Heat seal cover tape and preparation method of heat seal cover tape

A cover tape and heat-sealing layer technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of high production technology and equipment requirements, complex product structure, and high price, and achieve excellent The effect of heat sealability, low production cost and low production equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

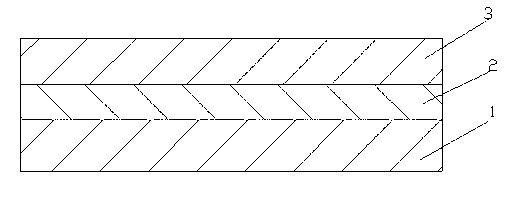

Image

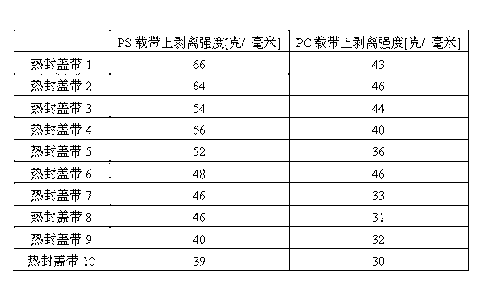

Examples

Embodiment 1

[0025] Substrate film layer: Biaxially oriented polyethylene terephthalate film, thickness 16 μm.

[0026] Primer coating: The primer prepared by grafting maleic anhydride with styrene-butadiene-styrene block copolymer is directly coated on the substrate film through a gravure roller coater, and the coating thickness is 5 μm .

[0027] Heat-sealing layer: apply the heat-sealing agent directly on the primer layer through a knife coater, with a coating thickness of 30 μm.

[0028] The formula of heat sealing agent is as follows, the unit is gram;

[0029] Styrene-butadiene-styrene block copolymer 100

[0030] hydrogenated C 9 Petroleum resin 10

[0031] Rosin modified phenolic resin 10

[0032] Polyethylene wax 5

[0034] Toluene 300

[0035] Ethyl acetate 100

[0036] Heat-sealing agent preparation process: Add polyethylene wax, polyamide wax and toluene into the reaction kettle, dissolve at 90°C for 1 hour; cool down to 60°C, add styrene-butad...

Embodiment 2

[0039] Substrate film layer: biaxially stretched polyethylene terephthalate film, thickness 20 μm.

[0040] Primer coating: The primer prepared by grafting acrylic acid with styrene-butadiene-styrene block copolymer is directly coated on the substrate film with a coating thickness of 5 μm through a gravure roller coater.

[0041] Heat-sealing layer: apply the heat-sealing agent directly on the primer layer through a knife coater, with a coating thickness of 25 μm.

[0042] The formula of heat sealing agent is as follows, the unit is gram;

[0043] Styrene-butadiene-styrene block copolymer 100

[0044] hydrogenated C 9 petroleum resin 5

[0045] Terpene-styrene resin 5

[0046] Terpene-phenolic resin 10

[0047] Polyethylene wax 5

[0049] Toluene 400

[0050] Heat-sealing agent preparation process: Add polyethylene wax, polyamide wax and toluene into the reaction kettle, dissolve at 90°C for 1 hour; cool down to 60°C, add styrene-butadiene-styr...

Embodiment 3

[0053] Substrate film layer: biaxially stretched polyethylene terephthalate film, thickness 20 μm.

[0054] Primer coating: The primer prepared by grafting methacrylic acid with styrene-butadiene-styrene block copolymer is directly coated on the substrate film through a gravure roller coater, and the coating thickness is 5 μm .

[0055] Heat-sealing layer: apply the heat-sealing agent directly on the primer layer through a knife coater, with a coating thickness of 30 μm.

[0056] The formula of heat sealing agent is as follows, the unit is gram;

[0057] Styrene-butadiene-styrene block copolymer 100

[0058] Rosin modified phenolic resin 5

[0059] Terpene-styrene resin 10

[0060] Terpene-phenolic resin 10

[0061] Polypropylene Wax 5

[0062] Polyamide Wax 2

[0063] Toluene 300

[0064] Ethyl acetate 100

[0065] Heat-sealing agent preparation process: Add polypropylene wax, polyamide wax and toluene to the reaction kettle, dissolve at 90°C for 1 hour; cool down to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com