Rotary injection pump

A technology of rotating jet pump and pump body, applied in the direction of pump, pump element, non-variable-capacity pump, etc., can solve the problems of prone to cavitation, anti-overflow capability and poor hydraulic efficiency of impeller, so as to improve the overflow capability. , the effect of increasing the flow capacity and reducing the hydraulic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

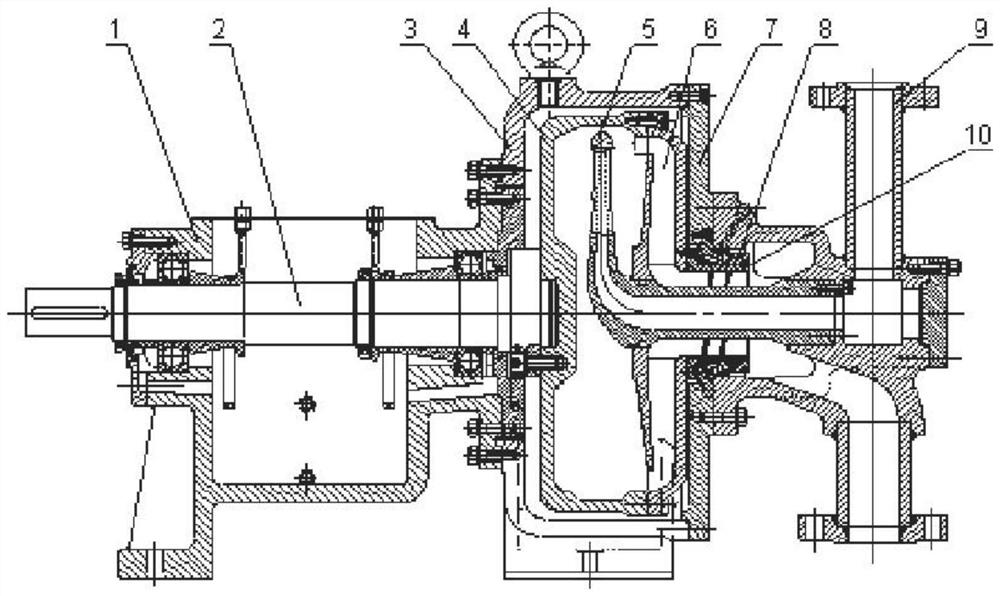

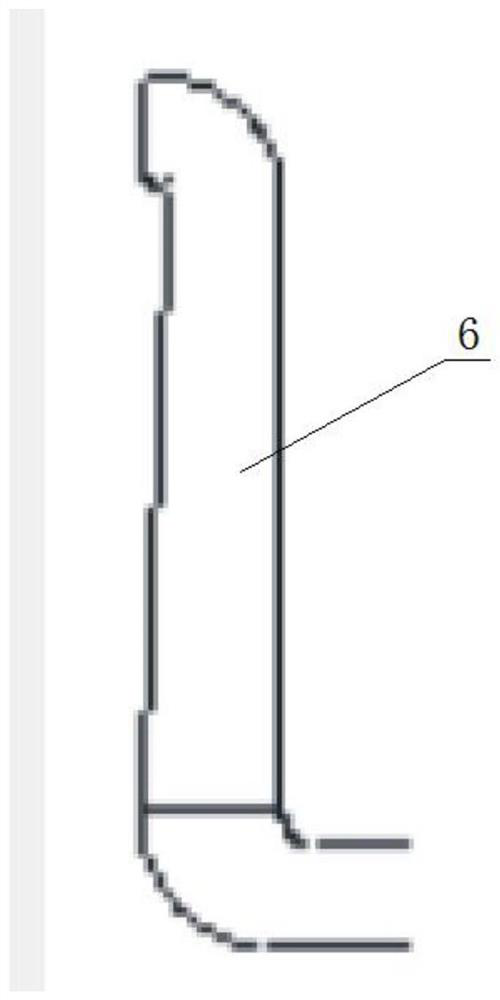

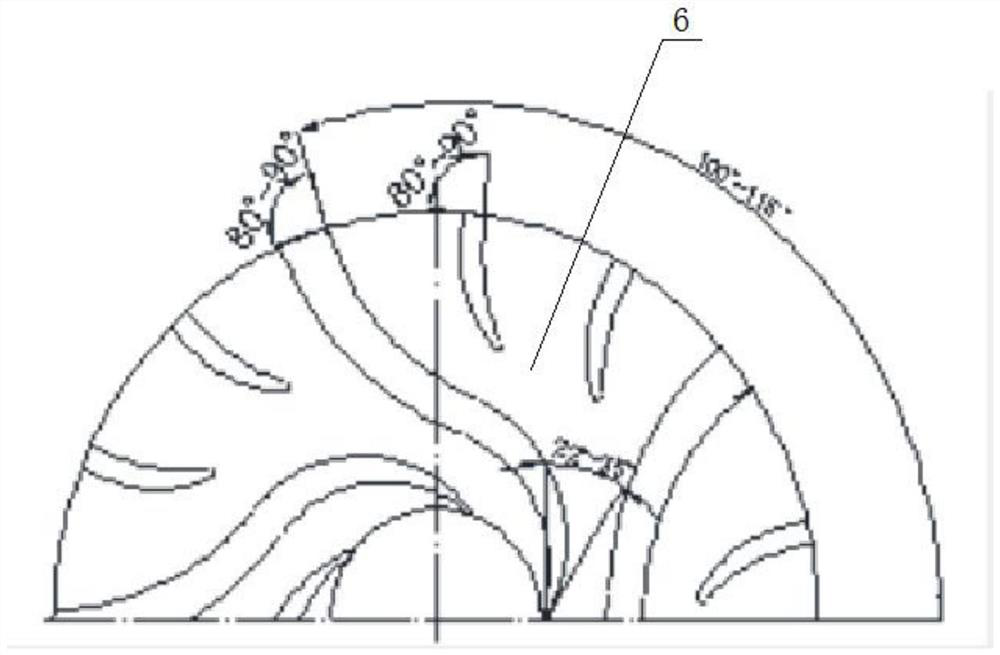

[0022] like Figure 1-3 As shown, a rotary jet pump includes a bearing housing 1, a main shaft 2 and a rotor chamber 4. A pump body 3 is installed behind the bearing housing 1, and a main shaft 2 runs through the middle of the inner side. The main shaft 2 is rotationally connected with the bearing housing 1 through a bearing group. One end of the main shaft is connected to the motor by a coupling, and the other end is connected to the rotor cavity 4 by a flange. The pump body 3 and the bearing box 1 are connected by bolts and precisely positioned by the seam to form a whole. Its feet are connected to the bearing box 1 The feet are adjusted to ensure the installation level of the pump. The rotor chamber 4 is arranged in the inner middle part of the pump body 3 and is fixedly connected with the main shaft 2. Its outer diameter is smaller than the inner diameter of the pump body 3, and the inner middle part of the rotor chamber 4 is equipped with a collecting pipe 5, and the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com