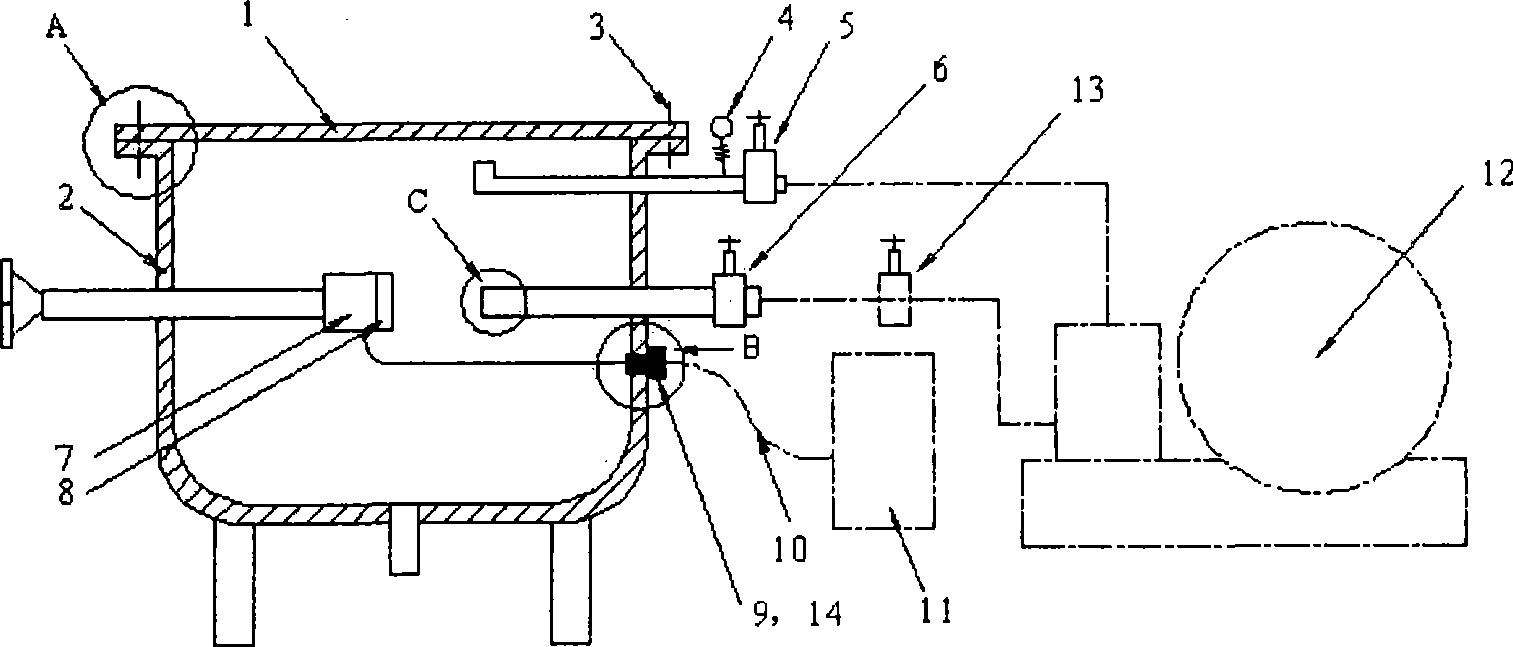

Multifunctional base injection type cavitation corrosion test device

A cavitation test and jetting technology, applied in the direction of testing wear resistance, can solve the problems of fixed sample, quantitative measurement of cavitation degree, complicated operation, etc., to achieve reliable structure principle, flexible work and use, and experimental effect. precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

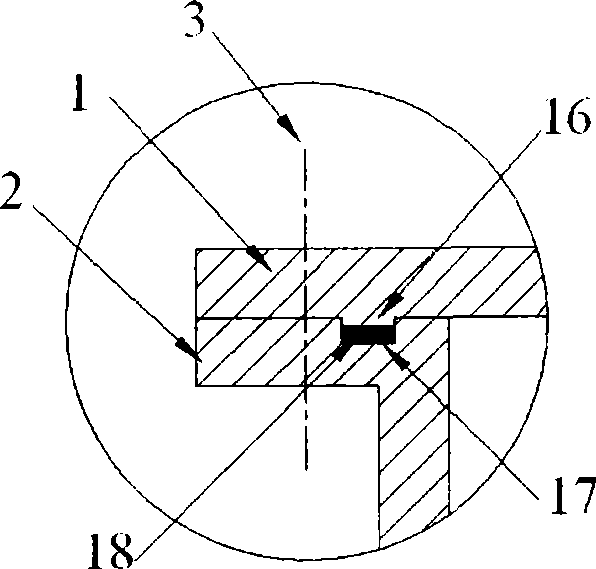

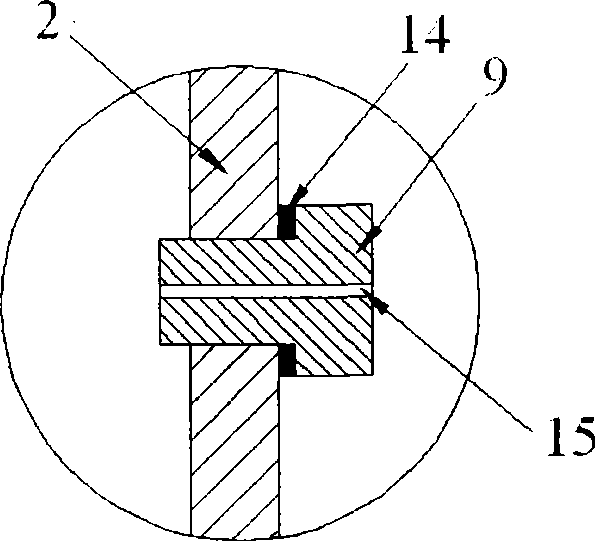

Method used

Image

Examples

Embodiment

[0018] Using the test device prepared by the above-mentioned embodiment, adopting the best test factors to test different test materials, it is determined that the test device can obtain the same test results as the actual working conditions for the material, and its test parameters are as follows:

[0019] Scouring coefficient: 0.03 (working pressure 10MPa, confining pressure 0.3MPa);

[0020] Erosion distance: 15mm;

[0021] Test time: 4 hours;

[0022] Water temperature: 20℃±5℃;

[0023] Test materials: ZQAl 12-8-3-2, ZCCu3.

[0024] In this example, the above-mentioned materials are tested according to the standard test method, and the samples are subjected to post-test treatment according to the requirements, and the corrosion morphology is observed, and the corrosion resistance of the materials is evaluated as follows:

[0025]

[0026] The accuracy of the test device in this embodiment is verified by observing the corrosion morphology and calculating the test weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com