Flow regulating valve element and valve seat with same

A flow regulating valve and spool technology, applied in the direction of coolant flow control, multi-way valve, valve device, etc., can solve the problems of branch flow drop, affect heat dissipation capacity, interfere with fluidity, etc., to increase the number of collisions, Avoid cavitation damage and reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

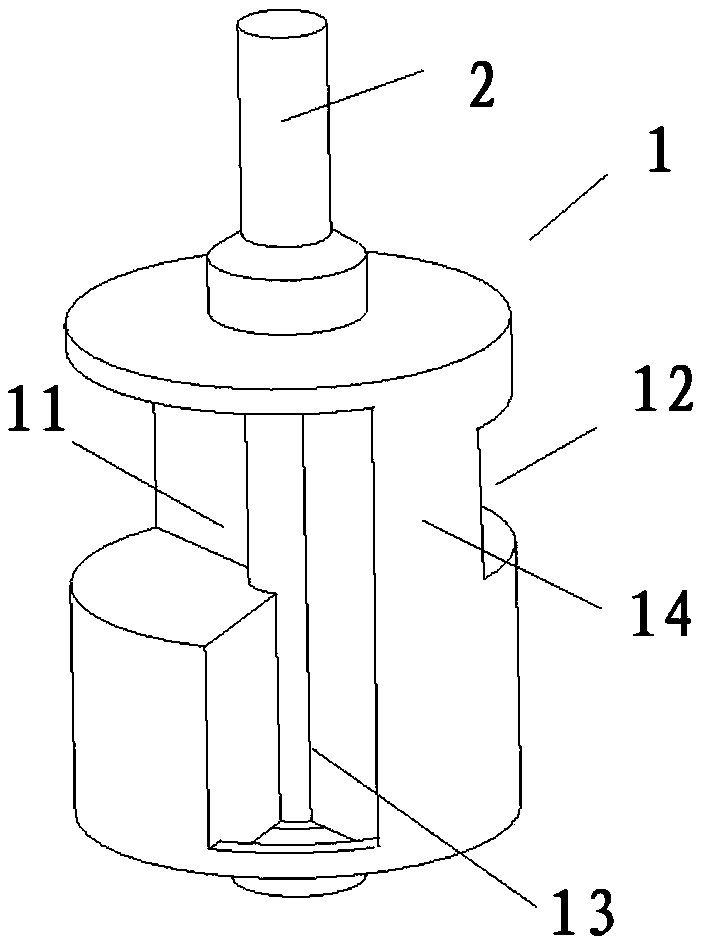

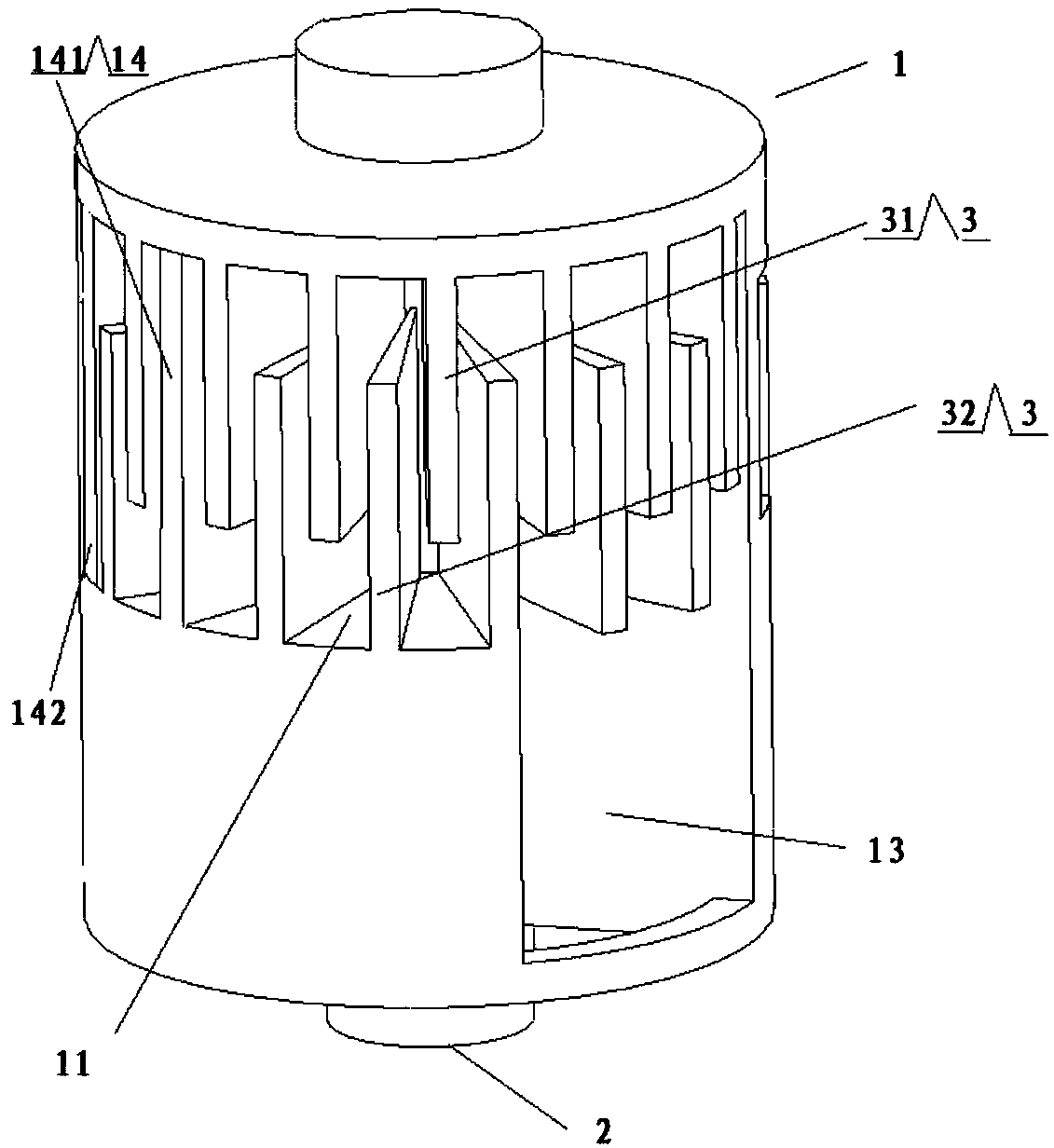

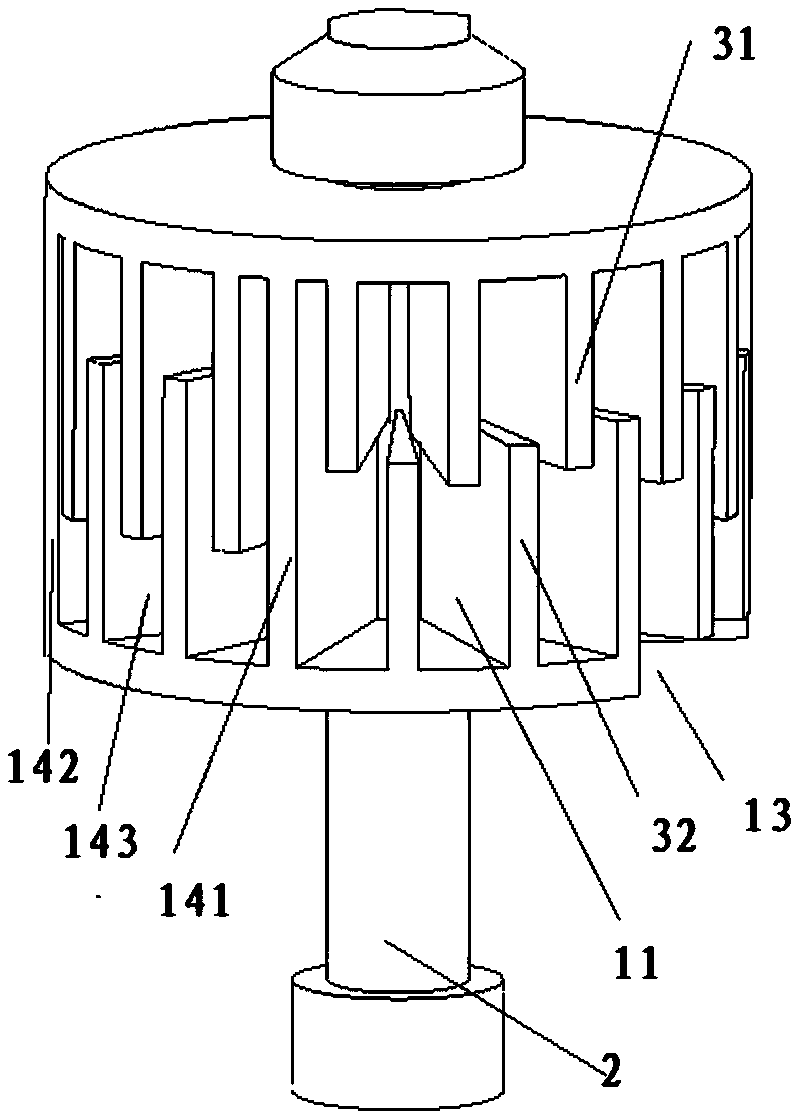

[0043] Such as Figure 1-3 As shown, the present invention discloses a flow regulating valve core, comprising: a valve core body 1 and a rotating shaft 2, the valve core body 1 is fixedly connected to the rotating shaft 2 to rotate synchronously with the rotating shaft 2; the valve The core body 1 has a cylindrical structure, and the central axis of the rotating shaft 2 is coaxial with the central axis of the valve core body 1 .

[0044] The valve core body 1 includes a first liquid inlet channel 11, a second liquid inlet channel 12, a first liquid outlet channel 13, a second liquid outlet channel and a blocking portion 14;

[0045]The first liquid inlet channel 11 communicates with the first liquid outlet channel 13, and the first liquid inlet channel 11 is set to communicate with the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com