Breathable and stretchable nanofiber composite thin film material for friction nano generator and preparation method of breathable and stretchable nanofiber composite thin film material

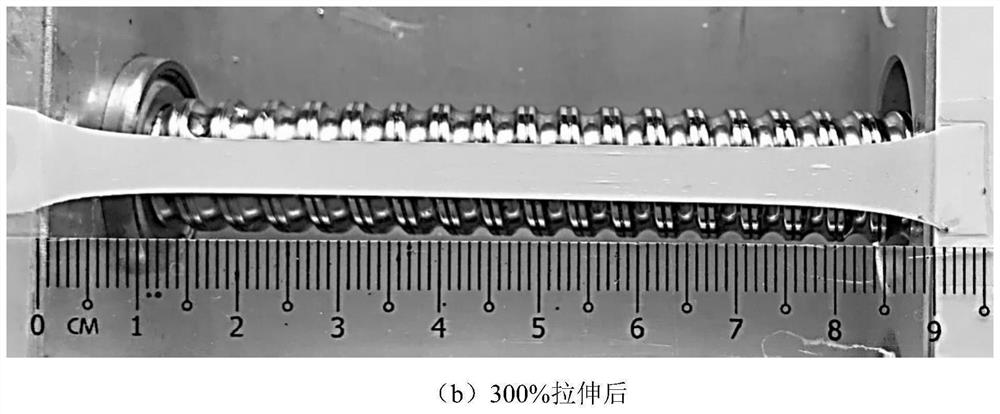

A technology of nanofibers and composite films, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of restricting the development and application of high-performance devices, low output voltage of triboelectric nanogenerators, and poor air permeability, etc., and achieve good triboelectricity Electric effect, guaranteed stretch-recovery performance, thickness controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

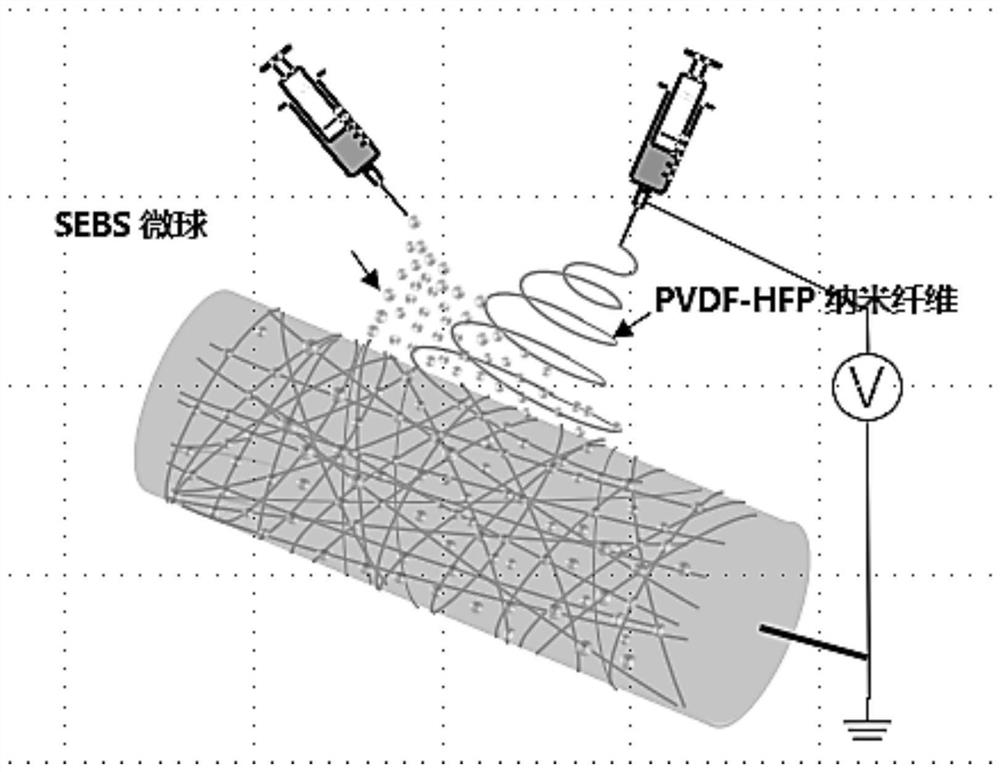

[0036] Nano fiber composite films, the following steps:

[0037] 1) Weigh 1.5g PVDF-HFP polymer particles, a glass vial was added 20ml; 10ml of acetone was added - dimethylformamide, a mixed solution, wherein the volume ratio of acetone and dimethyl formamide is 6: 4, using a magnetic stirred for 4h to give the sub-stirred solution electrospinning A;

[0038] 2) Weigh 1.2g SEBS elastomer particles, added to a glass vial 20ml; 10ml toluene was added - dimethylformamide mixed solution, wherein the volume ratio of toluene and dimethylformamide for 85:15, using a magnetic stirrer electrospinning solution obtained was stirred for 4h B;

[0039] 3) The solution A and solution B respectively, into two syringes, connected to an electrostatic spinning machine, adjusting electrospinning parameters (voltage -2kV, 20kV) to carry out electrostatic spinning conjugate, wherein the solution A is introduced rate 0.7ml / h, the solution B was introduced rate 2ml / h, to obtain the nanofiber composi...

Embodiment 2

[0041] Nano fiber composite films, the following steps:

[0042] 1) Weigh 1.5g PVDF-HFP polymer particles, a glass vial was added 20ml; 10ml of acetone was added - dimethylformamide, a mixed solution, wherein the volume ratio of acetone and dimethyl formamide is 6: 4, using a magnetic stirred for 4h to give the sub-stirred solution electrospinning A;

[0043] 2) Weigh 1.2g SEBS elastomer particles, added to a glass vial 20ml; 10ml toluene was added - dimethylformamide mixed solution, wherein the volume ratio of toluene and dimethylformamide for 85:15, using a magnetic stirrer electrospinning solution obtained was stirred for 4h B;

[0044] 3) The solution A and solution B respectively, into two syringes, connected to an electrostatic spinning machine, adjusting electrospinning parameters (voltage -2kV, 20kV) to carry out electrostatic spinning conjugate, wherein the solution A is introduced rate 1.1ml / h, the solution B was introduced rate 2ml / h, to obtain the nanofiber composi...

Embodiment 3

[0046] Nano fiber composite films, the following steps:

[0047] 1) Weigh 1.5g PVDF-HFP polymer particles, a glass vial was added 20ml; 10ml of acetone was added - dimethylformamide, a mixed solution, wherein the volume ratio of acetone and dimethyl formamide is 6: 4, using a magnetic stirred for 4h to give the sub-stirred solution electrospinning A;

[0048] 2) Weigh 1.2g SEBS elastomer particles, added to a glass vial 20ml; 10ml toluene was added - dimethylformamide mixed solution, wherein the volume ratio of toluene and dimethylformamide for 15:85, using a magnetic stirrer electrospinning solution obtained was stirred for 4h B;

[0049] 3) The solution A and solution B respectively, into two syringes, connected to an electrostatic spinning machine, adjusting electrospinning parameters (voltage -2kV, 20kV) to carry out electrostatic spinning conjugate, wherein the solution A is introduced rate 1.6ml / h, the solution B was introduced rate 2ml / h, to obtain the nanofiber composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com