Water-gas composite energy-storage power generation system and method

An energy storage power generation, water gas technology, applied in the direction of hydropower generation, engine components, machines/engines, etc., can solve the problems of cavitation damage, low energy storage efficiency, reducing the efficiency and durability of the energy storage power generation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

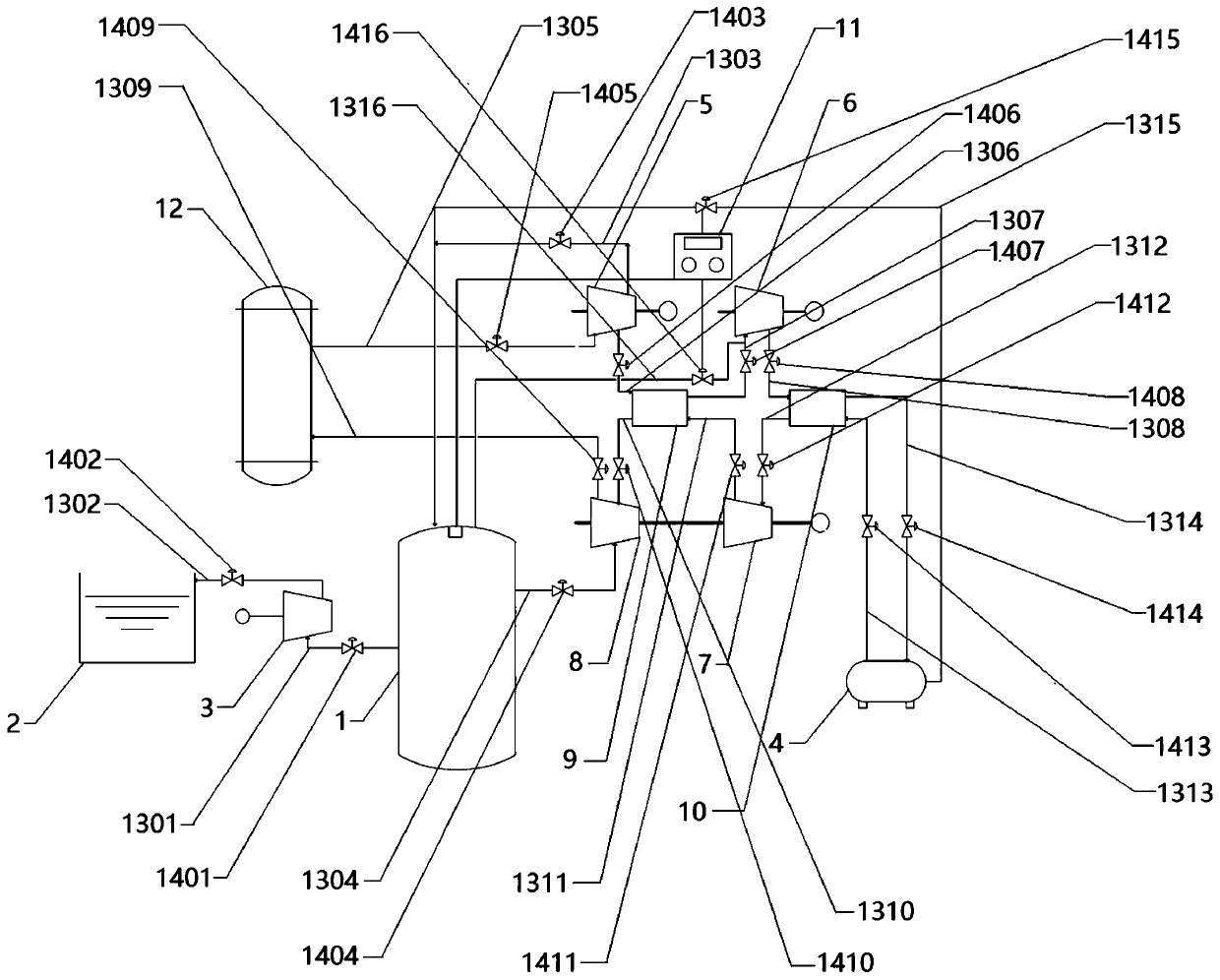

[0106] An embodiment of the present invention provides a water-gas composite energy storage power generation system, such as figure 1 As shown, it includes: pressure water tank 1, pool 2, water turbine 3, high-pressure nitrogen storage tank 4, primary compressor 5, secondary compressor 6, primary expander 7, secondary expander 8, low-temperature heat accumulator 9 , high-temperature accumulator 10, atmospheric pressure nitrogen storage tank 12, a plurality of communication pipelines 13 and a plurality of valves 14, wherein:

[0107] The first port of the water turbine 3 communicates with the pool 2 through the second communication pipe 1302 , and the second communication pipe 1302 is provided with a second valve 1402 .

[0108] The second port of the water turbine 3 communicates with the two-way port of the pressure water tank 1 through the first communication pipe 1301, and the first valve 1401 is arranged on the first communication pipe 1301. The two-way port of the pressure...

Embodiment 2

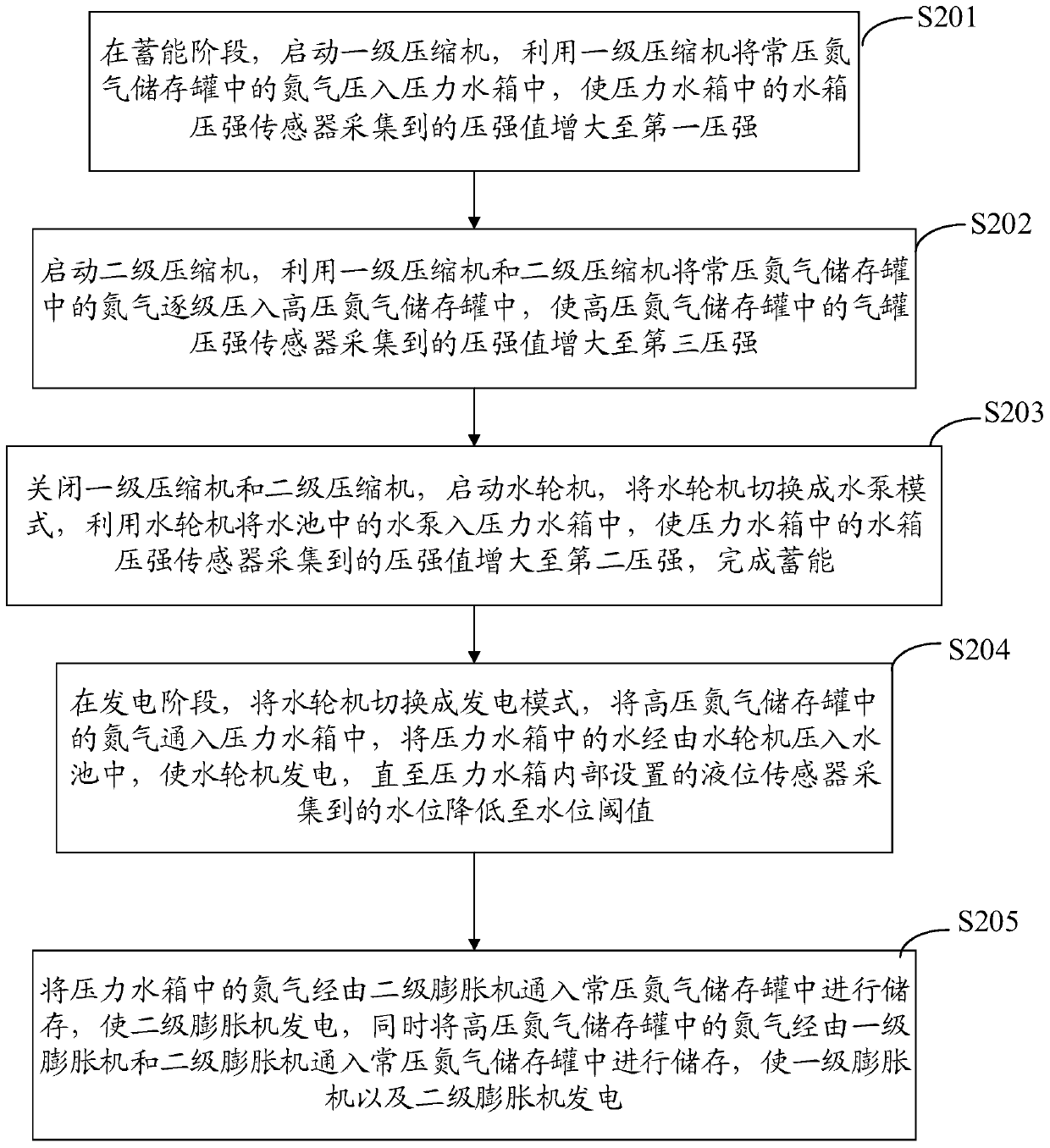

[0149] An embodiment of the present invention provides a water-gas composite energy storage power generation method, such as figure 2 As shown, the method includes steps S201, S202, S203, S204 and S205, wherein:

[0150] The whole method is divided into two main processes. The first process is used in the low power consumption period, that is, the power generation is greater than the power consumption, and the excess electric energy needs to be converted into other forms of energy for storage, including steps S201, S202 and S203; The second process is used in the peak period of power consumption, that is, the power consumption is greater than the power generation, and the energy stored in the first process needs to be used for power generation, including steps S204 and S205.

[0151] The first process is described in detail below:

[0152] In step S201, in the energy storage stage, start the primary compressor 5, and use the primary compressor 5 to press the nitrogen in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com