Resin type ointment with higher drug release performance and its preparation method and application

A resin-type and ointment technology, which is used in pharmaceutical formulations, medical preparations with non-active ingredients, and ointment delivery, etc., can solve the problems of poor drug release performance and strong adhesiveness of resin-type ointments, and achieve moderate adhesion performance, The effect of good drug release and high drug release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1. Preparation of resin paste

[0049]

[0050] With the raw material of above-mentioned quality, proceed as follows:

[0051] 1. Add thermoplastic elastomer SIS, plasticizer, and 50% antioxidant into the reactor, blow nitrogen for 5 minutes to remove the air, heat up to the mixture melts, and at the same time pass nitrogen protection, control the temperature between 120°C and 150°C, and stir , until the mixture forms a uniform and transparent viscous colloid.

[0052] 2. Put the tackifying resin and the remaining 50% of the antioxidant into the above mixture, control the temperature between 100°C and 110°C, stir for half an hour, and at the same time pass nitrogen protection until the mixture forms a uniform and transparent viscoelastic colloid.

[0053] 3. Cool the above colloid to below 100°C and pour it out.

[0054]2. Preparation of joint pain relief ointment

[0055] 1. make the Chinese medicine resin ointment with the above-mentioned method of embodiment 1;...

Embodiment 2

[0095] 1. Preparation of resin paste

[0096]

[0097] Prepared according to the above composition ratio, the method is the same as in Example 1.

[0098] 2. Preparation of joint pain relief ointment: Repeat the method of Example 1, the difference being that the matrix prepared in Example 1 is replaced with the resin ointment matrix prepared in Example 2.

[0099] 3. Product testing:

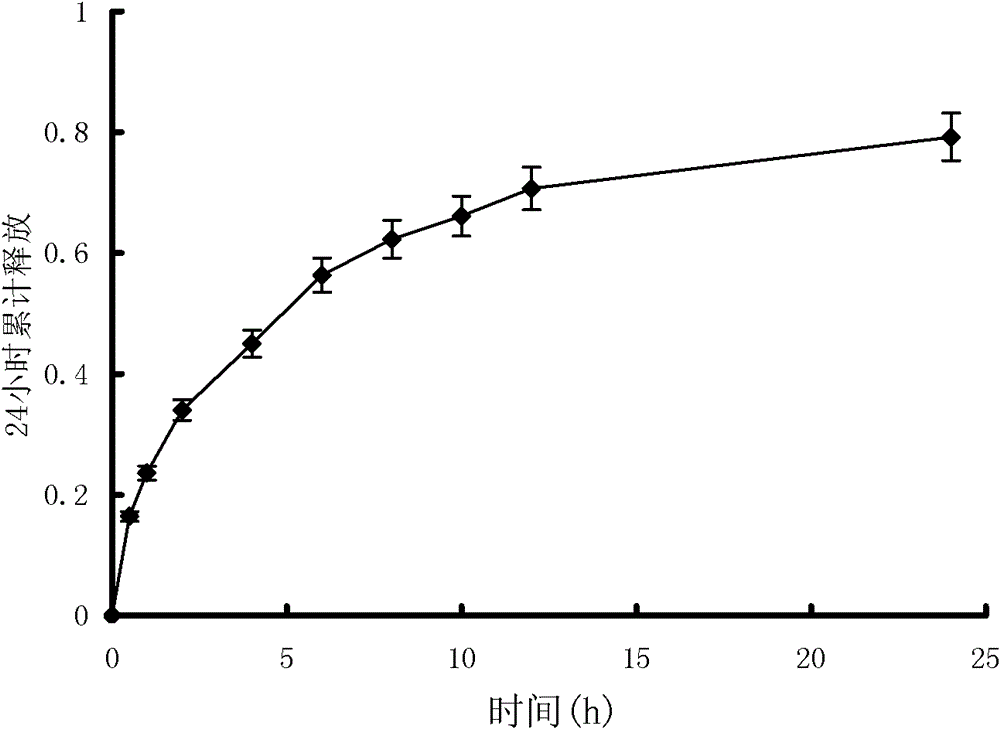

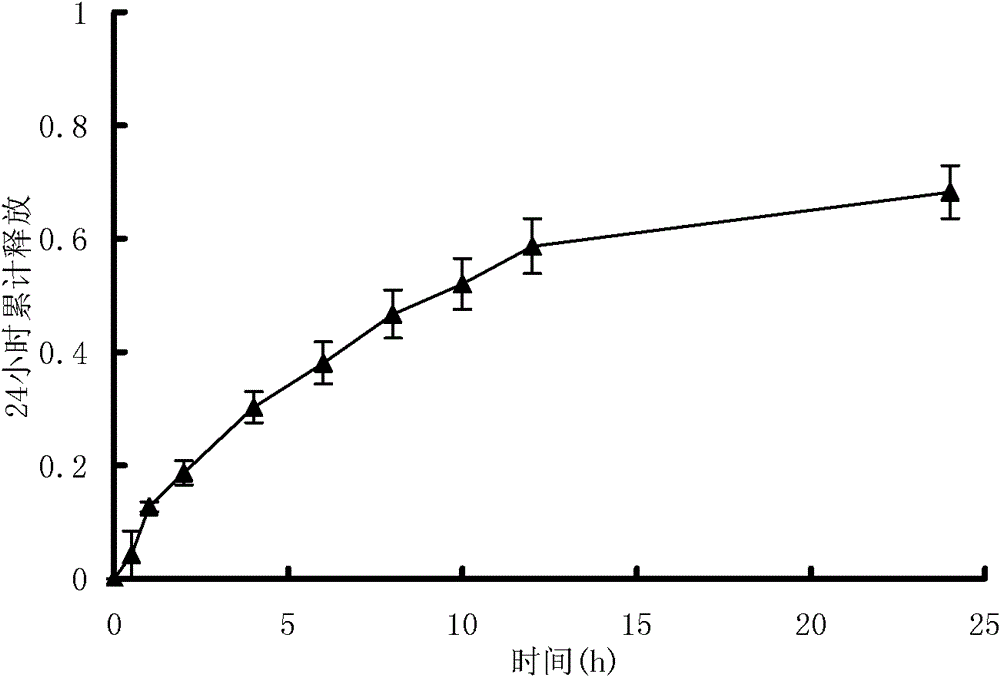

[0100] The initial viscosity, persistent viscosity, peeling strength, drug loading and drug release performance of the joint pain ointment prepared in Example 2 were investigated. Method is with embodiment 1. The test results are shown in Tables 4, 5, 6 and image 3 , Figure 4 .

[0101] Table 4

[0102]

[0103] The results in Table 4 show that the plaster prepared in Example 2 has moderate sticking force, peel strength between 1N and 2N, and good air permeability.

[0104] Table 5 affects the drug release of camphor in the patch

[0105]

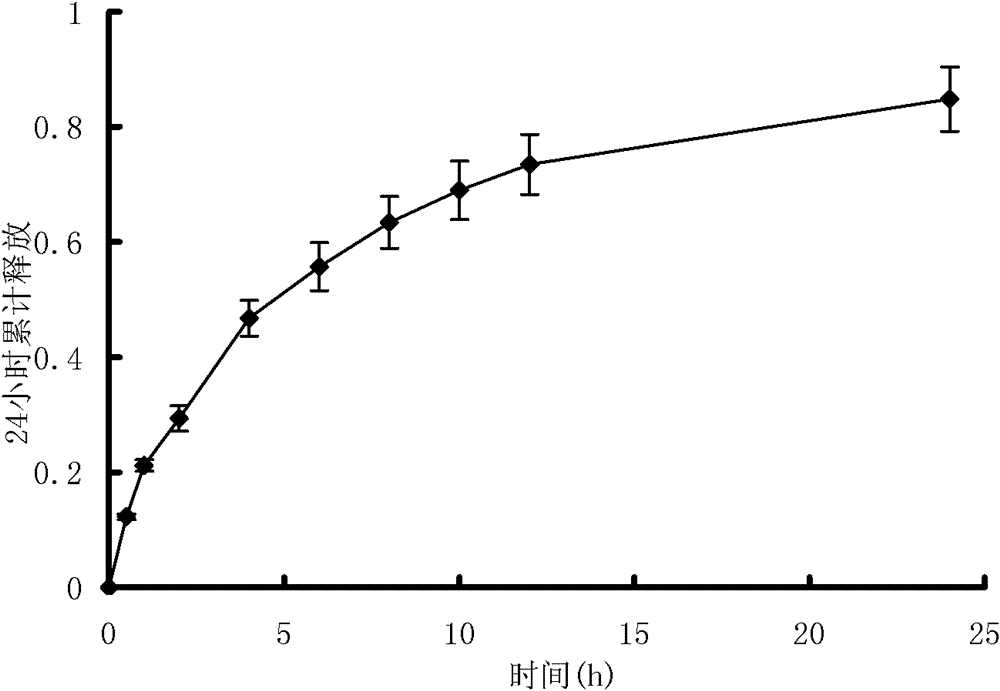

[0106] Table 5 and image 3 The res...

Embodiment 3

[0111] 1. Preparation of resin paste:

[0112]

[0113] With the raw material of above-mentioned quality, proceed as follows:

[0114] 1. Add thermoplastic elastomer SIS, plasticizer, and 50% antioxidant into the reactor, blow nitrogen for 5 minutes to remove air, heat up until the mixture melts, and at the same time pass nitrogen protection, control the temperature between 120°C and 150°C, and stir , until the mixture forms a uniform and transparent viscous colloid.

[0115] 2. Put the tackifying resin and 50% antioxidant into the above mixture, control the temperature between 100°C and 110°C, stir for half an hour, and at the same time pass nitrogen protection until the mixture forms a uniform and transparent viscoelastic colloid; then add Fillers and organic acids, stir to disperse evenly;

[0116] 3. Cool the above colloid to below 100°C and pour it out.

[0117] 2. Preparation of joint pain relief ointment

[0118] 1. make the Chinese medicine resin ointment with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com