Steam-free passing water cooler

A water-through cooler and steam condenser technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve problems such as increased air humidity, potential safety hazards, waste of energy and water resources, etc., to ensure personal safety, Effects of improving working conditions and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

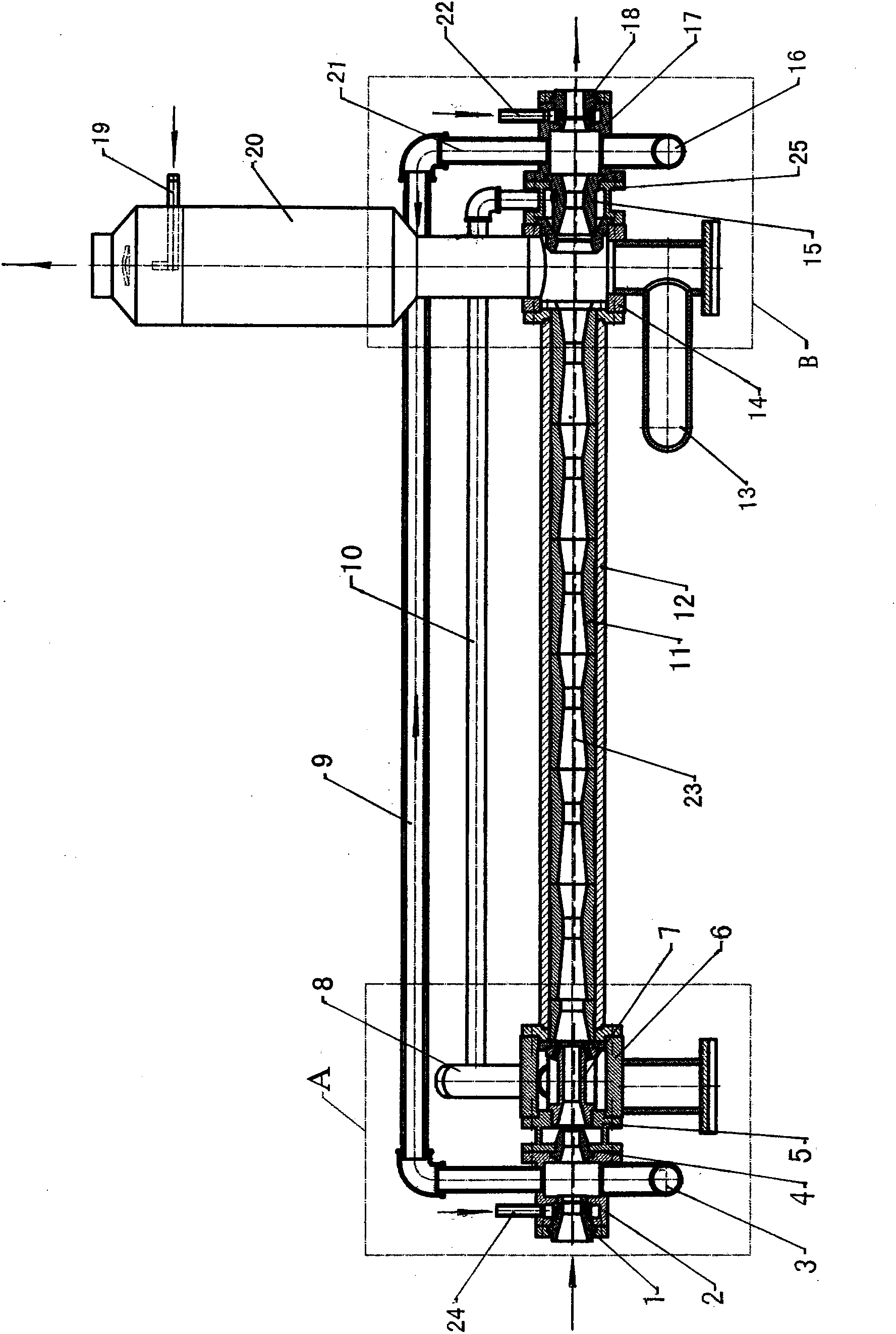

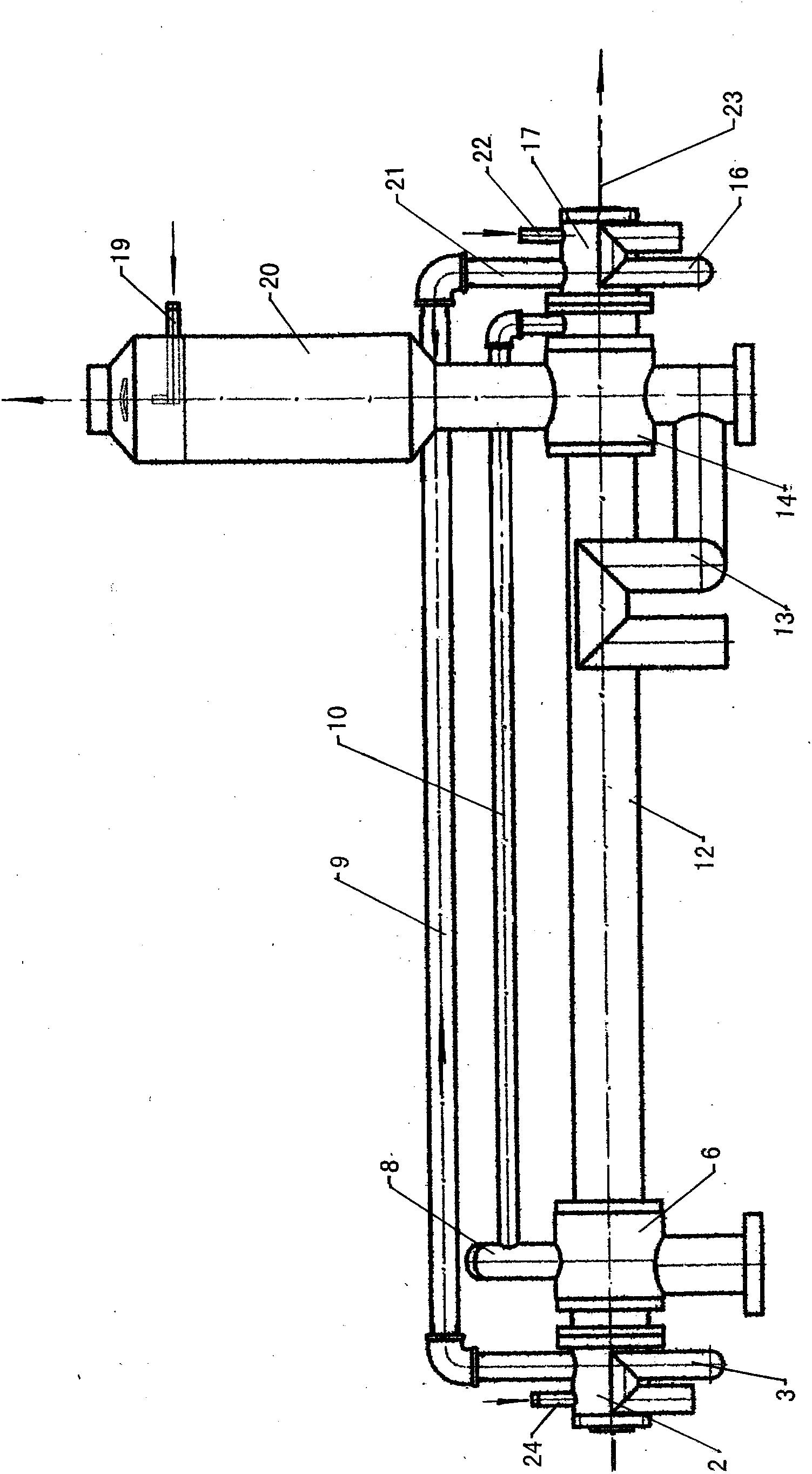

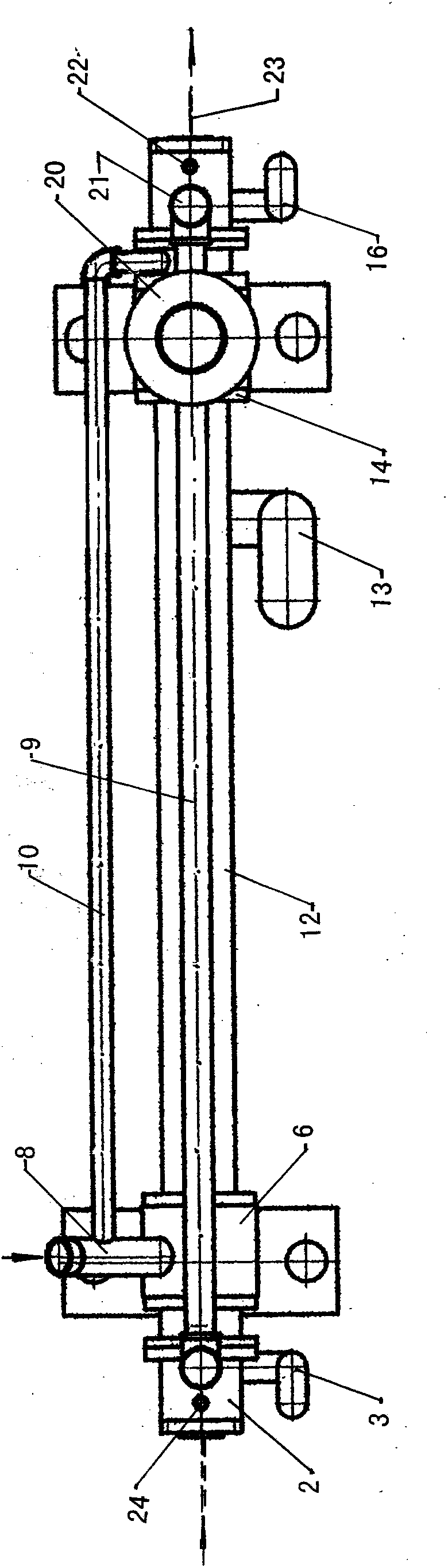

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] As shown in the accompanying drawings, the non-steam water-penetrating cooler includes a forward air slit nozzle 1 and a reverse air slit nozzle 18, a front steam / water separation box 2 and a rear steam / water separation box 17, an inlet End drain elbow 3 and outlet end drain elbow 16, transition duct 4, return water balance box 5, nozzle box 6, left end cover plate 6a, cooling water nozzle 7, cooling water inlet pipe 8, front air / steam delivery pipe 9 And rear air / steam conveying pipe 21, counterattack water pipe 10, venturi tube 11, outer casing 12, main drainage pipe 13, main steam / water separation box 14, right end cover plate 4a, counterattack water annular seam nozzle 15, cooling water spray Pipe 19, steam condenser 20, front compressed air inlet pipe 24 and rear compressed air inlet pipe 22 and counterattack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com