Heat-sealable silicone rubber elastomer film and production equipment and preparation method thereof

A technology of silicone rubber film and silicone rubber, applied in the direction of rubber layered products, chemical instruments and methods, synthetic resin layered products, etc., to achieve the effects of excellent weather resistance, strong bearing capacity, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

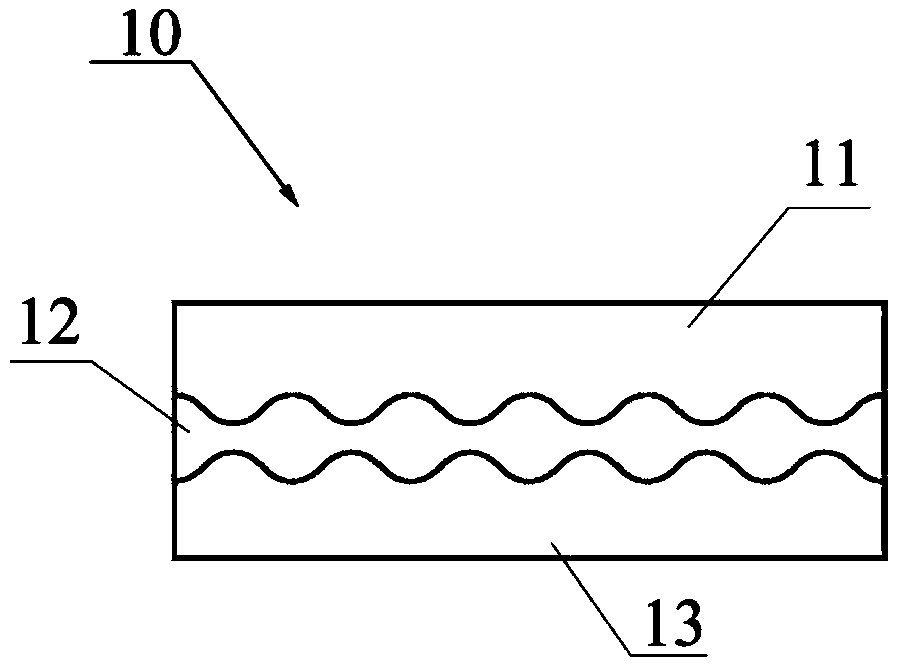

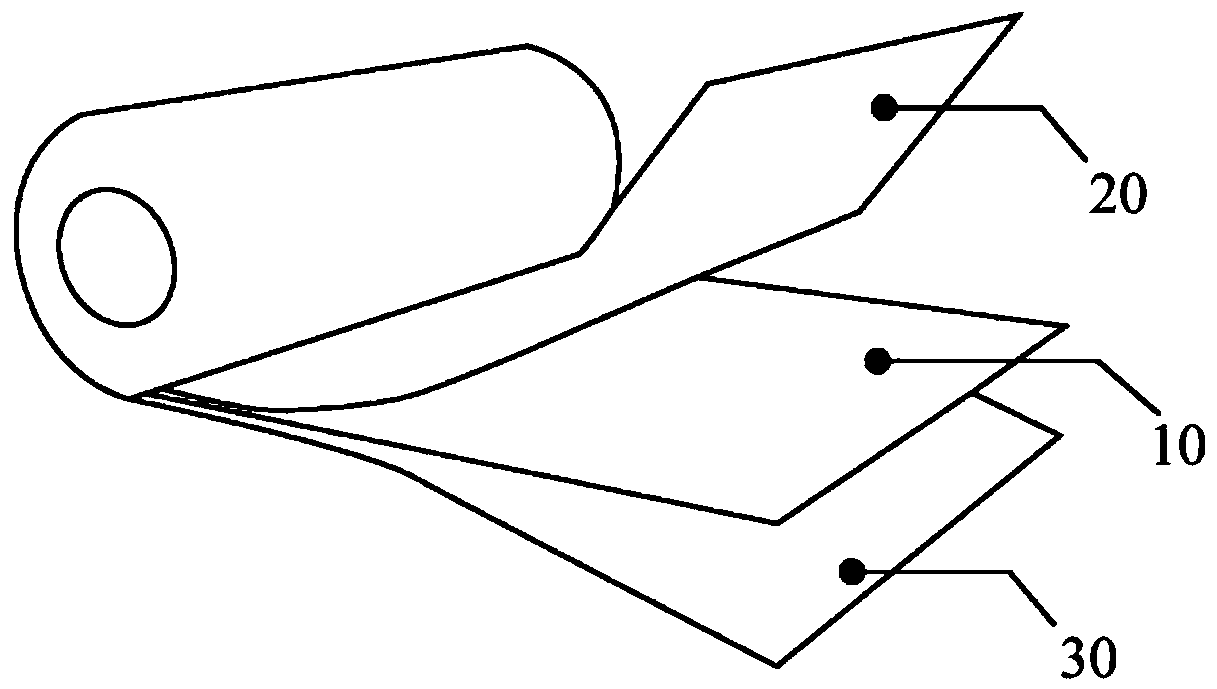

[0030] see figure 1 It is a structural schematic diagram of the heat-sealable silicone rubber elastomer film, and the heat-sealable silicone rubber elastomer film 10 includes a silicone rubber film layer 11, a polysiloxane copolymer layer 12 and a polyurethane elastomer film substrate 13, and polysiloxane copolymerization The material layer is coated on the surface of the polyurethane elastomer film substrate, and the silicone rubber film layer is attached to the polysiloxane copolymer layer.

[0031] The polysiloxane copolymer layer 12 is a grafting agent, and the polysiloxane copolymer layer 12 is coated on the surface of the polyurethane elastomer film substrate 13 by roll coating or manually, and is exposed to the air at normal temperature or in a heated environment, and the solvent After volatilization, a layer of silicone film is formed, which is firmly bonded to the surface of the attached substrate, which facilitates the bonding of the silicone rubber film layer and im...

Embodiment 2

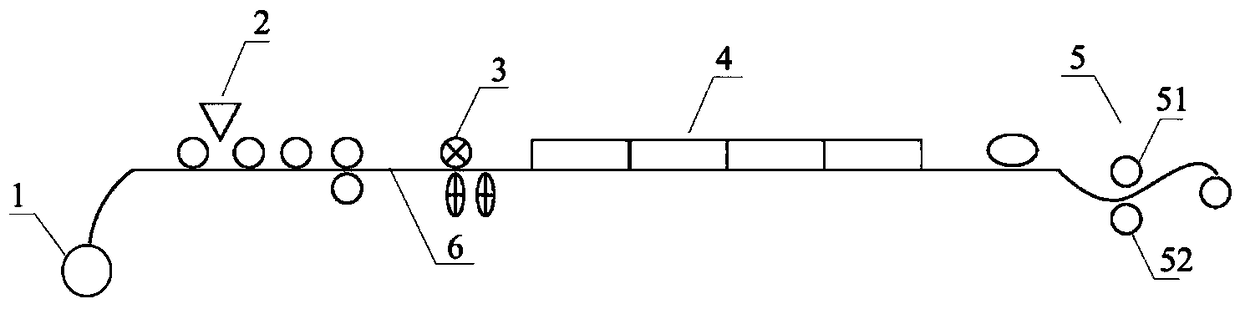

[0037] see image 3 It is a production equipment for heat-sealable silicone rubber elastomer film, including a substrate unwinding device 1, a calender 2, a feeding device 3, a segmented vulcanization tank 4 and a coiling device 5. The substrate unwinding device 1 , the calender 2 , the feeding device 3 , the segmented vulcanization tank 4 and the coiling equipment 5 are connected sequentially through a conveyor belt 6 .

[0038] Specifically, the substrate unwinding device 1 is used to place the pretreated polyurethane elastomer film substrate 13 on the conveyor belt 6, the calender in this embodiment is a 5-roll calender, and the segmented vulcanization tank includes 4 stages of vulcanization The temperature difference between each vulcanization tank 4 is controlled to be ±5°C. The coil equipment 5 includes a protective film roller 51 and a release paper roller 52. The protective film roller 51 is used to attach the protective film to the middle film. , The release paper cy...

Embodiment 3

[0040] see Figure 4 , the present invention is a production equipment for heat-sealable silicone rubber elastomer film, the difference from Embodiment 1 is that the calender 2 is replaced by the coating equipment 7, and the coating equipment is a doctor blade coating equipment, which is used to add liquid A shaped silicone rubber compound is applied to the substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com