Patents

Literature

84results about How to "Avoid cavitation damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

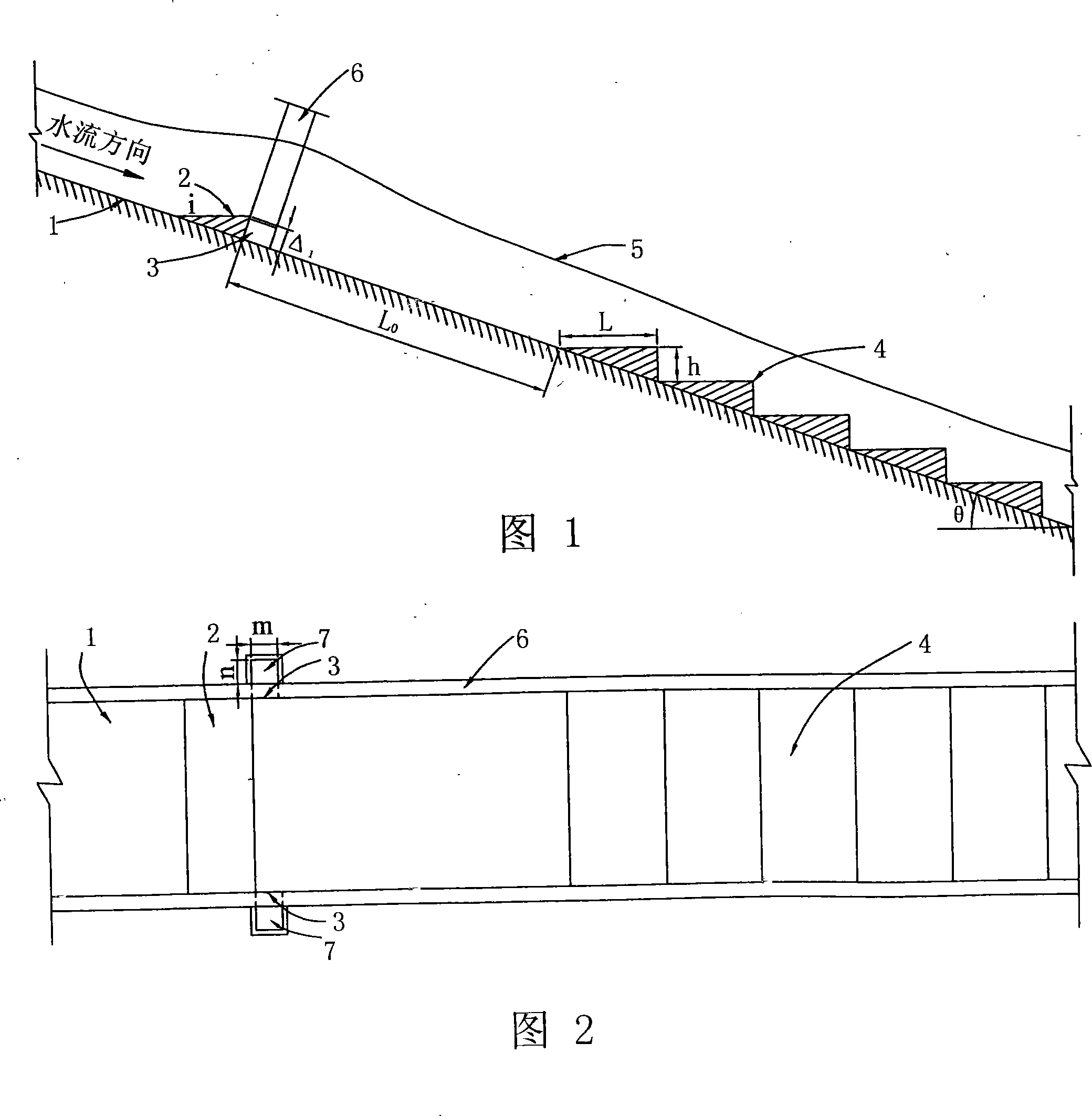

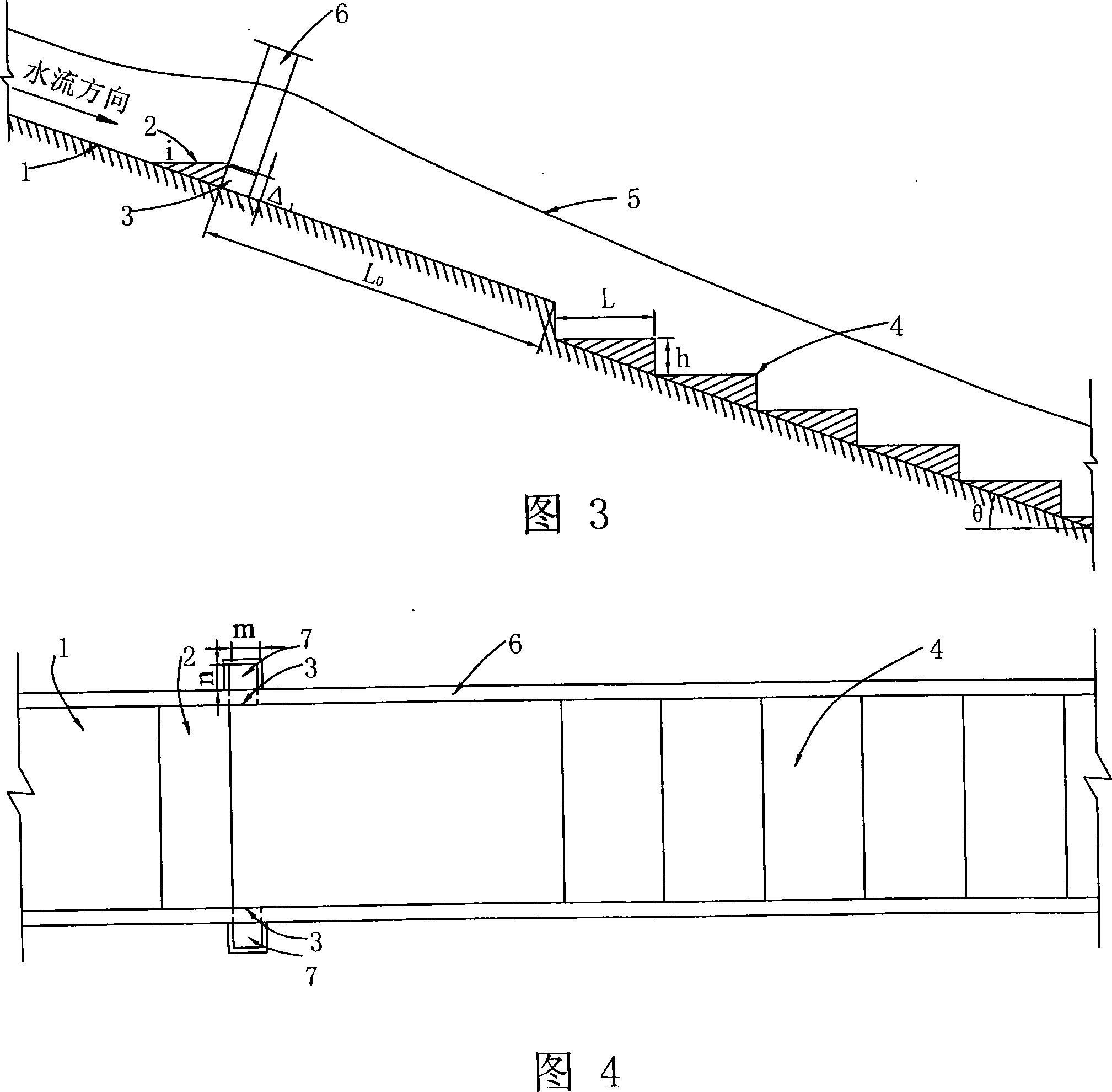

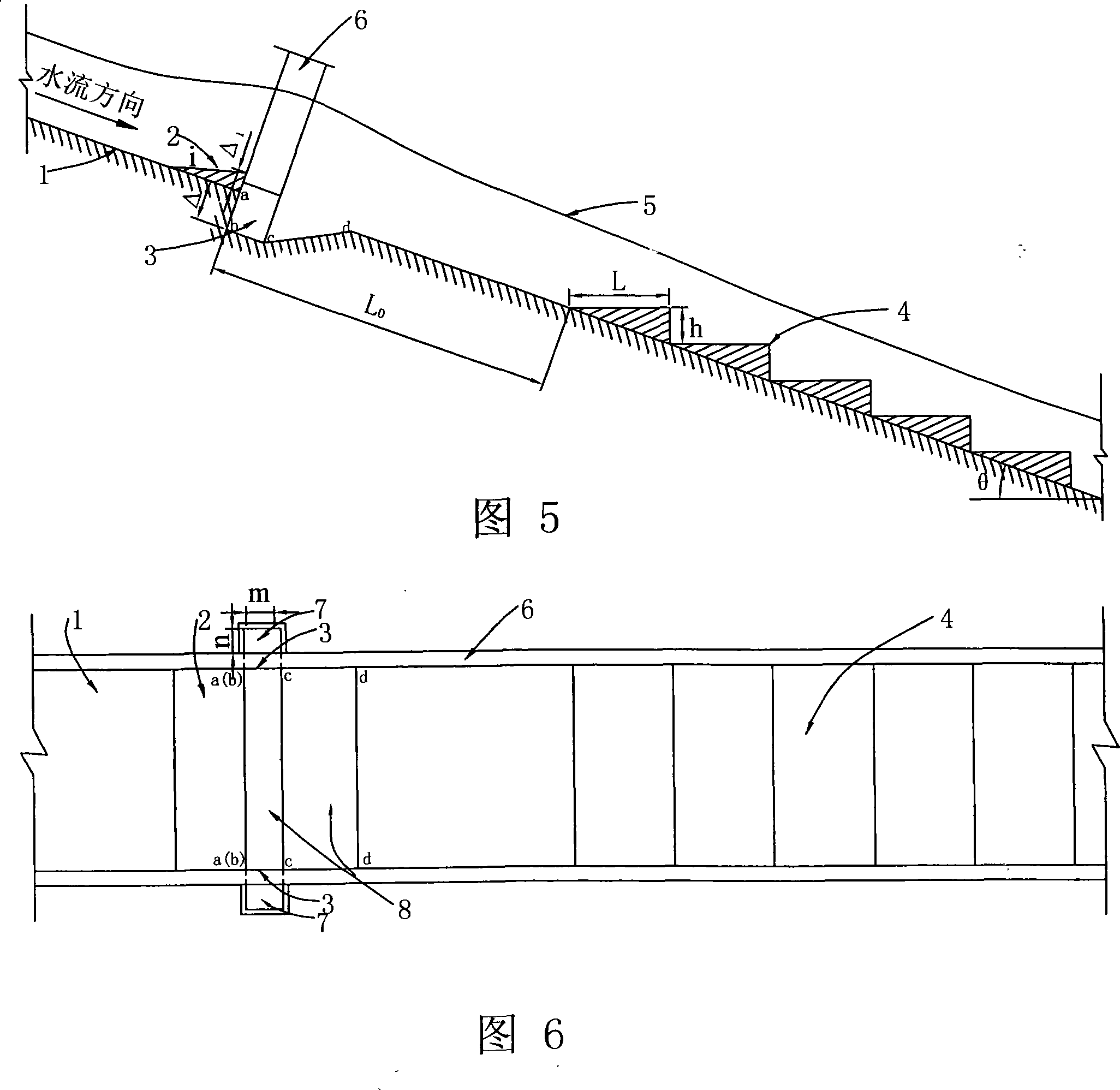

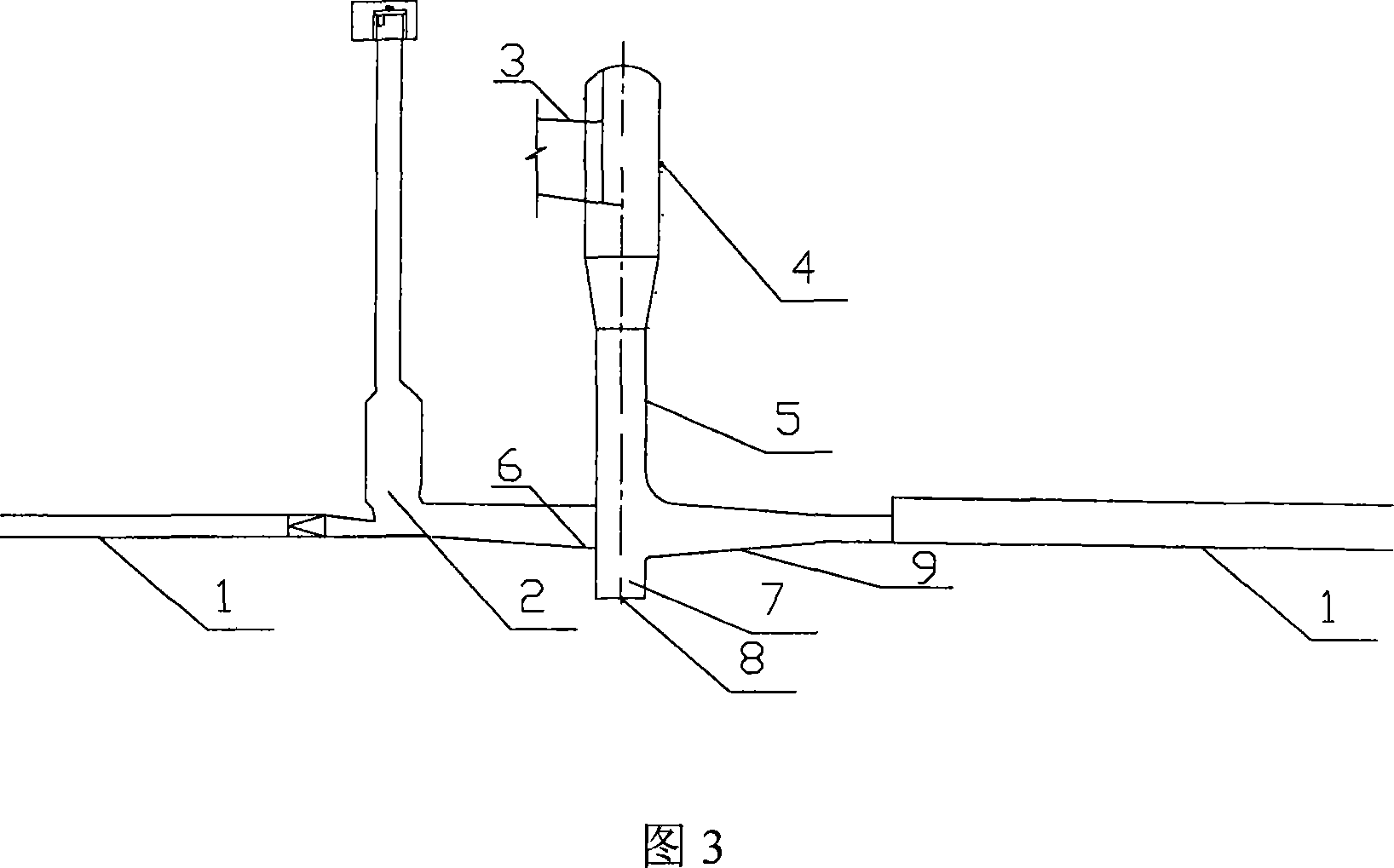

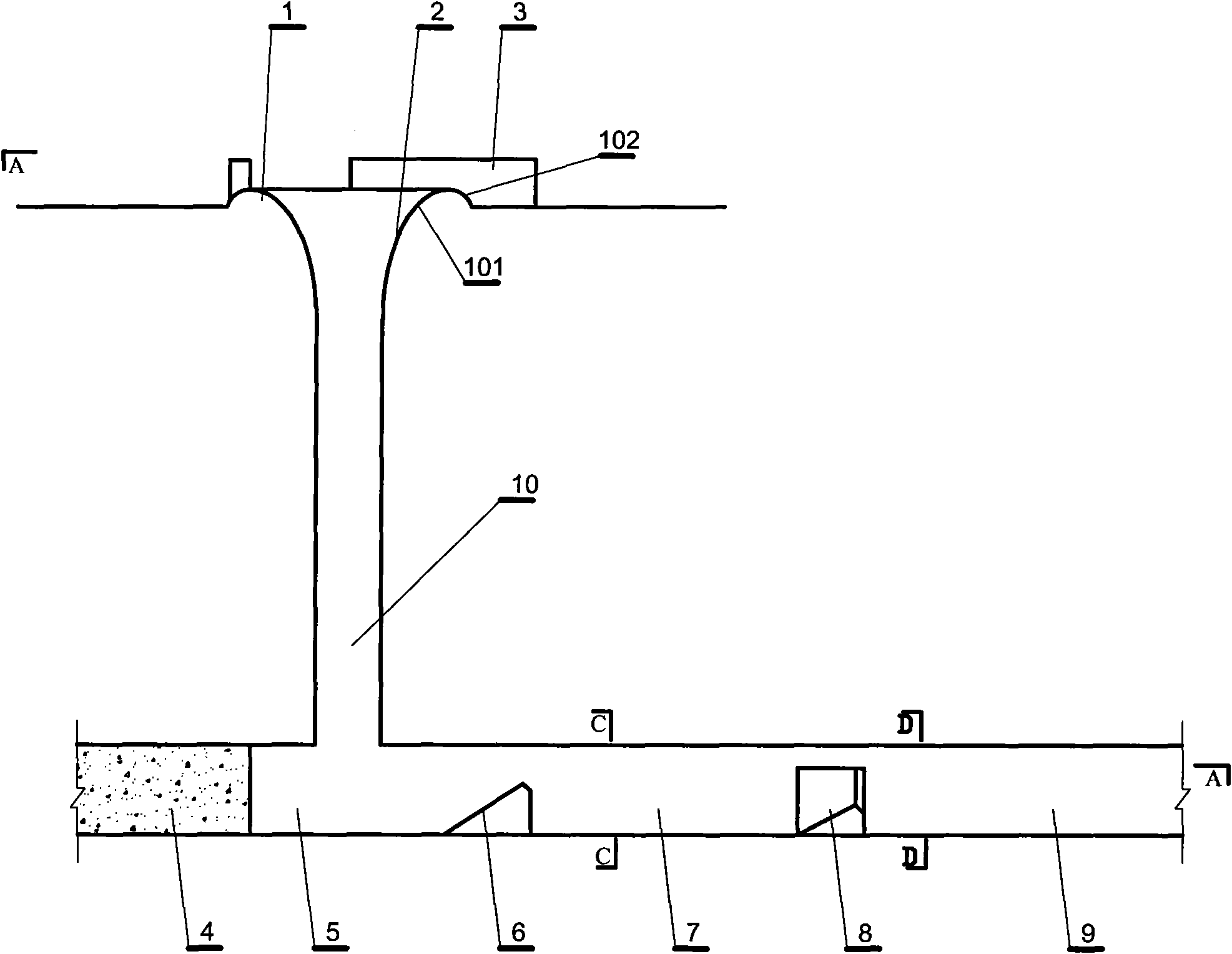

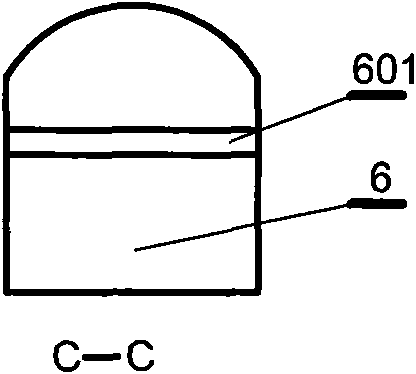

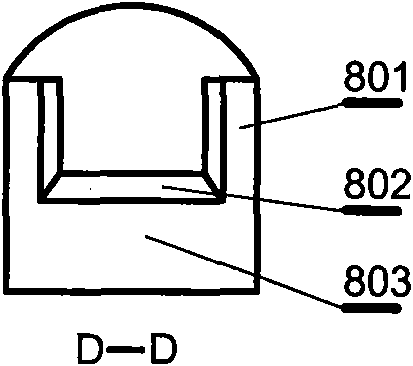

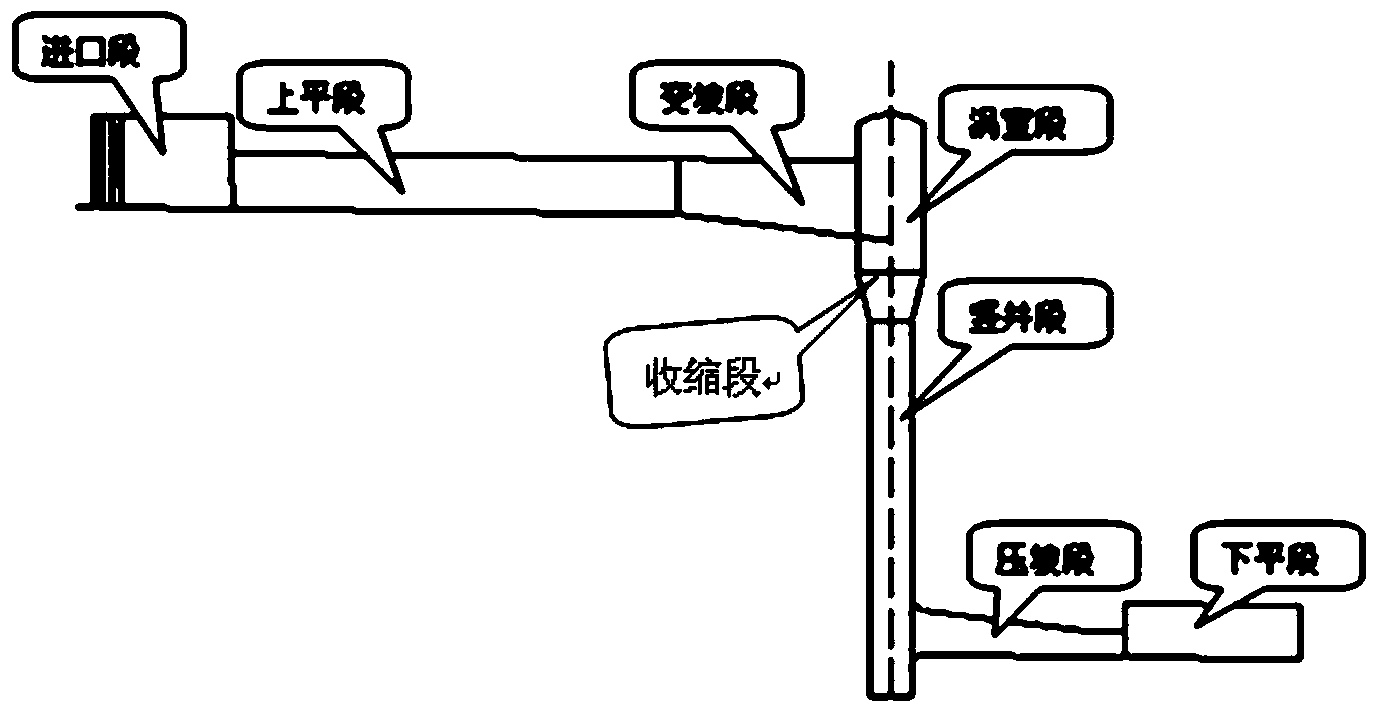

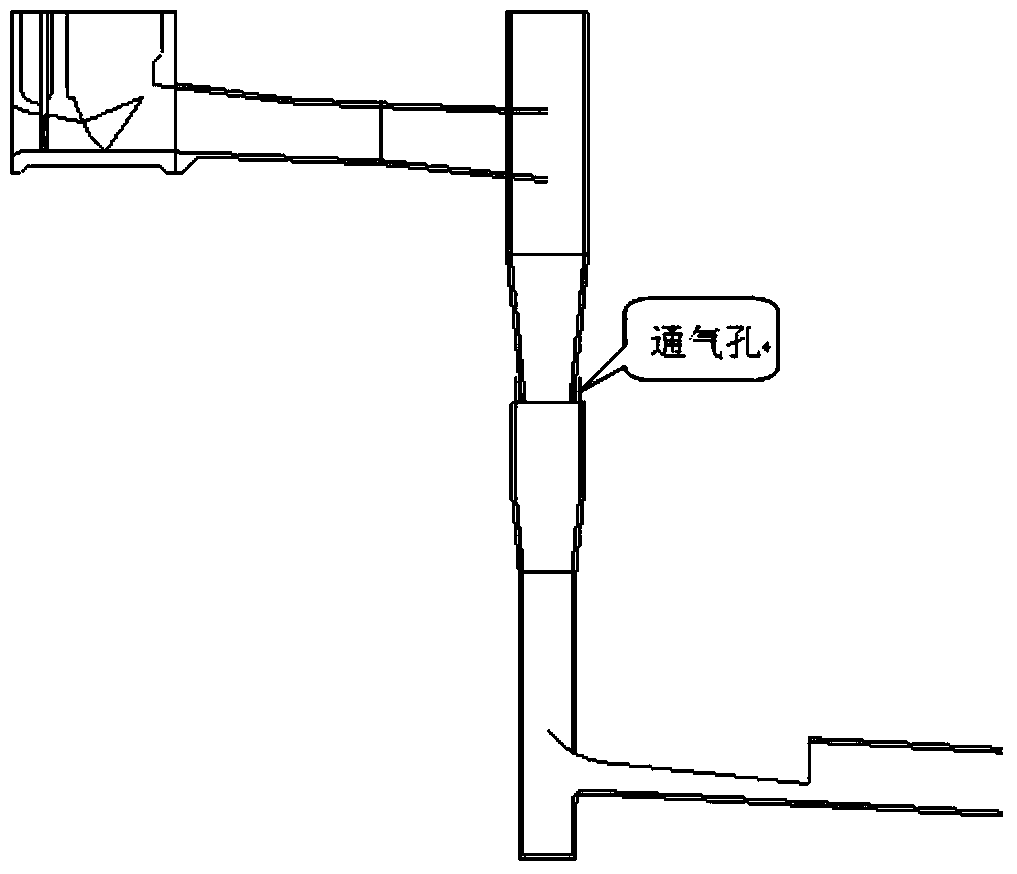

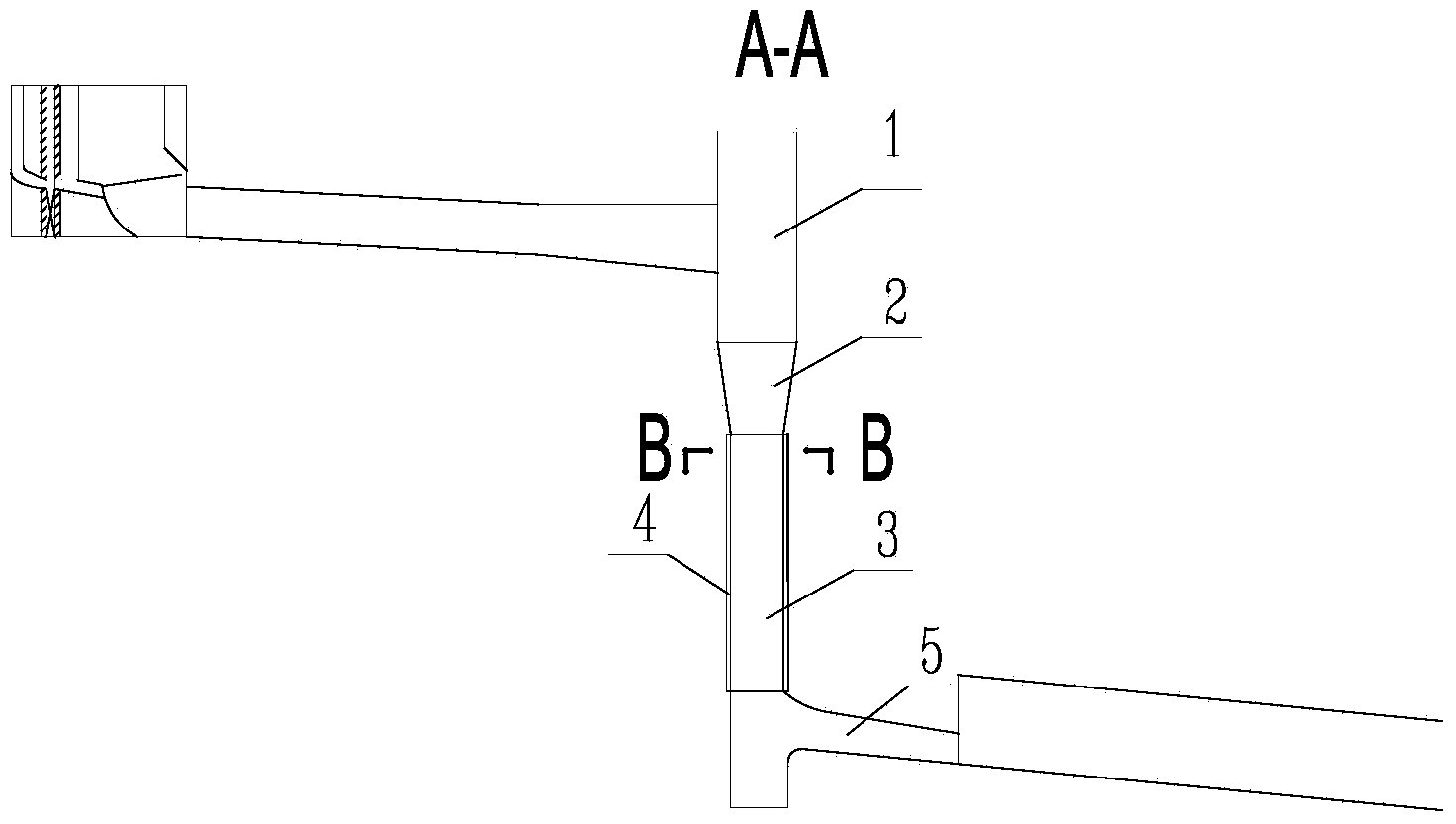

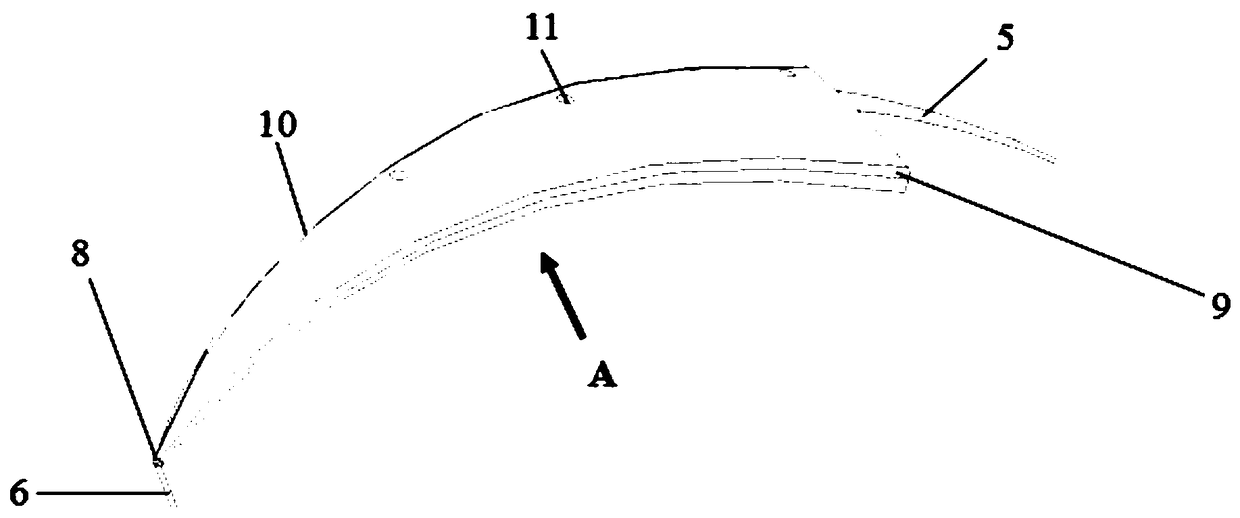

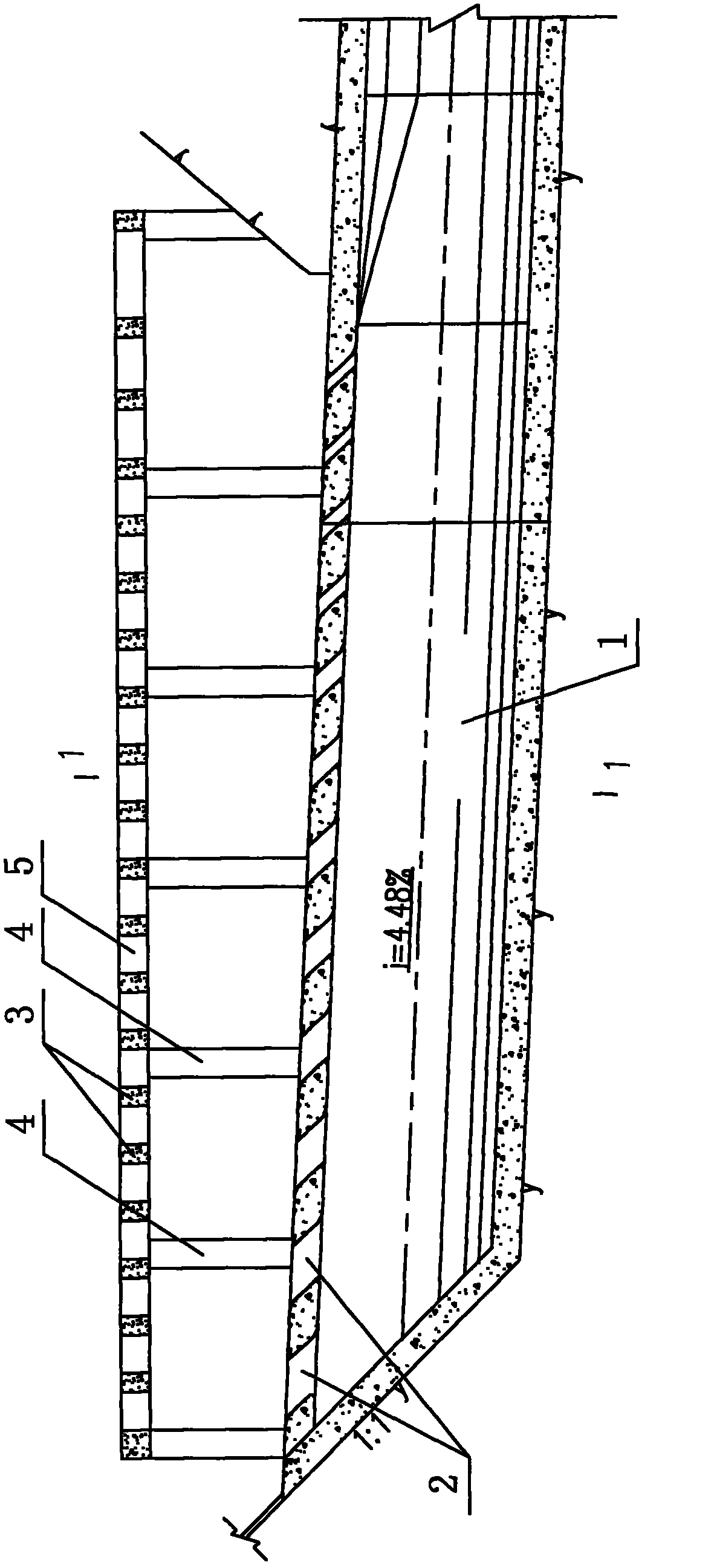

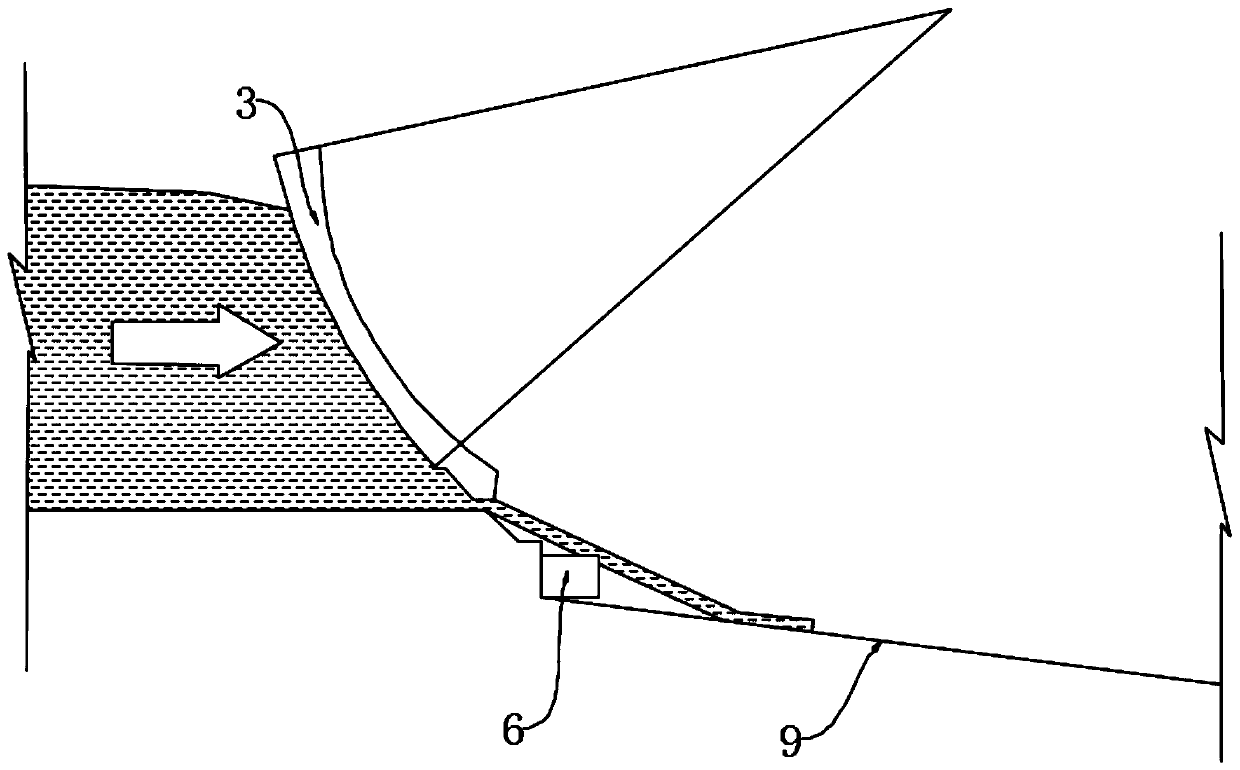

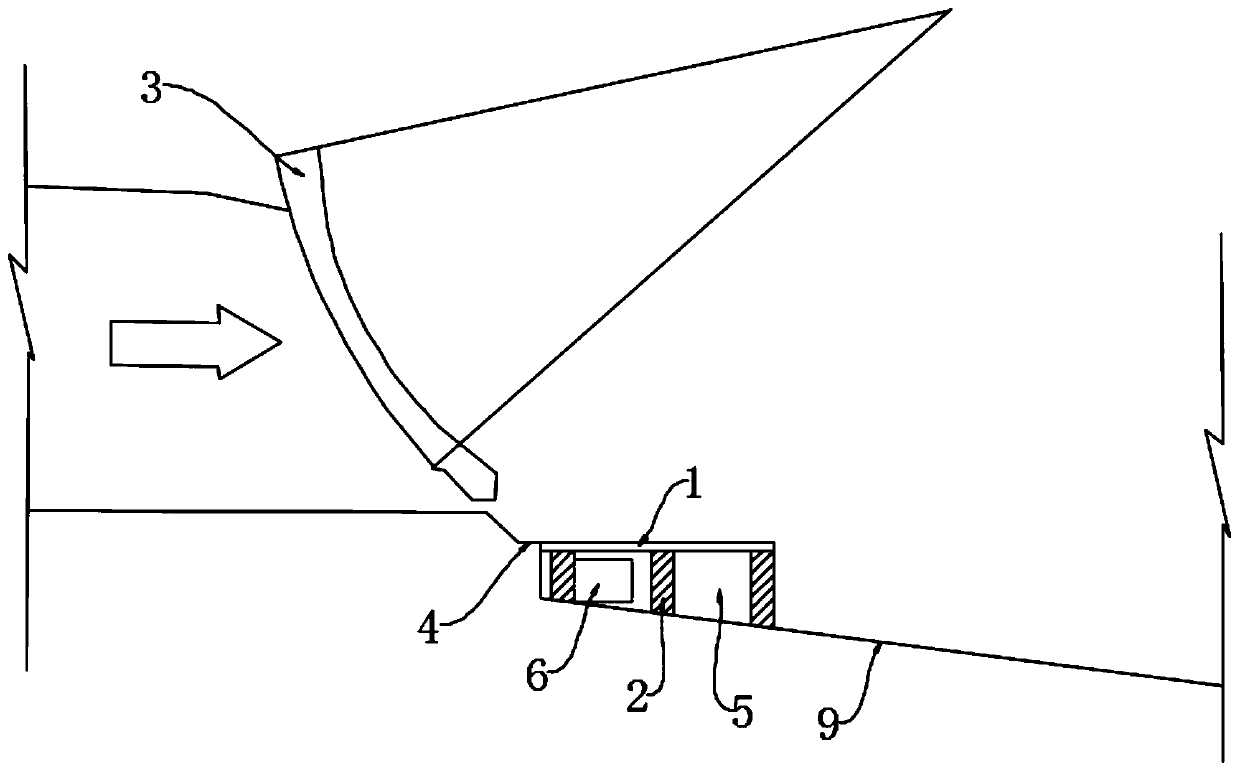

Ladder energy dissipater with doped gas device preposed

InactiveCN101195999AImprove energy dissipation rateAvoid cavitation damageBarrages/weirsEngineeringStreamflow

The invention relates to a stepped energy dissipater, which comprises steps arranged on a bottom slope and an aerating device positioned on the upstream of the steps. The aerating device is provided with four structural forms. In the first structural form, the aerating device is composed of a flip bucket, a vent hole and a vent shaft, in the second structural form, the aerating device is composed of a flip bucket, an aeration slot, a vent hole and a vent shaft, in the third structural form, the aerating device is composed of a flip bucket, a step-down floor, a vent hole and a vent shaft, and in the fourth structural form, the aerating device is composed of a flip bucket, a step-down floor, an aeration slot, a vent hole and a vent shaft. The energy dissipater can not only enhance the stepped energy dissipation rate, but also reduce or avoid the possibility of the cavitation corrosion and the damage to the steps, and thereby effectively solve the problems of the contradiction between the increase of the energy dissipation rate and the improvement of the cavitation corrosion and the damage resistance when an overflow spillway or an overflow dam surface is operated with large discharge per unit width.

Owner:SICHUAN UNIV

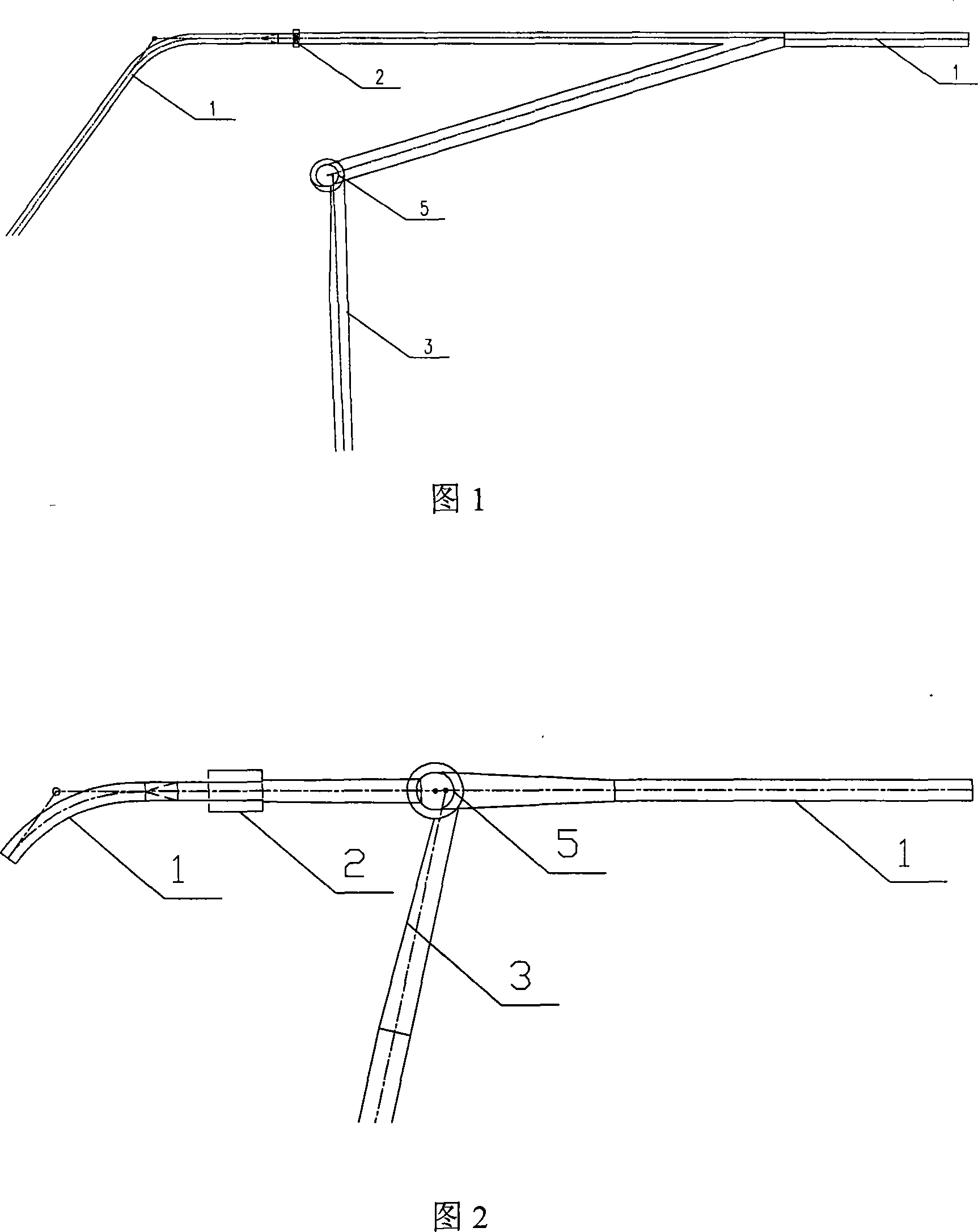

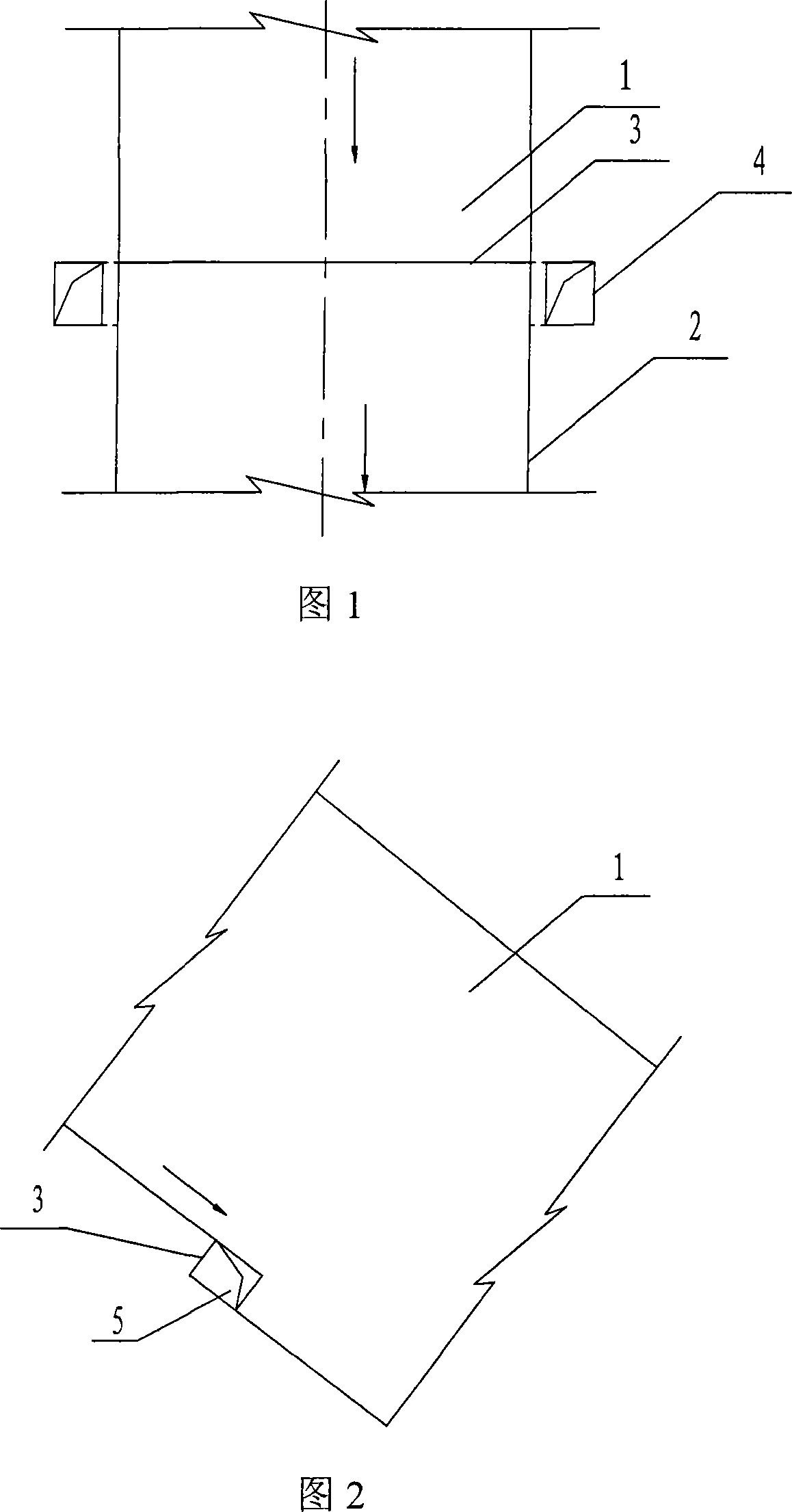

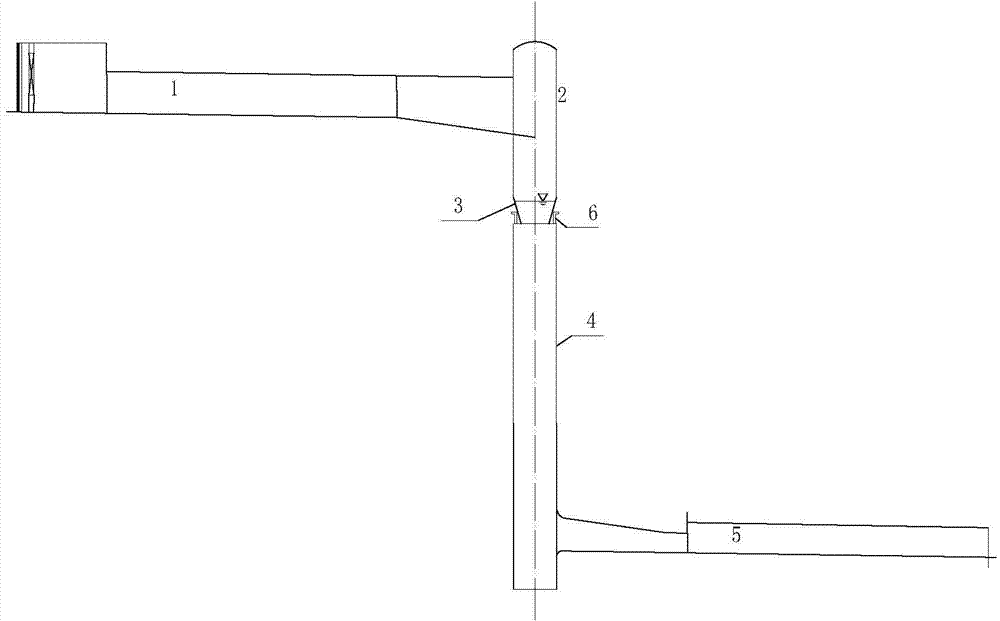

Vertical shaft rotational flow flood discharging tunnel and emptying tunnel or diversion tunnel square crossing arrangement hydraulic form

InactiveCN101215830ALow costSpeed up the progress of the projectBarrages/weirsWater-power plantsEngineeringHydraulic engineering

The invention discloses a hydraulic engineering type of a vertical crossing arrangement for a silo vortex flood discharging tunnel and a releasing tunnel or a diversion tunnel, which is characterized in that: the hydraulic engineering type is to make the flood discharging tunnel and the releasing tunnel or a diversion tunnel arranged in vertical crossing through a silo vortex chamber on the top of no pressure section behind a middle brake chamber of the releasing tunnel or the diversion tunnel, which combines the flood discharging tunnel behind the silo with the releasing tunnel or the diversion tunnel. The invention needs not to construct a section of drainage equipment from the silo exit to the connection place of two tunnels, and can avoid bad fluidization in a connection place of two tunnels in the prior inclined crossing technique scheme, has no particular requirements and limitations on the axis direction of the releasing tunnel or the diversion tunnel, can select a good and short path for construction according to the landform and geologic conditions, thereby greatly lowering cost, reducing engineering period, achieving the aim of a rapid start of operations.

Owner:SICHUAN UNIV +1

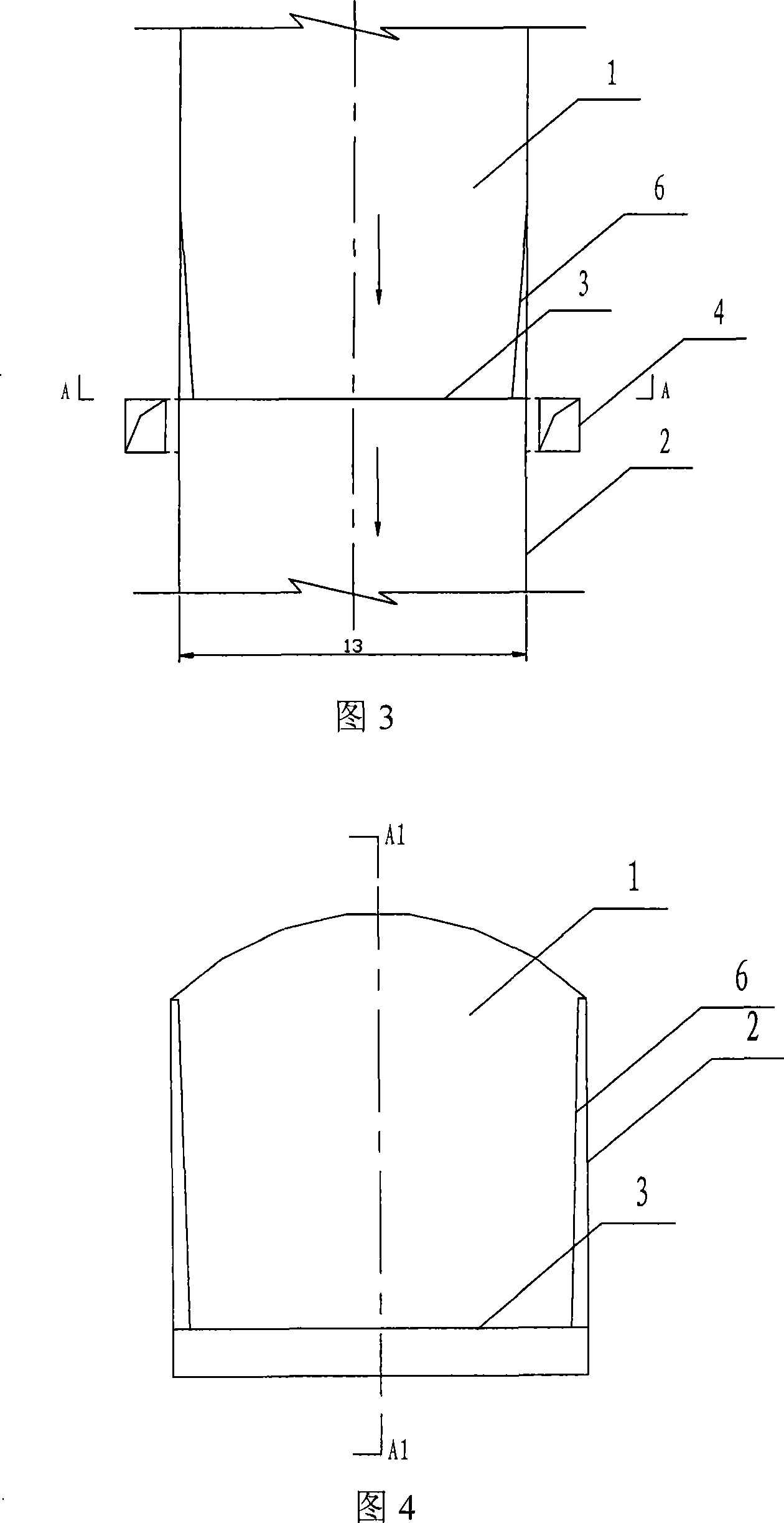

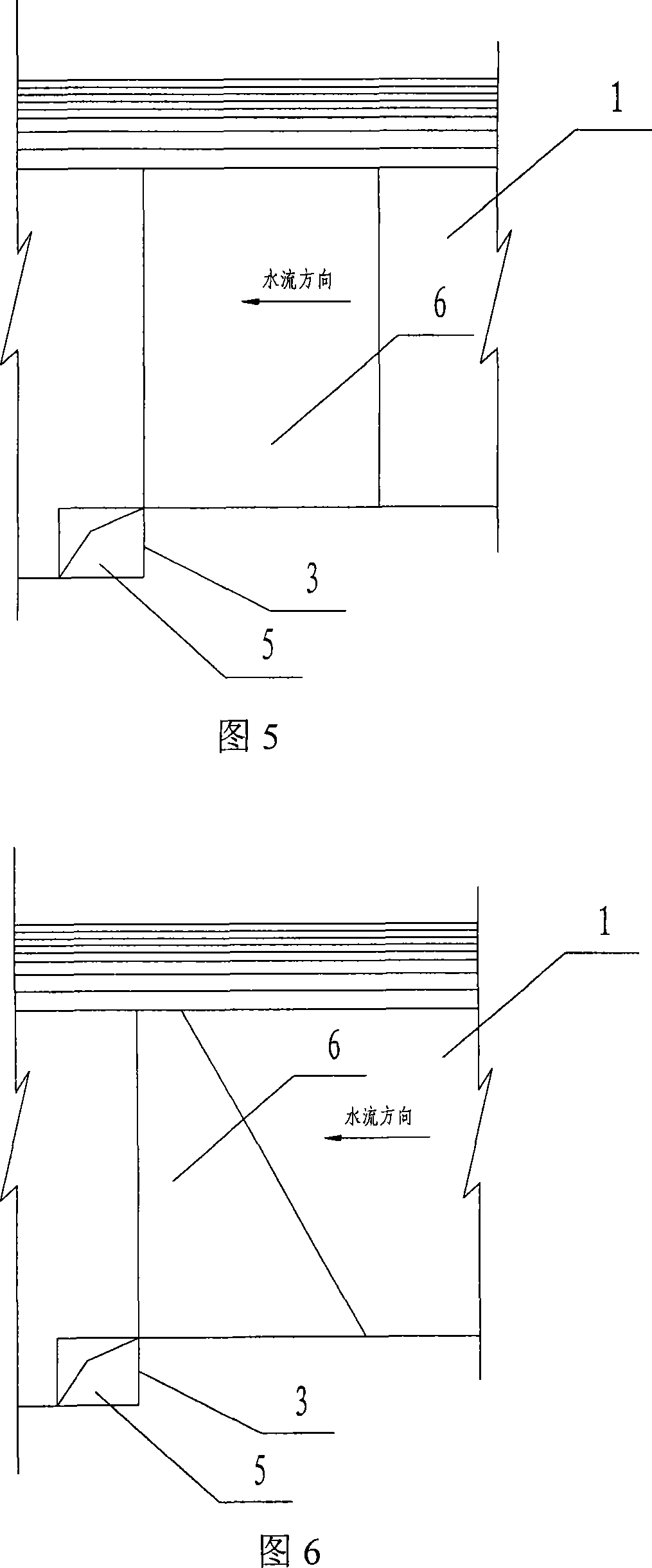

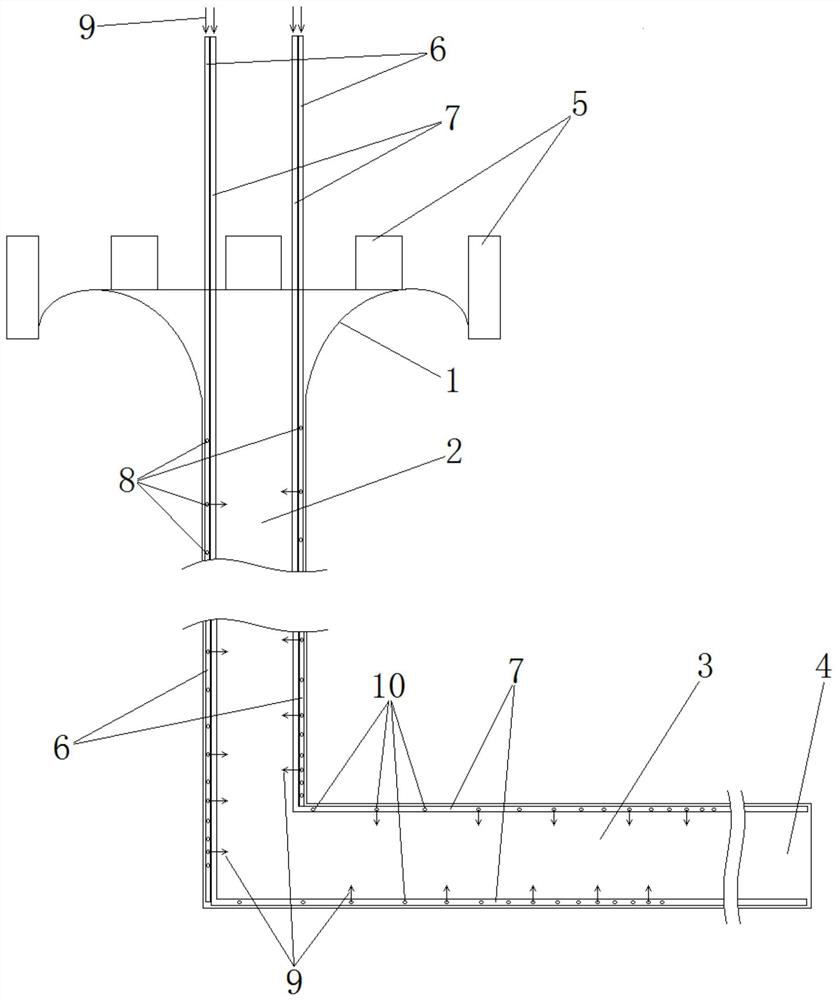

Spillway tunnel whole-section aeration method and spillway tunnel having whole-section aeration structure

InactiveCN101177937AGuaranteed air entrainmentAvoid cavitation damageBarrages/weirsCavitationEngineering

The invention discloses a whole section aeration method of a flood discharging tunnel. The bottom part of a free flow flood discharging tunnel is provided with a backward step and a ventilation shaft, which form bottom cavity aeration, based on which a lateral deflector is respectively arranged at side walls on two sides of the upstream of aeration backward step, therefore, an aeration side cavity is formed and the whole section aeration is further formed at the aeration backward step. The deflector inside the flood discharging tunnel with the whole section aeration structure designed according the method is a wedge deflector. Since the whole section aeration changes the former simplex method of bottom cavity aeration and guarantees the necessary aeration quantity when the flood discharging tunnel in normal operation, thus eliminating large-area fresh water flooding district at the side walls of the flood discharging tunnel and effectively avoiding the cavitation eroding damage of the side walls.

Owner:SICHUAN UNIV

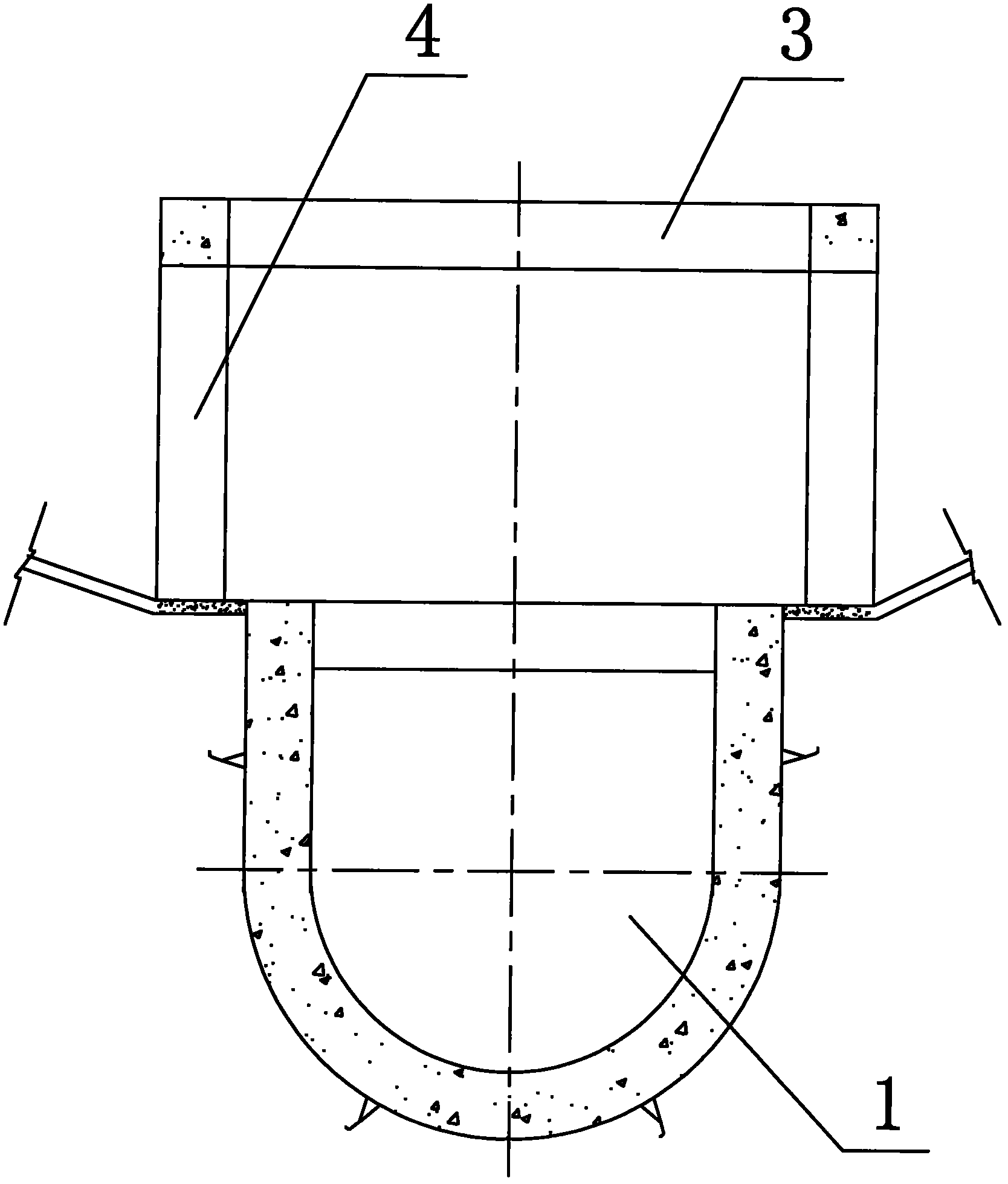

Flood discharging method for anticorrosion and energy dissipation of rotational flow ring dam and device thereof

The invention relates to a flood discharging method for anticorrosion and energy dissipation of a rotational flow ring dam and a device thereof. The device comprises a vertical well; the bottom of thevertical well is communicated with a horizontal energy dissipation hole; the energy dissipation hole is communicated with a flow guide hole; the inlet of the vertical well is provided with the ring dam; the inner ring of the ring dam is connected with a smooth contracted curved surface formed in the vertical well; the ring dam is externally provided with a plurality of flow guide piers; the central lines of the flow guide piers and the tangent lines of the flow guide piers form inclined angles Theta which is larger than and equal to 0 degree and is less than 45 degree; a connection part between the vertical well and the energy dissipation hole, which is relative to the energy dissipation hole, is provided with a space; the energy dissipation hole is provided with a water collecting pier and a contracting pier; and a plunge pool is arranged between the water collecting pier and the contracting pier. Because the flow guide piers are tangent with the edge of the ring dam or the flow guide piers are connected with the edge of the ring dam by forming a small angle, the water flow is rotary, and spiral flow moves in the vertical well. The invention has simple structure, convenient construction, less investment, no maintenance, good anticorrosion and energy dissipation effect, no pulverization phenomenon at the outlet of the flood discharging hole, and protects ecology environment.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

Use of plastic film or plastic composite film as architecture component protective film or decorative film

InactiveCN1884753AConstruction is inconvenientSolve the durability problemBuilding insulationsTectorial membraneComposite film

The invention relates to the application of plastic film or plastic composite film, used as building element protective film or decorating film, wherein the invention coats adhesive or polymer on the surface of building element, then adheres the plastic film or plastic composite film on the said surface. The invention has the advantages that: it can prolong the service life of decorate element, with low cost and simple operation, while the polymer is made by mixing adhesive and other stuff on site.

Owner:吴淑环

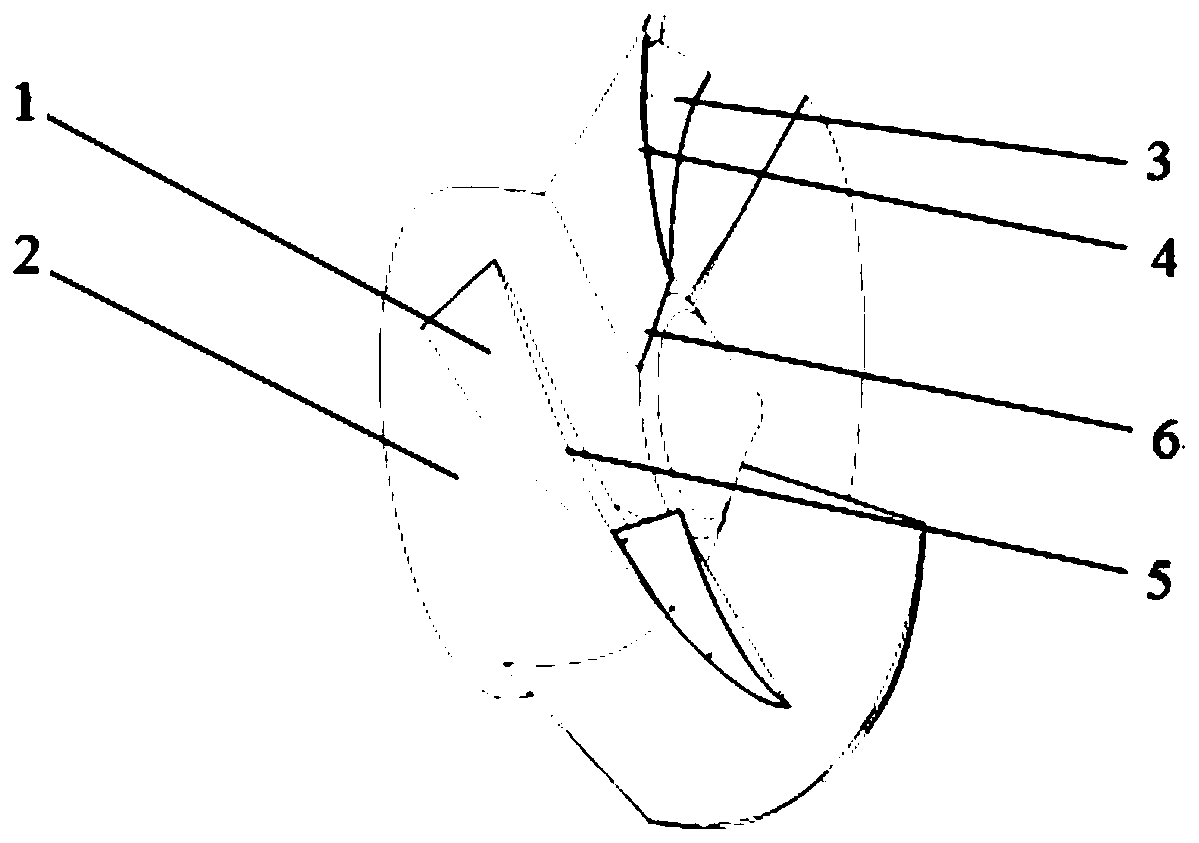

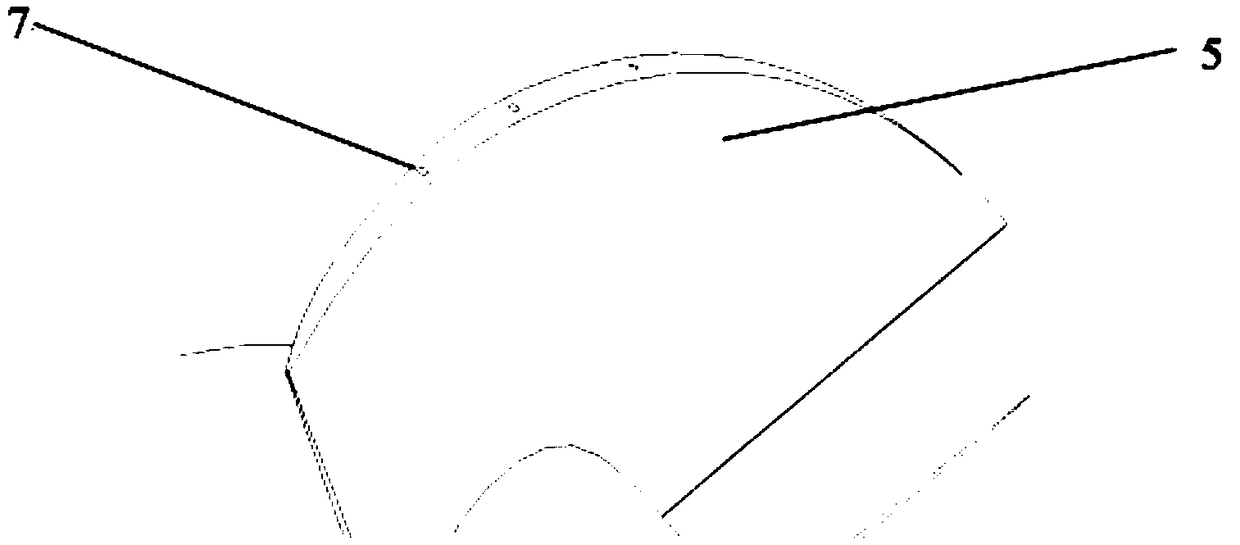

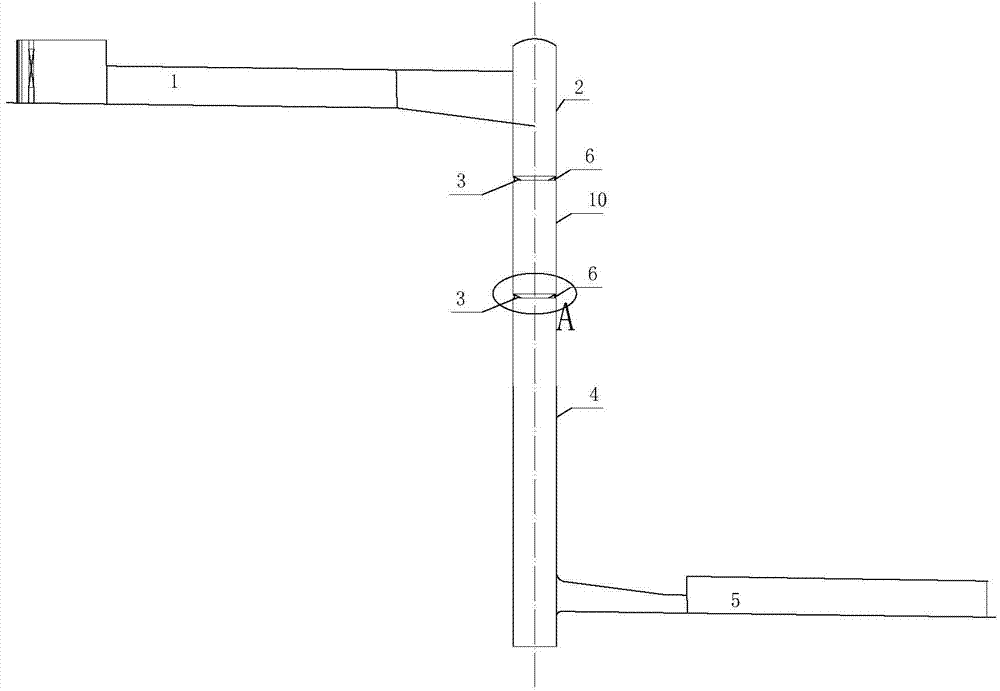

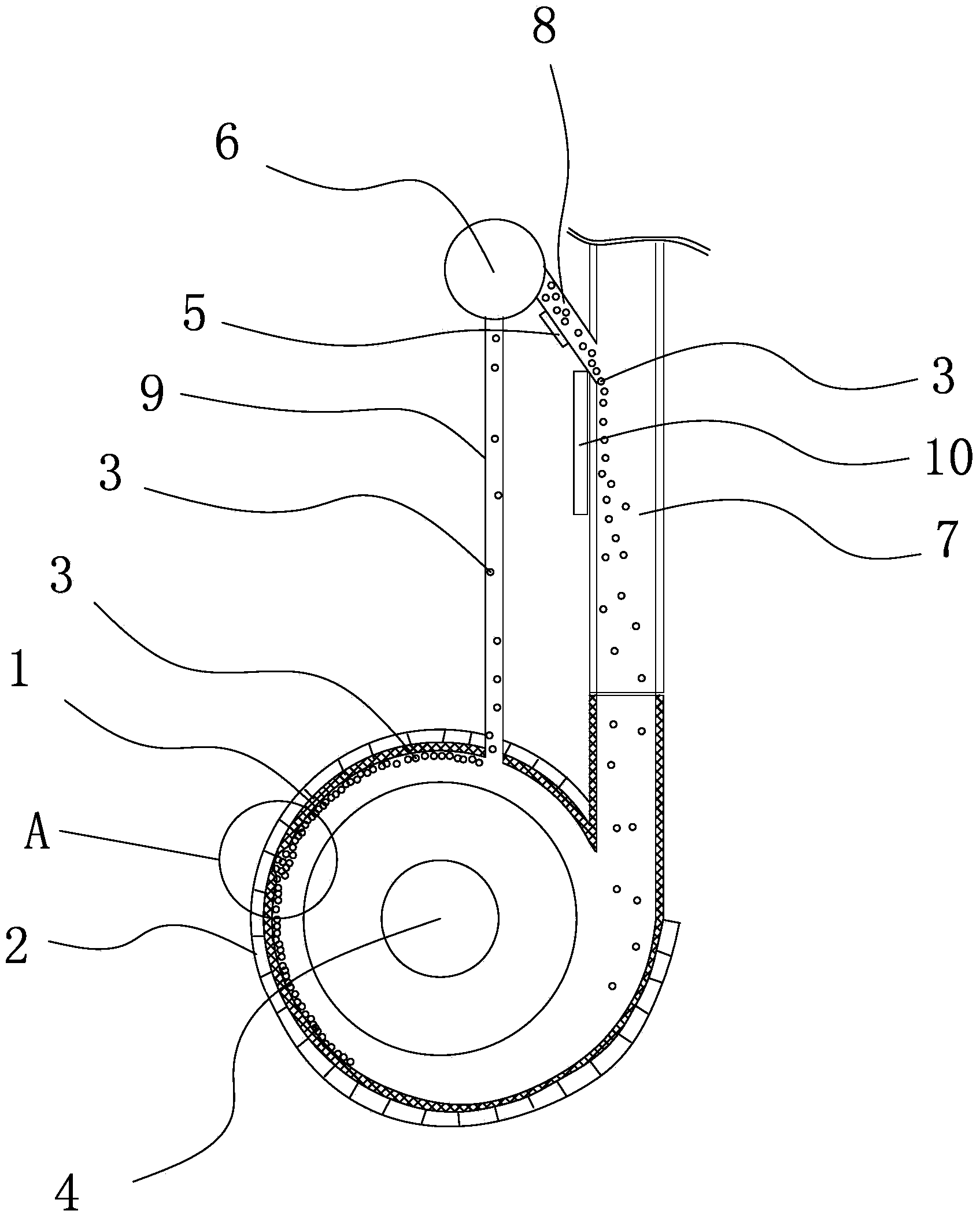

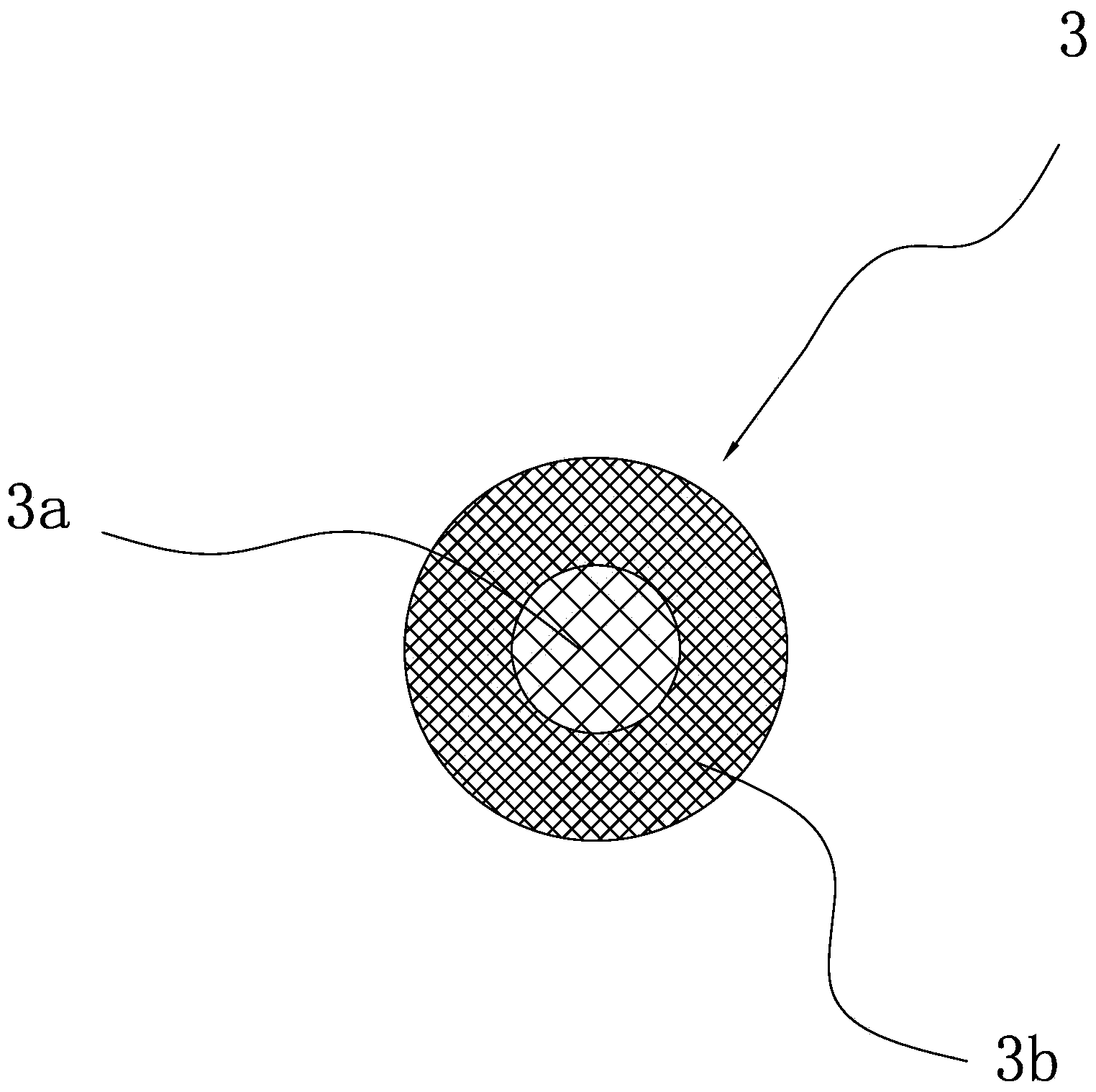

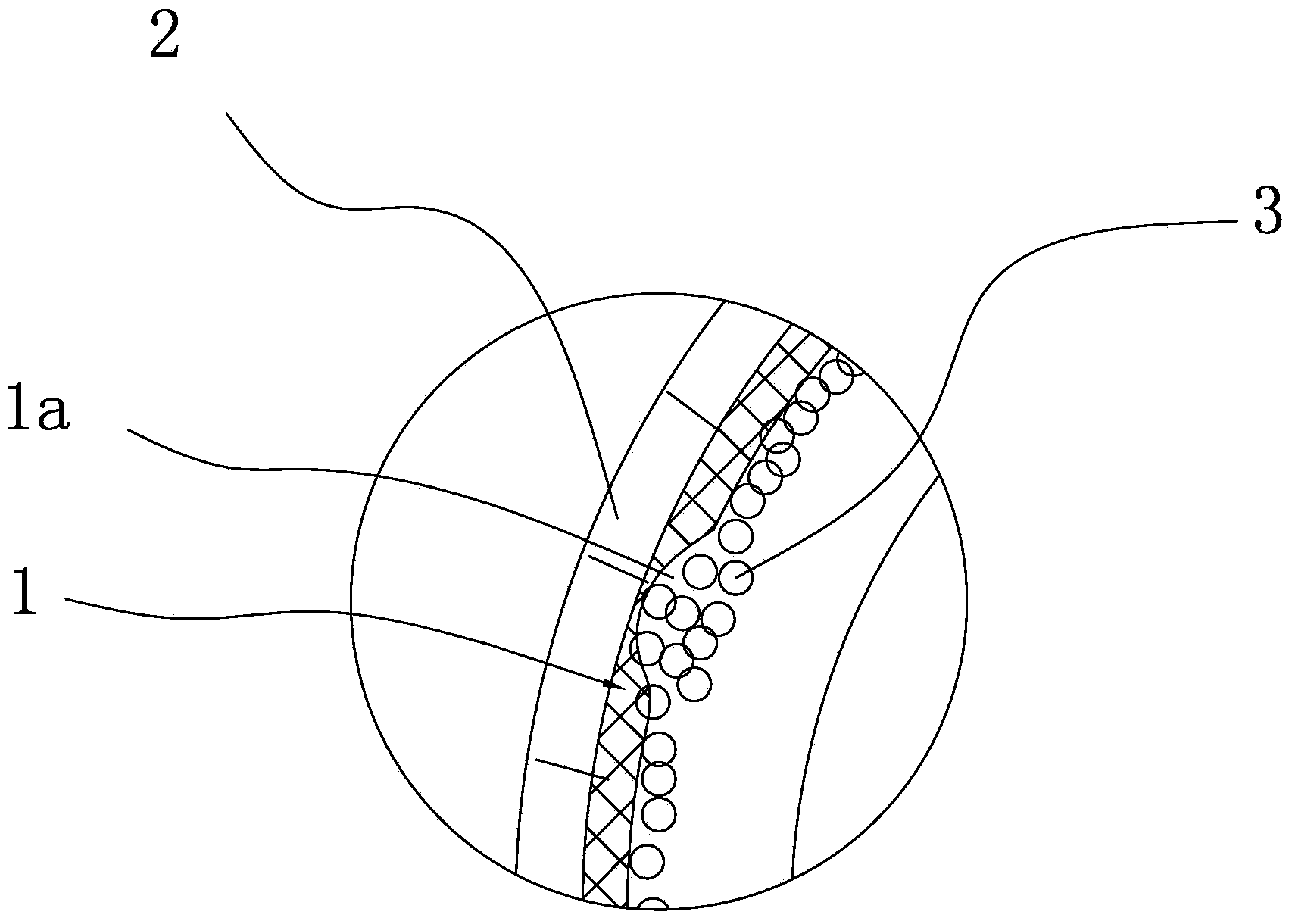

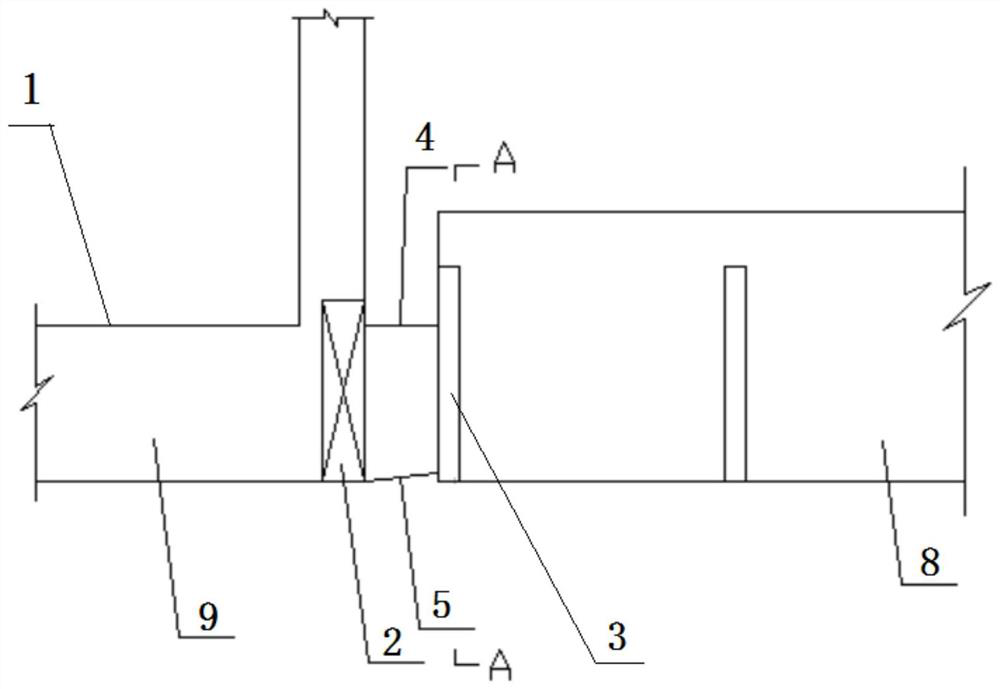

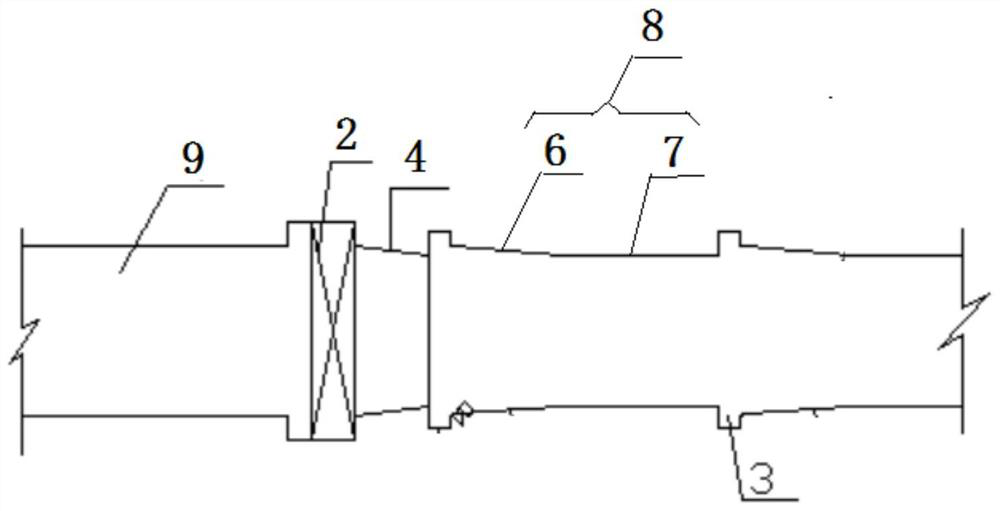

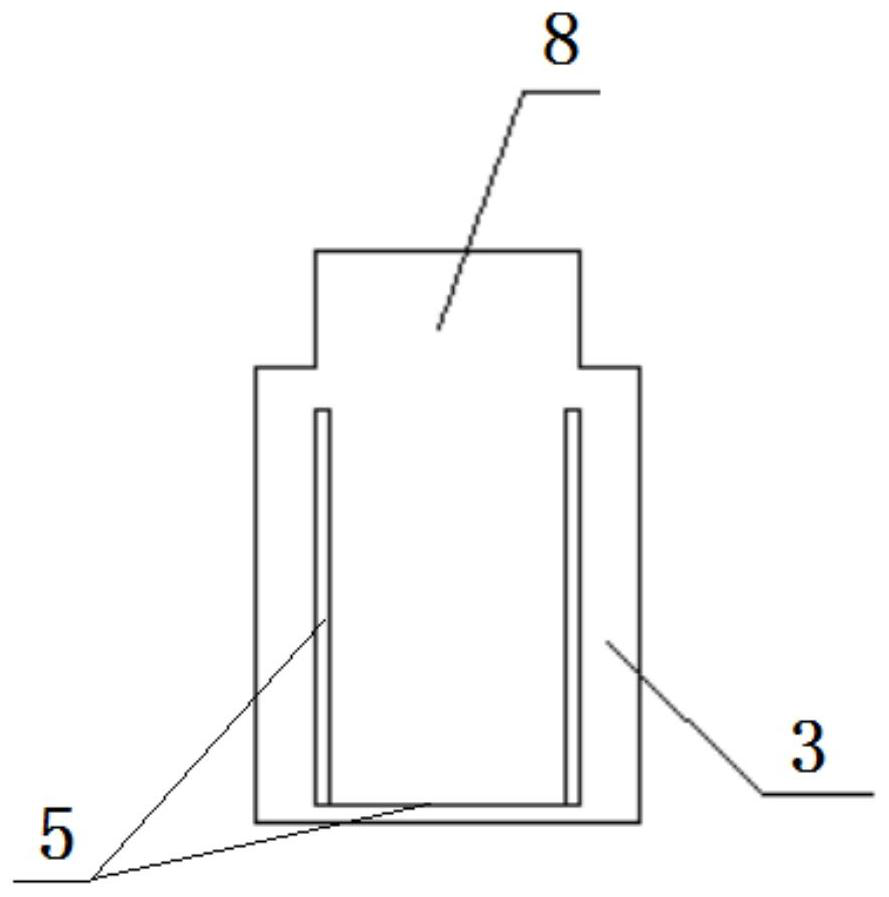

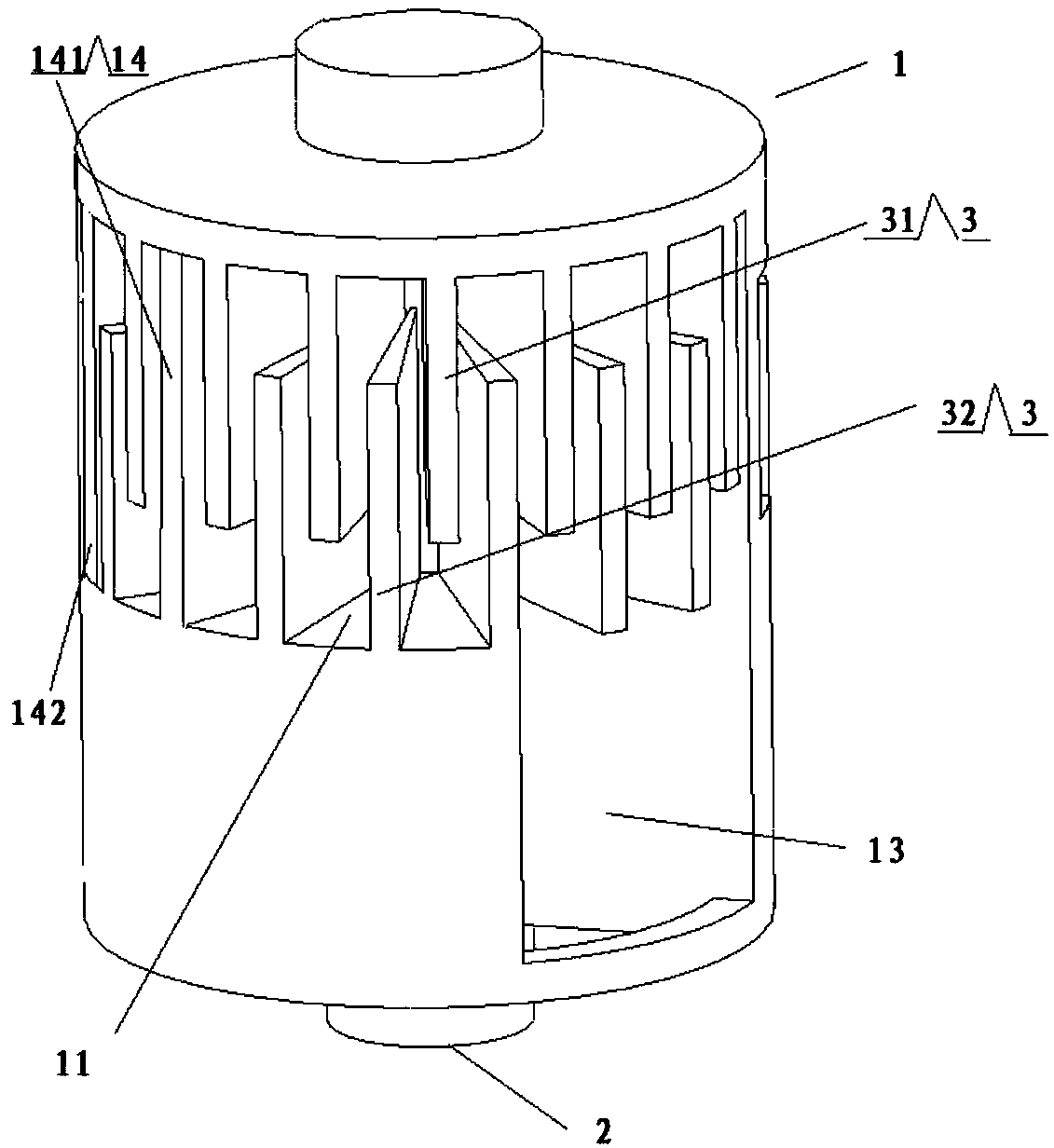

Whole aeration cyclone vertical shaft

The invention discloses a whole aeration cyclone vertical shaft which comprises a volute chamber section (1), a contraction section (2) and a vertical shaft section (3). At least one aerator (4) which penetrates the whole vertical shaft section (3) is arranged on the vertical wall surface of the vertical shaft section (3) of the cyclone vertical shaft in an outward sudden expansion manner along the radius direction of the vertical shaft section (3), smooth curved surfaces of the aerators (4) are gradually contracted to a wall surface after the aerators (4) are suddenly expanded, and the wall surface is formed by the original radius side of the vertical shaft. The whole aeration cyclone vertical shaft has the advantages that the aerators can guarantee that aeration cavities can be formed as long as water flows rotate in a wall clinging manner, so that the water flows which flow through the wall surface of the integral vertical shaft are aeration water flows containing gas with high concentration, and damage to the wall surface of the vertical shaft due to cavitation and erosion is completely prevented; the whole aeration cyclone vertical shaft is simple in structure, easy to construct and high in running safety, and the shape of the whole aeration cyclone vertical shaft is smooth and continuous.

Owner:SICHUAN UNIV

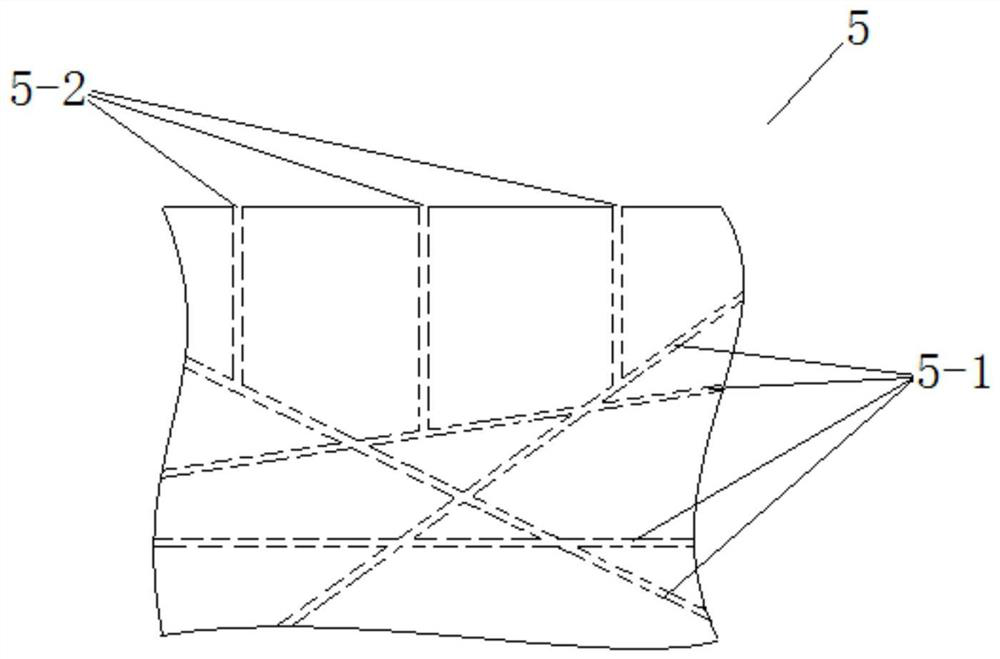

Mixed flow pump impeller structure for reducing cavitation erosion of blade rims

ActiveCN108869386AImprove cavitation damageExtended service lifePump componentsPumpsImpellerMixed flow

The invention provides a mixed flow pump impeller structure for reducing the cavitation erosion of blade rims. The mixed flow pump impeller structure comprises blades, an impeller hub and rim drainagepieces, wherein the blades are arranged on the impeller hub, and the rim drainage pieces are arranged on the blade rims and are located on one sides, where the inlet edges are located, of the blades.According to the mixed flow pump impeller structure, the rim drainage pieces are installed at the blade rims, so that bubbles generated by gap blowing-up vortexes of the blade rims are effectively isolated, moreover, bubbles generated by leakage vortex cavitation are killed in the areas away from the surfaces of the blades, then the cavitation erosion damage to the blade rims is reduced, and theservice life of an impeller is prolonged; and the rim drainage pieces are fixed at the blade rims through fastening screws, so that after the rim drainage pieces are damaged due to the cavitation erosion, the method that the rim drainage pieces are directly replaced can be also adopted, the whole impeller is not required to be disassembled, and then the whole life cycle cost is reduced.

Owner:JIANGSU UNIV

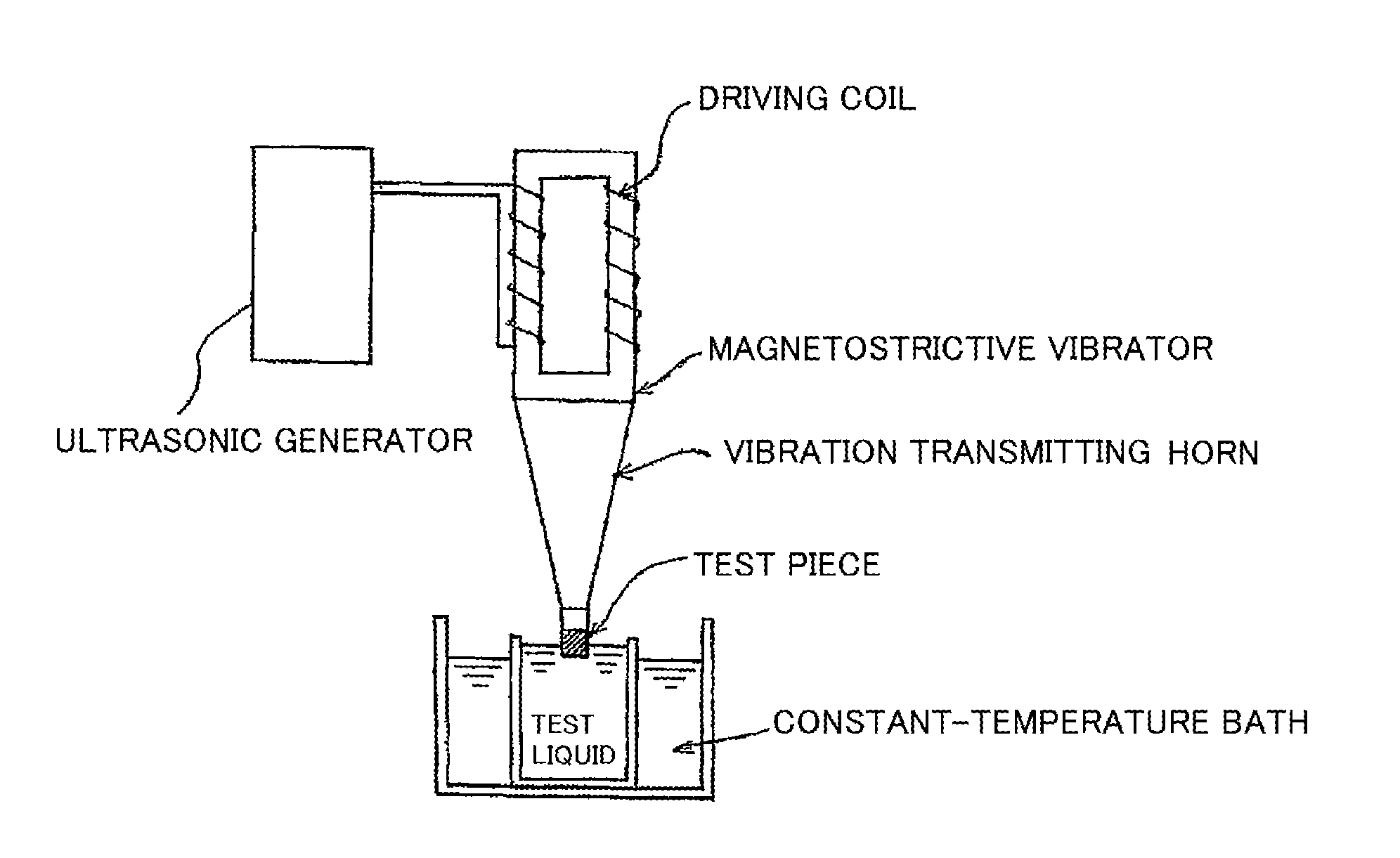

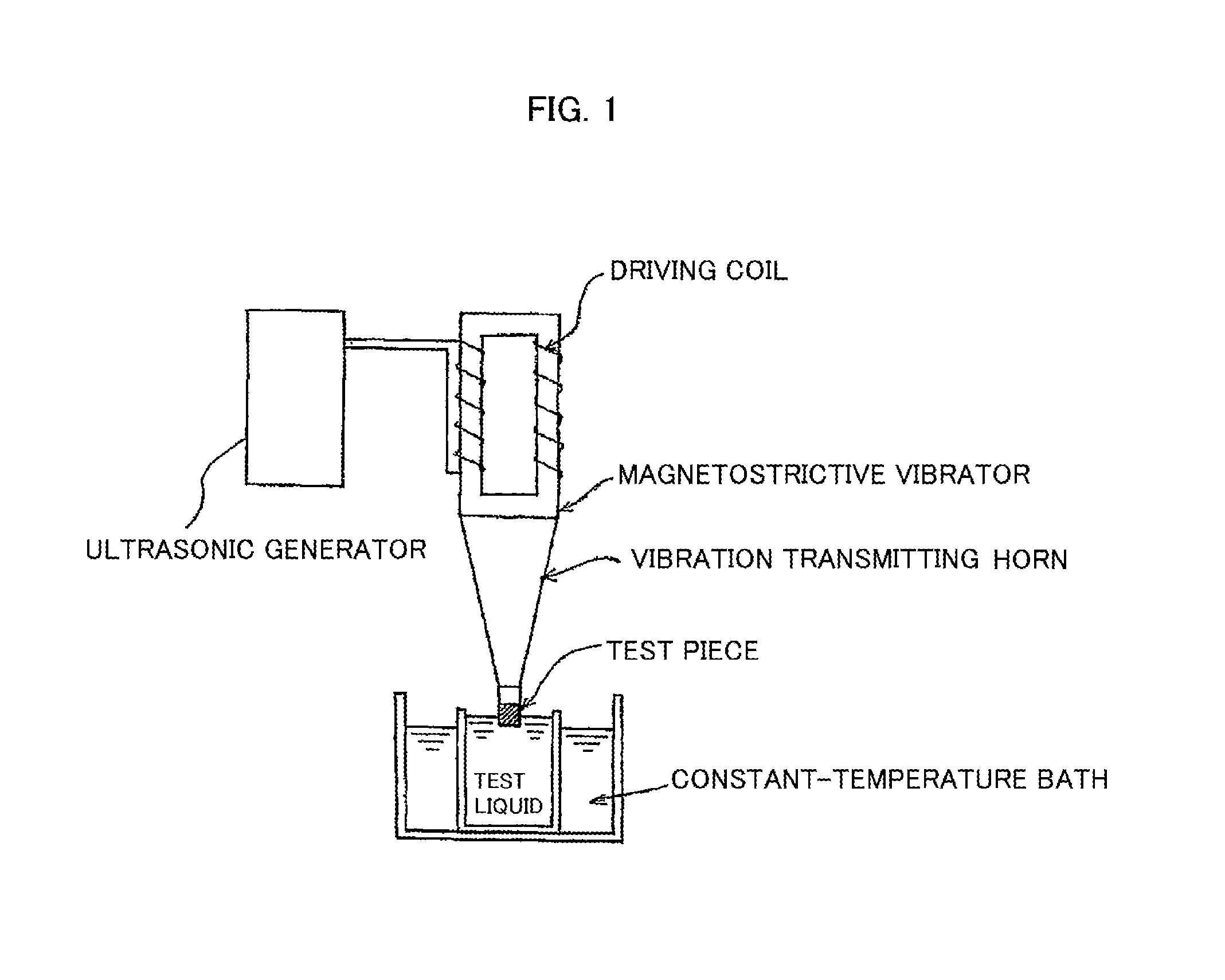

Liquid cooling composition

InactiveUS20130020530A1Reduce the amount requiredLong filling timeHeat-exchange elementsChemical inhibitorsCavitationSilicic acid

Disclosed is a cooling liquid composition, which has an excellent ability to prevent the corrosion of mainly a metal constituting a cooling system for an internal combustion engine or the like, particularly an iron-based metal, or alumninum or an aluminum alloy, and also can effectively inhibit cavitation damage. The composition contains a glycol as a base material, wherein the composition does not contain p-tert butyl benzoate or an alkali metal salt thereof, but contains (a) 0.05-0.5% by mass of silicic acid or an alkali metal salt thereof, (b) 0.1-8% by mass of sebacic acid or an alkali metal salt thereof, (c) 0.1-10% by mass of toluic acid or an alkali metal salt thereof, and (d) 0.001-0.5% by mass of at least one compound selected from a strontium compound, a magnesium compound, and a calcium compound.

Owner:SHISHIAI KK

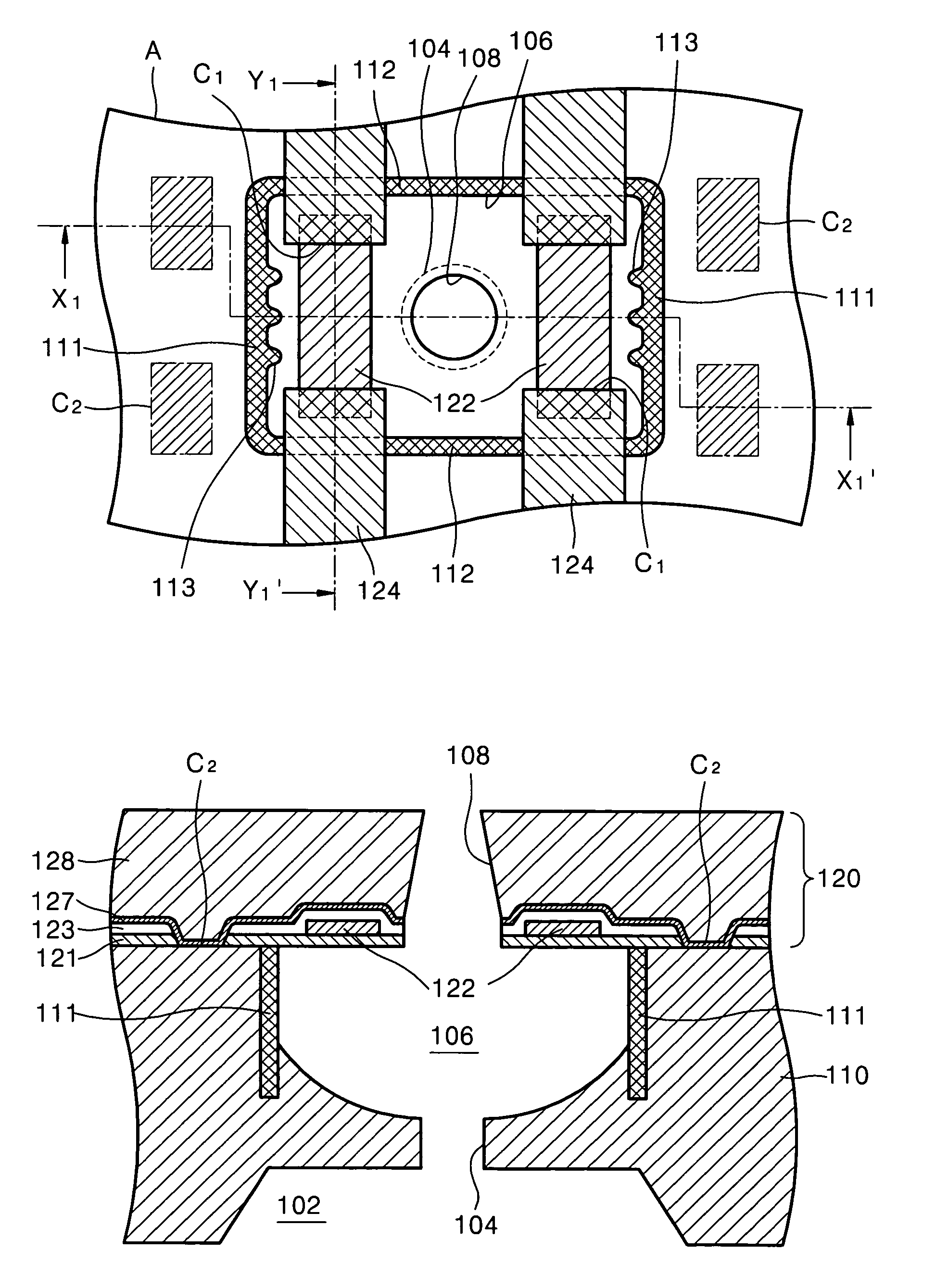

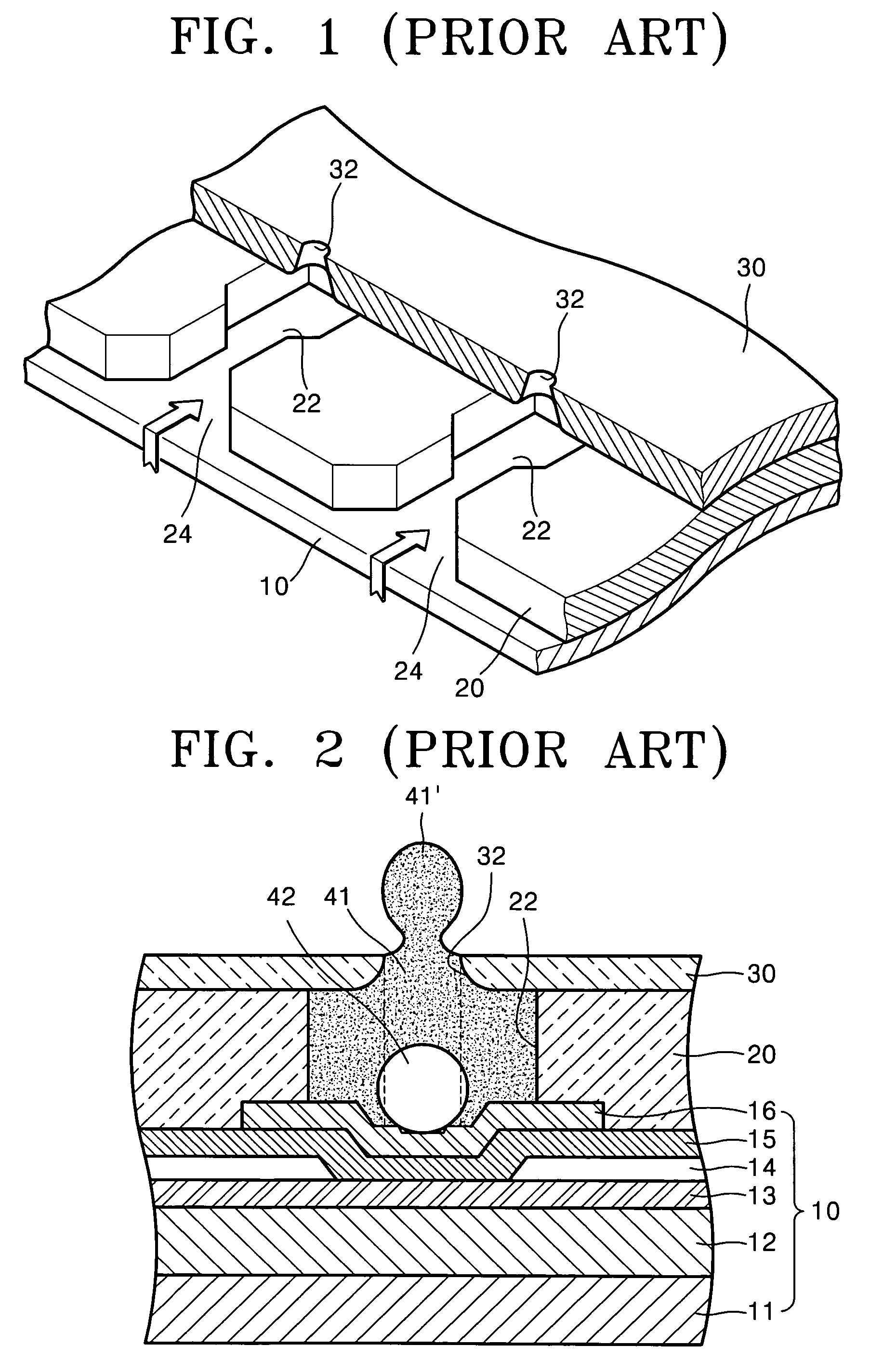

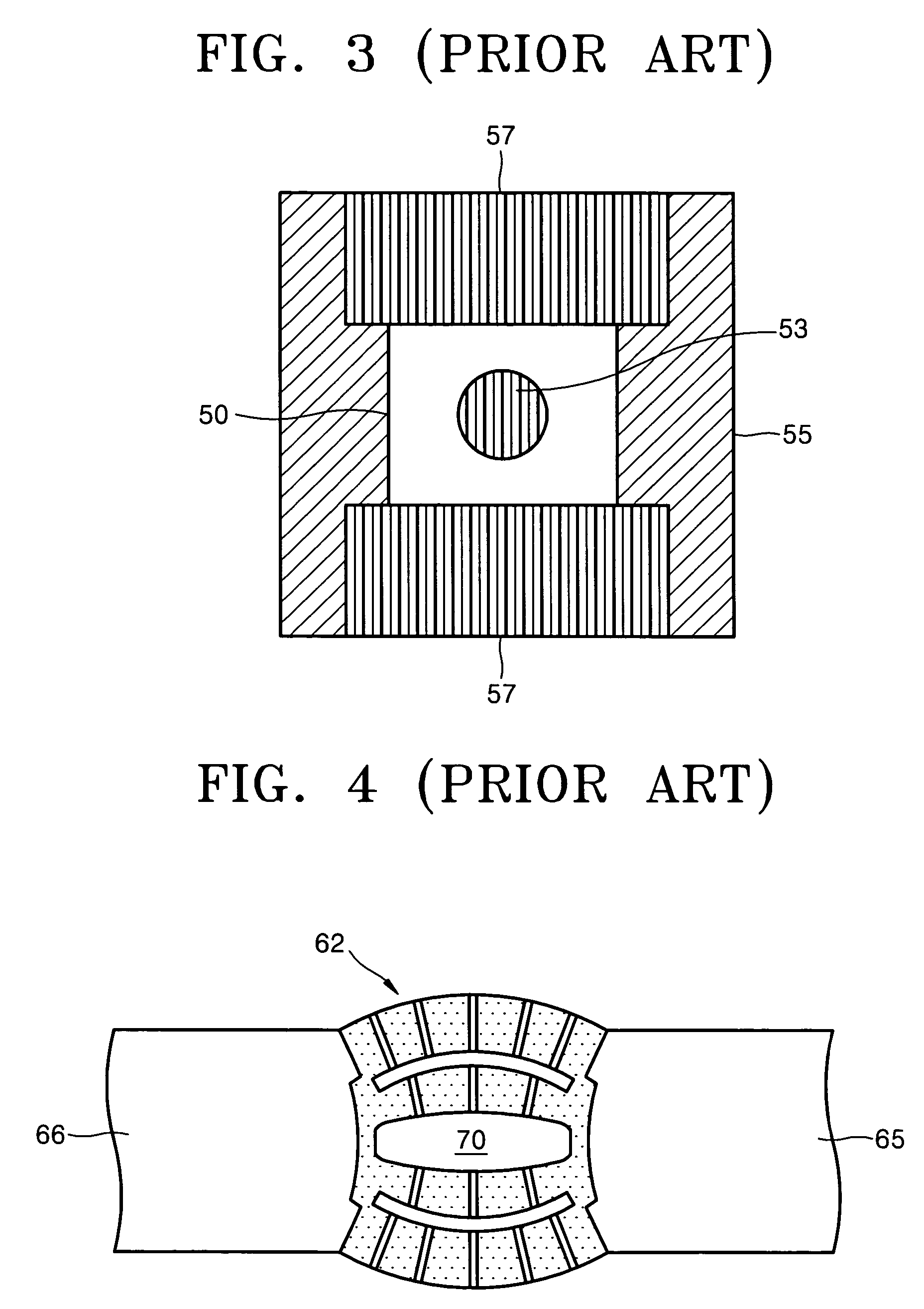

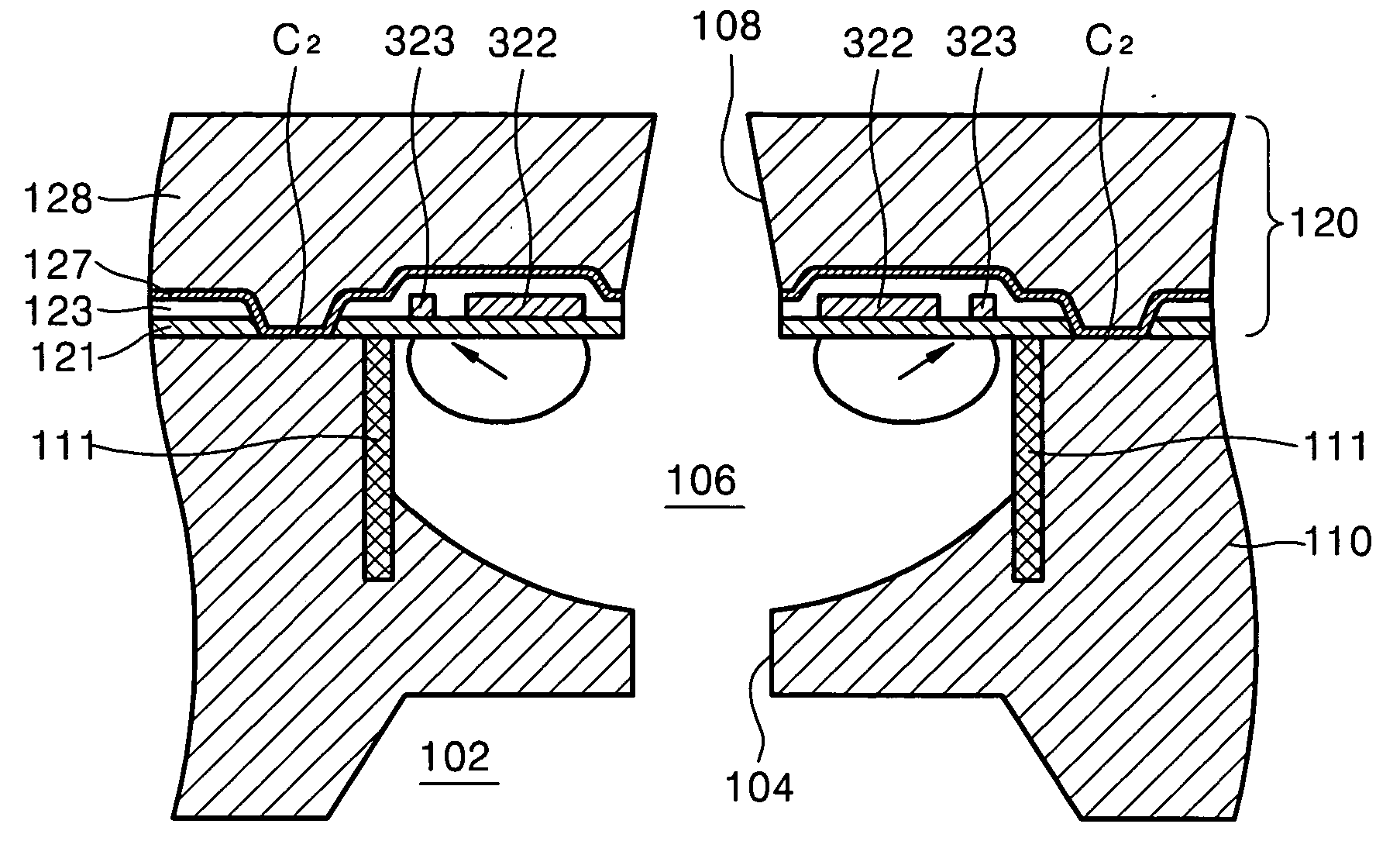

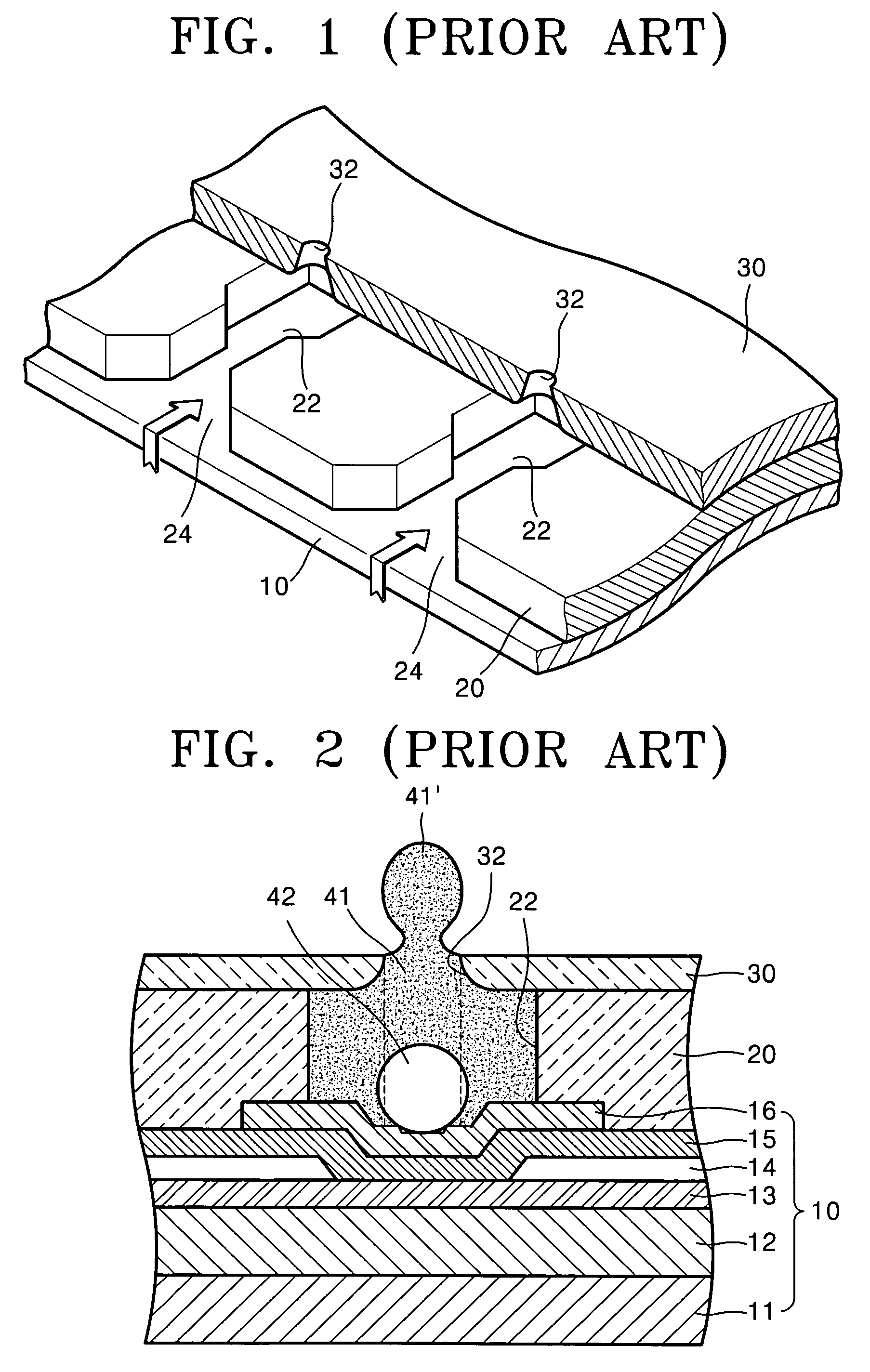

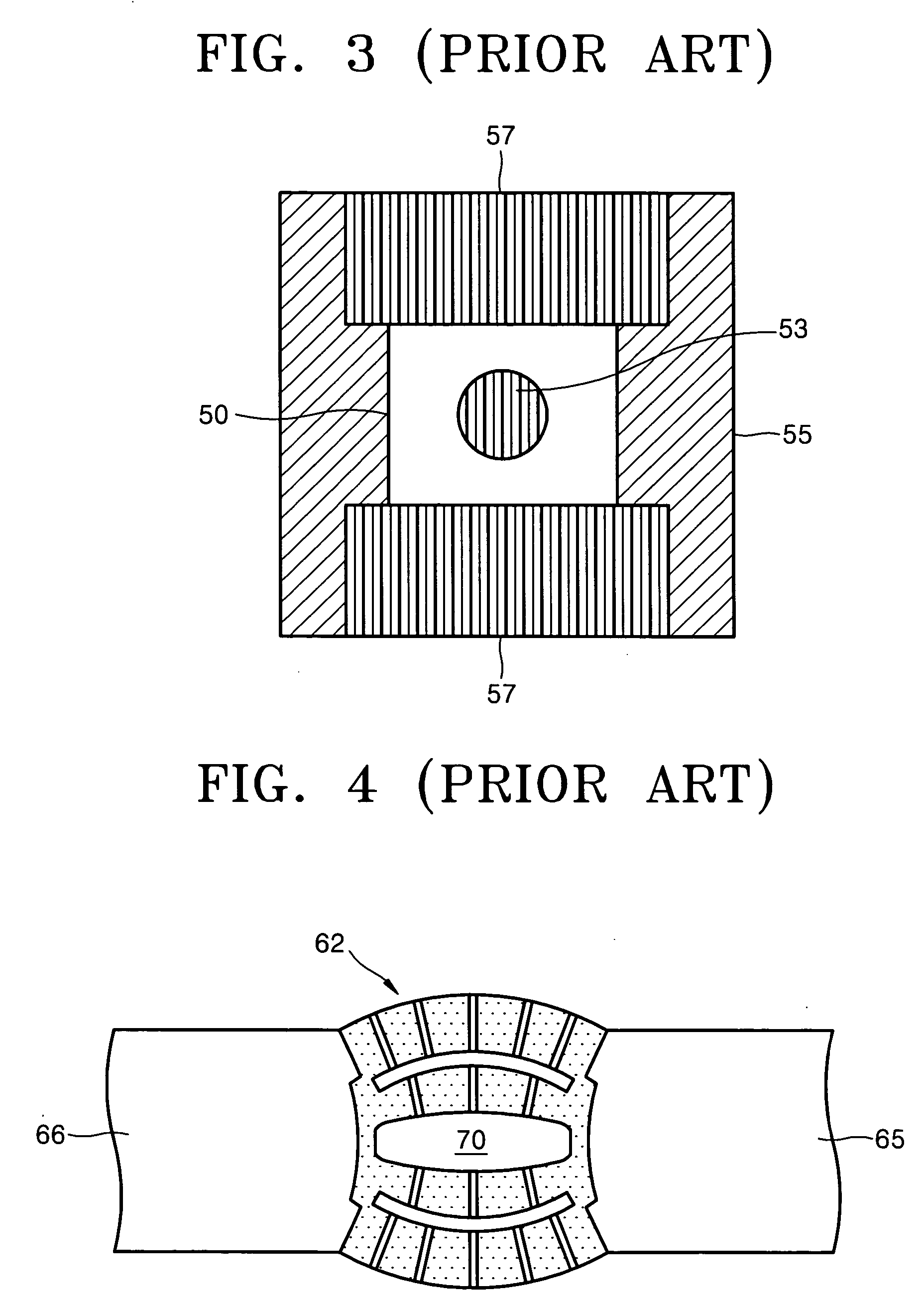

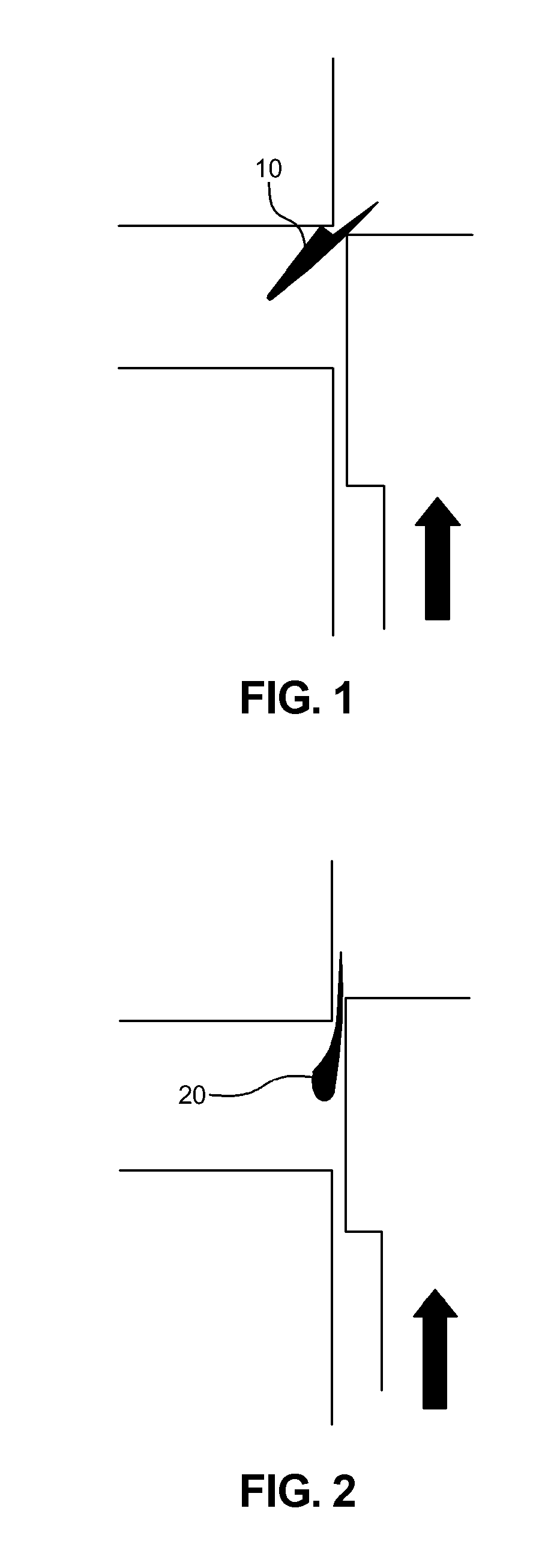

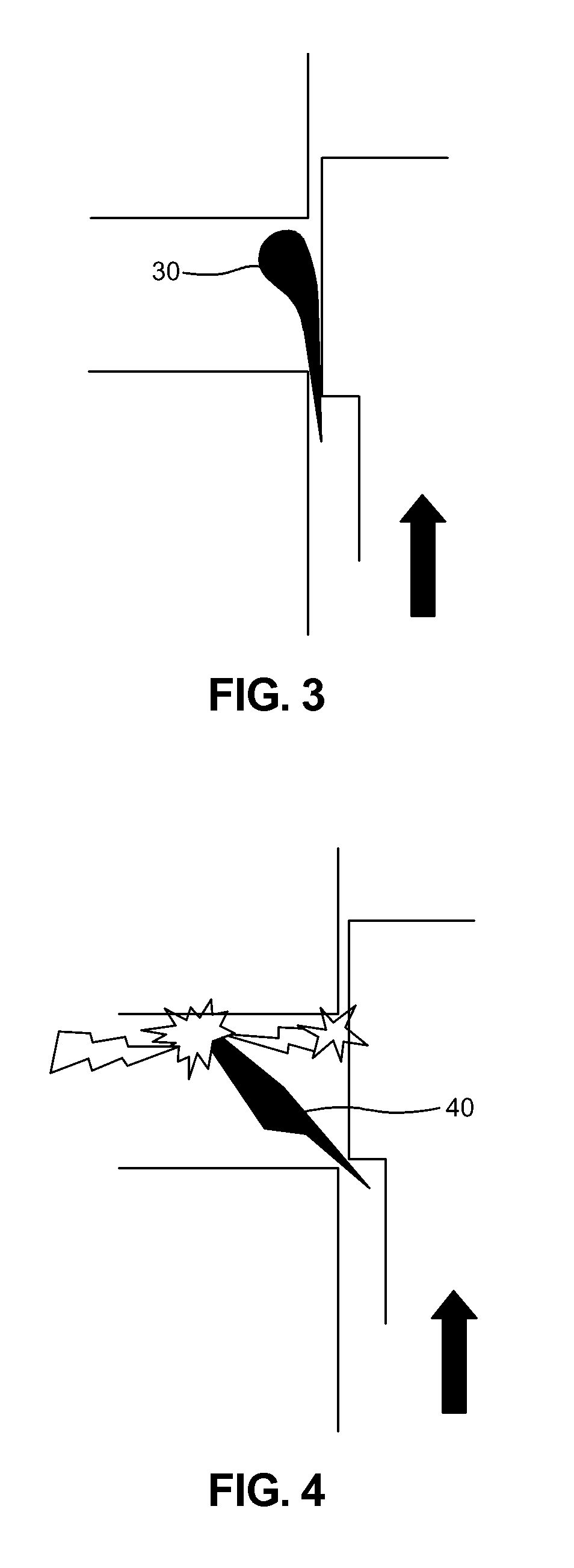

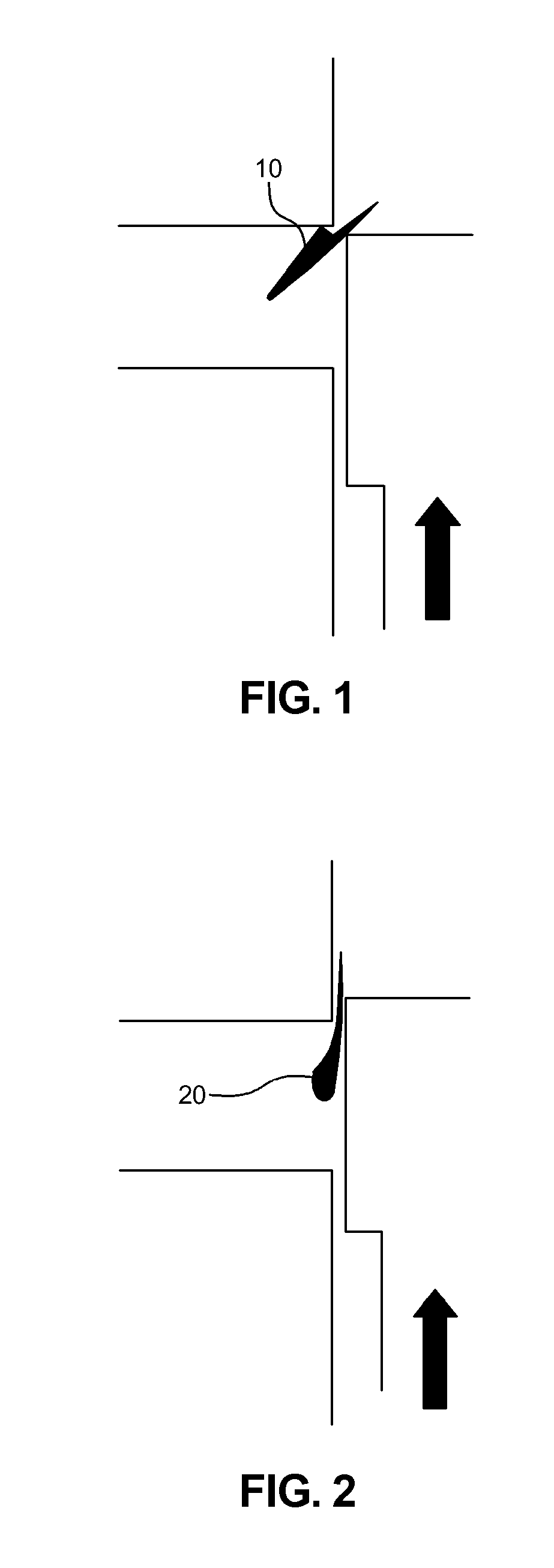

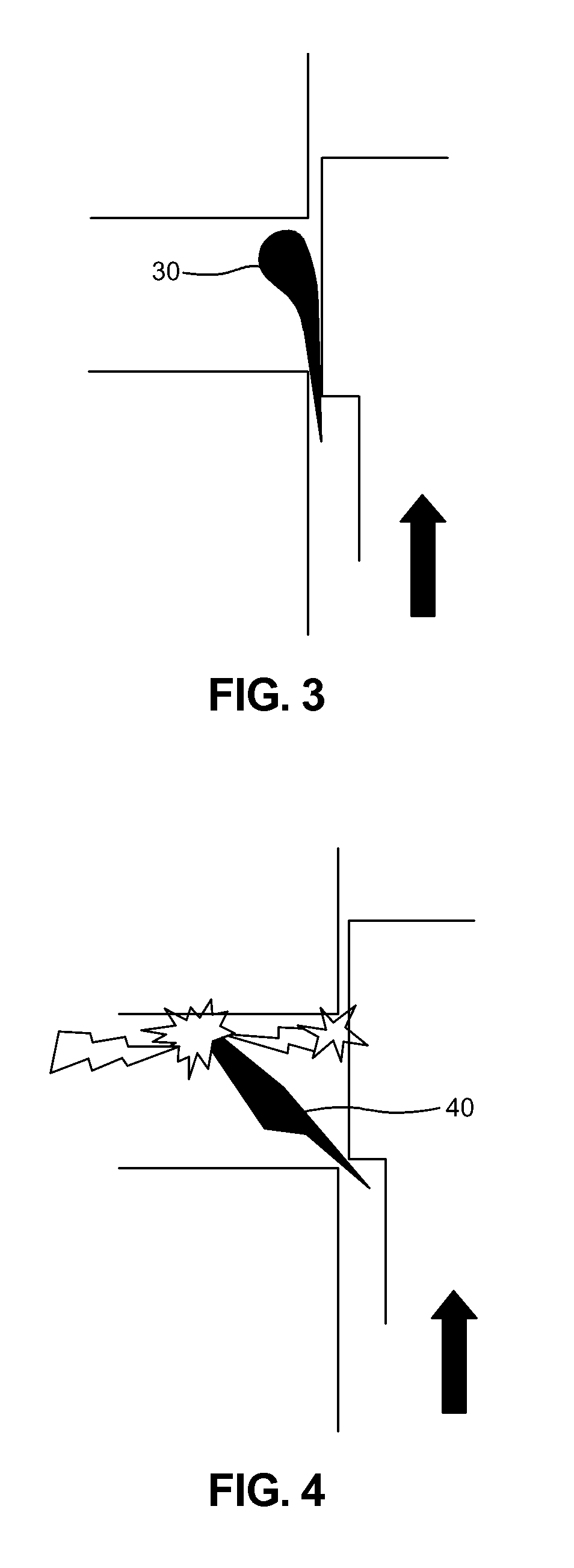

Thermally-driven ink-jet printhead capable of preventing cavitation damage to a heater

InactiveUS7210766B2Avoid cavitation damageSimple structureInking apparatusElectrical conductorCavitation

A thermally-driven ink-jet printhead includes a substrate having an ink chamber to be filled with ink to be ejected, a manifold for supplying ink, and an ink channel for providing flow communication therebetween. First and second sidewalls are formed to a predetermined depth from an upper surface of the substrate and define the ink chamber to have a substantially rectangular shape. A nozzle plate including a plurality of material layers is formed on the substrate. A nozzle passes through the nozzle plate and is in flow communication with the ink chamber. A heater is disposed between the nozzle and one of the first sidewalls above the ink chamber. A conductor is electrically connected to the heater. The conductor and the heater are disposed within the nozzle plate. A shifting feature moves cavitation points beyond an outer edge of the heater.

Owner:SAMSUNG ELECTRONICS CO LTD

Thermally-driven ink-jet printhead capable of preventing cavitation damage to a heater

InactiveUS20050012783A1Avoid cavitation damageSimple structureInking apparatusElectrical conductorCavitation

A thermally-driven ink-jet printhead includes a substrate having an ink chamber to be filled with ink to be ejected, a manifold for supplying ink, and an ink channel for providing flow communication therebetween. First and second sidewalls are formed to a predetermined depth from an upper surface of the substrate and define the ink chamber to have a substantially rectangular shape. A nozzle plate including a plurality of material layers is formed on the substrate. A nozzle passes through the nozzle plate and is in flow communication with the ink chamber. A heater is disposed between the nozzle and one of the first sidewalls above the ink chamber. A conductor is electrically connected to the heater. The conductor and the heater are disposed within the nozzle plate. A shifting feature moves cavitation points beyond an outer edge of the heater.

Owner:SAMSUNG ELECTRONICS CO LTD

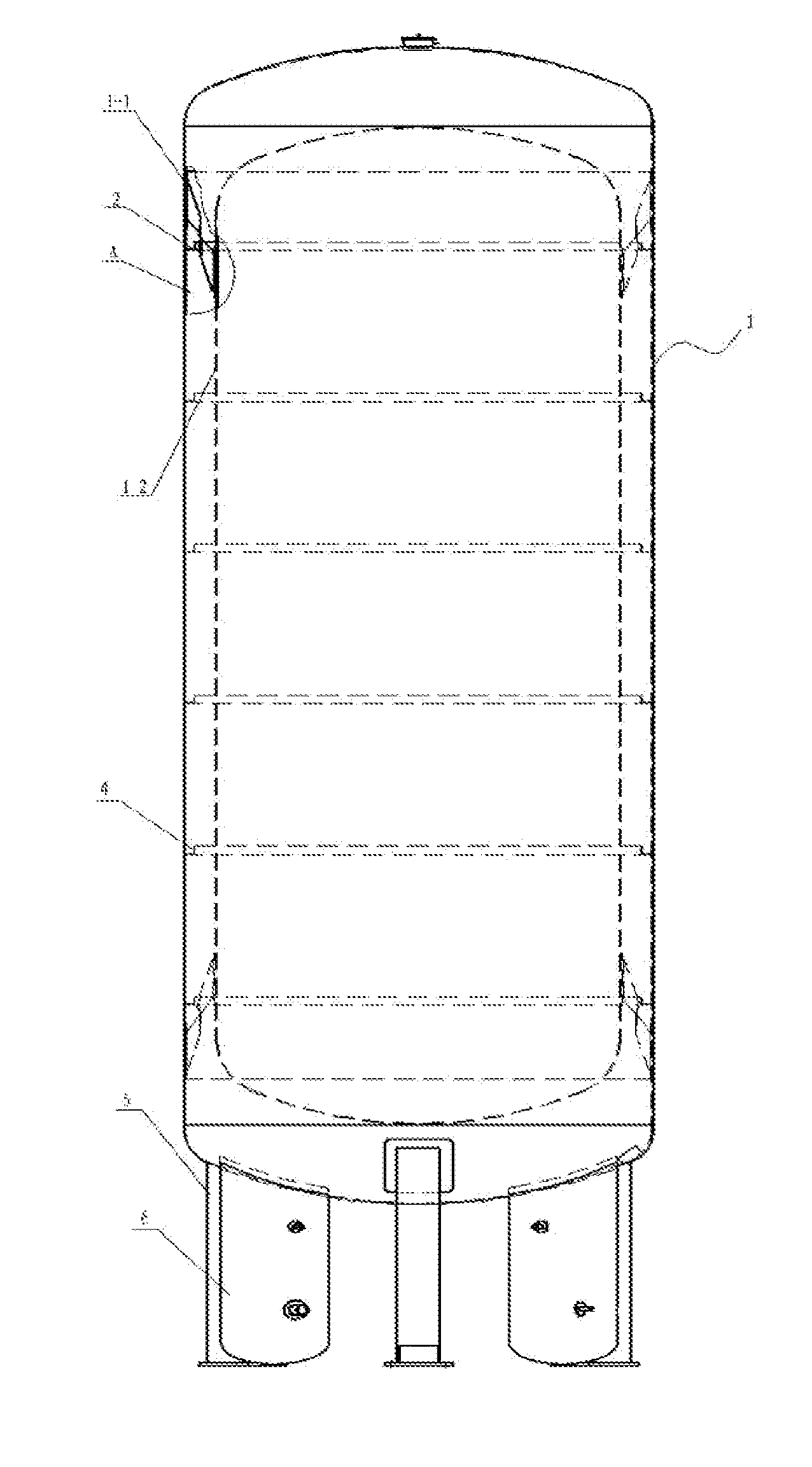

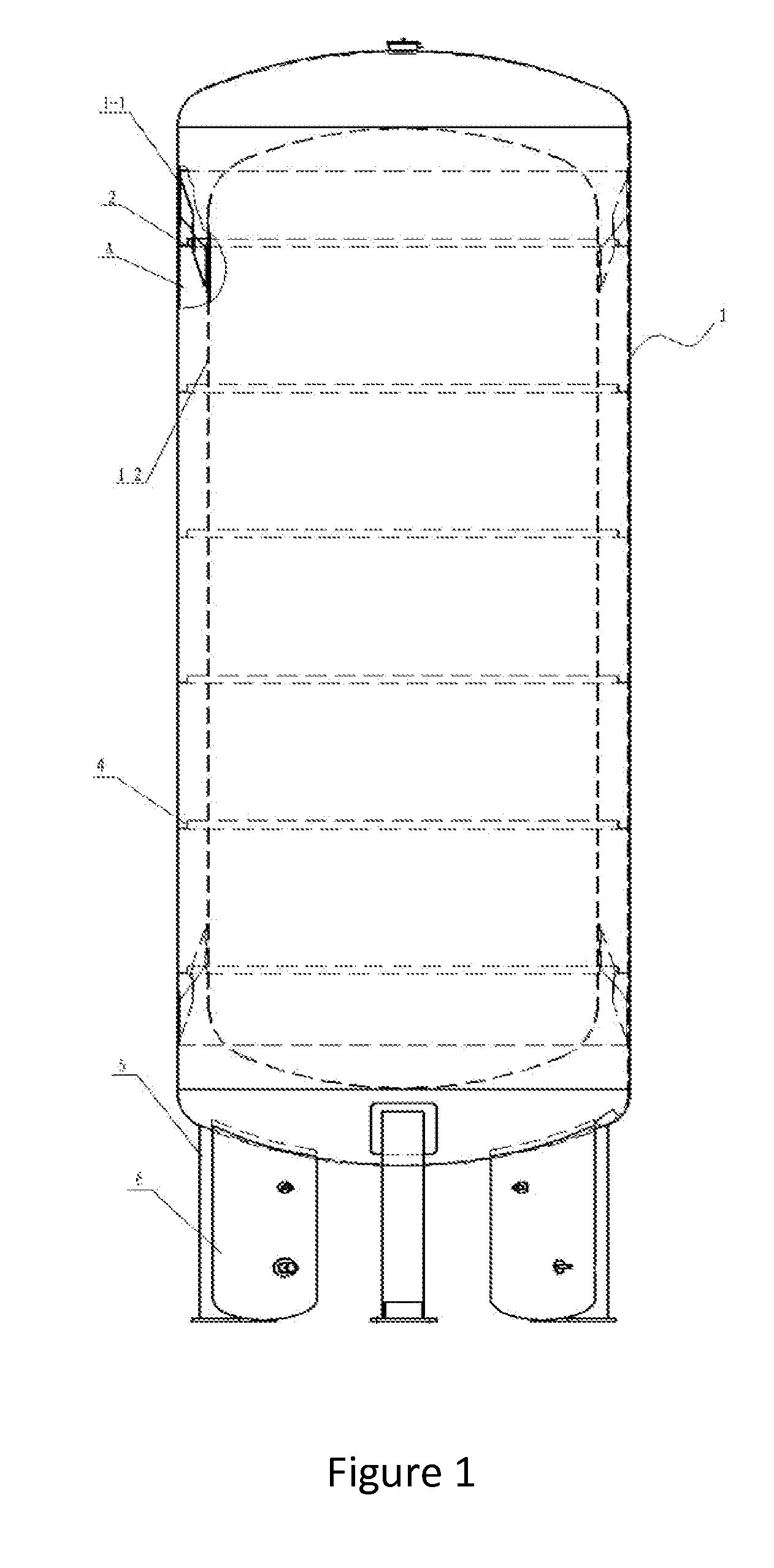

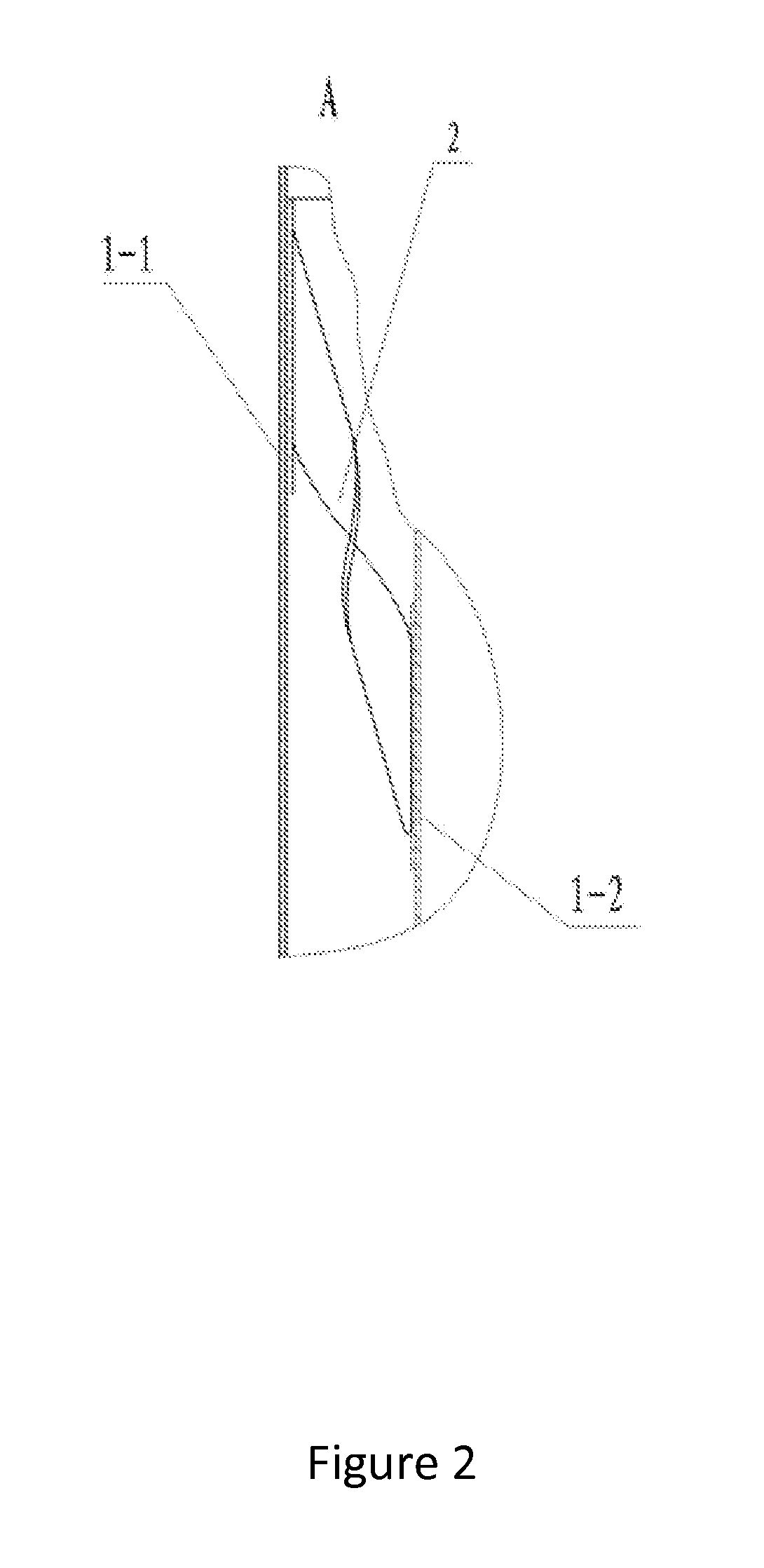

Energy Efficient Vertical Cryogenic Tank

InactiveUS20150330576A1High saturationAvoid cavitationVessel mounting detailsVessel geometry/arrangement/sizeFuel tankEngineering

Disclosed herein is an energy efficient vertical cryogenic tank, which comprises a tank body with a vacuum insulation interlayer, wherein the tank body comprises a transmission means including an air return pipe and a liquid outlet pipe, and positioning means including supporting legs provided at the bottom of the tank body, and a built-in saturation adjustment mechanism formed by a heat exchanger connected to an let of the air return pipe and a return air dispersing device. By using a saturation adjustment mechanism at the inlet of the air return pipe, the cryogenic storage tank can not only fully leverage the gasification gas produced at the pump, but also achieve the saturation function of the LNG in the tank, with such benefits as reduced energy loss, simplified tank interface settings, improved efficiency of saturation adjustment, and avoided pump cavitation.

Owner:SHIJIAZHUANG ENRIC GAS EQUIP

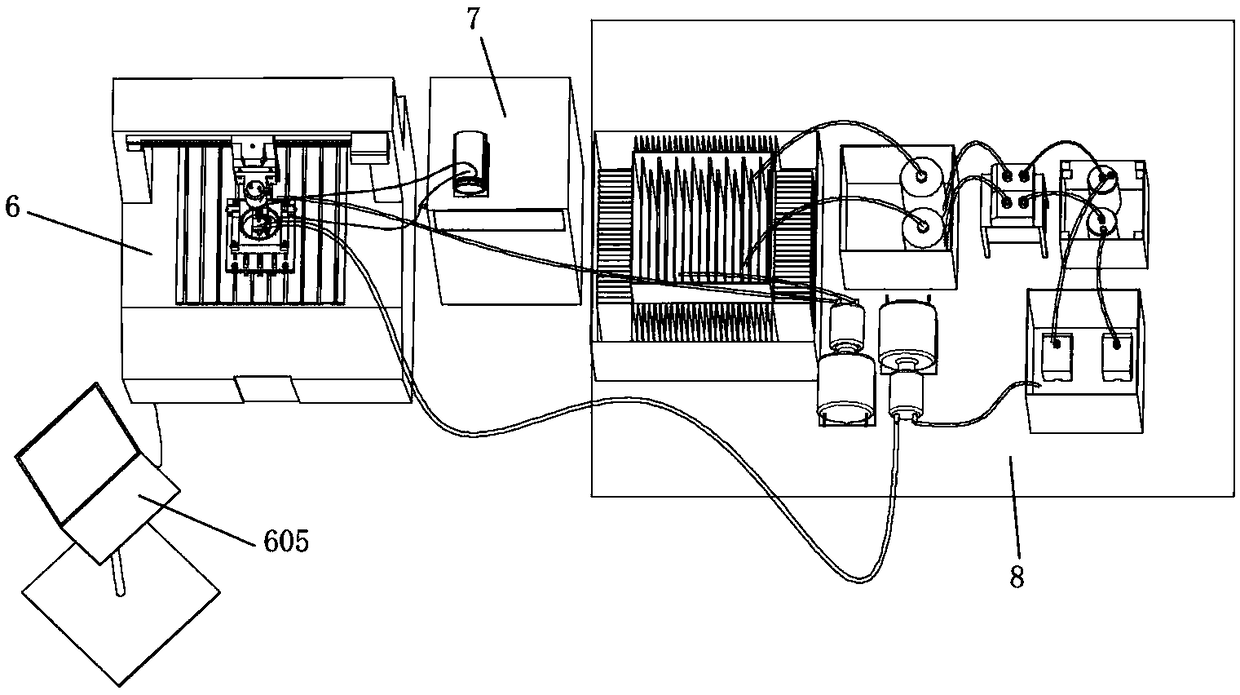

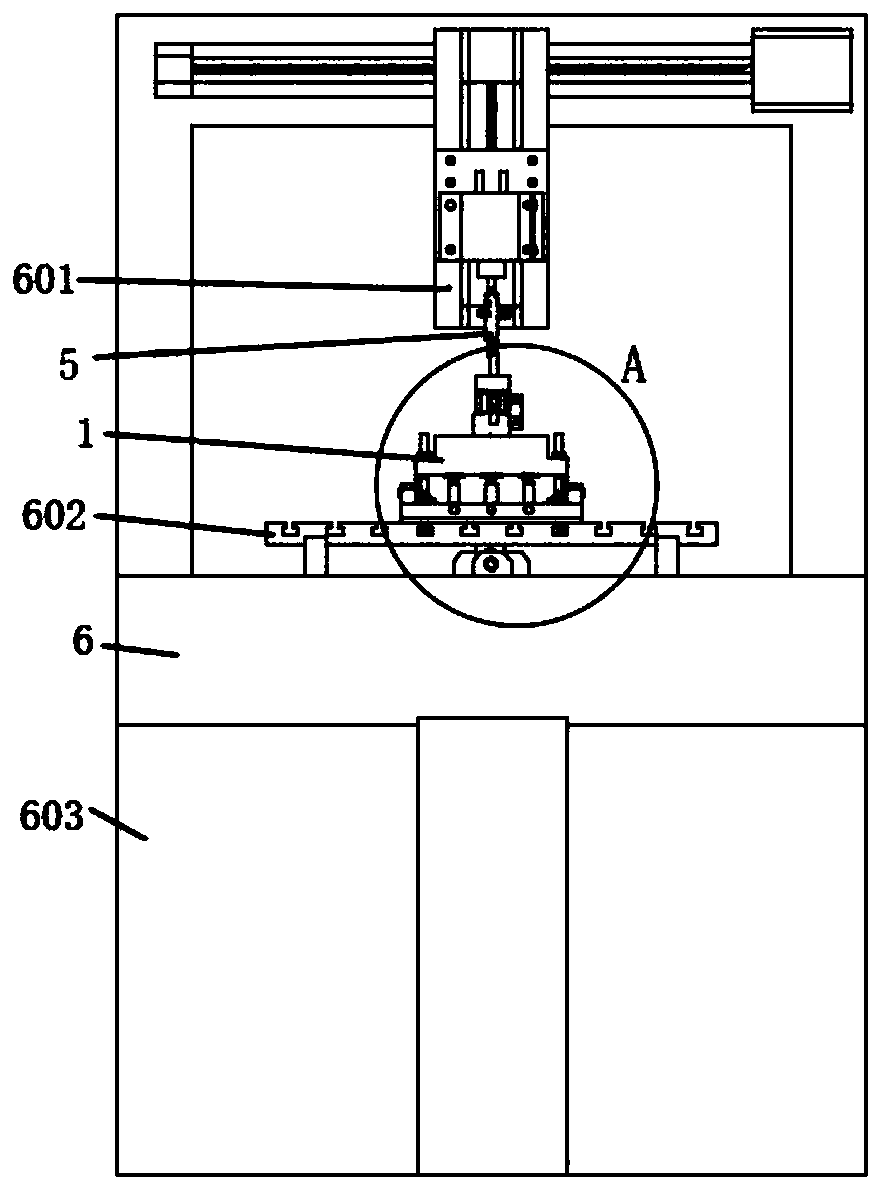

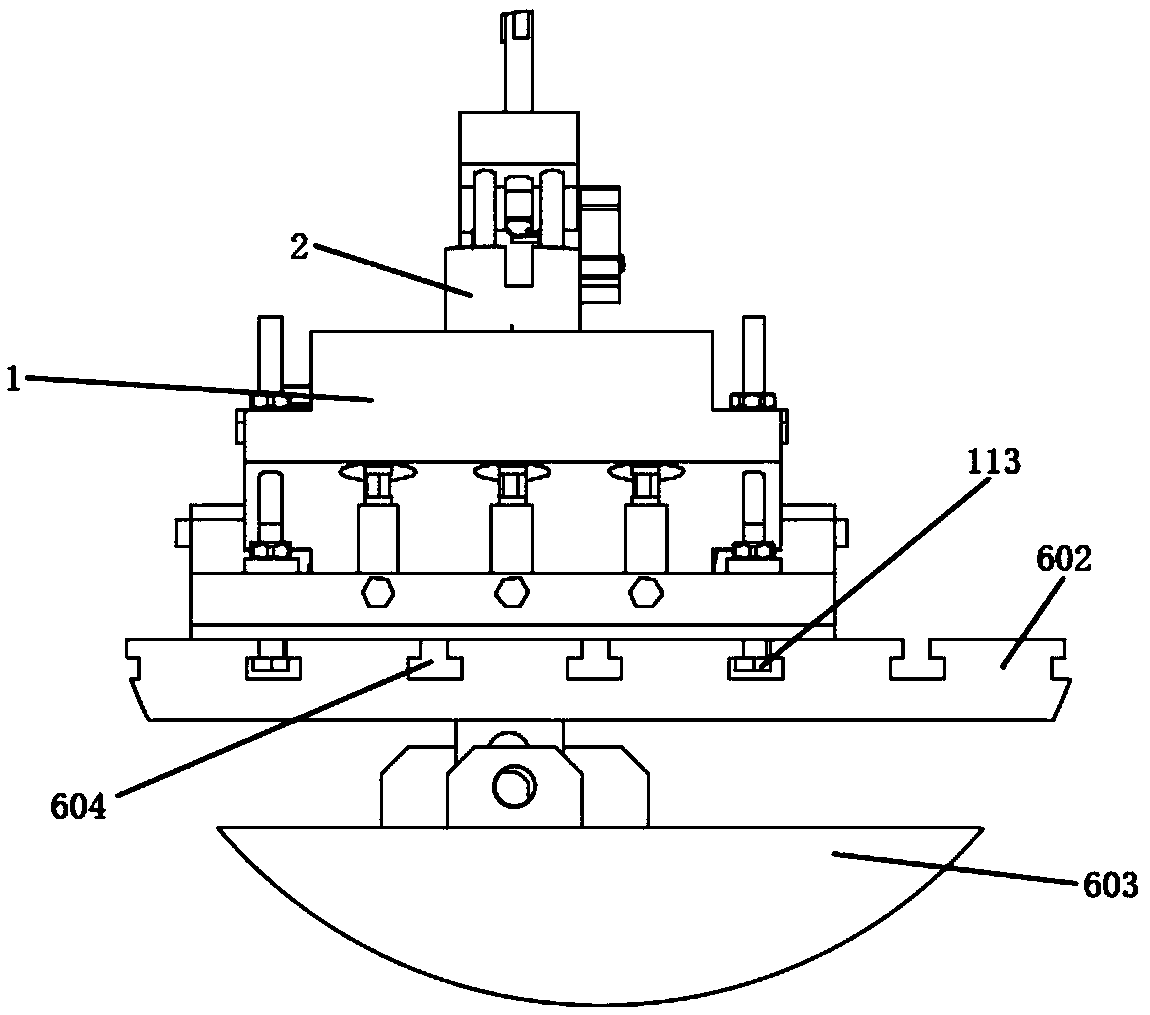

Tiny laval hole micro electrode electric spark machining device and assembling and machining method

ActiveCN109434225AAchieve mass productionGuaranteed machining accuracyElectrical-based auxillary apparatusNumerical controlCavitation

The invention belongs to the technical field of electric spark machining, and particularly relates to a tiny laval hole micro electrode electric spark machining device and an assembling and machiningmethod. The problem that a tiny laval hole fuel spray nozzle cannot be subjected to batched production is solved. The device comprises a device base table, a Y-axis rotating table, a Z-axis rotating table, a fuel spray nozzle clamp assembly, a fuel supply and power supply electrode assembly, a three-axis numerical control machine tool, an electric spark pulse power source and a high-voltage electric spark fuel conveying system. The three-axis numerical control machine tool, the high-precision dedicated clamp and micro electrode electric spark machining are combined for machining tiny laval holes, and machining precision is ensured while batched production is achieved, meanwhile, due to the micro electrode electric spark machining, micro pits are formed in the hole inner wall surface aftermachining, the size of the micro pits is about few microns, the surface microtexture effect is achieved, fluid and solid surface resistance is reduced, after micro electrode electric spark machining,a recast layer is formed on the surface, and the recast can achieve the effect of surface reinforcing and preventing cavitation damage.

Owner:ZHONGBEI UNIV

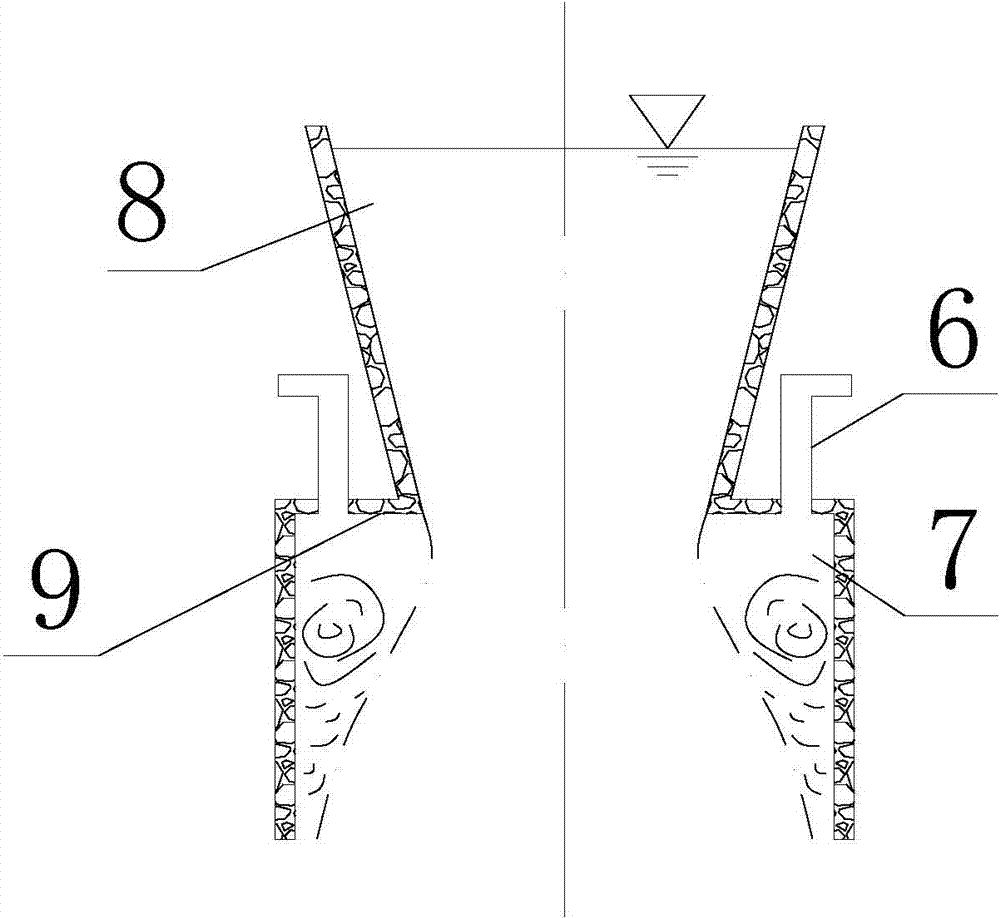

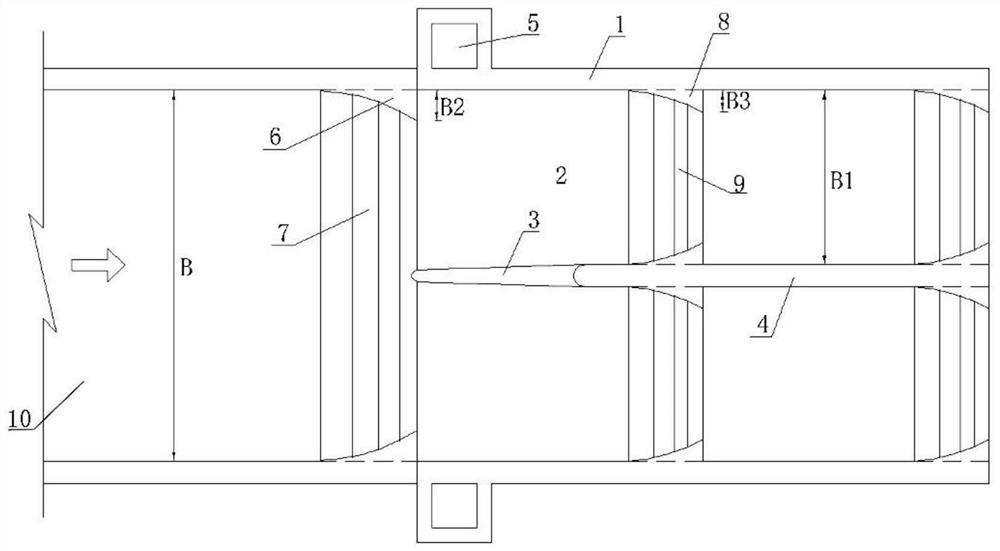

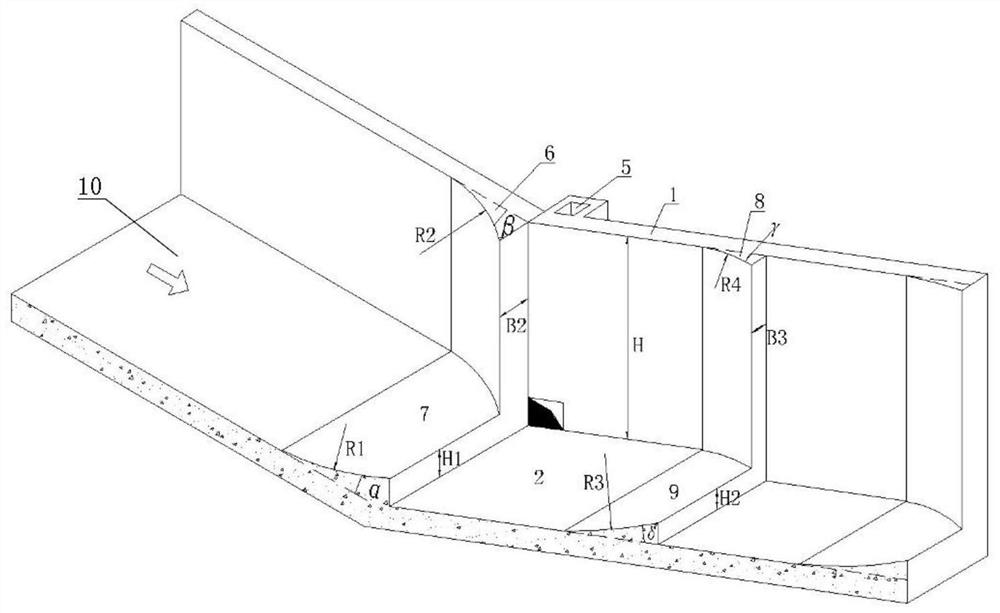

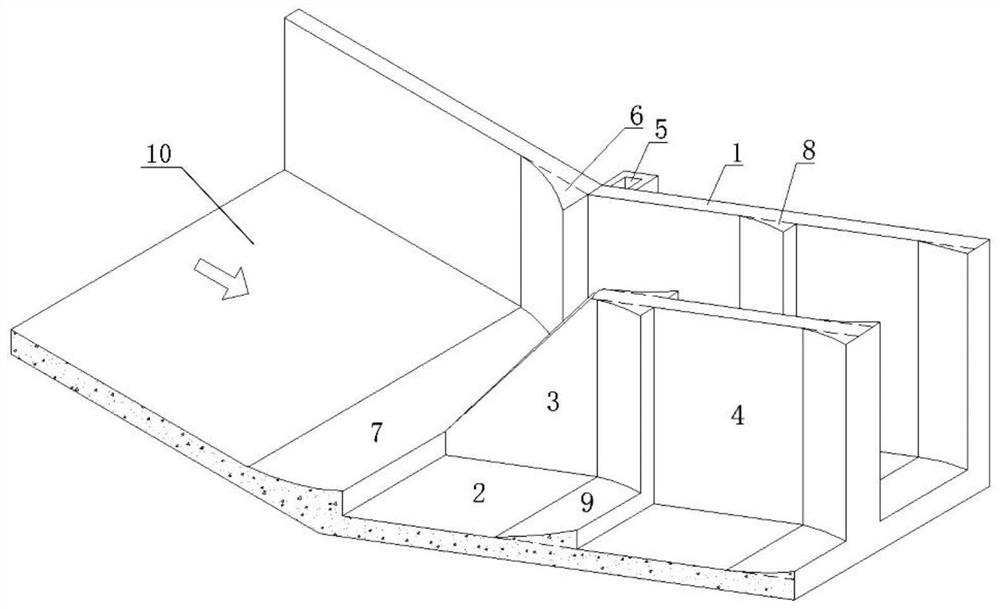

Sink-type top inflow sand flushing gallery structure

InactiveCN102304912APrevent cavitation damageEnsure safetyWater-power plantsConventional hydroenergy generationEngineeringHydropower

The invention relates to a sink-type top inflow sand flushing gallery structure, aiming to solve the technical problem of providing a sink-type top inflow sand flushing gallery structure which has simple structure and is convenient to construct. Silt along the sand flushing gallery can be removed; meanwhile, no dirt is accumulated on a power generation water inlet; during the working condition of flood discharge, suction eddy appearing above the sand flushing gallery can be eliminated to guarantee the safety of sand flushing cave structure. The technical problem for solving the problems is that the sink-type top inflow sand flushing gallery structure comprises a gallery main body, wherein the top of the gallery body is provided with one group of inflow holes. The sink-type top inflow sand flushing gallery structure is characterized in that one group of eddy beams is evenly distributed above the gallery body. The sink-type top inflow sand flushing gallery structure is mainly used in the hydropower station engineering, especially in the hydropower stations of rivers with more sand.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

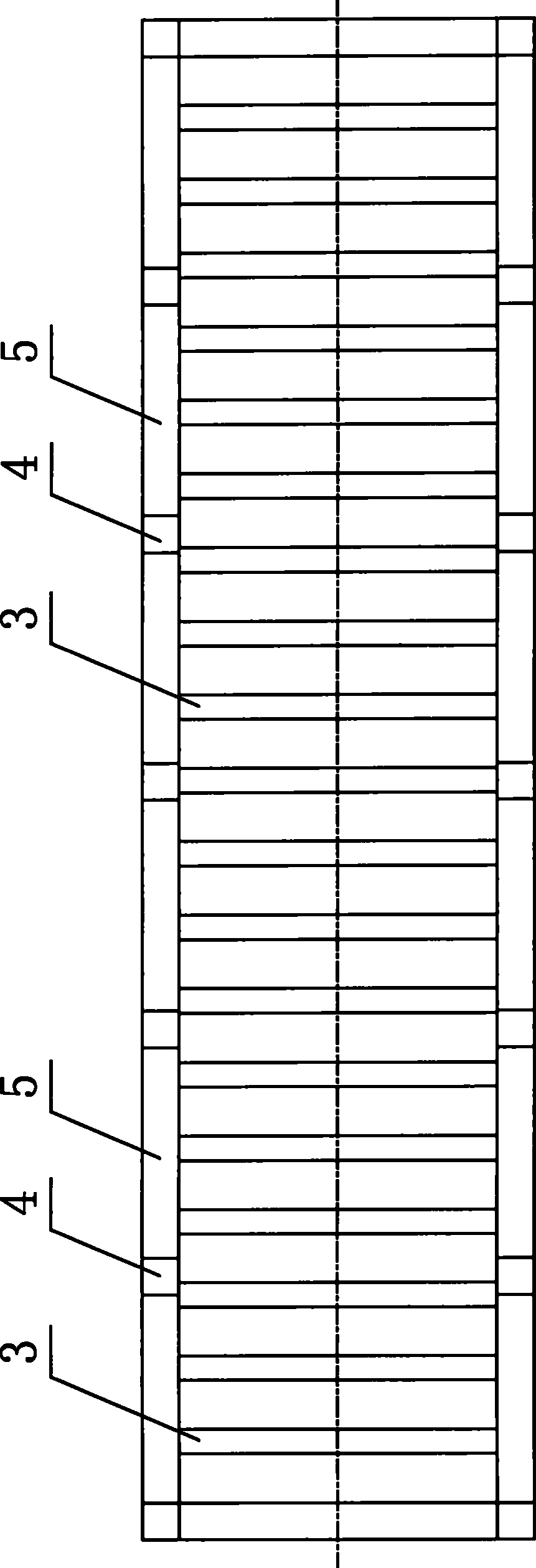

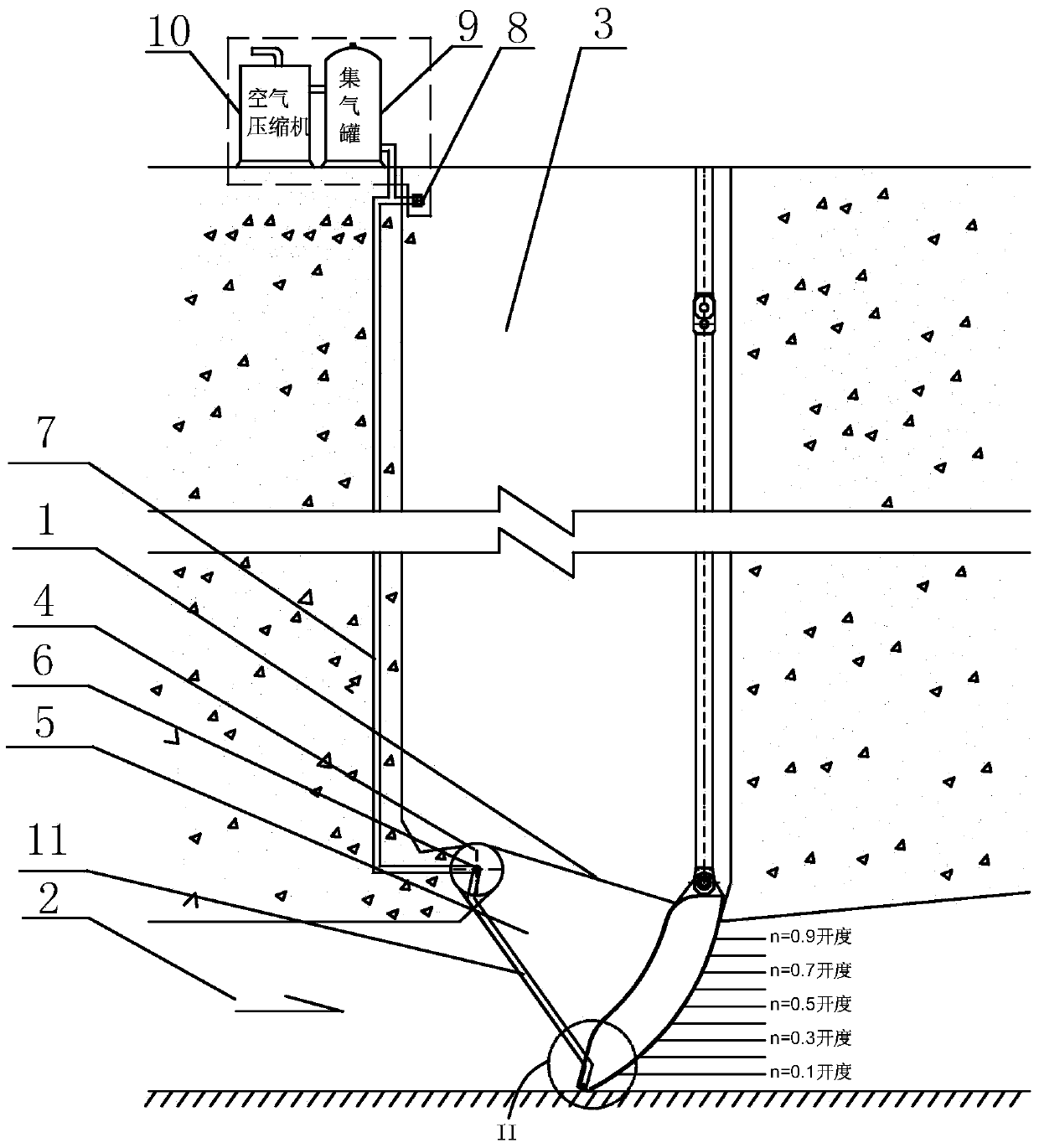

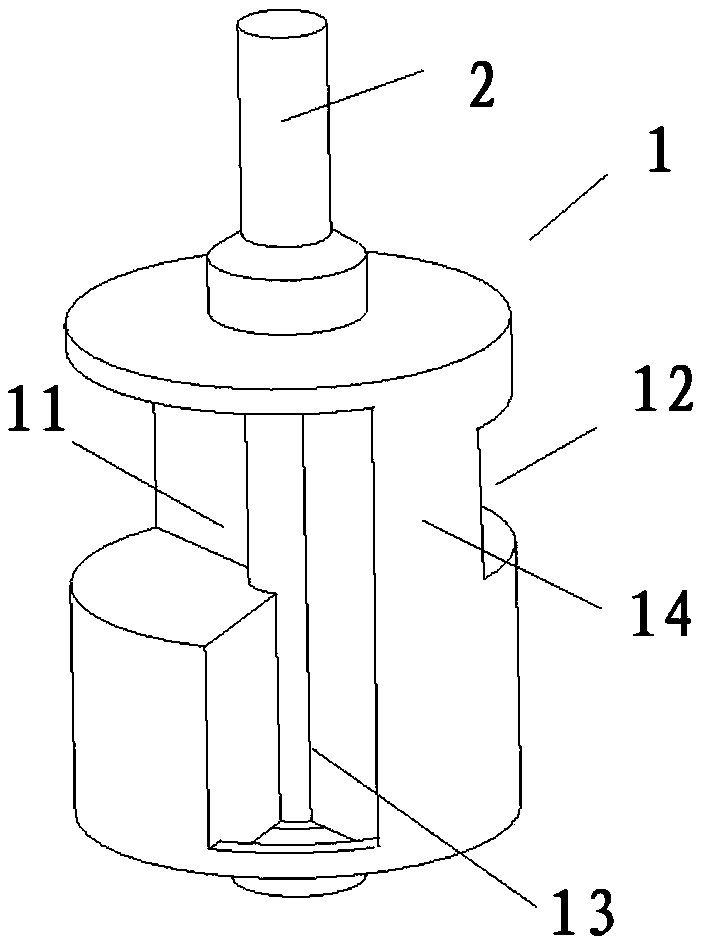

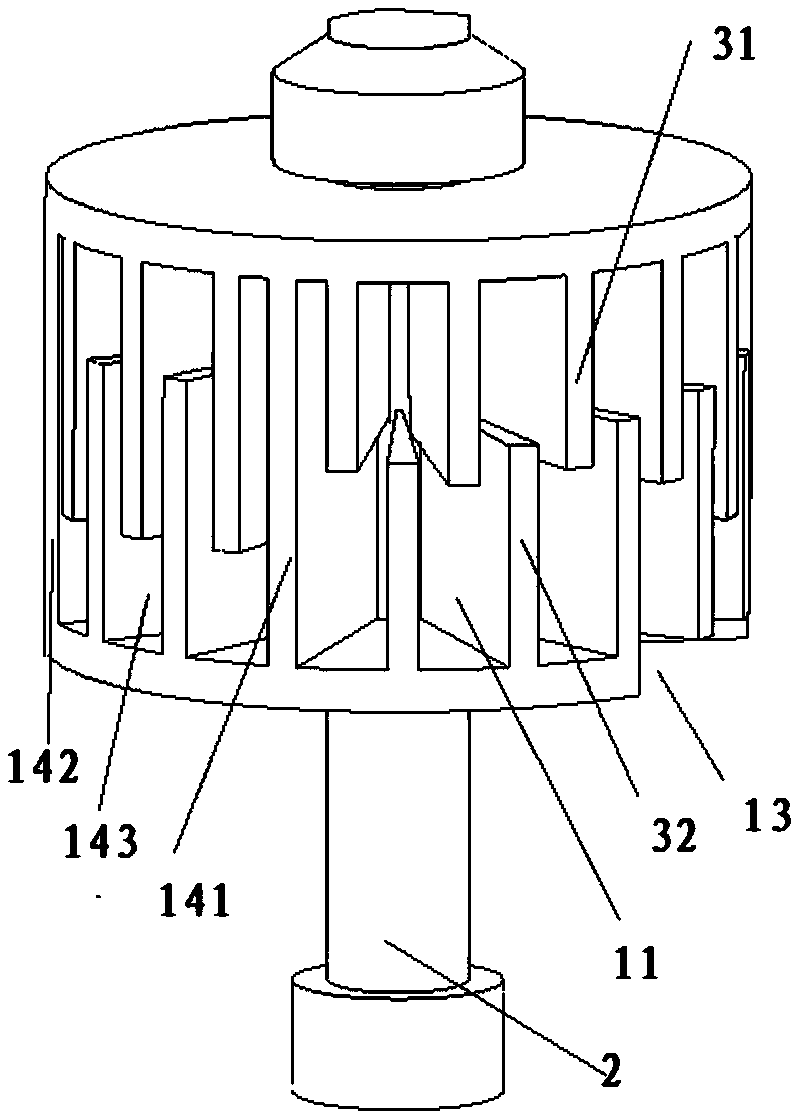

Multistage water cushion rotational flow vertical shaft flood discharging tunnel suitable for high water head

ActiveCN103758093AEnsure safe applicationCavitation damage does not occurBarrages/weirsWater flowEngineering

The invention discloses a multistage water cushion rotational flow vertical shaft flood discharging tunnel suitable for a high water head. The multistage water cushion rotational flow vertical shaft flood discharging tunnel comprises an upper horizontal section, a volute chamber section, a contraction section, a vertical shaft section and a lower horizontal section. An energy dissipation water cushion device is arranged at the position of the vertical shaft section with the water flow speed of 30-35m / s and formed by the contraction section, a protruded expanded ring plate and a straight drum section. The inner ring edge of the protruded expanded ring plate is connected with the lower end of the contraction section, the outer ring edge is connected with the upper end of the straight drum section, vent holes communicated with a blind area and outside atmosphere are arranged at the position of the water flow blind area formed by connecting the straight drum section with the protruded expanded ring plate so that air can be aerated into water flow, and the water flow can flow through the contraction section to be annularly contracted to solid water flow due to the inner diameter of the lower end of the contraction section so as to form a water cushion on the contraction section. The rotational flow vertical shaft flood discharging tunnel is suitable for high water head hydropower engineering and can greatly improve energy dissipation efficiency, vertical shaft cavitation damage can be effectively avoided, energy dissipation pressure of the bottom water cushion can be reduced simultaneously, and bottom plate damage is avoided.

Owner:SICHUAN UNIV

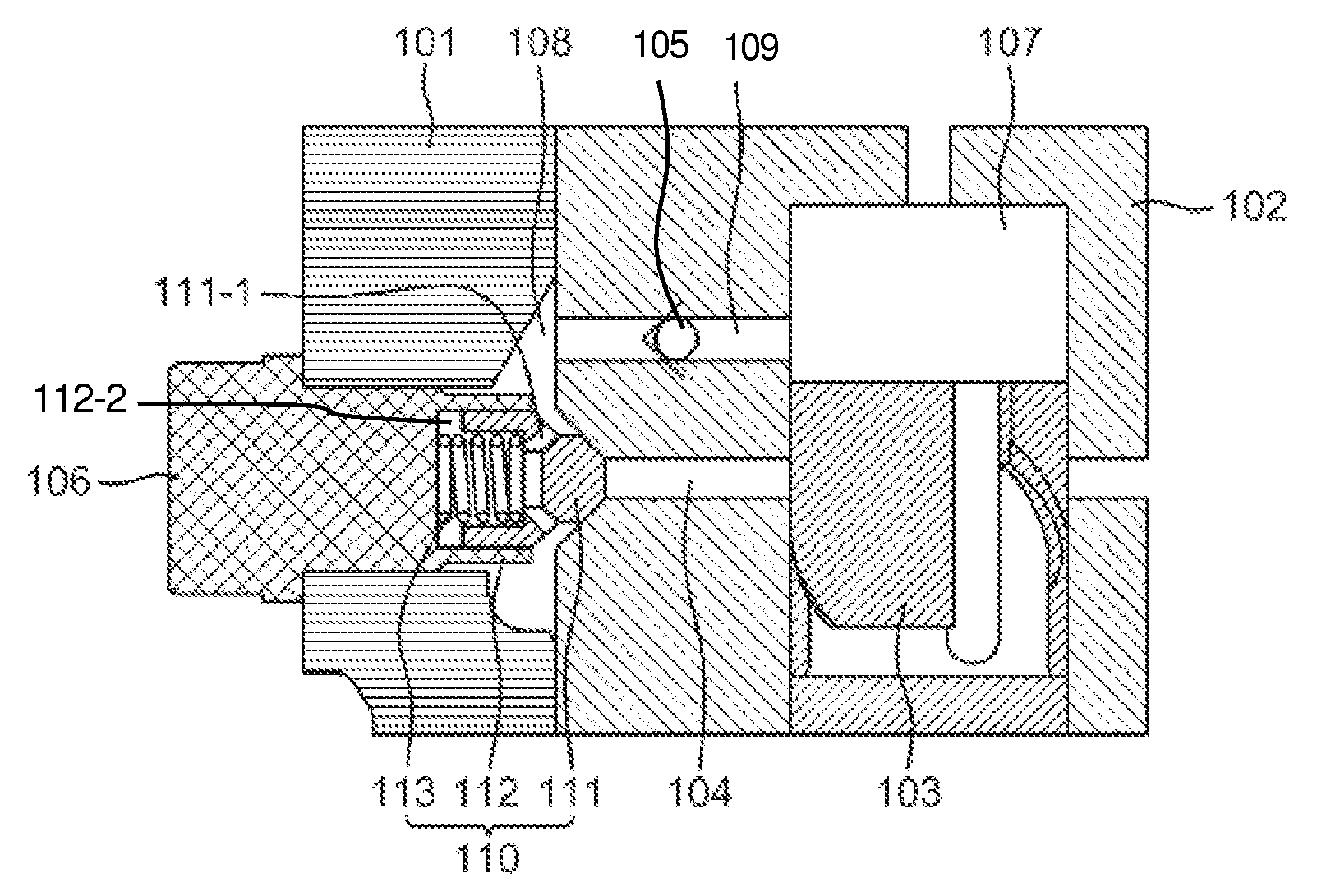

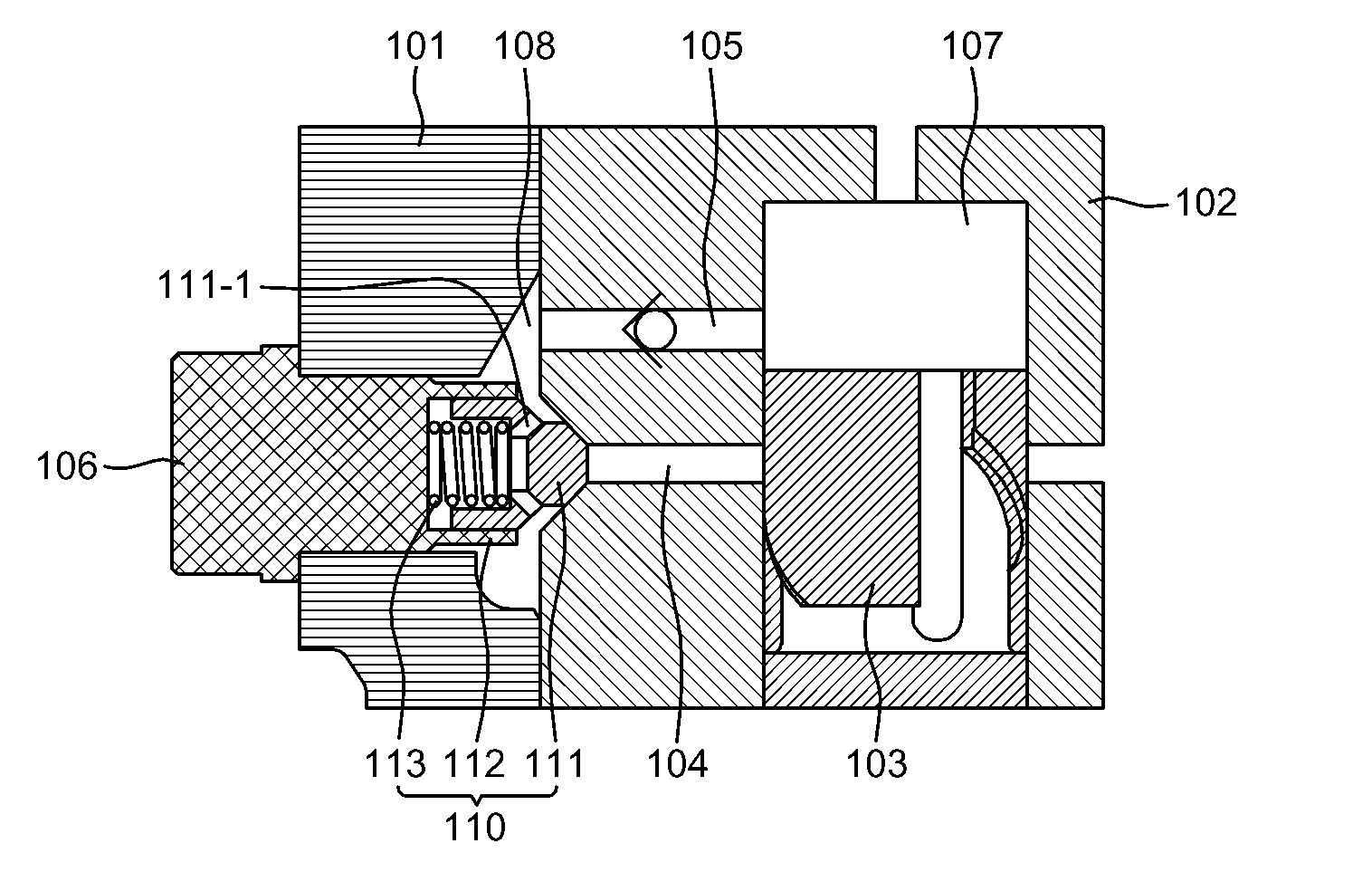

Apparatus for preventing cavitation damage to a diesel engine fuel injection pump

ActiveUS9200605B2Avoid cavitation damageAvoid erosion damageMachines/enginesFuel injecting pumpsCavitationEngineering

An apparatus for preventing cavitation damage to a diesel engine fuel injection pump comprises a valve member mounted on a barrel port to shut the barrel port during an early stage of fuel compression performed by the upward movement of a plunger to increase the pressure in the barrel port, a valve housing installed in the deflector or the barrel of a pump housing to support the valve member, and a pressure control valve constituted by a spring interposed between the valve member and the valve housing to elastically support the valve member. The barrel port is shut to increase the pressure therein during the early stage of fuel compression, and when the pressure of fuel in the barrel port exceeds a level higher than an open level, the barrel port opens to discharge fuel.

Owner:HYUNDAI HEAVY IND CO LTD

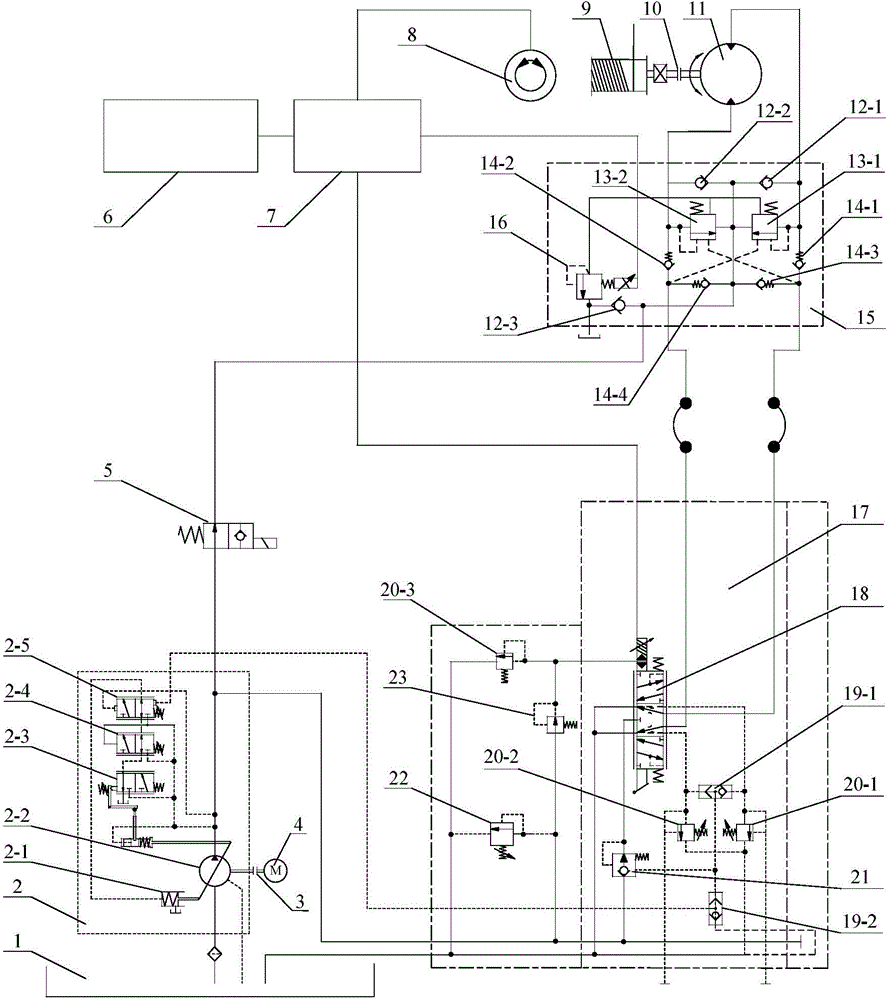

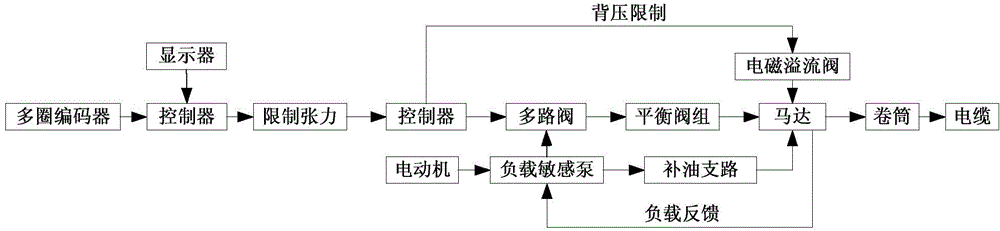

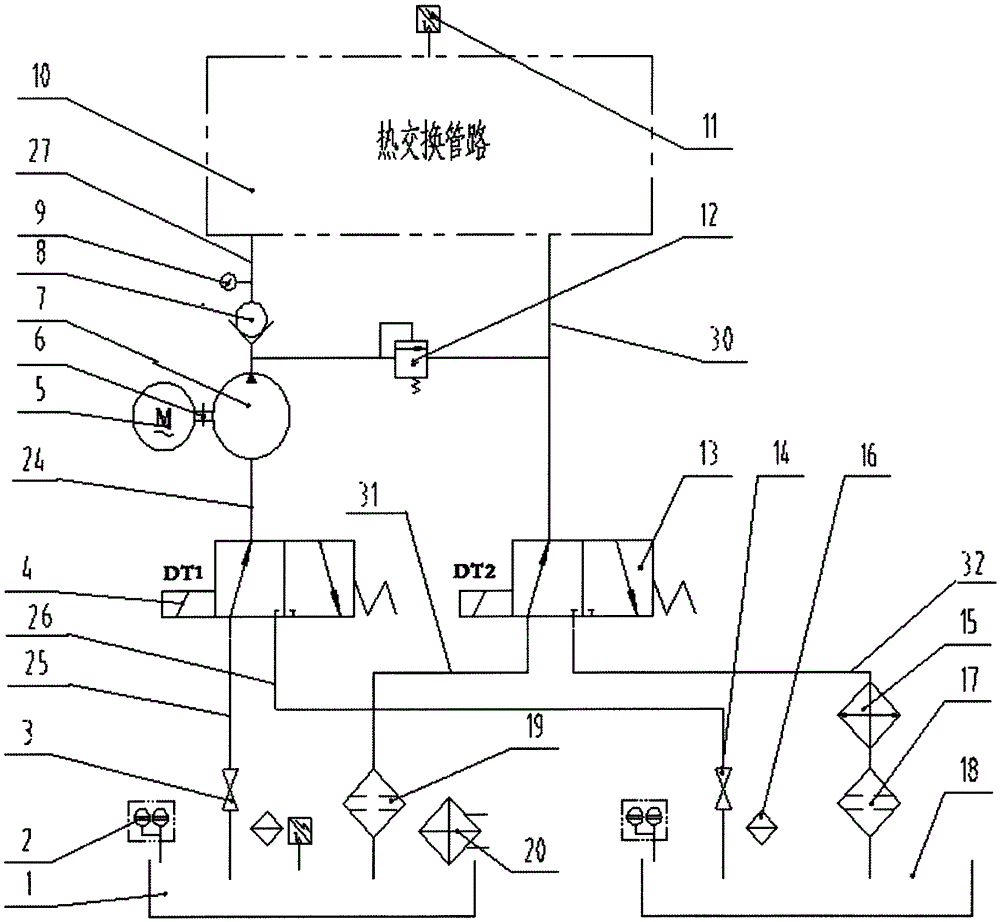

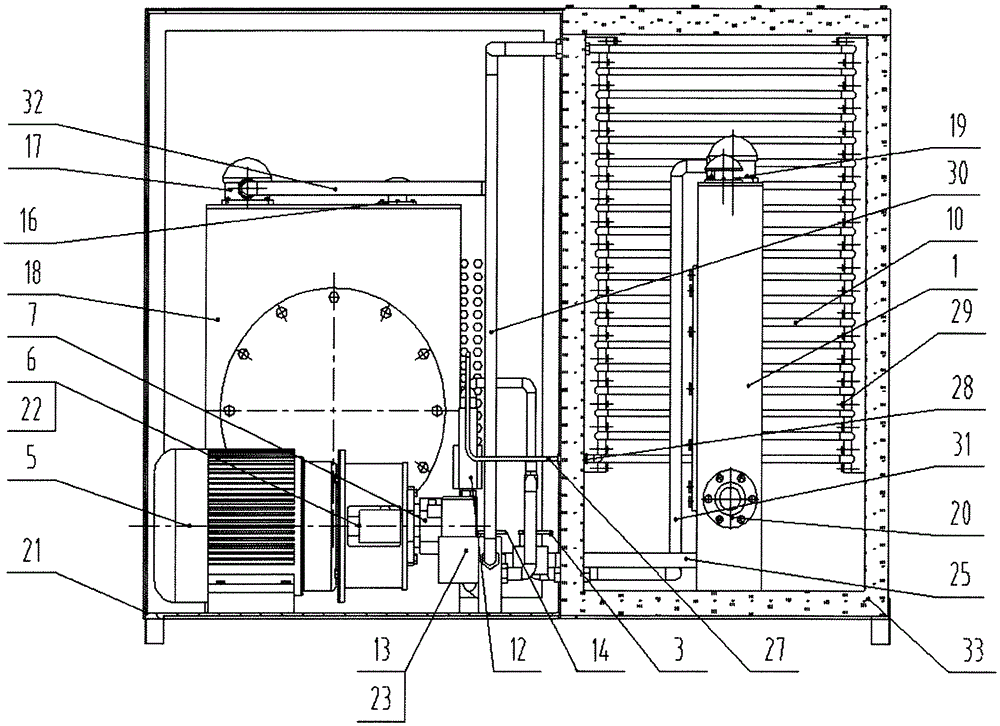

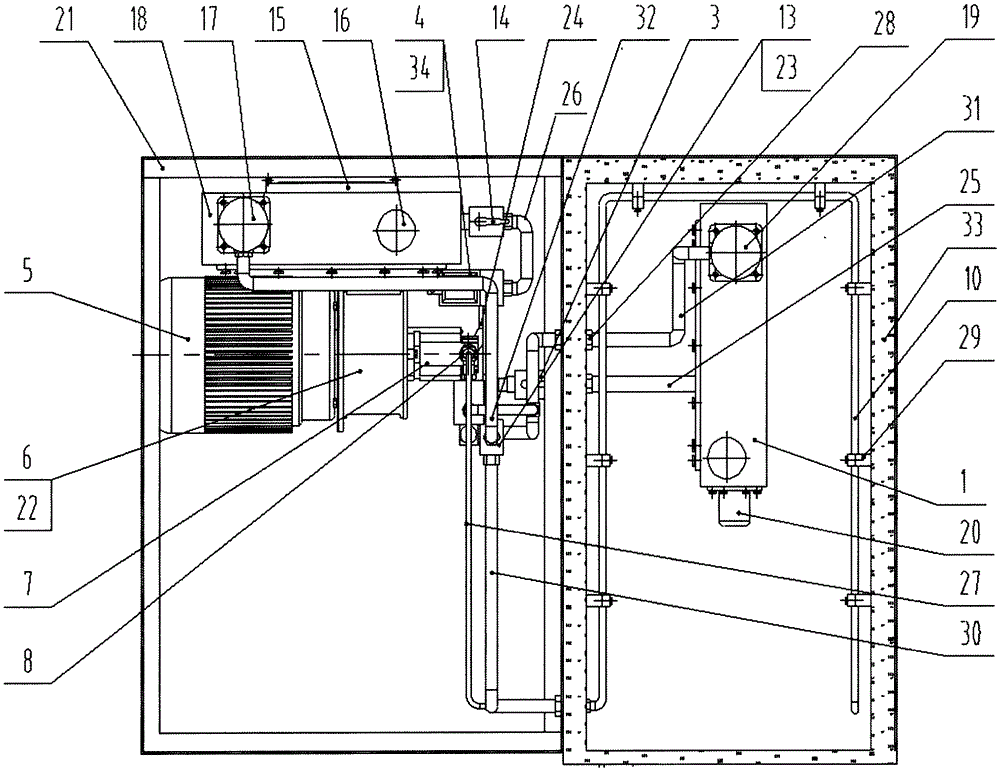

Hydraulic energy-saving control system of cable reeling and unreeling vehicle

ActiveCN104454696AAvoid damageAvoid breakingServomotorsFluid-pressure actuator componentsControl systemCoupling

A hydraulic energy-saving control system of a cable reeling and unreeling vehicle comprises an oil tank, a load-sensitive system, couplers, an electromotor, oil supplementing switch valve valves, a displayer with the touch input function, a controller, a multi-circle encoder, a coiling block, a motor, a balance valve assembly and a multi-path valve assembly. The electromotor and the load-sensitive system are connected through one coupler. The load-sensitive system and the multi-path valve assembly are connected through a hydraulic oil pipe. The multi-path valve assembly and the balance valve assembly are connected through a hydraulic oil pipe. The balance valve assembly and the motor are connected through a hydraulic oil pipe. The motor is connected with the coiling block through the other coupler. The controller is connected with the multi-circle encoder, the displayer with the touch input function, the balance valve assembly and the multi-path valve assembly through a circuit. The load-sensitive system, the multi-path valve assembly and the oil tank are communicated through a hydraulic oil pipe. The load-sensitive system is communicated with the balance valve assembly through a hydraulic oil pipe, the oil supplementing switch valves are installed on the oil pipes. The hydraulic energy-saving control system has the advantages of being reliable in work, diverse in function, high in responding speed, capable of reducing consumption and saving energy and the like.

Owner:YANSHAN UNIV

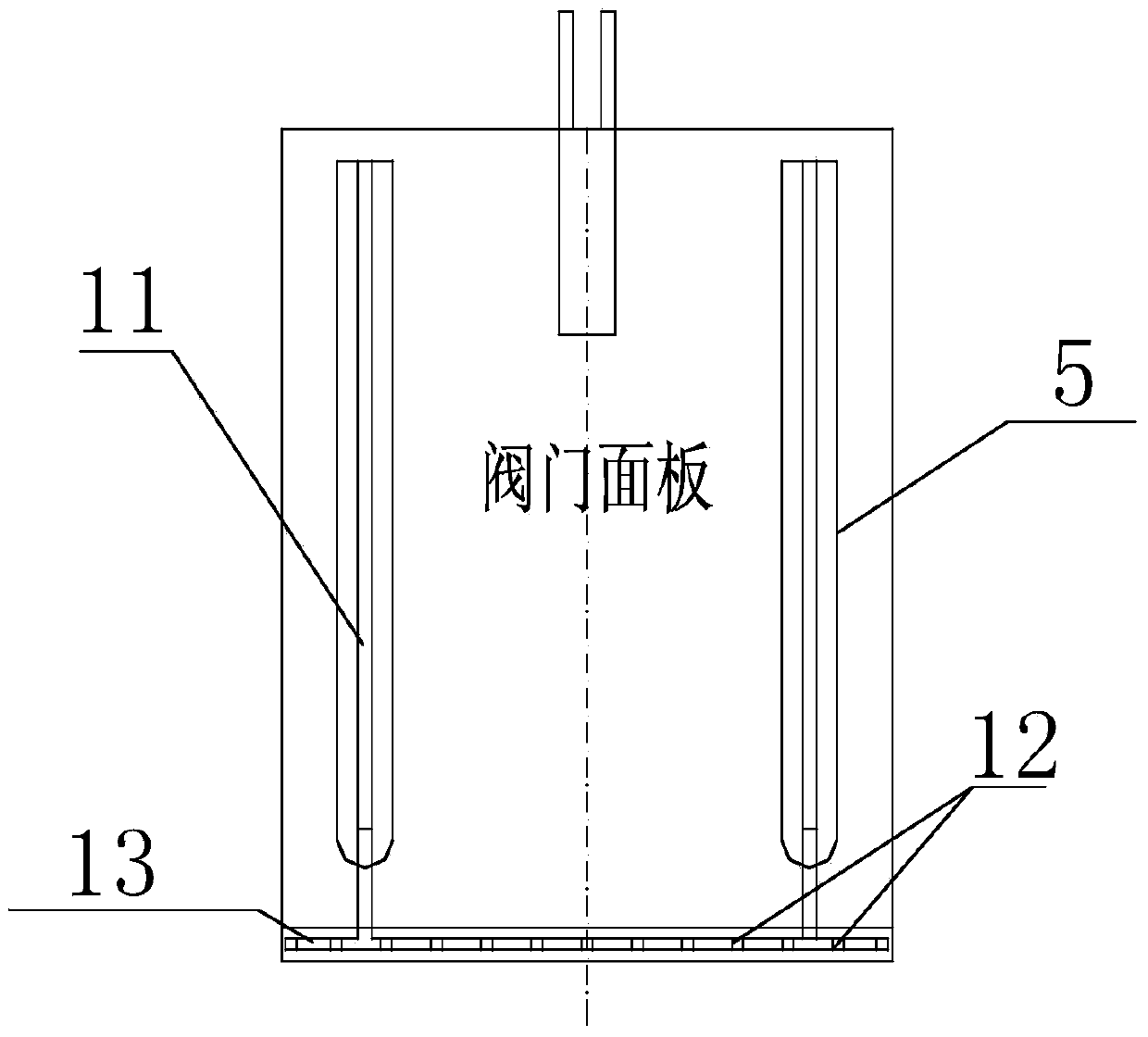

Bottom edge aerification system of water delivery valve of high lift lock

ActiveCN103758099AImprove water flow cavitation problemLow operating and management costsBarrages/weirsDry-docksWater flowHigh lift

The invention provides a bottom edge aerification system of a water delivery valve of a high lift lock. The bottom edge aerification system comprises a water delivery valve, a water gallery, a first vent pipe, a rotary joint and a second vent pipe. The water delivery valve adopts a slot-free anti-arc valve, and comprises a valve support hinge, a valve panel, and a valve support arm connecting the valve support hinge and the valve panel. The first vent pipe is buried in concrete when a valve chamber is poured, and an inlet end of the first vent pipe is positioned at the top of the valve chamber and connected with atmosphere. The second vent pipe communicated with the outside is led out of the bottom edge of the water delivery valve, and enters the valve support hinge along the valve support arm, and the rotary joint connecting the first vent pipe to the second vent pipe is arranged at the valve support hinge. The system can improve a water flow cavitation problem of a valve section of the lock, avoids cavitation erosion damage, can improve the operational safety of the lock, reduce the burial depth of the valve section and simplify a gallery body of the valve section, avoids a new cavitation source formed due to the excessively complicated body of the valve section, and can reduce the construction difficulty and construction cost of the gallery of the valve section.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

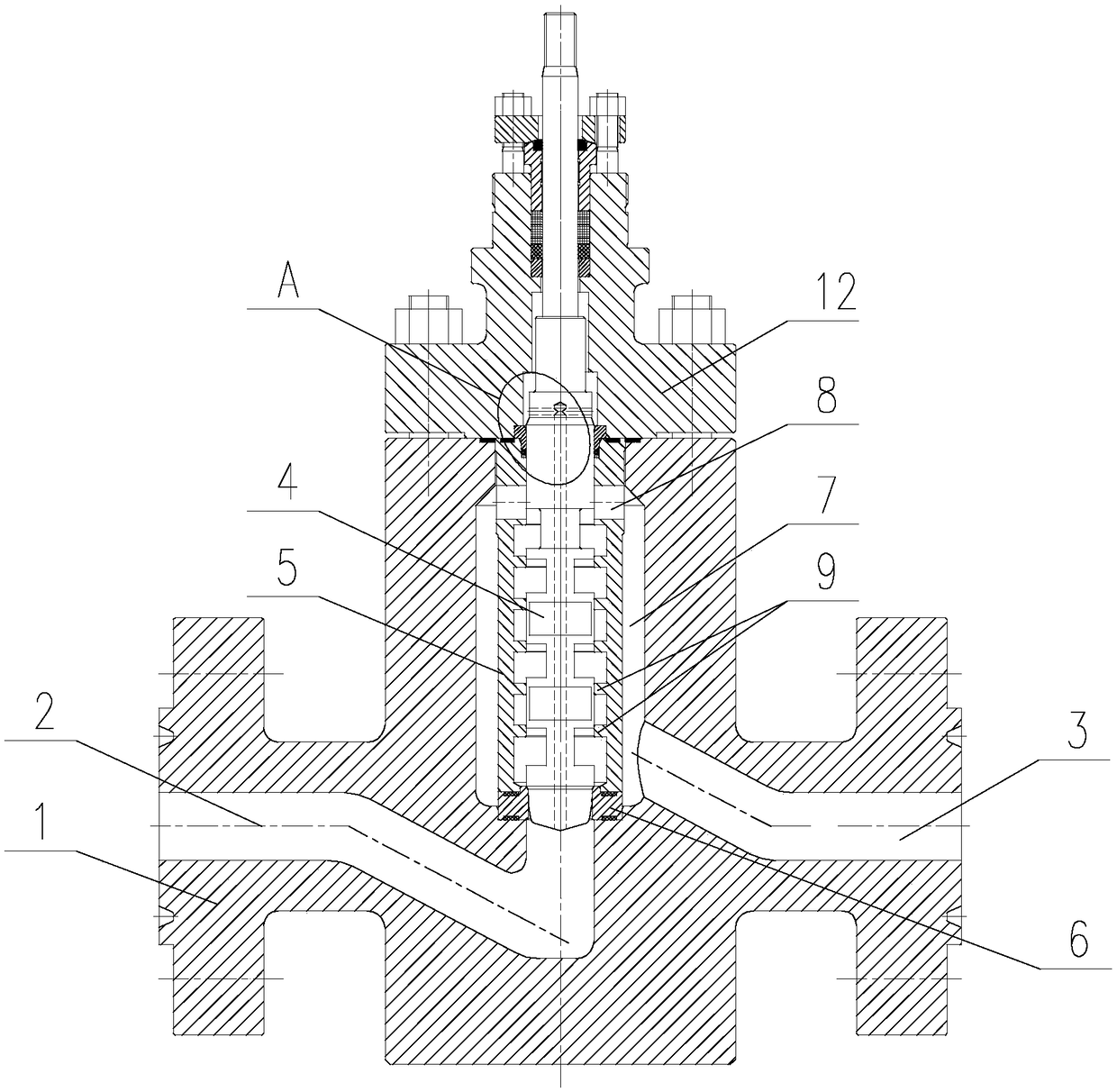

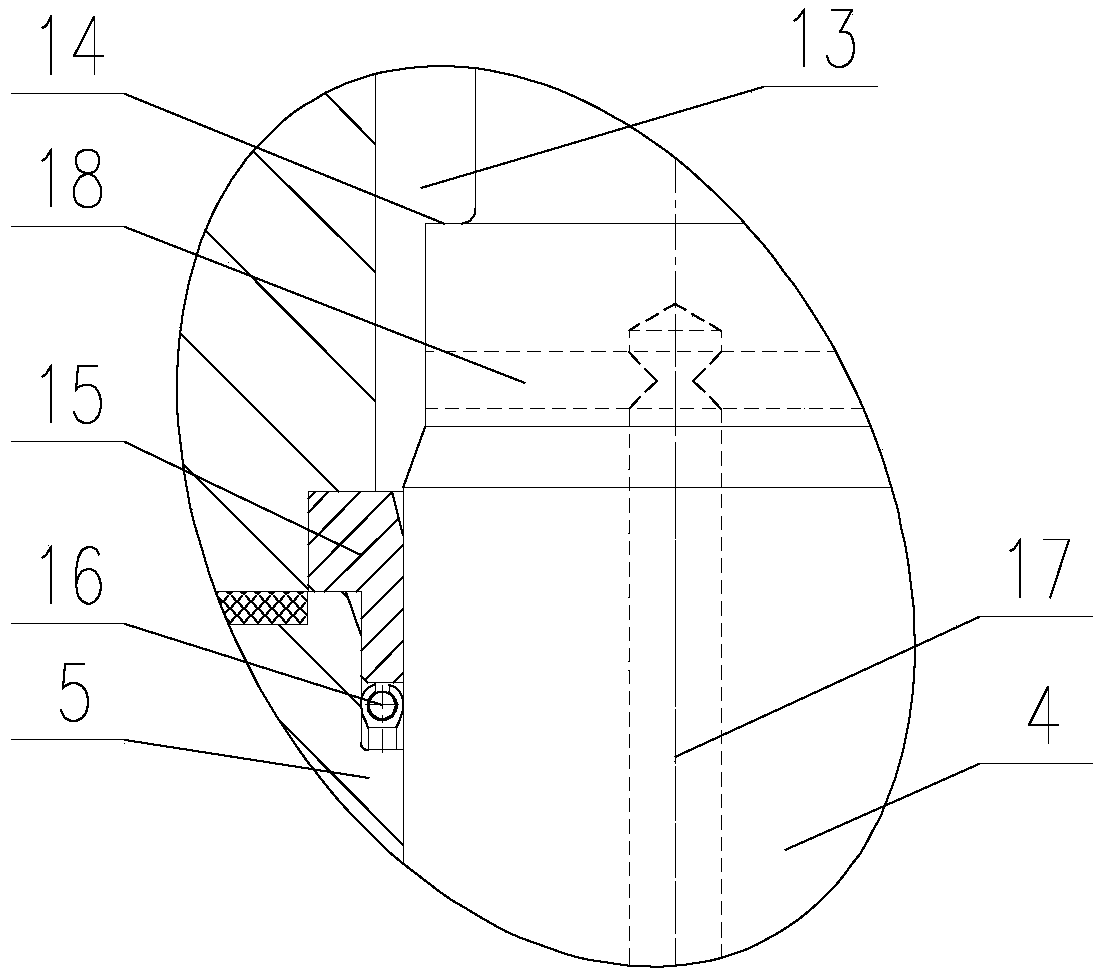

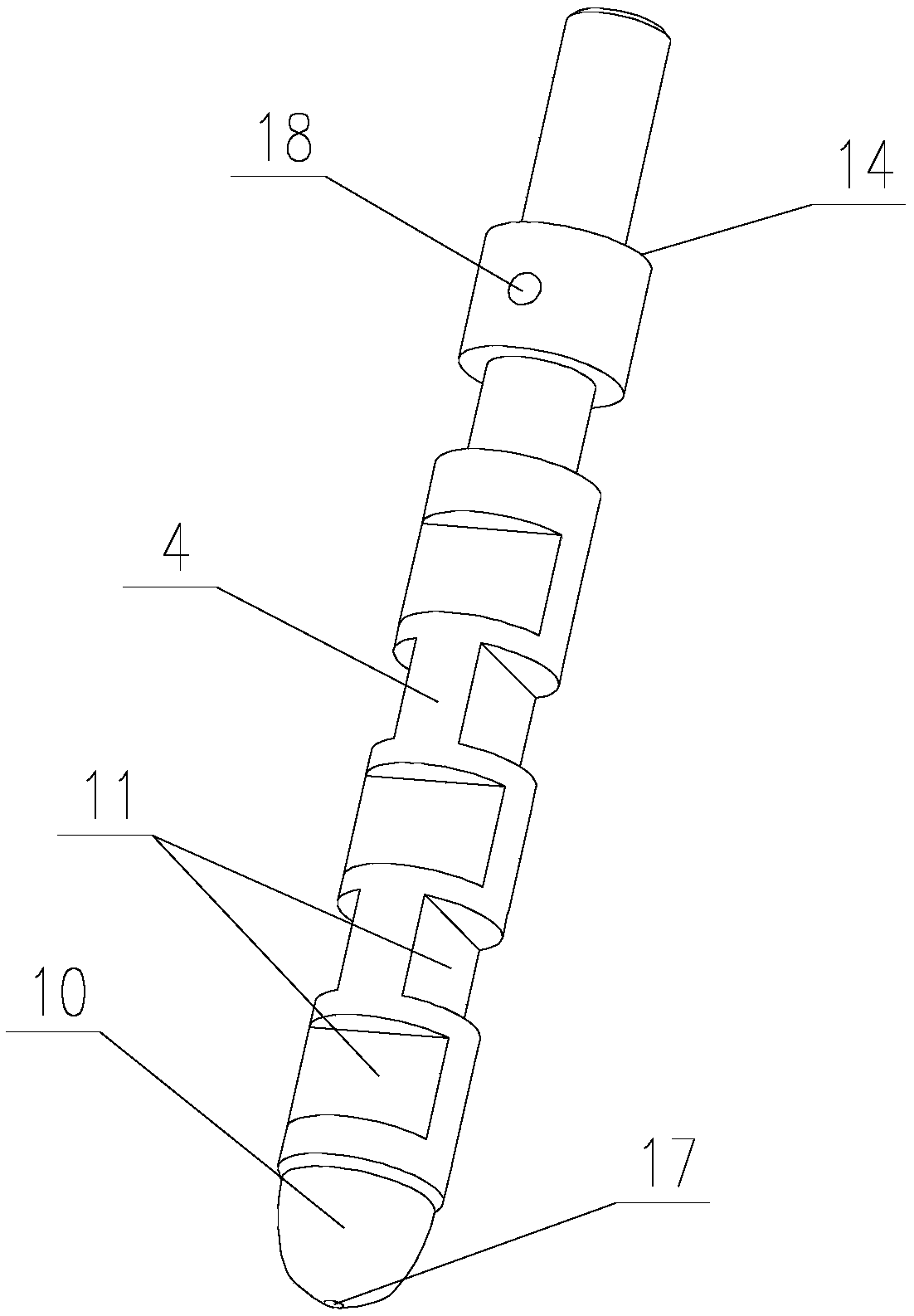

Pressure balancing type high-precision high-pressure-difference control valve

PendingCN109404606ALong runAchieving long-term operationPressure relieving devices on sealing facesValve members for absorbing fluid energyMultiple bufferingEngineering

The invention provides a pressure balancing type high-precision high-pressure-difference control valve which comprises a valve body and a pressure reducing channel. An inlet and an outlet are formed in the two sides of the valve body. The pressure reducing channel is composed of a valve core, a valve core sleeve and a valve base. A drainage runner is arranged between the valve core sleeve and thevalve body. A drainage opening communicating with the drainage runner is formed in the upper end of the valve core sleeve. The drainage runner communicates with the outlet. Multiple ring-shaped bossesare arranged on the inner wall face of the valve core sleeve at intervals. The valve base is arranged at the lower end of the valve core sleeve and communicates with the inlet. The valve core is arranged in the valve core sleeve and connected with the valve core sleeve in a sliding manner. A curved surface sealing face matched with the valve base is arranged at the lower end of the valve core. The valve core is provided with multiple buffering sets at intervals in the axial direction. Each buffering set comprises two buffering grooves arranged symmetrically. The adjacent buffering sets are arranged in a staggering manner. When the curved surface sealing face is matched with the valve base, the buffering grooves and the ring-shaped bosses are partially overlapped. According to the controlvalve, the valve core, the valve core sleeve and the valve base are adopted, control over high-pressure-difference media is achieved, adjusting performance is good, and adjusting precision is high.

Owner:WUZHONG INSTR +1

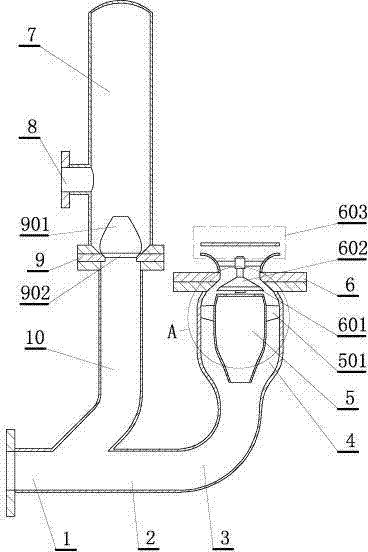

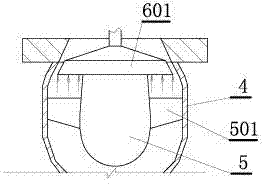

Resistance and vibration reduction hydraulic ram pump

ActiveCN104121240AAvoid violent vibrationAvoid cavitation damageMachines/enginesPumpsHydraulic ramEngineering

The invention relates to a resistance and vibration reduction hydraulic ram pump. The resistance and vibration reduction hydraulic ram pump comprises a power pipe, the power pipe is connected with a pump body, the pump body is connected with the bottom of a bend and the bottom of a vertical water inlet pipe, the water inlet pipe is connected with a water conveying valve, the water conveying valve is connected with an air tank, the air tank is connected with a water outlet pipe, the bend is connected with the small end of a reducing pipe, the large end of the reducing pipe is connected with a drain valve, the back side of a water outlet valve clack of the water conveying valve is provided with a water outlet deflector, the upstream face of a drain valve clack of the drain valve is provided with a drain deflector, the back side of the drain valve clack is provided with a runner cone, the drain deflector is fixedly connected with the reducing pipe, and the runner cone is fixedly connected with the drain valve clack. The deflectors are arranged on two check valves of the hydraulic ram pump, so that the purposes of decreasing the resistance coefficient of the check valves, reducing the weight of the valve clacks and preventing the hydraulic ram pump from violent vibration and cavitation erosion are achieved, the service life of the hydraulic ram pump can be prolonged, the noise and vibration of the hydraulic ram pump are reduced remarkably, and efficiency of the hydraulic ram pump can be improved remarkably.

Owner:北京宇豪胜水利科技咨询有限公司

Wear-resistant cutter-suction pump

ActiveCN104235077ARealize all-round protectionAvoid wear and tearPump componentsPumpsImpellerCavitation

The invention provides a wear-resistant cutter-suction pump, belongs to the field of electromechanical techniques and solves the problem that a case of the existing cutter-suction pump is easily caused to be damaged due to sand and stone impact and cavitation. The wear-resistant cutter-suction pump comprises a pump case, an impeller and a delivery pipe, wherein the impeller is arranged in the pump case and the delivery pipe is communicated with an inner chamber of the pump case. The wear-resistant cutter-suction pump is characterized in that a plurality of magnetic wear-resistant blocks are arranged in the inner chamber of the pump case, and first magnets which can attract the wear-resistant blocks onto the inner wall of the pump case are arranged at the external part of the pump case. By attracting the wear-resistant blocks in the inner chamber of the pump case onto the inner wall of the pump body through the first magnets, a wear-resistant layer is formed on the inner wall, thus the pump body can be prevented from being worn by sand and stones, the inner wall can also be prevented from being damaged due to cavitation and the service life of the cutter-suction pump is prolonged.

Owner:ZHEJIANG OCEAN UNIV

Apparatus for preventing cavitation damage to a diesel engine fuel injection pump

ActiveUS20110259302A1Avoid cavitation damageAvoid erosion damageMachines/enginesFuel injecting pumpsCavitationPump chamber

The present invention relates to an apparatus for preventing cavitation damage to a diesel engine fuel injection pump, wherein a pressure control valve for shutting a barrel port is mounted on a deflector or a barrel of the fuel injection pump to increase the fuel pressure in the barrel port during an early stage of fuel compression. This prevents fountain-type or jet-type cavitation from occurring before and after the opening of the barrel port during a late stage of fuel compression, thereby preventing corrosion damage caused by cavitation occurring mainly in a plunger and the barrel port of the fuel injection pump. The key technical features of the present invention are for an apparatus for preventing cavitation damage to a diesel engine fuel injection pump having a fuel intake valve and the barrel port for the inflow and outflow of fuel, respectively, comprising: a valve member mounted on the barrel port to shut the barrel port during an early stage of fuel compression performed by the upward movement of the plunger to increase the pressure in the barrel port; a valve housing installed in the deflector or the barrel of a pump housing to support the valve member; and a pressure control valve constituted by a spring interposed between the valve member and the valve housing to elastically support the valve member. The barrel port is shut to increase the pressure therein during the early stage of fuel compression, and thus preventing cavitation caused by the pressure difference between the barrel port and a pump chamber before and after the opening of the barrel port during the late stage of fuel compression. When the pressure of fuel in the barrel port exceeds a level higher than an open level, the barrel port opens to discharge fuel.

Owner:HYUNDAI HEAVY IND CO LTD

Air-entrained anti-cavitation structure behind the gate of flood discharge tunnel

ActiveCN111809580BIncrease flow rateAvoid cavitation damageBarrages/weirsWater-power plantsJet flowWater flow

The invention discloses an aerated anti-cavitation structure behind the gate of a flood discharge tunnel, comprising a flood discharge tunnel, on which a gate is installed, and at least one ventilation slot is arranged downstream of the gate, and the ventilation slot communicates with the external atmospheric environment, The flood discharge tunnel between the gate and the first ventilation slot is a closed section, and a deflector is arranged in the closed section. Adopting the technical solution of the present invention, by setting a closed section on the downstream flood discharge tunnel at the position where the gate is installed in the flood discharge tunnel, and setting a deflector in the closed end, the water flow forms a high-speed jet after flowing through the closed section, which speeds up the flow rate of the water flow, and By setting the venting groove connected to the atmospheric environment in the downstream unpressurized section of the closed section, aeration is performed on the jet flow, which effectively avoids cavitation damage to the flood discharge tunnel downstream of the gate, ensures the safety of water conservancy facilities, and prolongs the use of water conservancy facilities. life.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

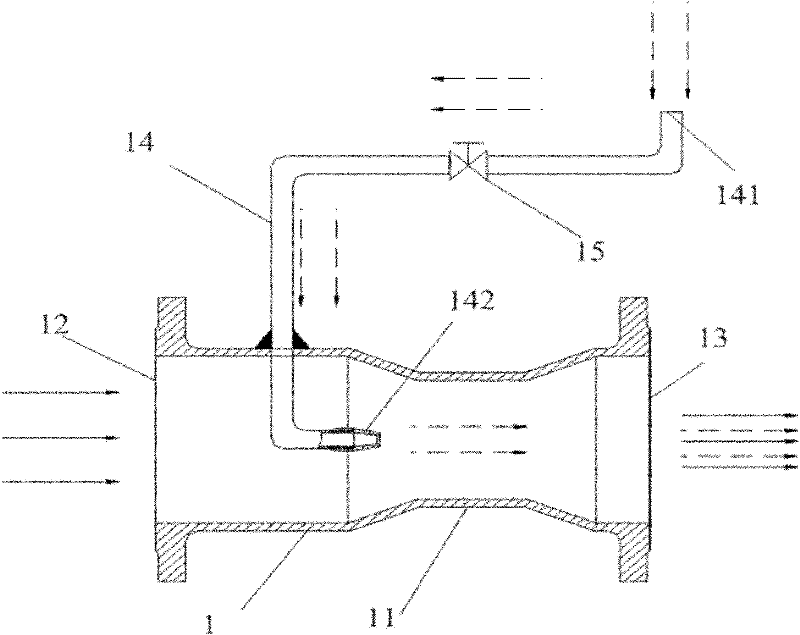

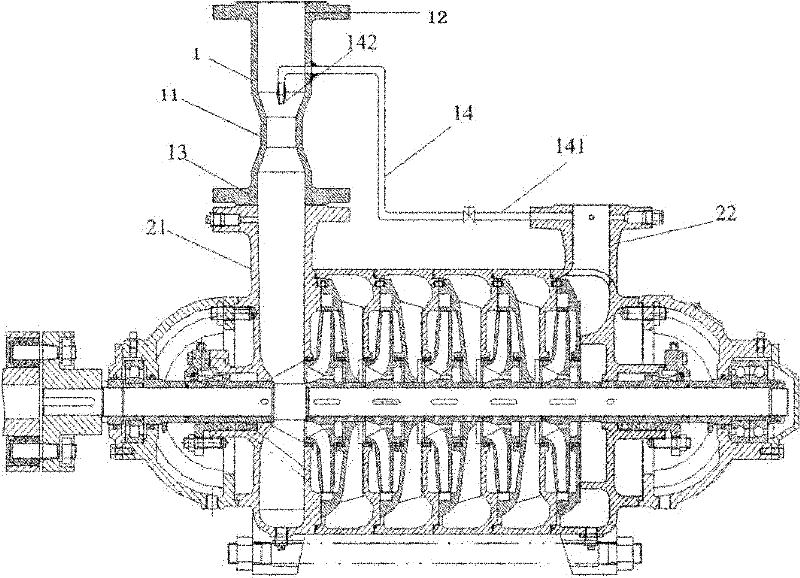

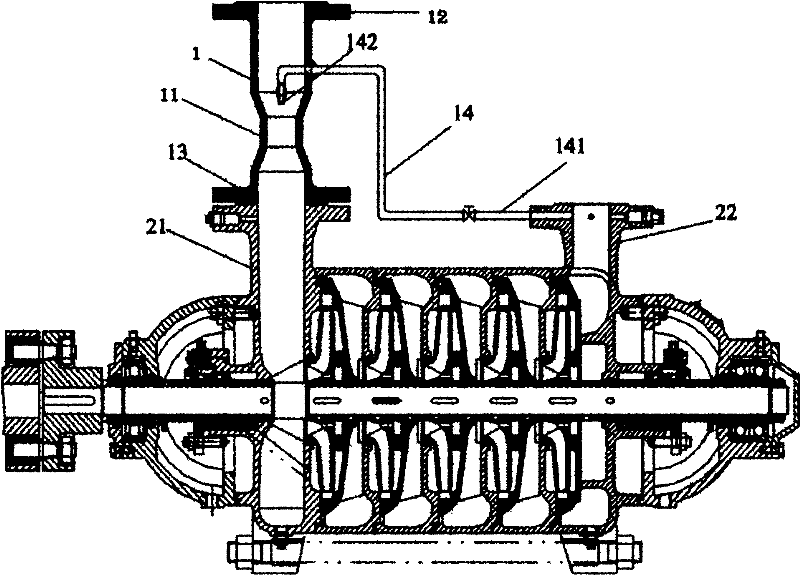

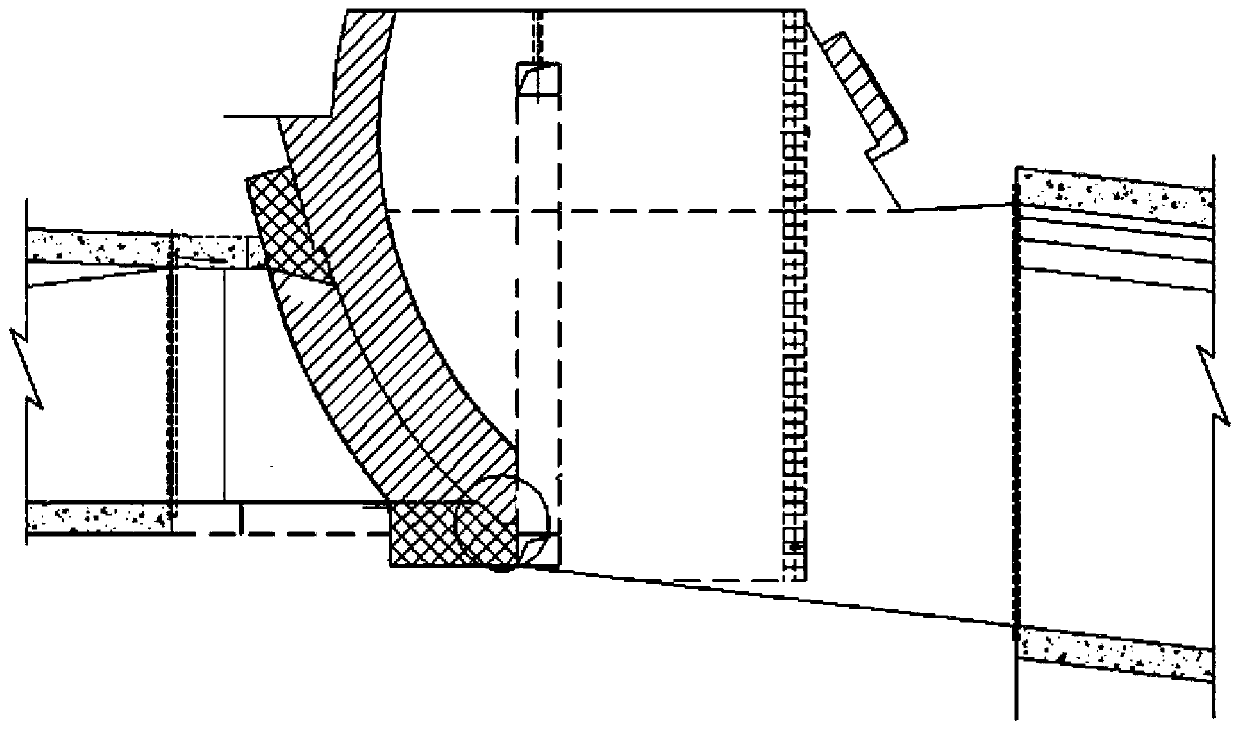

Energy recovery device for multi-stage pump

InactiveCN102454570AIncrease pressureAvoid cavitation damagePump installationsPositive-displacement liquid enginesImpellerWater flow

The invention discloses an energy recovery device for a multi-stage pump, which comprises a hollow columnar flow mixer and a pressurized pipe, wherein a liquid inlet is arranged at one end of the flux mixer, a liquid outlet is arranged at the other end of the flux mixer, a pressurized segment is arranged at the middle of the flux mixer, the pressurized pipe is used for collecting return liquid, one end of the pressurized pipe extends into the flux mixer and is provided with a nozzle, and the nozzle is positioned between the pressurized segment and the liquid inlet and faces the liquid outlet. By adopting the energy recovery device, high-pressure liquid obtained from a discharge segment of the multi-stage pump and liquid sucked by a liquid storage container of the multi-stage pump are mixed and then are sent to a suction segment, the kinetic energy of high-pressure water flow is transformed into pressure energy of the liquid in the suction segment, the pressure of the entrance of a first-stage impeller is increased, and the first-stage impeller is prevented from being cavitated and damaged due to extremely low pressure of the sucked liquid.

Owner:SHANGHAI KAIQUAN PUMP IND GROUP

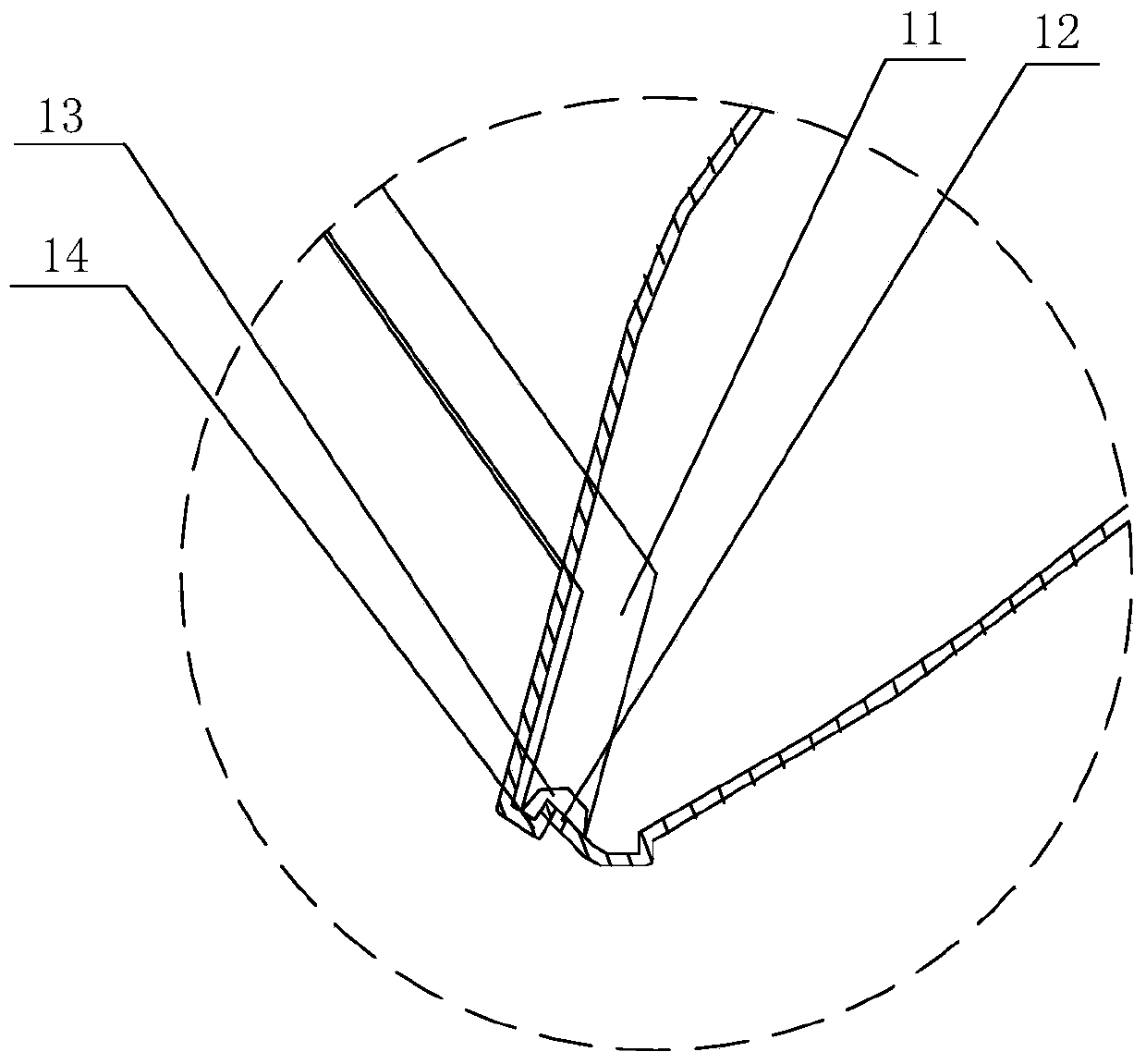

Short platform preventing water flow oblique injecting of outlet of pressurized flood discharging radial gate

The invention provides a short platform preventing water flow oblique injecting of an outlet of a pressurized flood discharging radial gate and belongs to the field of water resources and hydropower engineering. The short platform comprises a platform, a supporting structure and a bottom cavity. The front end of the platform is connected with a water stop platform of a water outlet in the bottom end of the radial gate, and the supporting structure is located at the bottom of the platform. The bottom cavity is formed in the bottom of the platform, and the left side and the right side of the front end of the bottom cavity communicate with ventilation holes. By means of the short platform, water flow downwards and obliquely injected through the radial gate falls on the platform, and the phenomenon that the water flow impacts a bottom plate with a large oblique injecting angle for a long time, and the bottom plate is scoured and damage is avoided; in addition, due to the fact that the oblique injecting water flow falls on the platform only through a very short distance when the radial gate is locally opened, and the impact force of the oblique injecting water flow on the platform is far smaller than the impact force of the oblique injecting water flow directly impacting the bottom plate. The water flow is horizontally injected out from the platform, the length of the bottom cavityis greatly increased, and the bottom gas seepage effect is improved; and the phenomenon that the bottom cavity is short, water flow gas seepage is insufficient, and cavitation erosion damage is causedis avoided.

Owner:SICHUAN UNIV

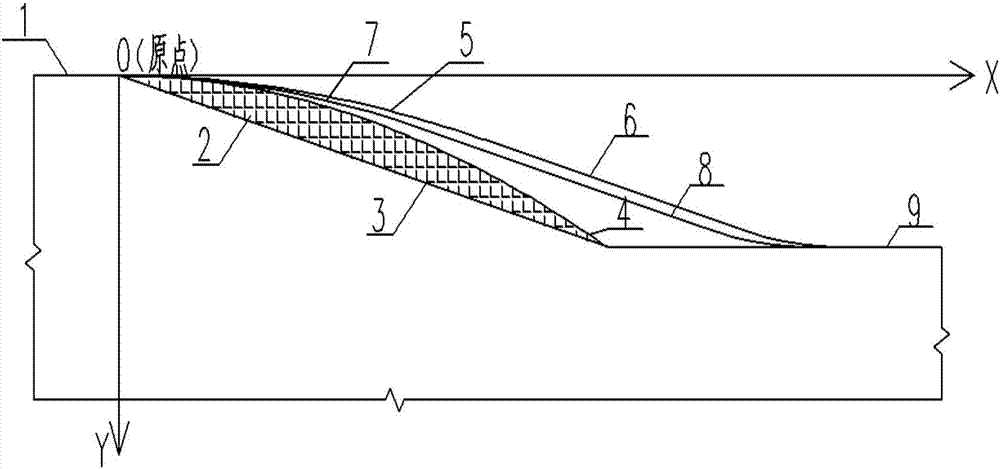

Dam gate bottom plate downstream connection section body shape and setting method thereof

ActiveCN107451334ANo detachment phenomenonEnsure structural safetyGeometric CADClimate change adaptationBody shapeDesign flood

The invention discloses a dam gate bottom plate downstream connection section body shape and a setting method thereof. The method comprises the steps of collecting hydrological data of a dam site region; calculating gate-passing discharge per unit width under a design flood standard in each working condition; selecting maximum gate-passing discharge per unit width to calculate an average flow velocity vH of the fracture surface at the beginning of a slope section; by adopting a Lagrangian liquid motion method, establishing a coordinate system by taking the beginning of the slope section as a coordinate origin, and obtaining a reference curve equation; according to the reference curve equation, setting a starting curve by considering the situation that water flow separated from a wall is not generated on a flow-passing surface; and through verification of a hydraulic model experiment and actual conditions of engineering, determining the final dam gate bottom plate downstream connection section body shape. The designed body shape avoids the situation that the water flow generates a region separated from the wall in conventional slope section design, so that the flow state of the water flow at the beginning of the slope section is stable and the effect of hydraulic jump energy dissipation is improved; and the slope section is prevented from being subjected to cavitation damage.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Flow regulating valve element and valve seat with same

ActiveCN109114252AAvoid Hedge CollisionsReduce trafficCoolant flow controlMultiple way valvesEngineeringStreamflow

The invention discloses a flow regulating valve element and a valve seat with the same. The flow regulating valve element comprises a valve element body and a rotating shaft, wherein the valve elementbody is fixedly connected with the rotating shaft to rotate synchronously with the rotating shaft. The valve element body comprises a first liquid inlet passage, a second liquid inlet passage, a first liquid outlet passage, a second liquid outlet passage and a plugging portion. The first liquid inlet passage is in communication with the first liquid outlet passage, and the first liquid inlet passage is arranged to be in communication with a first liquid inlet pipe of the valve seat. The second liquid inlet passage is in communication with the second liquid outlet passage, and the second liquid inlet passage is arranged to communicate with a second liquid inlet pipe of the valve seat. The first liquid outlet passage and the second liquid outlet passage are arranged to communicate with a valve seat outlet pipe. The first liquid inlet passage and the second liquid inlet passage are separated by the plugging portion. Compared with the prior art, the hedging collision of liquid of two branches is avoided by arranging the two independent liquid inlet passages and the two independent liquid outlet passages in the valve element, so that the flow drop caused by hedging is avoided, and theimpact on heat dissipation capability is reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

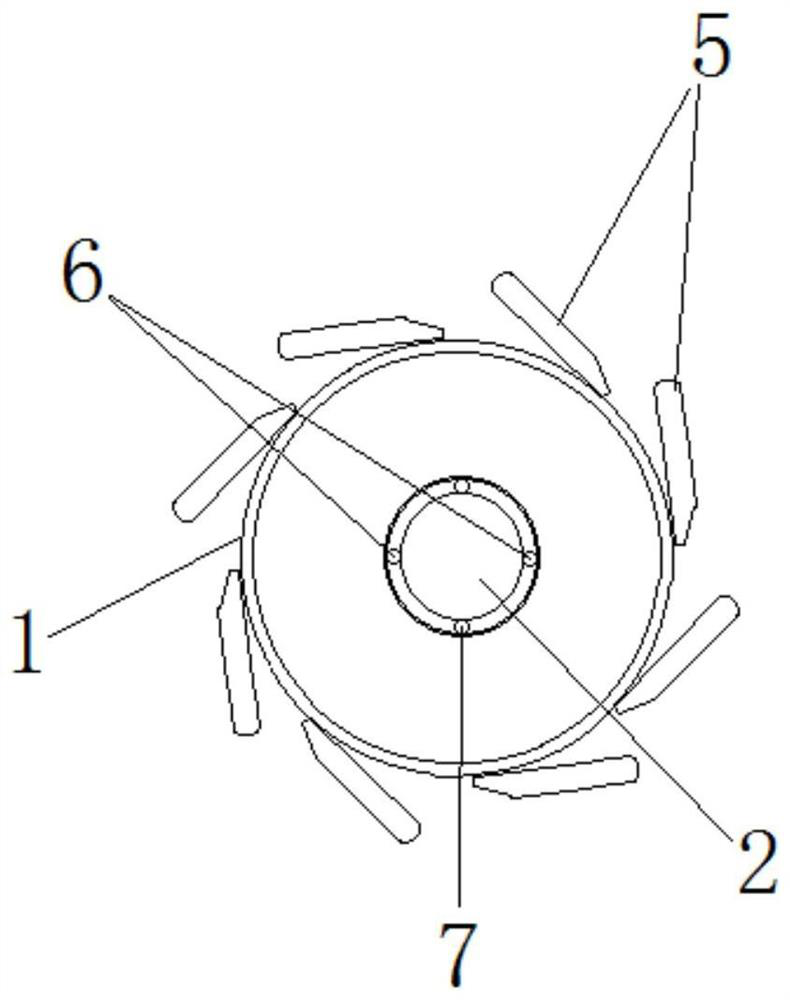

Shaft rotational flow and energy dissipation tunnel spillway with diving spinning pier

ActiveCN111851435AAvoid cavitation damageReduce water flow energyBarrages/weirsStructural engineeringAdit

The invention provides a shaft rotational flow and energy dissipation tunnel spillway with a diving spinning pier. An outer circumference of a water inlet of the tunnel spillway is provided with an annular weir, a plurality of spinning piers are arranged outside the annular weir, the water inlet is connected with a shaft, the shaft is connected with an adit, the adit is connected with a water outlet, the tunnel spillway further comprises a plurality of shaft air supplementary pipes and a plurality of adit air supplementary pipes, the shaft air supplementary pipes are used to supplement air tothe wall of the shaft, an air inlet at the upper end of each shaft air supplementary pipe is higher than the highest water level of a reservoir, and each shaft air supplementary pipe is provided witha plurality of air outlets on the pipe wall of the shaft; the adit air supplementary pipes are used to supplement air to the wall of the adit, the air inlet at the upper end of each adit air supplement pipe is higher than the highest water level of the reservoir, and each adit air supplementary pipe is provided with a plurality of second air outlets on the pipe wall of the audit. The shaft rotational flow and energy dissipation tunnel spillway can use negative pressure generated by the water flow separation phenomenon of the tunnel spillway to introduce outside air so as to reduce the negativepressure and increase the pressure on the wall of the tunnel spillway, and the cavitation damage of the tunnel spillway is prevented.

Owner:洛阳水利勘测设计有限责任公司

High-temperature performance environment simulation testing device of air compressor

ActiveCN105402114AImprove cooling effectGuaranteed reliabilityPump testingPositive-displacement liquid enginesGas compressorFuel tank

The invention relates to the technology of air compressor performance testing, in particular to a high-temperature performance environment simulation testing device of an air compressor. An insulating tank is arranged on one side above a base. A plurality of paster type temperature sensors are arranged on the inner side wall of the insulating tank. A hot oil tank filled with high-temperature oil is arranged in the insulating tank. A cooling oil tank filled with normal-temperature oil liquid is arranged on the other side above the base. The cooling oil tank is provided with a cooler, and the hot oil tank is provided with a heater. By means of temperature detection, a cold and hot oil source is selected for a control valve, and the high-temperature environment simulation in the insulating tank is achieved. Compared with the prior art at present, the high-temperature performance environment simulation testing device has the beneficial effects that reliability is high, the temperature in the insulating tank is accurate, and the heat loss generated by a gap of the cold and hot environment is low.

Owner:HUNAN UNIV OF SCI & TECH

Self-air-entraining ternary hydraulic jump stilling basin

ActiveCN111809579AChange structureIncrease constraintsBarrages/weirsWater-power plantsWater flowEnvironmental engineering

The invention discloses a self-air-entraining ternary hydraulic jump stilling basin. The stilling basin is provided with reverse-arc fillets and a reverse-arc step-down floor on a junction of a discharge chute and the stilling basin; two sides of a head side wall of the stilling basin are independently provided with an aeration shaft; the middle of the stilling basin is provided with a flow splitting pier and a middle partition wall; the middle part and the tail parts of the side wall and the middle partition wall of the stilling basin are independently provided with a lateral fillet; the middle and the tail of the bottom plate of the stilling basin are independently provided with a stilling ridge; therefore, binary hydraulic jump of a conventional stilling basin is transformed into ternary hydraulic jump, a strong friction and mixing function of a water body in the hydraulic jump can be enhanced, the energy dissipation power of the stilling basin is improved, the length and the depthof the conventional stilling basin can be reduced, the engineering quantity of the stilling basin is lowered, and engineering investment is lowered. Due to the arrangement of the shaft, the bottom ofthe stilling basin can be subjected to self air entraining, under a turbulent fluctuation function of a high-speed water flow, a great quantity of air is forced to be mixed into the water flow so as to form a gas and water two-phase mixing phenomenon, the air-entraining concentration of the water body is guaranteed, the bottom plate and the side wall of the stilling basin are protected from cavitation destruction, and the safety of a structure is guaranteed.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD +1

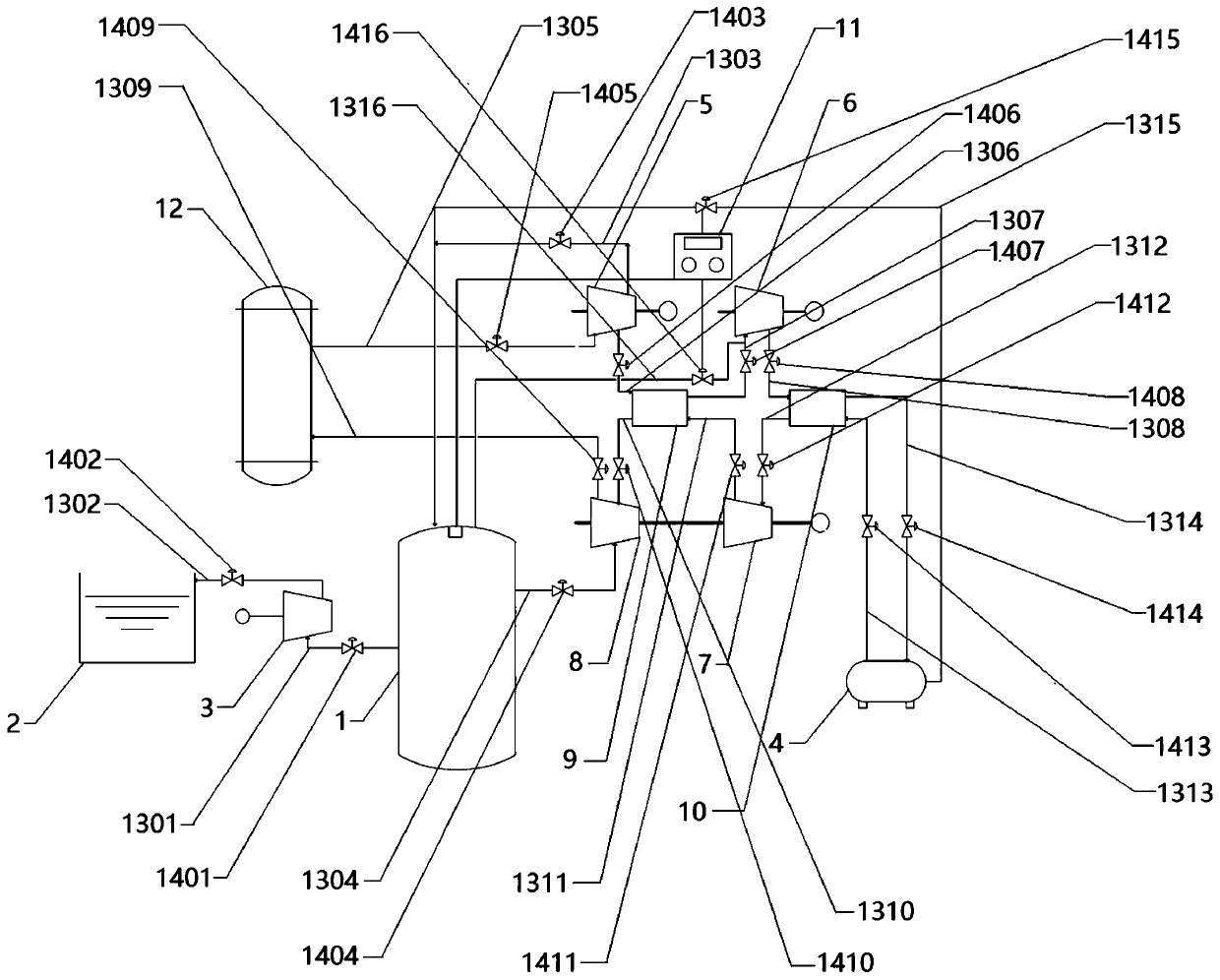

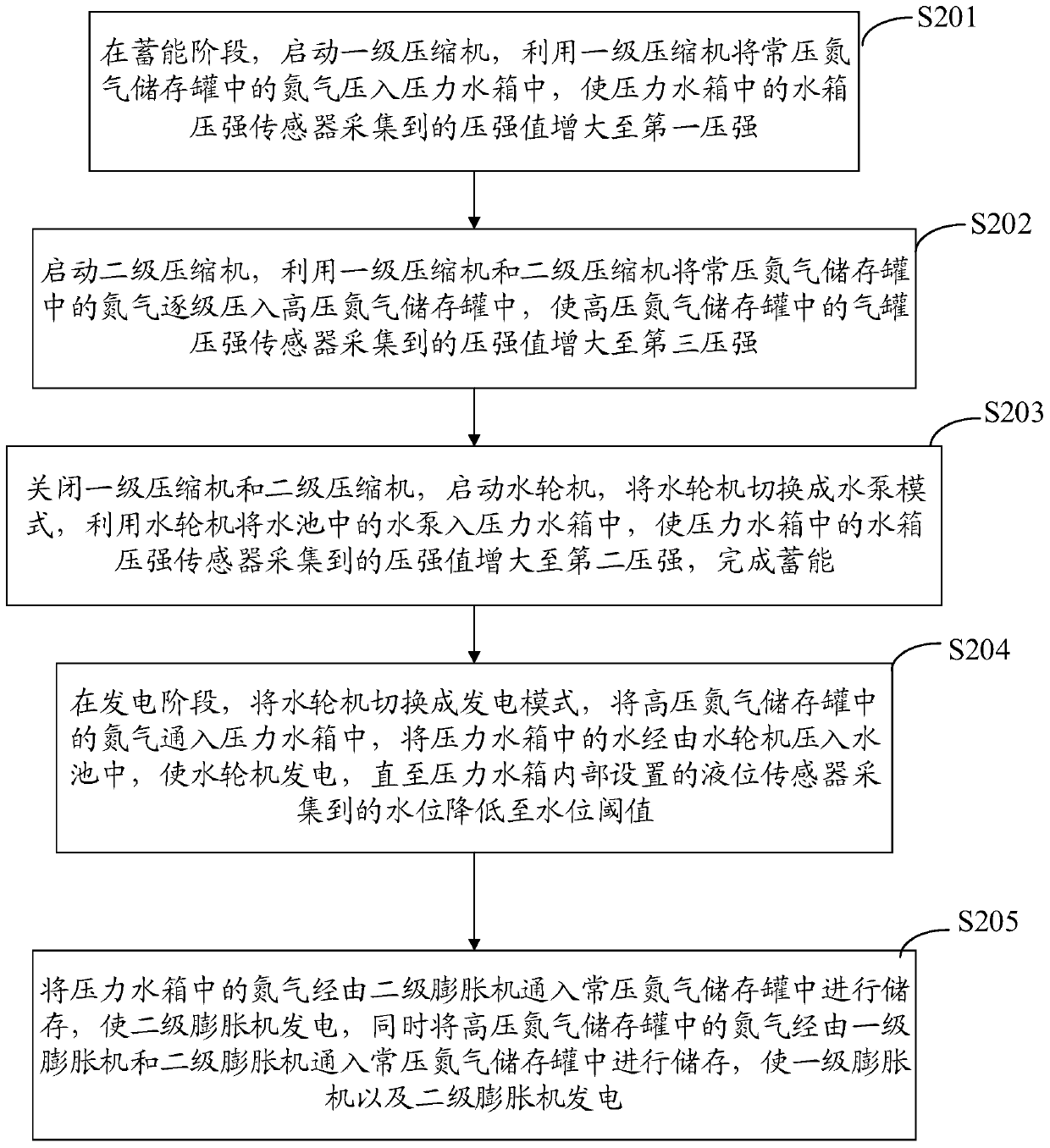

Water-gas composite energy-storage power generation system and method

ActiveCN109899217AAvoid cavitation damageIncreased durabilityHydro energy generationReaction enginesCavitationWater turbine

The invention provides a water-gas composite energy-storage power generation system and method, and belongs to the field of peak shaving of power grids. The system comprises a pressure water tank (1),a water pool (2), a water turbine (3), a high-pressure nitrogen storage tank (4), a first-stage compressor (5), a second-stage compressor (6), a first-stage expansion machine (7), a second-stage expansion machine (8), a low-temperature heat accumulator (9), a high-temperature heat accumulator (10), a normal-pressure nitrogen storage tank (12), multiple communicating pipelines (13) and multiple valves (14). The air is replaced by nitrogen which is not dissolved in water easily, so that the cavitation damage to blades of a hydro-generator is avoided, and the durability of the energy-storage power generation system is improved; and gradient utilization is performed on the energy of compressed nitrogen during energy storage, one part of low-pressure nitrogen is stored in the pressure water tank (1), and the other part of high-pressure nitrogen is stored in the high-pressure nitrogen storage tank (4), so that the nitrogen under different pressure intensity can be utilized sufficiently, andthe energy storage efficiency of the energy-storage power generation system can be improved.

Owner:国家电投集团综合智慧能源科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com