Heating structure of sealing machine

A sealing machine and heating element technology, applied in the direction of electric heating device, ohmic resistance heating, packaging sealing/fastening, etc., can solve the problem of increasing the overall volume and weight of the sealing machine, sealing It solves the problems of inconvenient use and carrying of the machine, and achieves the effect of simple structure, reduced volume and weight, and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

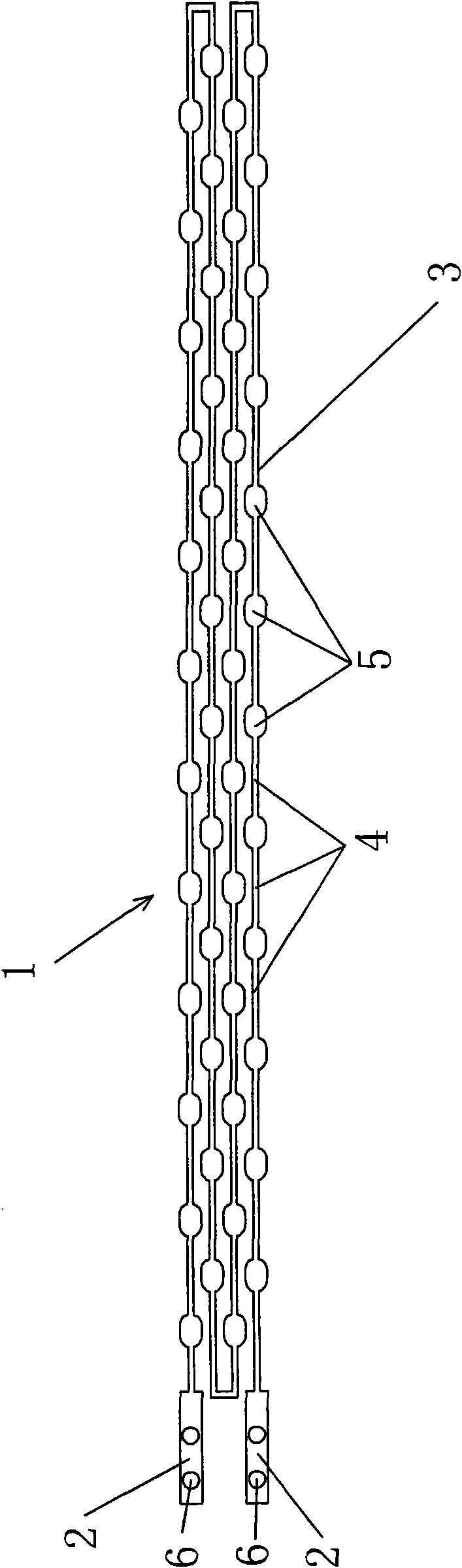

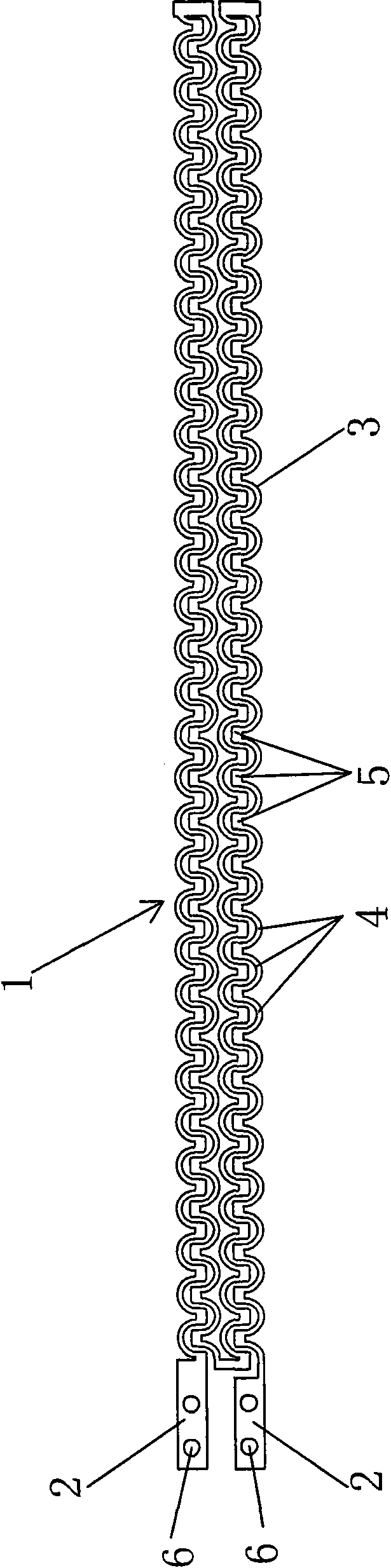

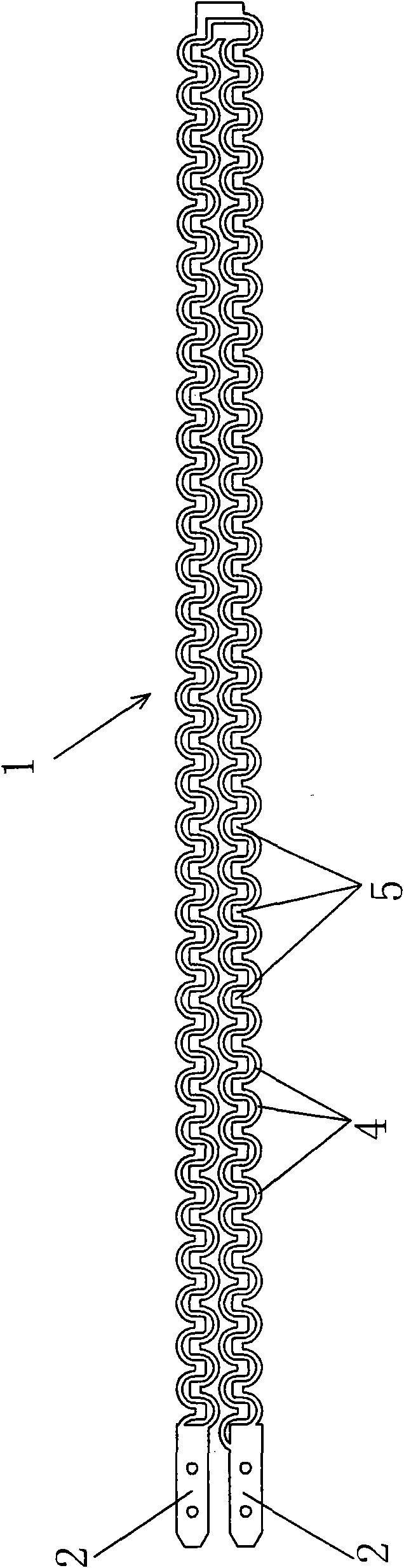

[0022] figure 1 It is a structural schematic diagram of the first embodiment of the present invention. The heating structure includes a heating body 1 and joints 2 connected to both ends of the heating body 1, wherein the joint 2 is provided with an installation hole 6 that is convenient for buckling on the sealing machine. The heating body 1 includes Four heating strips 3, heating strips 3 are placed side by side in series, and the outlets of the heating element 1 are located on the same side after being placed in series. Since the connector 2 is connected to the outlet, the connector 2 will also be located on the side of the heating element 1. On the same side, the heating strip 3 in this embodiment is composed of several high-resistance blocks 4 made of high-resistance heating wires and several low-resistance blocks 5, and the low-resistance blocks 5 and the high-resistance blocks 4 are arranged at intervals. Wherein the high-resistance block 4 is a narrow and thin straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com