Gas density relay with online self-checking function and checking method thereof

A gas density, relay technology, applied in the field of electric power, can solve problems such as potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

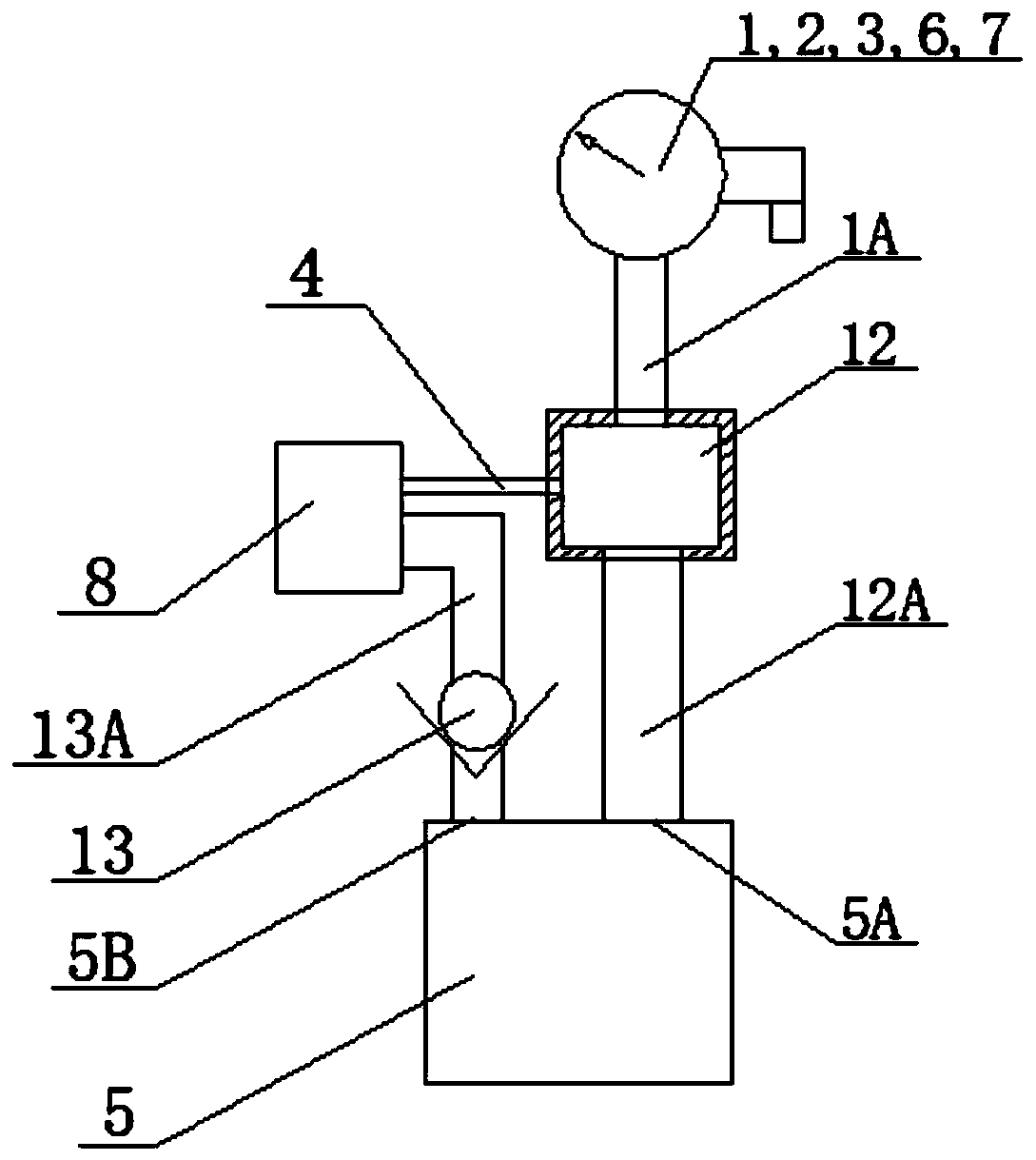

[0161] like figure 1As shown, the first embodiment of the present invention provides a gas density relay or a gas density monitoring device with an online self-verification function, including: a gas density relay body 1, a pressure sensor 2, a temperature sensor 3, and a gas flow restrictor 4 , Pressure regulating mechanism 5, online verification contact signal sampling unit 6, intelligent control unit 7, electrical equipment 8, inertial air chamber 12, one-way valve 13. Pressure sensor 2, temperature sensor 3, online verification contact signal sampling unit 6, intelligent control unit 7 and gas density relay body 1 are set together, that is, pressure sensor 2, temperature sensor 3, online verification contact signal sampling unit 6 and intelligent The control unit 7 is arranged on the body 1 of the gas density relay. The gas density relay body 1 communicates with the inertial gas chamber 12 through the air channel 1A, and the inertial gas chamber 12 communicates with the e...

Embodiment 2

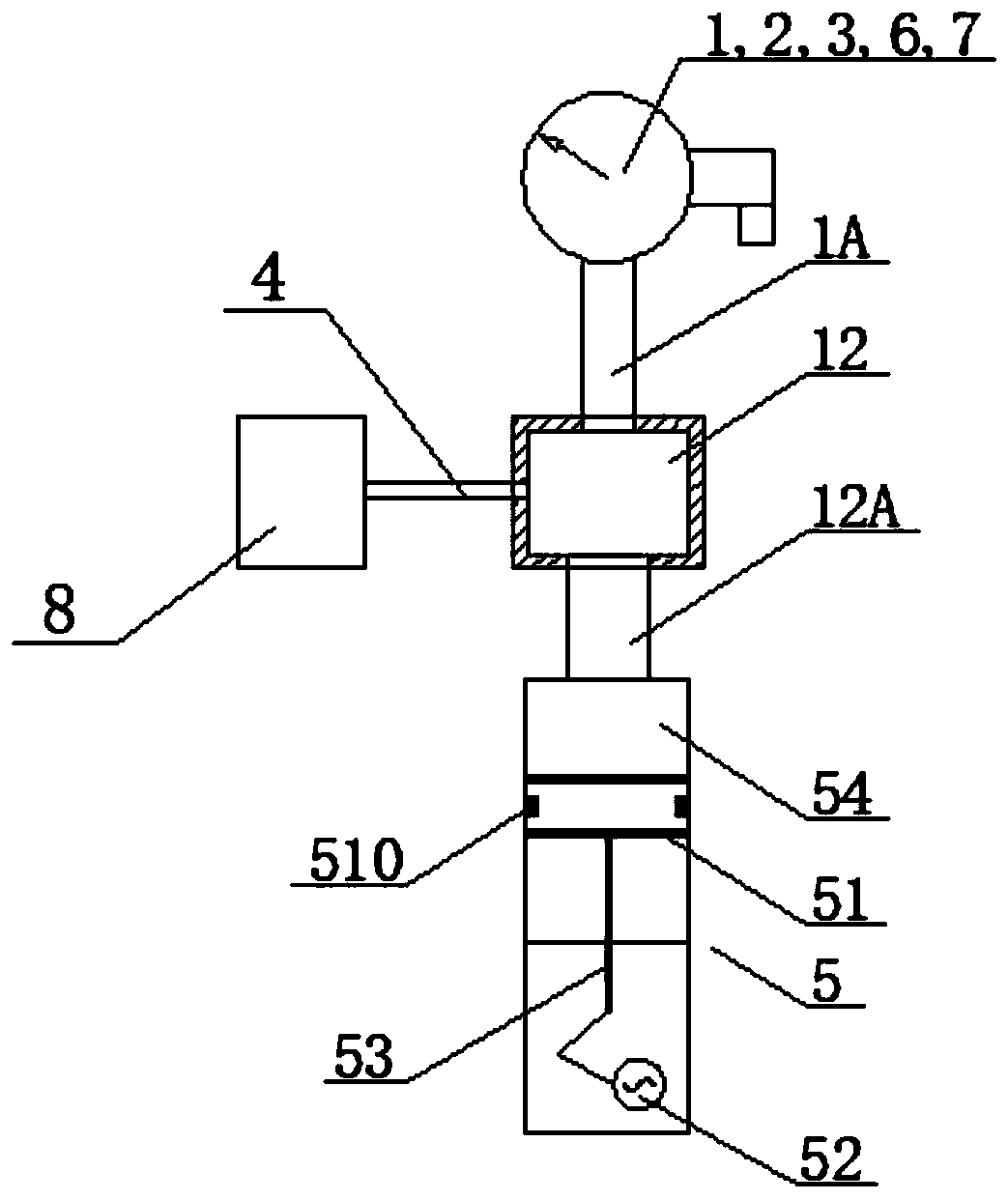

[0174] like figure 2 As shown, a gas density relay or a gas density monitoring device with an online self-verification function provided by Embodiment 2 of the present invention includes: a gas density relay body 1, a pressure sensor 2, a temperature sensor 3, and a gas flow limiting member 4 , pressure regulating mechanism 5, online verification contact signal sampling unit 6, intelligent control unit 7, electrical equipment 8. Pressure sensor 2, temperature sensor 3, online verification contact signal sampling unit 6, intelligent control unit 7 and gas density relay body 1 are set together, that is, pressure sensor 2, temperature sensor 3, online verification contact signal sampling unit 6 and intelligent The control unit 7 is arranged on the body 1 of the gas density relay. Same as the first embodiment, the gas density relay body 1 communicates with the inertial gas chamber 12 through the air channel 1A, and the inertial gas chamber 12 communicates with the electrical equ...

Embodiment 3

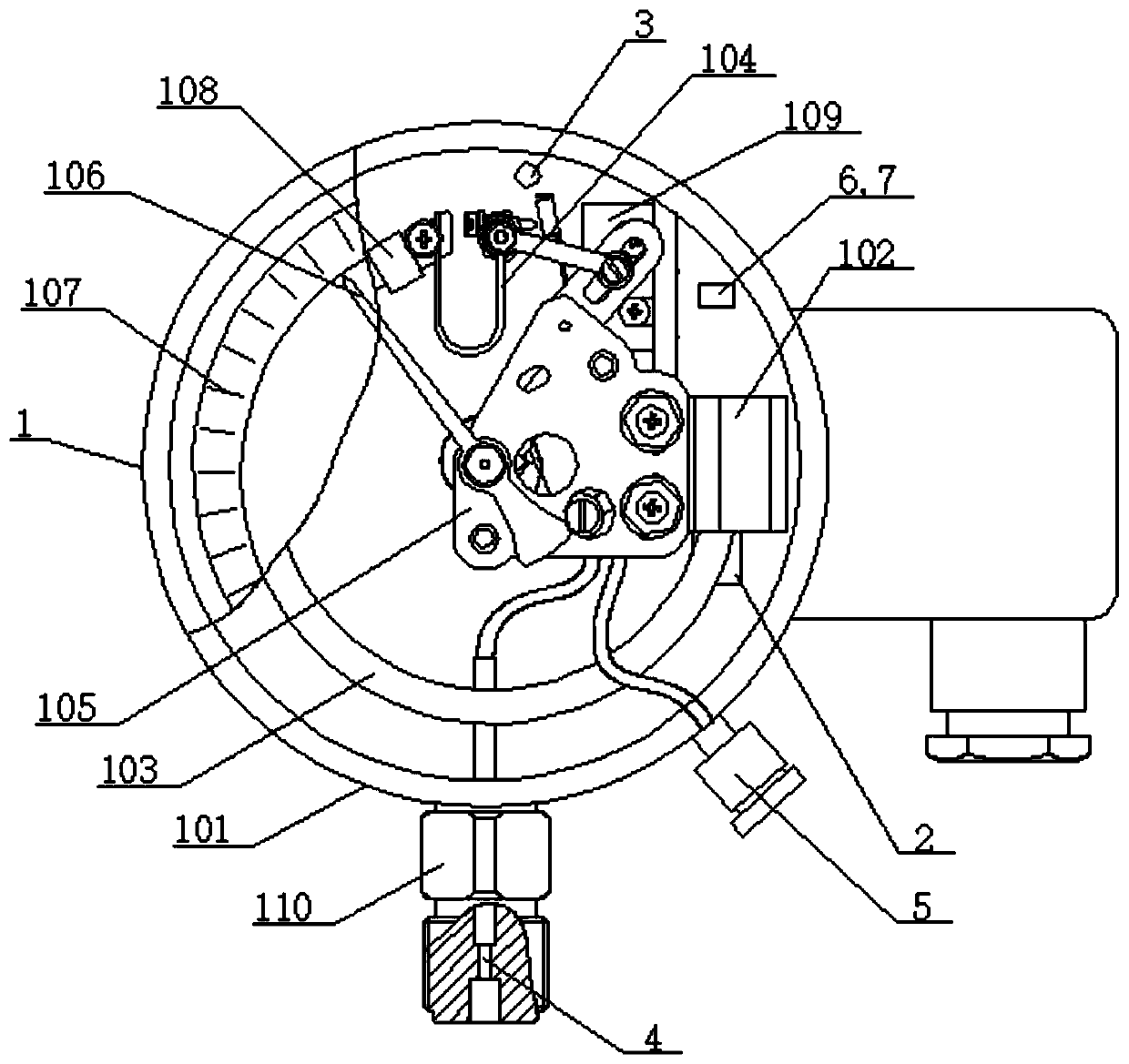

[0183] like image 3 As shown, a gas density relay or a gas density monitoring device with an online verification function includes a gas density relay body 1, and the gas density relay body 1 includes: a housing 101, and a base set in the housing 101 Seat 102, end seat 108, pressure detector 103, temperature compensation element 104, several signal generators 109, movement 105, pointer 106, dial 107. One end of the pressure detector 103 is fixed on the base 102 and communicated with it, and the other end of the pressure detector 103 is connected to one end of the temperature compensation element 104 through the end seat 108, the The other end of the temperature compensating element 104 is provided with a crossbeam, and the crossbeam is provided with an adjusting member that pushes the signal generator 109 to make the contacts of the signal generator 109 on or off. The movement 105 is fixed on the base 102; the other end of the temperature compensation element 104 is also con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com