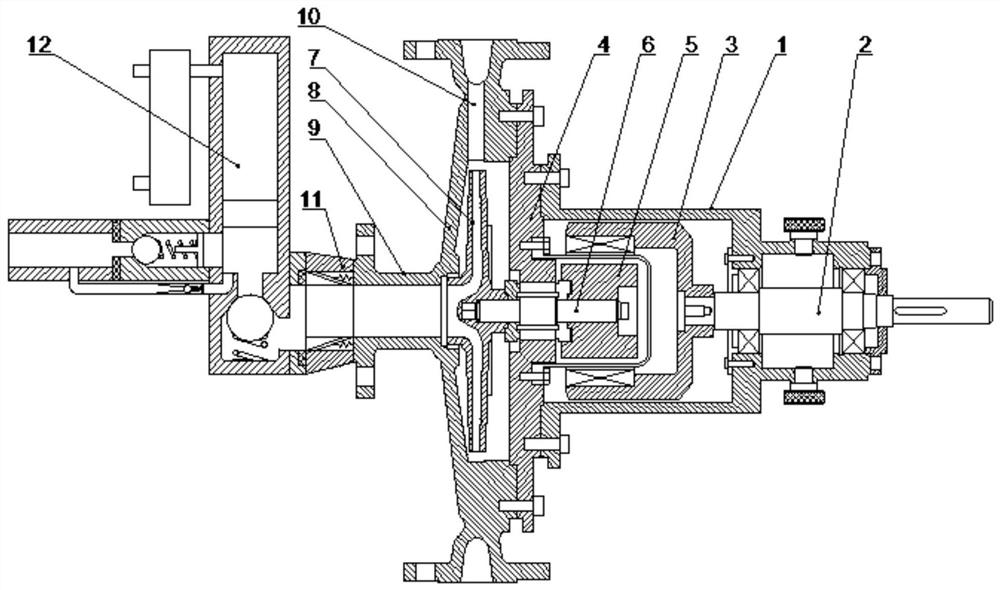

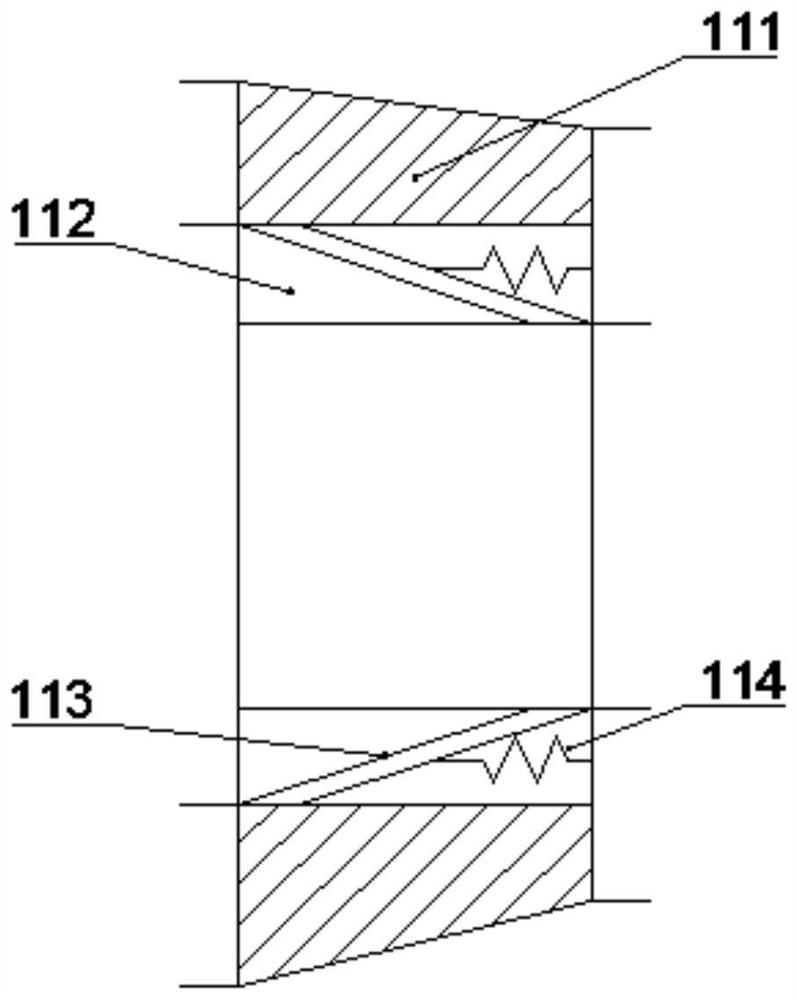

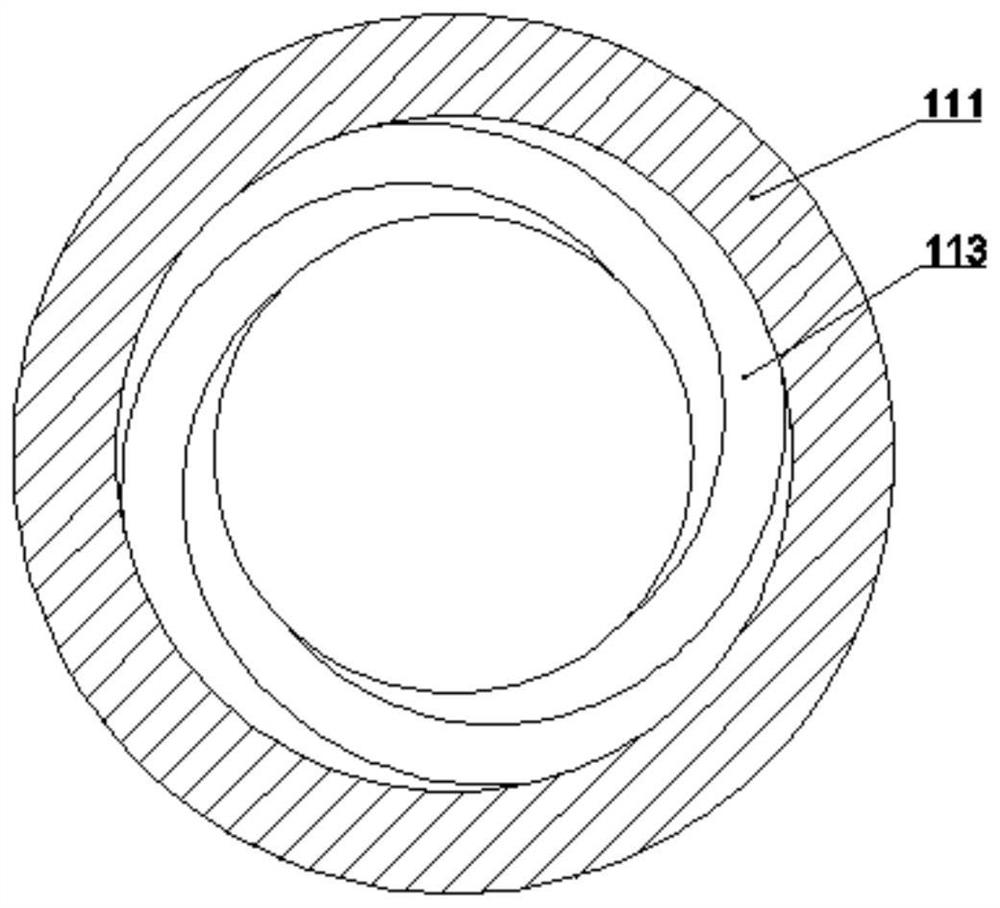

[0031] like Figure 1-5 The high-seal centrifugal sand pump shown to reduce water erosion includes: pump casing 1, motor shaft 2, outer magnetic rotor 3, spacer sleeve 4, inner magnetic rotor 5, transmission shaft 6, impeller 7, end cover 8, inlet The material port 9, the material outlet 10 and the slow flow mechanism 11, the pump casing 1 is pierced with a motor shaft 2, and one end of the motor shaft 2 located in the pump casing 1 is fixedly provided with an external magnetic rotor 3, and the external magnetic A spacer 4 is arranged inside the rotor 3, and the spacer 4 is fixedly arranged on the inner surface of the pump casing 1. An inner magnetic rotor 5 is arranged inside the spacer 4, and a transmission shaft 6 is fixedly arranged at one end of the inner magnetic rotor 5. The transmission shaft 6 is arranged on the spacer sleeve 4 through a bearing, and the end of the transmission shaft 6 away from the inner magnetic rotor 5 is fixedly provided with an impeller 7, and th...

Embodiment 2

[0042] like Figure 1-3 The high-seal centrifugal sand pump shown to reduce water erosion includes: pump casing 1, motor shaft 2, outer magnetic rotor 3, spacer sleeve 4, inner magnetic rotor 5, transmission shaft 6, impeller 7, end cover 8, inlet The material port 9, the material outlet 10 and the slow flow mechanism 11, the pump casing 1 is pierced with a motor shaft 2, and one end of the motor shaft 2 located in the pump casing 1 is fixedly provided with an external magnetic rotor 3, and the external magnetic A spacer 4 is arranged inside the rotor 3, and the spacer 4 is fixedly arranged on the inner surface of the pump casing 1. An inner magnetic rotor 5 is arranged inside the spacer 4, and a transmission shaft 6 is fixedly arranged at one end of the inner magnetic rotor 5. The transmission shaft 6 is arranged on the spacer sleeve 4 through a bearing, and the end of the transmission shaft 6 away from the inner magnetic rotor 5 is fixedly provided with an impeller 7, and the ...

Embodiment 3

[0045] like figure 1 and 4 The high-seal centrifugal sand pump shown to reduce water erosion includes: pump casing 1, motor shaft 2, outer magnetic rotor 3, spacer sleeve 4, inner magnetic rotor 5, transmission shaft 6, impeller 7, end cover 8, inlet The material port 9, the material outlet 10 and the slow flow mechanism 11, the pump casing 1 is pierced with a motor shaft 2, and one end of the motor shaft 2 located in the pump casing 1 is fixedly provided with an external magnetic rotor 3, and the external magnetic A spacer 4 is arranged inside the rotor 3, and the spacer 4 is fixedly arranged on the inner surface of the pump casing 1. An inner magnetic rotor 5 is arranged inside the spacer 4, and a transmission shaft 6 is fixedly arranged at one end of the inner magnetic rotor 5. The transmission shaft 6 is arranged on the spacer sleeve 4 through a bearing, and the end of the transmission shaft 6 away from the inner magnetic rotor 5 is fixedly provided with an impeller 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com