Flood discharging method for anticorrosion and energy dissipation of rotational flow ring dam and device thereof

A ring-shaped, energy-dissipating technology, applied in the direction of barrage/weir, water conservancy engineering, marine engineering, etc., can solve the problems of complex ventilation pipeline system, large fluctuation of water surface in the cave, damage to the ecological environment, etc., to protect the ecological environment and prevent corrosion. And the effect of good energy dissipation and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

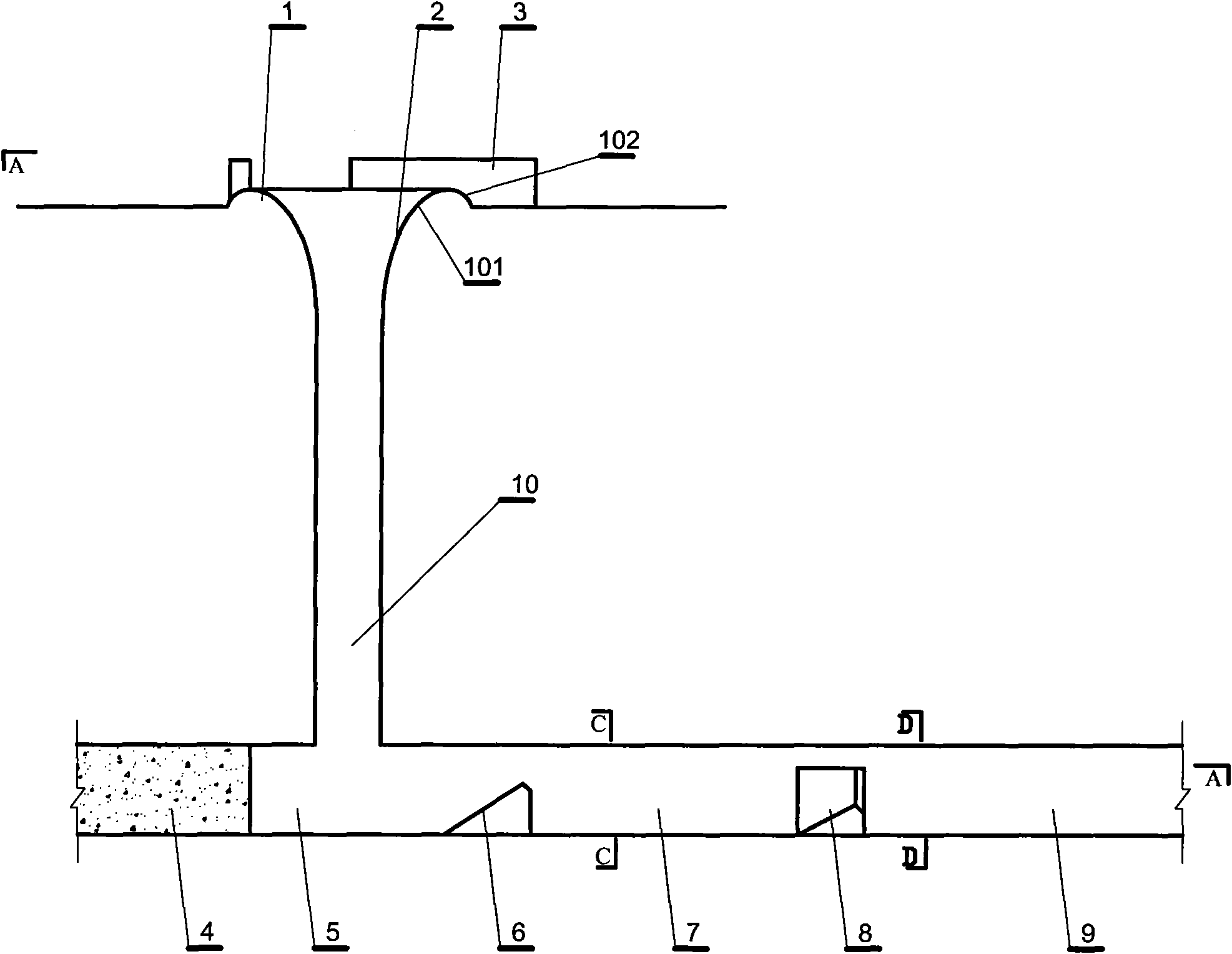

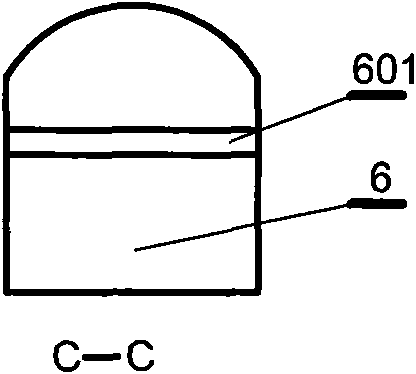

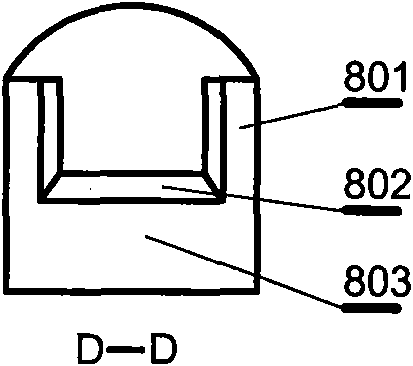

[0038] This embodiment is a flood discharge device for corrosion prevention and energy dissipation of a swirling annular weir, such as figure 1 , 4 shown. The device described in this embodiment includes: a shaft 10, the bottom of the shaft is connected to the horizontal energy dissipation tunnel, the energy dissipation tunnel is connected to the diversion tunnel 9, an annular weir 1 is arranged at the entrance of the shaft, and the inner ring of the annular weir Form a smooth constriction surface connection with the shaft to form a constriction 2. Several diversion piers 3 are arranged outside the annular weir, and the center line of the diversion piers and the tangent line of the annular weir form an included angle greater than or equal to 0° and less than 45°. There is a space 5 at the position where the vertical shaft connects with the energy dissipation tunnel and the position opposite to the energy dissipation tunnel, see figure 1 , 4 shown. The energy dissipation t...

Embodiment 2

[0054] This embodiment is an improvement of the first embodiment, and it is an improvement of the first embodiment about the diversion pier. The number of diversion piers described in this embodiment is 4-8.

[0055] Figure 4 Shown is the case of 4 diversion piers. Figure 5 is the case of five diversion piers. Image 6 is the case of eight diversion piers.

Embodiment 3

[0057] This embodiment is an improvement of the second embodiment, and is an improvement of the second embodiment on the diversion pier. The cross-sectional shape described in this embodiment is a rectangle 303 connected to a wedge 302, the wedge-shaped head 301 of the diversion pier from the proximal end of the annular weir is blunt and round, and the rectangular tail 304 of the diversion pier is circular, such as Figure 4 shown.

[0058] More precisely, the diversion pier should be a diversion wall, similar to a short wall. The cross-sectional shape of the short wall is rectangular. In order to improve the diversion effect, the head used in this embodiment is wedge-shaped, the angle of the wedge is relatively sharp, and the tip of the wedge transitions with a circular arc. In order to make the water flow smoothly, all the corners of the diversion piers use arc transitions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com