Patents

Literature

79 results about "Styrene-ethylene-butylene-styrene-block copolymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Halogen-free flame-retardant thermoplastic elastomer electrical cable material using polyphenylene ether as base material and preparation method thereof

InactiveCN101358028AGood compatibilityReduce stratificationInsulated cablesInsulated conductorsElastomerPolyphenylene oxide

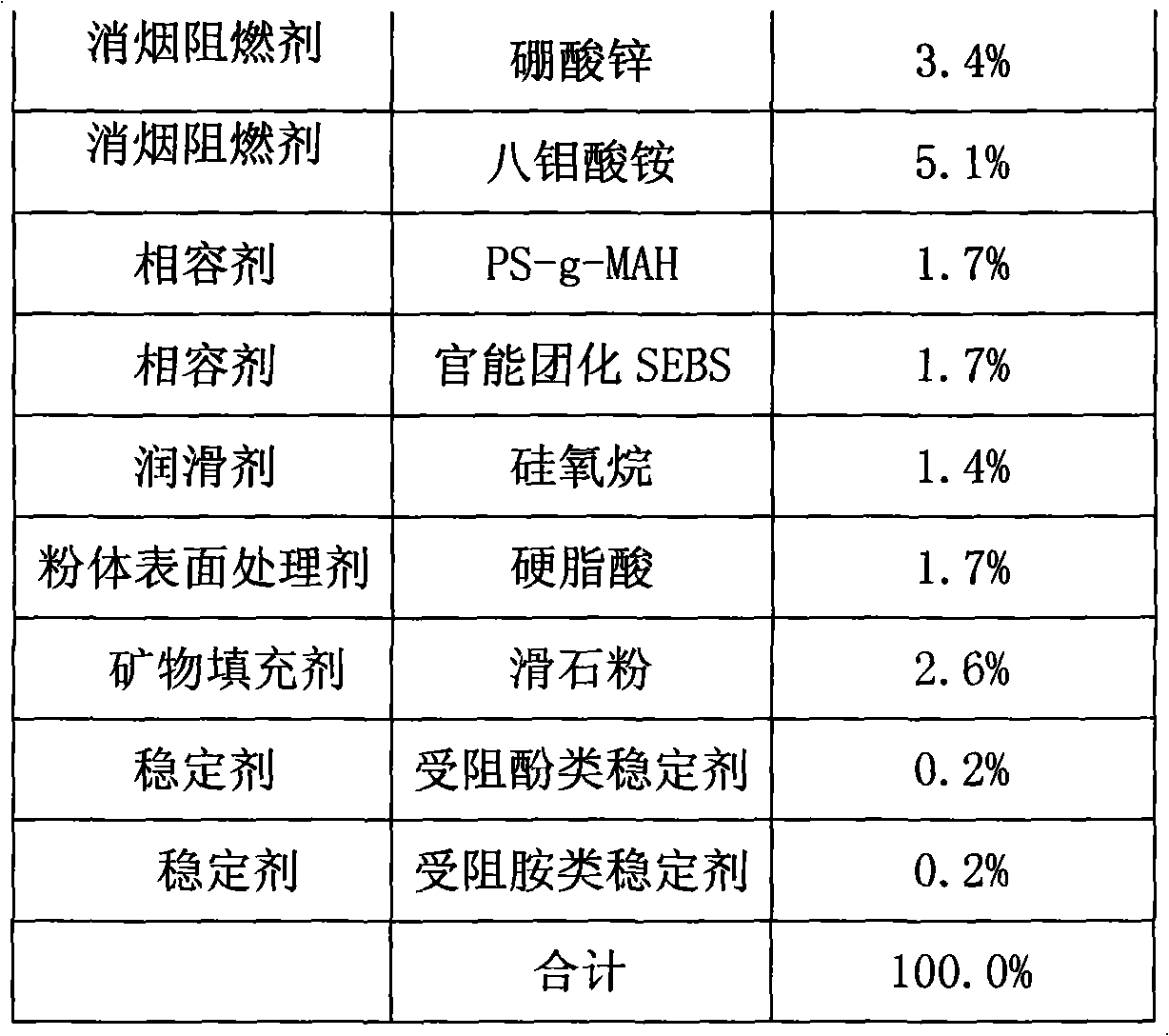

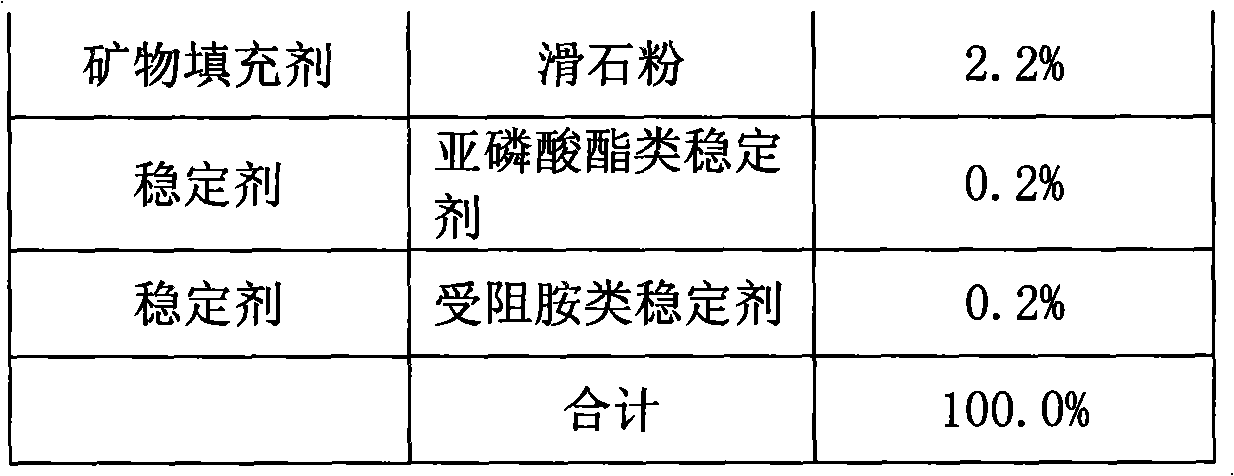

The invention discloses a halogen-free flame-retardant thermoplastic elastomer cable material with polyphenylether as the base materials and a preparation method thereof. The raw material of the cable material contains the components with the following weight percentage: 10 to 35 percent of matrix resin A; 5 to 15 percent of matrix resin B; 10 to 25 percent of elastomer; 5 to 25 percent of softening plasticizer; 8 to 15 percent of flame-retardant plasticizer; 20 to 40 percent of smoke-suppression flame retardant; 3 to 10 percent of compatilizer; 1 to 5 percent of lubricant; 1 to 5 percent of powder surface conditioner; 0 to 10 percent of mineral filler; 0.1 to 1 percent of stabilizing agent. The invention adds matrix resin, polyphenylether of strong polarity and functional group of styrene-ethylene / butylene-styrene segmented copolymer, which effectively improves the compatibility of non-polar elastomer with polyphenylether; the invention also adds plasticizer, which reduces the hardness of the material and increases the flexibility; and through the optimization and interaction of the softening plasticizer and the flame-retardant plasticizer, the invention reduces the hardness and improves the tactility of the material, and the flame retardant performance is excellent.

Owner:NINGBO SHIP PLASTIC CO LTD

Polypropylene compositions for automotive parts

There are disclosed a polypropylene composition for automotive parts which has a melt index at 230° C. and at 2.16 kgf of at least 30 g / 10 minutes and which comprises 55 to 60% by weight of (1) propylene / ethylene block copolymer; 20 to 25% by weight of (2) rubber comprising a styrene / ethylene / propylene / styrene block copolymer and / or a styrene / ethylene / 1-butene / styrene block copolymer and an olefinic elastomer; and 18 to 23% by weight of (3) talc, and also an automotive part which comprises the above polypropylene composition.

Owner:TOYOTA JIDOSHA KK +1

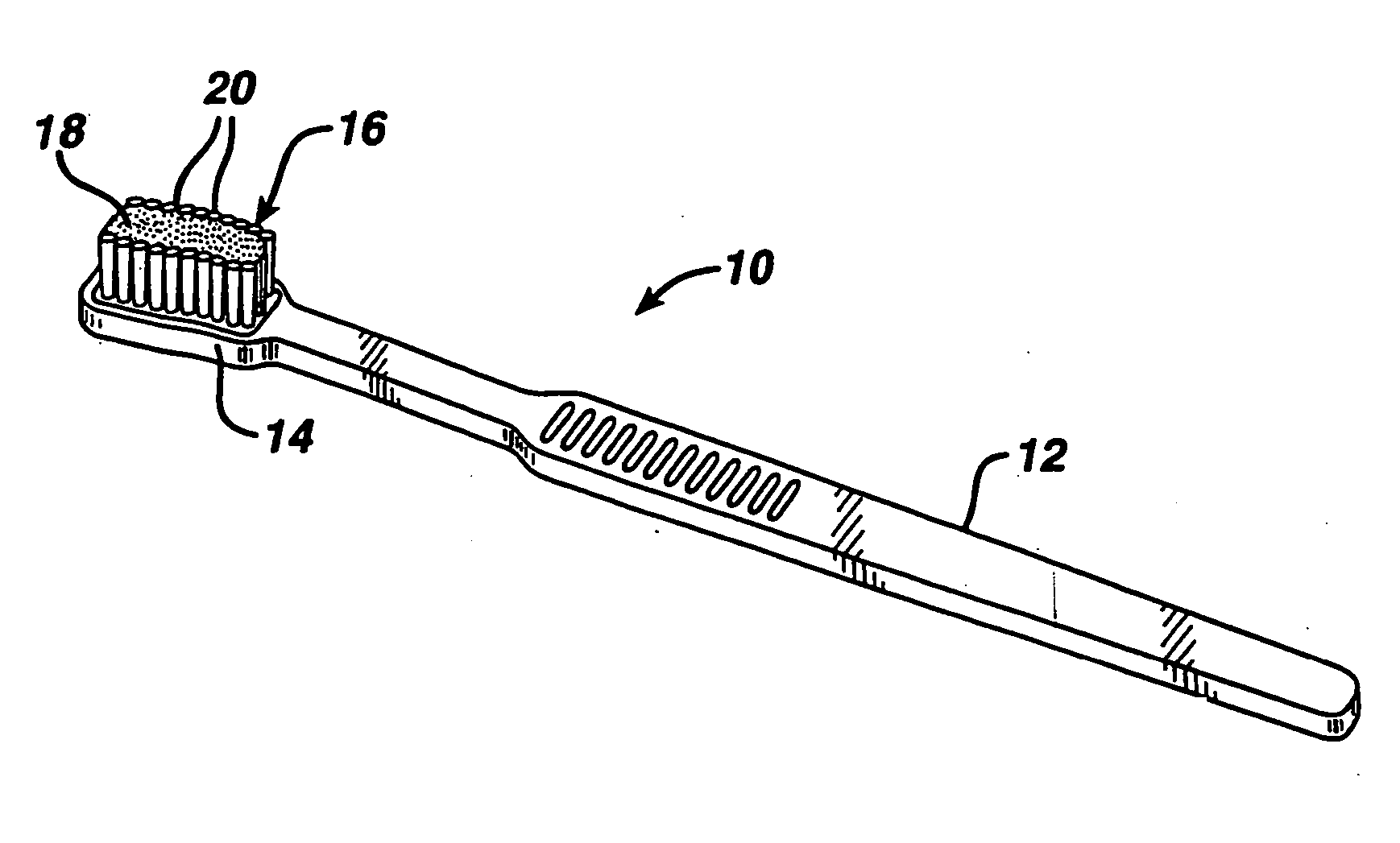

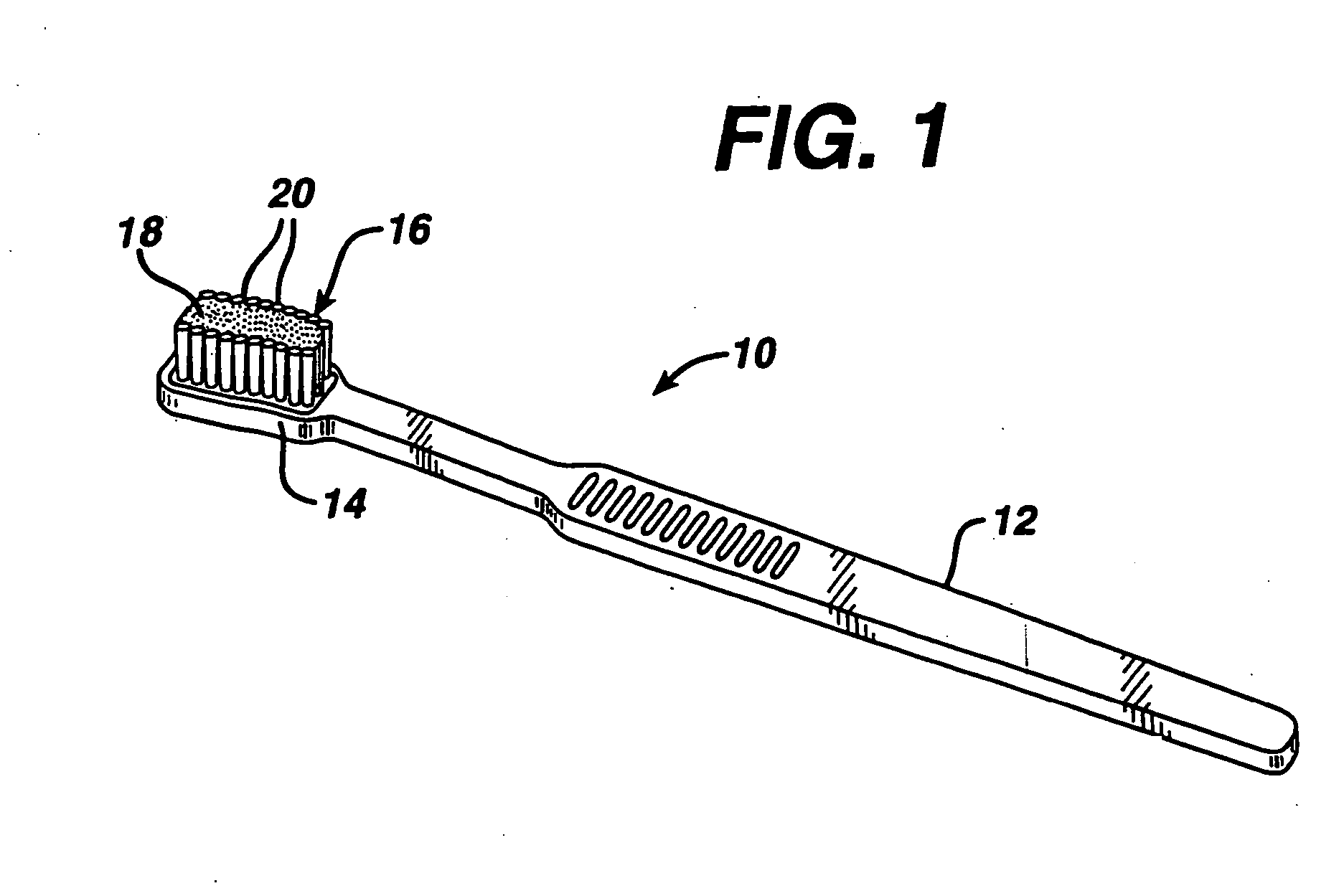

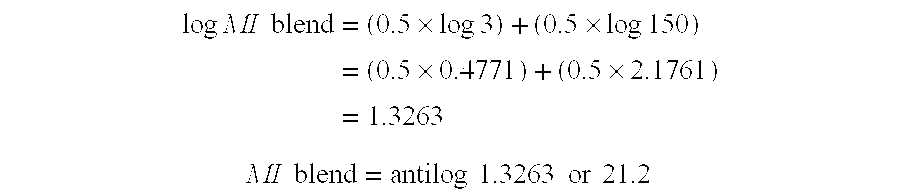

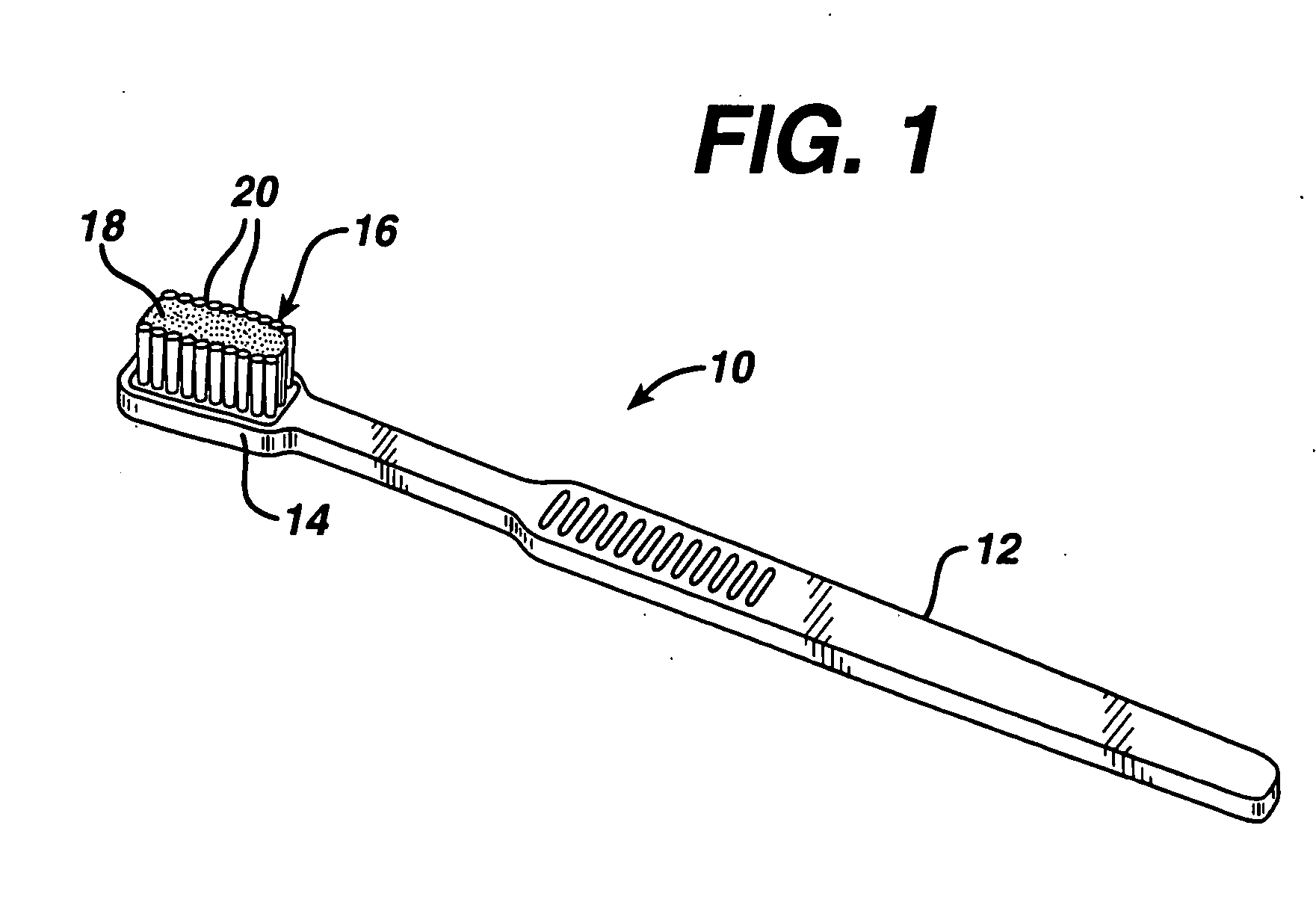

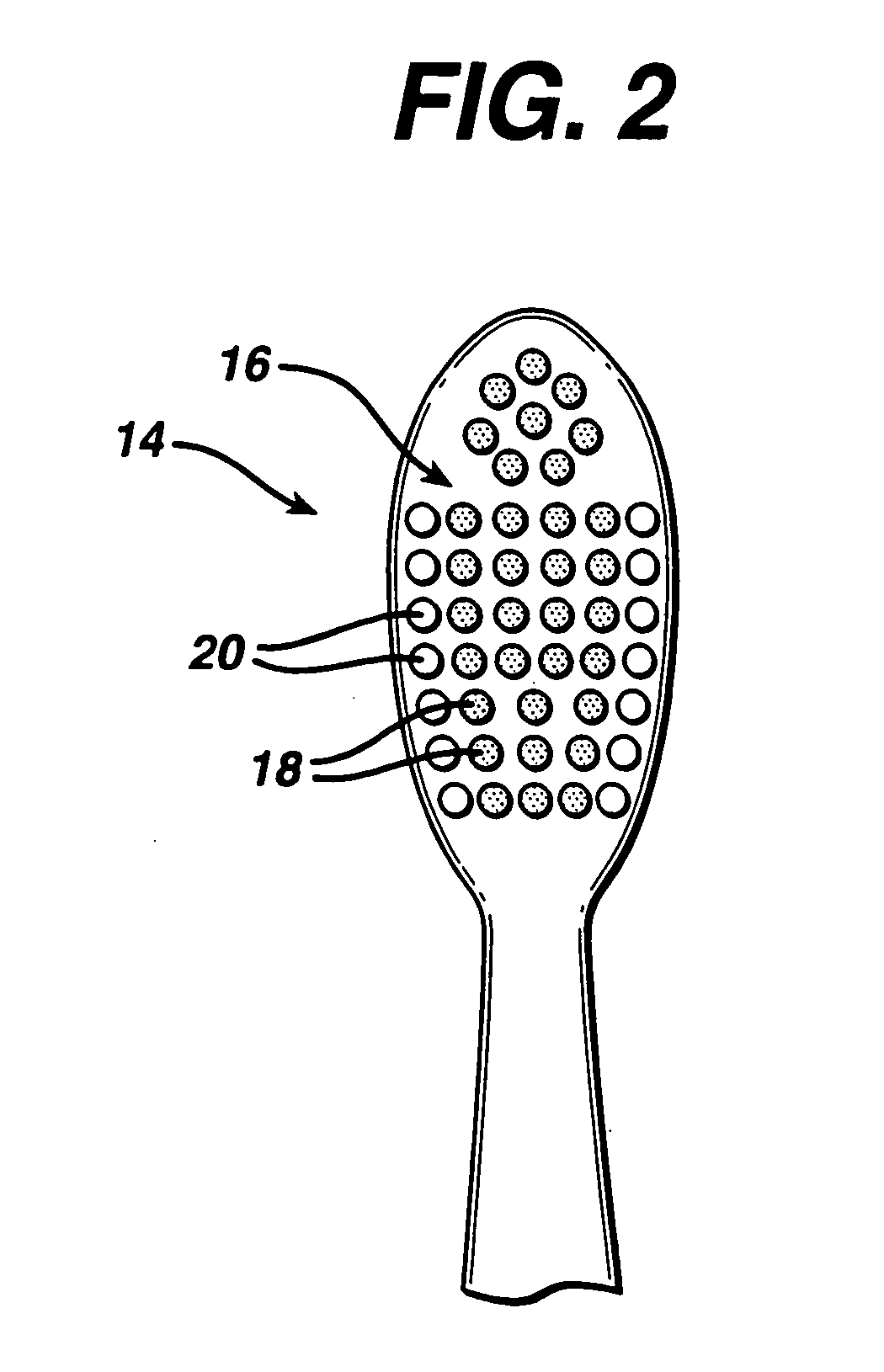

Gum-massaging oral brush

InactiveUS20060085931A1Decreasing the amount of plaque in the mouthReduce plaqueCarpet cleanersFloor cleanersElastomerPolyester

An oral brush is provided that includes an elongated body, a head portion extending from the body, and a plurality of bristles, formed of particular thermoplastic elastomers, extending from the body. In various embodiments, the thermoplastic elastomer has a Shore A hardness of at least 30; the thermoplastic elastomer is selected from the group consisting of polyetheramides, polyesters, styrene-ethylene-butylene-styrene block copolymers, polyurethanes, polyolefin elastomers, and mixtures thereof; and the thermoplastic elastomer has a flexural modulus of at least 5 MPa.

Owner:GILLETTE CANADA

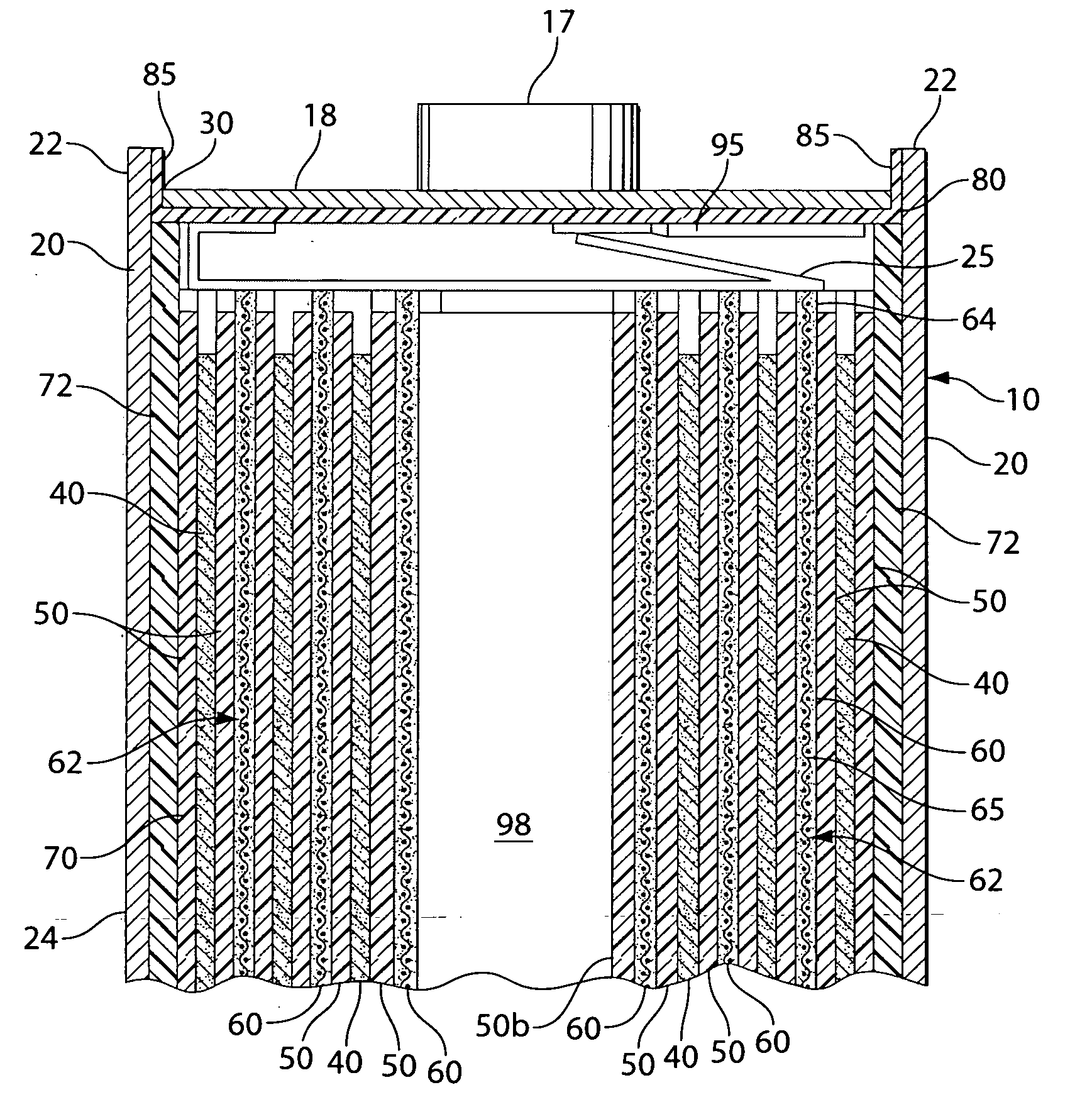

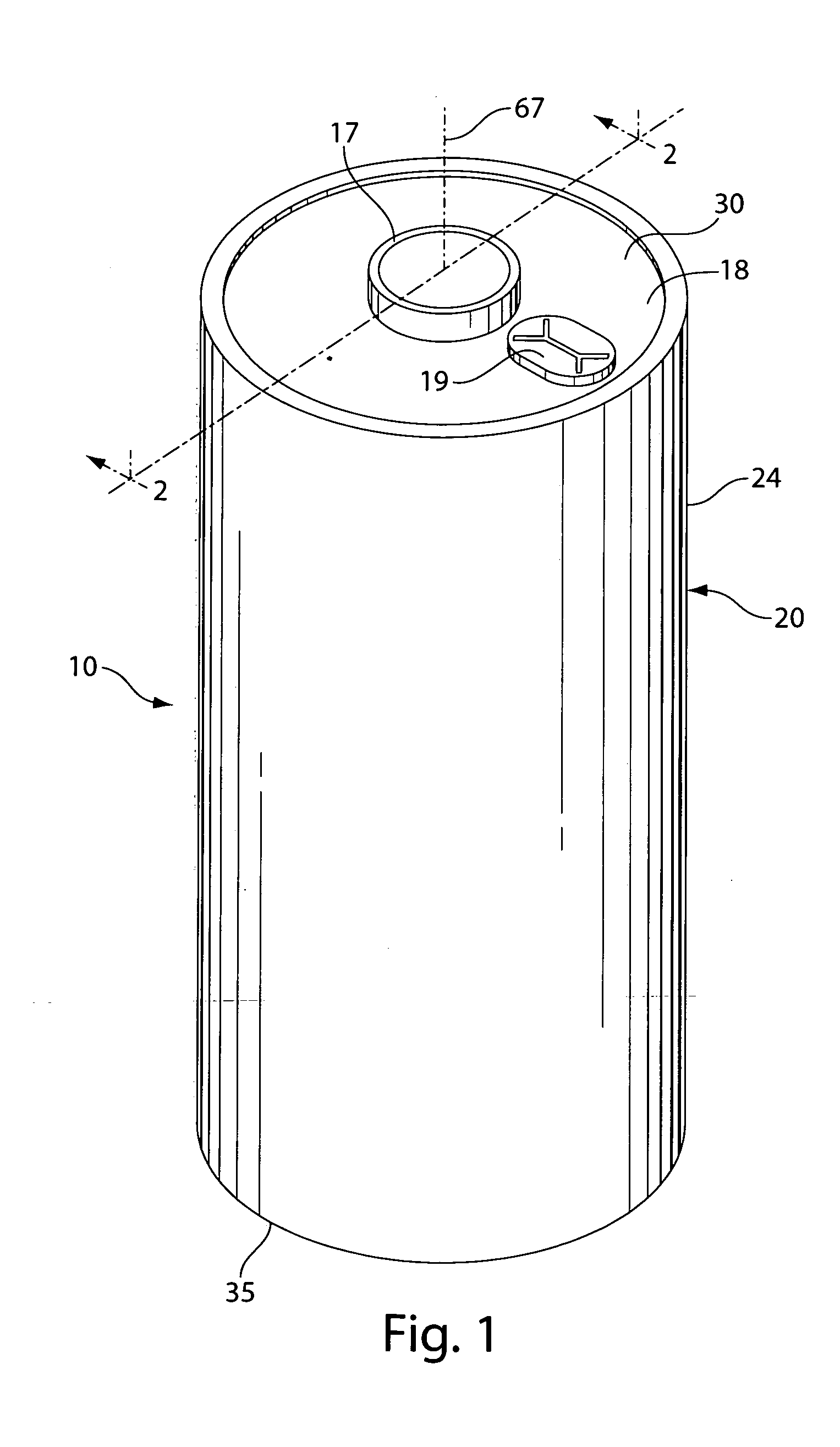

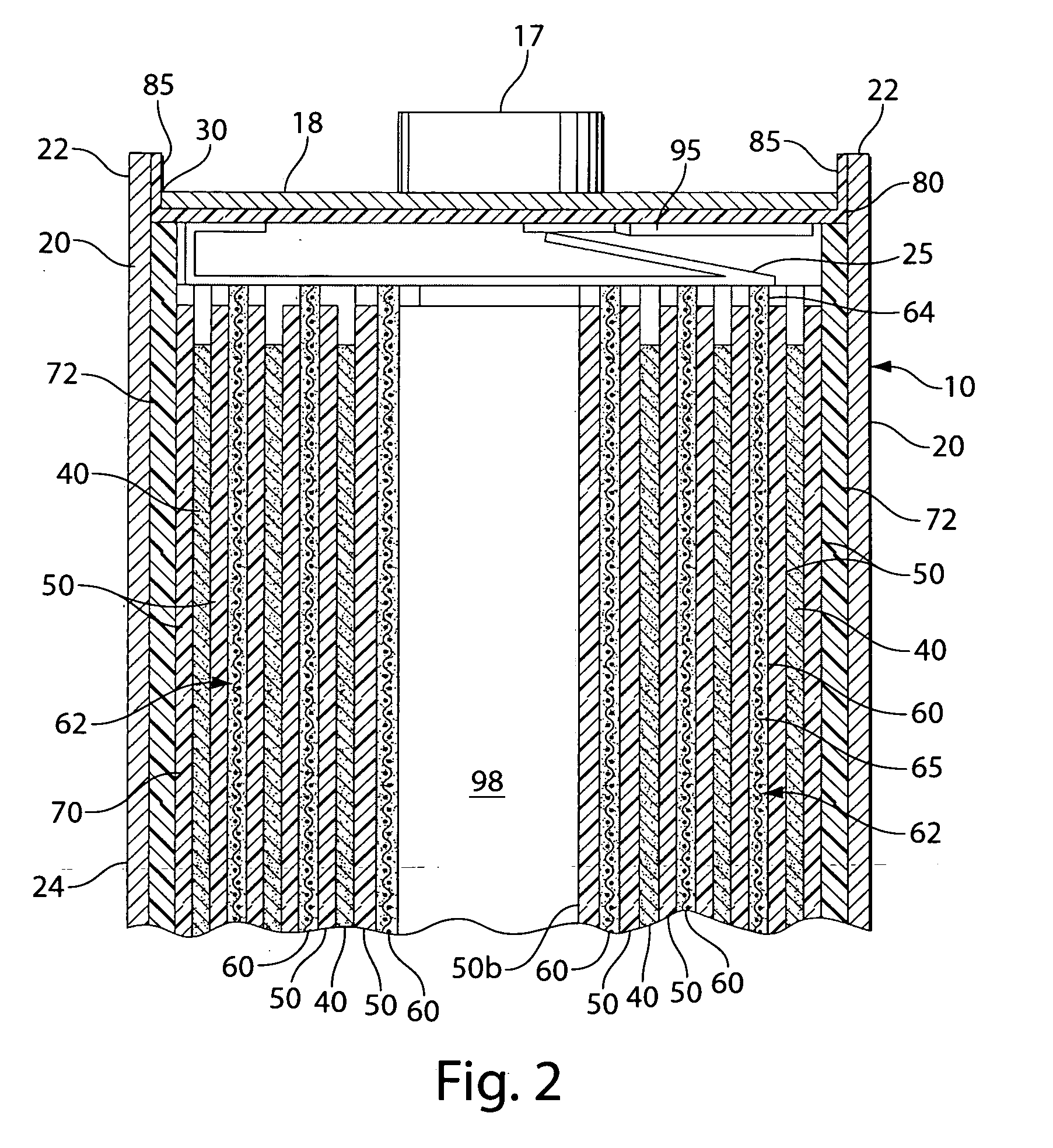

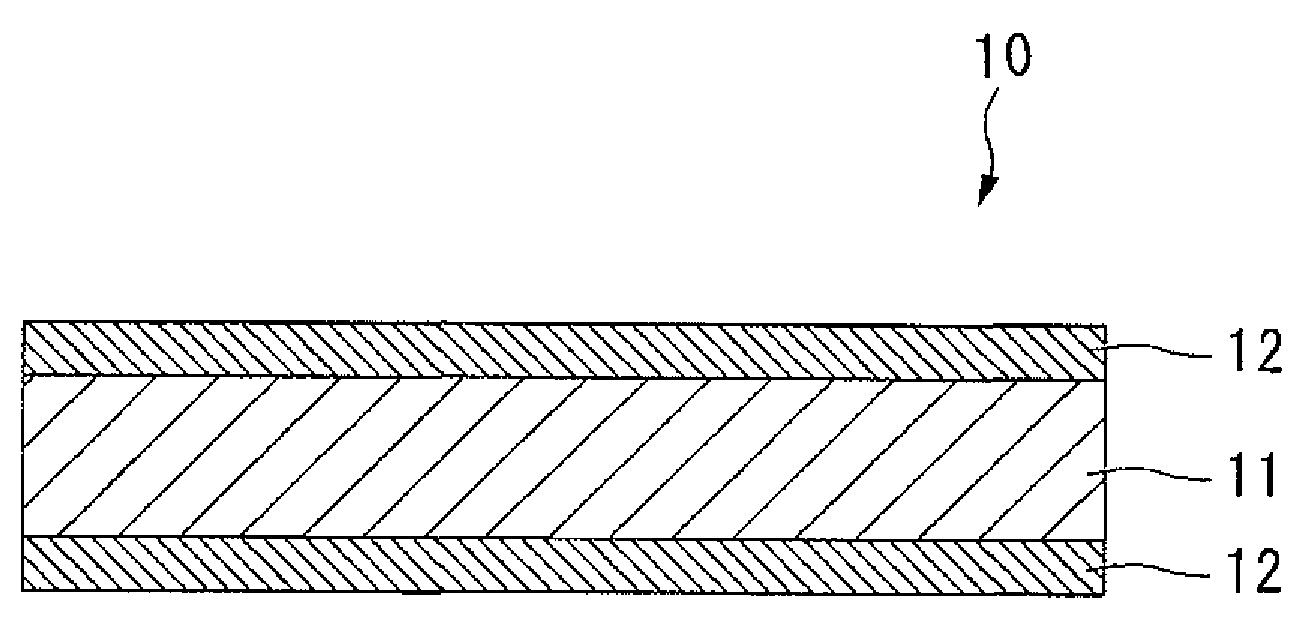

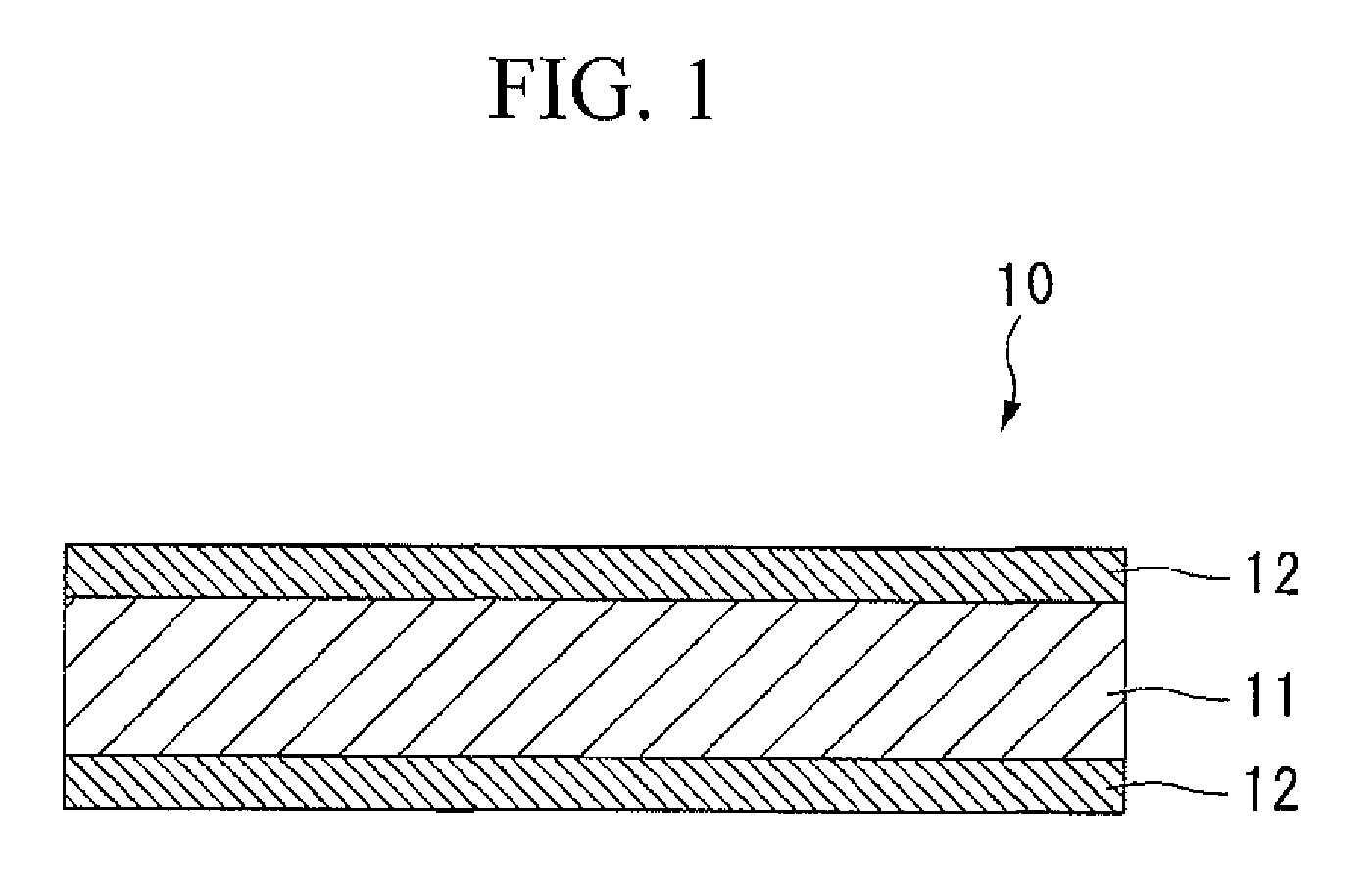

Method of preparing cathode containing Iron disulfide for a lithium cell

ActiveUS20090291366A1Improve discharge efficiencyUseful electrical energyFinal product manufactureOrganic electrolyte cellsPrimary cellAlloy

A primary cell having an anode comprising lithium or lithium alloy and a cathode comprising iron disulfide (FeS2) or a mixture of iron disulfide (FeS2) and iron sulfide (FeS) and conductive carbon particles. A cathode slurry is prepared comprising the FeS2 or FeS2 plus FeS powder, conductive carbon, binder, and a solvent. The binder is preferably a styrene-ethylene / butylene-styrene (SEBS) block copolymer. There is an advantage discovered in utilizing a hydronaphthalene solvent to form the cathode slurry. The preferred solvent is 1,2,3,4-tetrahydronaphthalene or decahydronaphthalene and mixtures thereof. The slurry mixture is coated onto a conductive substrate and the solvent evaporated leaving a dry cathode coating on the substrate. Higher drying temperature may be used resulting in a dry cathode coating which resists cracking. The anode and cathode can be spirally wound with separator therebetween and inserted into the cell casing with electrolyte then added.

Owner:DURACELL U S OPERATIONS

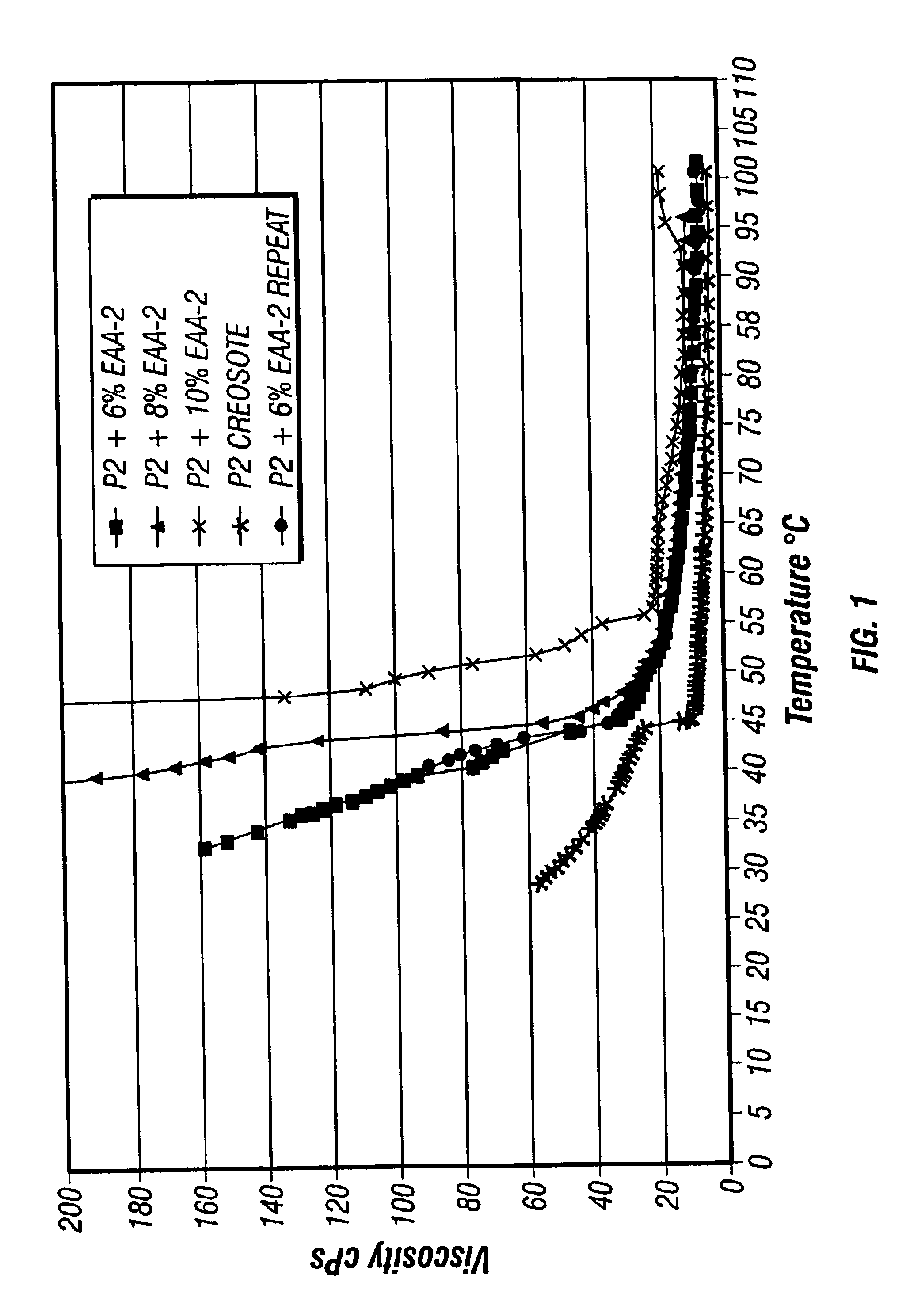

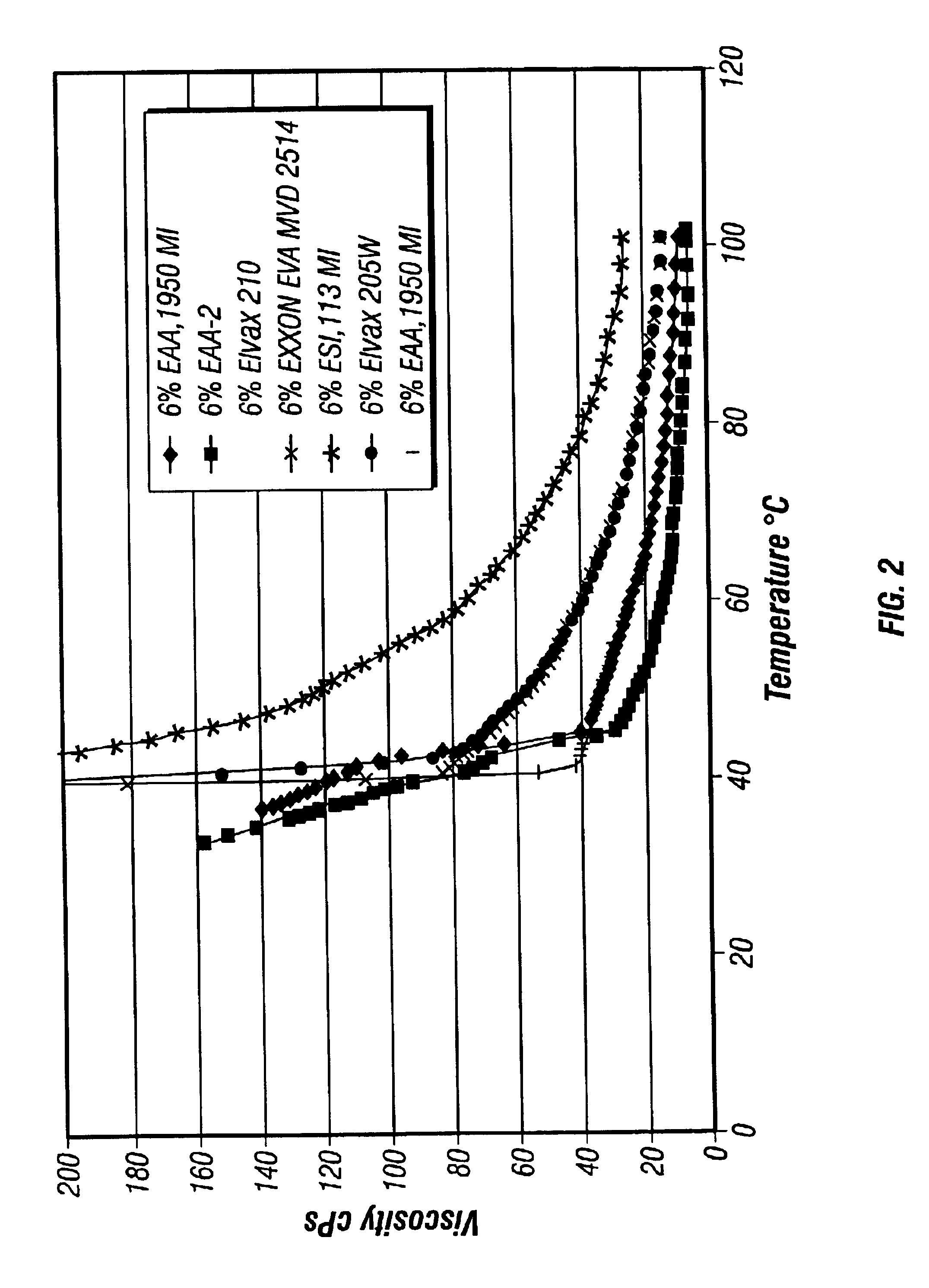

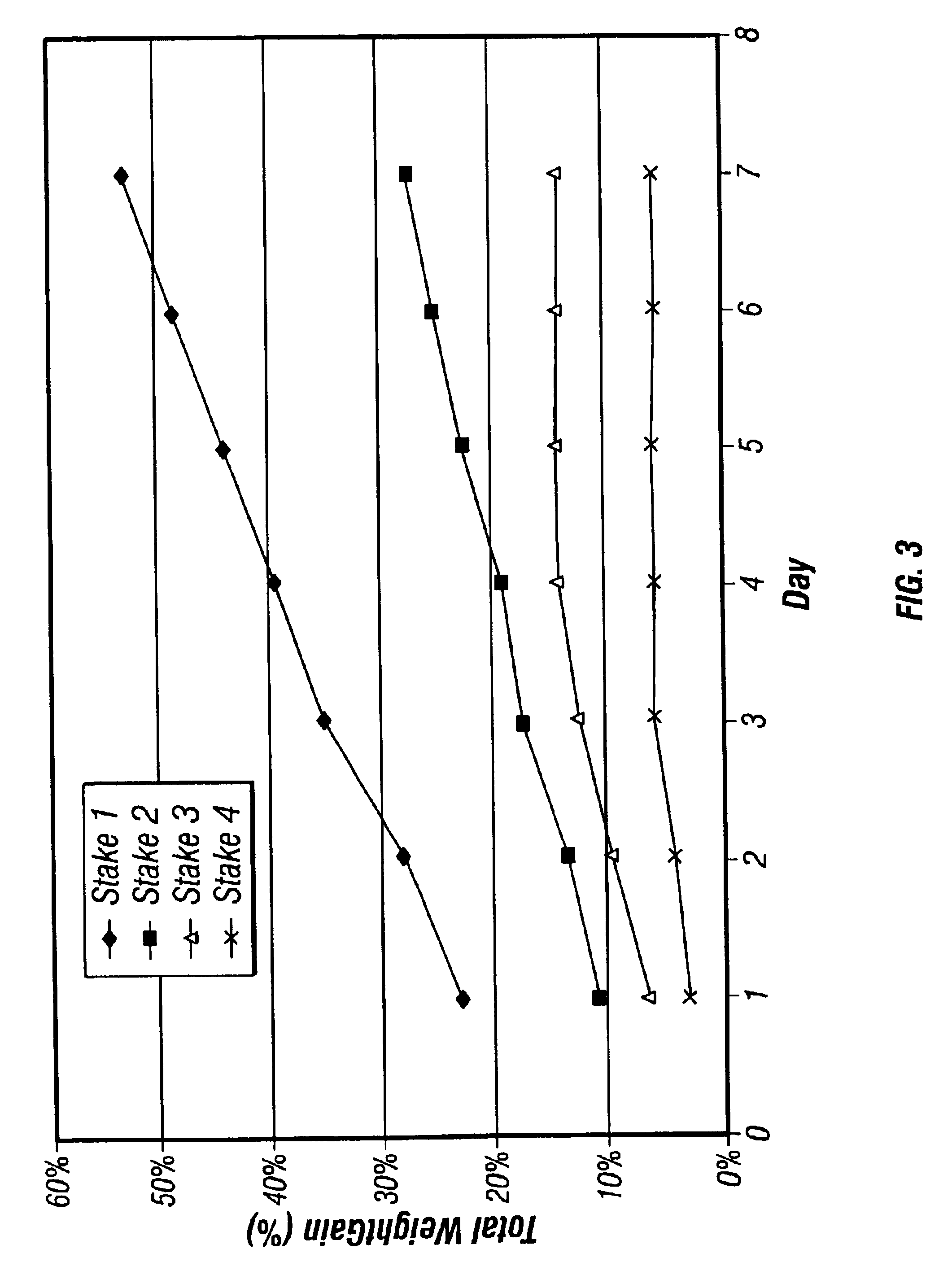

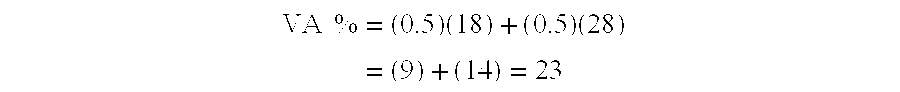

Wood treatment composition and method of use

A wood treatment composition for the preservation of wood comprises a mixture of creosote and a polymer which is miscible with the creosote at about 200° F. and does not substantially phase-separate when the wood treatment composition is under ambient conditions. The polymer may include, but is not limited to, ethylene vinyl acetate copolymers, ethylene methyl acrylate copolymers, ethylene ethyl acrylate copolymers, ethylene butyl acrylate copolymers, ethylene acrylic acid copolymers, ethylene methacrylic acid copolymers, ethylene methyl methacrylic acid copolymers, ethylene styrene interpolymers, styrene acrylic acid copolymers, styrene methacrylic acid copolymers, styrene methyl acrylate copolymers, styrene butadiene styrene block copolymers, styrene ethylene butylene styrene block copolymers, or a blend thereof. Preferably, the creosote is present in an amount of at least 50 percent by weight of the composition. Such compositions can be used to treat wood surfaces to prolong the service life of the wood.

Owner:DOW GLOBAL TECH LLC

Hot melt adhesive composition

A hot melt adhesive composition includes ethylene vinyl acetate copolymer(s) having average vinyl acetate content of from about 10% to about 30%, styrene-ethylene-butylene-styrene block copolymer, tackifying resin, and optionally, a plasticizer or a wax.

Owner:H B FULLER LICENSING & FINANCING INC

Gum massaging oral brush

InactiveUS20070234496A1Increase stimulationEasy to cleanCarpet cleanersBrush bodiesElastomerPolyester

An oral brush is provided that includes an elongated body, a head portion extending from the body, and a plurality of bristles, formed of particular thermoplastic elastomers, extending from the body. In various embodiments, the thermoplastic elastomer has a Shore A hardness of at least 30; the thermoplastic elastomer is selected from the group consisting of polyetheramides, polyesters, styrene-ethylene-butylene-styrene block copolymers, polyurethanes, polyolefin elastomers, and mixtures thereof; and the thermoplastic elastomer has a flexural modulus of at least 5 MPa.

Owner:GILLETTE CANADA

Heat shrinkable multi-layer film and method for preparing the same

InactiveUS20080124563A1Strength of film is ensuredGuaranteed StrengthLamination ancillary operationsSynthetic resin layered productsEngineeringPolypropylene

A heat shrinkable multi-layer film including an intermediate layer containing polypropylene, and outer layers formed on both sides of the intermediate layer, wherein the outer layers contain a styrene-butadiene-styrene block copolymer, polypropylene, and a styrene-ethylene-propylene-styrene block copolymer or styrene-ethylene-butylene-styrene block copolymer.

Owner:CI KASEI COMPANY

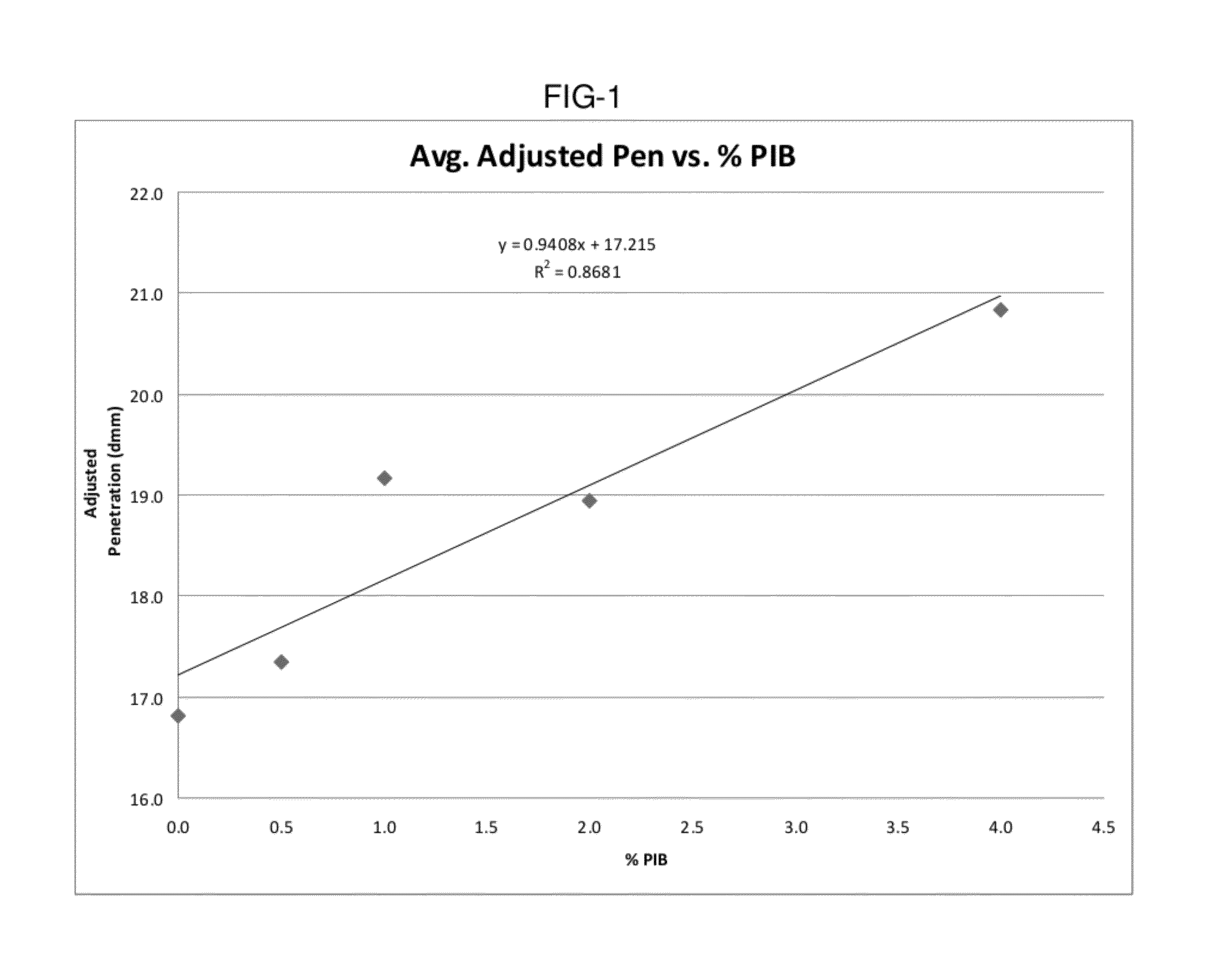

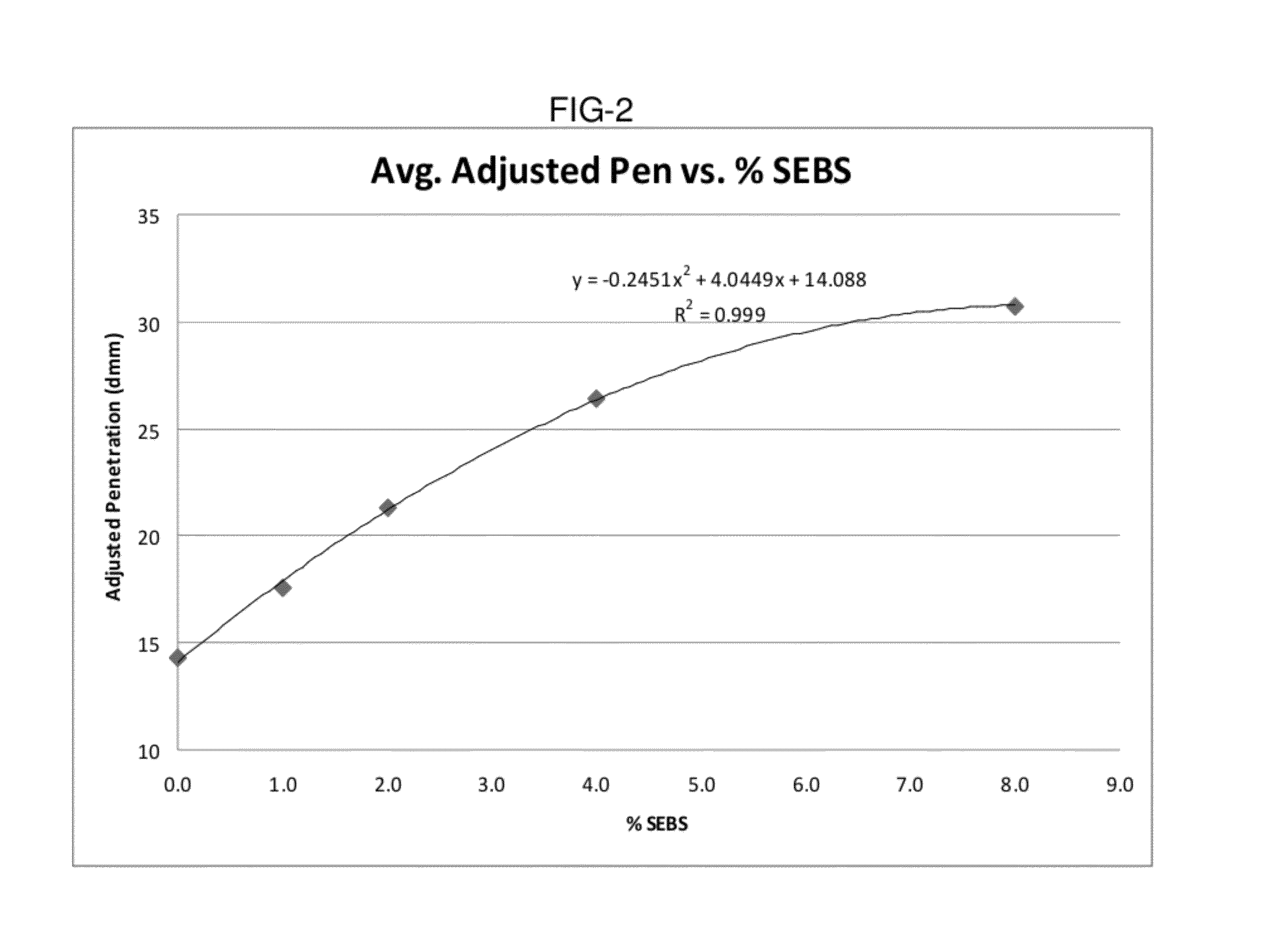

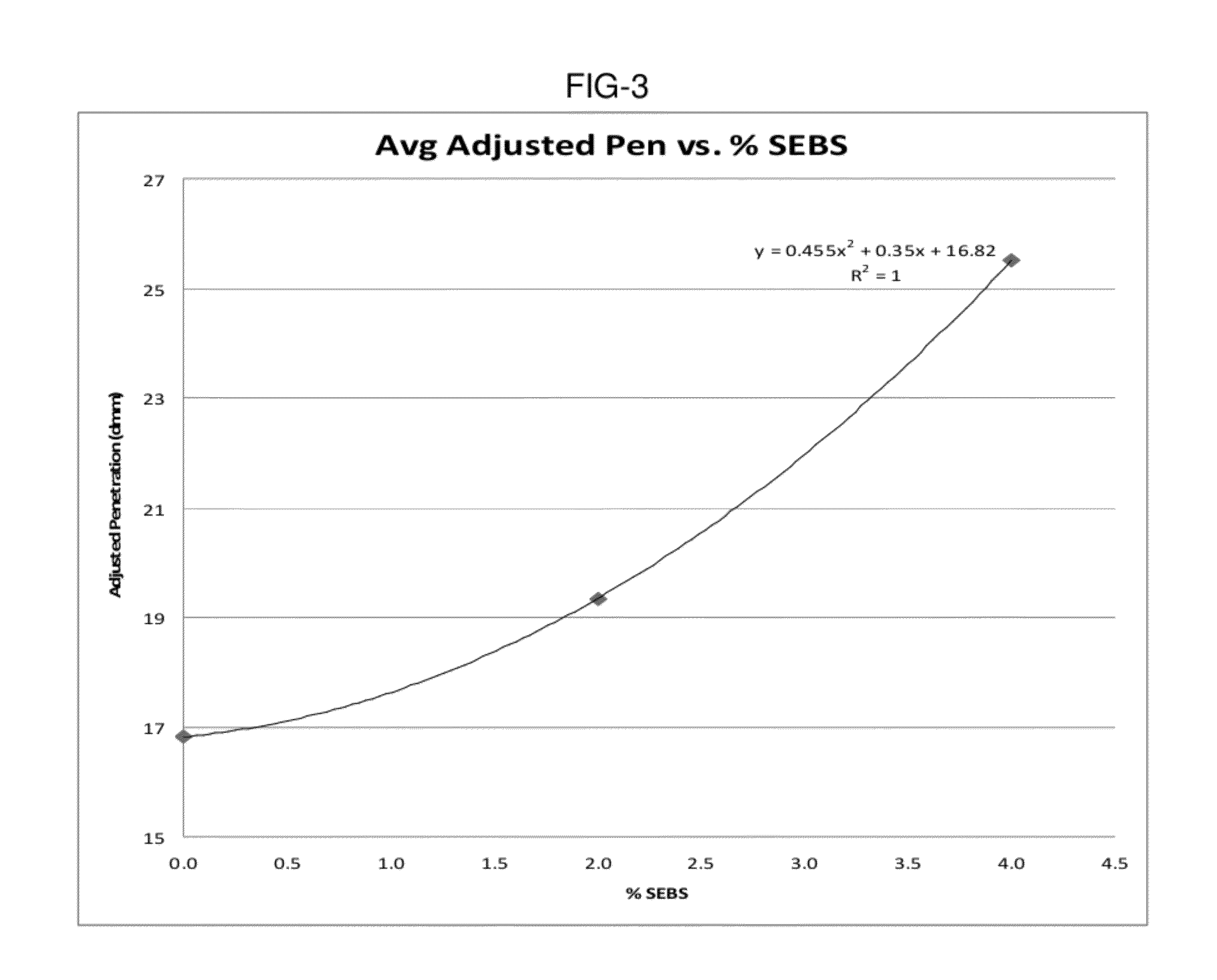

Preparation of industrial asphalt

ActiveUS20120302673A1Increase capacityReduce environmental impactRoof covering using tiles/slatesBuilding insulationsPolymer scienceAsphalt

The present invention relates to a method for preparing an industrial asphalt comprising sparging an oxygen containing gas through an asphalt flux in the presence of 0.25 weight percent to about 12 weight percent of a highly saturated rubbery polymer at a temperature within the range of about 400° F. to about 550° F. for a period of time which is sufficient to increase the softening point of the asphalt flux to a value which is within the range of 185° F. to 250° F. and a penetration value of at least 15 dmm to produce the industrial asphalt. The highly saturated rubbery polymer can be a styrene-ethylene / butylene-styrene block copolymer rubber or a highly saturated styrene-ethylene / propylene-styrene block copolymer rubber.

Owner:BMIC LLC

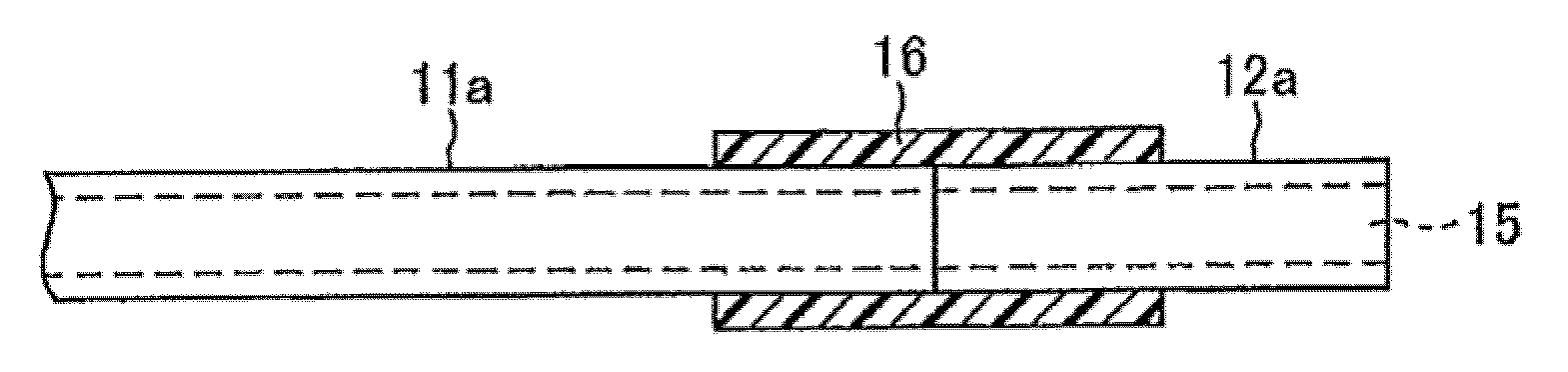

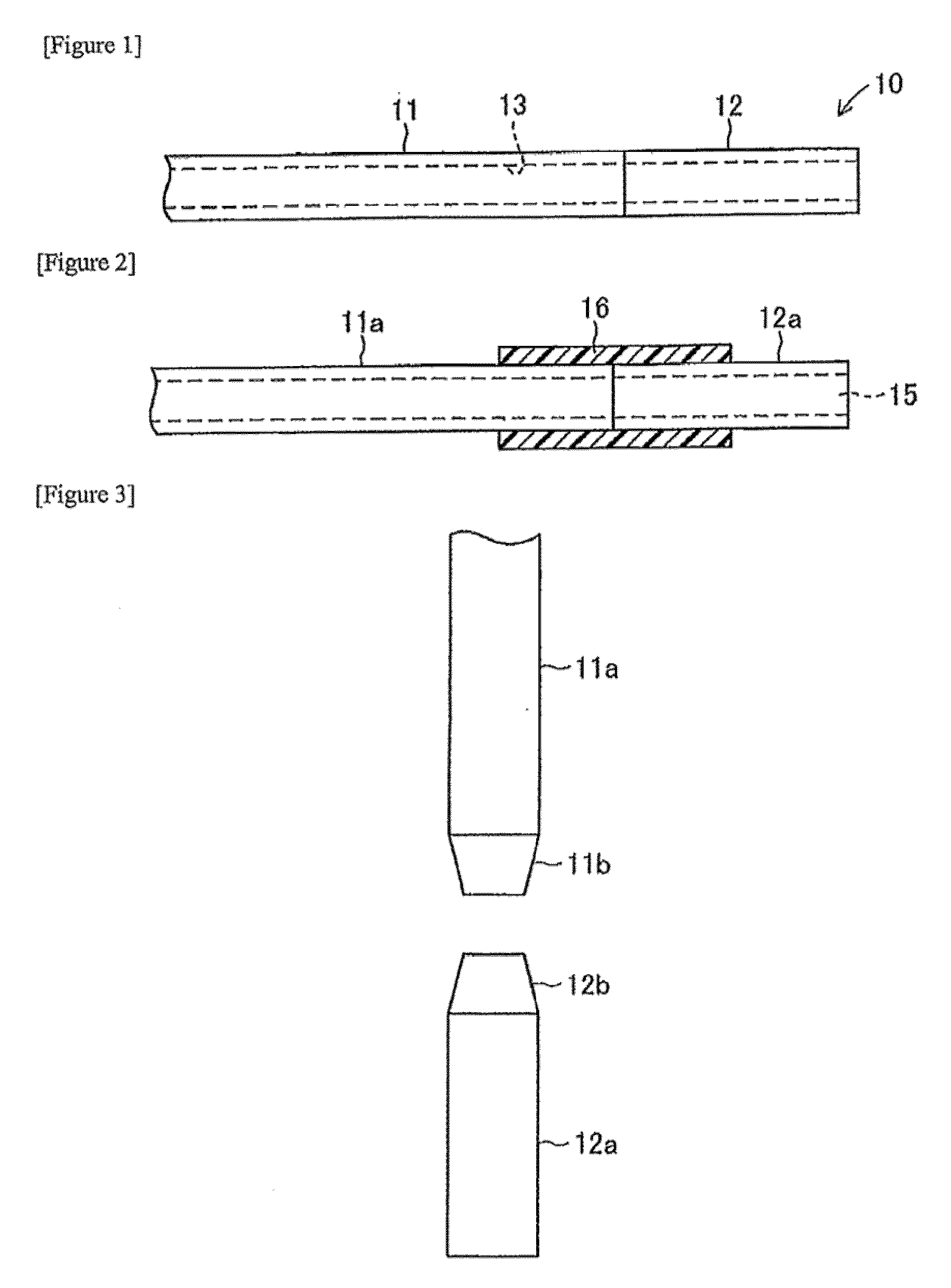

Medical Tubing with a Flexible Tip and Method of Preparation

InactiveUS20100063477A1LaminationLamination apparatusPolypropyleneStyrene-ethylene-butylene-styrene-block copolymer

Medical tubing having a flexible tip comprising medical tubing formed from a polyurethane resin, and a flexible tip formed from a mixture comprising a styrene-ethylene-butylene-styrene block copolymer, polypropylene, polyurethane, and mineral oil. The flexible tip may be formed from a mixture that comprises 20-40% by weight of the styrene-ethylene-butylene-styrene block copolymer, a total of 15-50% by weight of polypropylene and polyurethane, and 30-45% by weight of mineral oil. Also, a method for producing medical tubing having a flexible tip comprising medical tubing formed from a polyurethane resin, and a flexible tip formed from a mixture comprising a styrene-ethylene-butylene-styrene block copolymer, polypropylene, polyurethane, and mineral oil, comprising fusion bonding the medical tubing and the flexible tip.

Owner:TYCO HEALTHCARE GRP LP

Reflective insulating fire-retardant coating for waterproof roll, and preparation method and use thereof

ActiveCN103173088AImprove fire safetyImprove insulation effectFireproof paintsRoof covering using flexible materialsPolymer scienceAcrylic resin

The invention relates to a reflective insulating fire-retardant coating for a waterproof roll, and a preparation method and use thereof. The coating comprises the following material formulas by weight percent of 20-25% of styrene-ethylene-butene-styrene butadiene styrene block copolymer, 8-15% of terpene resin, 5-10% of acrylic resin, 10-15% of n-butyl acetate, 10-15% of titanium dioxide, 1-8% of hollow microsphere, 5-8% of halogen-free flame retardant phosphate, 5-10% of antimonous oxide, 5-15% of talcum powder, 0.5-1% of antioxidant, 0.3-0.8% of defoamer, and 20-35% of 200# solvent oil, wherein the sum of weight percents of all materials is 100%. The coating disclosed by the invention can be directly matched with the waterproof roll, has an excellent insulating fire-retardant property, and can be used for effectively improving the fire security and the thermal insulating property of the rolled roofing material.

Owner:中建材苏州防水研究院有限公司

High viscosity modified asphalt for water draining pavement and preparation method thereof

The invention relates to a high viscosity modified asphalt which comprises the following constituents (by weight ratio): asphalt 100, styrene-polyethylene / butylene-styrene segmented copolymer 3-12 having an average molecular weight of 30-350 thousand, petroleum resin 5-40 with a softening point of 70-150 deg C. By mixing styrene-ethane / butylenes-styrene segmented copolymer and petroleum resin into the asphalt, high viscosity, good dispersity and stability can be achieved, the PG classification can reach 82-28. The obtained high-performance modified asphalt can be used for both the general water seeping pavements, and specific sites such as bridge pavement and stress absorption layer.

Owner:SHANGHAI QUNKANG ASPHALTUM TECH CO LTD

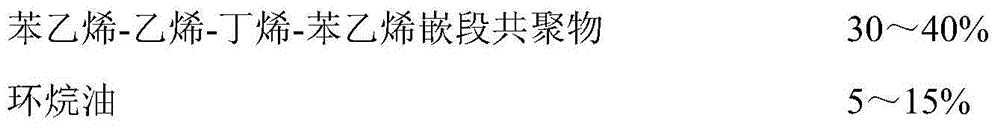

Thermoplastic elastomer composition with low TVOC and low Fogging for automotive trim and preparation method of thermoplastic elastomer composition

InactiveCN104927285AAnti-slip, vibration and noise reductionLight weightElastomerThermoplastic elastomer

The invention relates to a thermoplastic elastomer composition with low TVOC and low Fogging for automotive trim and a preparation method of the thermoplastic elastomer composition. The thermoplastic elastomer composition is prepared from the following raw materials with the following content in percentage by weight: 30-40% of styrene-ethylene-butylene-styrene block copolymers, 5-15% of naphthenic oil, 35-45% of alkene block copolymers, 5-15% of homopolymerized polypropylene and 0.1-0.2% of an antioxidant. The thermoplastic elastomer composition disclosed by the invention has the advantages that Infuse 9807 and SEBS are added for compounding, the Infuse 9807 novel alkene block copolymers (OBC) enable the high-low temperature compression and the deformation without separation of the excellent properties of elastomers after modification by polyblending to be improved, the Infuse 9807 novel alkene block copolymers and PP are in stable secondary injection molding and bonding or direct injection molding, when the thermoplastic elastomer composition is used as components of the automotive trim, the thermoplastic elastomer composition can be used for a long time, separation cannot be generated, the thermoplastic elastomer composition is a non-toxic harmless environment-friendly material for human bodies and environment, the thermoplastic elastomer composition completely passes the inspection according to the standard of 'Air Qualitative Assessment Guide in Passenger Vehicle' (GB / These 7630-2011) and meet the using requirements of automotive trim workpieces.

Owner:中广核俊尔(上海)新材料有限公司

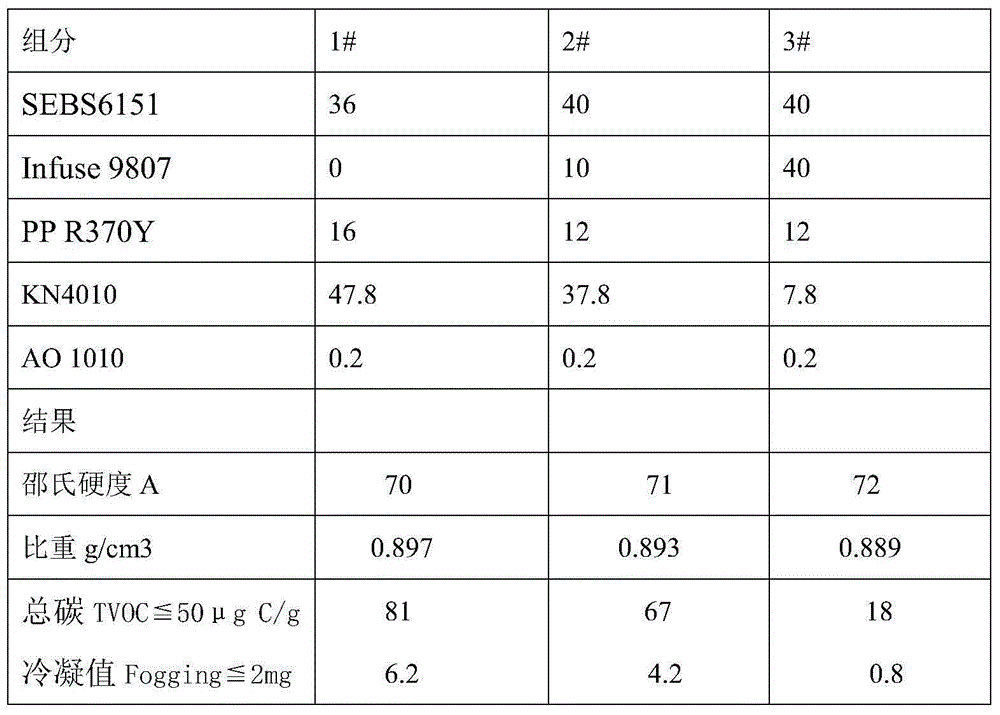

Baby product TPE (Thermoplastic Elastomer) and preparation method of baby product TPE

The invention discloses a baby product TPE (Thermoplastic Elastomer) and a preparation method of the baby product TPE, and solves the problems that: adding a plasticizer in the TPE material causes baby allergies easily, and as the plasticizer contains phthalate ester in environmental estrogen and forms pseudo-hormone easily, the hormone content in the body is affected, the original mechanism of internal secretion is further disturbed and the endocrine dyscrasia of a baby is caused. The key point of the technical scheme is as follows: the material of the baby product TPE comprises the following components by mass: 20-40 parts of SEBS (Styrene Ethylene Butylene Styrene block copolymer), 50-60 parts of cosmetics grade white oil, 5-15 parts of shell powder, 5-15 parts of polyolefin, 5-10 parts of a compatilizer, 0.5-1.5 parts of a slipping agent, 0.1-0.3 part of an antioxygen, 0.1-0.2 part of an antiaging agent and 0.1-0.5 part of an antibacterial agent, no plasticizer is added, and the condition that the allergy of the baby skin is caused by the addition of the plasticizer is avoided.

Owner:余姚优信塑业有限公司

Anti-flaming polyamide composite material with good printing performance and preparation method thereof

The invention relates to the field of high polymer materials, and particularly discloses an anti-flaming polyamide composite material with good printing performance. The anti-flaming polyamide composite material is prepared from the following raw materials in parts by weight: 30 to 90 parts of polyamide resin, 1 to 20 parts of polybenzimidazole, 3 to 15 parts of ethylene-vinyl acetate copolymer, 1 to 10 parts of SEBS (Styrene-Ethylene-Butylene-Styrene Block Copolymer), 1 to 15 parts of maleic anhydride modified polypropylene, 1 to 15 parts of cyclodextrin-polyethylene glycol composite, 1 to 10 parts of liquid paraffin, 1 to 10 parts of filler, 0.5 to 1 part of brominated flame retardant and 0.5 to 3 parts of synergistic flame retardant.

Owner:上海耐特复合材料制品有限公司

Waterproof paint

InactiveCN101993660AIncrease elasticityGood low temperature flexibilityRubber derivative coatingsConjugated diene hydrocarbon coatingsManganeseSolvent

The invention discloses a waterproof paint which comprises thermoplastic styrene-butadiene rubber, asphalt and solvent oil. The waterproof paint also comprises drier and filler, wherein the drier is composed of one or more oxides of cobalt, manganese, zinc and calcium; and the filler is talcum powder, fly ash, pulverized asbestos, vermiculite powder, mica powder, heavy calcium carbonate or light calcium carbonate. Due to the adoption of styrene-ethylene-butylene-styrene block copolymer (SEBS), the waterproof paint of the invention has the advantages of excellent elasticity, low-temperature flexibility, low temperature resistance and aging resistance, and does not flow at high temperature, thereby improving the quality of products and widening the use temperature range of the products.

Owner:张轶

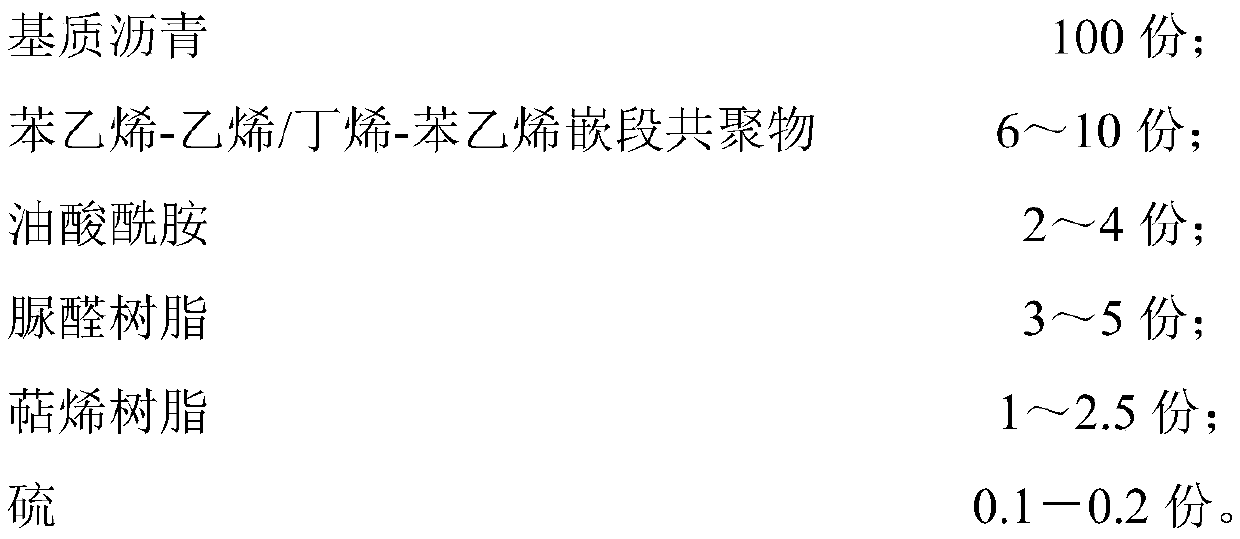

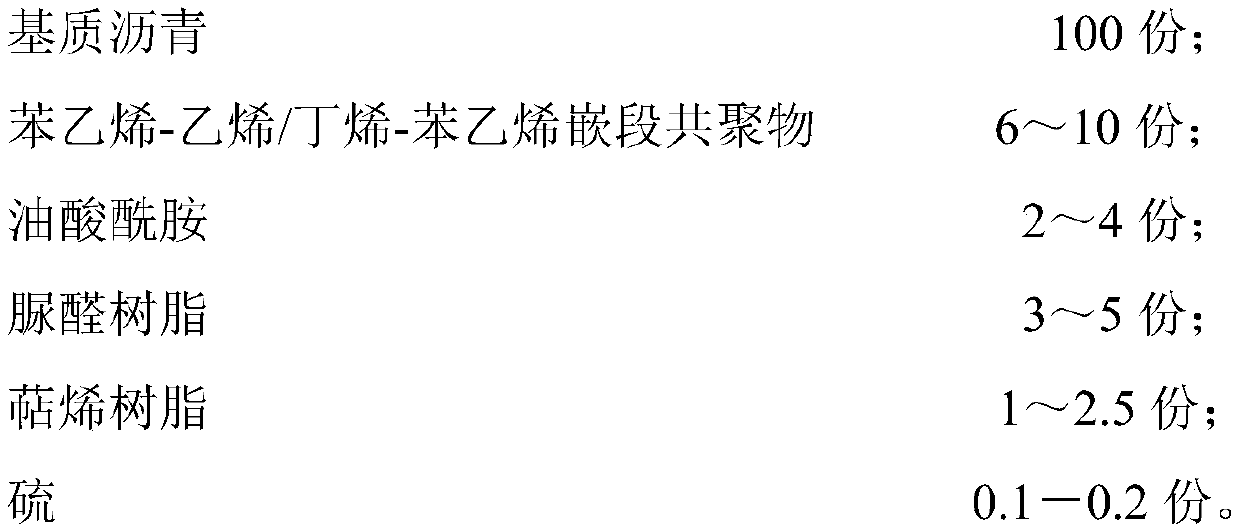

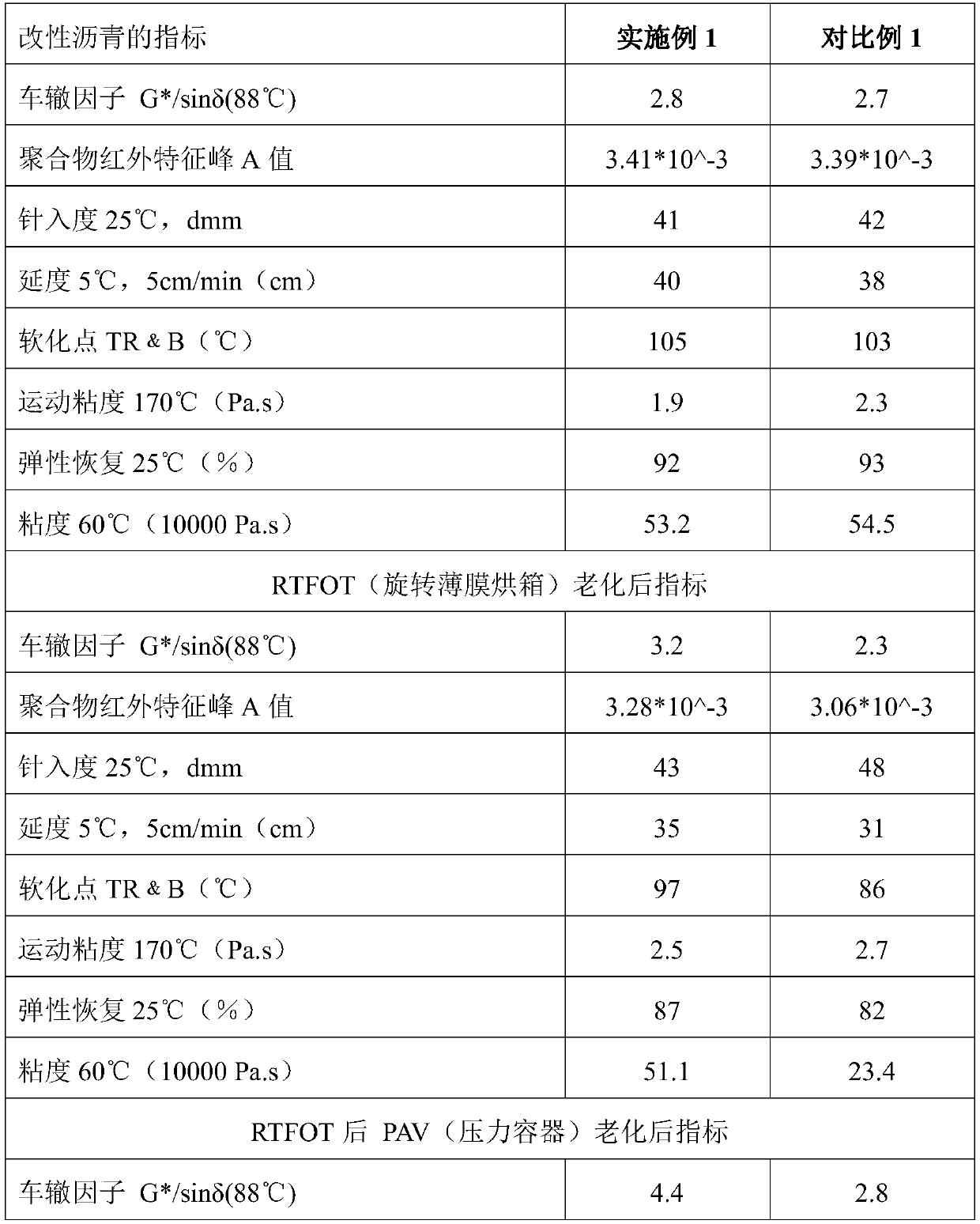

Modified asphalt for warm-mixed thin overlay and preparation method and application thereof

InactiveCN111205663AHigh viscosityGood anti-scatter performanceBuilding insulationsPolymer scienceActive agent

The invention relates to modified asphalt for a warm-mixed thin overlay and a preparation method and application thereof. The modified asphalt is prepared from the following raw material components: matrix asphalt, a styrene-ethylene / butylene-styrene block copolymer, oleamide, urea resin, terpene resin and sulfur. Compared with the prior art, the styrene-ethylene / butylene-styrene block copolymer and the urea resin are introduced into the asphalt composition, and the anti-aging agent or stabilizer terpene resin and sulfur are further added, so that the bonding strength between asphalt and aggregate is improved, the high-viscosity asphalt composition is ensured to have extremely excellent water loss resistance, and the warm-mixed thin overlay can still have good anti-scattering performance and anti-aging performance after being used for many years; and meanwhile, oleamide is added to achieve the effect of a surfactant, and it can be guaranteed that the modified asphalt special for the warm-mixed thin overlay has good workability in the construction process.

Owner:成都交通投资集团有限公司

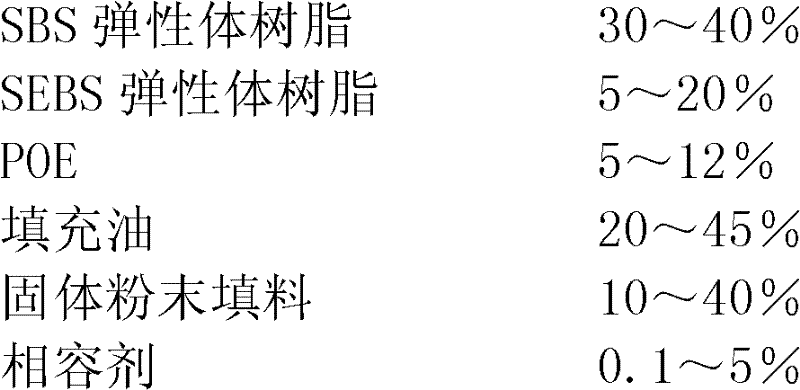

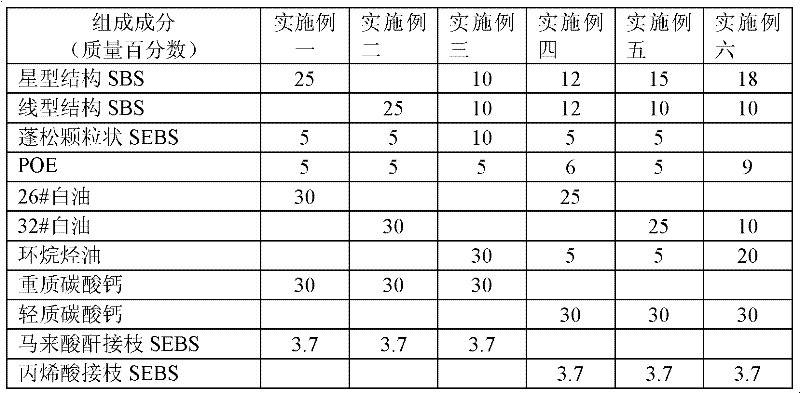

Field hokey injection molding material and preparation method thereof

InactiveCN102408662AMeet the requirements of environmental regulationsFlat surfaceElastomerPolyolefin

The invention relates to a field hokey injection molding material and a preparation method thereof. The field hokey injection molding material is characterized by comprising the following components by mass percent: 30-40% of SBS (styrene-butadiene-styrene block copolymer) elastomer resin, 5-20% of SEBS (hydrogenated styrene-ethylene-butylene-styrene block copolymer) elastomer resin, 5-12% of POE (polyolefin elastomer), 20-45% of extending oil, 10-40% of solid powder filling material, 0.1-5% of compatilizer, 0.1-2% of antioxidant and 0.01-2% of processing aid.

Owner:江苏安格特新材料科技有限公司 +1

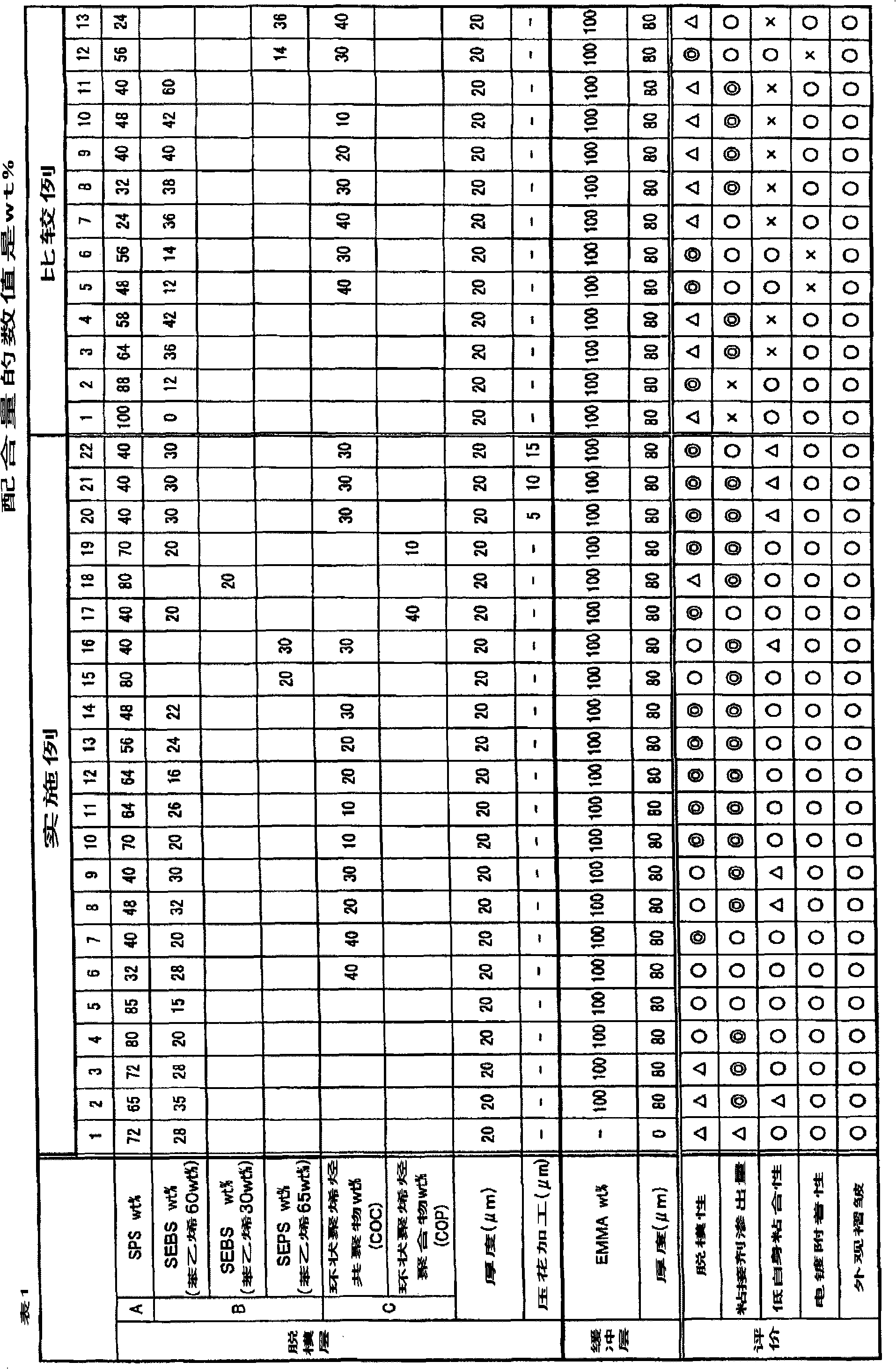

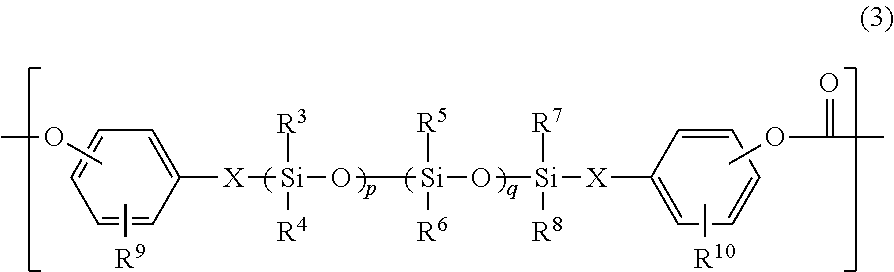

Mold release film

InactiveCN101778887AImprove features"Excellent landfillability" in the characteristicsFilm/foil adhesivesSynthetic resin layered productsPolyolefinThermoplastic elastomer

Disclosed is a practical mold release film which has excellent embeddability, while maintaining excellent properties of a mold release film using a syndiotactic polystyrene. Specifically disclosed is a mold release film having a mold release layer containing a syndiotactic polystyrene and a hydrogenated styrene thermoplastic elastomer. This mold release film is characterized in that the blending ratio of the hydrogenated styrene thermoplastic elastomer relative to the entire resin of the mold release layer is within the range of 15-35 wt%. The hydrogenated styrene thermoplastic elastomer is preferably (i) a styrene-ethylene-butylene-styrene block copolymer or (ii) a styrene-ethylene-propylene-styrene block copolymer. The mold release layer may further contain a cyclic polyolefin resin.

Owner:SUMITOMO BAKELITE CO LTD

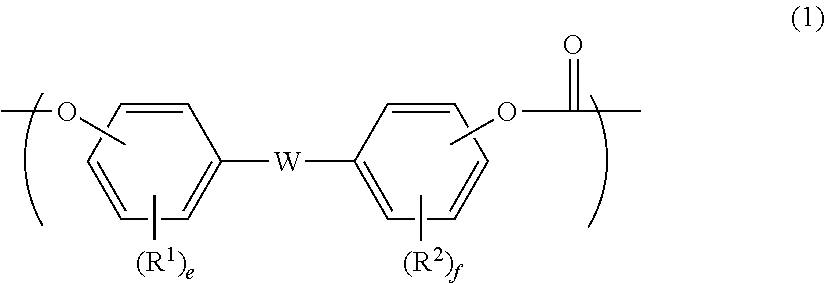

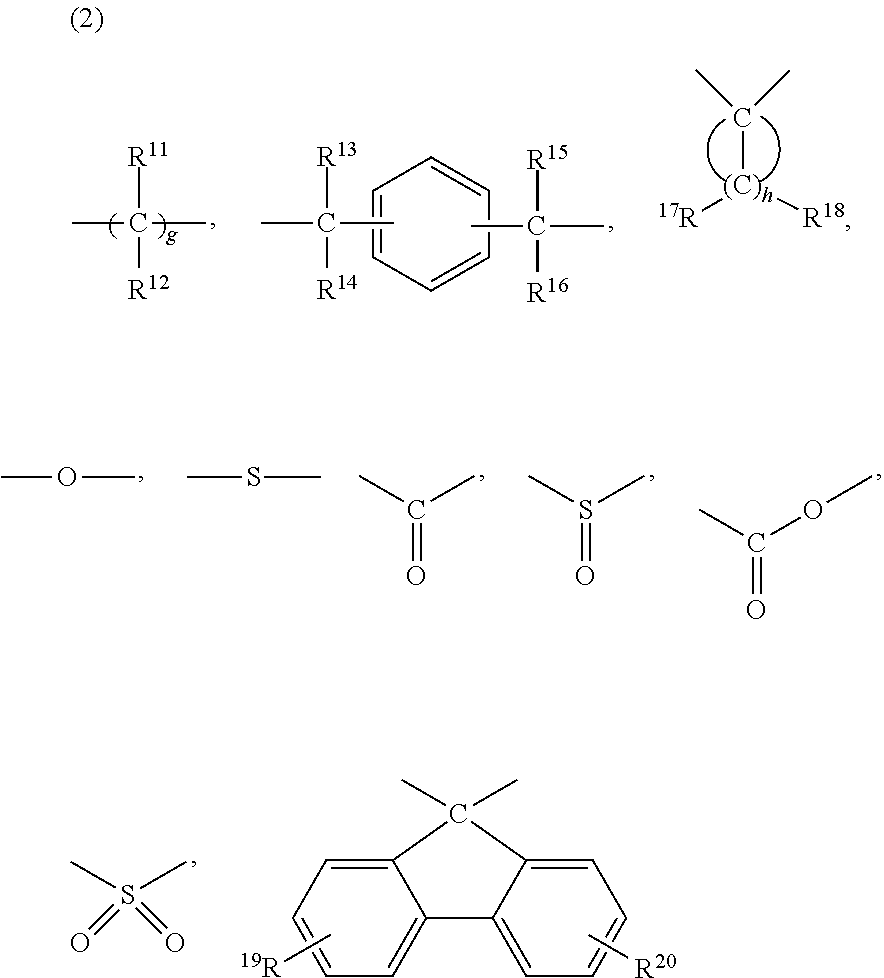

Polycarbonate resin composition

A resin composition comprising 1 to 20 parts by weight of (C) at least one styrene-based thermoplastic elastomer (component C) selected from the group consisting of a styrene-ethylene.propylene-styrene block copolymer (SEPS), a styrene-ethylene-butylene-styrene block copolymer (SEBS) and a styrene-butadiene-butylene-styrene block copolymer (SBBS) based on 100 parts by weight of the total of (A) a polycarbonate-based resin (component A) and (B) a polyolefin-based resin having a MFR at 230° C. under a load of 2.16 kg of not less than 40 g / 10 min (component B). The resin composition is excellent in mechanical properties, chemical resistance, appearance and tape peeling resistance.

Owner:TEIJIN LTD

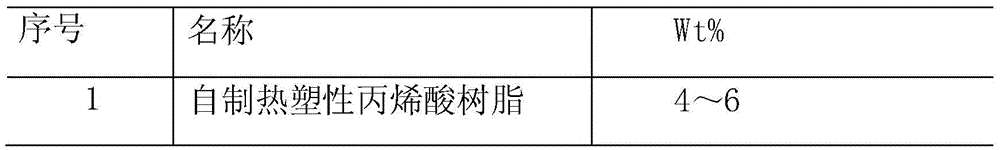

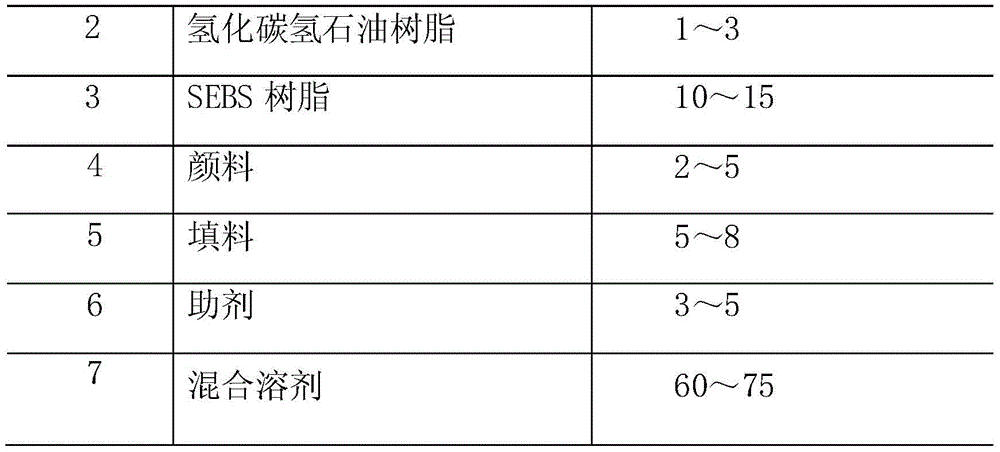

Special strippable protection glue for hard chromium plating

The invention provides a temporary protection coating which can be resistant to high-temperature chromic acid solution for a long time under the powered-on condition, cannot bubble, cannot be dissolved, cannot automatically fall off, has good control performance on a final etching ratio and has good strippable performance after a hard chromium plating process is finished. According to the invention, low-molecular-weight tackifying resin containing phosphate ester groups is synthesized through a polymerization reaction of isobornyl methacrylate and acrylic phosphate during synthesis of thermoplastic acrylic resin, the adhesive force with a base material is increased, and then the matching ratio with hydrogenated hydrocarbon petroleum resin with good initial adhesion is optimized, so that the tackifying resin has the adhesive force which is high under the hot condition and low under the cold condition; the tackifying resin is matched with SEBS (Styrene-ethylene-butylene-styrene block copolymer) resin with good chromic acid resistance and high temperature resistance in certain proportion, accordingly, the electroplating protection glue can keep good flexibility and excellent adhesive force in a long-term electroplating process, and use requirements of the hard chromium plating process under different conditions are met.

Owner:中昊北方涂料工业研究设计院有限公司

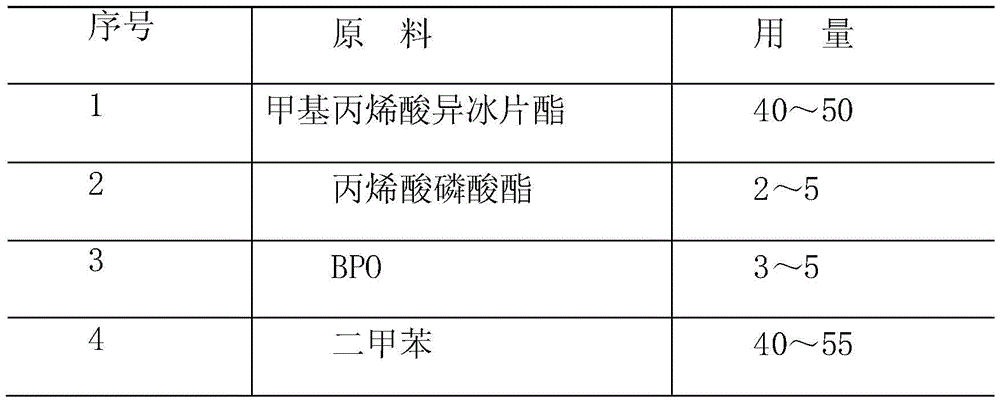

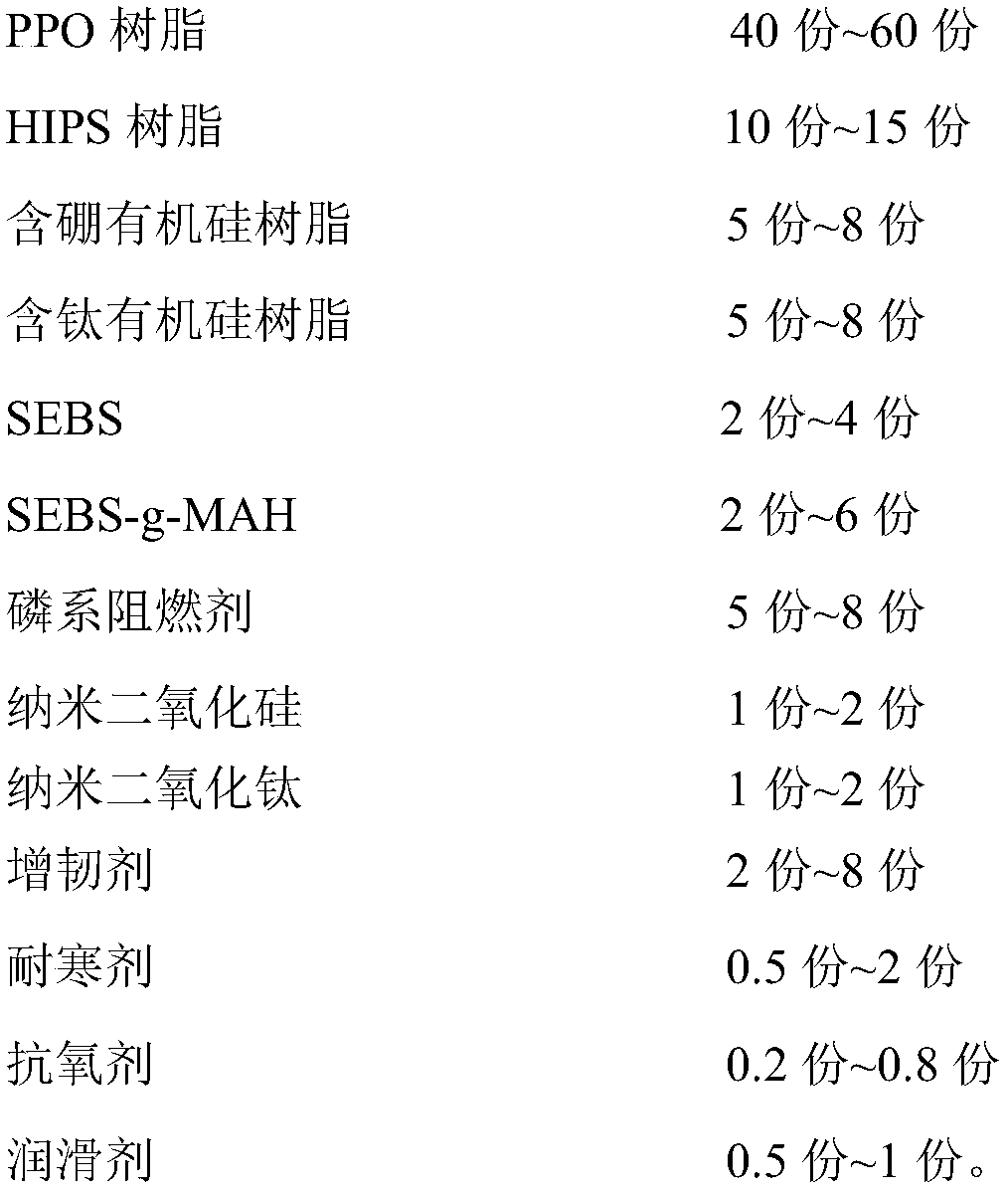

High-heat flame-retardant PPO (polyphenylene oxide) alloy material and preparation method thereof

The invention relates to the technical field of macromolecule modification, in particular to a high-heat flame-retardant PPO (polyphenylene oxide) alloy material and a preparation method thereof. Thehigh-heat flame-retardant PPO alloy material is prepared from the following ingredients including PPO resin, HIPS (high impact polystyrene) resin, boron-containing organic silicone resin, titanium-containing organic silicone resin, SEBS (styrene-ethylene-butylene-styrene block copolymer), SEBS-g-MAH (maleic anhydride), a phosphorus-series flame retardant, nanometer silicon dioxide, nanometer titanium dioxide, a toughening agent, a cold resistant agent, an antioxidant and a lubricating agent. The modification is performed on the PPO resin and the HIPS resin through the boron-containing organicsilicone resin and the titanium-containing organic silicone resin, and SEBS and SEBS-g-MAH are combined for compatibility modification, so that the prepared PPO alloy material has both rigidity and flexibility. The PPO alloy material has the advantages of good heat-resistant flame-retardant performance and good mechanical performance; in addition, the injection molding process requirements can becompletely met, and the dyeing is easy. The preparation method has the characteristics that the preparation method is simple, and the production cost is low.

Owner:GUANGDONG GUOLI SCI & TECH CO LTD

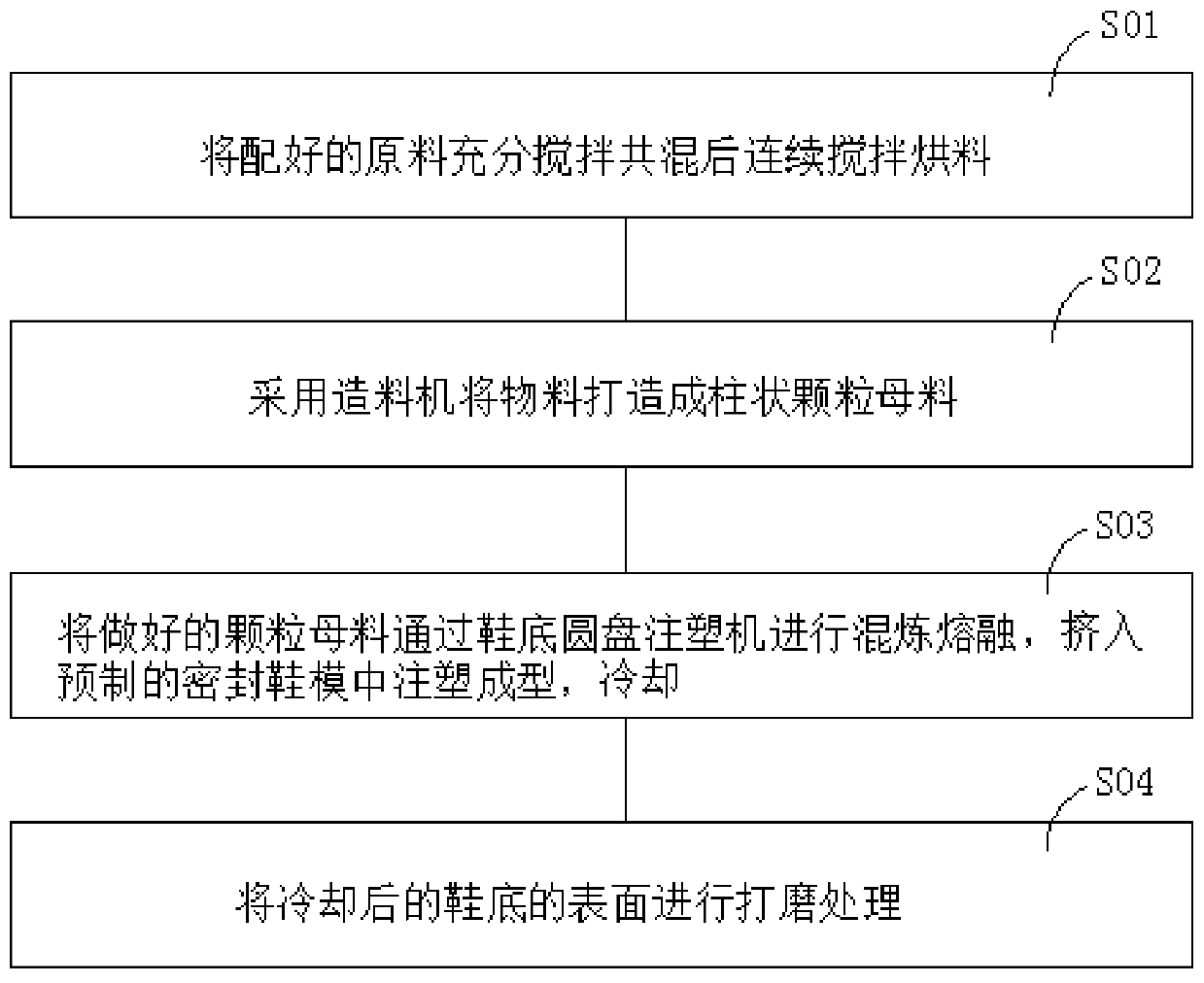

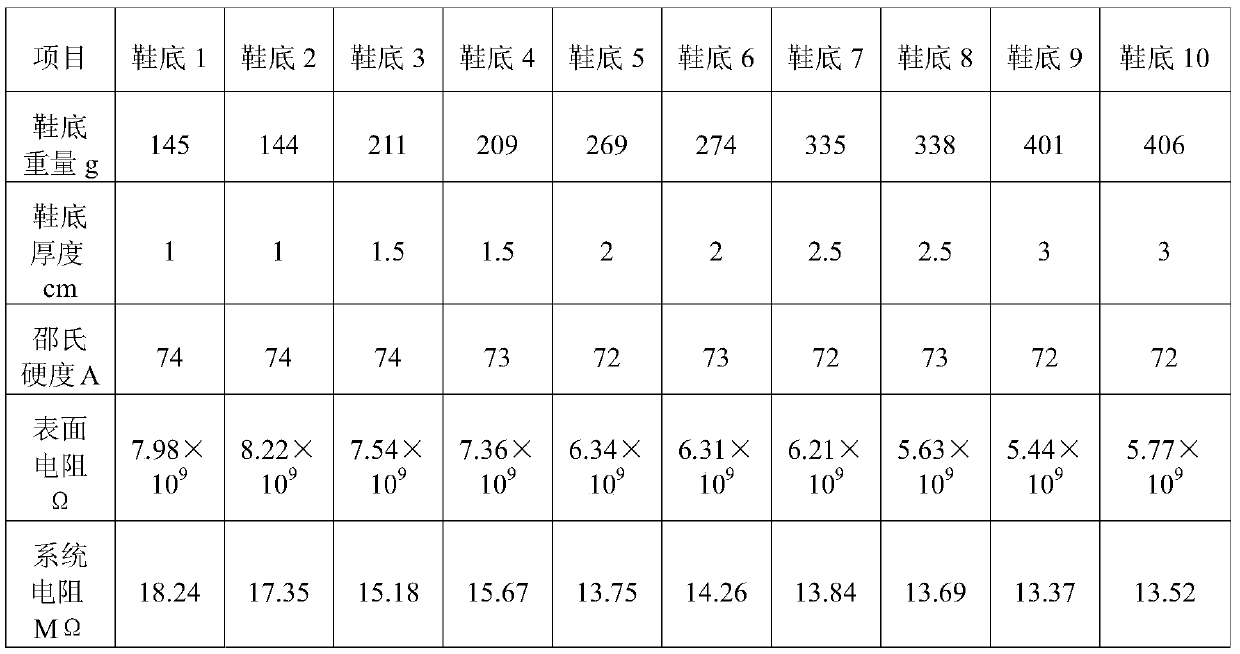

Formula and process for manufacturing TPR antistatic soles and antistatic soles

InactiveCN110183813AImprove antistatic performanceImprove wear resistanceSolesDomestic footwearPolymer scienceStearic acid

The invention relates to a formula and a process for manufacturing TPR antistatic soles. The formula comprises the following components: 40-46% of styrene-butadiene-styrene block copolymer; 5-8% of styrene-ethylene-butylene-styrene block copolymer; 8-11% of styrene-butadiene copolymer; 6-9% of ethylene-vinyl acetate copolymer; 5-8% of high impact polystyrene; 8-11% of nano calcium carbonate; 0.2-0.3% of nano zinc oxide; 3-6% of titanium dioxide; 2-4% of slip stopping agent; 2-3% of wear-resisting agent; 0.3-0.6% of stearic acid; 0.3-0.6% of lauroyl diethanol amine; 3-5% of octylphenol polyoxyethylene ether; 3-5% of octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate; 1-3% of pyridinium p-toluenesulfonate; 1-3% of sorbitan fatty acid ester; 0.3-0.6% of plasticizer; 1-3% of bridgingagent; 1-1.5% of bridging auxiliary agent; and 3-4% of white oil. The produced product has excellent antistatic performance, the resistivity is stabilized at 1-35M omega, and the product is soft and comfortable, has good wear resistance, is suitable for being used in a static sensitive dust-free workshop, and provides a reliable solution for low-cost antistatic soles.

Owner:深圳市兴业卓辉实业有限公司

High-cost-performance medical soft transparent SEBS (Styrene-Ethylene-Butylene-Styrene block copolymer) material and preparation method thereof

The invention discloses a high-cost-performance medical soft transparent SEBS (Styrene-Ethylene-Butylene-Styrene block copolymer) material and a preparation method thereof. A low-cost medical soft transparent SEBS provided by the invention basically copies all performance of an SEBS, is high-temperature-resistant, aging-resistant, has good elasticity; meanwhile, materials with lower costs are used, and problems that an ordinary medical SEBS has higher surface hardness and is difficultly made into a softer product are solved.

Owner:常州恒方大高分子材料科技有限公司 +2

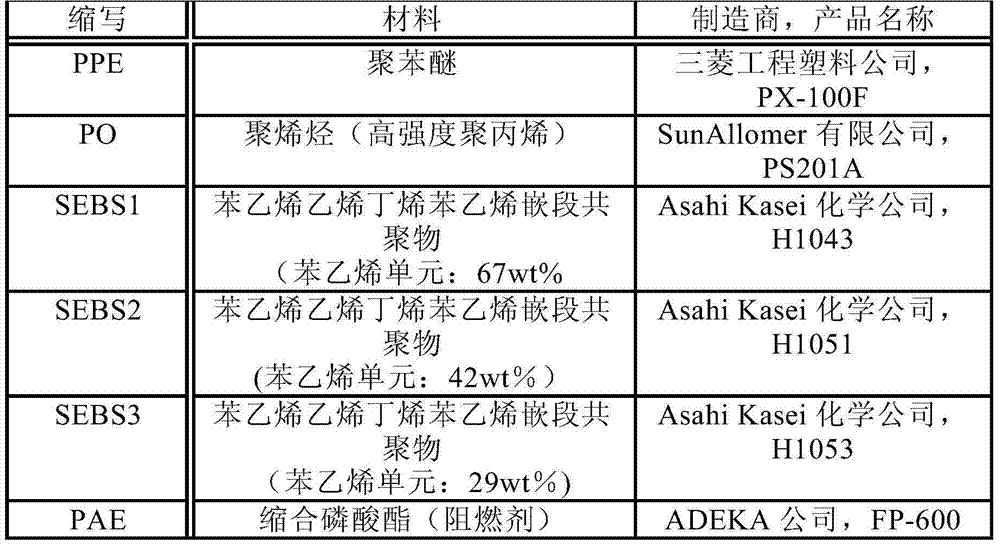

Flame retardant resin composition and insulated electrical wire

InactiveCN103946295AReduce thicknessMeet wear resistanceInsulated cablesInsulatorsPhosphoric Acid EstersPolyolefin

Owner:YAZAKI CORP

Insulating heat-conducting cable material and preparation method thereof

The invention discloses an insulating heat-conducting cable material. The cable material comprises the following raw materials in parts by weight: 20-30 parts of polyvinyl chloride resin, 15-25 partsof an ethylene-vinyl acetate copolymer, 18-27 parts of a styrene-ethylene-butylene-styrene block copolymer, 3-6 parts of graphene oxide, 6-9 parts of butyl rubber, 3-4 parts of trioctyl trimellitate,3-6 parts of modified talc powder, 2-4 parts of a flame retardant, 1-2 parts of a lubricant, and 2-3 parts of an antioxidant. According to the cable material disclosed by the invention, the raw materials and a ratio of the raw materials are controlled, so that the prepared cable material has the characteristics of a high heat conductivity coefficient, high compressive strength and breaking strength, good aging resistance, strong toughness and excellent comprehensive performance.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

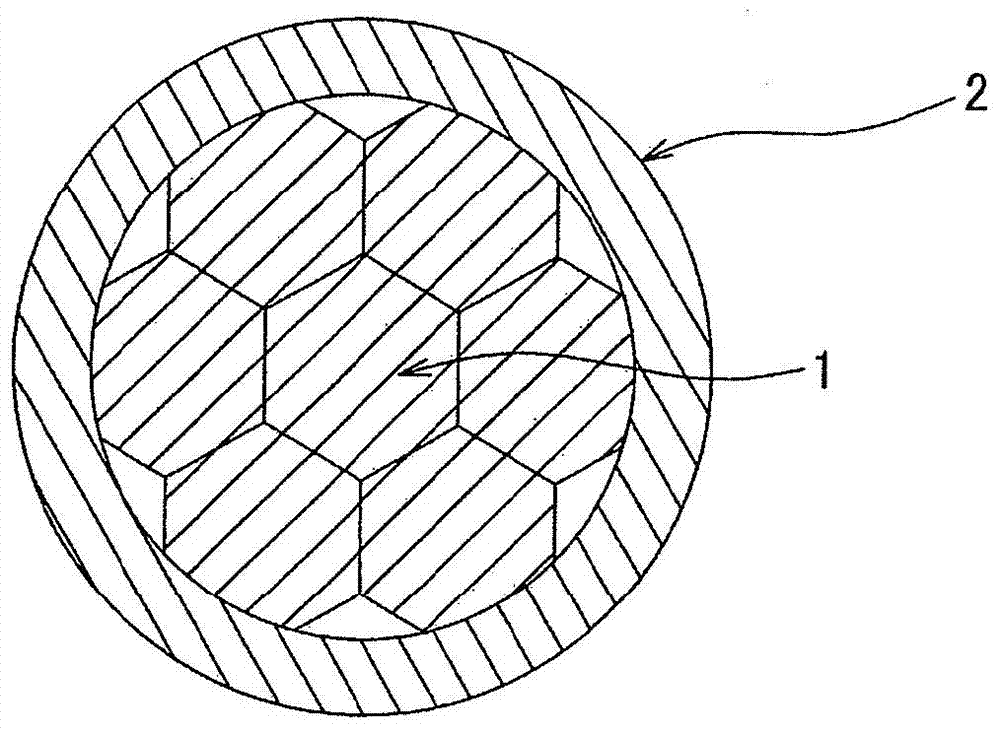

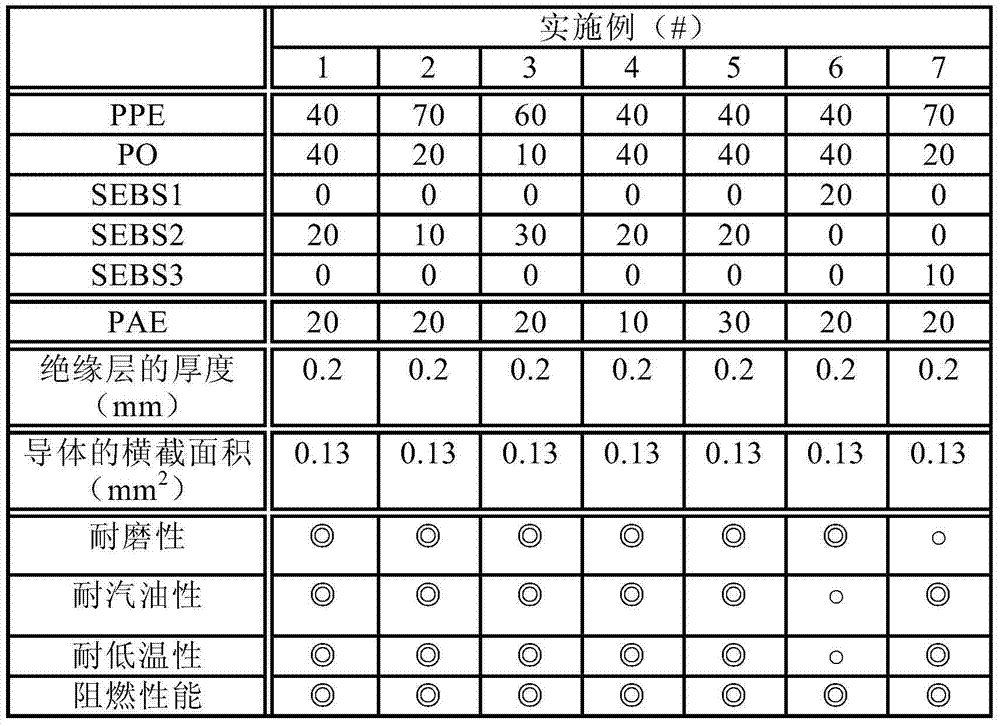

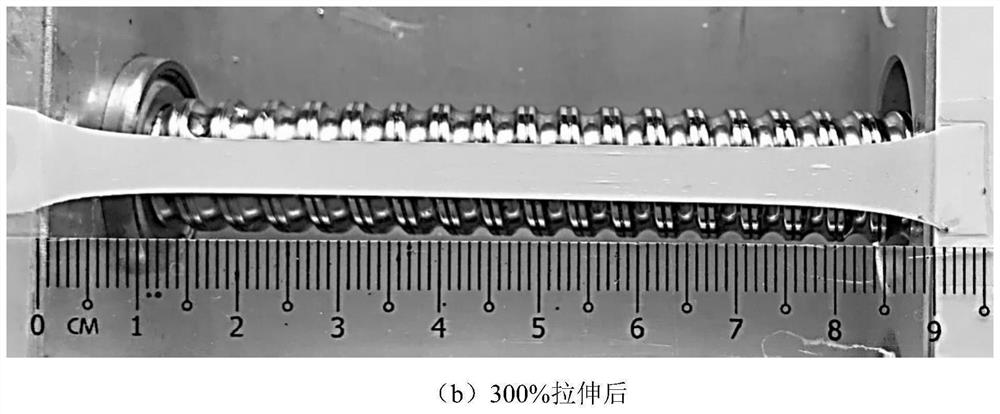

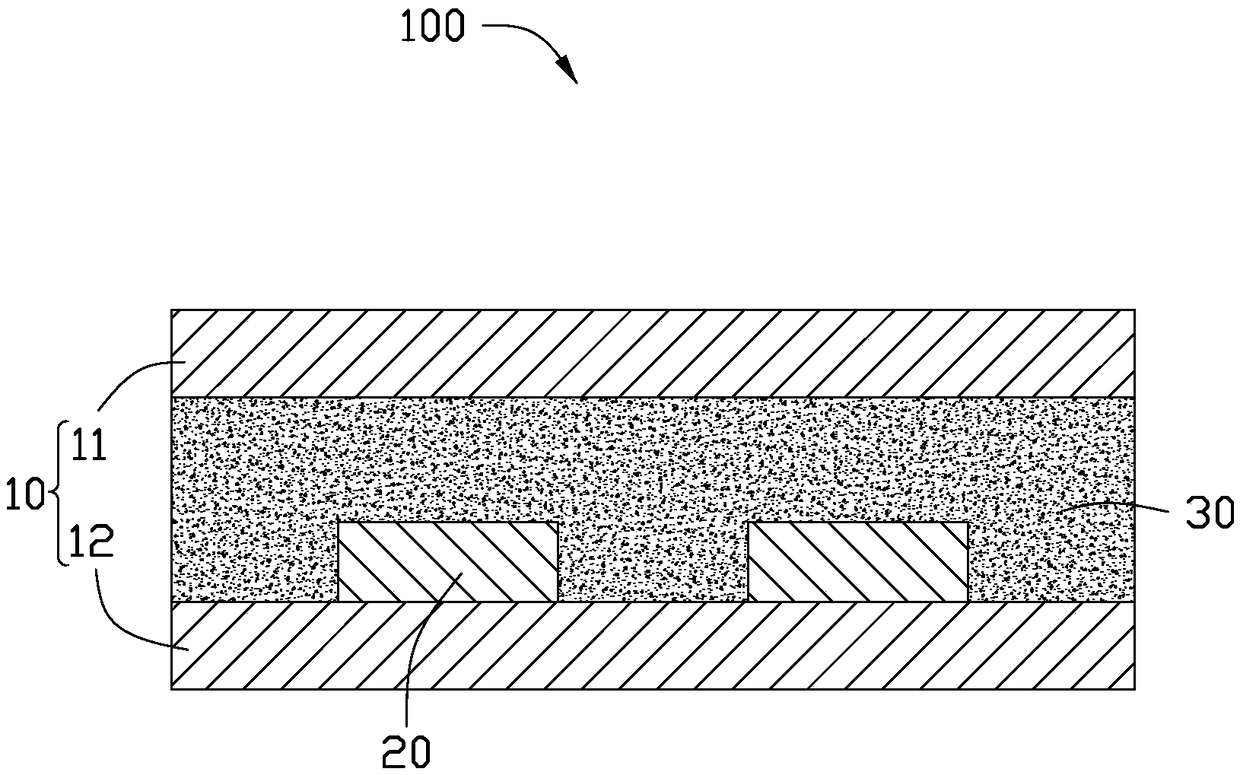

Breathable and stretchable nanofiber composite thin film material for friction nano generator and preparation method of breathable and stretchable nanofiber composite thin film material

The invention discloses a breathable and stretchable nanofiber composite thin film material for a friction nano-generator and a preparation method of the breathable and stretchable nanofiber composite thin film material. The material is formed by blending nanofibers and elastomer microspheres through electrostatic spinning, wherein the nanofibers are polyvinylidene fluoride-hexafluoropropylene copolymer (PVDF-HFP), and the elastomer microspheres are styrene-ethylene-butylene-styrene block copolymer. The preparation method comprises the following steps of (1) dissolving a nanofiber precursor into a solution A for electrostatic spinning; (2) dissolving the elastomer microspheres into a solution B for electrostatic spinning; and (3) spinning the nanofibers and the elastomer microspheres synchronously by adopting a conjugate electrostatic spinning processing technology to obtain a nanofiber composite thin film. The nanofiber composite thin film material prepared by the invention has the advantages of adjustable thickness, air permeability, waterproofness and stretchability, has a good triboelectrification effect, is simple in preparation method and suitable for industrial production, and can be applied to the breathable and stretchable wearable friction nano-generator.

Owner:WUHAN UNIV

High viscosity modified asphalt for water permeable pavement and preparation method thereof

InactiveCN1990584AImprove performanceHigh viscosityIn situ pavingsBuilding insulationsDispersityRoad surface

The invention relates to a high viscosity modified asphalt which wherein the asphalt comprises the following constituents (by weight ratio): asphalt 100, styrene-polyethylene / butylene-styrene segmented copolymer 3-12 having an average molecular weight of 30-350 thousand, petroleum resin 5-30 with a softening point of 70-150 deg C, polyethylene wax 1-6 having an average molecular weight of 500-15000 and a softening point of 90-160 deg. By mixing styrene-ethane / butylenes-styrene segmented copolymer, petroleum resin and polyethylene wax into the asphalt, high viscosity, good dispersity and stability can be achieved, the PG classification can reach 82-28. The obtained high-performance modified asphalt can be used for both the general water seeping pavements, and specific sites such as bridge pavement and stress absorption layer.

Owner:SHANGHAI QUNKANG ASPHALTUM TECH CO LTD

Thermoplastic elastomer and preparation method therefor

The invention provides a thermoplastic elastomer. The thermoplastic elastomer is prepared from the following raw materials in parts by weight: 33-40 parts of base oil, 35-45 parts of calcium powder with the grain size of 1,000 to 1,250 meshes, 15-20 parts of styrene-butadiene-styrene block copolymer, 15-20 parts of styrene-ethylene-butylene-styrene block copolymer, 1-3 parts of cyclohexane and 1-3 parts of polyurethane. The invention further provides a preparation method for the thermoplastic elastomer. The thermoplastic elastomer and the preparation method therefor have the beneficial effects that the cyclohexane and the polyurethane are added into the original thermoplastic elastomer formula according to certain proportions, so that the Akron attrition volume of prepared soles is lower than 0.6cm<3> / 1.61km, and the wear resistance is close to the requirements of automobile tires; the surface roughness of the thermoplastic elastomer is improved due to the polyurethane, so that the skid resistance is good; and the cyclohexane is highly volatile, so that a certain space is reserved for the free expansion of the thermoplastic elastomer, and the density is lowered while the resistance to temperature is improved.

Owner:江苏联其材料科技有限公司

Vapor chamber and production method thereof

ActiveCN109233705AImprove temperature uniformityIncrease cross-link densityNon-macromolecular adhesive additivesPrinted circuit aspectsInsulation layerOligomer

A vapor chamber comprises a release film and a vapor chamber board, wherein the vapor chamber board comprises at least one insulation layer and a glue layer arranged on the at least one insulation layer; the release film is arranged on the outer surface of the glue layer; the glue layer is prepared from 35-85 parts by weight of a styrene-butadiene-styrene block copolymer, 5-65 parts by weight of astyrene- ethylene-butylene-styrene block copolymer, 5-35 parts by weight of polyphenyl ether and 3-45 parts by weight of dendritic acrylic oligomer.

Owner:QING DING PRECISION ELECTRONICS HUAIAN CO LTD +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com