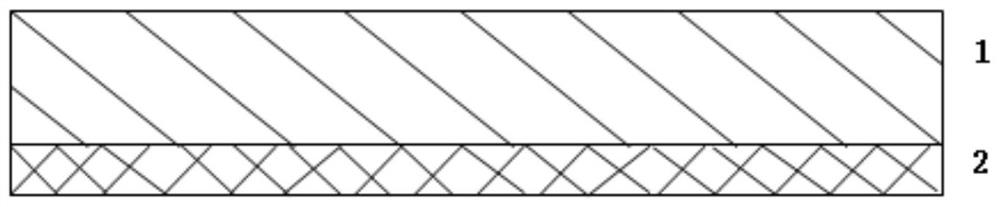

PET anti-fog easy-to-uncover film and manufacturing method thereof

A manufacturing method and anti-fog technology, which can be applied to coatings, polyurea/polyurethane coatings, etc., can solve the problems of tearing of the cover film, affecting the heat-sealing effect, and uneven thickness of the coating film, and achieve stable heat-sealing strength and anti-fog. Good effect, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

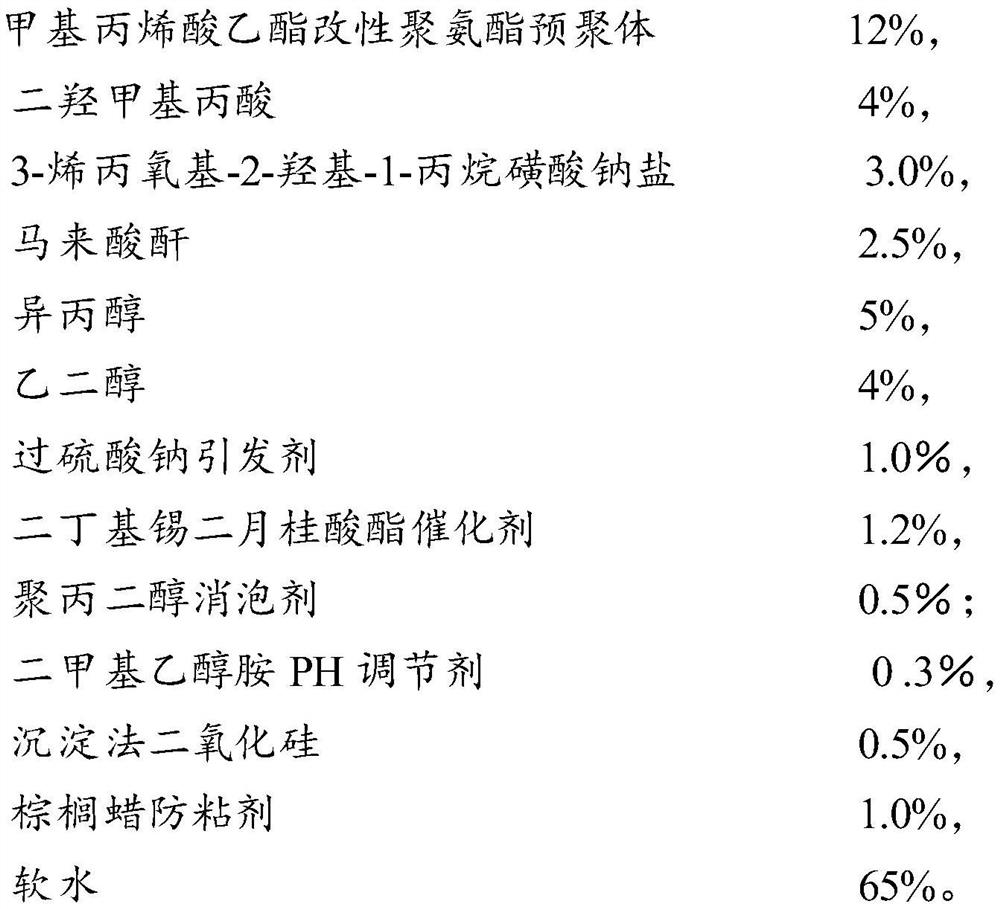

Embodiment 1

[0077] The mass percentage of anti-fog heat-sealing emulsion preparation is as follows:

[0078]

[0079] The anti-fog heat-sealing emulsion produced in this case is coated on BOPET, which has good heat-sealing strength and anti-fog effect. The coating steps are as follows:

[0080] (1) Unwinding process: Under the tension of 80N, unfold the 25μm BOPET optical film roll, the film roll moves forward continuously through multiple guide rollers, and uses two identical stations to work alternately, using automatic splicing and quick film change , to achieve the purpose of continuous unwinding and changing rolls.

[0081] (2) Corona process: under the power of 8.0KW, the BOPET film passes through the corona electrode, so that the surface to be coated reaches a value of 50 dynes.

[0082] (3) Anti-fog heat-seal emulsion coating process: the anti-fog heat-seal emulsion is coated on the corona surface of the BOPET optical film by the reverse roller kissing method of the coating r...

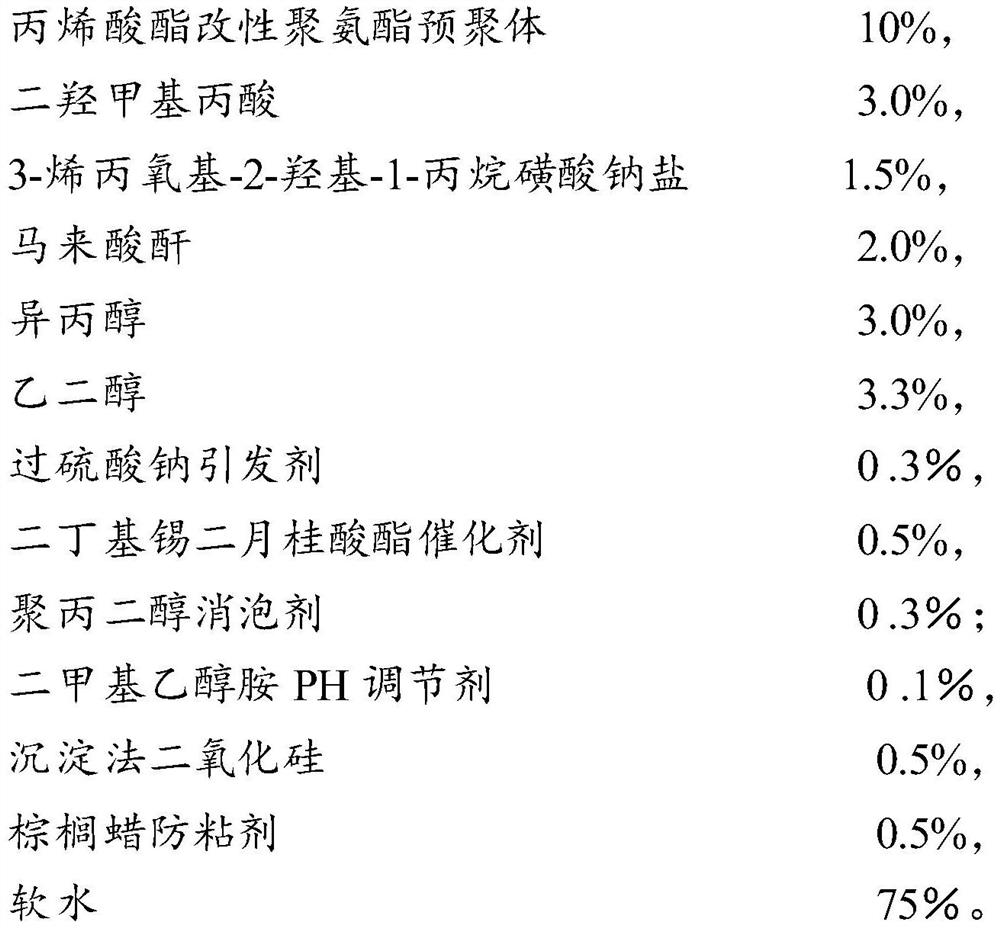

Embodiment 2

[0087]

[0088] The anti-fog heat-sealing emulsion produced in this case is coated on BOPET, which has good heat-sealing strength and anti-fog effect. The coating steps are as follows:

[0089] (1) Unwinding process: Under the tension of 80N, unfold the 25μm BOPET optical film roll, the film roll moves forward continuously through multiple guide rollers, and uses two identical stations to work alternately, using automatic splicing and quick film change , to achieve the purpose of continuous unwinding and changing rolls.

[0090] (2) Corona process: under the power of 8.0KW, the BOPET film passes through the corona electrode, so that the surface to be coated reaches a value of 50 dynes.

[0091] (3) Anti-fog heat-seal emulsion coating process: the anti-fog heat-seal emulsion is coated on the corona surface of the BOPET optical film by the reverse roller kissing method of the coating roller, and the speed is 200m / min.

[0092] (4) Anti-fog heat-seal coating drying process: ...

Embodiment 3

[0096]

[0097]

[0098] The anti-fog heat-sealing emulsion produced in this case is coated on BOPET, which has good heat-sealing strength and anti-fog effect. The coating steps are as follows:

[0099] (1) Unwinding process: Under the tension of 80N, unfold the 25μm BOPET optical film roll, the film roll moves forward continuously through multiple guide rollers, and uses two identical stations to work alternately, using automatic splicing and quick film change , to achieve the purpose of continuous unwinding and changing rolls.

[0100] (2) Corona process: under the power of 8.0KW, the BOPET film passes through the corona electrode, so that the surface to be coated reaches a value of 50 dynes.

[0101] (3) Anti-fog heat-seal emulsion coating process: the anti-fog heat-seal emulsion is coated on the corona surface of the BOPET optical film by the reverse roller kissing method of the coating roller, and the speed is 200m / min.

[0102] (4) Anti-fog heat-seal coating dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com