Nozzle capable of achieving dual fuel injection

A dual-fuel, fuel technology, applied in the direction of fuel injection device, charging system, engine components, etc., can solve problems such as reducing engine power performance, affecting engine charge coefficient, etc., achieving easy implementation, solving the problem of in-cylinder direct injection, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific embodiment:

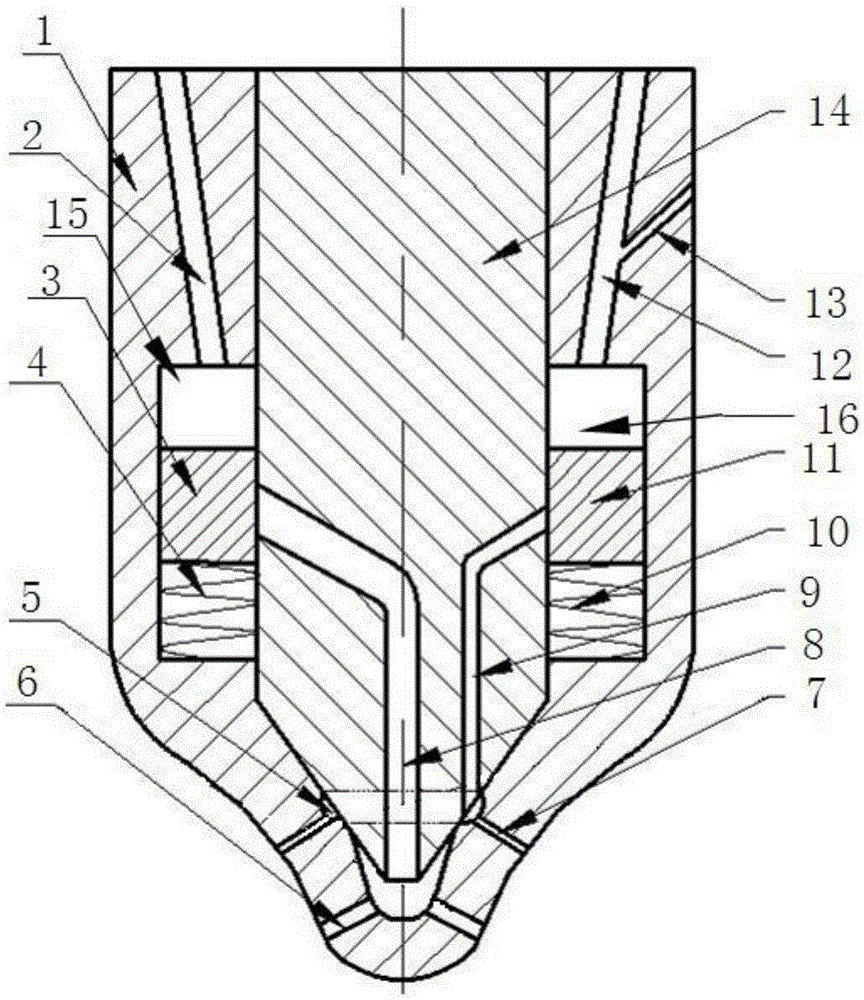

[0016] Such as figure 1 As shown, a nozzle for dual fuel injection includes a valve body 1 and a fixed needle valve 14, the fixed needle valve 14 is fixedly arranged in the valve body 1, and the valve body 1 is provided with a first fuel 1 passage 2, Fuel 2 first passage 12, first arc chute, second arc chute, annular oil groove 5, fuel 1 injection hole 6 and fuel 2 injection hole 7, said fuel 1 first passage 2 and first arc chute The chute is connected, the first arc chute and the fixed needle valve 14 form the first arc cavity 15, and the first arc cavity 15 is provided with an interference fit with the first arc cavity 15 and can The movable first arc-shaped slider 3 is provided with a first elastic member 4 between the side of the first arc-shaped slider 3 away from the first channel 2 of the fuel 1 and the first arc-shaped cavity 15; A channel 12 communicates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com