Middle high pressure directly-acting hydraulic overflow valve

A direct-acting, relief valve technology, applied in the field of pressure control valves, can solve problems such as vibration, noise, working stability, inability to use seawater, and easy polarization of the valve core.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

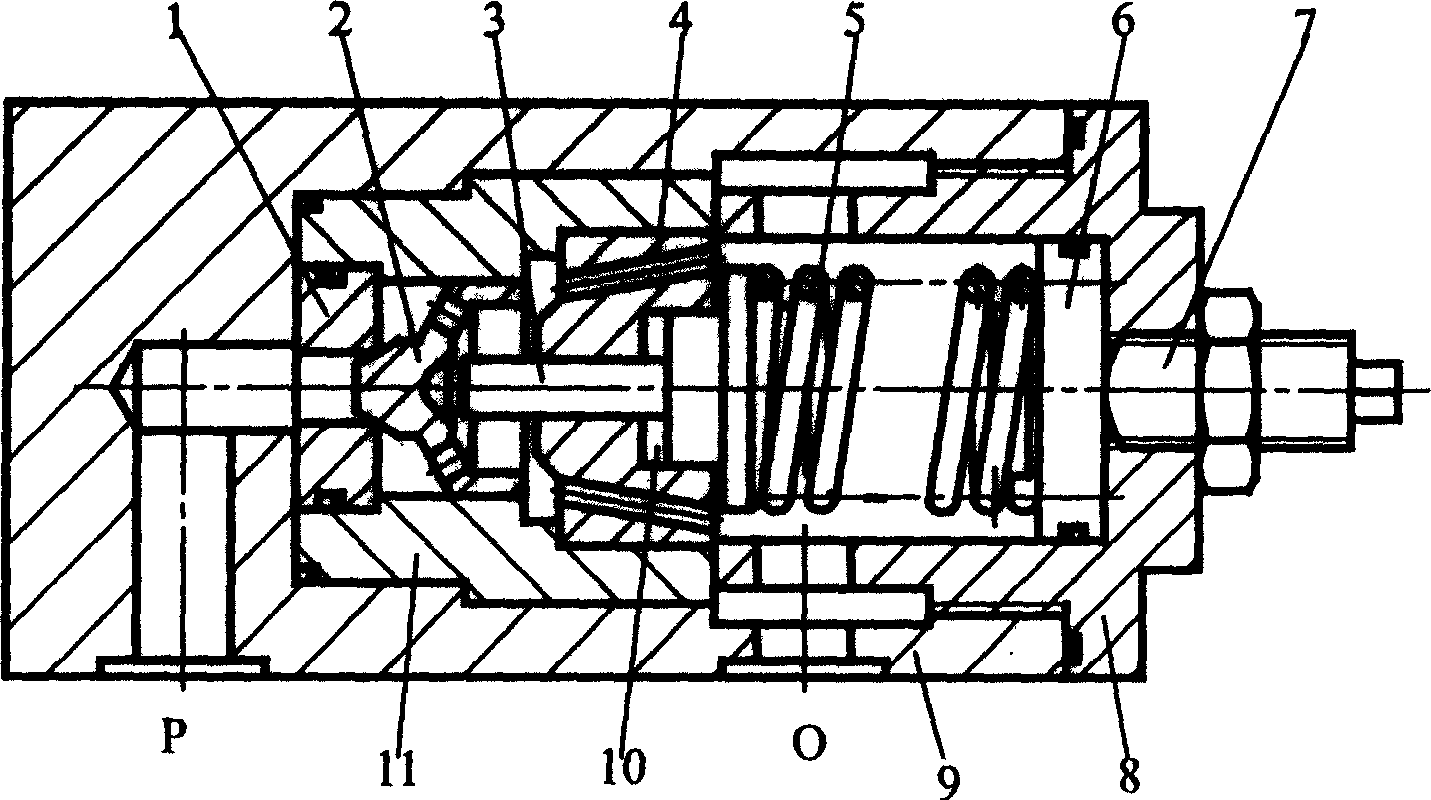

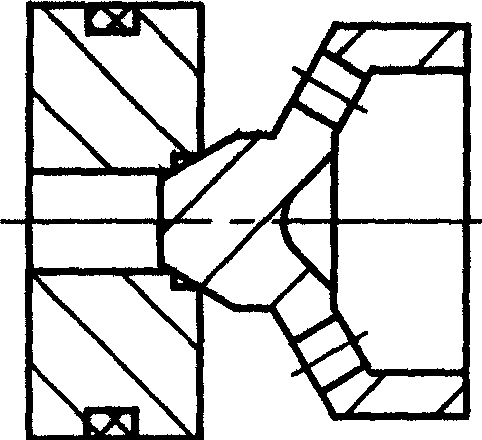

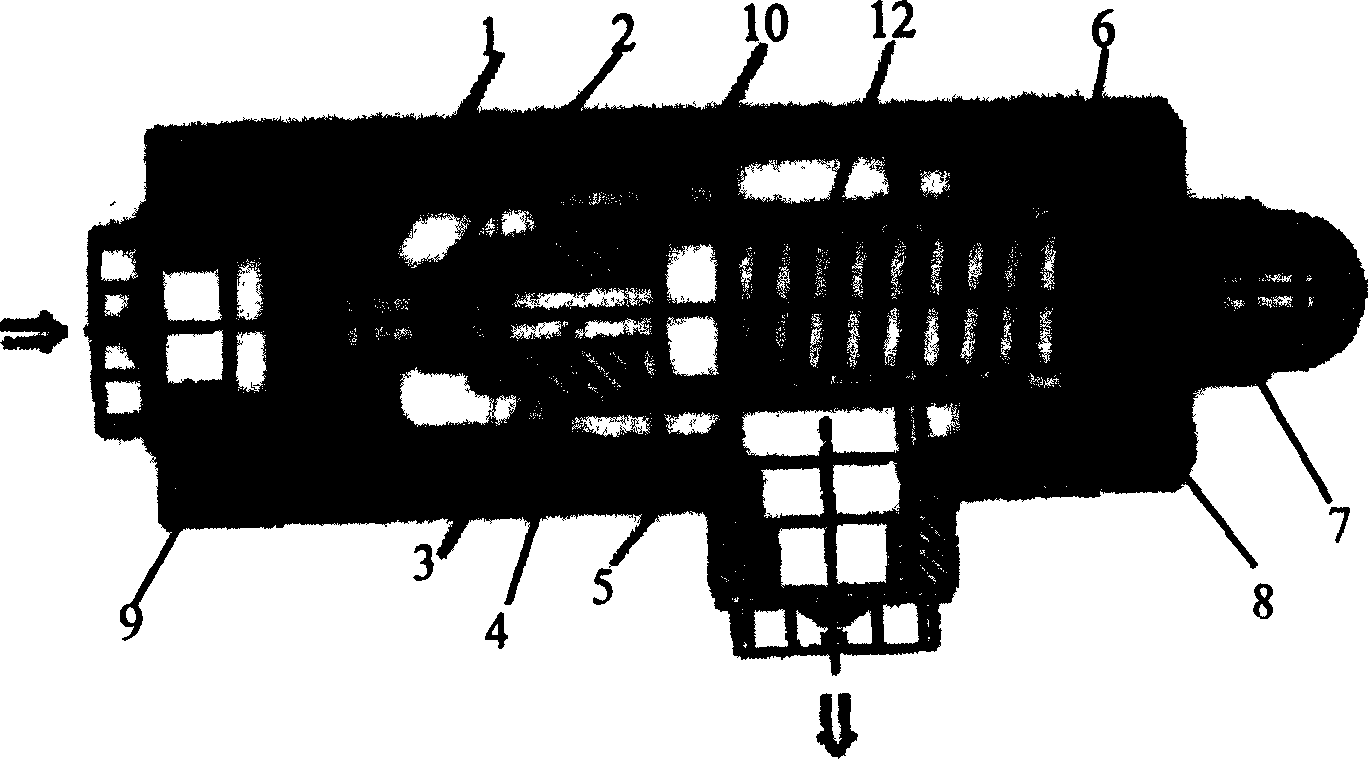

[0017] like figure 1 As shown, an embodiment of the present invention includes: valve seat 1, valve core 2, damping rod 3, damping sleeve 4, pressure regulating spring 5, spring seat 6, adjusting screw rod 7, end cover 8, valve body 9, valve sleeve 11 etc. The spool is a cone valve structure. The tail end of the valve core is provided with a guiding cylindrical surface, which forms a matching gap with the inner hole of the valve body to provide guidance for the movement of the valve core. A damping rod is arranged at the rear end of the spool, and a matching gap is formed between the large and small cylindrical surfaces on the damping rod and the corresponding inner holes of the damping sleeve, and the cavity between the two matching gaps forms a damping chamber 10 . The contact part on the damping rod and the valve core is a spherical structure. When assembling, the valve seat 1 is pressed on the left end surface of the inner hole of the valve body 9 through the valve sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com