Whitening, Moisturizing Toner

A technology of softening water and facial skin, applied in the field of skin softening water, can solve the problems of color, rough method, and smell of traditional Chinese medicine, and achieve the effect of preventing skin allergies and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] Example 1: It can be produced according to the following formula and process (parts are weight units):

[0030] Group A: 1, 3 butanediol-4 parts, propylene glycol-4 parts, sodium pyrrolidone carboxylate-5 parts, dipotassium glycyrrhizinate-0.3 parts, NMF-50-3 parts, antiallergic agent-5 parts, EDTA- 2Na - 0.05 parts, methylparaben - 0.1 parts, purified water - 105 parts.

[0031] Group B: 1% hyaluronic acid-5 parts, arbutin-2 parts, CO-40-0.3 parts, azelaic acid derivatives-5 parts, 75% ethanol-5 parts, Genma-115-0.03 parts.

[0032] Group C: essence - appropriate amount; citric acid - appropriate amount;

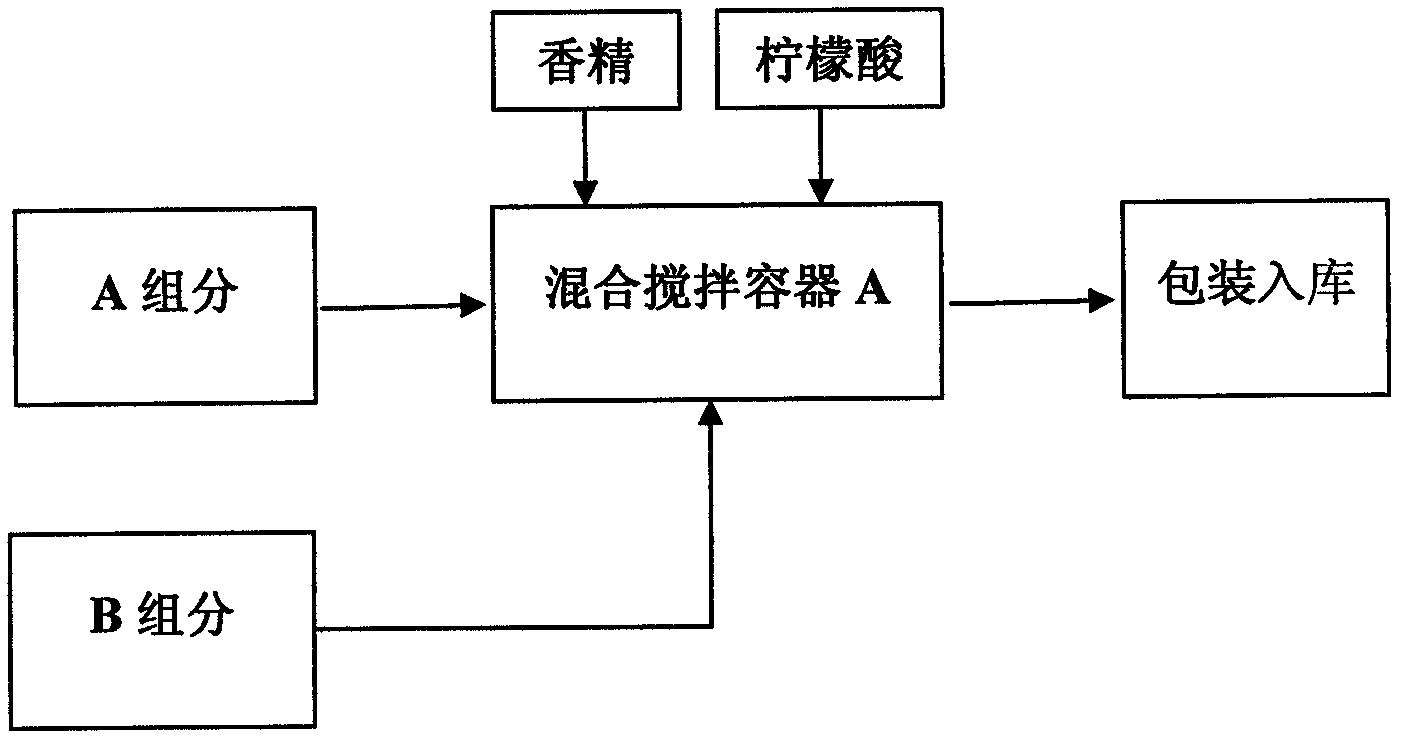

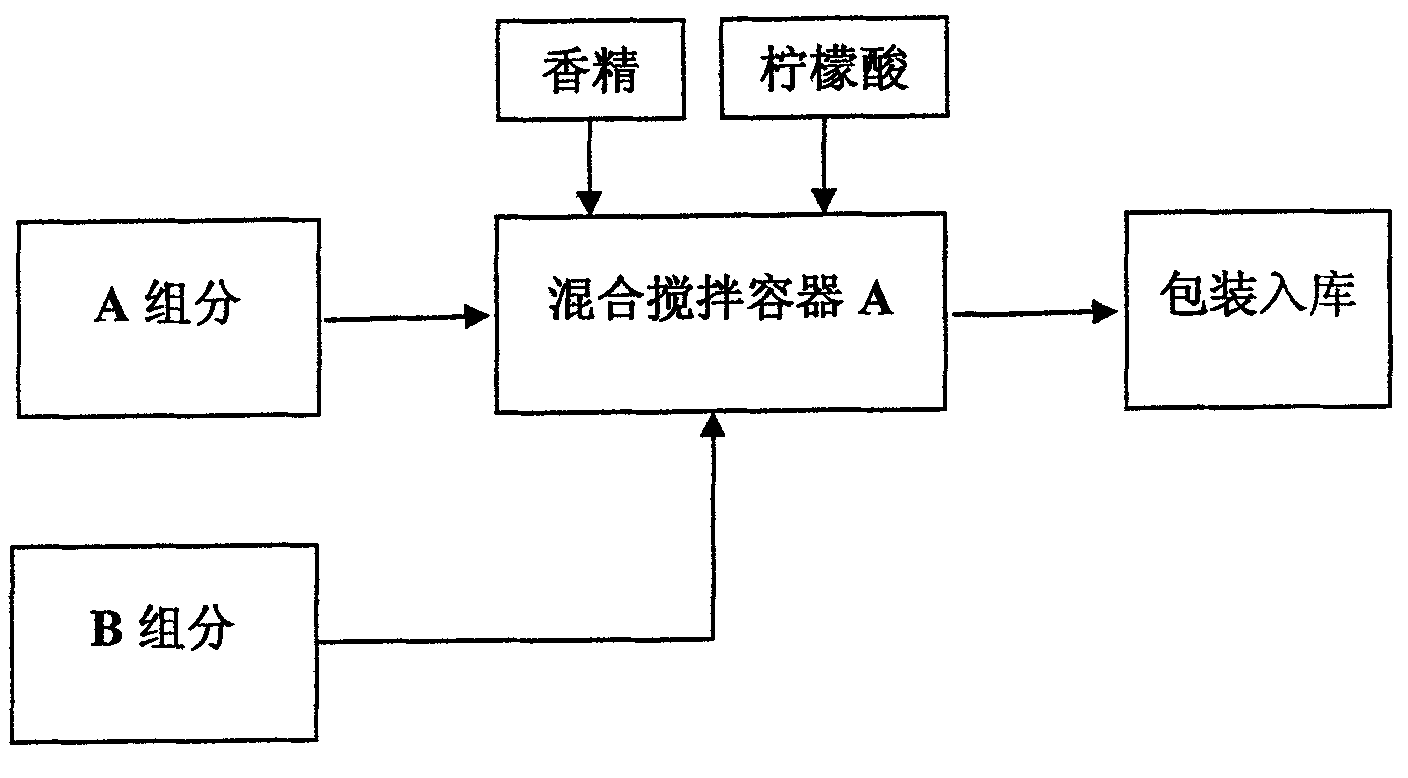

[0033] The preparation process is as follows: first put the components of component A into the mixer A, stir, heat, heat up to 60°C, keep warm for 20 minutes, then stir, heat up to 95°C, keep warm for 20 minutes; then cool down, When stirring to 45°C, add component B; when stirring continuously and cooling down to 40°C, add an appropriate amount of spices, and test...

example 2

[0034] Example 2: It can be produced according to the following formula and process (parts are weight units):

[0035] Group A: 1, 3 butanediol: 3 parts; propylene glycol: 3 parts; sodium pyrrolidone carboxylate: 4 parts; dipotassium glycyrrhizinate: 0.2 parts; NMF-50: 2 parts; antiallergic agent (CD-2901): 4 parts, EDTA-2Na: 0.04 parts; Methylparaben: 0.05 parts; Purified water: 100 parts;

[0036] Group B: hyaluronic acid (1%): 4 parts; arbutin: 1.5 parts; CO-4O: 0.2 parts; azelaic acid derivatives: 4 parts; Genma-115: 0.2 parts; ethanol (75%) :4 parts;

[0037] Group C: appropriate amount of essence; appropriate amount of citric acid;

[0038] Its preparation process is as follows:

[0039] First, put the components of A component into the mixing mixer A, heat to 55°C while stirring, and keep it for 15 minutes; then heat, stir, raise the temperature to 90°C, and keep it for 15 minutes; then cool down and stir to 44°C , add the components of B, continue to stir, and when...

example 3

[0040] Example 3: It can be produced according to the following formula and process (parts are weight units):

[0041] Group A: 1, 3 butanediol: 5 parts; propylene glycol: 5 parts; sodium pyrrolidone carboxylate: 6 parts; dipotassium glycyrrhizinate: 0.4 parts; NMF-50: 4 parts; antiallergic agent (CD-2901): 6 parts, EDTA-2Na: 0.06 parts; Methylparaben: 0.15 parts; Purified water: 110 parts;

[0042] Group B: Hyaluronic acid (1%): 6 parts; Arbutin: 2.5 parts; CO-4O: 0.4 parts; Azelaic acid derivatives: 6 parts; Genma-115: 0.4 parts; Ethanol (75%): 6 copies;

[0043] Group C: appropriate amount of essence; appropriate amount of citric acid;

[0044] Its preparation process is as follows:

[0045] First, put the components of A component into the mixer A, heat to 65°C while stirring, and keep it for 25 minutes; then heat, stir, raise the temperature to 100°C, and keep it for 25 minutes; then cool down and stir to 46°C , add component B; keep stirring, when the temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com