Anti-penetration performance testing device for waterproof membrane

A test device and waterproof membrane technology, which is applied in the direction of measurement device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of not being able to detect the real performance of waterproof membrane, and achieve the effect of ensuring long-lasting simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

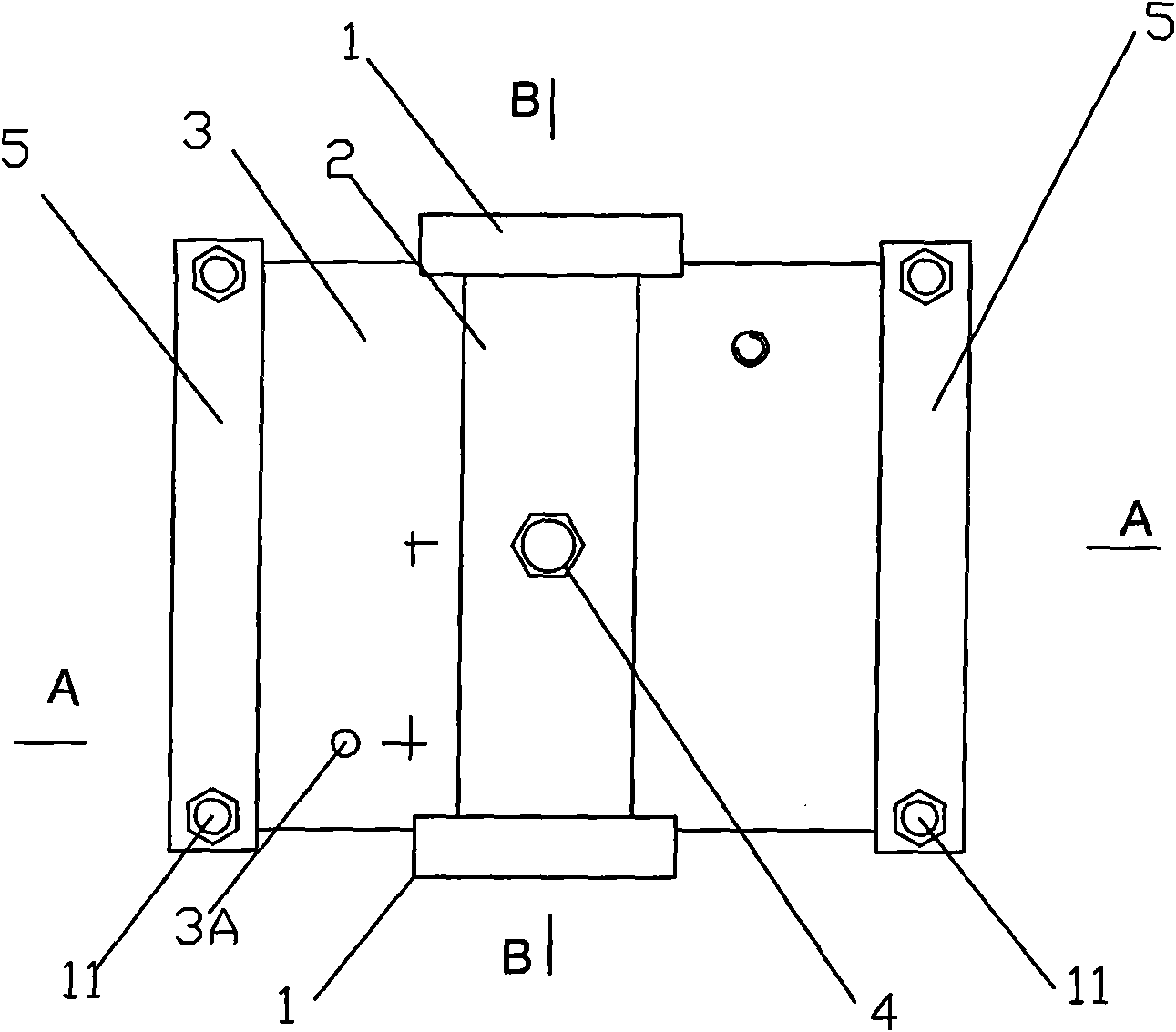

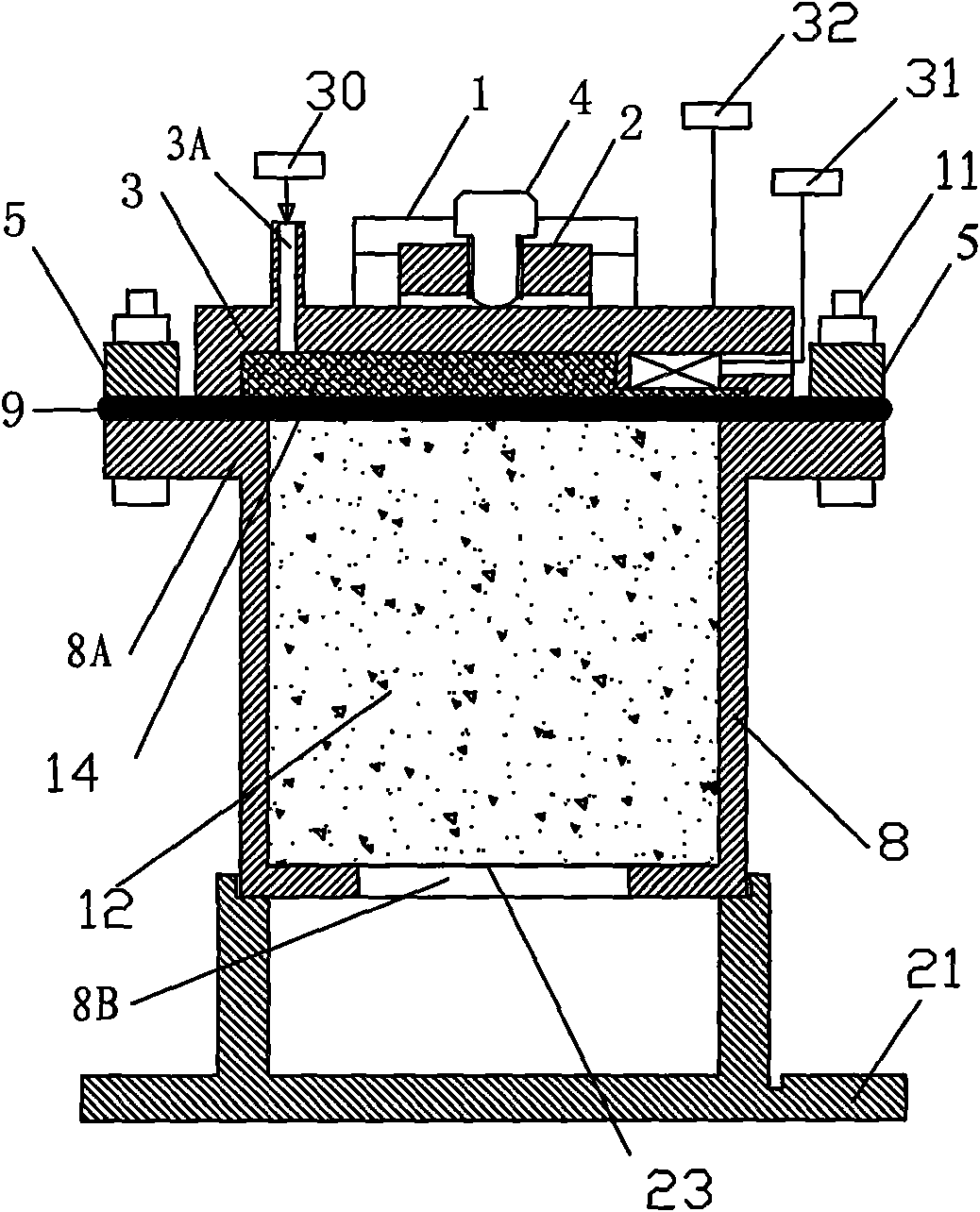

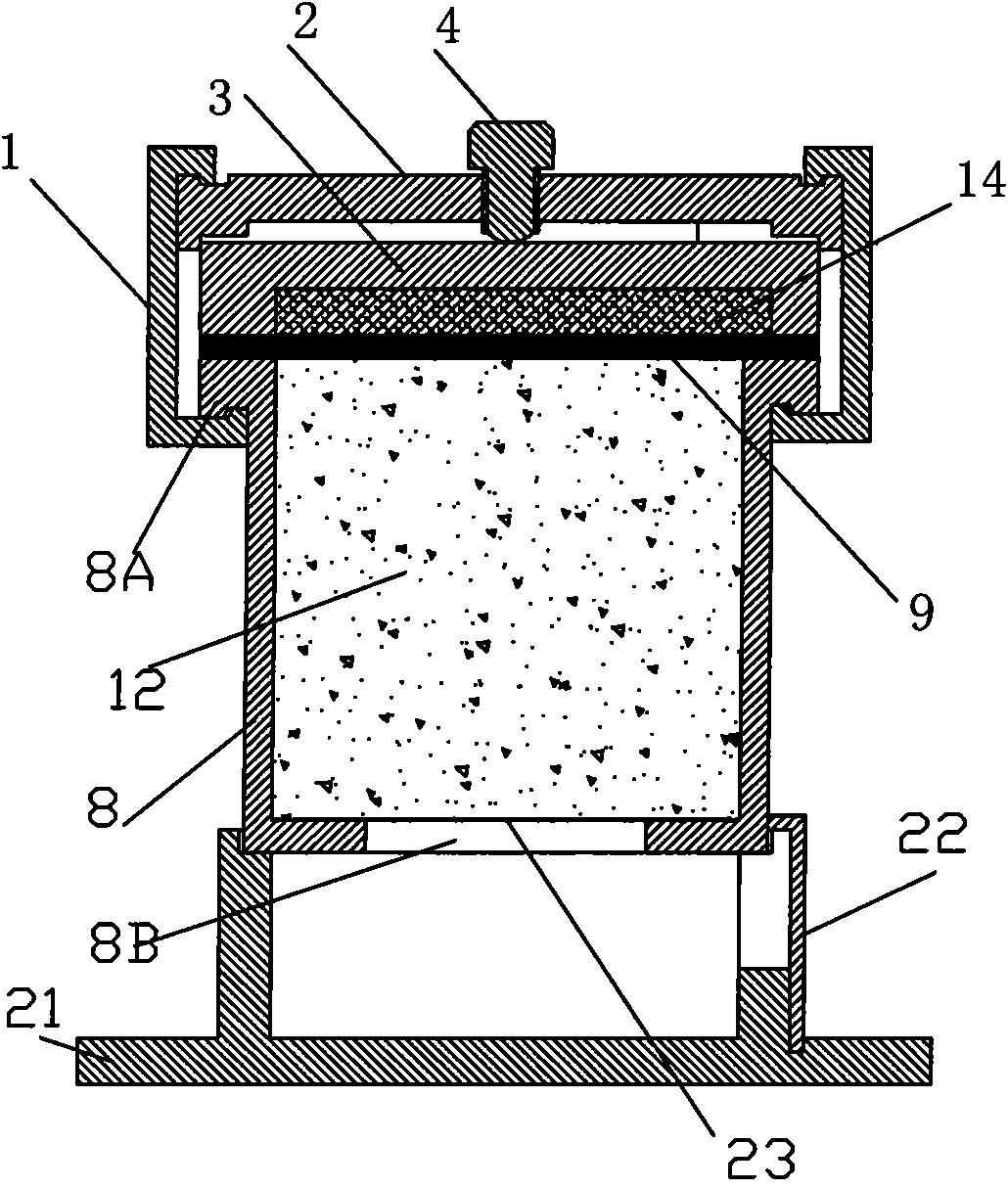

[0051] figure 1 , 2 , 3 shows, a kind of specific implementation of this example is, a kind of waterproof membrane impermeability test device, its composition is:

[0052] The square groove 8 with a convex edge 8A on the top is filled with a concrete block 12 flush with the top of the square groove 8, and the top of the square groove 8 is covered with a waterproof membrane 9 to be tested;

[0053] The top of the square groove 8 is provided with a top cover 3 adapted to the square groove 8, and the concave groove on the lower surface of the top cover 3 is filled with high-elastic foam 14; there is a pressing plate 2 on the top cover 3, and the fastening buckle 1 connects the pressing plate 2 to the top. The cover 3 is fastened on the front and rear convex edges 8A of the top of the square groove 8; the pressure bolt 4 penetrating through the pressure plate 2 is installed in the middle of the pressure plate 2;

[0054] The top cover 3 has a water inlet hole 3A connected to the...

Embodiment 2

[0078] Figure 4 , 5 , 6 shows, a kind of specific implementation of this example is, a kind of waterproof membrane impermeability test device, its composition is:

[0079] The square groove 8 with a convex edge 8A on the top is filled with a concrete block 12 flush with the top of the square groove 8, and the top of the square groove 8 is covered with a waterproof membrane 9 to be tested;

[0080] The top of the square groove 8 is provided with a concave top cover 3 adapted to the square groove 8, and the concave groove on the lower surface of the top cover 3 is filled with high elastic foam 14; Fasten with the top cover 3 on the front and rear convex edges 8A of the top of the square groove 18; the middle of the pressure plate 2 is installed with a pressure bolt 4 vertically penetrating the pressure plate 2;

[0081] The top cover 3 has a water inlet hole 3A connected to the pressure stabilizing liquid storage device 30; the water pressure gauge 32 is installed on the wate...

Embodiment 3

[0090] Figure 7 , 8 , 9 shows, a kind of specific implementation of this example is: a kind of waterproof film anti-penetration performance test device, its composition is:

[0091] The square groove 8 with convex edge 8A on the top is filled with upper and lower layers of concrete blocks. The upper layer of concrete block 12 is composed of left block and right block 12A, 12B. The lower layer of concrete block 12C and the upper layer of concrete block 12 are cushioned with high elastic Foam 12E, high-density non-woven fabric 12D is also padded between the right block 12B of the upper concrete block and the high-elastic foam 12E, and the waterproof membrane 9 to be tested is covered on the top of the upper concrete block 12 and the convex edge 8A of the square groove 8;

[0092] The top of the square groove 8 is provided with a top cover 3 adapted to the square groove 8, and the concave groove on the lower surface of the top cover 3 is filled with the left block 13A and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com