An online double-layer composite plastic blown film and its manufacturing method

A manufacturing method and double-layer compounding technology, applied in the direction of chemical instruments and methods, layered products, flat products, etc., can solve the problems of less functionality and easy sticking to rolls, so as to inhibit melting softening, inhibit roll sticking, and improve materials The effect of the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

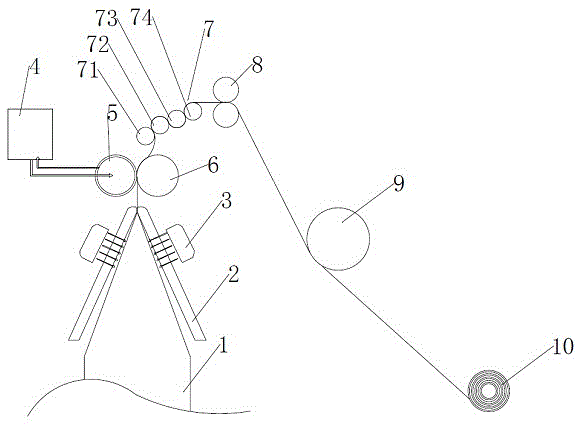

[0045] The invention is an online double-layer composite plastic blow molding film. The plastic blown film is formed by heat-sealing the inner layer of the multi-layer co-extrusion blown bubble 1; the composition and weight percentage of the inner layer of the bubble 1 are: EVA10~30%, COC40~60% and SEBS10 ~30%; the material of the outer layer of the bubble 1 has a melting point higher than the Vicat softening point of the material of the inner layer of the bubble 1, such as one of PE, PP and PA.

[0046] The manufacture method of this plastic blow molding film comprises the following steps:

[0047] S1. Melting and extruding each layer of material for manufacturing the bubble 1 in an extruder;

[0048] S2. The film bubble 1 co-extruded from the extrusion die is compressed into a double-layer film by the herringbone frame 2, and at the same time, it is heated to 55°C by the far-infrared heating device 3 on the ~75°C, reaching near the Vicat softening point of the inner layer ...

Embodiment 2

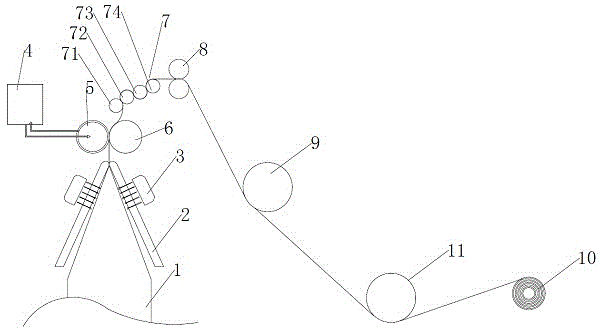

[0055] On the basis of Example 1, such as figure 2 As shown, after the cooling roller 9 is cooled and before the wind-up roller 10 winds up, the edge of the cooled sheet can also be cut off by the trimming roller 11, so that the performance of the film is more uniform.

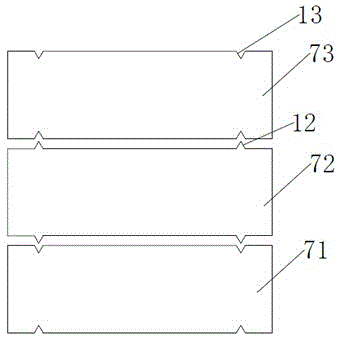

[0056] In addition, during the heat-sealing process, the bubble 1 can also be vented at the same time, for example, on both sides of at least one heat-sealing steel roller of the heat-sealing roller group 7, there are openings for forming an exhaust port on the edge of the bubble 1 after being flattened. mechanism. Such as image 3 As shown, the opening mechanism is provided on both sides of the second steel roller 72 with the teeth 12 having a triangular cross-section. At the same time, the first steel roller 71 and the third steel roller 73 are provided with grooves 13 matching with the notches 12 at positions corresponding to the notches 12 of the second steel roller 72 . Arranging the notched teeth 12 ...

Embodiment 3

[0058] The invention is an online double-layer composite plastic blow molding film. The difference from Example 1 is that the film bubble 1 obtained by multi-layer co-extrusion blow molding is subjected to online unidirectional longitudinal stretching and annealing after the inner layer of the line is heat-sealed and shaped before cooling, so that the heat-sealed thickness is doubled, stretched and stretched. Unidirectional longitudinally stretched plastic blown film of half-stretch thickness. The specific longitudinal stretching and annealing steps are:

[0059] S* 1 . Unidirectional longitudinal stretching of the shaped double-layer film in a heated state: Specifically, the shaped double-layer film is preheated to 60-85°C by two preheating rollers 14, and then passed by four stretching rollers 15 When stretching at a temperature of 75-110°C, the stretching ratio of each stretching roller 15 is kept increasing in the range of 1.0-2.0 times along the direction of material tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com