Field hokey injection molding material and preparation method thereof

A technology of plastic injection and hockey, applied in the field of thermoplastic elastomer injection plastic and its preparation, can solve problems such as injection plastic vulcanization, and achieve the effect of smooth surface and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

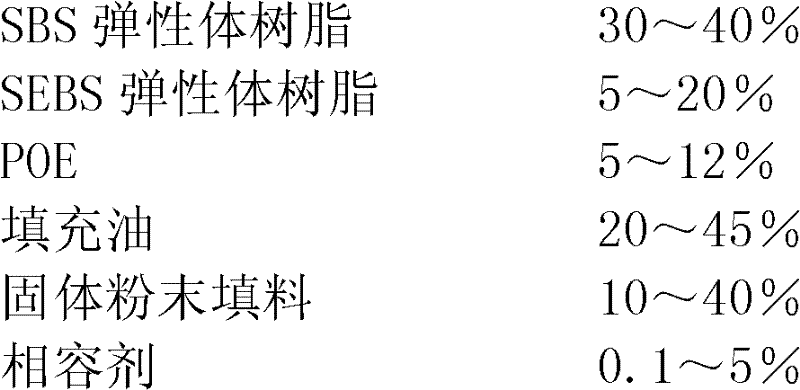

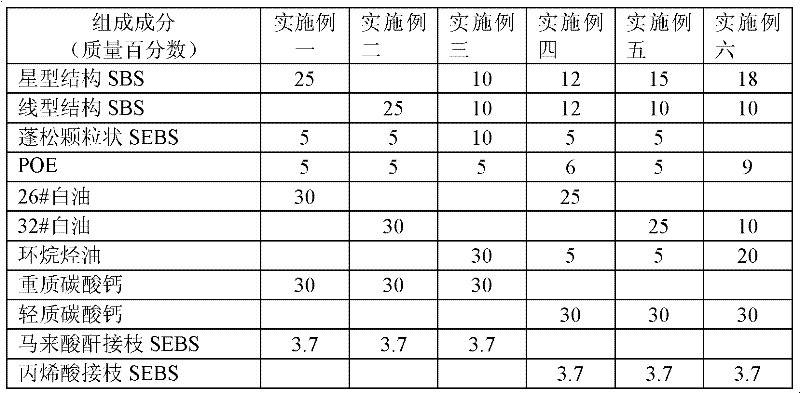

[0021] Produce according to the following process, the ratio of raw materials used in production is with reference to the data in Table 1,

[0022] 1) Accurately weigh SBS, SEBS resin and filler oil according to the mass ratio set by the formula, put them into the mixer and mix them at high speed for 15-20min, then let them stand for 12 hours and set aside;

[0023] 2) Divide the components of the above step 1) into three parts according to the resin / extending oil mixture, solid powder filler, small material, etc. The small material includes POE, compatibilizer, antioxidant and processing aid, and add them separately Weightlessness electronic scale;

[0024] 3) Through the weight loss electronic weighing system, it enters the twin-screw machine evenly from the feeding port according to the preset ratio, and completes the granulation by mixing, underwater granulation, etc.

[0025] Table 1 Related Examples

[0026]

[0027] Product performance parameters refer to Table 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com