Method for preparing direct-current zinc oxide resistance card

A technology of zinc oxide resistors and zinc oxide, which is applied in the field of overvoltage protection resistors or lightning arresters, can solve the problems of grain boundary coarsening, increased leakage current, and affecting the aging resistance of zinc oxide resistors, so as to achieve the purpose of suppressing volatilization, Low cost and suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

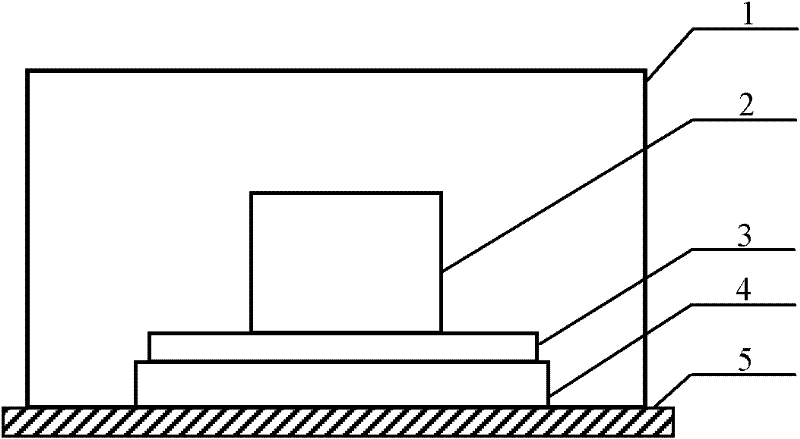

Image

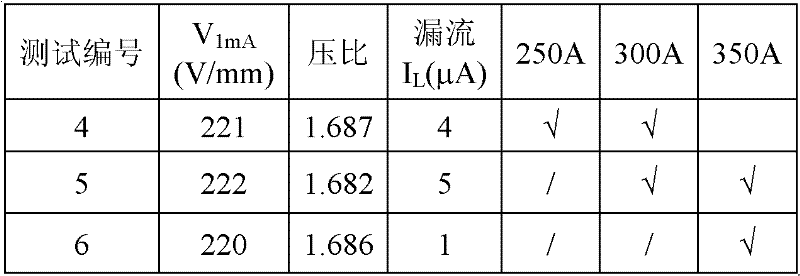

Examples

Embodiment 1

[0027] In this embodiment, the main material is zinc oxide, and the content of each added element is calculated according to the mass percentage of its oxide, respectively Bi 2 o 3 : 5.1%; Sb 2 o 3 : 3.8%; CoO: 1.15%; MnO: 0.7%; Ni 2 o 3 : 0.75%; Al 2 o 3 : 0.03%; B 2 o 3 : 0.008%; Ag 2 O: 0.015%; the balance is ZnO.

[0028] Among them, aluminum nitrate is used for aluminum oxide, silver oxide and boron oxide are added in the form of glass powder, and oxides are used for the rest of the components.

[0029] The specific preparation method is as follows:

[0030] (1) Calcination of additives: Weigh other additives except zinc oxide and aluminum nitrate in proportion, add a certain amount of deionized water, use high-energy sand mill to finely grind, mix for 5 hours and then dry, the dried powder The material is calcined at 800°C for 1 hour, and then finely ground by a high-energy ball mill, and the particle size is controlled below 2 μm;

Embodiment 2

[0055] In this embodiment, the main material is zinc oxide, and the content of each added element is calculated according to the mass percentage of its oxide, respectively Bi 2 o 3 : 4.4%; Sb 2 o 3 : 3.6%; CoO: 0.96%; MnO: 0.55%; Ni 2 o 3 : 0.35%; SnO 2 : 0.8%; Al 2 o 3 : 0.005%; B 2 o 3 : 0.01%; Ag 2 O: 0.006%,; the balance is zinc oxide.

[0056] Among them, aluminum nitrate is used for aluminum oxide, silver oxide and boron oxide are added in the form of glass powder, and oxides are used for the rest of the components.

[0057] The specific preparation method is as follows:

[0058] (1) Calcination of additives: Weigh other additives except zinc oxide and aluminum nitrate in proportion, add a certain amount of deionized water, use high-energy sand mill to finely grind, mix for 3 hours and then dry, the dried powder The material is calcined at 950°C for 2 hours, and then finely ground by a high-energy ball mill, and the particle size is controlled below 2 μm;

...

Embodiment 3

[0076] In this embodiment, the main material is zinc oxide, and the content of each added element is calculated according to the mass percentage of its oxide, respectively Bi 2 o 3 : 3.5%; Sb 2 o 3 : 2.8%; CoO: 1.0%; MnO: 0.5%; Ni 2 o 3 : 0.45%; Y 2 o 3 : 0.65%; Al 2 o 3 : 0.01%; B 2 o 3 : 0.015%; Ag 2 O: 0.004%; the balance is 4.4% of zinc oxide.

[0077] Among them, aluminum nitrate is used for aluminum oxide, silver oxide and boron oxide are added in the form of glass powder, and oxides are used for the rest of the components.

[0078] The specific preparation method is as follows:

[0079] (1) Calcination of additives: Weigh other additives except zinc oxide and aluminum nitrate in proportion, add a certain amount of deionized water, use high-energy sand mill to finely grind, mix for 4 hours and then dry, the dried powder The material is calcined at 850°C for 3 hours, and then finely ground with a high-energy ball mill, and the particle size is controlled belo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com