Pressure balancing type high-precision high-pressure-difference control valve

A balanced, high-precision technology, applied in the direction of valve lift, valve device, valve details, etc., can solve the problems of low adjustment performance and adjustment accuracy, poor adjustment performance and accuracy, easy damage to the flow window, etc., to achieve energy consumption, The effect of controlling flow speed and preventing valve clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

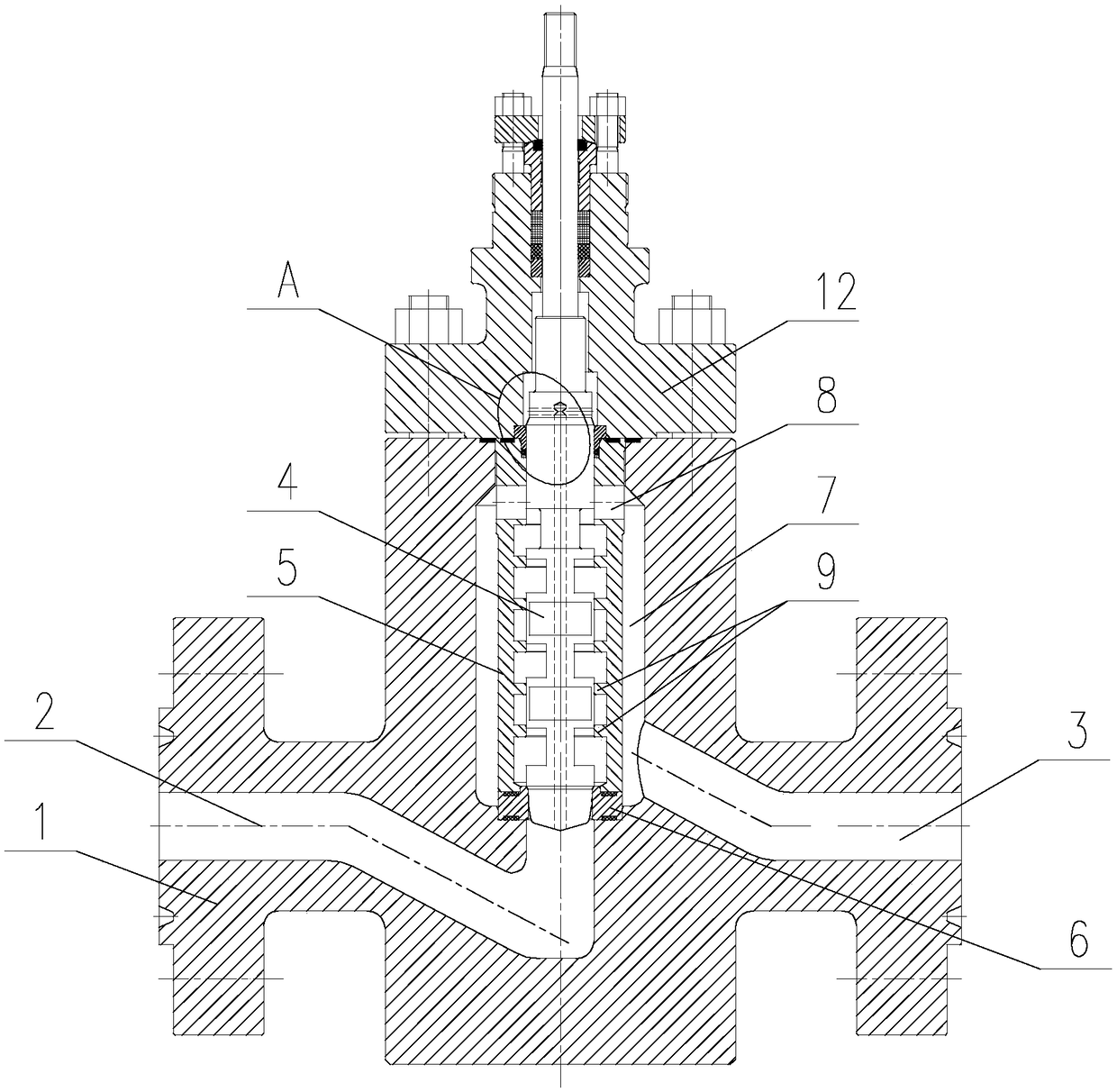

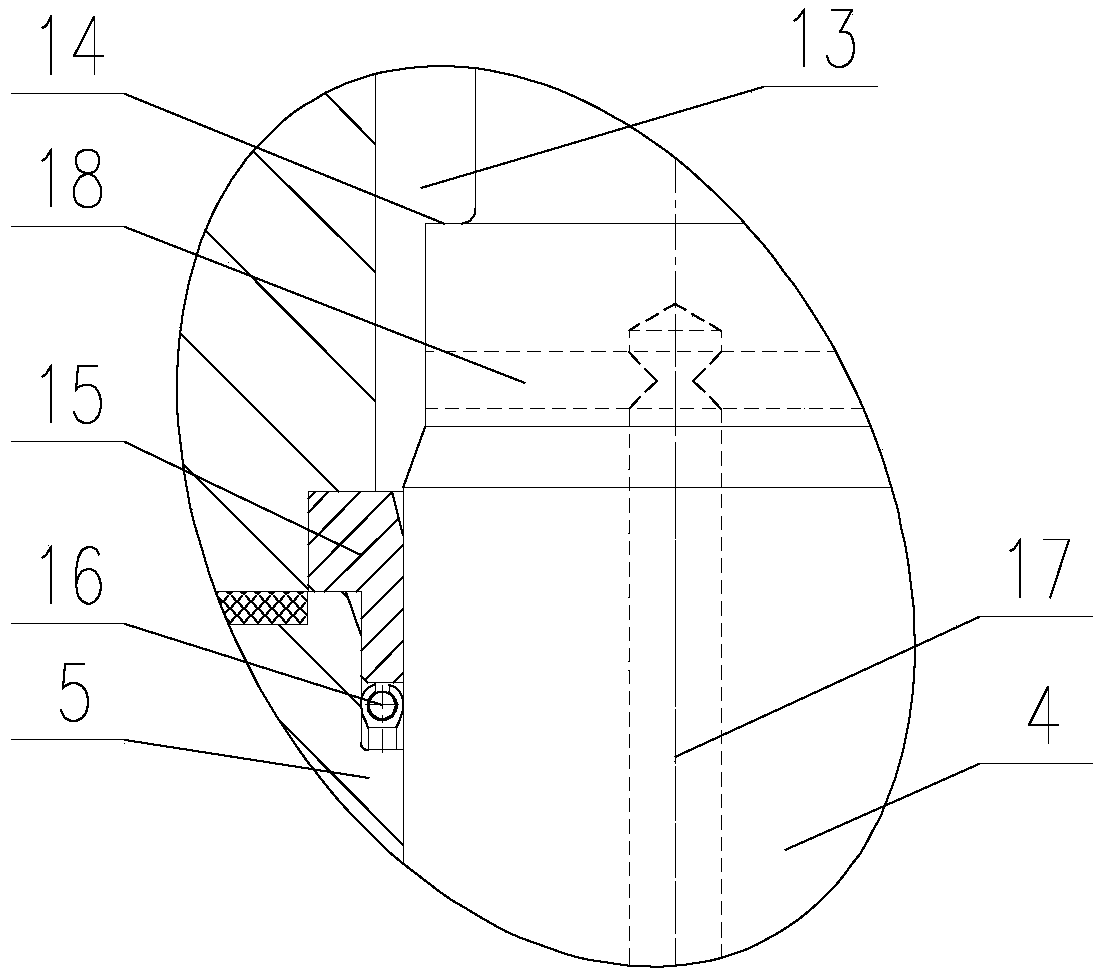

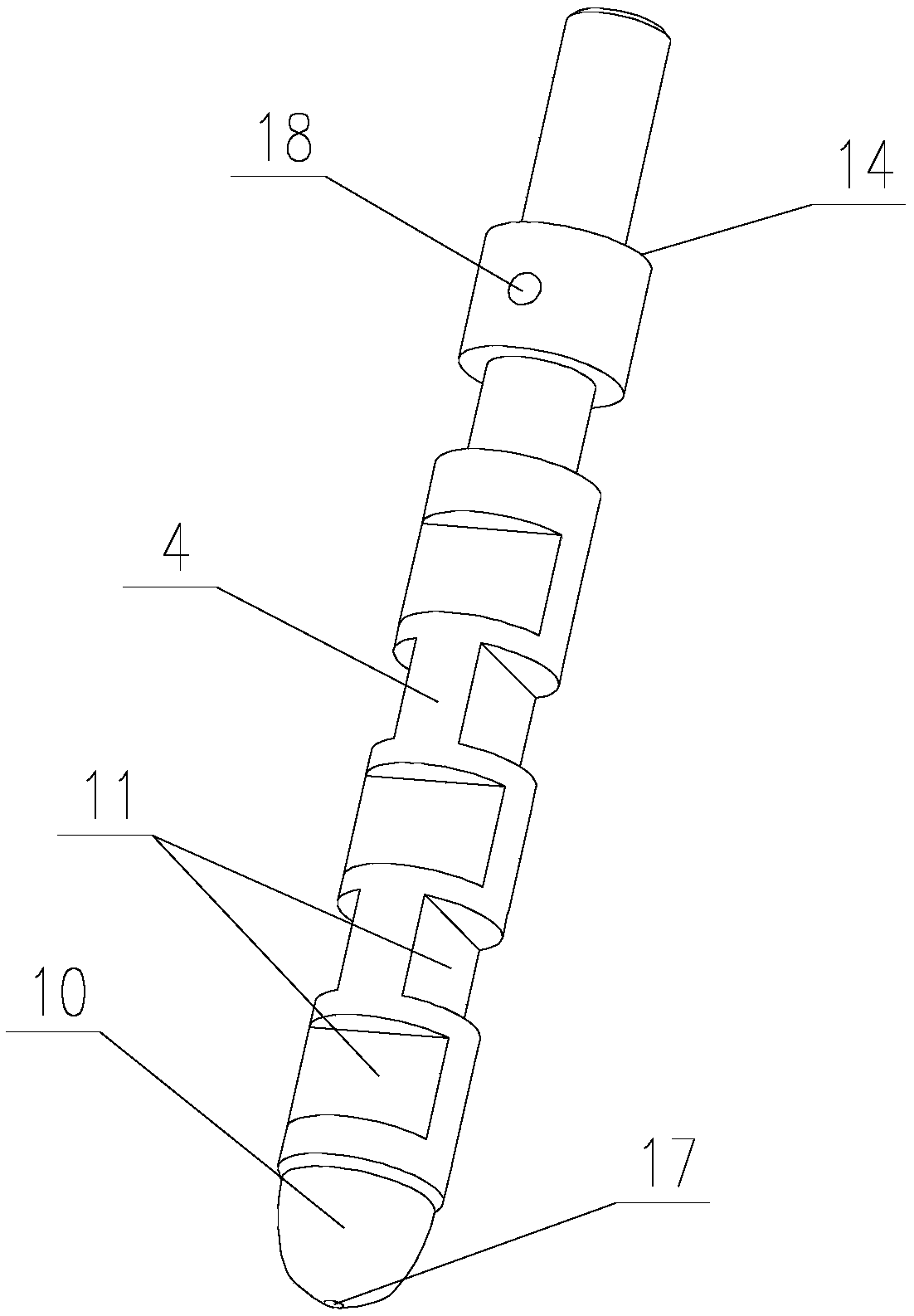

[0020] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0021] Such as Figure 1-7 As shown, a pressure-balanced high-precision high-pressure differential control valve of the present invention includes a valve body 1 and a decompression passage arranged in the valve body 1. The inlet 2 and the outlet 3 connected by the channel, the decompression channel is composed of a valve core 4, a valve core sleeve 5 and a valve seat 6, the valve core sleeve 5 is vertically arranged in the valve body 1, and the valve core A discharge channel 7 is provided between the sleeve 5 and the valve body 1, and the upper end of the valve core sleeve 5 is provided with a discharge port 8 communicating with the discharge channel 7, and the discharge chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com