High-temperature performance environment simulation testing device of air compressor

An environmental simulation test, high temperature performance technology, applied in pump testing, mechanical equipment, machines/engines, etc., can solve the problems of large air vents, large vibration in a constant temperature and closed environment, and low utilization rate of energy transfer, to increase the heat dissipation area, Guaranteed accuracy and enhanced heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

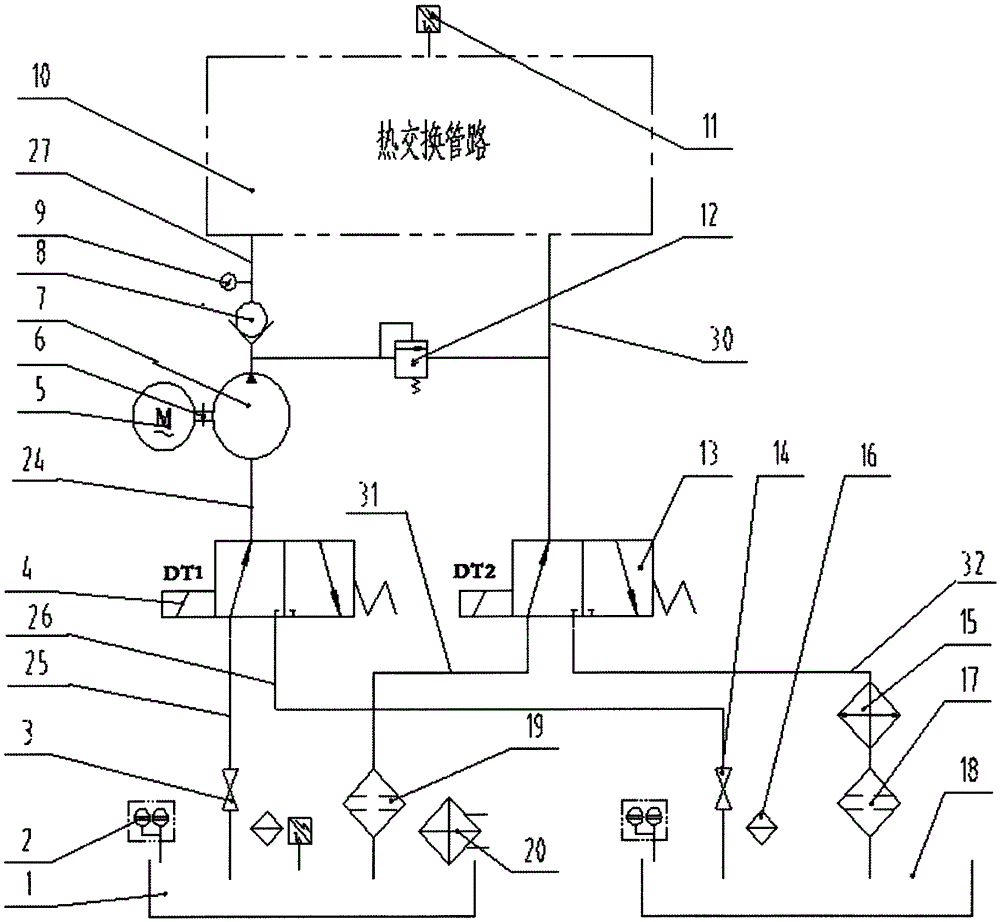

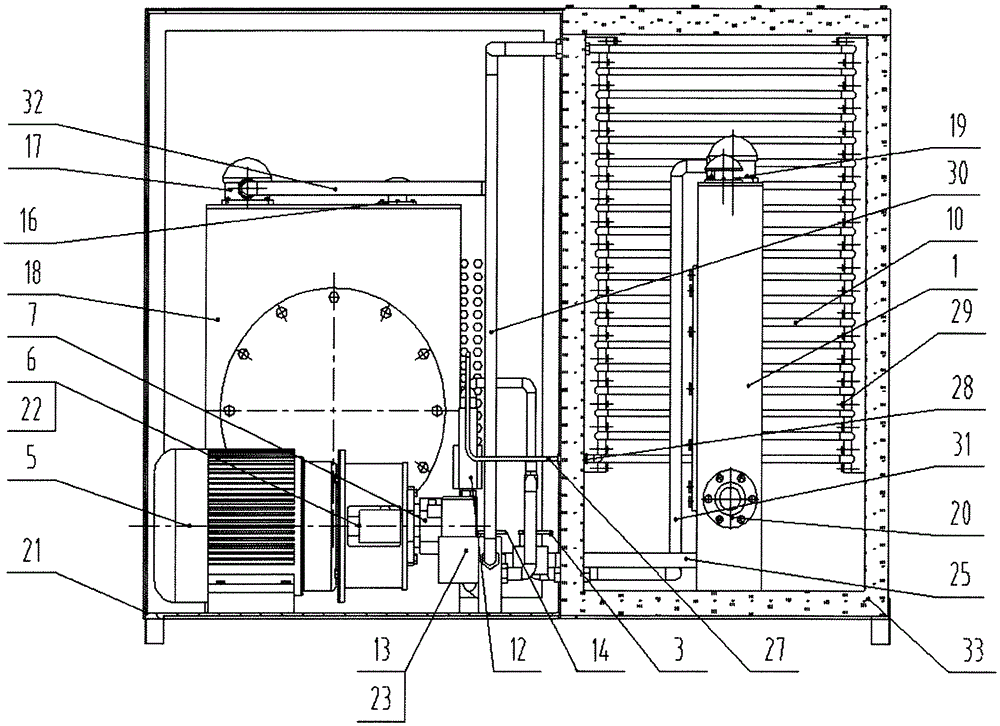

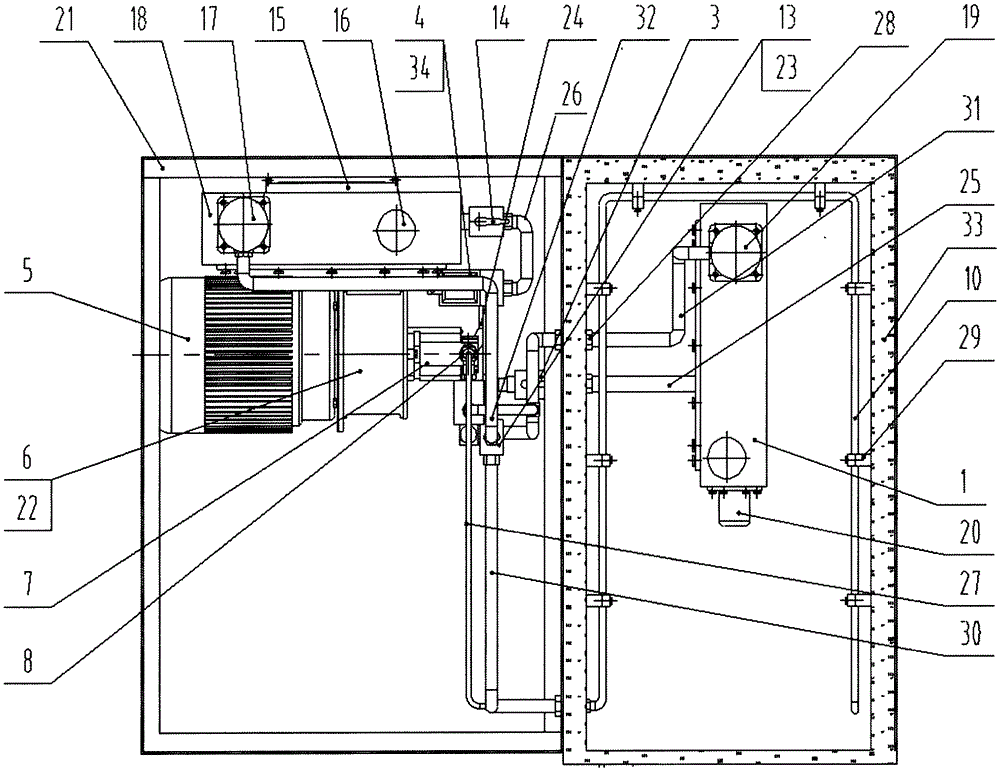

[0022] Such as figure 1 , figure 2 , image 3 As shown, in the air compressor high temperature performance environment simulation test device of the present invention, an incubator 33 is installed on one side above the base 21, and several patch type temperature sensors 11 are installed on the inner side wall of the incubator 33, and inside the incubator 33 are installed A thermal oil tank 1 containing high-temperature oil, a cooling oil tank 18 containing normal temperature oil is installed on the other side above the base 21, a cooler 16 is installed on the cooling oil tank 18, and a heater 20 is installed on the thermal oil tank 1;

[0023] A heat exchange pipeline 10 is installed on the inner wall of the incubator 33 , and the heat exchange pipeline 10 is supported by a support 29 and evenly arranged on the three inner walls of the incubator 33 . The oil inlet and the oil return port of the heat exchange pipeline 10 are respectively connected to the pressure oil pipe 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com