High sealing flexible composite film material for cold punching molding and its manufacturing method

A composite film, high-sealing technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of failure of package contents, influence of barrier properties of packaging materials, improper molding, etc., and achieve easy stretching. Molding and mold release, stable interlayer peel strength, and the effect of reducing friction coefficient values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

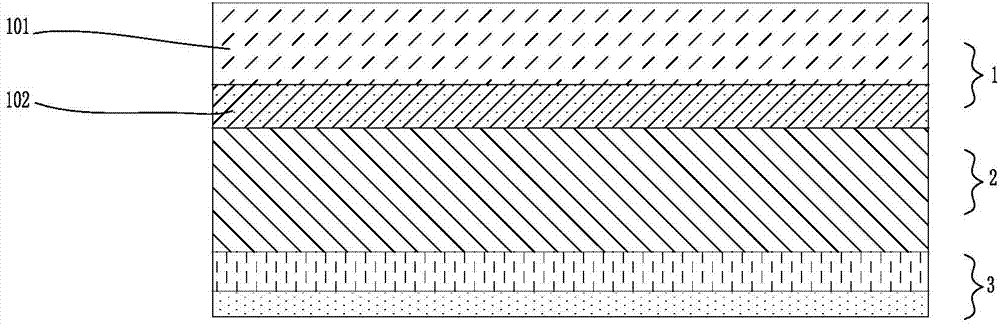

[0043] Such as figure 1 As shown, the flexible composite film material of this embodiment is sequentially from top to bottom: thermoplastic resin film inner layer 1, aluminum foil metal core layer 2 and heat-resistant film outer layer 3; wherein, thermoplastic resin film inner layer 1 is two A layer co-extrusion film, which includes a surface heat-sealing layer 101 and an inner composite layer 102. Aluminum foil made of aluminum-iron alloy (AA specification 8079) with a thickness of 45 μm is selected as the aluminum foil metal core layer 2, metallocene polyethylene (PE) with a thickness of 35 μm is used as the surface heat-sealing layer 101, and acid-modified aluminum foil with a thickness of 15 μm is selected. Polyethylene (MPE) is used as the inner layer composite layer 102, and polyamide (PA) with a thickness of 15 μm and polyester (PET) with a thickness of 12 μm are selected as the outer layer 3 of the heat-resistant film, which is made of PET(12) / ON( 15) / AL(45) / PE(15) / MP...

Embodiment 2

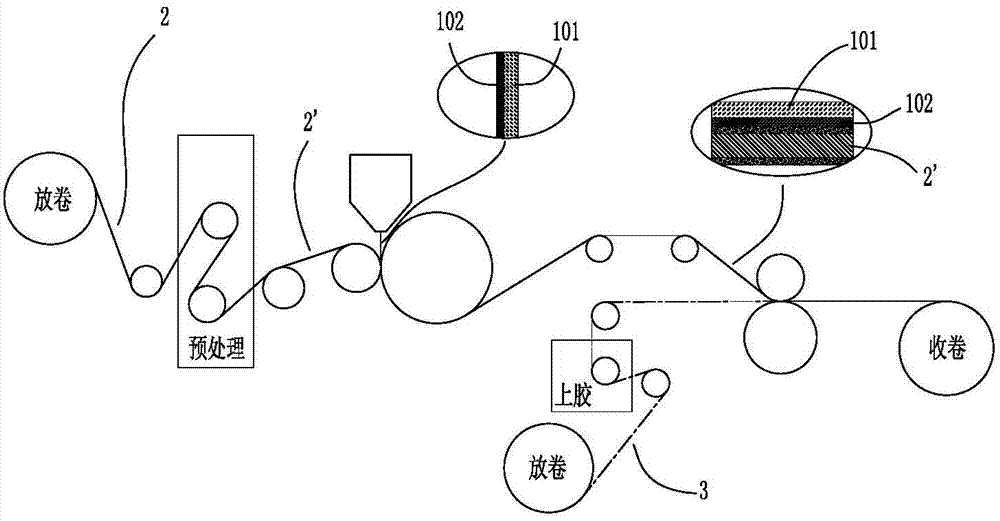

[0050] This embodiment and embodiment 1 have the same material composition, and its preparation process is as follows (such as figure 2 shown):

[0051] A, adopt chrome-free surface treatment agent to carry out double-sided chemical oxidation treatment to the surface of aluminum foil metal core layer 2, obtain double-sided pretreated aluminum foil metal core layer 2';

[0052] B. The inner layer 1 of the thermoplastic resin film is prepared through the casting and co-extrusion process, wherein 5% diatomaceous earth is added to the surface heat-sealing layer (101); The composite layer 102 is directly in contact with one side of the double-sided pretreated aluminum foil metal core layer 2'.

[0053] C. The heat-resistant film outer layer 3 is contacted with the other side of the uncoated aluminum foil metal core layer 2' in step B by dry compounding to prepare the multilayer aluminum-plastic composite film material.

[0054] Carry out the same experimental test as embodiment ...

Embodiment 3

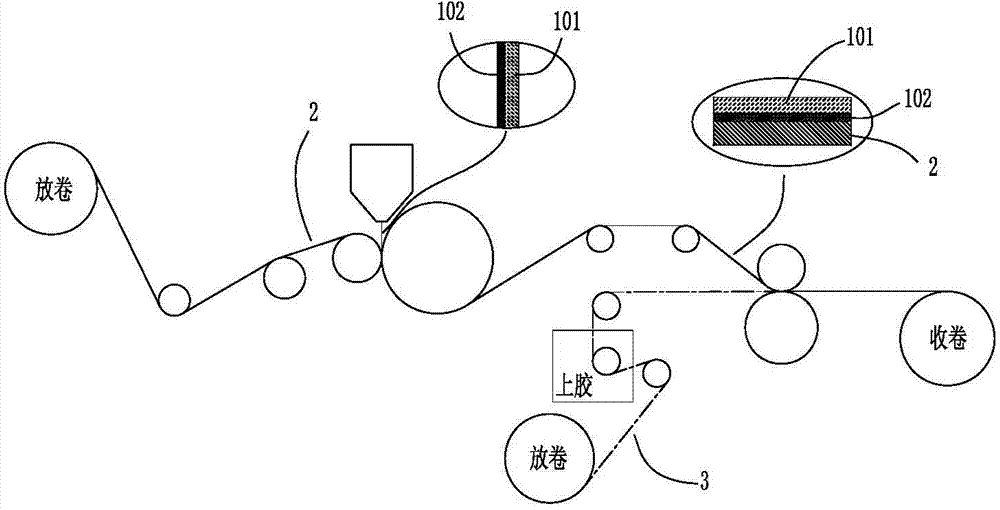

[0056] This embodiment and embodiment 1 have the same material composition, and its preparation process is as follows (such as figure 2 shown):

[0057] A, adopt silane coupling agent to carry out double-sided primer treatment to the surface of aluminum foil metal core layer 2, obtain double-sided pretreated aluminum foil metal core layer 2';

[0058] B. The inner layer 1 of the thermoplastic resin film is prepared by casting and co-extrusion process, wherein the surface heat-sealing layer 101 is added with 5% precipitation-type smooth agent erucamide, and the inner composite layer 102 is added with 5% modified phenolic aldehyde Resin; while casting and co-extruding, the inner layer composite layer 102 is directly contacted and composited with one side of the double-sided pretreated aluminum foil metal core layer 2' by adopting a hot-compression composite process.

[0059] C. The heat-resistant film outer layer 3 is contacted and compounded with the other side of the uncoate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com