Film material for transfusion

A technology of film and material for infusion, applied in the field of medical packaging materials, can solve problems such as film materials that have not yet been seen, and achieve the effects of ensuring stable concentration and long-term storage effectiveness, smooth and beautiful film surface, and reducing gas permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

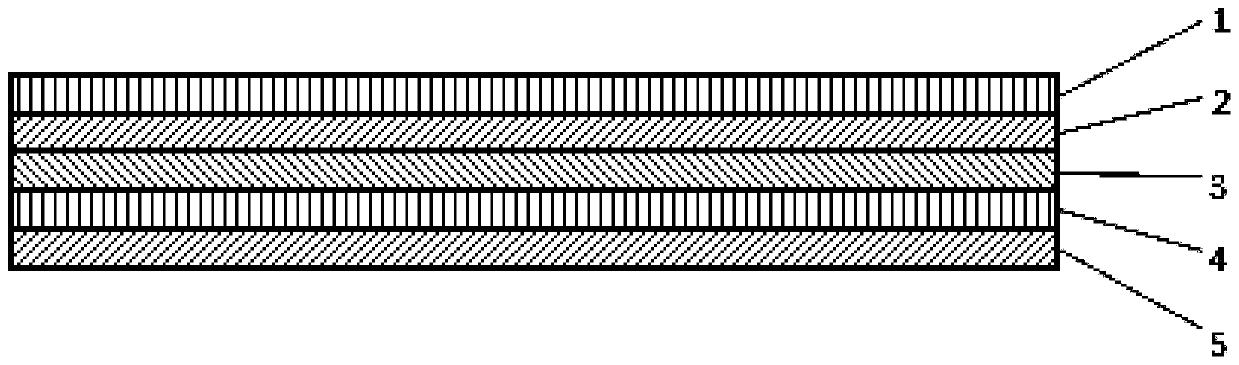

[0022] A film material for transfusion, which includes an outer layer, a sub-outer layer, a middle layer, a sub-inner layer and an inner layer from outside to inside; the outer layer is made of polypropylene and styrene-ethylene-butylene-styrene block copolymer Mixture 1 obtained by mass ratio 80:20; second outer layer material is polypropylene and styrene-ethylene-butylene-styrene block copolymer obtained mixture 2 by mass ratio 40:60; middle layer material is polypropylene, ethylene- The mixture obtained by vinyl alcohol copolymer and polypropylene grafted maleic anhydride copolymer in a mass ratio of 40:40:20; the second inner layer is made of polypropylene, polyethylene and polyethylene grafted maleic anhydride in a mass ratio of 20:20 : 60 obtained mixture four; inner layer material is cycloalkane olefin copolymer or cycloalkane olefin polymer, polypropylene and polyethylene obtained mixture five by mass ratio 40:40:20.

[0023] Among them, the thickness of the film mater...

Embodiment 2

[0027] A film material for transfusion, which includes an outer layer, a sub-outer layer, a middle layer, a sub-inner layer and an inner layer from outside to inside; the outer layer is made of polypropylene and styrene-ethylene-butylene-styrene block copolymer Mixture 1 obtained in a mass ratio of 90:10; the second outer layer is made of polypropylene and styrene-ethylene-butylene-styrene block copolymer and mixed in a mass ratio of 60:40; the middle layer is made of polypropylene, ethylene- Mixture of vinyl alcohol copolymer and polypropylene grafted maleic anhydride copolymer in a mass ratio of 40:40:20; the second inner layer is made of polypropylene, polyethylene and polyethylene grafted maleic anhydride in a mass ratio of 25:25 :50 obtained mixture four; inner layer material is cycloalkane olefin copolymer or cycloalkane olefin polymer, polypropylene and polyethylene obtained mixture five by mass ratio 45:50:5.

[0028] Among them, the thickness of the film material for ...

Embodiment 3

[0032]A film material for transfusion, which includes an outer layer, a sub-outer layer, a middle layer, a sub-inner layer and an inner layer from outside to inside; the outer layer is made of polypropylene and styrene-ethylene-butylene-styrene block copolymer Mixture 1 obtained by mass ratio 85:15; second outer layer material is polypropylene and styrene-ethylene-butylene-styrene block copolymer obtained mixture 2 by mass ratio 70:30; middle layer material is polypropylene, ethylene- The mixture obtained by vinyl alcohol copolymer and polypropylene grafted maleic anhydride copolymer in a mass ratio of 45:45:10; the second inner layer is made of polypropylene, polyethylene and polyethylene grafted maleic anhydride in a mass ratio of 25:25 :50 obtained mixture four; inner layer material is cycloalkane olefin copolymer or cycloalkane olefin polymer, polypropylene and polyethylene obtained mixture five by mass ratio 40:45:15.

[0033] Among them, the thickness of the film materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com