Energy recovery device for multi-stage pump

A multi-stage pump and flow technology, which is applied in the direction of pump devices, pumps, liquid displacement machinery, etc., can solve the problems of cavitation damage of the first stage impeller, and achieve the effect of avoiding cavitation damage and increasing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

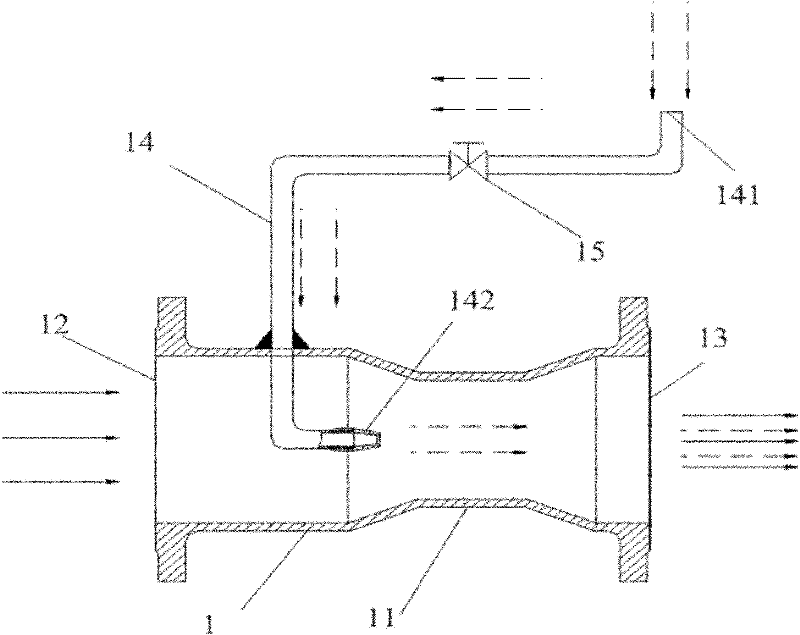

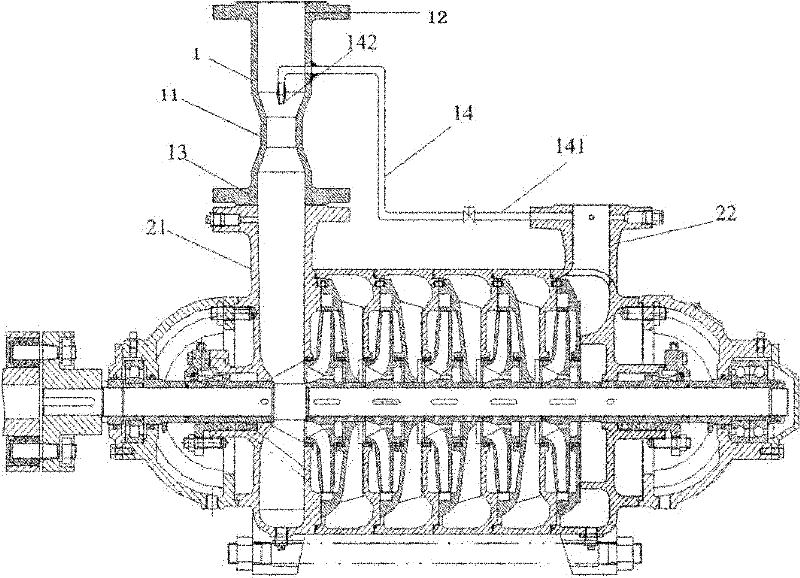

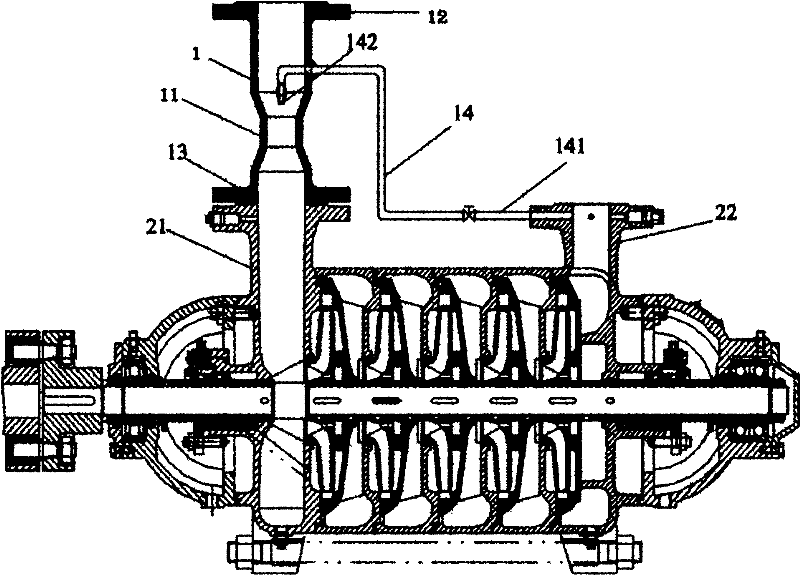

[0014] like figure 1 and 2 As shown, the energy recovery device in the present invention includes a hollow cylindrical flow mixer 1, which includes a liquid inlet 12 and a liquid outlet 13, located in the middle of the liquid inlet 12 and the liquid outlet 13 There is a pressurized section 11 constricting toward the center of the flow mixer 1 . The energy recovery device also includes a booster tube 14, one end 141 of the booster tube 4 is used to connect with the water discharge section 22 of the multi-stage pump, and the other end is passed through the inside of the flow mixer 1, and is located at the liquid inlet 12 and Between the pressurization sections 11 , at the end of the pressurization pipe 4 inside the flow mixer 1 is provided a nozzle 142 whose water outlet points to the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com