Wear-resistant cutter-suction pump

A wear-resistant, twist-suction pump technology, applied in the direction of pumps, pump components, non-variable pumps, etc., can solve problems such as poor improvement effects, achieve low cost, avoid wear and cavitation damage, and have a long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

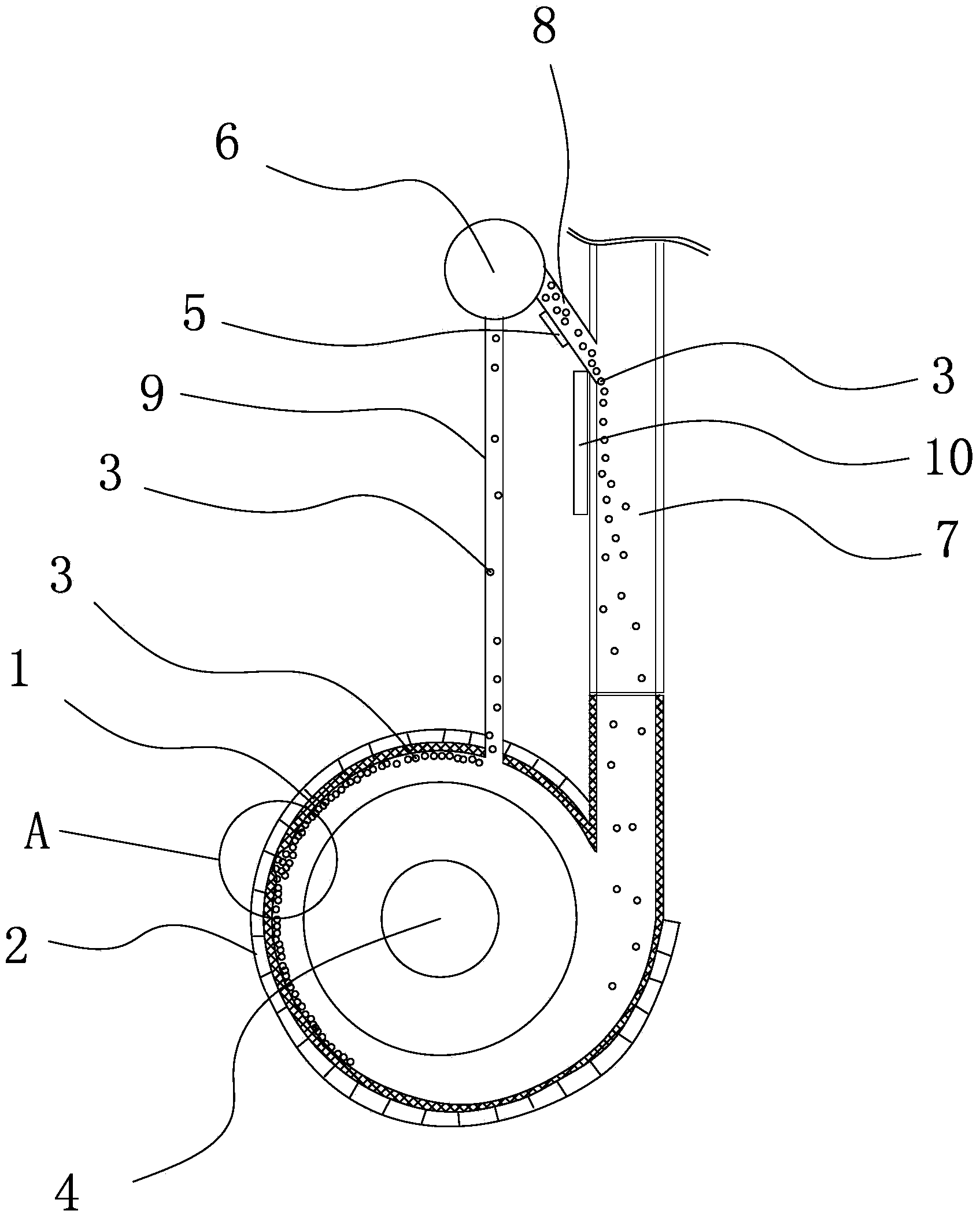

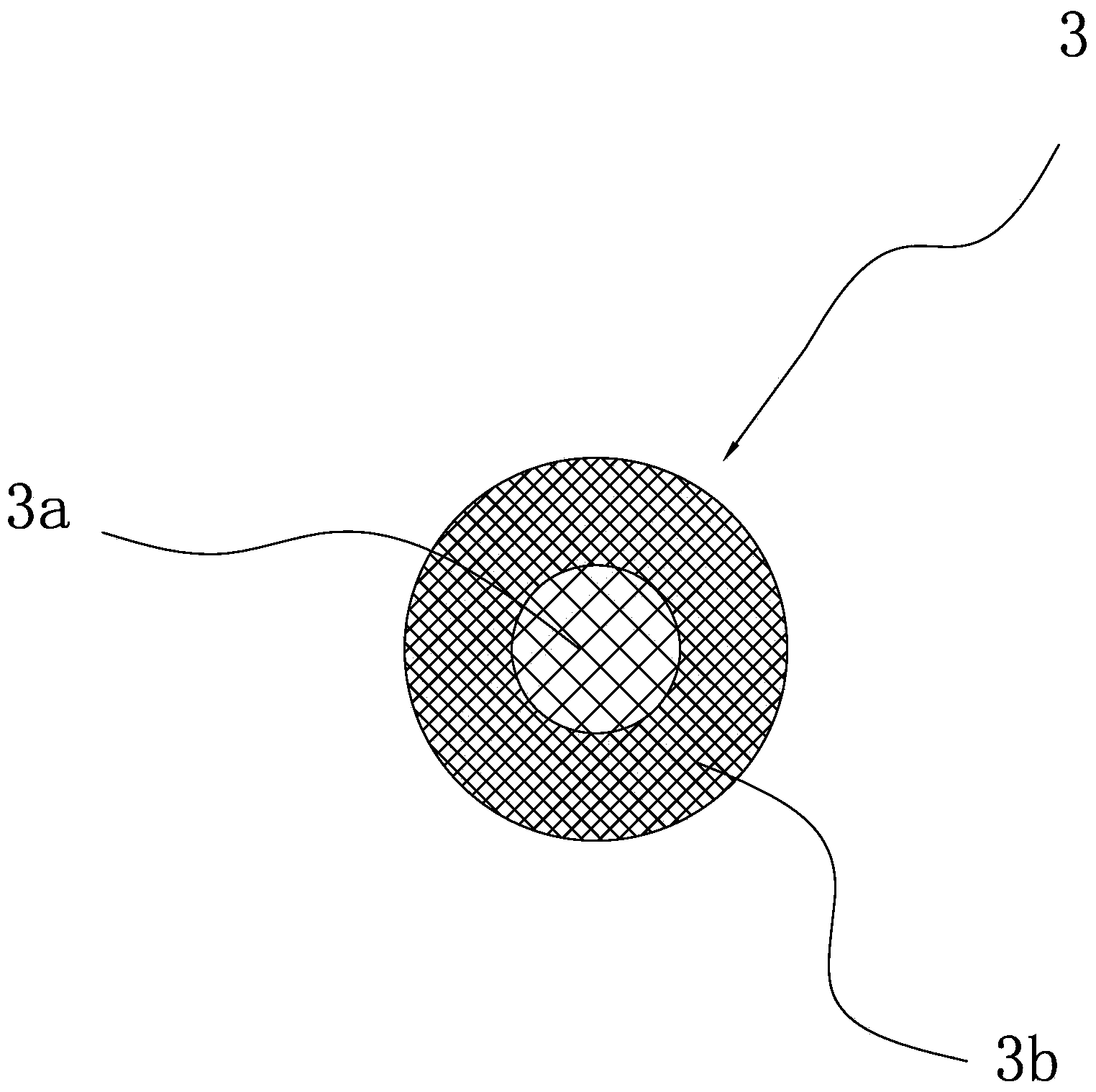

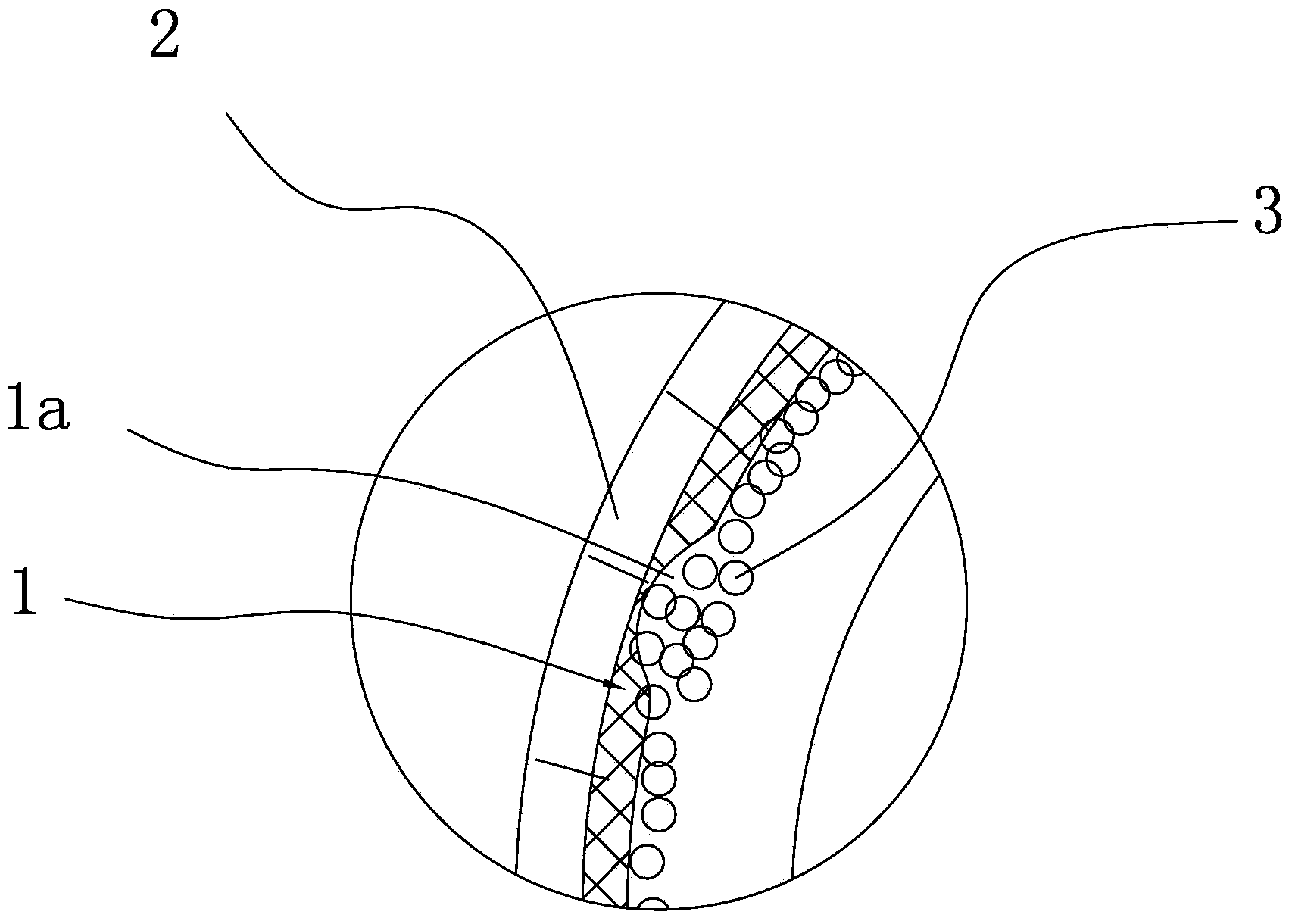

[0023] refer to figure 1 , this embodiment is an anti-wear twister suction pump, the twister suction pump includes a pump casing 1, an impeller 4 and a delivery pipe 7, the impeller 4 is arranged in the pump casing 1, and several magnetic pumps are arranged in the inner cavity of the pump casing 1. A spherical anti-wear block 3, the diameter of the anti-wear block 3 is 1-2mm. The outside of the pump casing 1 is provided with a first magnet 2 that can absorb the anti-wear block 3 to the inner wall of the pump casing 1. The first magnet 2 is a shell-shaped covering on the outside of the pump casing 1 and closely attached to the outer wall of the pump casing 1. structure. The conveying pipe 7 is arranged vertically and comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com