Cooling fluid in use for super fine milling functional crystal of potassium dihydrogen phosphate

A technology of potassium dihydrogen phosphate and coolant, which is applied in the petroleum industry, additives, lubricating compositions, etc. It can solve the problems of easy deliquescence, high brittleness, sensitivity to temperature changes, etc., and achieve the effect of reducing brittle damage and reducing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

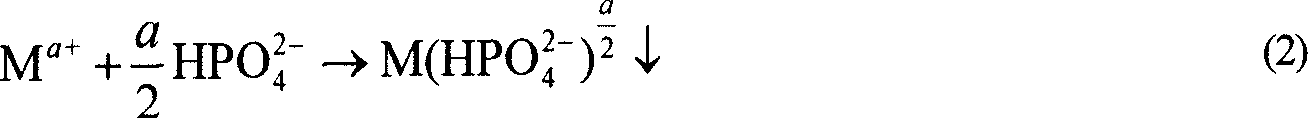

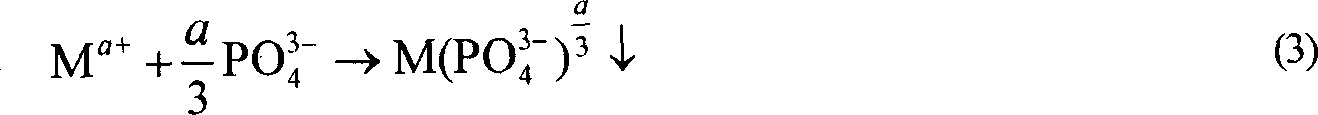

Method used

Image

Examples

specific Embodiment approach 1

[0031] Embodiment 1: The coolant in this embodiment is composed of aviation kerosene, EDTA and SSal, wherein aviation kerosene is used as the matrix, the addition amount of EDTA is 1.598mg / L~3.2mg / L, and the addition amount of SSal is 0.031mg / L L~0.1mg / L.

specific Embodiment approach 2

[0032] Embodiment 2: This embodiment is different from Embodiment 1 in that the amount of EDTA added is 1.6 mg / L, and the amount of SSal added is 0.04 mg / L.

specific Embodiment approach 3

[0033] Embodiment 3: This embodiment is different from Embodiment 1 in that the amount of EDTA added is 2.4 mg / L, and the amount of SSal added is 0.062 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com