Heat sealing mechanism of band and film heat sealing molding device

A technology of thermal synthesis and filming, which is applied in the lamination device, lamination system, lamination and other directions, and can solve problems such as unevenness, inability to ensure bonding, and incomplete thermal sealing of local parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

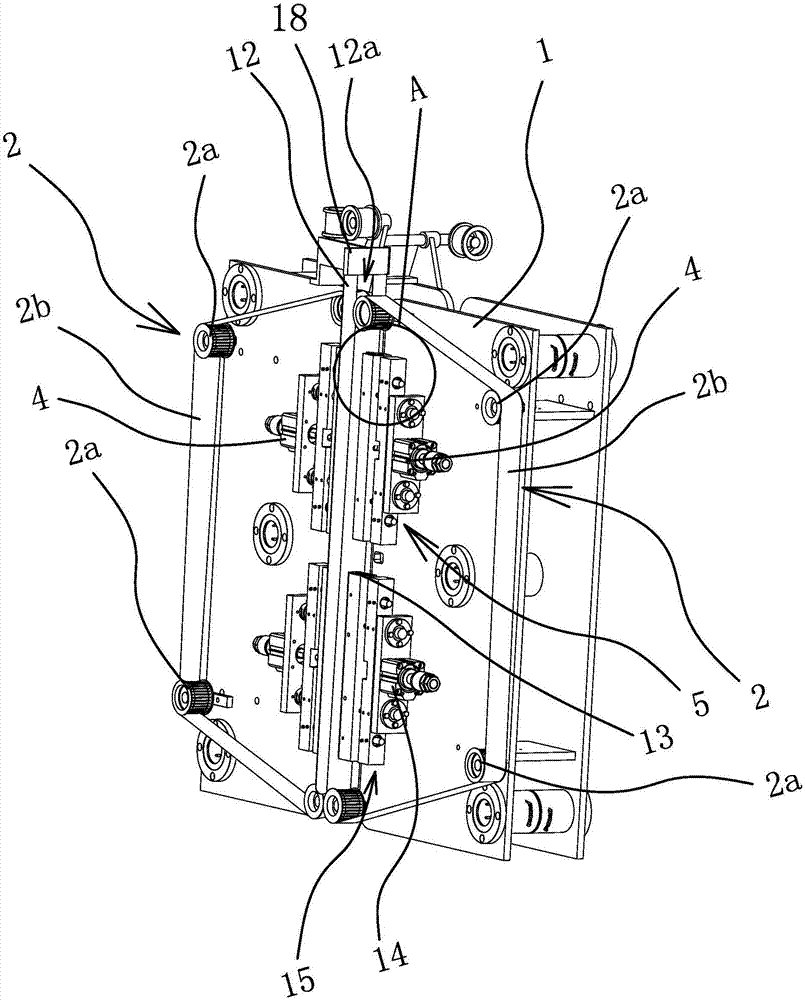

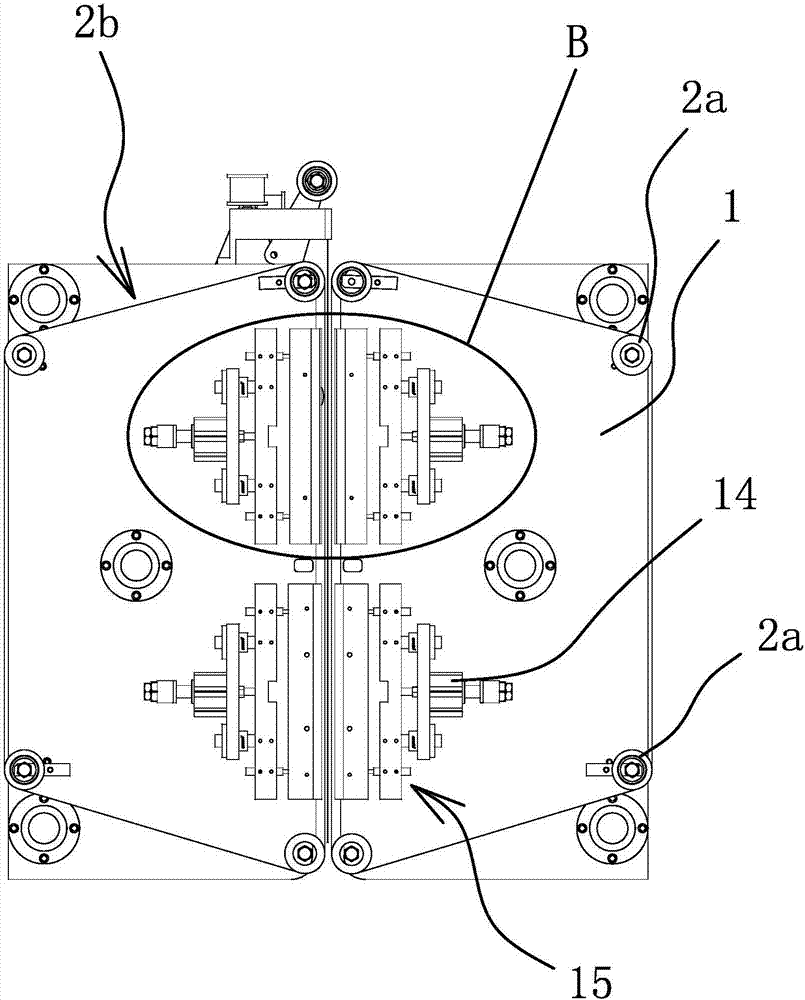

[0043] Such as Figure 1-12 As shown, the heat-sealing mechanism of the film heat-synthesizing device includes a mounting base 1, two guide rulers 12, two sets of driving rollers 2 that are arranged oppositely and are composed of several driving rollers 2, two oppositely arranged Heat-sealing cutter head 3 and two cooling cutter heads 13 which are elongated and oppositely arranged.

[0044]Two cooling cutter heads 13 and two heat-sealing cutter heads 3 are arranged side by side, and each group of driving rollers 2 includes four driving rollers 2a, and the four driving rollers 2a are arranged in an isosceles trapezoidal shape and are all rotatably connected to the mounting base 1. The driving rollers 2a in the driving roller group 2 are connected by a driving belt 2b made of a high-temperature-resistant heat-conducting material, and the driving belts 2b located at the bottom edge of the isosceles trapezoid on the two groups of driving roller groups 2 are parallel to each other ...

Embodiment 2

[0050] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: Figure 13 As shown, the adjustment assembly one 5 includes a slide block 5d and a slide rail 5c, the drive source one 4 is a cylinder, the cylinder body of the cylinder is fixed on the slide block 5d, the heat sealing cutter head 3 is fixed on the cutter head seat 7, and the piston rod of the cylinder It is connected with the cutter head seat 7, the slide rail 5c is fixed on the mounting base 1, the slide block 5d is slidably connected on the slide rail 5c, and there is also a set between the slide block 5d and the slide rail 5c that can position the slide block 5d on the slide rail 5c. Positioning piece two on the The piston rod of the air cylinder is directly connected with the cutter head holder 7 of the fixed heat sealing cutter head 3. Initially, the distance between the cylinder and the driving belt 2b can be adjusted by adjusting the position of the slide block 5d ...

Embodiment 3

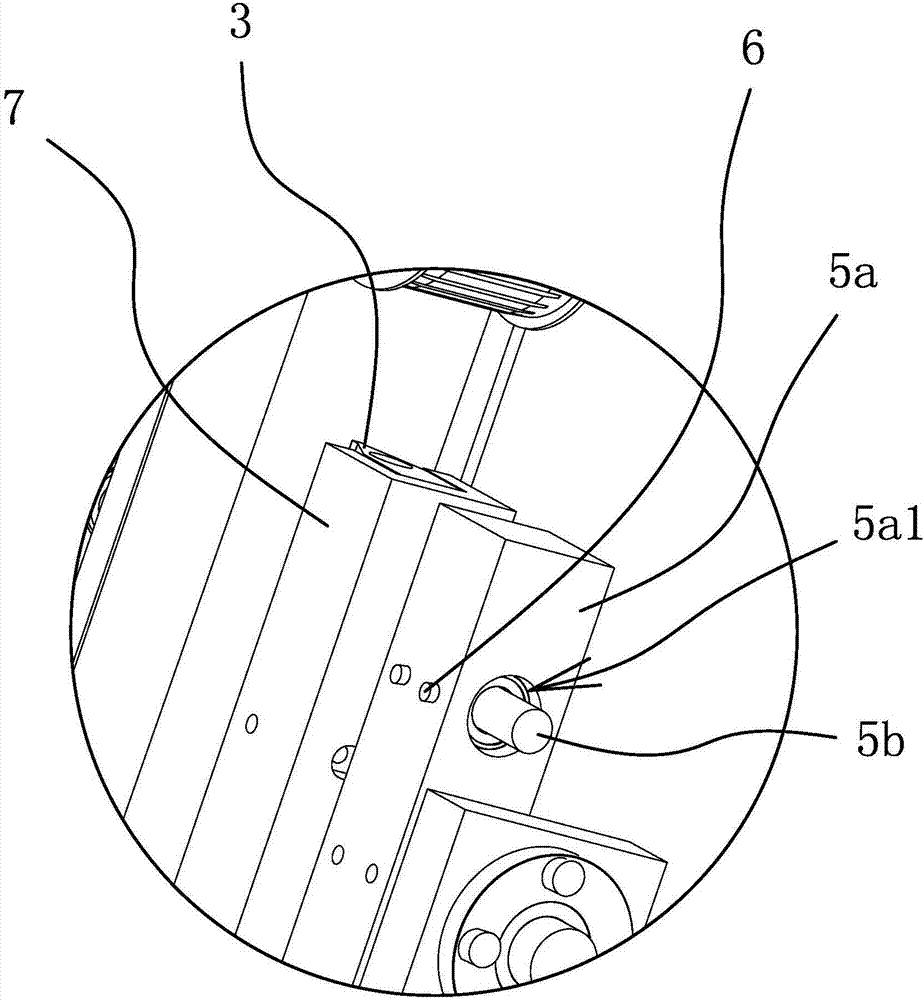

[0052] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: Figure 15 As shown, the heat-sealed cutter head 3 is cylindrical, and the heat-sealed cutter head 3 is rotatably connected to the cutter head seat 7. There are two adjusting rods 5b which are fixedly connected to the two ends of the cutter head seat 7 respectively. The adjustment block 5a and the cutter head The seats 7 are arranged side by side, both ends of the adjustment block 5a are provided with adjustment holes 5a1, and the adjustment rods 5b slide through the corresponding adjustment holes 5a1 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com