Device for measuring optical performance of material under strong laser condition

A technology of optical properties and measuring devices, which is applied in measuring devices, scattering characteristics measurement, material analysis through optical means, etc., can solve the problems of high-energy laser damage mechanism materials anti-laser ability test, etc., to reduce volume and provide cooling Capable, scalable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

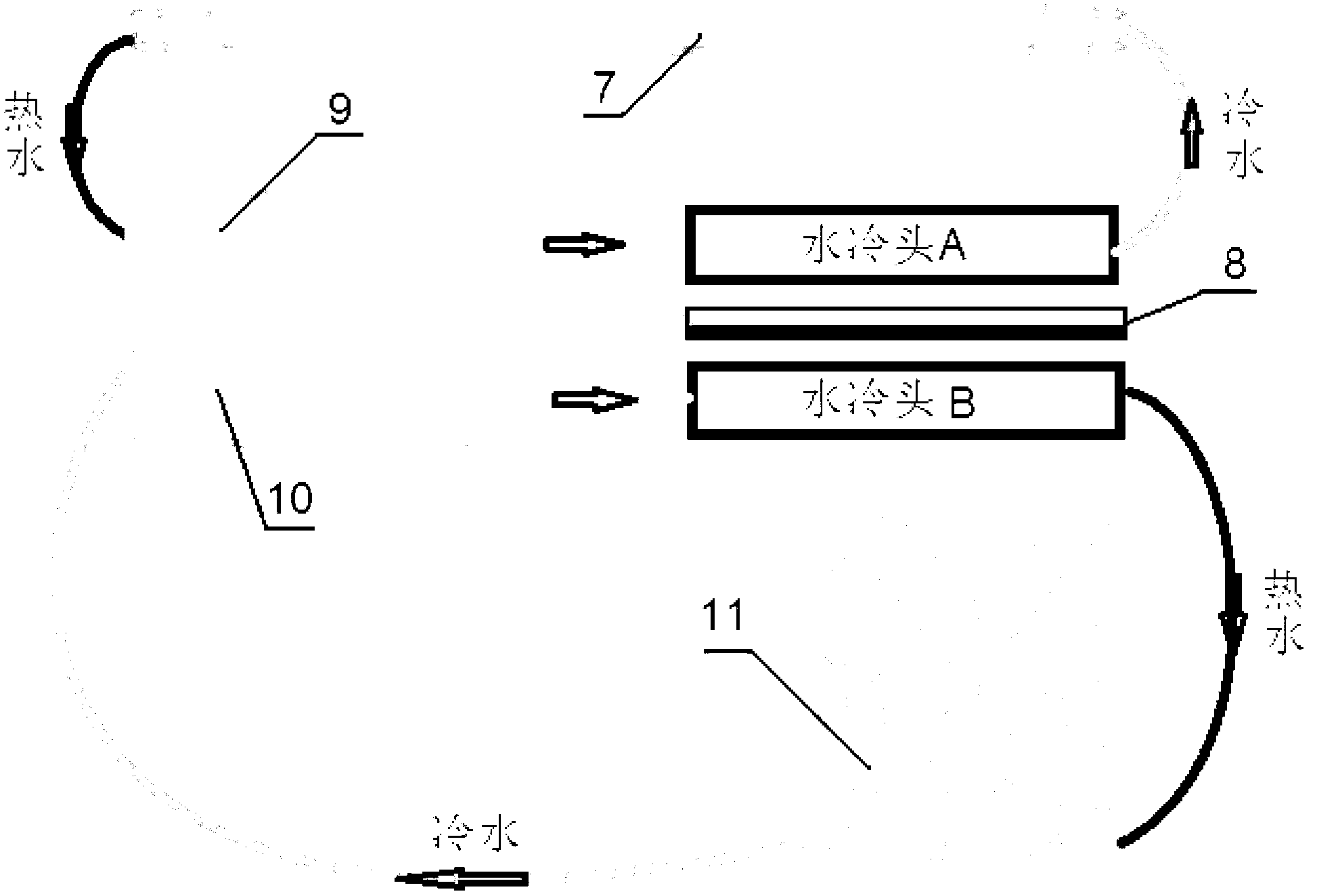

[0036] The cooling device includes a laser circulating water tank 9, a radiator circulating water tank 10, a heat exchanger 11, a semiconductor cooling chip and two water cooling heads (water cooling head A and water cooling head B respectively). The cooling end of the semiconductor refrigerating sheet is attached to the water cooling head A, and the heating end is attached to the water cooling head B. CO 2 The water inlet end of the laser tube 7 is connected to the water cooling head A, and the water outlet end is connected to the water cooling head A through the laser circulating water tank 9 . The water inlet end of the heat exchanger 11 is connected to the water cooling head B, and the water outlet end is connected to the water cooling head B through the radiator circulating water tank 10 . In this embodiment, the heat exchanger adopts an air-cooled heat exchanger to realize heat exchange between water and air. A fan is installed in the air-cooled heat exchanger, and the ...

Embodiment 2

[0039] In this embodiment, the refrigerating capacity of the cooling device is controllable through three water cooling heads, four semiconductor refrigerating plates, three temperature sensors 12, a temperature controller and two electromagnetic relays, so as to achieve the purpose of artificially controlling the refrigerating capacity. Its structural diagram is as Figure 4 As shown, the three water cooling heads are respectively water cooling head A, water cooling head B and water cooling head C; two of the four semiconductor cooling chips are connected in parallel to form two semiconductor cooling chip groups, and one semiconductor cooling chip group is installed on Between water-cooling head A and water-cooling head B, wherein water-cooling head A is attached to the heating end of the semiconductor cooling chip group, and water-cooling head B is attached to the cooling end of the semiconductor cooling chip group; another semiconductor cooling chip group is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com