Shaft rotational flow and energy dissipation tunnel spillway with diving spinning pier

A technology of flood discharge tunnel and swivel pier, which can be used in water conservancy projects, marine engineering, coastline protection and other directions, and can solve problems such as reduction of water flow energy in shafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

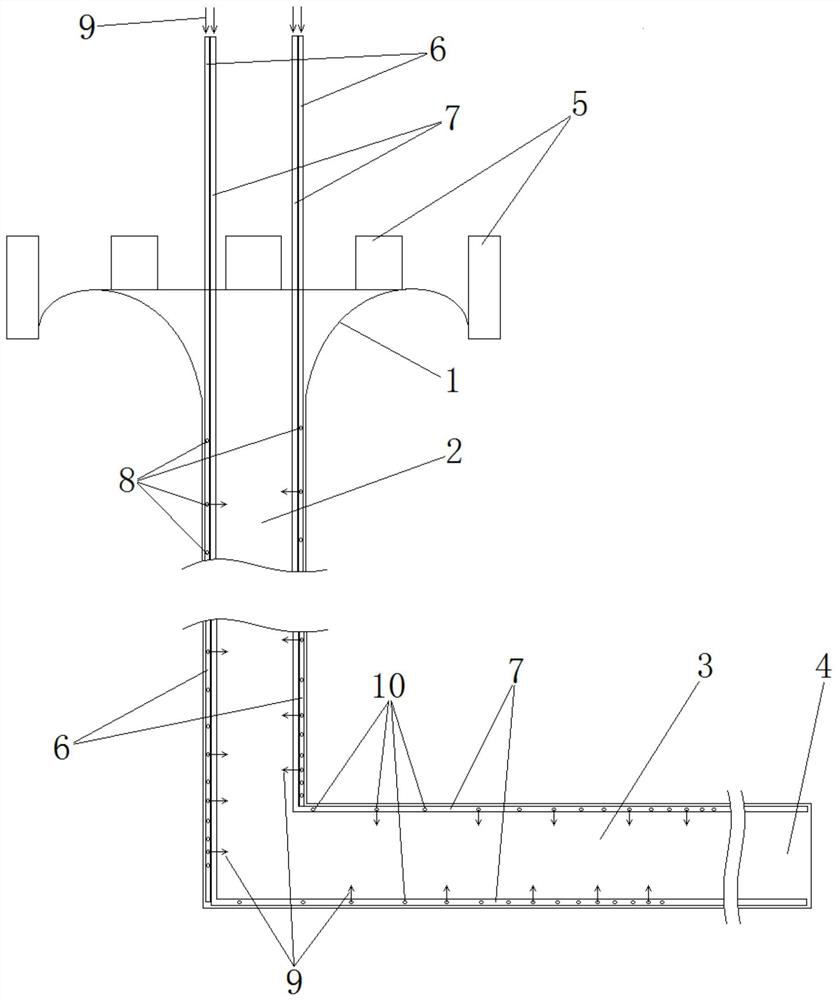

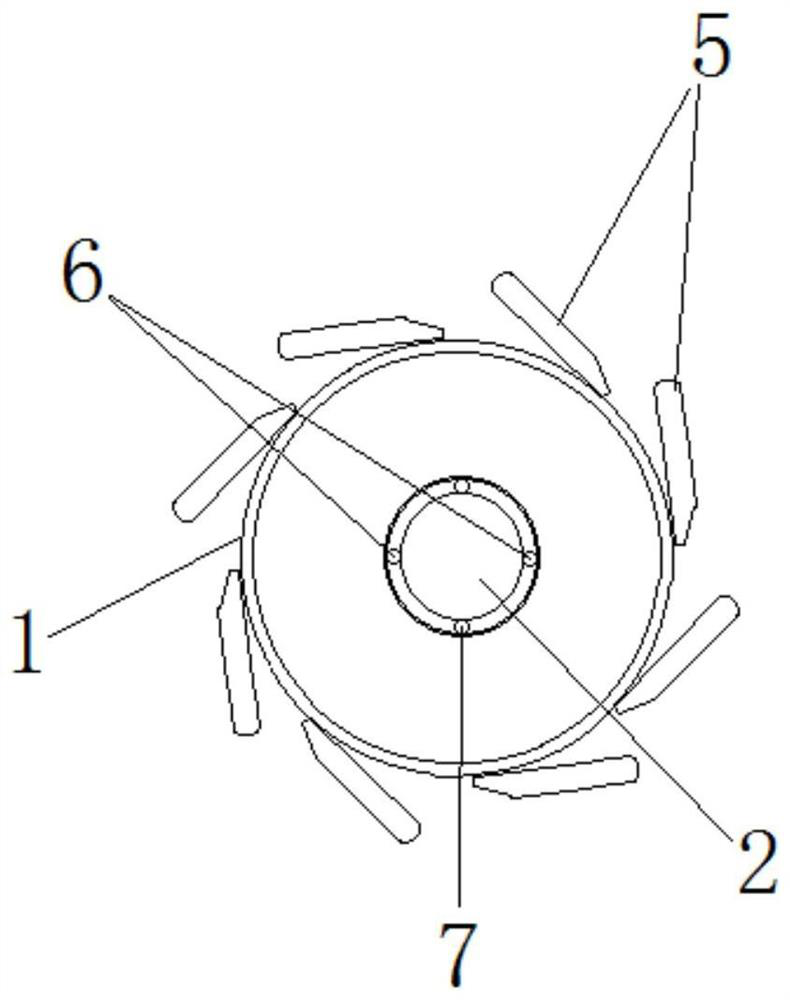

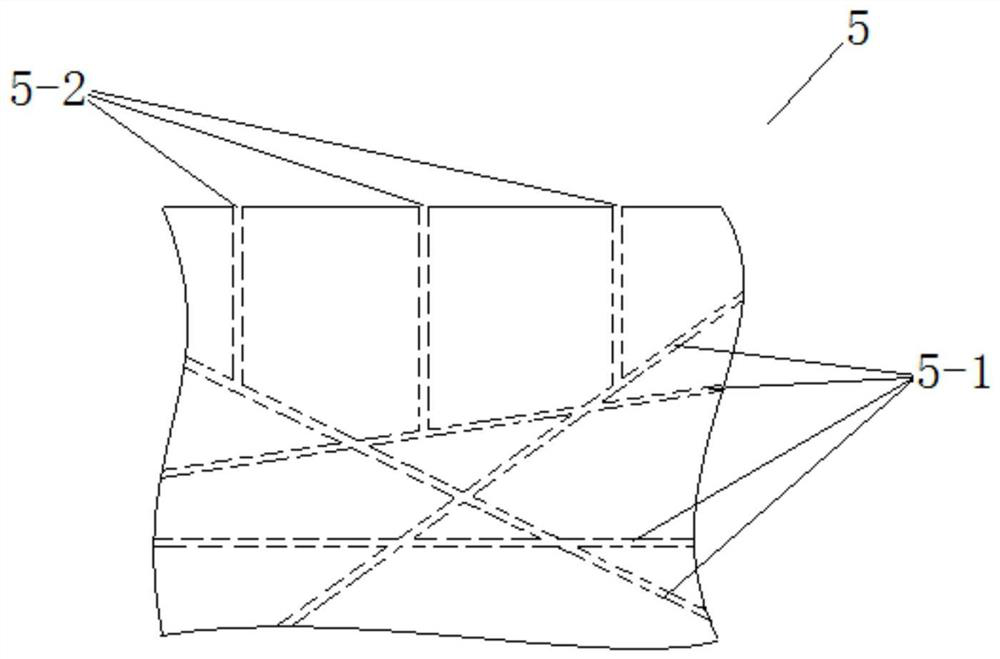

[0019] See figure 1 with figure 2 , The embodiment of the present invention provides a diving pier shaft swirling energy dissipation flood discharge tunnel, including a water inlet, an annular weir 1 is provided on the outer circumference of the water inlet, and a plurality of piers 5 are provided on the outer periphery of the annular weir 1. The water inlet is connected to the shaft 2, the shaft 2 is connected to the flat hole 3, and the flat hole 3 is connected to the water outlet 4, and further includes a plurality of shaft supplementary pipes 6 and a plurality of flat hole supplementary pipes 7; wherein the plurality of vertical shaft supplementary pipes 6 are used for the vertical shaft 2 is supplemented with air 9 at the wall of the well, each vertical well air supply pipe 6 is evenly arranged along the circumference of the shaft wall of the shaft 2 and fixed on the well wall, and the air inlet at the upper end of each vertical well air supply pipe 6 is higher than the res...

Embodiment 2

[0021] On the basis of Example 1, the number of openings of the first air outlet holes 8 along the longitudinal direction of each vertical well supplementary pipe 6 gradually increases from top to bottom, because the air flow in the vertical well supplementary pipe 6 will gradually increase from top to bottom. The first air outlet 8 is discharged, so the airflow will gradually decrease. Therefore, the airflow output is equalized by gradually increasing the number of openings along the vertical shaft supplementary pipe 6 from top to bottom, so that the entire shaft wall The upper can uniformly output the air flow introduced from the outside, so that the pressure on the entire shaft wall is even, and it is also conducive to better mixing the outside air into the water flow, so as to achieve the effect of uniform energy dissipation; The part of the air supply pipe 7 located in the flat hole 3 gradually increases in the number of openings along the longitudinal direction of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com