Baby product TPE (Thermoplastic Elastomer) and preparation method of baby product TPE

A technology for products and infants, which is applied in the field of TPE for baby products and its preparation, can solve the problems of interfering with the original mechanism of endocrine, affecting hormone content, endocrine disorders, etc., to prolong the service life, improve compatibility, and reduce water absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

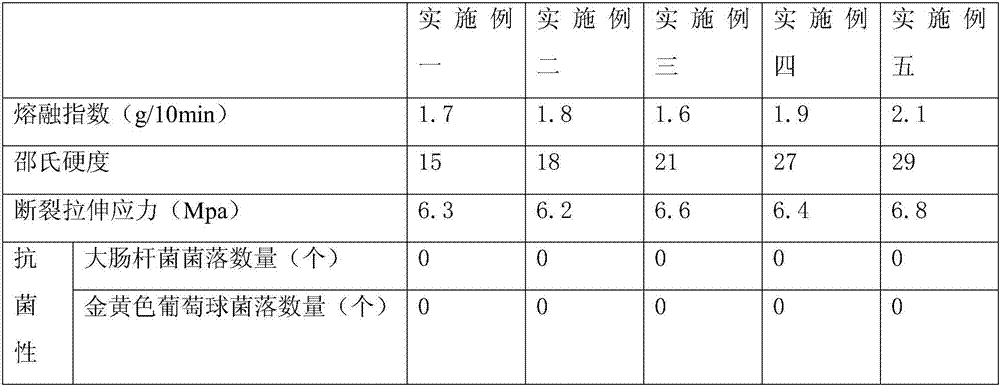

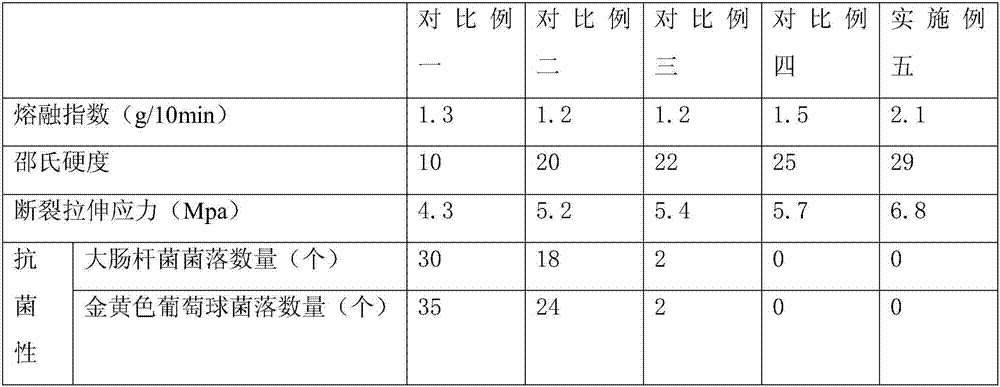

Examples

Embodiment 1

[0045] (1) After mixing 20 parts of SEBS and 0.05 parts of antioxidant, uniformly heat up to 100°C and keep it warm for 2 hours;

[0046] (2) Add 50 parts of cosmetic grade white oil to SEBS heated to 100°C, and stir at a low speed of 100r / min until SEBS completely absorbs the white oil;

[0047] (3) SEBS, 5 parts of shell powder, 5 parts of random copolymerized polypropylene, 5 parts of compatibilizer A, 0.5 part of slip agent A, 0.05 part of antioxidant, 0.05 part of antioxidant Blend 0.1 part of aging agent and 0.1 part of antibacterial agent in a high mixer at 1500r / min for 2 minutes until uniformly mixed;

[0048] (4) The material mixed in step (3) is added into a twin-screw extruder with a length-to-diameter ratio of 48:1 for melt extrusion and granulation to obtain a TPE material for manufacturing baby shower caps.

Embodiment 2

[0050] (1) After mixing 40 parts of SEBS and 0.15 parts of antioxidant, evenly heat up to 100°C and keep it warm for 2 hours;

[0051] (2) Add 60 parts of cosmetic grade white oil to SEBS heated to 100°C, and stir at a low speed of 200r / min until SEBS completely absorbs the white oil;

[0052] (3) SEBS, 15 parts of seashell powder, 15 parts of random copolymerized polypropylene, 10 parts of compatibilizer B, 1.5 parts of slip agent B, 0.15 parts of antioxidant, 1.5 parts of slip agent B, 0.15 parts of antioxidant Blend 0.2 parts of aging agent and 0.5 parts of antibacterial agent in a high mixer at 800r / min for 3 minutes until uniformly mixed;

[0053] (4) The material mixed in step (3) is added into a twin-screw extruder with a length-to-diameter ratio of 48:1 for melt extrusion and granulation to obtain a TPE material for manufacturing baby shower caps.

Embodiment 3

[0055] (1) After mixing 30 parts of SEBS and 0.1 part of antioxidant, evenly heat up to 100°C and keep it warm for 2 hours;

[0056] (2) Add 55 parts of cosmetic grade white oil to SEBS heated to 100°C, and stir at a low speed of 150r / min until SEBS completely absorbs the white oil;

[0057] (3) SEBS, 10 parts of shell powder, 10 parts of high-density polyethylene, 7 parts of compatibilizer C, 1 part of slip agent C, 0.1 part of antioxidant, anti-aging 0.15 parts of antibacterial agent and 0.25 parts of antibacterial agent were blended for 2 minutes in a high mixer at 1200r / min until uniformly mixed;

[0058] (4) The material mixed in step (3) is added into a twin-screw extruder with a length-to-diameter ratio of 48:1 for melt extrusion and granulation to obtain a TPE material for manufacturing baby shower caps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com