Anti-flaming polyamide composite material with good printing performance and preparation method thereof

A technology of flame retardant nylon and composite material, which is applied in the field of flame retardant nylon composite material and its preparation, and can solve the problems of difficulty in obtaining flame retardancy and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

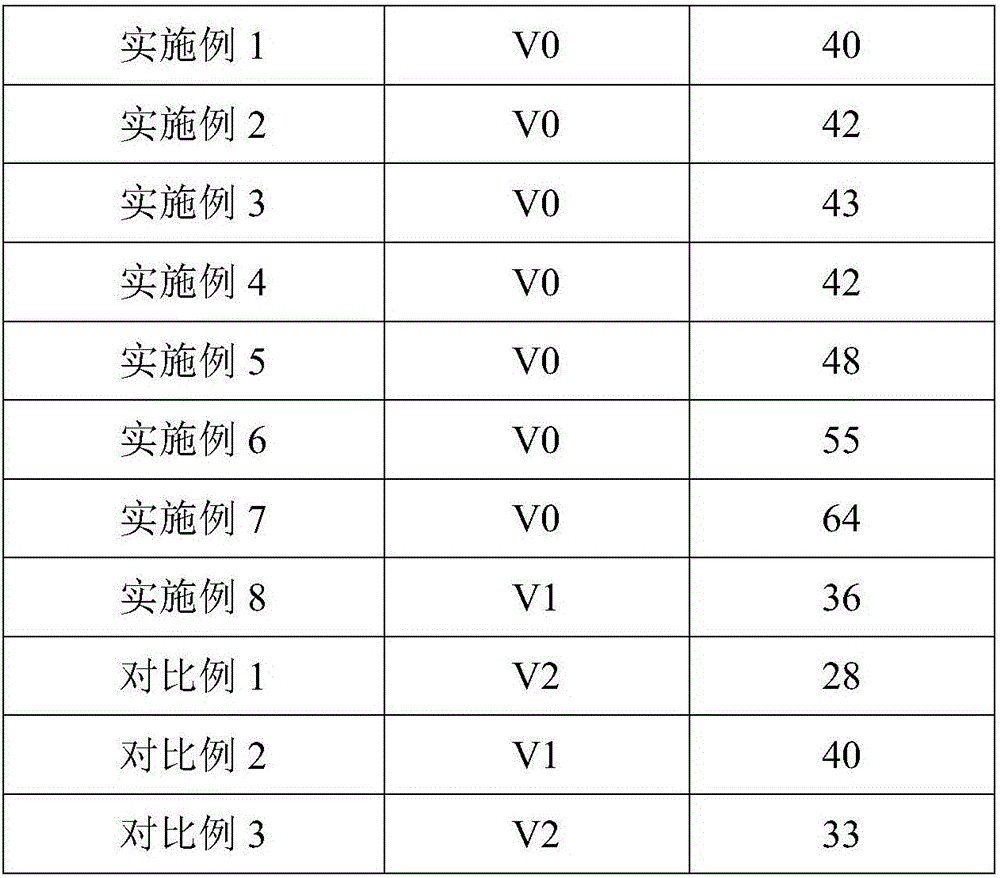

Examples

preparation example Construction

[0070] The preparation method of maleic anhydride graft modified polypropylene in the present invention is not particularly limited, it can be commercially available, or can be obtained by solution method, supercritical CO 2 It can be synthesized by methods well known to those skilled in the art such as solution method, melting method, radiation method and solid phase method.

[0071] For example, the maleic anhydride graft-modified polypropylene is prepared by the melting method: mix styrene and the initiator dicumyl peroxide, dissolve, and make a styrene solution of the initiator. Mix polypropylene and maleic anhydride into a mixture, feed the mixture of polypropylene and maleic anhydride into the twin-screw extruder, after it melts, put the styrene solution of the initiator in different screw barrel sections of the twin-screw extruder Continuous metering input, melt grafting reaction, to obtain maleic anhydride graft modified polypropylene.

[0072] In the maleic anhydride...

Embodiment 1

[0130] Embodiment 1 of the present invention provides a flame-retardant nylon composite material with good printing performance, including the following raw materials in parts by weight, 30 parts of polyamide resin, 20 parts of polybenzimidazole, 15 parts of ethylene-vinyl acetate copolymer 1 part, SEBS 10 parts, maleic anhydride modified polypropylene 1 part, cyclodextrin-polyethylene glycol compound 15 parts, liquid paraffin 1 part, filler 10 parts, brominated flame retardant 0.5 part, synergistic flame retardant 3 doses.

[0131] The polyamide resin is polyhexamethylene terephthalamide, purchased from Mitsui Chemicals in Japan;

[0132] The polybenzimidazole was purchased from Gail, Germany;

[0133] The ethylene-vinyl acetate copolymer is purchased from DuPont, USA;

[0134] The SEBS was purchased from Taiwan TSRC;

[0135] The maleic anhydride-modified polypropylene was purchased from Guangzhou Qiansan Chemical Technology Co., Ltd., and the grafting rate of maleic anhy...

Embodiment 2

[0148] Embodiment 2 of the present invention provides a flame-retardant nylon composite material with good printing performance, including the following raw materials in parts by weight, 90 parts of polyamide resin, 1 part of polybenzimidazole, 3 parts of ethylene-vinyl acetate copolymer 1 part, SEBS 1 part, maleic anhydride modified polypropylene 15 parts, cyclodextrin-polyethylene glycol compound 1 part, liquid paraffin 10 parts, filler 10 parts, brominated flame retardant 1 part, synergistic flame retardant 0.5 parts.

[0149] In Example 2, polyamide resin, polybenzimidazole, ethylene-vinyl acetate copolymer, SEBS, maleic anhydride modified polypropylene, cyclodextrin-polyethylene glycol complex, liquid paraffin, filler, brominated barrier Flaming agent, synergistic flame retardant are all with embodiment 1.

[0150] The preparation method of the flame-retardant nylon composite material with good printing performance is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com