Mixed flow pump impeller structure for reducing cavitation erosion of blade rims

A technology of vane rim and mixed-flow pump, which is applied to components, pumps, and pump components of pumping devices for elastic fluids, and can solve problems such as hydraulic loss, decline in hydraulic performance, and insignificant improvement in pump cavitation performance. , to reduce costs, improve cavitation damage and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

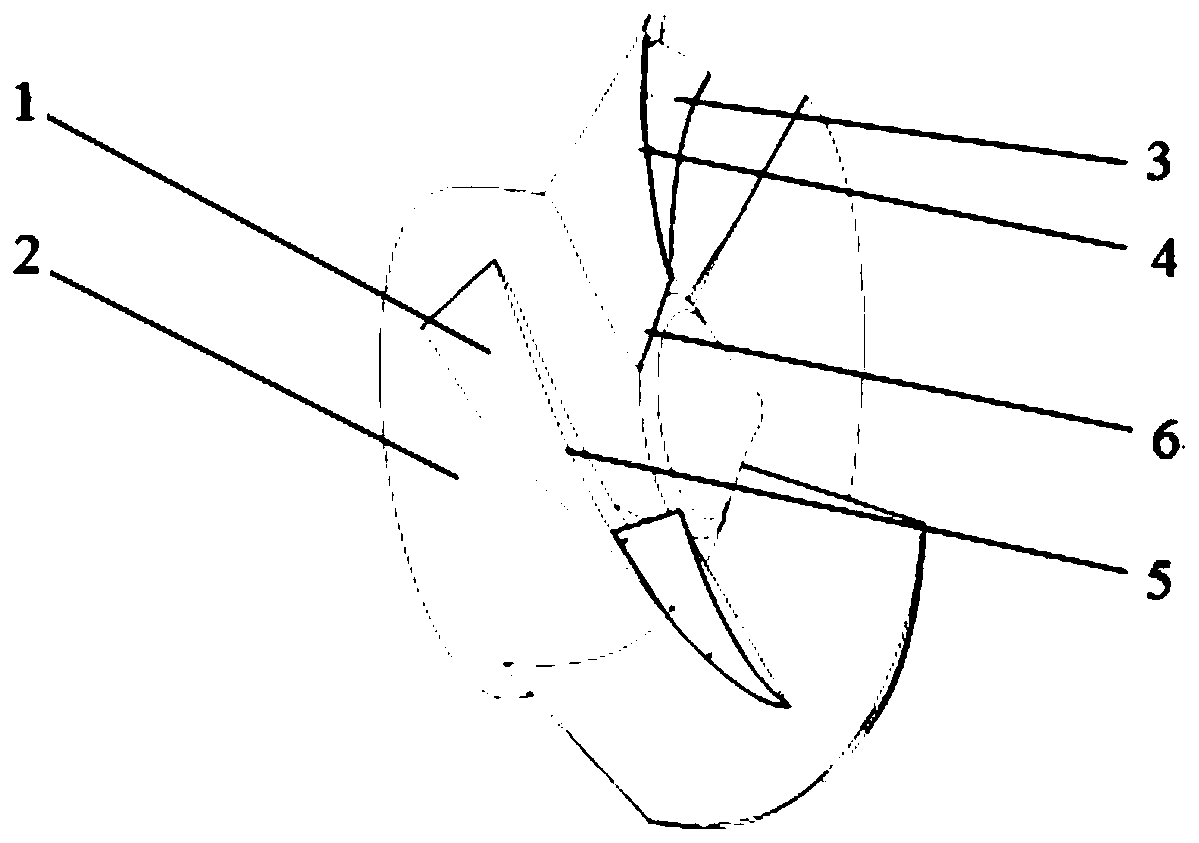

[0024] like figure 1 As shown, the mixed-flow pump impeller structure for improving blade rim cavitation according to the present invention includes a blade 1 , an impeller hub 2 , and a rim drain piece 3 . The blade 1 is installed on the hub 2 of the impeller, and the rim guide piece 3 is installed on the rim 5 of the blade and is located on the side of the inlet edge 6 of the blade.

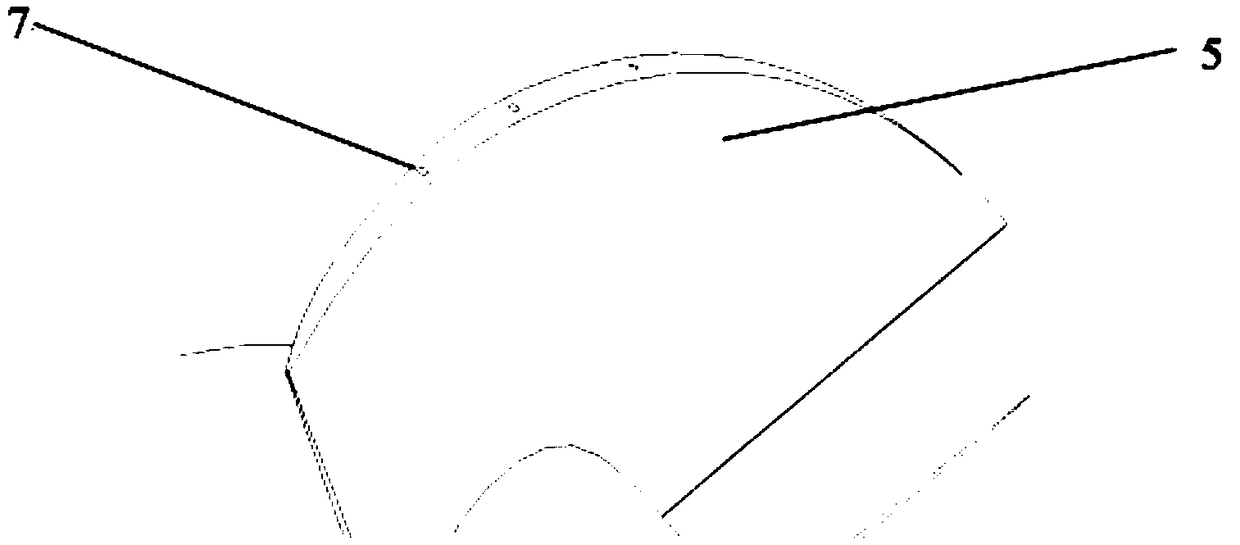

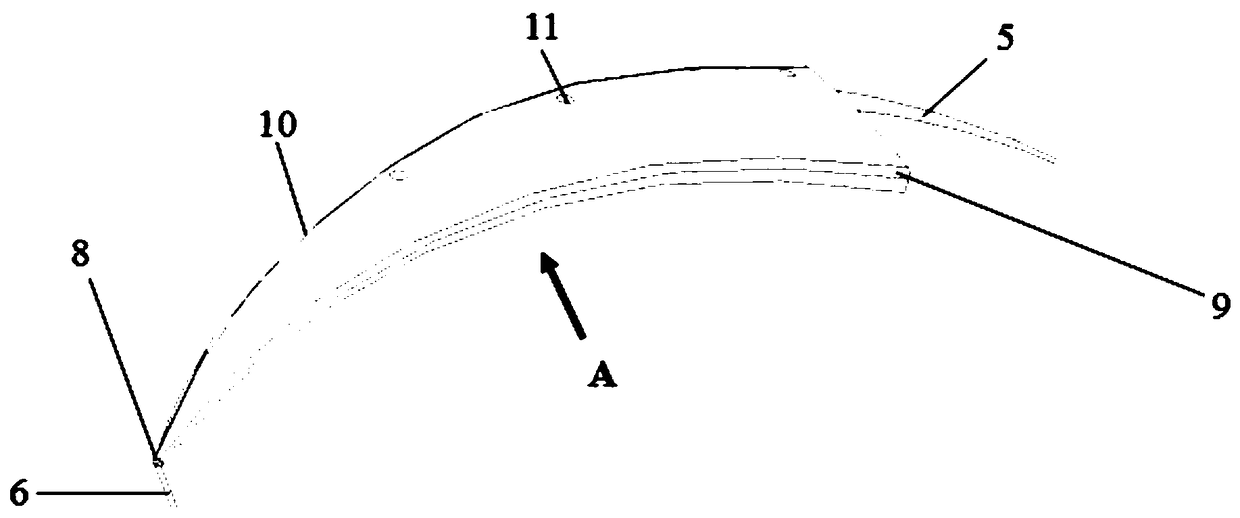

[0025] Specifically, the rim baffle 3 is mounted on the blade rim 5 through set screws 11 . The blade rim 5 is provided with a threaded hole 7 for installing the rim drain piece 3, and the inner diameter of the threaded hole 7 is smaller than the thickness of the blade at the position, such as figure 2 shown. The rim drain piece 3 is drilled with a counterbore 4 for fixing the rim drai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com