Patents

Literature

56results about How to "Good heat sealing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

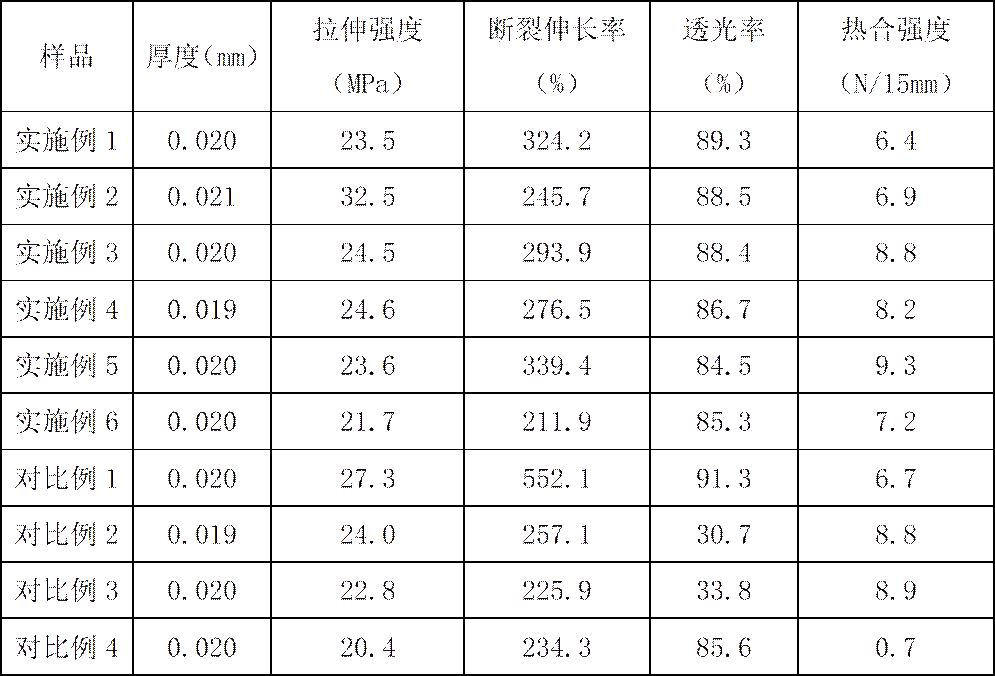

Film for suction plastic packaging of medical equipment and method for preparing same

InactiveCN101559854AGood heat sealing effectReduce production linksFlexible coversWrappersMaleic anhydrideMetal

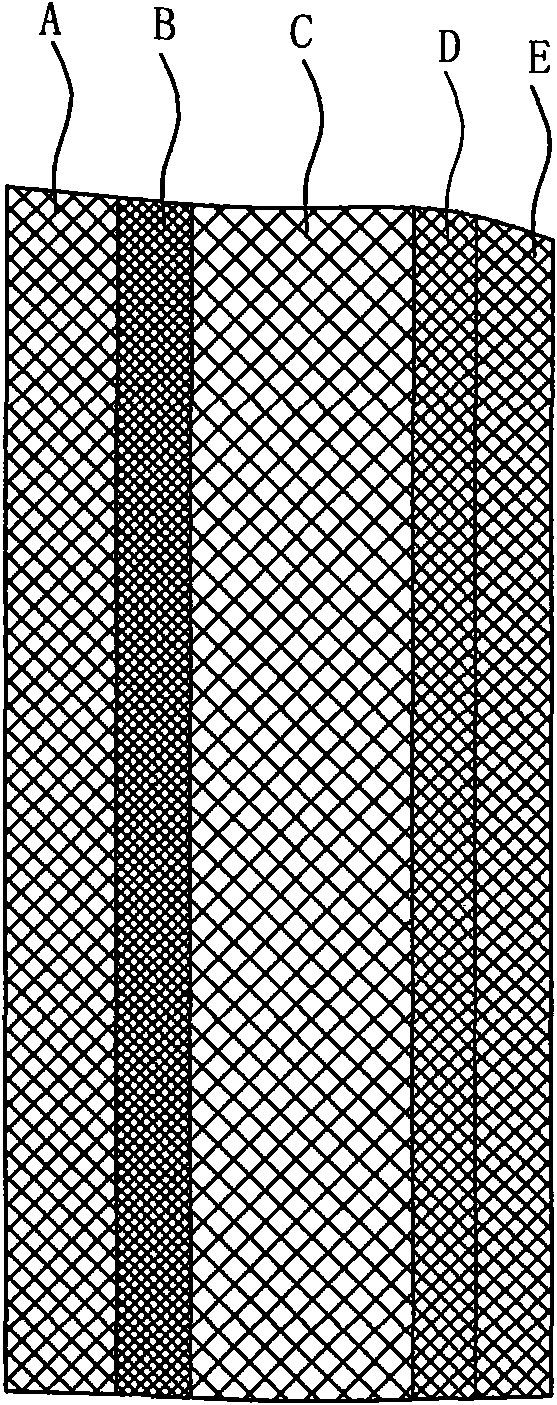

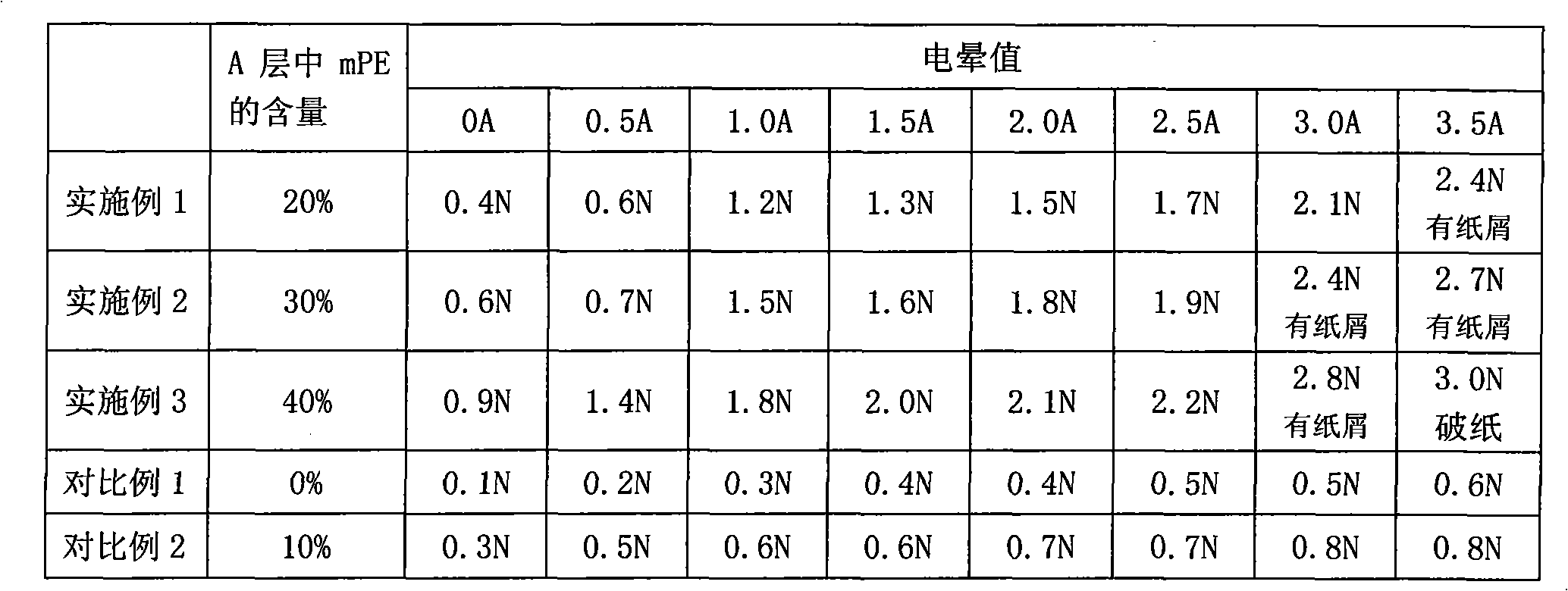

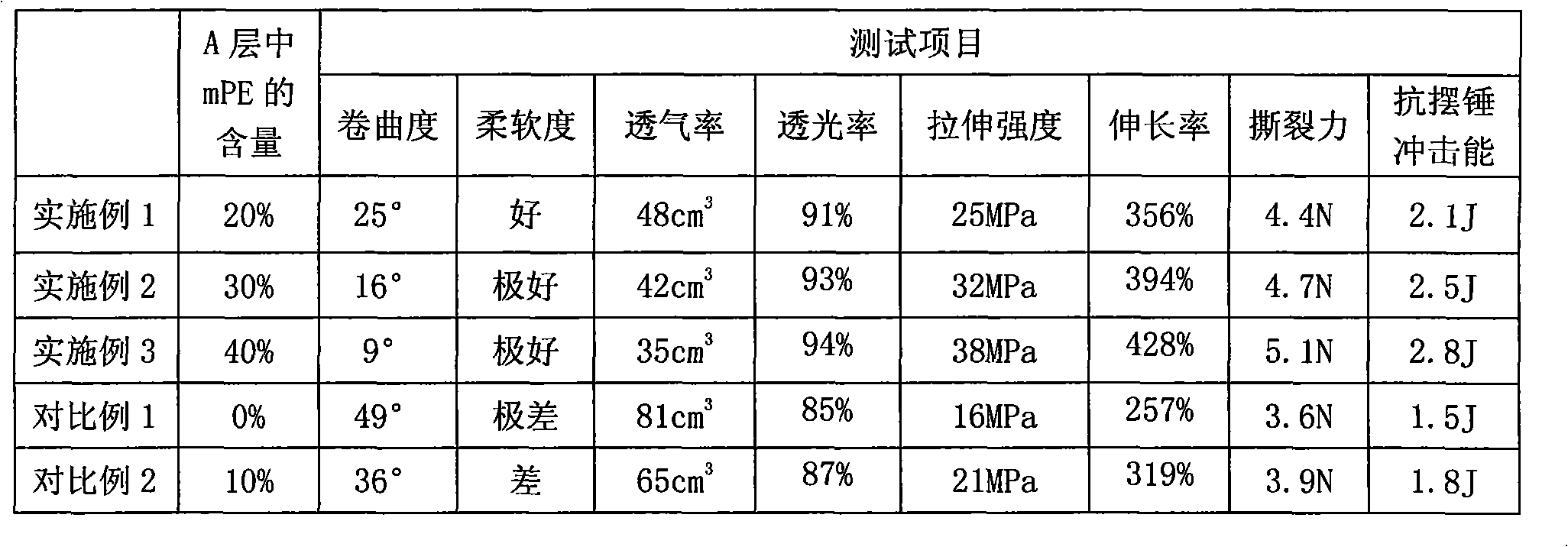

The invention relates to a film for suction plastic packaging of medical equipment and a method for preparing the same. The film adopts a five-layer structure; the first layer is a heat seal layer A, of which the component is co-mixing resin of linear low-density polyethylene and metallocene catalytic polyethylene taking octene as a comonomer, wherein the content of the metallocene catalytic polyethylene in the co-mixing resin is 20 to 40 weight percent; the second layer is an inner layer B, of which the component is linear low-density polyethylene containing a hexene comonomer; the third layer is a core layer, of which the component is linear low-density polyethylene containing a butene comonomer; the fourth layer is a bonding layer D, of which the component is maleic anhydride grafted polyethylene; and the fifth layer is a weathering resistant layer E, of which the component is nylon 6 or 66. The preparation method comprises the following steps that: the bottom blowing water cooling type co-extrusion process or flow casting method is adopted, and the plastics is subjected to fusion and die inflation or flow casting, and quick cooling at water temperature of between 15 and 18 DEG C. The film and the preparation method have the advantages that: the method is simple; the products have merits of various resins; the film can be thermally sealed with the dialyzing paper without glum spreading; and moreover, the method and the film also have the advantages of low film thickness, good comprehensive property and reutilization.

Owner:NINGBO HUAFENG PACKAGE

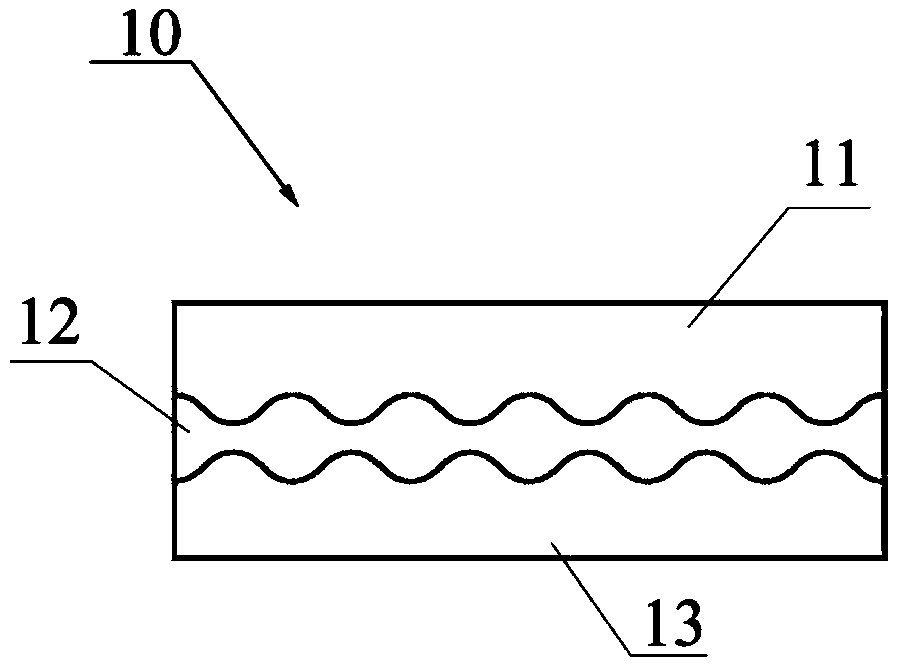

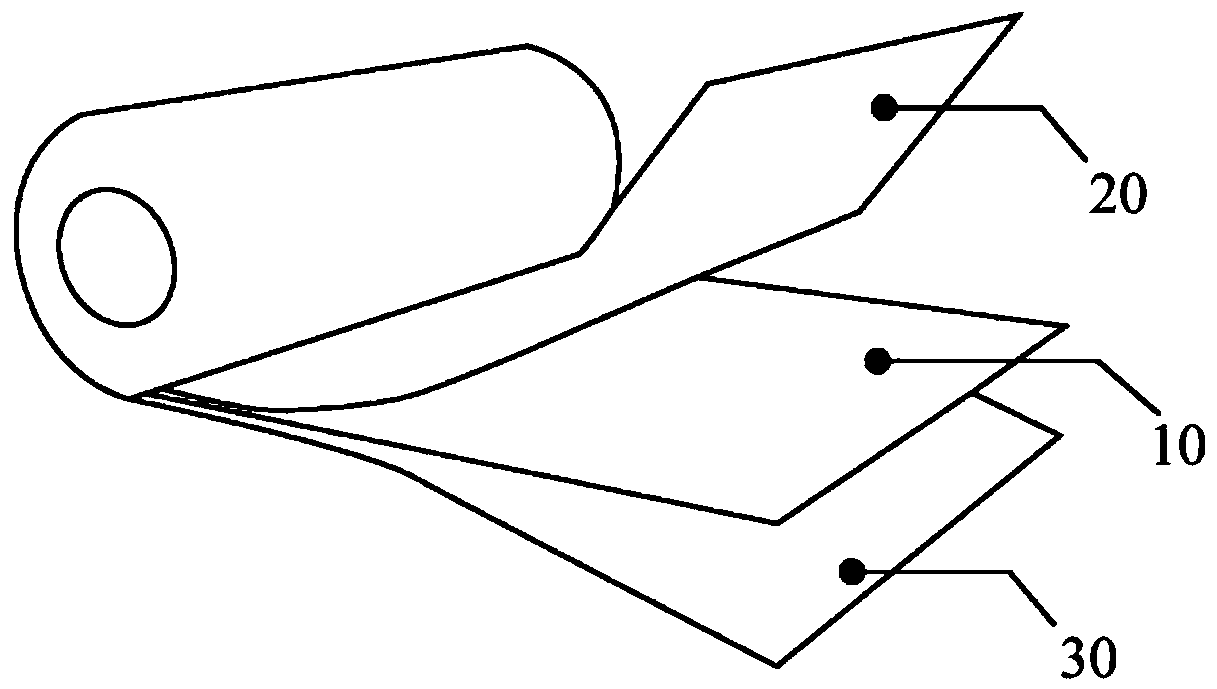

Online double-layer composite plastic blow-molding film sheet and manufacturing method thereof

ActiveCN104527189AImproved material designReduce the temperatureSynthetic resin layered productsBoxesHot pressingMelting point

The invention discloses an online double-layer composite plastic blow-molding film sheet which is formed by softening inner layers of a plurality of layers membrane bubbles which are co-extruded and blow-molded, wherein the inner layers of the membrane bubbles consist of EVA, COC and SEBS; a melting point of materials of the outer layers of the membrane bubbles is higher than a Vica softening point of the materials of the inner layer of the membrane bubbles. By optimizing the materials of the inner layers of the membrane bubbles, sticking is inhibited when the hot-pressing effect is improved, the thickness uniformity, the transparency, the heat-sealing uniformity, and the like of the membrane sheet are improved, the prepared membrane sheet has extensive re-processing capacity; after being heat-sealed and thickened, the membrane sheet is stretched and thinned, so that the film sheet has the performances of a blow-molding material and a flow casting material, and can be used as a packaging box back seal strip on a high-speed packaging body production line. Besides, the invention further discloses a manufacturing method for the online double-layer composite plastic blow-molding film sheet.

Owner:JIANGYIN BAOBO PACKING

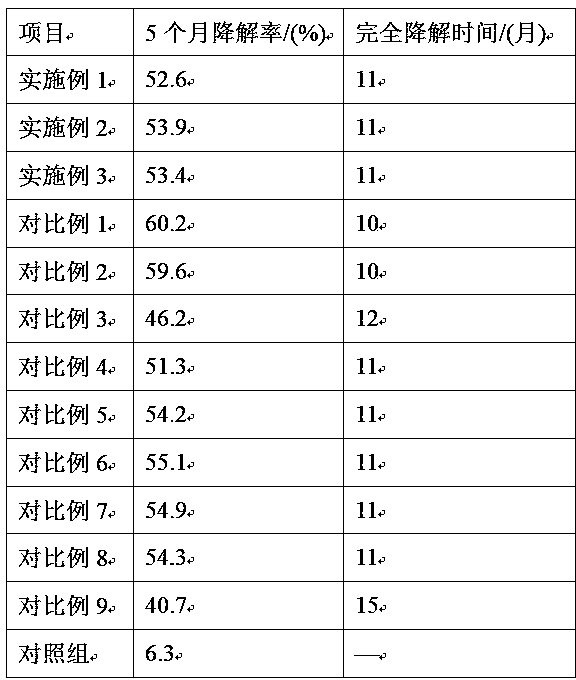

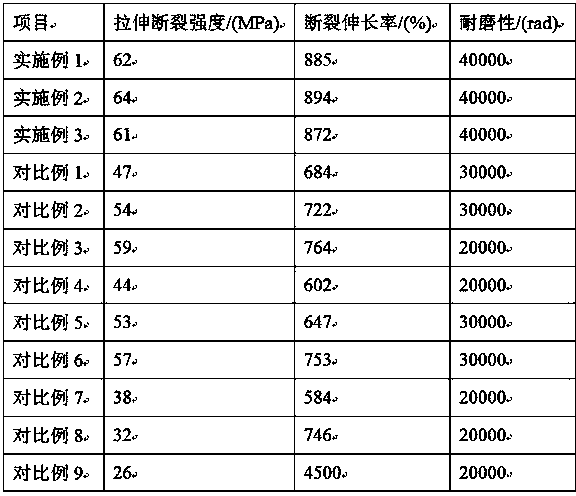

Plant fibre reinforced biodegradable film material and preparation thereof

The invention relates to a biodegradable thin-film material strengthened by plant fibers and a preparation method thereof. Raw materials and parts by weight thereof used are as follows: 20 parts to 45 parts of plant fibers, 30 parts to 50 parts of starch, 20 parts to 35 parts of vinyl monomers, 20 parts to 30 parts of biodegradable plastics, 10 parts to 15 parts of plasticizers, 3 parts to 5 parts of water and 0.5 part to 3 parts of heat stabilizers. The preparation method of the thin-film material comprises the steps: the plant fibers, starch, vinyl monomers and water of certain quantities are evenly mixed and radiated by a cobalt Gamma 60 source or an electron accelerator for 0.5kGy to 20kGy; the material after radiation is mixed with the biodegradable plastics, the plasticizers and the heat stabilizers; then a twin screw is used for preparing a thin-film special material; and finally the thin-film is formed by means of blow molding using a single screw. The completely biodegradable thin-film has good water resistance and heat combination performance and is applicable to producing farming terra films and packing films so as to solve the white pollution problem caused by the heavy use of oil-based plastic.

Owner:JILIN NORMAL UNIV

Three-layer co-extrusion full-biodegradable delivery packaging bag and preparation method thereof

InactiveCN109229812AFully biodegradableImprove mechanical propertiesBio-packagingBagsBlow moldingEngineering

The invention relates to a three-layer co-extrusion full-biodegradable delivery packaging bag and a preparation method thereof, and belongs to the field of high polymer materials. Raw material components of an inner layer, a middle layer and an outer layer are mixed to be uniform respectively according to the formula, master batches are prepared through a twin-screw extruding machine, and then a three-layer full-biodegradable film is prepared through a three-layer co-extrusion blow molding process. The film is subjected to the gluing, heat sealing and cutting procedures of a delivery packagingbag making machine, and the delivery packaging bag is prepared. The material formula good in opening performance and film forming performance is adopted on the middle layer and the inner layer, and the material formula good in mechanical performance and film forming performance is adopted on the middle layer and the outer layer. The delivery packaging bag has full biodegradability, has excellentmechanical performance, heat sealing performance and seal adhesive sealing performance and can replace a delivery packaging bag prepare from a non-biodegradable plastic PE film.

Owner:JILIN COFCO BIOCHEM

Disposable biodegradable gloves and preparation method thereof

InactiveCN103740022APromote degradationMeet the use requirementsCoatingsWater leakagePolyvinyl chloride

The invention discloses a pair of disposable biodegradable gloves and a preparation method thereof. The pair of disposable biodegradable gloves consists of the following components in percentage by weight: 35-41% of starch, 10-35% of polyvinyl chloride resin, 20-38% of plasticizer, 1.0-1.7% of liquid calcium-zinc stabilizer, 5-25% of viscosity reducer, 3-5% of dispersing agent, 10-30% of methyl methacrylate and 10-25% of mixed monomer of butyl acrylate. According to the pair of disposable biodegradable gloves and the preparation method thereof disclosed by the invention, by mixing the starch, environment-friendly plasticizer, ethylene-methyl acrylate copolymer, salt additive and polyvinyl chloride resin and controlling the content thereof, excellent biodegradability is guaranteed by use of the starch with relatively high content in the gloves; the strength of the gloves can completely meet the using requirements; and moreover, the pair of gloves has good processability, excellent heat sealing performance and good water leakage resistance and can be widely applied to the healthcare industry.

Owner:BYTECH DONGTAI

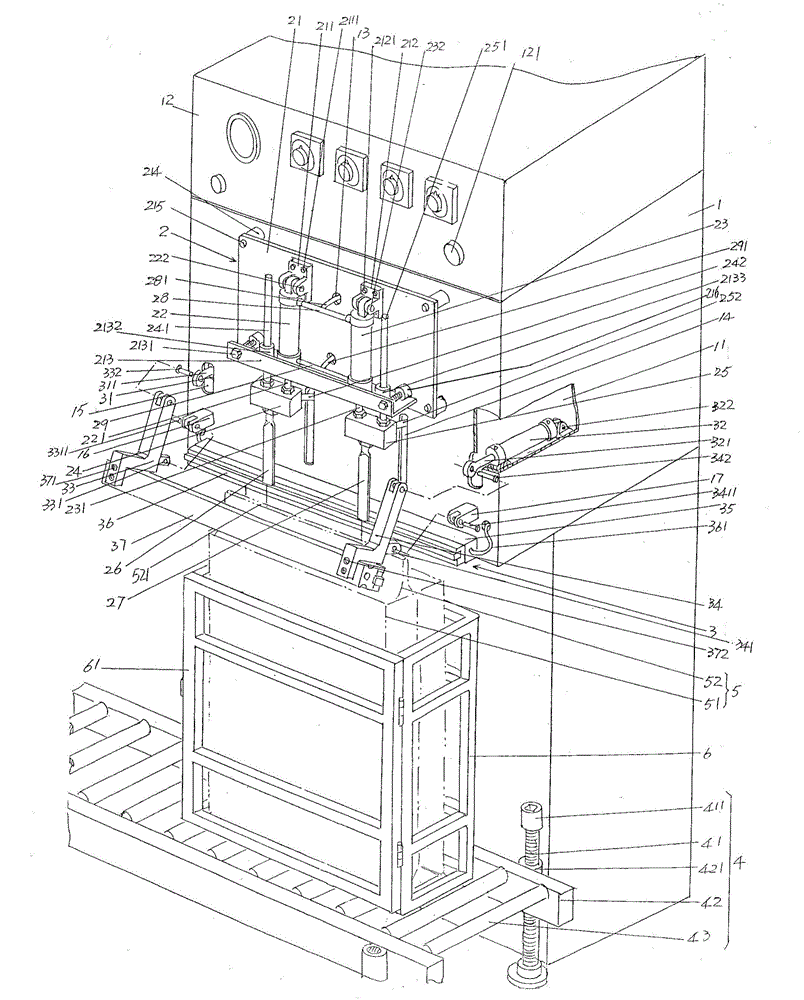

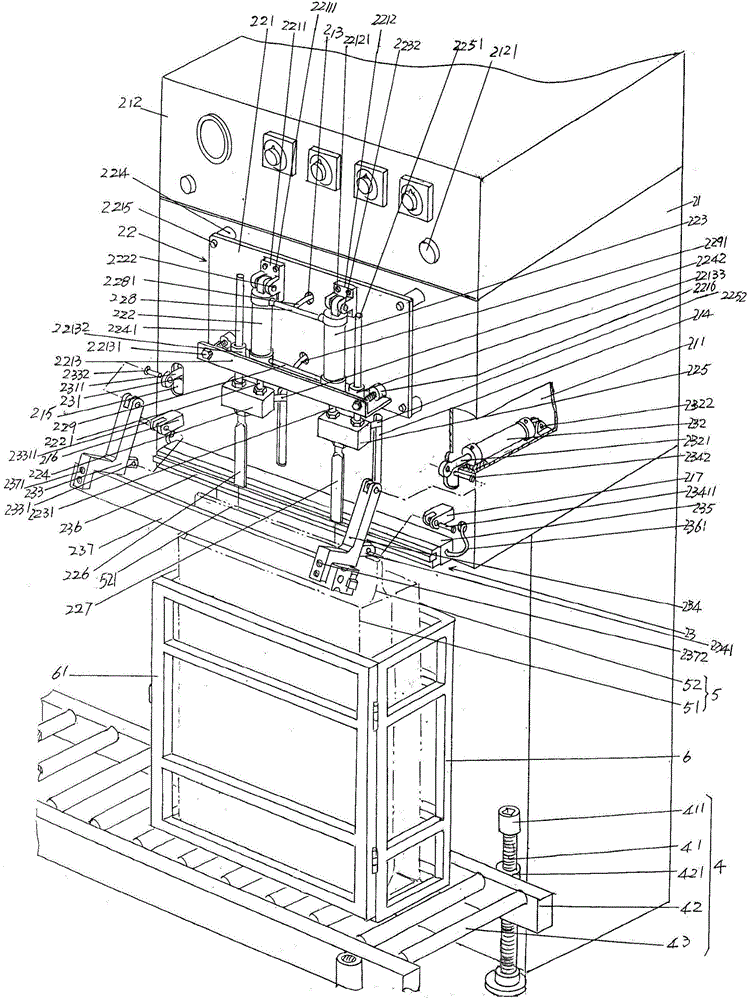

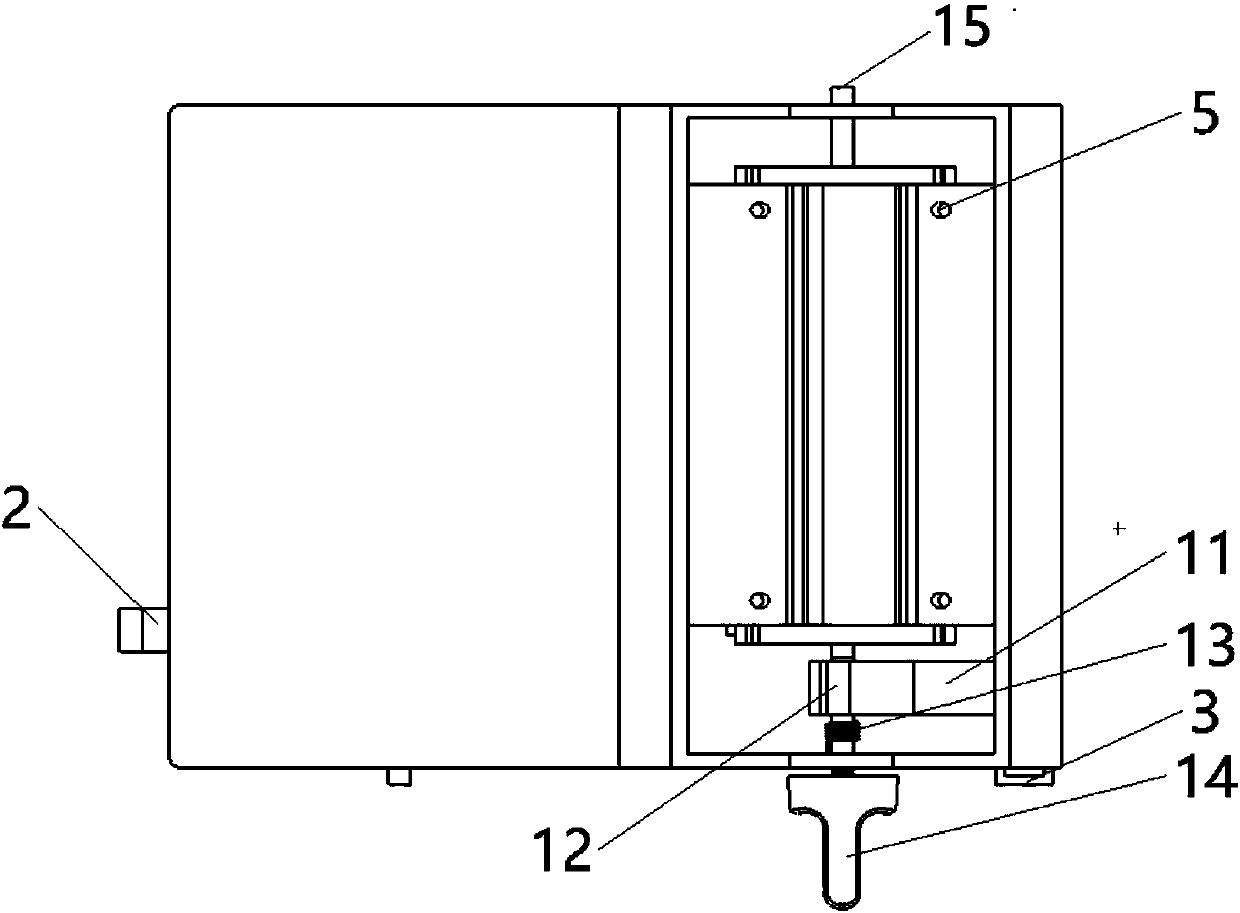

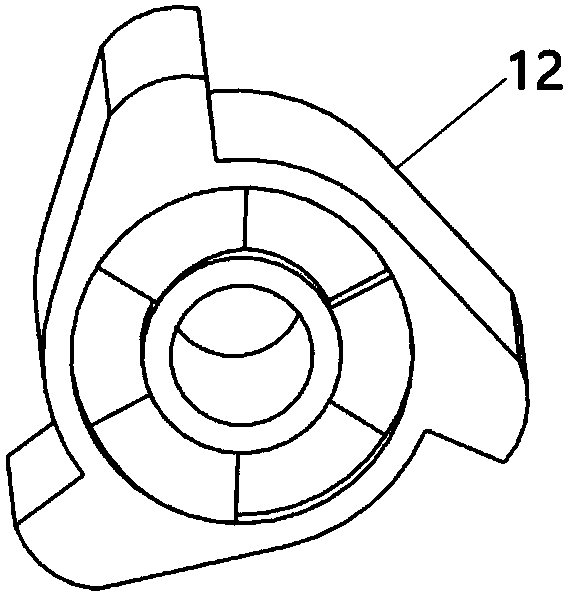

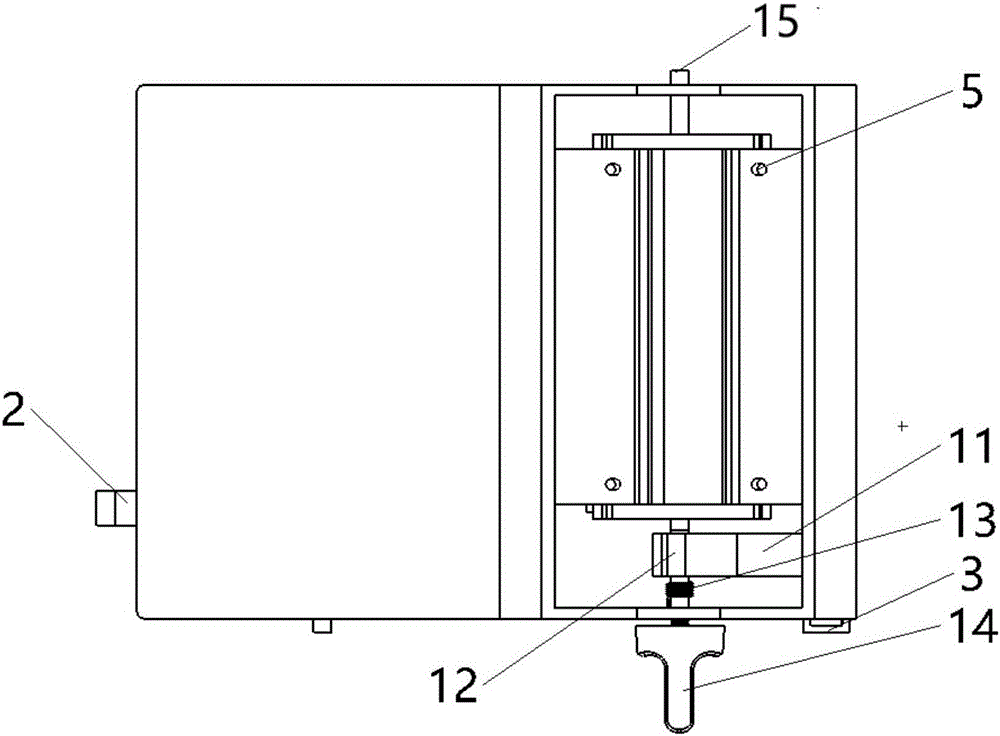

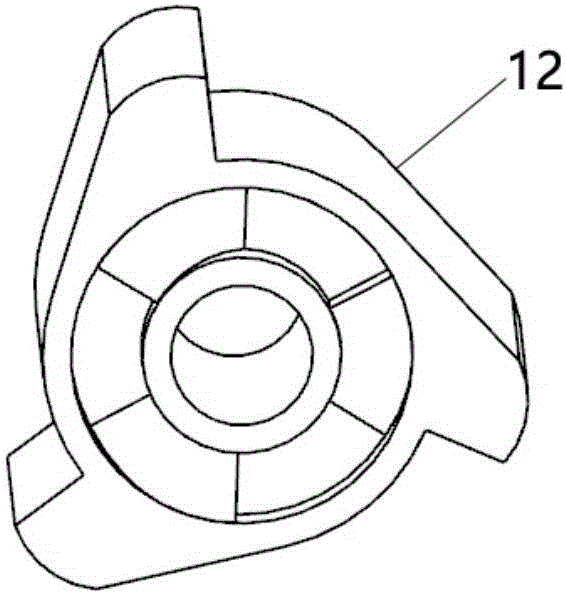

Air exhaust and sealing device for wire and cable material packaging bag

ActiveCN104670553ASimple structureGood heat sealing effectPackaging by pressurising/gasifyingWrapper twisting/gatheringElectrical controlUltimate tensile strength

The invention discloses an air exhaust and sealing device for a wire and cable material packaging bag, and belongs to the technical field of packaging machinery for plastic particles for wires and cables. The air exhaust and sealing device comprises a box body, an air exhaust mechanism, a bag opening heat-sealing mechanism and a packaging bag supporting mechanism, wherein a box body cavity is formed in the box body; an electrical operation control box is arranged at the top of the box body; the air exhaust mechanism is arranged at the upper part of the front side of the box body; the bag opening heat-sealing mechanism is arranged at a position, corresponding to the lower side of the air exhaust mechanism, on the front side of the box body; the packaging bag supporting mechanism is positioned at a position corresponding to the lower side of the bag opening heat-sealing mechanism and is supported on a terrace of a use place along with the box body; the air exhaust mechanism and the bag opening heat-sealing mechanism are connected with the electrical operation control box in an electrical control manner. According to the air exhaust and sealing device, the sealing efficiency is improved, and the packaging requirement on wire and cable materials for industrial enlargement production is met; the labor intensity is alleviated; the packaging bag can be sealed under the vertical state.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF +1

Preparation method of aramid fiber filter bag and aramid fiber filter bag

ActiveCN105642034ASolve the problem of weak bondsGood heat sealing effectDispersed particle filtrationFibre typesPolymer scienceRoom temperature

The invention relates to the technical field of aramid fibers and in particular relates to a preparation method of an aramid fiber filter bag and the aramid fiber filter bag. According to the method, aramid fibers are used as fiber raw materials, and are sewed through a heat sealing process; a sewed part is coated with a silane coupling agent solution and the aramid fibers are aramid fibers 1313. With the adoption of the preparation method of the aramid fiber filter bag, provided by the invention, the problems that the surfaces of existing aramid fibers are inert, the bonding between the fibers is relatively weak at a room temperature, the fibers are directly carbonized and decomposed when the temperature is more than 400 DEG C and the like are solved, and the aramid fiber filter bag with strong power and high filtering precision is obtained.

Owner:南京际华三五二一环保科技有限公司

Heat-sealable silicone rubber elastomer film and production equipment and preparation method thereof

PendingCN109483977AEliminate shortcomings in component performanceImprove carrying capacityLamination ancillary operationsSynthetic resin layered productsPolyesterPolyurethane elastomer

The invention discloses heat-sealable silicone rubber elastomer film, comprising a silicone rubber film layer, a polysiloxane copolymer layer and a polyester elastomer film base. The polysiloxane copolymer layer is applied to the surface of the polyester elastomer film base. The silicone rubber film layer is attached to the polysiloxane copolymer layer. The invention also discloses production equipment and preparation method of the heat-sealable silicone rubber elastomer film. The advantages of polyurethane elastomer and the advantages of organosilicon rubber are integrated herein; a vulcanized silicone rubber compound and the polysiloxane copolymer layer are applied to the polyester elastomer film base to form the heat-sealable organosilicon elastomer in organosilicon block copolymerization manner; the defects of single polymer film components in terms of performance are eliminated; a polymer alloy with complementary integrated properties is attained.

Owner:深圳市鑫银环保橡塑制品有限公司

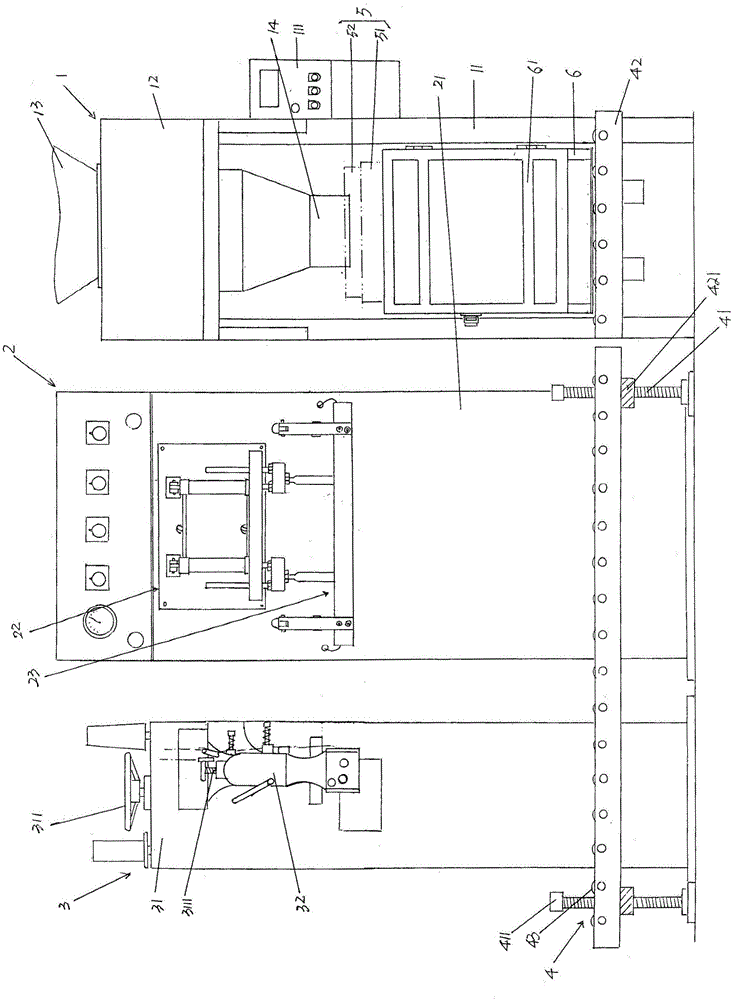

Automatic weighing, sealing and seaming device for wire and cable material

ActiveCN104670569AReduce the distanceGood coherent effectWrapper twisting/gatheringEngineeringCoherence effect

The invention discloses an automatic weighing, sealing and seaming device for a wire and cable material, and belongs to the technical field of packaging machinery for plastic particles for the wires and cables. The automatic weighing, sealing and seaming device comprises a weighing device supported on the terrace under a used state, a sealing device, a seaming device and a packaging bag supporting device, and is characterized in that the weighing device, the sealing device and the seaming device are arrayed on the same straight line in an arranging manner of left to right; the packaging bag supporting device is supported on a terrace of the use place at the position simultaneously corresponding to the lower parts of the front sides of weighing device, the sealing device and the seaming device. The automatic weighing, sealing and seaming device achieves a good coherence effect; the space is saved, and the adaptability to a packaging place is improved; the labor investment is reduced; furthermore, the sealing efficiency is improved; the labor intensity of an on-line worker is relieved, and the labor cost is reduced so as to save precious labor resources; the sealing quality is guaranteed; the packaging bag can be sealed under a vertical state; the automatic weighing, sealing and seaming device has an effect of preventing the wire and cable material in the bag from leaking from the bag opening.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF +1

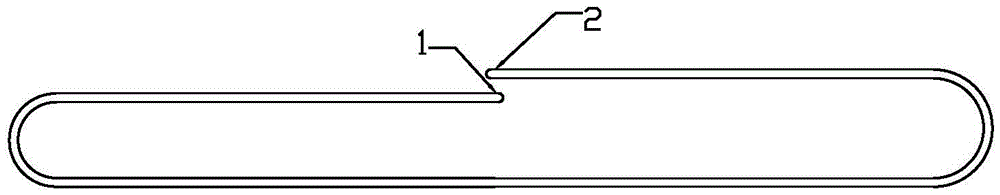

Heating structure of sealing machine

InactiveCN101835293AReduce volumeReduce weightWrapper twisting/gatheringOhmic-resistance heatingHigh resistanceTransformer

The invention discloses a heating structure of a sealing machine, which comprises a heating body and joints, wherein the joints are connected to both ends of the heating body; the heating body comprises at least one heating strip; and the heating strip comprises a plurality of high-resistance blocks made of high-resistance electric heating wires. The heating structure of a sealing machine can be directly operated in a high-voltage value; the sealing machine using the heating structure can omit a transformer device, the volume and the weight of the sealing machine can be reduced, the structure is simpler, and the use and the carrying are more convenient; and specially, when the heating structure contains a plurality of heating strips, the heating and sealing effect is better, and the appearance is more attractive.

Owner:许丁木 +1

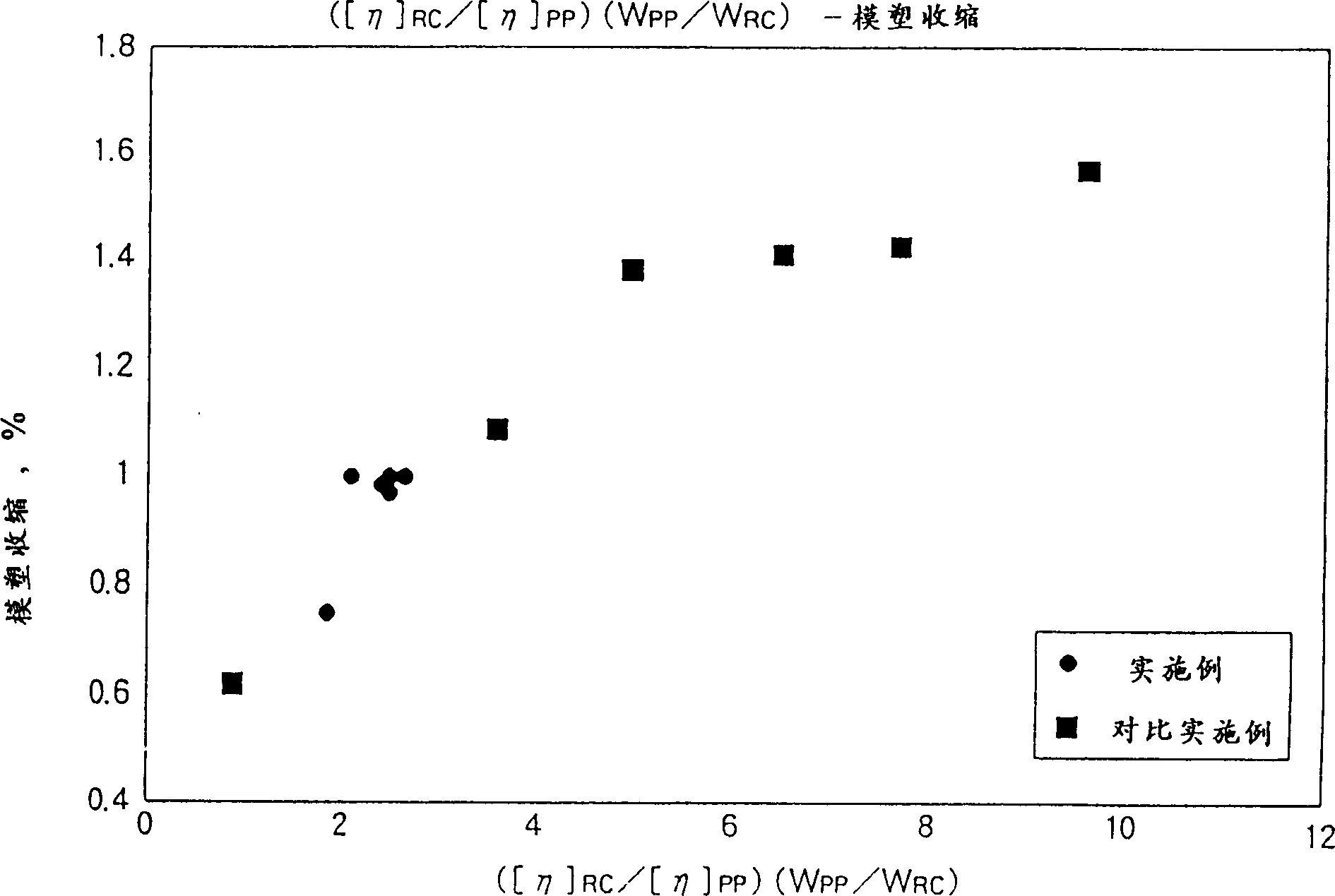

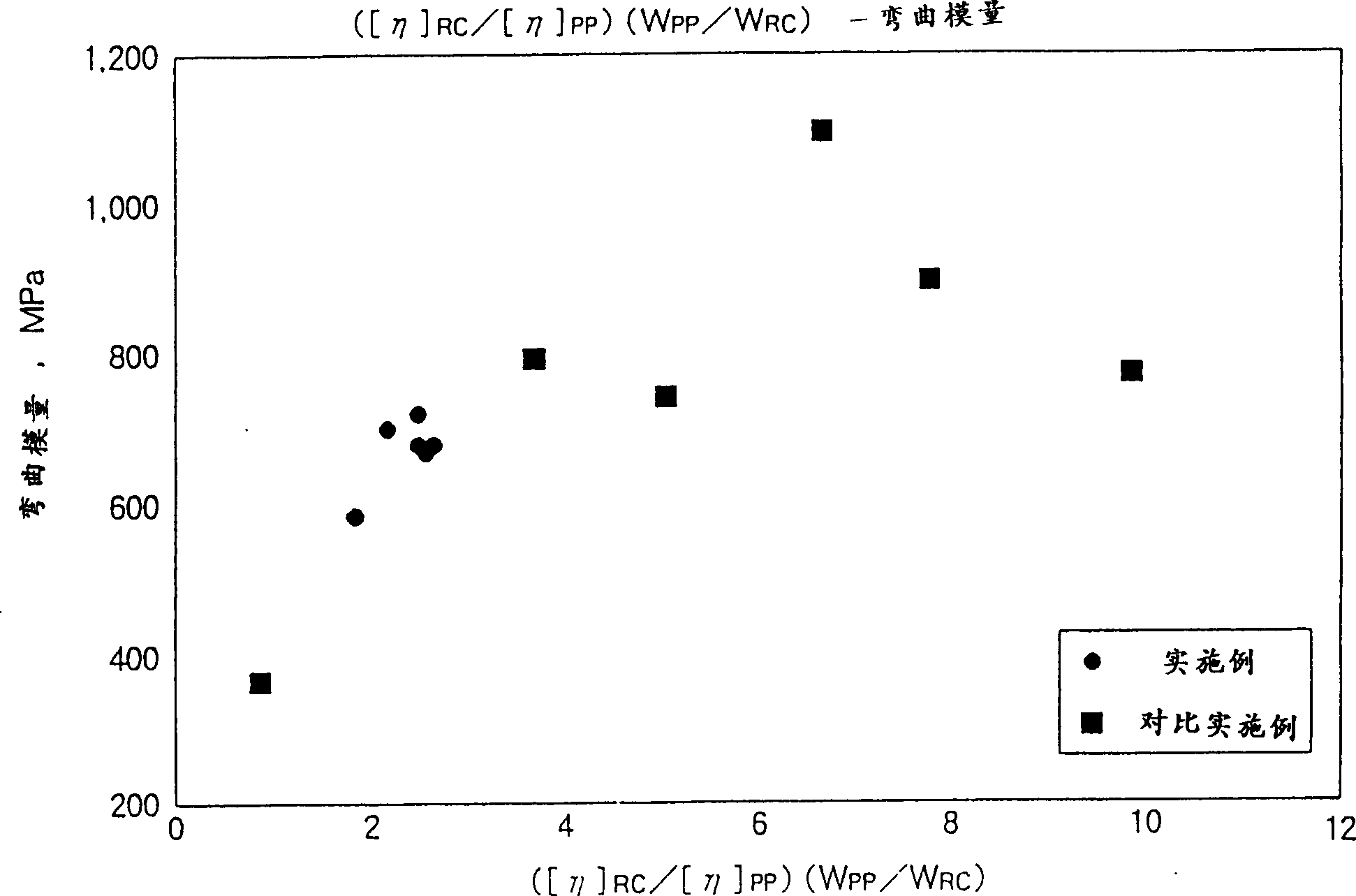

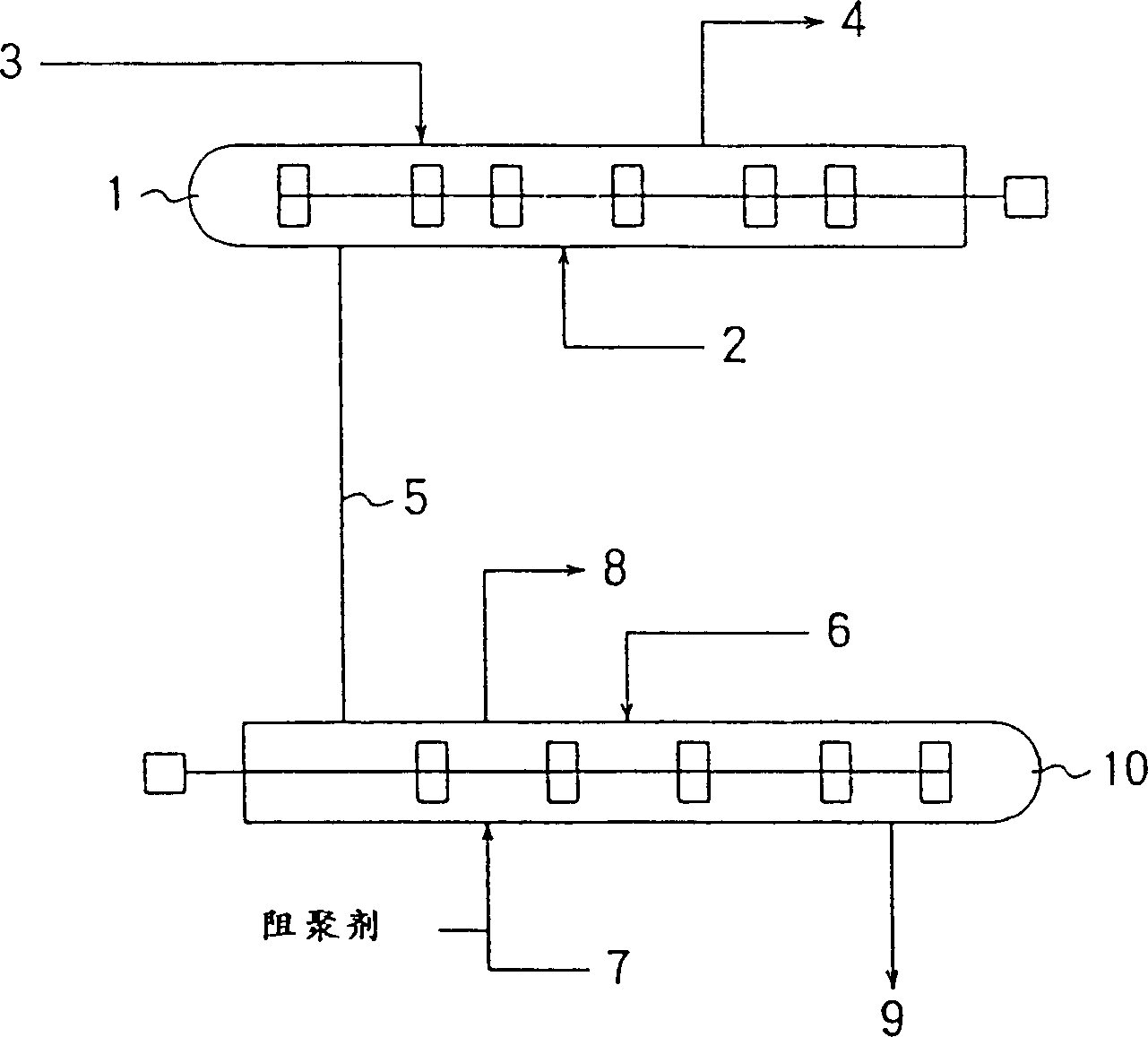

Propylene compsn, process for preparing same, polypropylene compsn., and molded articles

InactiveCN1109715CGood moldabilityExcellent mold shrinkageSynthetic resin layered productsPolymer sciencePolypropylene

A polypropylene composition for preparing various molded articles having well-balanced properties among moldability, molding shrinkage, rigidity, flexibility, impact resistance particularly at low temperatures, transparency, gloss and blushing resistance; various molded articles possessing the above properties; a propylene composition suitable as a base resin for the polypropylene composition; and a process for preparing the same. The propylene composition is characterized by comprising a homopolymer of propylene and a propylene / ethylene copolymer, the intrinsic viscosity ([ eta ]RC) of the copolymer being in the range of from 1.7 to 2.8 dl / g, the intrinsic viscosity ratio ([ eta ]RC / [ eta ]PP) of the homopolymer to the copolymer being in the range of from 0.7 to 1.2, and the product of the homopolymer to copolymer weight ratio (WPP / WRC) and the intrinsic viscosity ratio thereof, (WPP / WRC)x([ eta ]RC / [ eta ]PP), being in the range of from 1.0 to 3.0.

Owner:JNC CORP

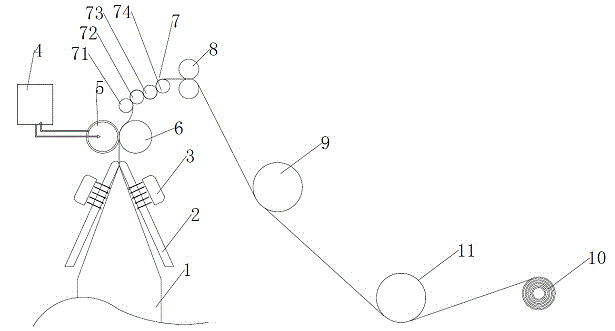

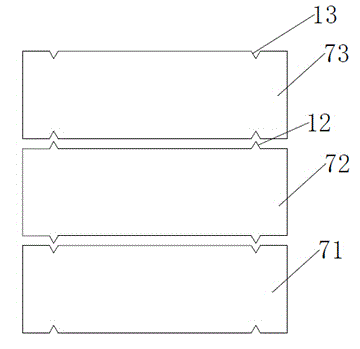

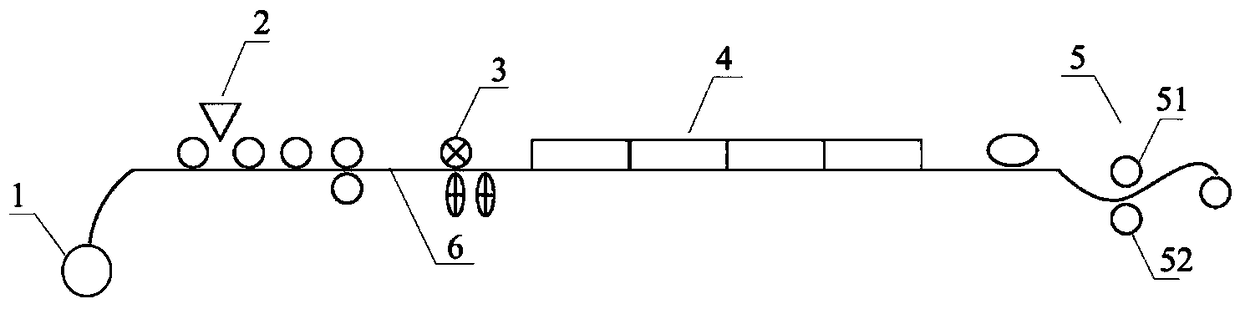

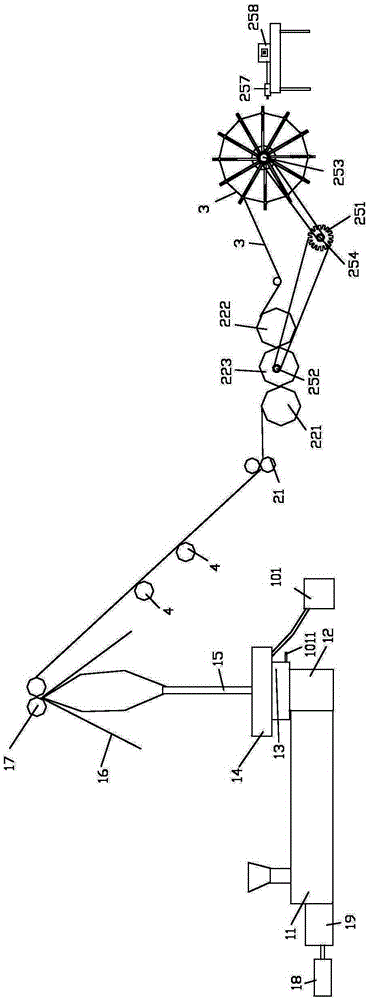

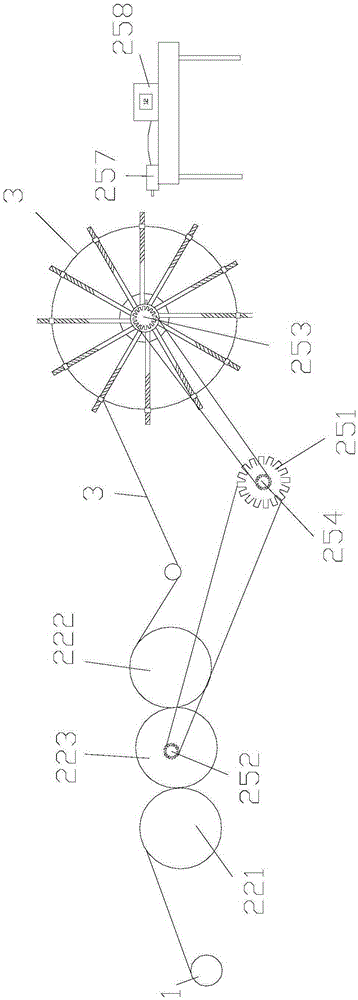

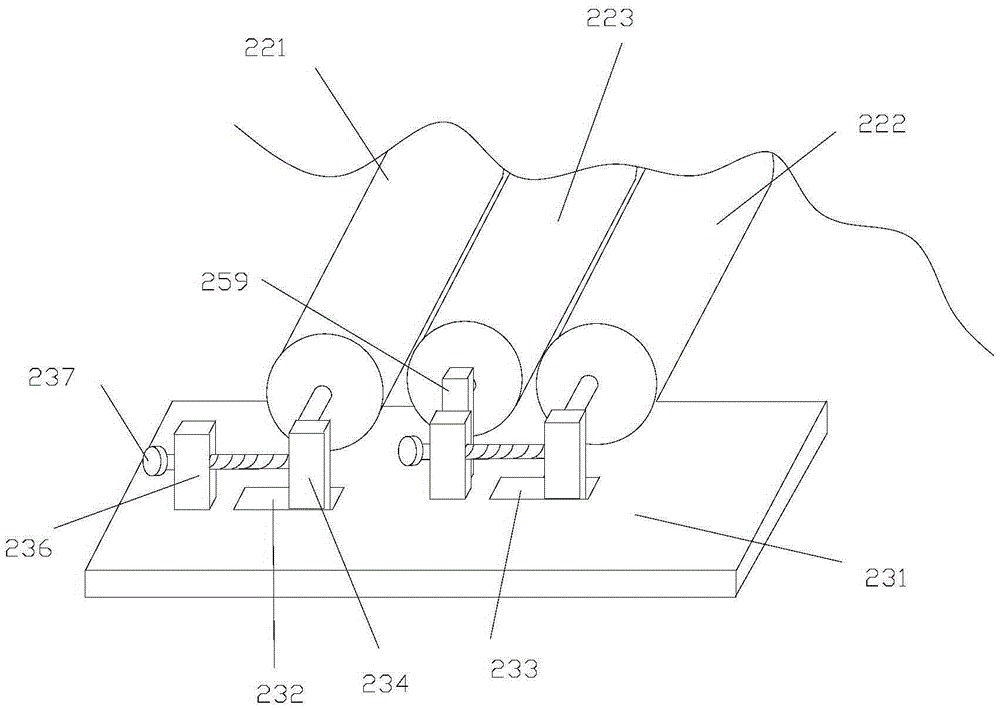

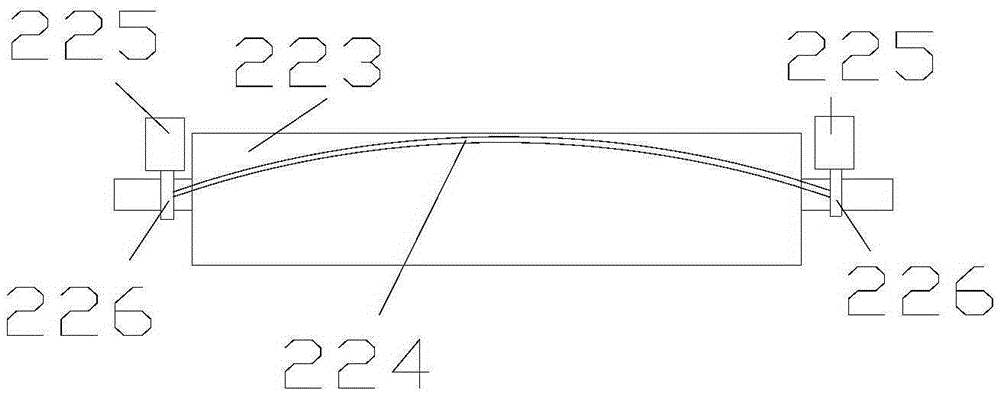

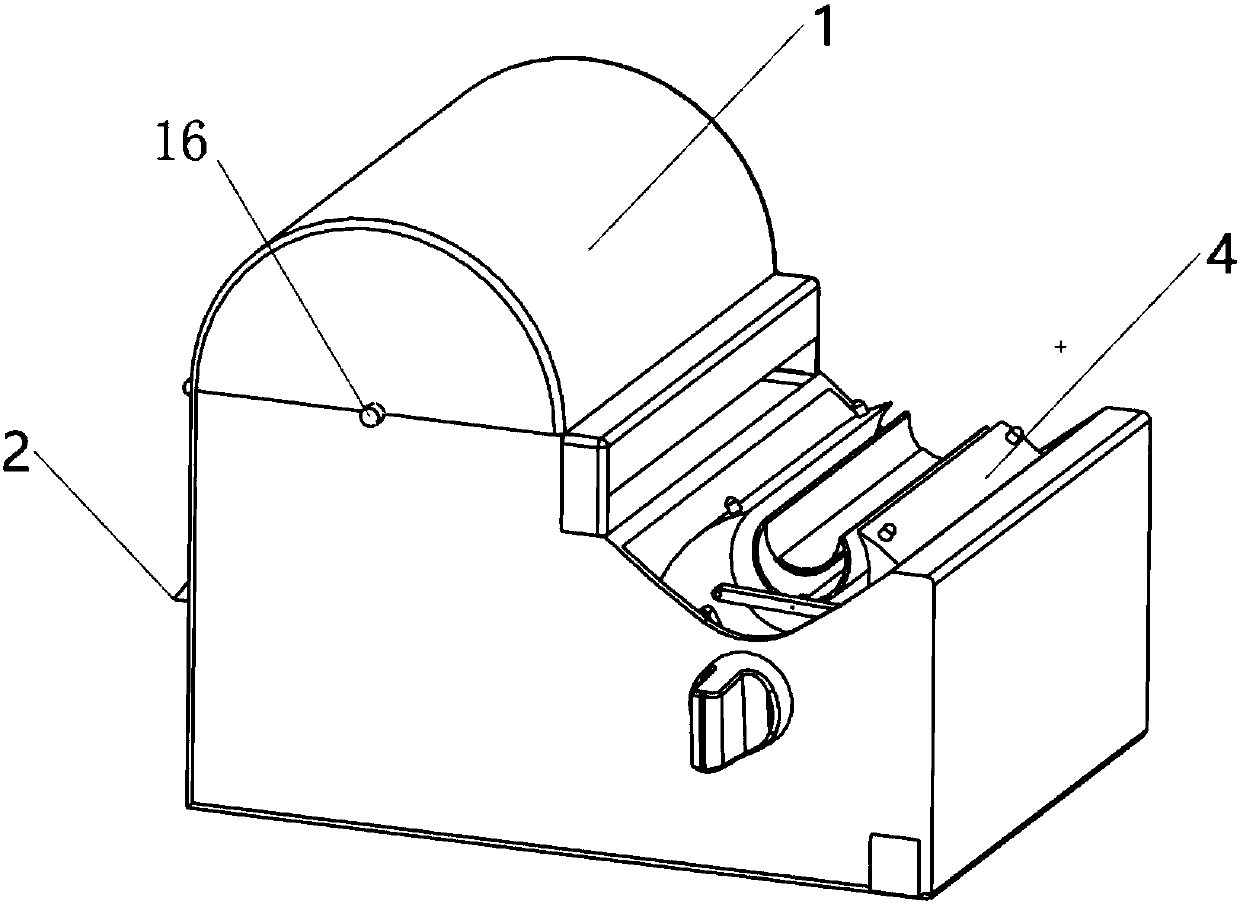

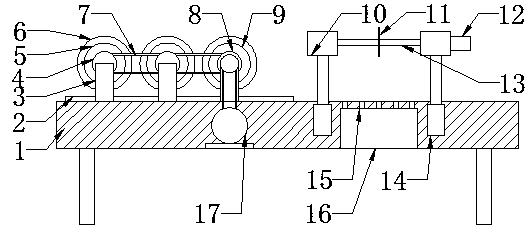

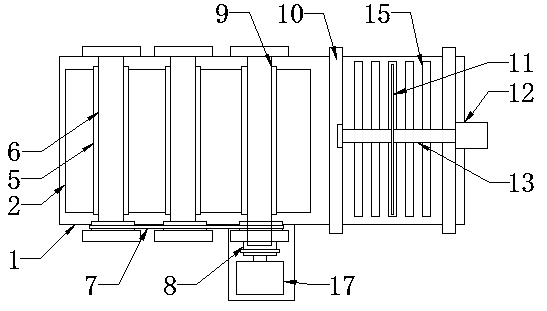

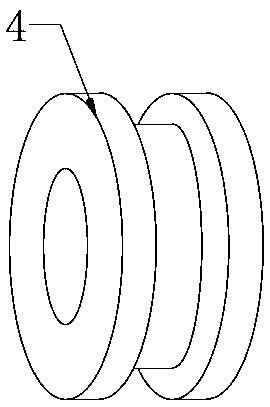

Film blowing and heat sealing integrated machine

InactiveCN105383094ASmall footprintLow costEnvelopes/bags making machineryWebs handlingSmall footprintFilm blowing machine

The invention relates to a film blowing and heat sealing integrated machine which comprises a film blowing machine body, wherein the film blowing machine body comprises an extruder, a filtering device, a die head, an air ring, a mandrel, a herringbone plate and a first draft gear; the die head is arranged at the extruding end of the extruder, the air ring is arranged on the die head, the mandrel is coaxially arranged in the middle of the die head, the herringbone plate is arranged above the mandrel, and the first draft gear is arranged above the herringbone plate; and the integrated machine also comprises a heat sealing machine body, wherein the heat sealing machine body comprises a second draft device and a heat sealing roll assembly, the second draft device is used for carrying out second time of traction on a film pulled by the first draft device, and the heat sealing roll assembly is used for carrying out heat sealing on the film pulled by the second draft device. The integrated machine has the advantages that occupation area is small, manufacture cost is low, maintenance rate is low, heat sealing stationarity is good, noise is low, and a prepared film bag is convenient to take and easy to open.

Owner:ANQING XINSHUN PLASTIC CO LTD

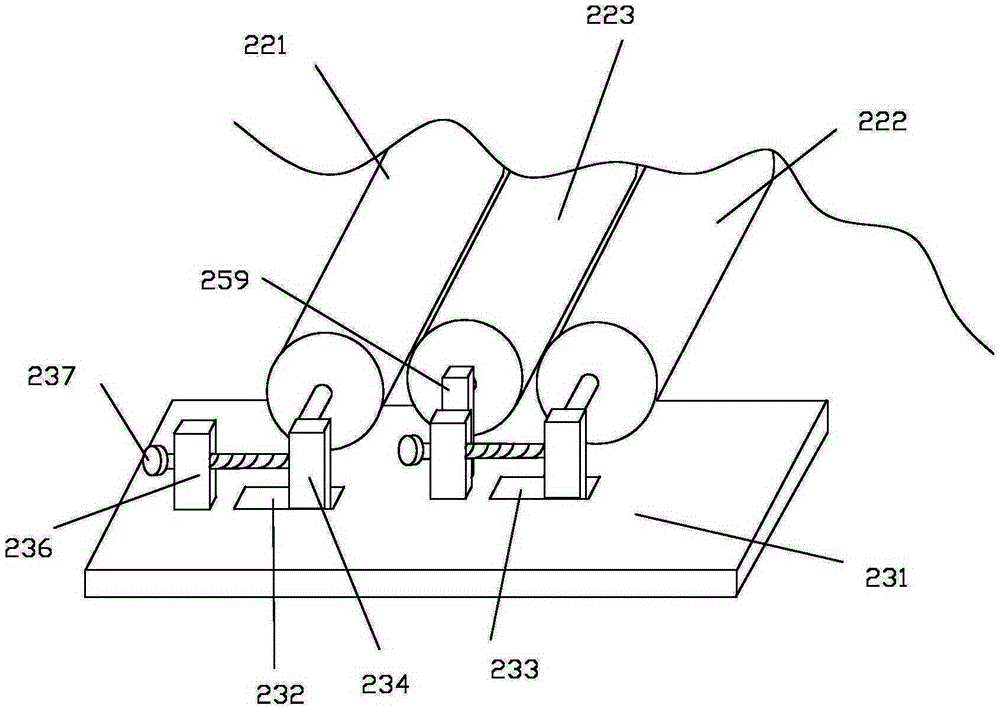

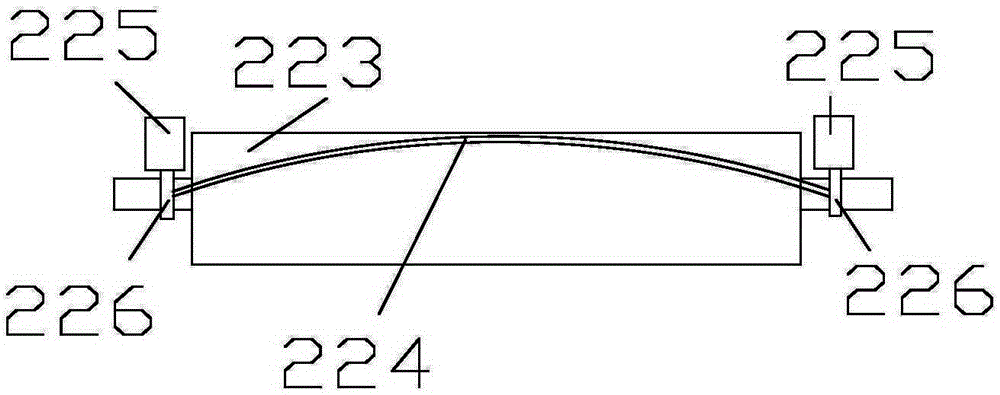

Heat sealing mechanism of band and film heat sealing molding device

ActiveCN106863981AImprove fitGuaranteed to be straightLamination plant layoutLaminationHeat conducting

The invention provides a heat sealing mechanism of a band and film heat sealing molding device and belongs to the technical field of machinery, aiming at solving the problem that the heat sealing effect on a thin film and a film pressing band of an existing heat sealing mechanism is poor. The heat sealing mechanism of the band and film heat sealing molding device comprises a mounting base, two groups of driving roller sets and two heat sealing tool bits; each driving roller in each group of driving roller set is rotatably connected onto the mounting base and is connected through a driving belt made of a high-temperature-resisting heat-conducting material; the driving belts on the two groups of driving roller sets penetrate through the two heat sealing tool bits; each heat sealing tool bit is connected with a driving source I; each heat sealing tool bit is further connected with an adjusting assembly I; after adjustment, the driving sources I can drive the heat sealing tool bits to get close to the corresponding driving belts or form a gap with the corresponding driving belts. By adopting the heat sealing mechanism provided by the invention, the thin film and the film pressing band can be enabled to keep a straight state and are fitted relatively well; the heat sealing between an ultra-wide type greenhouse thin film and the film pressing band can be realized and the heat sealing effect is improved.

Owner:BOEN SOLAR TECH

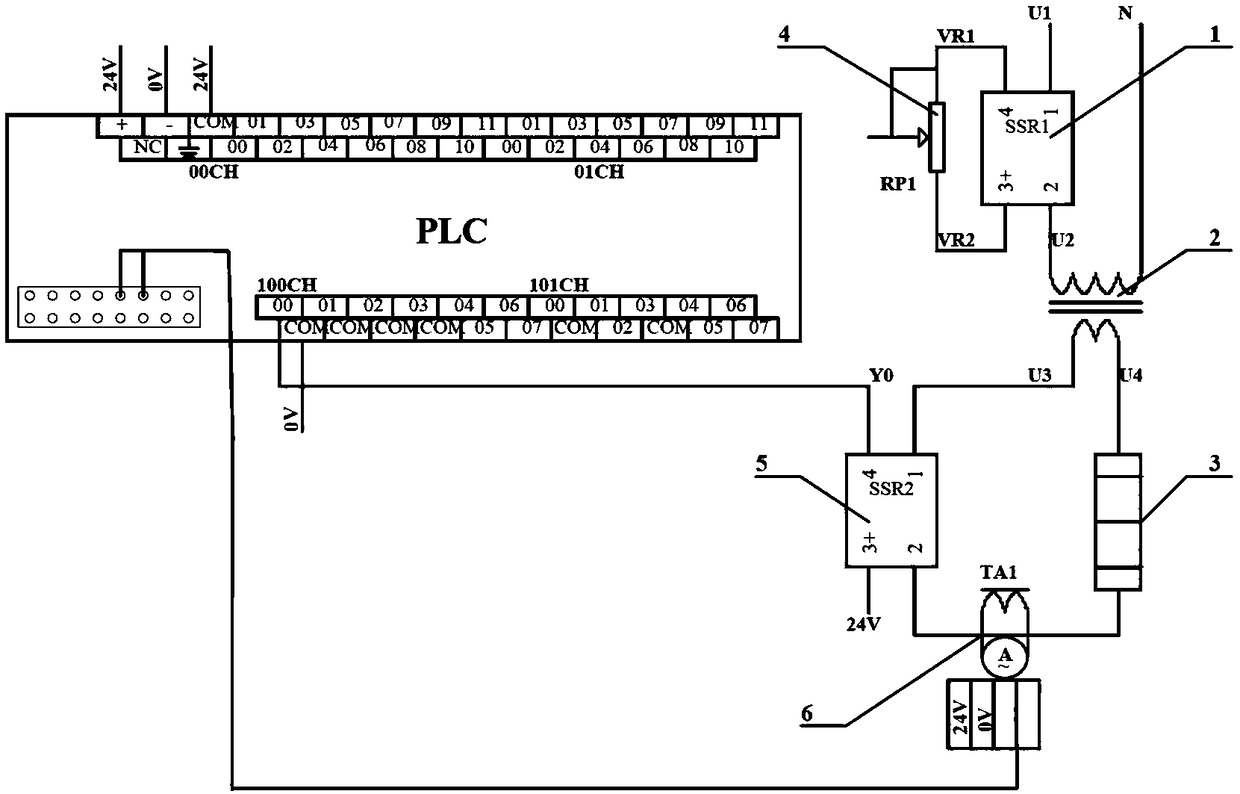

Method and mechanism for accurately controlling heat-seal temperature of heating wire

ActiveCN108621475AGood heat sealing effectImprove product qualityBag making operationsPaper-makingCurrent sensorComputer module

The invention relates to a mechanism for accurately controlling the heat-seal temperature of a heating wire. The mechanism for accurately controlling the heat-seal temperature of the heating wire comprises a first power generation component, a second power generation component, a PLC, a PID module and a PWM controller, wherein the second variable voltage is the PWM direct current voltage; the output end of a second solid-state relay is connected with a Hall current sensor in series and connected with the heating wire; the PID module and the PWM controller are contained in the PLC, the temperature change of the heating wire is worked out by using the PID module of the PLC according to the resistance value of the heating wire fed back by the hall current sensor, and accordingly the on-off time of the second solid-state relay is prolonged or shortened. According to the method and mechanism for accurately controlling the heat-seal temperature of the heating wire, two groups of voltages aresuperposed, the temperature change of the heating wire is accurately detected by the Hall current sensor, the heat-seal time of a film body by the heating wire is further adjusted, the temperature inthe heat-seal process is accurately monitored, and the heat-seal effect is improved, so that the method has the beneficial effect of remarkably improving the product quality.

Owner:SHANTOU LONGHUA PACKING MACHINERY

High-filling high-transparency biodegradable air bubble film and preparation method thereof

The invention discloses a highly-filled high-light-transmittance biodegradable air bubble film and a preparation method thereof. The highly-filled high-light-transmittance biodegradable air bubble film is prepared from the following raw materials in parts by weight: 45-70 parts of PBAT, 4-12 parts of polylactic acid, 3-8 parts of polycaprolactone, 20-40 parts of inorganic filler, 0.5-2 parts of plasticizer, 0.2-1 part of antioxidant and 0.2-1 part of chain extender. The preparation method comprises the following steps: S1, carrying out vacuum drying on the PBAT, the polylactic acid, the polycaprolactone and the inorganic filler; s2, weighing the dried PBAT, polylactic acid, polycaprolactone and an inorganic filler, weighing a plasticizer, an antioxidant and a chain extender according to a ratio, and carrying out high-speed mixing in a high-speed mixer; s3, blending, extruding and granulating to obtain blended granules; and S4, putting the obtained blended granules into an air bubble film casting machine, and extruding to obtain the high-filling and high-light-transmission biodegradable air bubble film. High heat sealing strength can still be kept under the condition that high filling is added, the produced air bubble film is not prone to air leakage, and the air bubble film can be composted and degraded after being used up and is a novel environment-friendly material.

Owner:杭实科技发展(杭州)有限公司

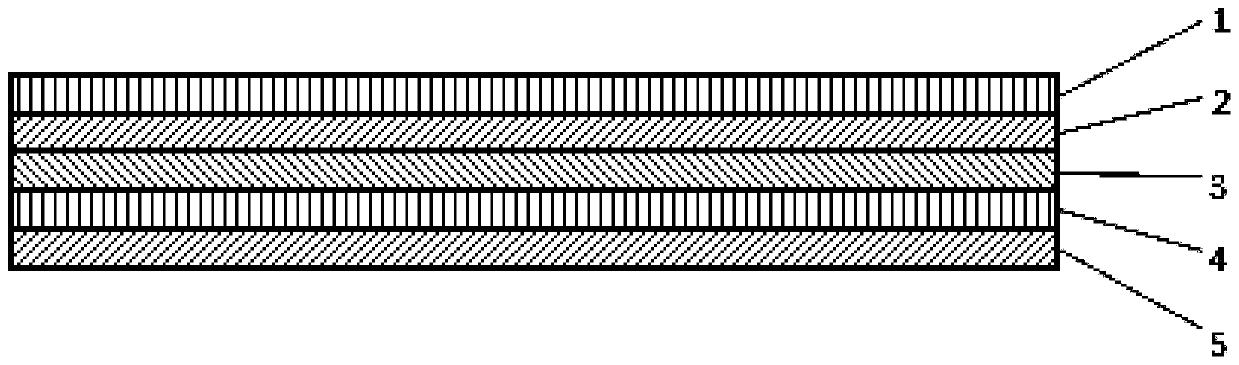

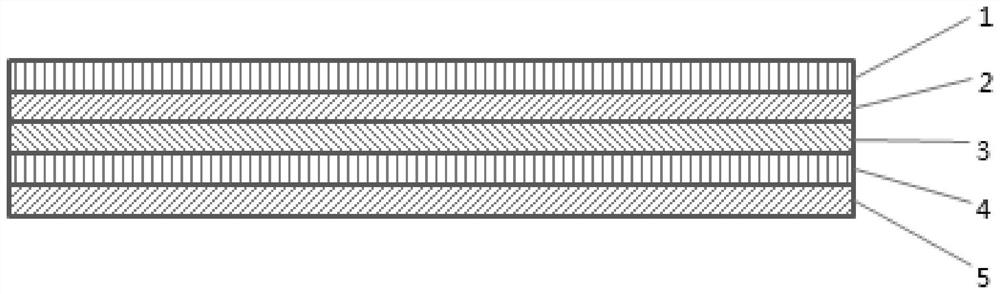

Film material for transfusion

ActiveCN111452471AGood drug compatibilityNot easy to adsorbInfusion devicesSynthetic resin layered productsPolypropyleneFilm material

The invention discloses a film material for infusion. The film material comprises an outer layer, a secondary outer layer, a middle layer, a secondary inner layer and an inner layer, the outer layer is made of a mixture I of polypropylene and a styrene-ethylene-butylene-styrene block copolymer, the secondary outer layer is made of a mixture II of polypropylene and a styrene-ethylene-butylene-styrene block copolymer, the middle layer is made of a mixture III of polypropylene, an ethylene-vinyl alcohol copolymer and a polypropylene grafted maleic anhydride copolymer, the secondary inner layer ismade of a mixture IV of polypropylene, polyethylene and polyethylene grafted maleic anhydride, and the inner layer is made of a naphthenic olefin copolymer or a mixture V of the naphthenic olefin polymer, polypropylene and polyethylene. The invention further provides an application of the film material for infusion, an infusion soft bag and a medicine packaging material. The film material provided by the invention has excellent drug compatibility, can block permeation of gas and water vapor, enables drugs not to be easily adsorbed on the surface of the material, and is suitable for soft bag packaging of transfusion and drugs.

Owner:CHONGZHOU JUNJIAN PLASTIC CO LTD

Paper imitated anti-skid environmental-friendly film

The invention discloses a paper imitated anti-skid environmental-friendly film. The film is prepared by mixing multiple raw materials of different characteristics. The raw materials comprise the following components with the following ratios: 1-3% of EPI, 28-32% of a matt master batch, 28-32% of metallocene polyethylene A and 36-40% of metallocene polyethylene B. The matt master batch is added into the raw materials, micro particles having the diameter of less than 2 microns can be formed on the surface of the extruded film, lots of irregular micro particles attached onto the surface achieve diffuse reflection effects on surrounding light, and the smoothness and glossiness of the product surface are greatly reduced, so that the plastic film achieves a paper-like effect. The EPI degradablematerial is added into the raw materials, so that the product can be decomposed within 180 days, any white pollution is not produced, the product is green and environmental-friendly, and the AmericanFDA (Food and Drug Administration) food safety law is met. The metallocene polyethylene A is added into the raw materials, so that the plastic film has excellent hardness and stiffness. The metallocene polyethylene B is added into the raw materials, so that the plastic film has excellent tear resistance.

Owner:GUANGZHOU TONGYUAN PLASTIC PROD CO LTD

Rolling type film heat sealing machine

InactiveCN105398089AAvoid stampingGood thermal stabilityEnvelopes/bags making machineryWebs handlingEngineeringResistance wire

The invention discloses a rolling type film heat sealing machine which comprises a feeding roll and further comprises a heat sealing roll assembly. The heat sealing roller assembly is used for conducting heat sealing on a film fed by the feeding roll. The heat sealing roll assembly comprises a first traction roll, a second traction roll and a heat sealing roll arranged between the first traction roll and the second traction roll. The first traction roll and the second traction roll are arranged in parallel. The heat sealing roll is driven by a transmission mechanism to rotate and is further provided with an electric resistance wire. The electric resistance wire extends to the other end of the heat sealing roll from one end of the heat sealing roll to be connected with an external power source. The rolling type film heat sealing machine has the beneficial effects that the maintenance rate is low, the heat sealing stability is good, noise is small and a manufactured film bag is convenient to carry and easy to open.

Owner:ANQING XINSHUN PLASTIC CO LTD

Medical stone toughened polyvinyl alcohol film for preservation of fruits and vegetables and preparation method of polyvinyl alcohol film

InactiveCN106700361AInhibit growthLong antibacterial timeFlexible coversWrappersEndogenous metabolismCarvacryl acetate

A medical stone toughened polyvinyl alcohol film for preservation of fruits and vegetables is characterized by being prepared from raw materials as follows: camellia seeds, mint leaves, dried ginger, folium artemisiae argyi, clove flowers, acetone, anhydrous sodium sulfate, medical stone, whey protein, propylene glycol, agaric polysaccharide, corn starch, caustic soda, vinyl acetate, polyvinyl alcohol, an ammonium persulfate solution, hydroxyethyl acrylate, glyceryl monooleate, glycerin and a proper amount of deionized water. The medical stone toughened polyvinyl alcohol film for preservation of fruits and vegetables has good mechanical performance, is stable in structure and good in air permeability, also has a good antibacterial function, can reduce endogenous metabolism ageing of the fruits and vegetables and rotting caused by exogenous microorganisms, substantially prolongs the preservation time and effectively keeps the quality of the fruits and vegetables.

Owner:陈强

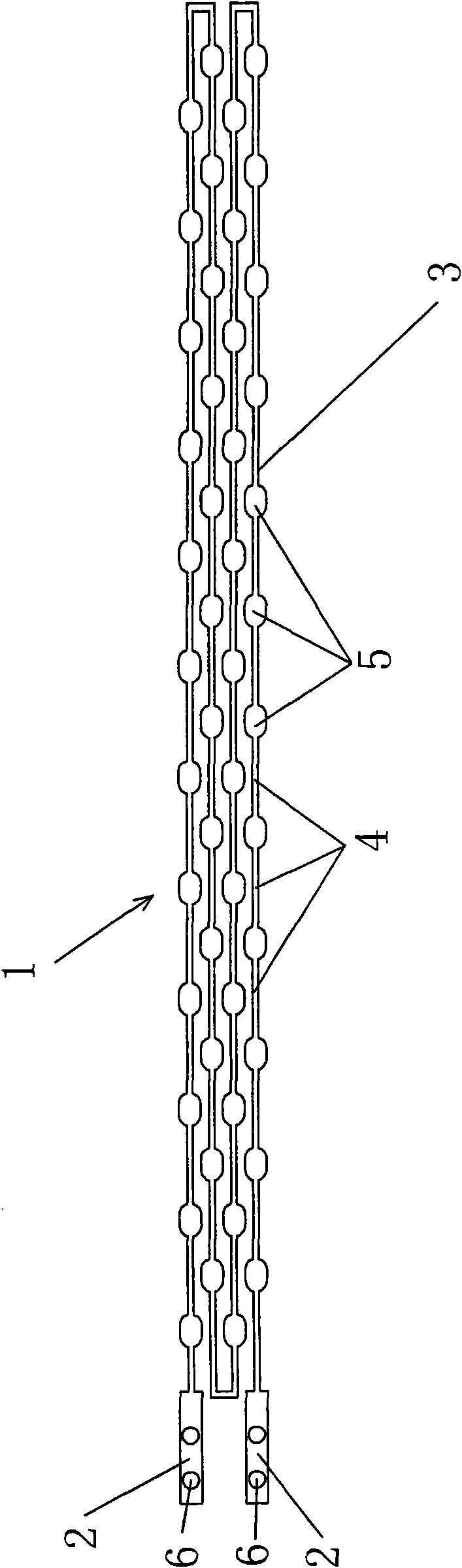

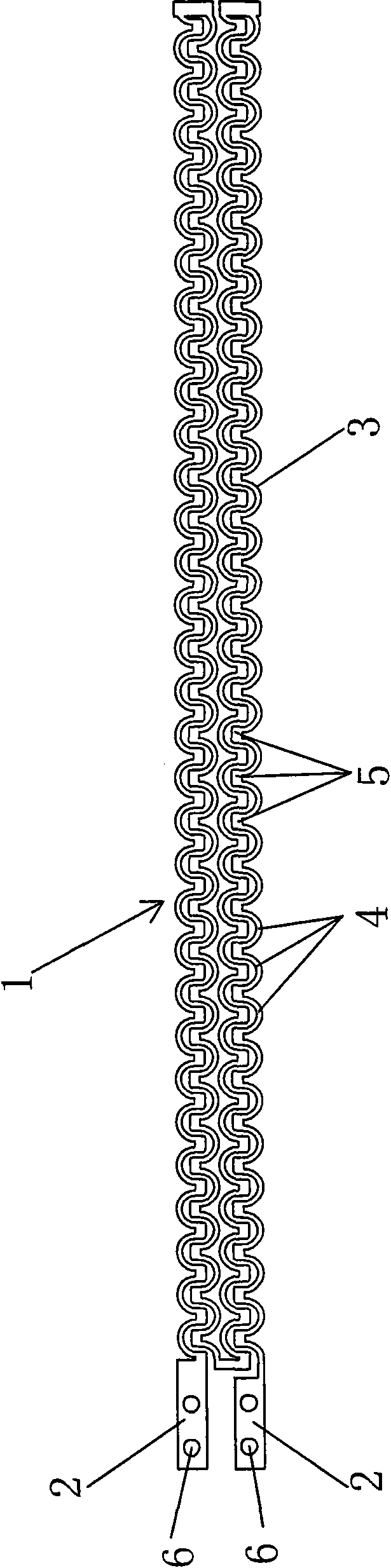

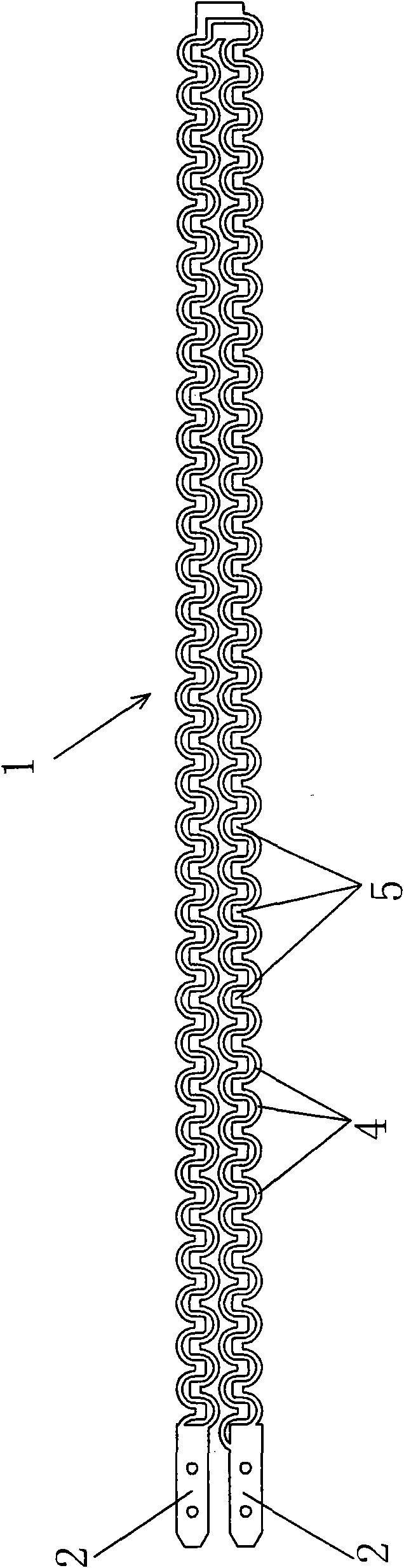

A wire sewing device

ActiveCN106786230BQuick stitchingImprove packaging efficiencyApparatus for repairing insulation/armouring cablesEngineeringManipulator

The invention provides a wire stitching device which is of an integral from outer appearance. The wire stitching device is integrally provided with an accommodating box, a grooved pulley, shaft pins, a manipulator, connecting brackets, switch pillars, spring pieces, fixing rods, a catch, a lock pulley, a spring, a grooved roller shaft, a support shaft and fixing shafts; a power switch and a knob are arranged on the outside of the wire stitching device; the movable manipulator is arranged in the groove of the grooved pulley, and the spring pieces which are fixedly connected are arranged inside the manipulator; each of the spring piece is wrapped with a layer of heating wires from the outside, and the lower end of the spring piece is provided with the switch pillar capable of moving vertically; the switch pillars are hinged with the connecting brackets, and one ends of the connecting brackets are fixed on the outside of the manipulator; the fixing pin shafts are arranged on the contour surface of the grooved pulley, the lock pulley rotating in uniform angle is fixed on the end surface, and the lock pulley and the pressure spring are nested in the grooved roller shaft. The wire stitching device is reasonable in design, convenient in operation, high in security and capable of performing wire stitching, and efficiency and quality in wrapping breakage of wires are improved.

Owner:JIANGXI UNIV OF SCI & TECH

Medical environment-friendly easily degradable glove

The invention mainly relates to the technical field of medical products, and discloses a medical environment-friendly easily degradable glove. The glove is prepared from 57-59 parts of modified konjakstarch, 26-28 parts of polyvinyl alcohol, 20-22 parts of polyvinyl chloride resin, 7-9 parts of nanometer zeolite and 11-13 parts of polylactic acid; the medical environment-friendly easily degradable glove is simple in raw materials and convenient to prepare, can be produced in batch, is high in toughness, and can inhibit breeding of pathogenic bacteria in the using process, after using, biodegradation can be promoted, and it is greatly avoided that waste gloves cause white pollution on the environment; the modified konjak starch is firstly added into the polyvinyl alcohol for high-temperature stirring to make the modified konjak starch and the polyvinyl alcohol subjected to comprehensive branch junction, the strength and membrane-forming performance of the modified konjak starch are strengthened, and the glove can be biodegraded.

Owner:安徽一升医疗设备有限公司

A kind of high barrier liquid container bag and preparation method thereof

ActiveCN113211919BLong shelf lifeHigh strengthBio-packagingSynthetic resin layered productsLow-density polyethyleneButanedioic acid

The invention discloses a high-barrier liquid container bag and a preparation method thereof, belonging to the technical field of packaging and transportation. The invention comprises an outer film and an inner film heat-sealed and connected to the inner wall of the outer film, and is characterized in that: the inner film is degraded The membrane, a barrier layer is arranged in the degradable membrane, and the degradable special material other than the barrier layer of the degradable membrane is composed of PBAT, polylactic acid, polybutylene succinate, chain extender, first antioxidant and hydrated aluminum magnesium carbonate; The outer film is a modified polyethylene film, the inner wall of the outer film is a heat-sealing layer, the heat-sealing layer is made of a special material for heat-sealing, and the special material for heat-sealing is made of low-density polyethylene, ethylene and vinyl acetate copolymer, second antioxidant and Lubricant composition. The flexitank can only peel off the degradable inner film adhering to the packaged material after use, and the outer film can be reused to avoid environmental pollution; at the same time, the barrier property of the flexitank is improved, the air permeability is reduced, and the preservation of the packaged material is prolonged. cycle.

Owner:高青澳森特集装箱包装材料有限公司

Tear-resistant polyvinyl alcohol fruit/vegetable preservative film and preparation method thereof

The invention relates to a tear-resistant polyvinyl alcohol fruit / vegetable preservative film. The invention is characterized in that the preservative film is prepared from the following raw materials: camellia seed, peppermint leaf, evening primrose, Lilac, acetone, anhydrous sodium sulfate, wool, titanium white, sodium dodecylsulfate, trypsinase, hydrogen peroxide, wheat starch, acetic acid, acetic anhydride, lauryl methacrylate, polyvinyl alcohol, citrate, corn starch, zinc stearate and a right amount of deionized water. The tear-resistant polyvinyl alcohol fruit / vegetable preservative film has the advantages of favorable mechanical properties, stable structure and favorable air permeability, has favorable antibacterial actions, and is capable of decelerating the fruit / vegetable deterioration caused by endogenous metabolic aging and exogenous microbes, greatly prolonging the preservation period and effectively keeping the fruit / vegetable quality.

Owner:陈强

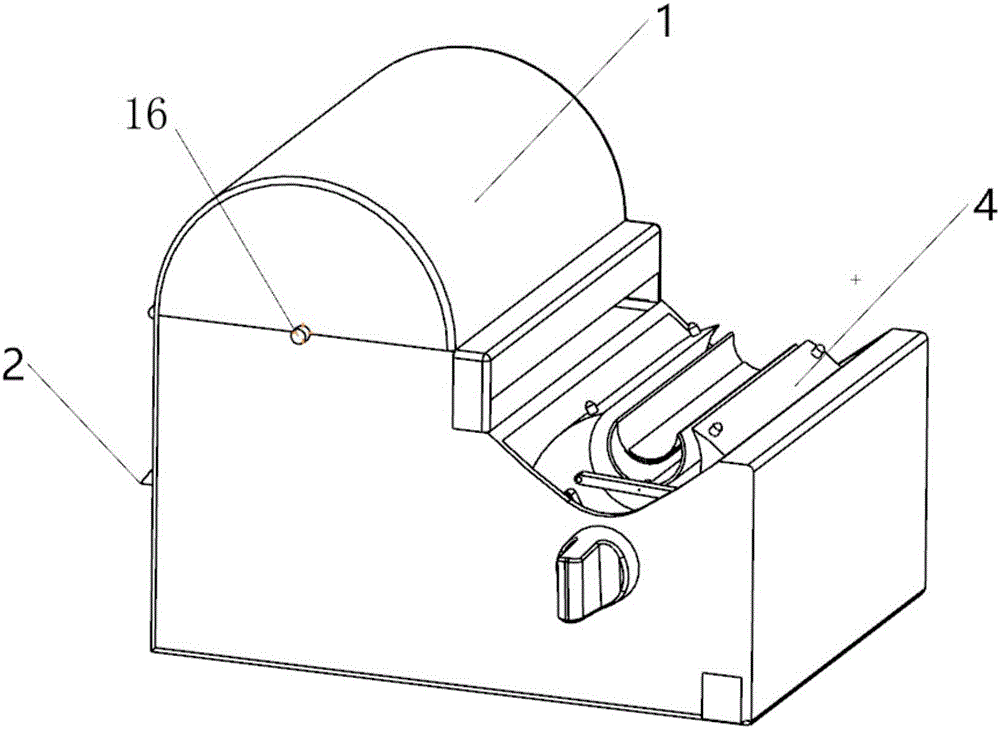

Flavoring bag sealing device and powder packaging machine

PendingCN110539928AExtend heating timeGood heat sealing effectWrapper twisting/gatheringHeating timeEngineering

The invention relates to the technical field of powder packaging, and provides a flavoring bag sealing device and a powder packaging machine. The flavoring bag sealing device comprises a workbench, apre-heating device and an extrusion sealing device, wherein the pre-heating device and the extrusion sealing device are both supported on the workbench, the workbench is used for allowing a folded packaging film with an opening in the top to move, the pre-heating device is used for heating the top edge of the packaging film, and the extrusion sealing device is used for laminating the top edge of the packaging film penetrating out of the pre-heating device. Compared with the prior art, the flavoring bag sealing device has the advantages that the top edge of the packaging film is heated by usingthe pre-heating device, and then the top edge of the packaging film penetrating out of the pre-heating device is laminated by means of the extrusion sealing device, thus, the heating time of the packaging film is prolonged, the heating laminating and sealing effect of the opening of the packaging film is improved, and the opening sealing part is good in firmness.

Owner:SHENZHEN RUIFEI TECH

Preparation method of aramid filter bag and aramid filter bag

ActiveCN105642034BSolve the problem of weak bondsGood heat sealing effectDispersed particle filtrationFibre typesPolymer scienceRoom temperature

The invention relates to the technical field of aramid fibers and in particular relates to a preparation method of an aramid fiber filter bag and the aramid fiber filter bag. According to the method, aramid fibers are used as fiber raw materials, and are sewed through a heat sealing process; a sewed part is coated with a silane coupling agent solution and the aramid fibers are aramid fibers 1313. With the adoption of the preparation method of the aramid fiber filter bag, provided by the invention, the problems that the surfaces of existing aramid fibers are inert, the bonding between the fibers is relatively weak at a room temperature, the fibers are directly carbonized and decomposed when the temperature is more than 400 DEG C and the like are solved, and the aramid fiber filter bag with strong power and high filtering precision is obtained.

Owner:南京际华三五二一环保科技有限公司

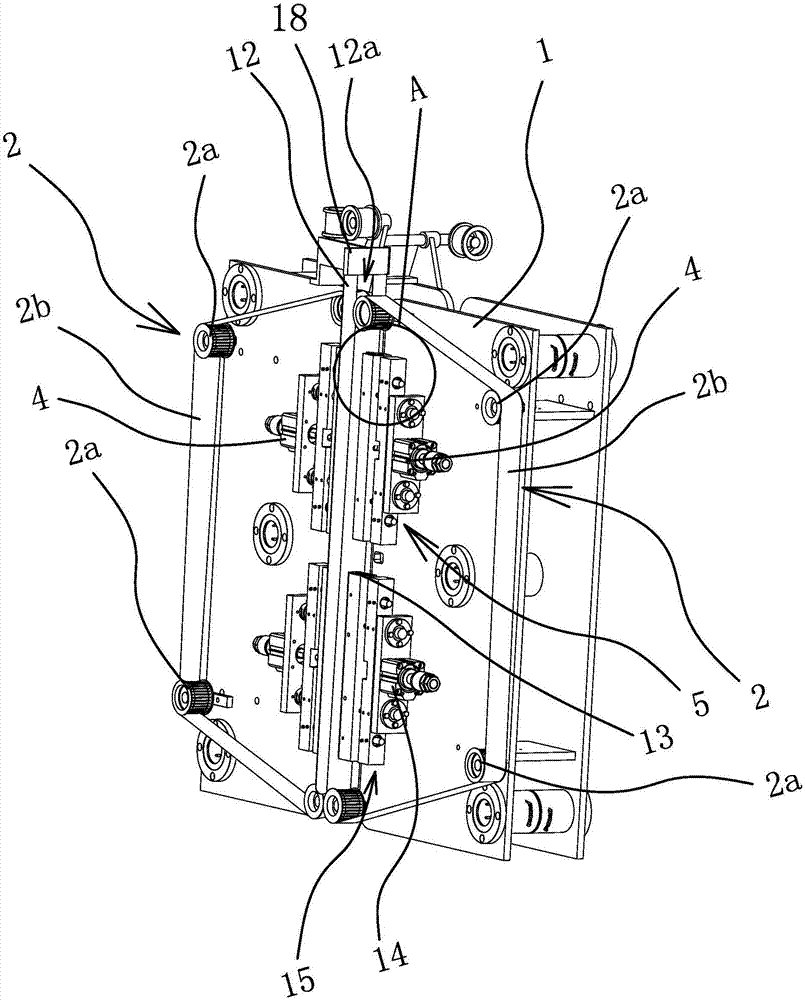

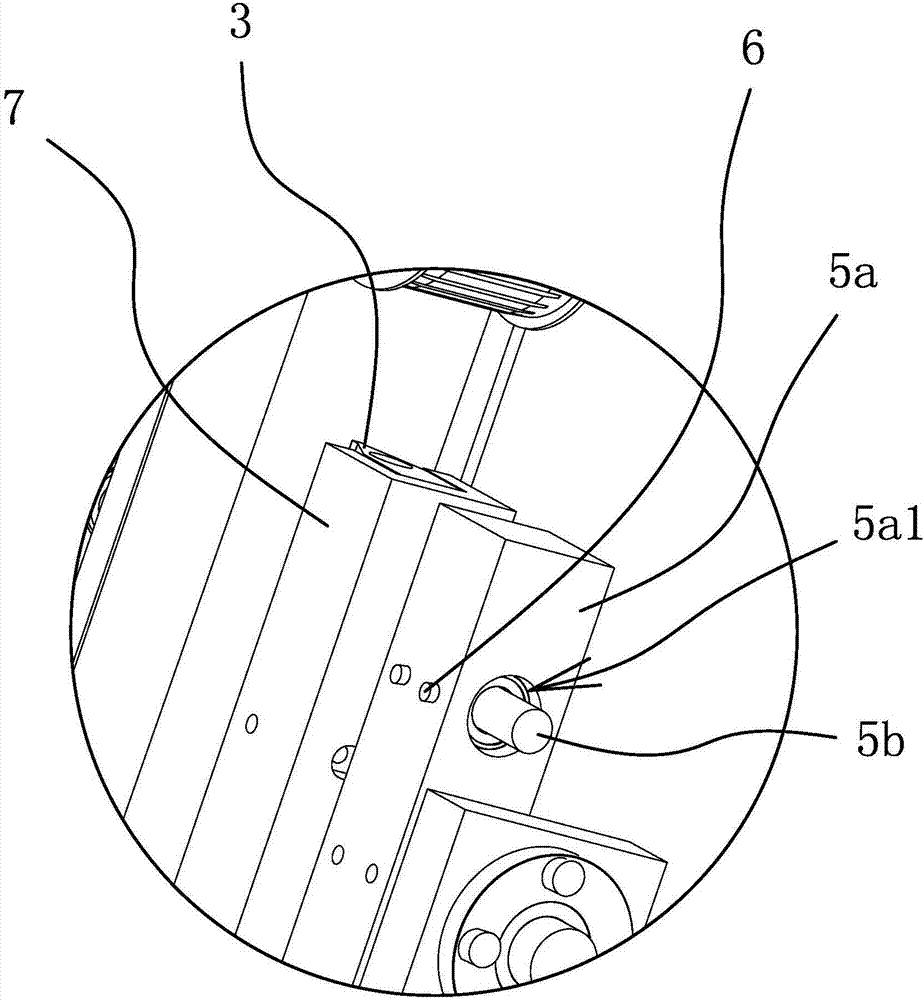

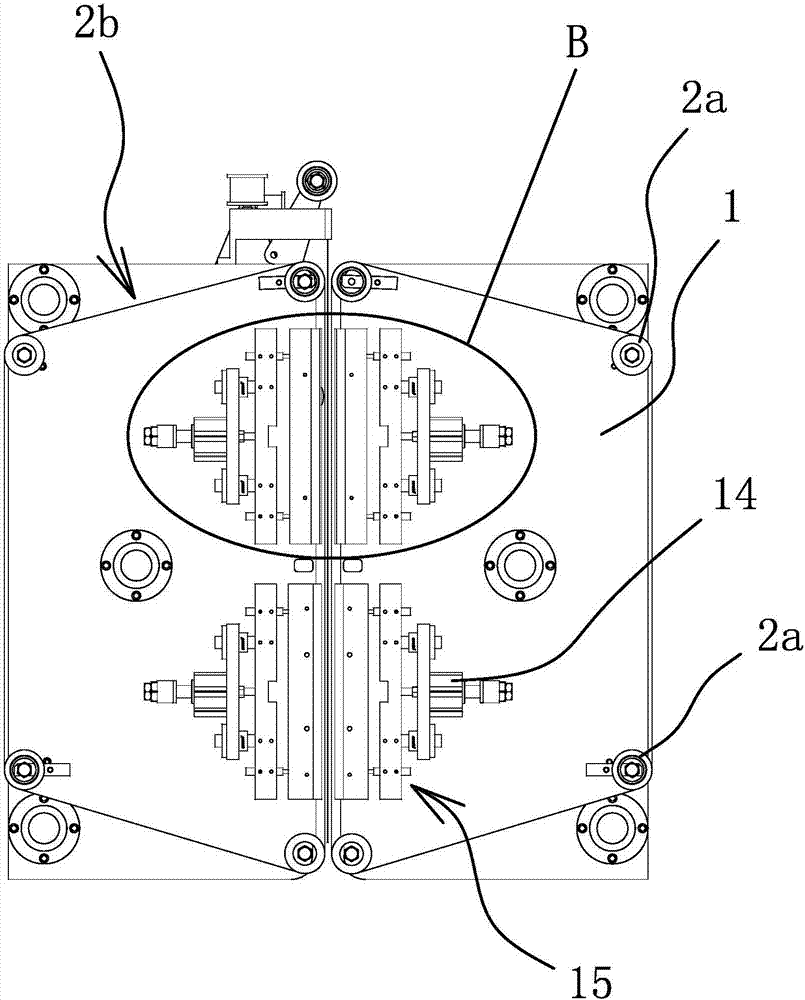

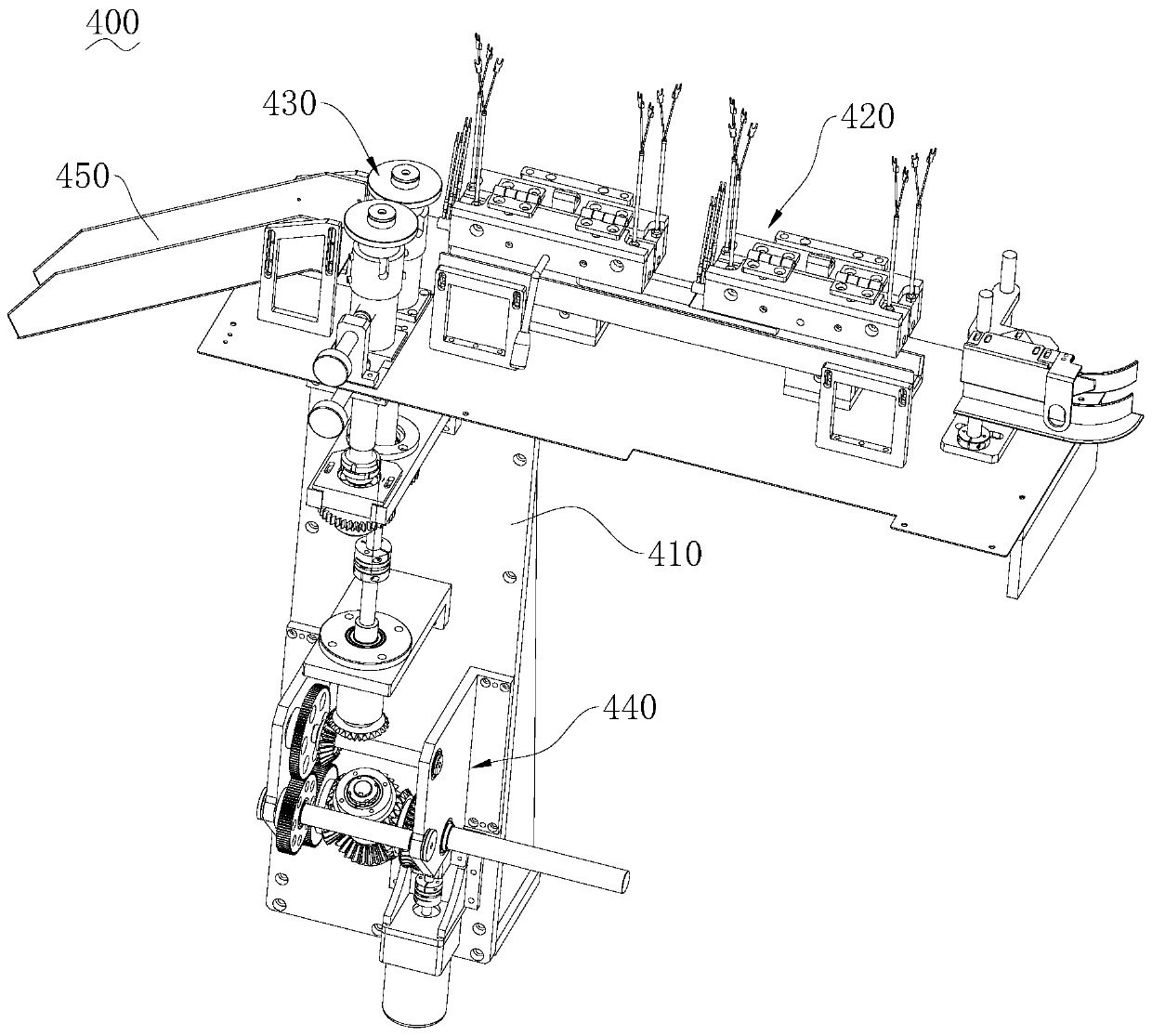

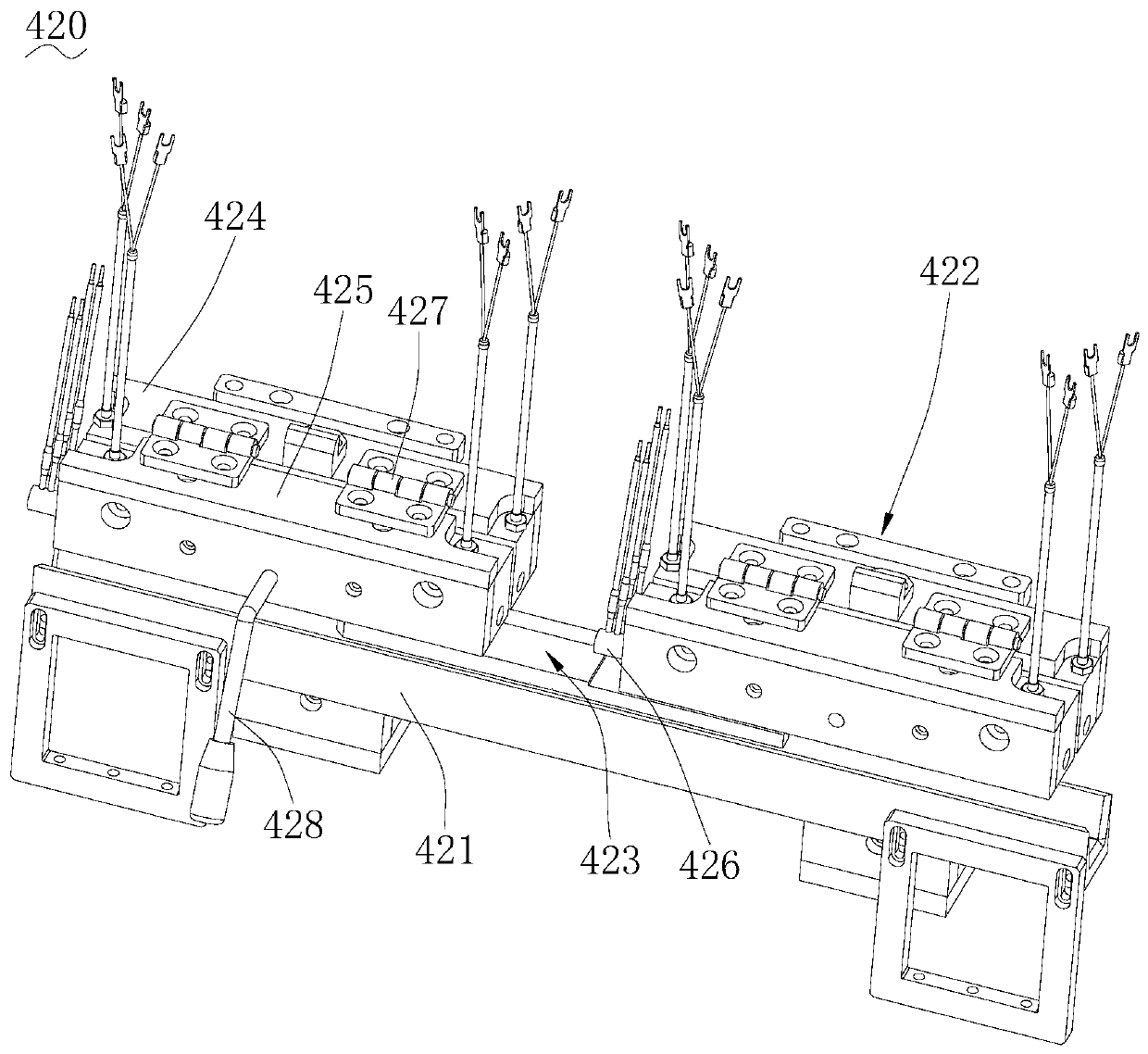

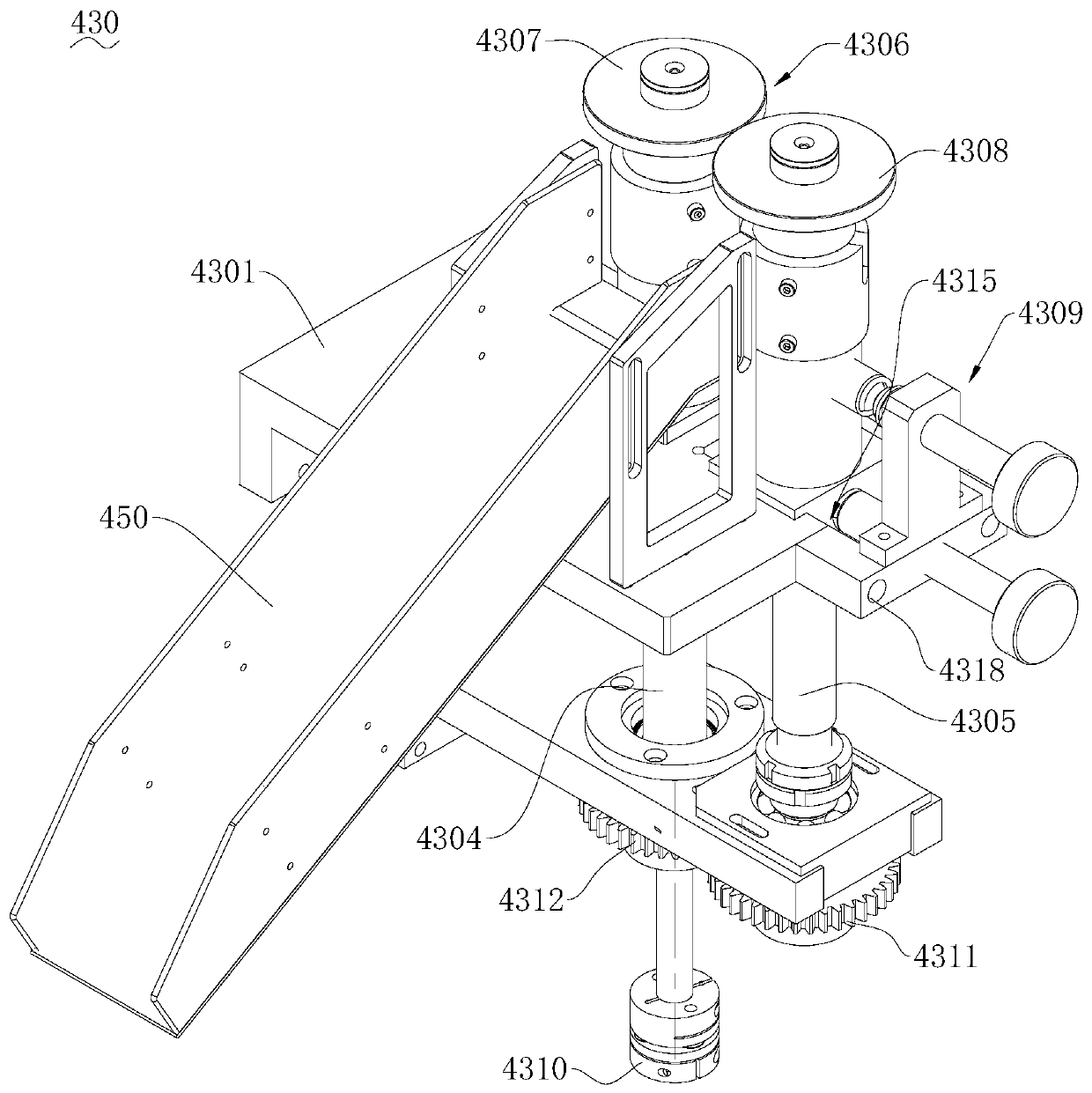

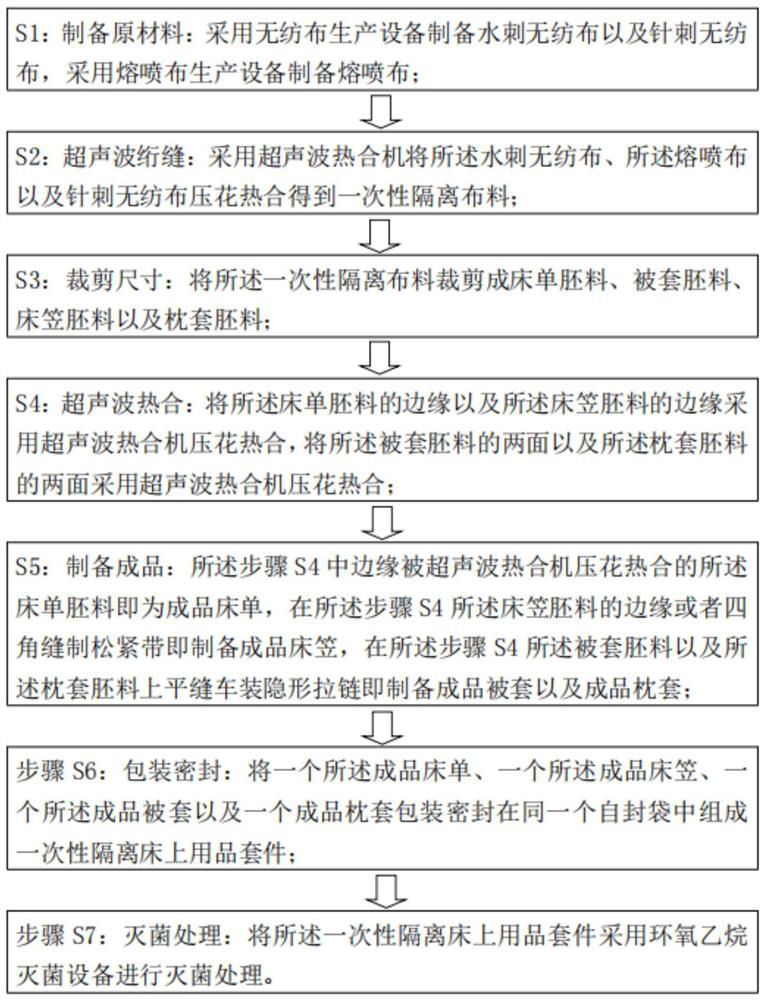

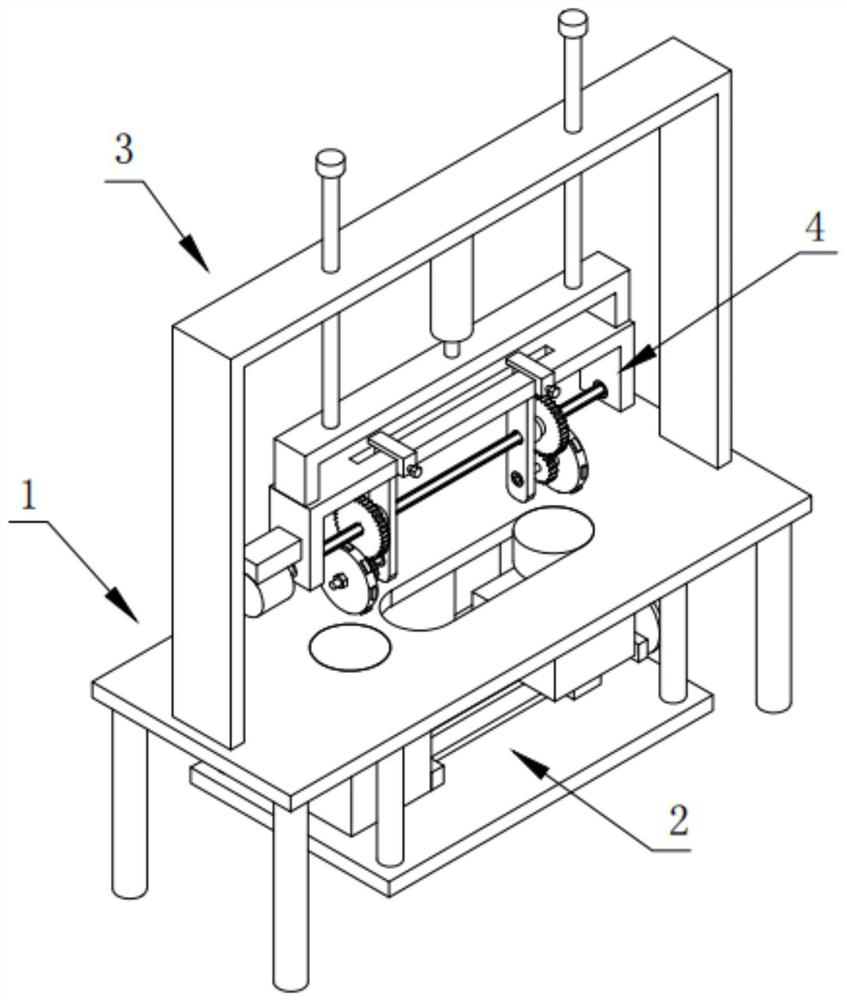

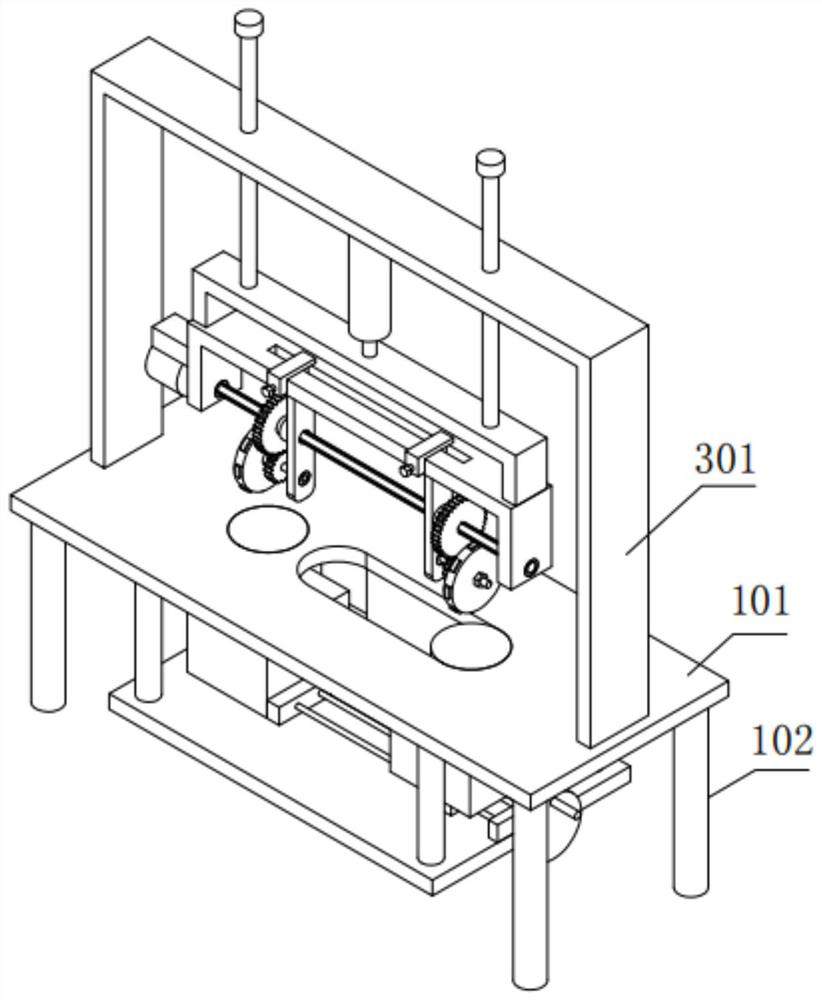

Disposable isolation bedding manufacturing process and equipment

ActiveCN112956878BSimple stepsGood heat sealing effectPattern makingBlanketManufacturing technologyElectric machinery

The invention discloses a manufacturing process and equipment for the disposable isolation bedding. The disclosed manufacturing process for the disposable isolation bedding includes 7 steps. The disclosed manufacturing equipment for the disposable isolation bedding consists of a rack, an ultrasonic generating mechanism, a lifting mechanism and a The composition of the pressing mechanism. The manufacturing process of the disposable isolation bedding provided by the invention has the advantages of simple steps, good heat sealing effect, various complex flower-shaped patterns can be pressed on the product according to customer requirements, no need to use a sewing machine, no need for needles and threads, and the trouble of frequently changing needles and threads is saved. There is no broken thread joint of traditional thread stitching, low cost and high efficiency; the disposable isolation bedding manufacturing equipment provided by the present invention can extrude two rows of embossed patterns at one time, and can also be adapted to heat sealing and fixing products of different specifications. , the design is more reasonable, and one motor can be used to drive two embossing discs to rotate at the same time, which can save the manufacturing cost and greatly improve the work efficiency.

Owner:VIOLET HOME TEXTILE TECH

Packing bag heat-seal cutting device

InactiveCN108819347AEasy heat cuttingSolve problemsBag making operationsPaper-makingHydraulic cylinderEngineering

The invention provides a packing bag heat-seal cutting device which comprises a heat-seal plate, supporting frames, first belt pulleys, electric heating rollers, driven electric heating rollers, driving electric heating rollers, a cutting blade and hydraulic cylinders. The heat-seal plate is mounted on the left side of the upper end face of a workbench; the supporting frames are symmetrically mounted on the front end face and the rear end face of the workbench; the driven electric heating rollers are mounted on the inner sides of the supporting frames, the driving electric heating rollers aremounted on the right sides of the driven electric heating rollers, and the driven electric heating rollers and the driving electric heating rollers are both mounted on the upper side of the heat-sealplate; the first belt pulleys are mounted on the front end faces and the rear end faces of the driven electric heating rollers; belts are mounted on the annular side faces of the first belt pulleys; the hydraulic cylinders are mounted on the front end face and the rear end face of the workbench; and the cutting blade is mounted on the annular side face of a rotating rod. According to the packing bag heat-seal cutting device, the problem that an original packing bag has defects in the heat-seal cutting device is solved, and the packing bag heat-seal cutting device is reasonable in structure, convenient to combine and mount, high in stability and good in heat-seal cutting effect.

Owner:解晓莉

Wire stitching device

ActiveCN106786230AQuick stitchingImprove packaging efficiencyApparatus for repairing insulation/armouring cablesEngineeringManipulator

The invention provides a wire stitching device which is of an integral from outer appearance. The wire stitching device is integrally provided with an accommodating box, a grooved pulley, shaft pins, a manipulator, connecting brackets, switch pillars, spring pieces, fixing rods, a catch, a lock pulley, a spring, a grooved roller shaft, a support shaft and fixing shafts; a power switch and a knob are arranged on the outside of the wire stitching device; the movable manipulator is arranged in the groove of the grooved pulley, and the spring pieces which are fixedly connected are arranged inside the manipulator; each of the spring piece is wrapped with a layer of heating wires from the outside, and the lower end of the spring piece is provided with the switch pillar capable of moving vertically; the switch pillars are hinged with the connecting brackets, and one ends of the connecting brackets are fixed on the outside of the manipulator; the fixing pin shafts are arranged on the contour surface of the grooved pulley, the lock pulley rotating in uniform angle is fixed on the end surface, and the lock pulley and the pressure spring are nested in the grooved roller shaft. The wire stitching device is reasonable in design, convenient in operation, high in security and capable of performing wire stitching, and efficiency and quality in wrapping breakage of wires are improved.

Owner:JIANGXI UNIV OF SCI & TECH

A membrane material for transfusion

ActiveCN111452471BGood drug compatibilityNot easy to adsorbInfusion devicesSynthetic resin layered productsPolymer sciencePolypropylene

Owner:CHONGZHOU JUNJIAN PLASTIC CO LTD

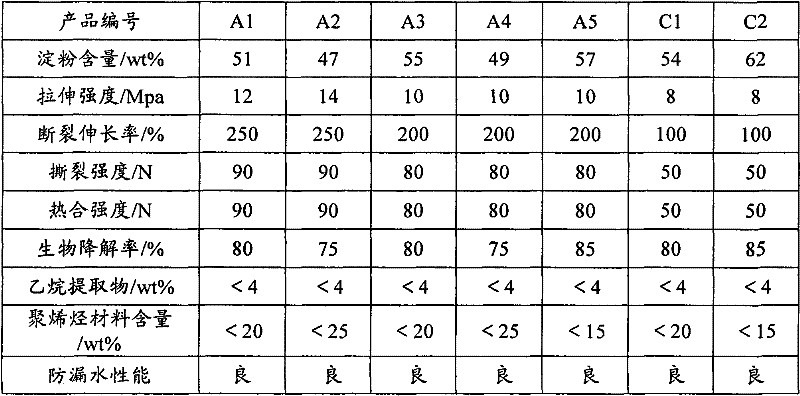

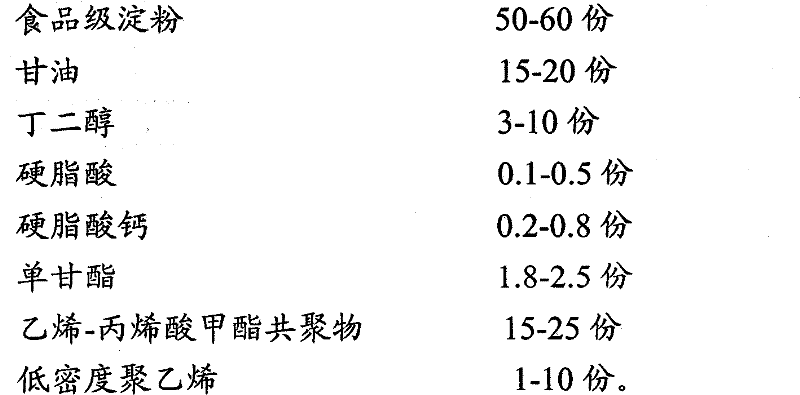

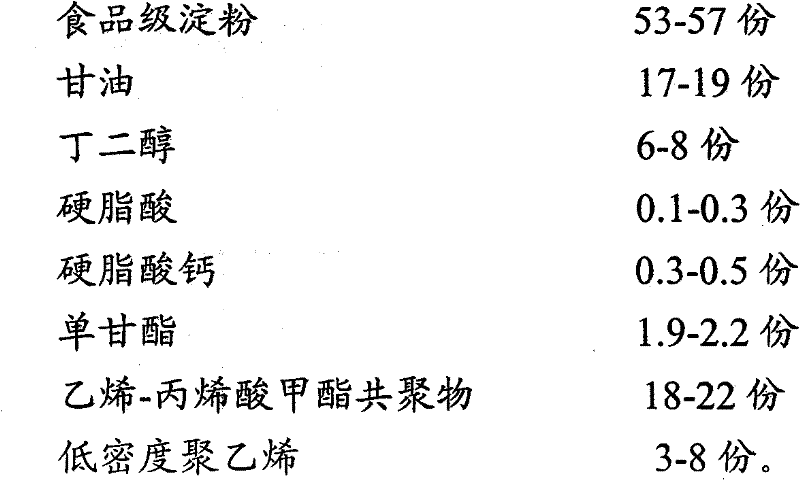

Biodegradable thermoplastic starch resin for thin-film material, preparation method thereof and products thereof

The invention provides a biodegradable thermoplastic starch resin for a thin-film material, a preparation method thereof and products thereof. The resin comprises the following components in part by weight: 50 to 60 parts of food grade starch, 15 to 20 parts of glycerol, 3 to 10 parts of butanediol, 0.1 to 0.5 part of stearic acid, 0.2 to 0.8 part of calcium stearate, 1.8 to 2.5 parts of monoglyceride, 15 to 25 parts of ethyl-methyl acrylate copolymer and 1 to 10 parts of low-density polyethylene. Compared with the traditional biodegradable thermoplastic starch resin, the biodegradable thermoplastic starch resin provided by the invention has the advantages of good processing performance, high biomass content, high biodegradation rate, very good thermal bonding performance and leakage-proof performance. The biodegradable thermoplastic starch resin can be used for manufacturing bath curtains, sleeves, films, medical bed spreads, surgical pads, disposable gloves, diapers, sanitary towels, table linens or table cloth.

Owner:NANJING WURUI BIODEGRADABLE NEW MATERIAL RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com